Underground drift coal bunker

A technology for coal bunkers and tunnels, which is applied in the field of coal bunkers in underground coal mines. It can solve the problems of difficult construction, large maintenance, and high cost, and achieve the effects of saving shaft engineering, simple construction, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

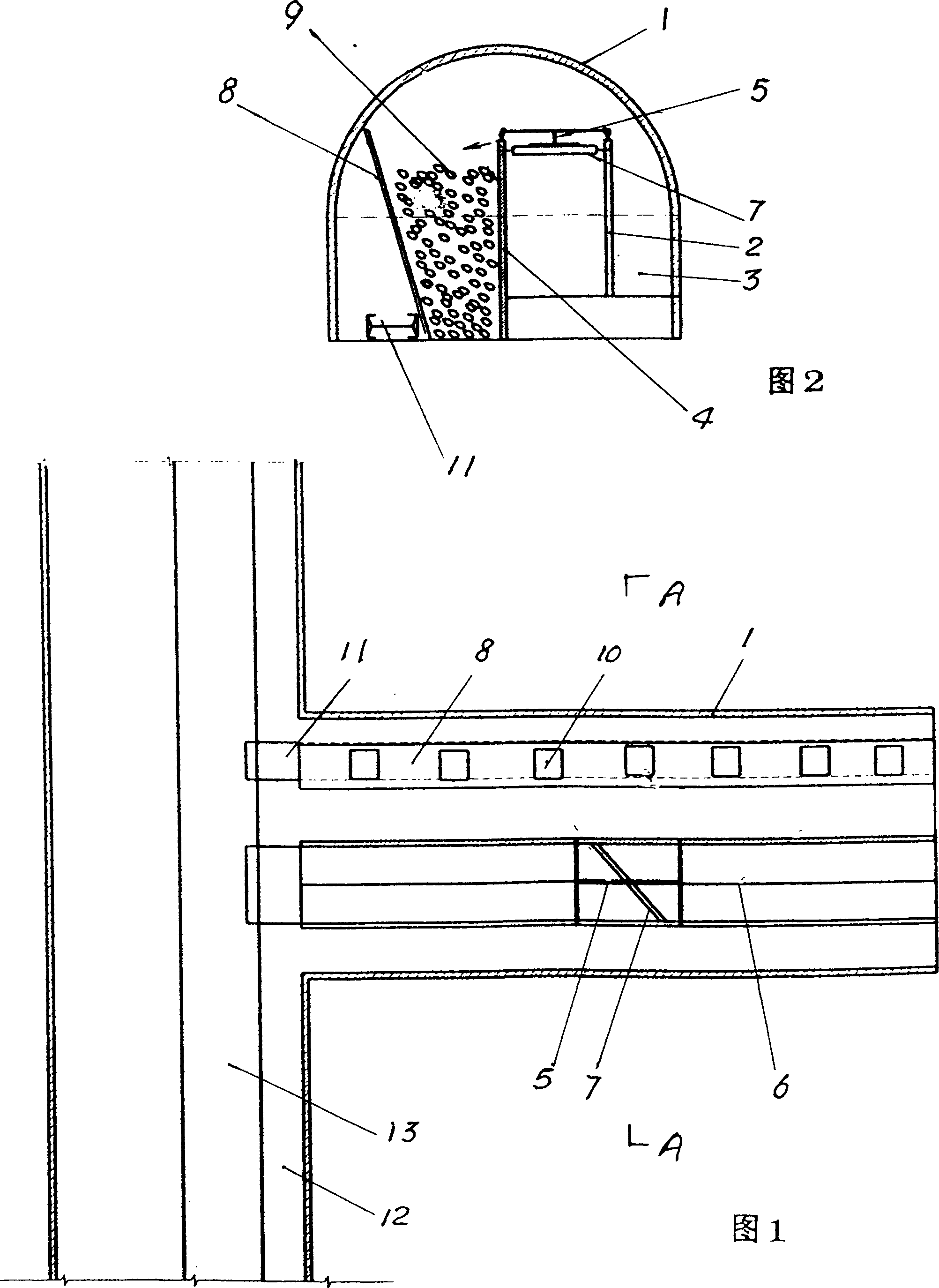

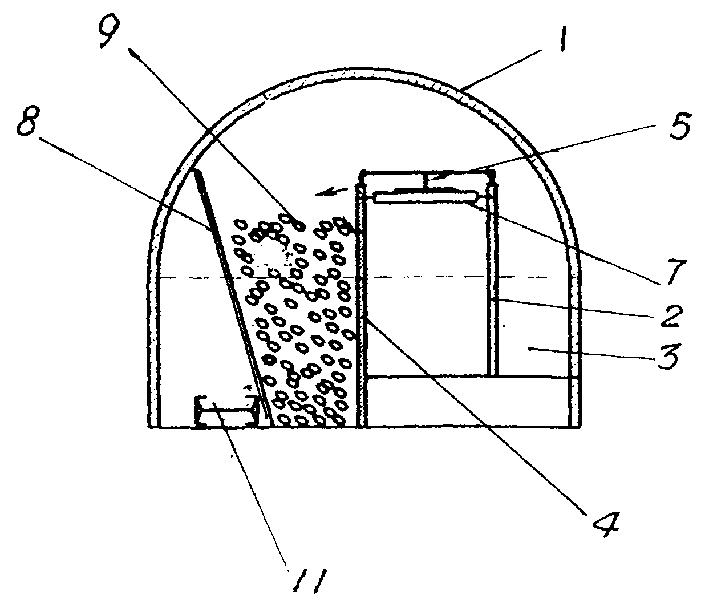

[0021] Please refer to Fig. 1 and Fig. 2. The present invention is an underground coal bunker, including a coal separator, a walking trolley, a belt conveyor, and a scraper conveyor;

[0022] In the roadway 1 with a semi-circular arch in the upper part of the cross section, a sidewalk 3 is provided between the side wall of the roadway and the belt rack 2, and a coal separator and a walking trolley 5 are erected on the track of the belt rack 2 and the middle partition wall 4 , the trolley is connected with a traction steel rope 6, a belt conveyor 7 is arranged under the coal separator, and the space between the inner side of the partition wall 4 and the outer side of the inclined partition 8 arranged in the roadway forms a coal bunker 9 with a wide top and a narrow bottom. There are several coal discharge holes 10 on the inclined partition 8, and a scraper conveyor 11 is arranged on the roadway bottom surface outside the inclined partition 8. The scraper conveyor 11 is aligned w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com