Mining machine with rocker arm provided with coal-passing space

A mining machine and space technology, applied in the field of machinery, can solve problems such as difficulty in loading materials, failure to bring out the advantages and comprehensive performance of the mining head, and failure to transport coal out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

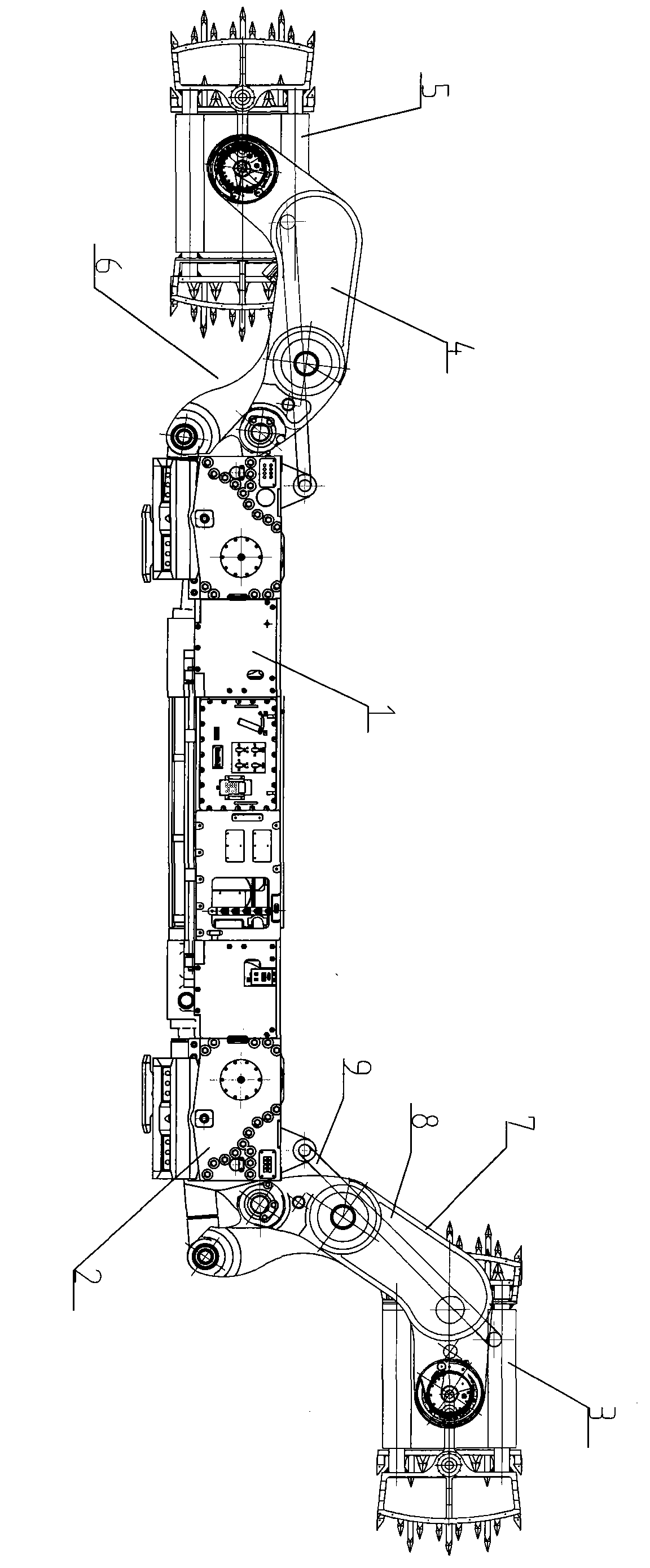

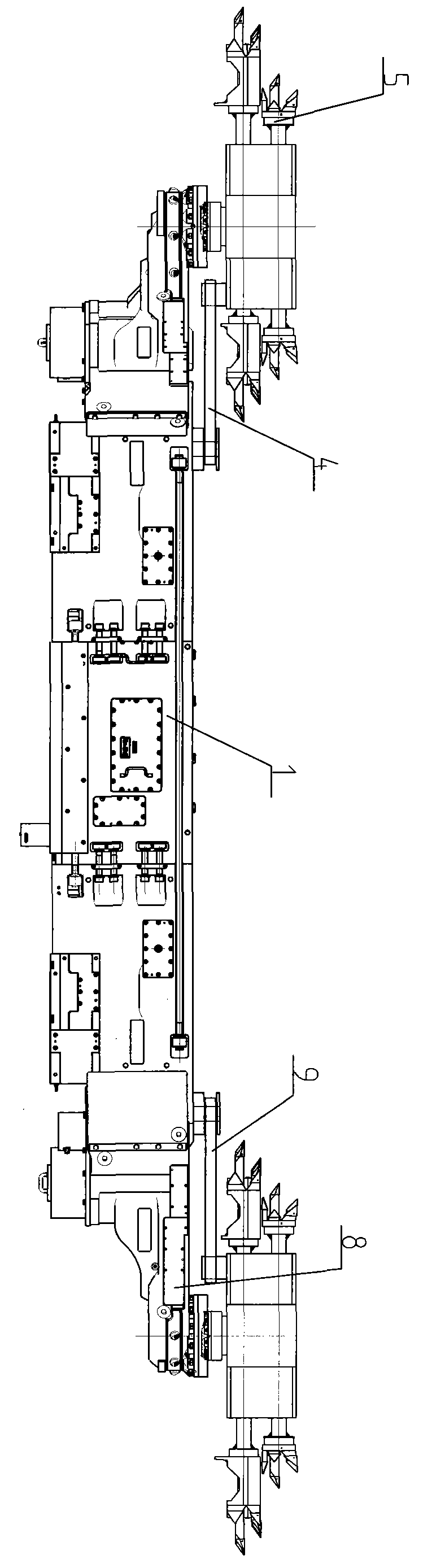

[0484] figure 1 , figure 2 The rocking arm 4 described in Embodiment 1 is provided with a coal passing space 6 mining machine, and the rocking arm 4 is provided with a coal passing space 6 mining machine including a fuselage 1, a walking part 2, a cutting part 3, etc., and the cutting part 3 includes a rocker arm 4, a cutting head 5, etc., the running part 2 is arranged at the bottom of the fuselage 1, the cutting part 3 is arranged at both ends of the fuselage 1, one end of the rocker arm 4 is connected with the fuselage 1, and the rocker arm 4 The other end of the rocker arm 4 is connected with the cutting head 5, and the rocker arm 4 arches upwards to form a coal-passing space 6.

[0485] The rocker arm 4 used in this embodiment is a parallelogram rocker arm 7. The parallelogram rocker arm 7 includes a main rocker arm 8 and an auxiliary rocker arm 9. The auxiliary rocker arm 9 is arranged on the upper part of the main rocker arm 8. The main rocker arm 8 Arch upwards to f...

Embodiment 2

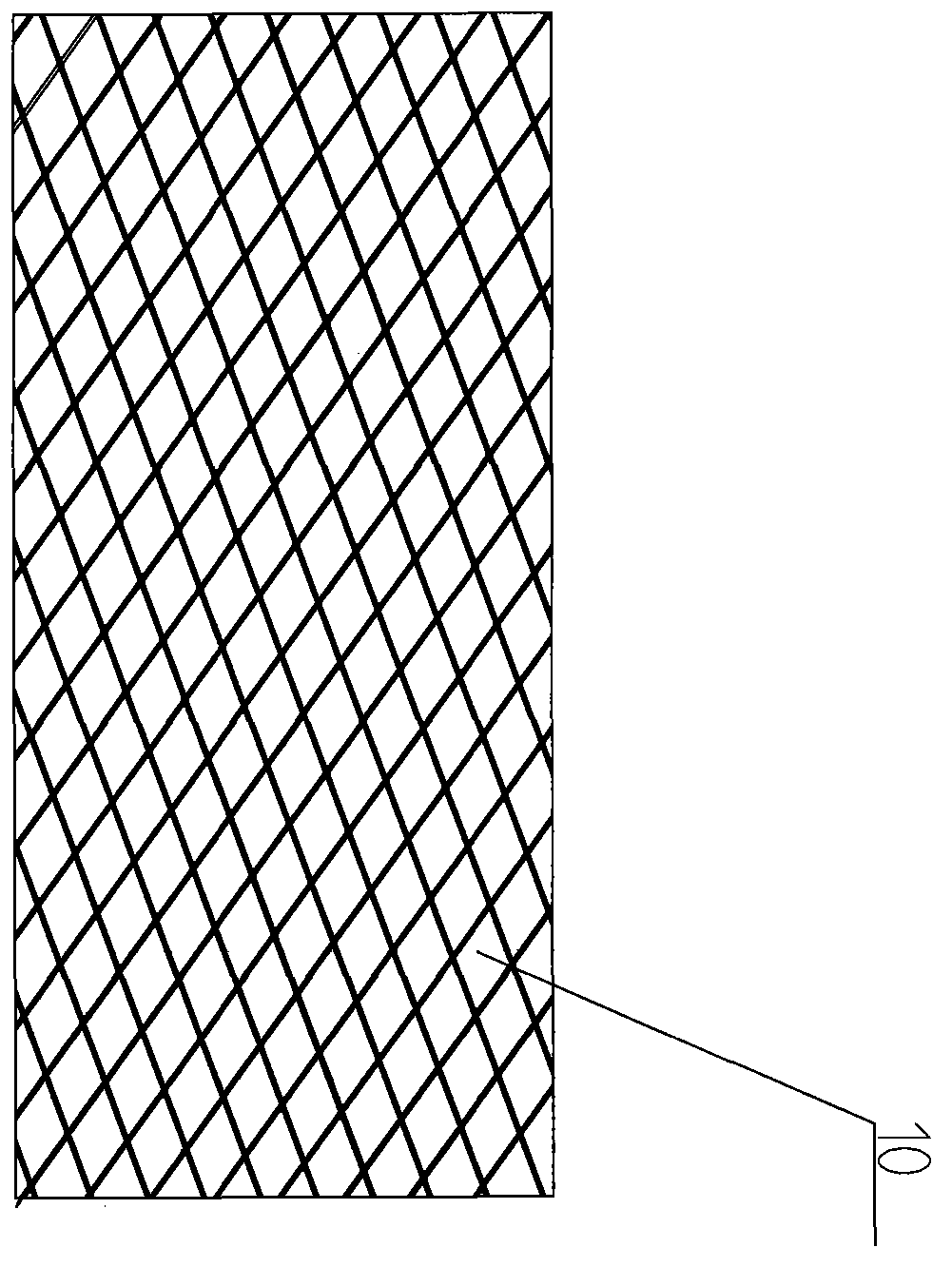

[0495] image 3 The rocker arm 4 described in Example 2 is provided with a coal passing space 6 mining machine, and the coal passing surface of the rocker arm 4 is made of surfacing wear-resistant materials, and the shape of the surfacing wear-resistant materials is a rhombus grid 10 arrangement.

[0496] Others are with embodiment 1.

Embodiment 3

[0498] Figure 4 The rocking arm 4 described in Embodiment 3 is provided with a coal-passing space 6 mining machine, the cutting head 5 includes an impact power box 11, an impact head 14, an impact guide mechanism 13, and an impact power mechanism 12, and the impact head 14 includes an impact gear seat 15. The impact tooth 16, the impact tooth holder 15 and the impact tooth 16 are separate or integrated structures. The impact power mechanism 12 is a crank power mechanism 17 .

[0499] The impact power mechanism 12 can also be a hydraulic power mechanism or a pneumatic power mechanism.

[0500] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com