Water cutting falling coal mining method and water cutting falling coal mining machine

A coal mining method and shearer technology, which are applied in cutting machinery, slitting machinery, earthwork drilling and other directions, can solve the problems of high lump coal rate, poor coal seam adaptability, and low production efficiency of coal plow, and achieve equipment The effect of simplified structure, high lump coal rate and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention is achieved through the following technical solutions: a method of water cutting and splitting coal mining, wherein the water knife cutting device of the water cutting and split coal mining machine performs horizontal cutting on the coal wall and / or after cutting, the water knife cutting The falling device cuts and drops coal on the divided coal seam, and the machine body advances to drive the water-jet cutting device and the water-jet cutting device to realize continuous coal mining.

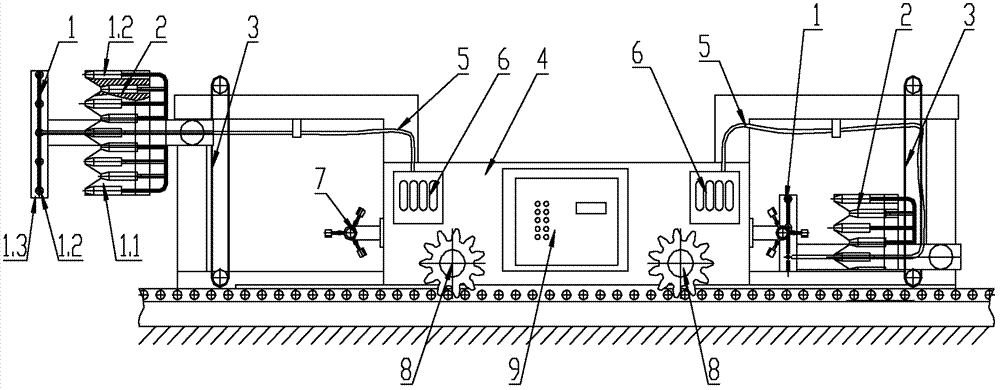

[0038] The present invention also includes a kind of water cutting split coal mining machine, such as figure 1 or figure 2 As shown, it includes a water jet cutting device 1, a water jet cutting device 2, a high-pressure pipeline 5, a high-pressure water pump station 6, and a fuselage 4, etc., and the water jet cutting device 1 is arranged at the front of the water jet cutting device 2 , the high-pressure water pumping station 6 is connected with the water-jet cut...

Embodiment 2

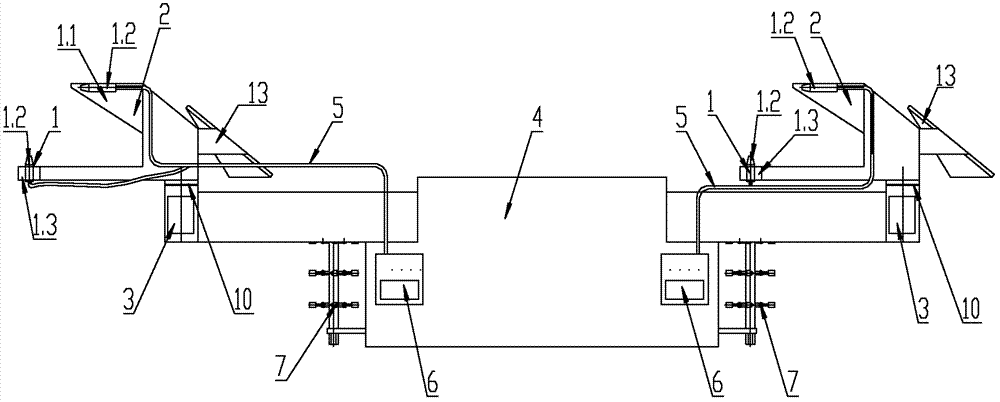

[0048] Such as image 3 or Figure 4As shown, a kind of water cutting and splitting shearer includes a water jet cutting device 1, a water jet cutting device 2, a high pressure pipeline 5, a high pressure water pump station 6 and a fuselage 4, etc., and the water jet cutting device 1 is arranged on The front part of the water-jet cutting device 2, the high-pressure water pump station 6 is connected with the water-jet cutting device 1 and the water-jet cutting device 2 through the high-pressure pipeline 5, the water-jet cutting device 1, the water-jet cutting device 2, the high-pressure The water pumping station 6 is arranged on the fuselage.

[0049] The coal dropping mechanism 1.1 is a wedge fork, and a cone head, a wedge shovel, a hammer, a nozzle, a dial and / or a pry bar can also be used, and the coal dropping mechanism 1.1 will expand or drop the cut coal seam.

[0050] The water jet cutting device 1 includes a moving mechanism 11, and the water jet cutting device 2 and ...

Embodiment 3

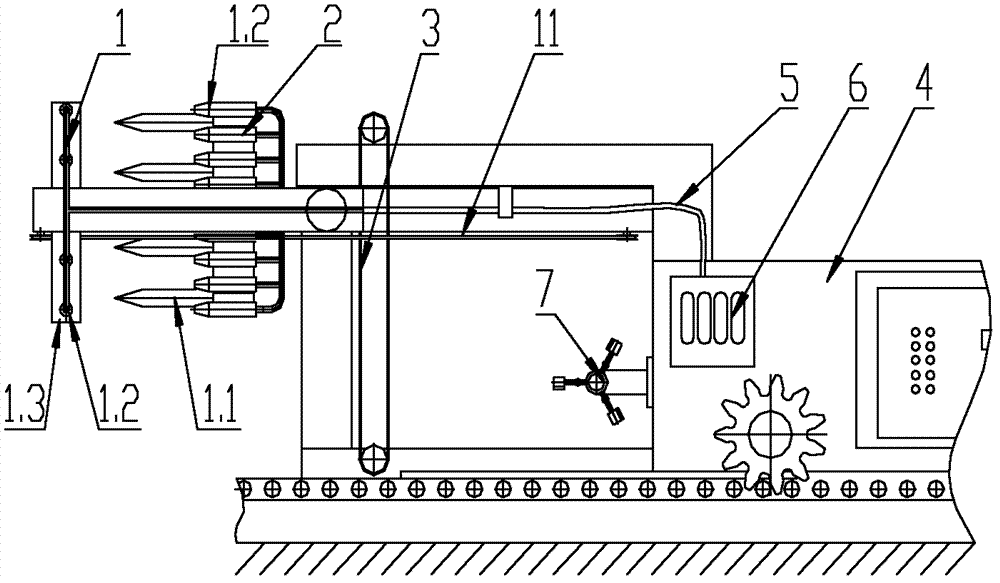

[0053] Such as Figure 5 As shown, a kind of water cutting and splitting shearer includes a water jet cutting device 1, a water jet cutting device 2, a high pressure pipeline 5, a high pressure water pump station 6 and a fuselage 4, etc., and the water jet cutting device 1 is arranged on The front part of the water-jet cutting device 2, the high-pressure water pump station 6 is connected with the water-jet cutting device 1 and the water-jet cutting device 2 through the high-pressure pipeline 5, the water-jet cutting device 1, the water-jet cutting device 2, the high-pressure The water pumping station 6 is arranged on the fuselage.

[0054] Described lifting device 3 adopts the vertical lifting device 3 of screw nut structure, also can adopt rack and pinion, rope and rope reel, sprocket wheel and chain, hydraulic cylinder and / or air cylinder etc.

[0055] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com