Coal leakage preventive device of belt conveyor

A belt conveyor, anti-running technology, applied in transportation and packaging, underground transportation, earth-moving drilling, etc., can solve the problems of reducing lump coal rate, coal smashing, etc., to improve lump coal rate and reduce stress Area, the effect of reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

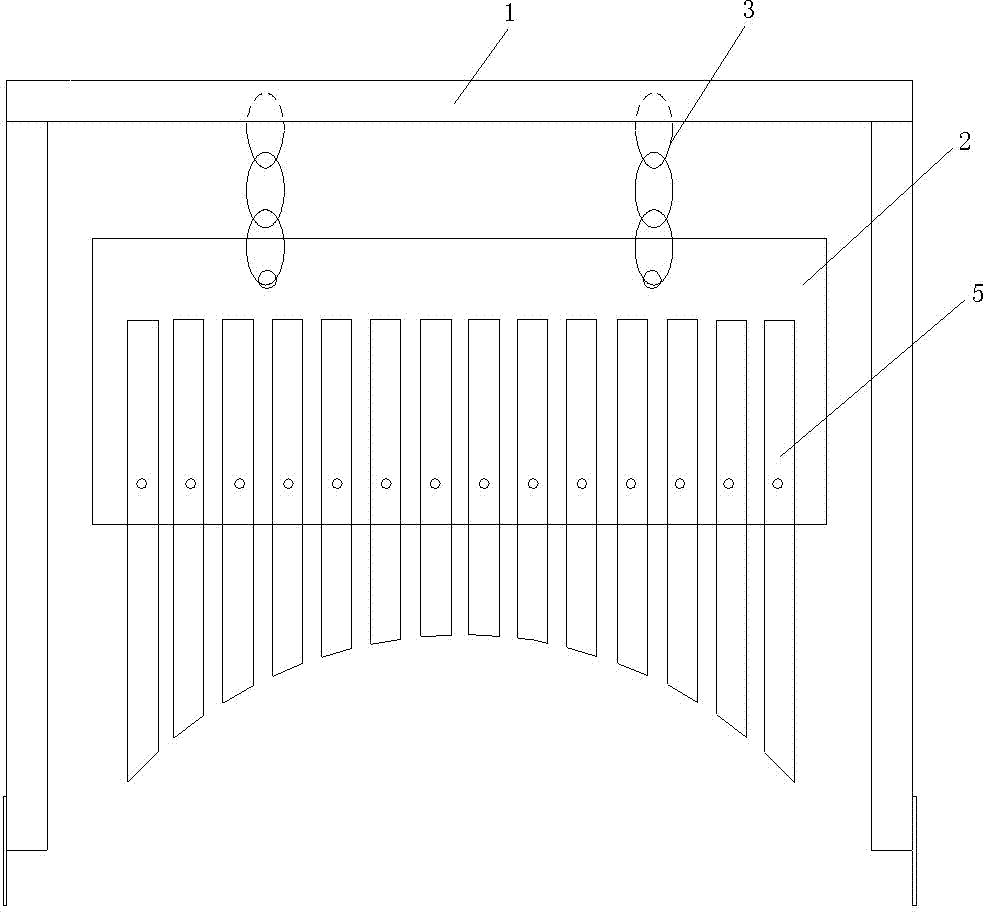

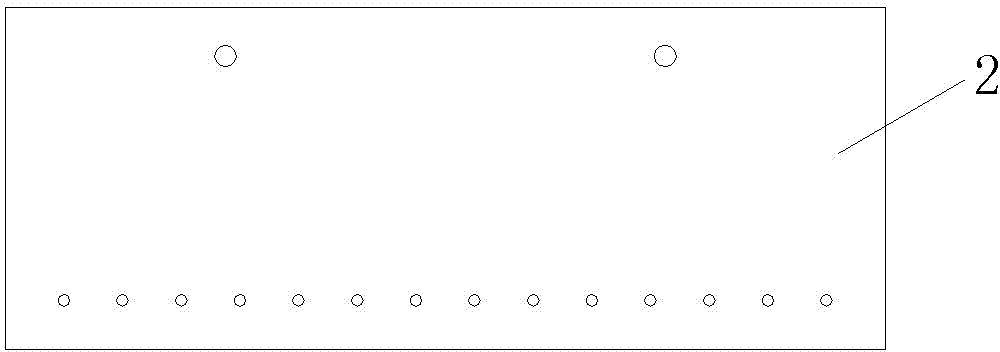

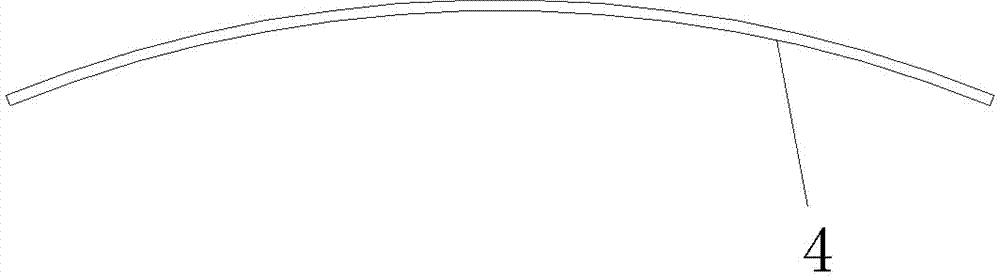

[0014] Embodiment 1 of the present invention, such as Figure 1-3 Shown: the anti-running coal device of the belt conveyor, including the door frame support 1, the coal retaining plate 2 for blocking coal blocks is suspended on the door frame support 1, and the door frame support 1 and the coal retaining plate 2 are connected together by a chain 3 , the coal retaining plate 2 has an inner concave arc surface 4 for reducing the speed of the coal block with an opening facing the coal block, a buffer layer is fixed on the inner concave arc surface 4, and the buffer layer includes an adhesive tape strip 5 extending in the up and down direction, The adhesive tape strips 5 are evenly distributed along the circumference of the concave arc surface, the height of the lowermost end of the adhesive tape strips 5 is lower than that of the coal retaining plate, and the lower part of the buffer layer is an arched structure.

[0015] In addition to the above-mentioned Exception 1, other embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com