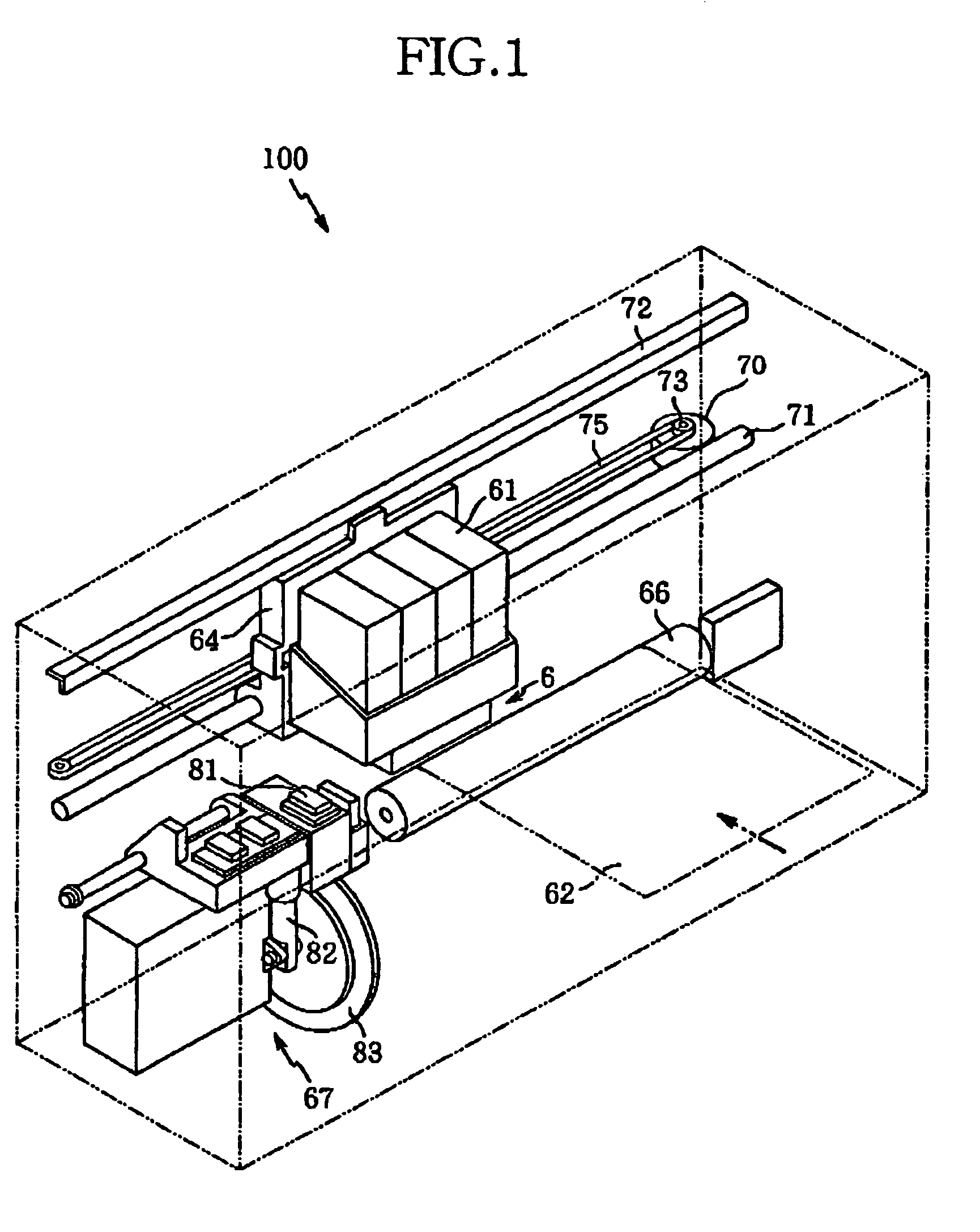

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Increase liquid pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

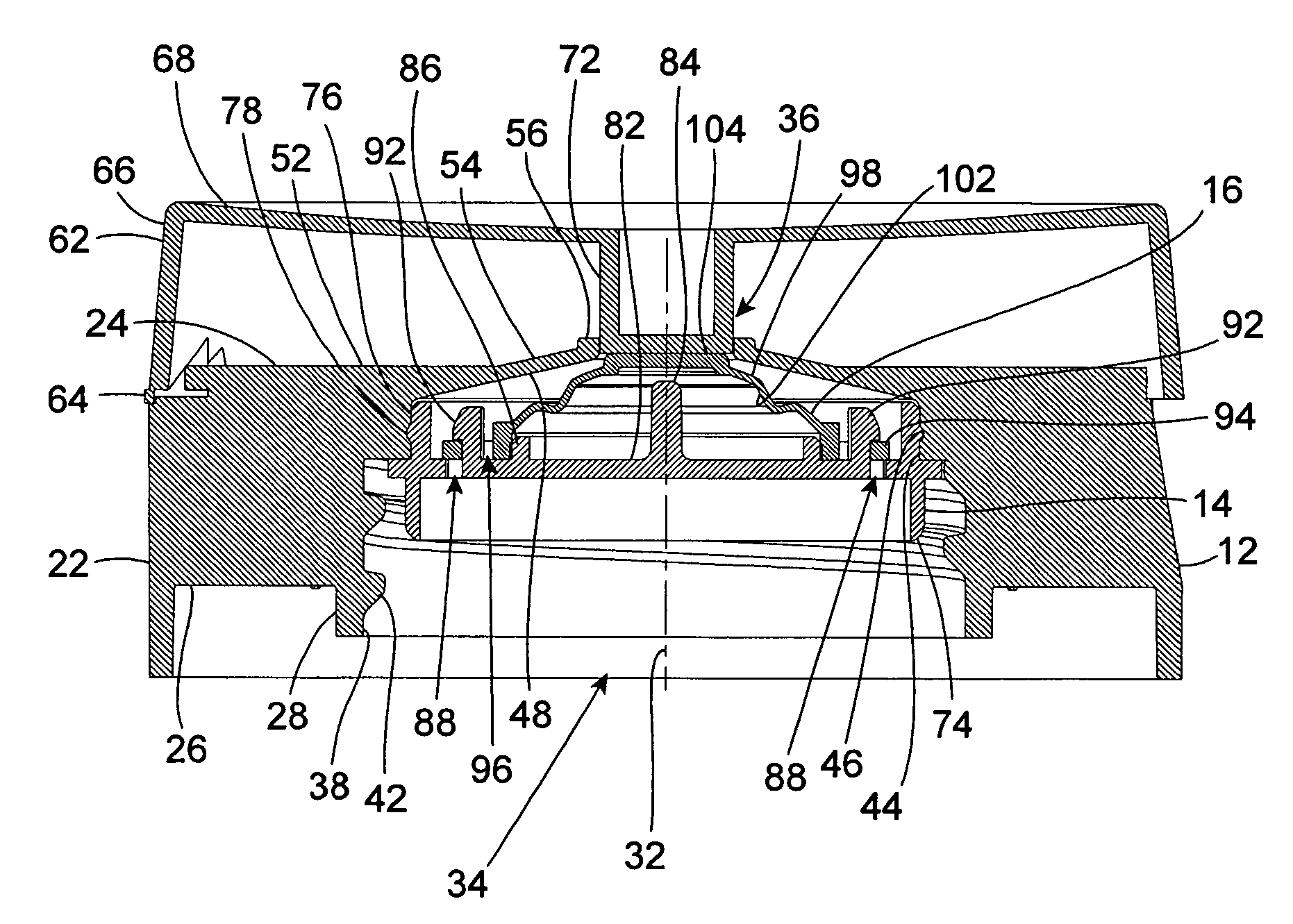

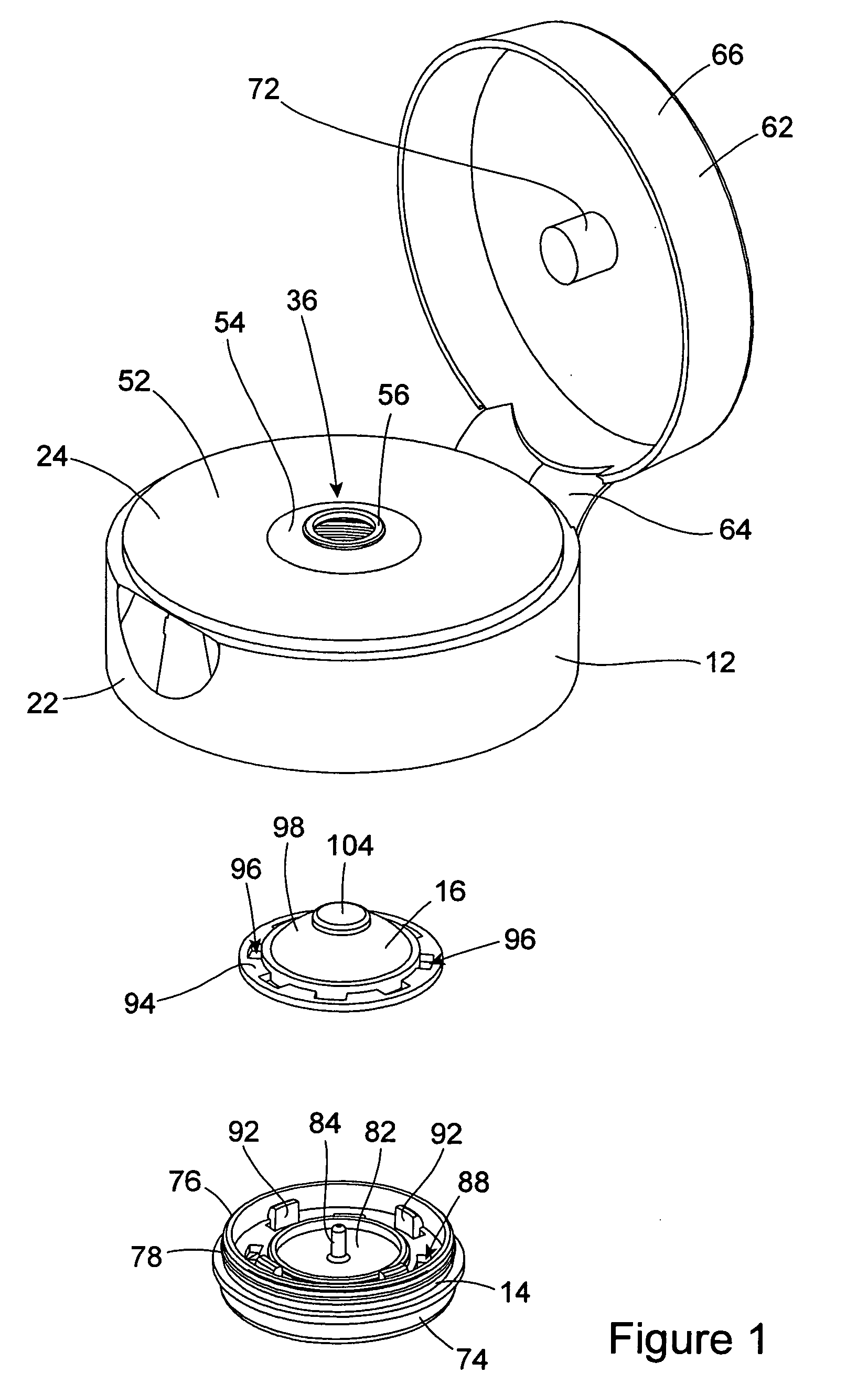

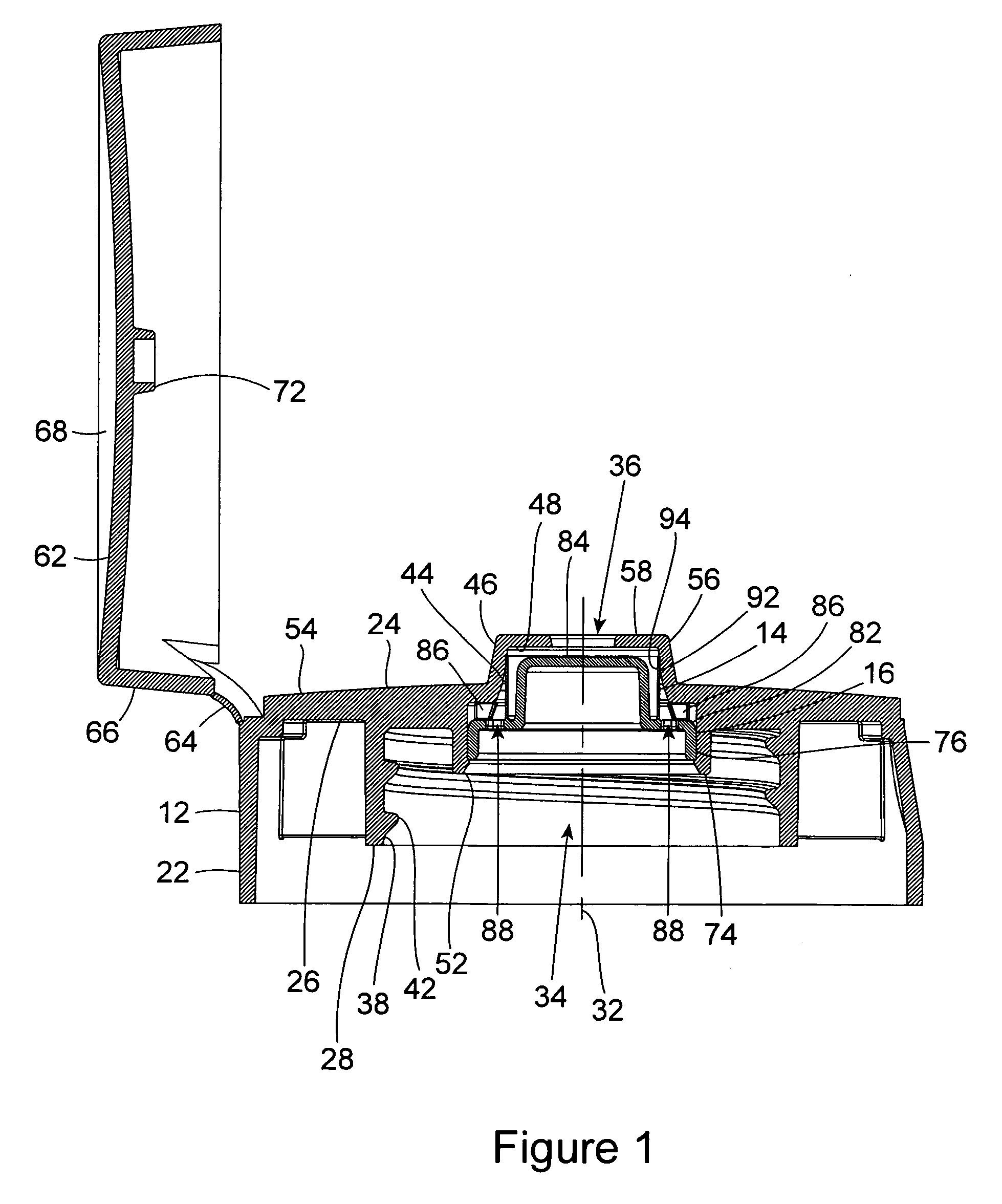

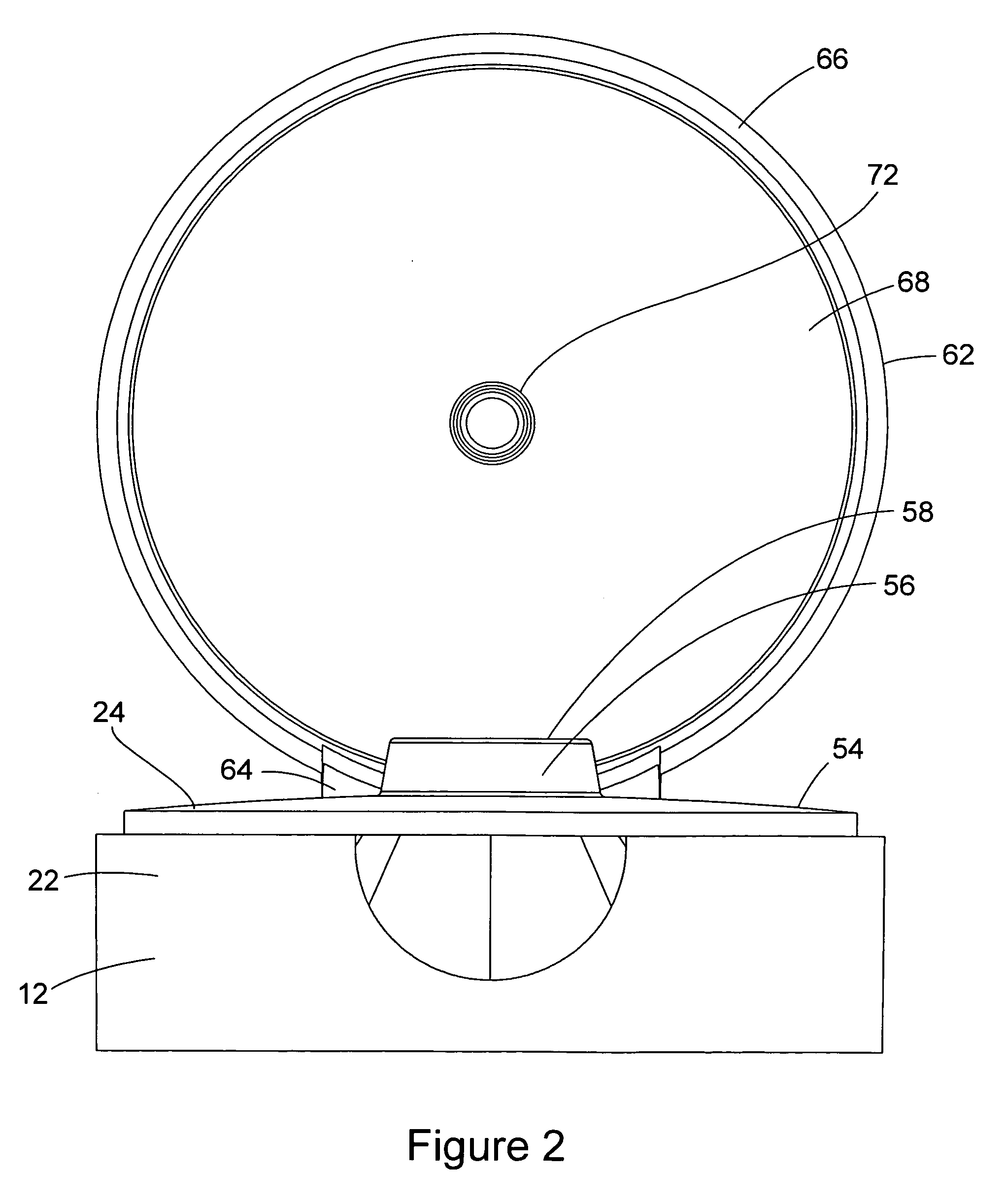

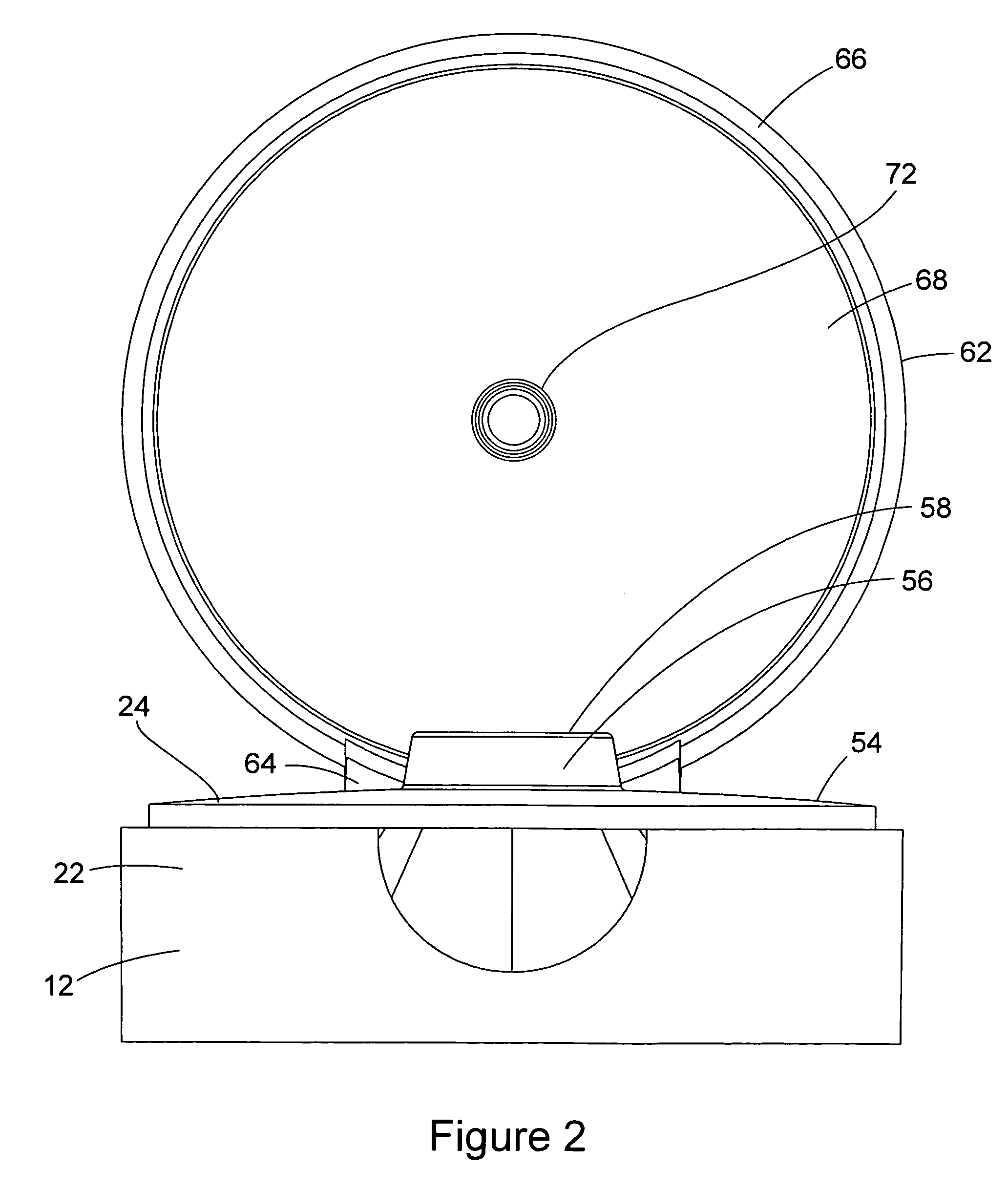

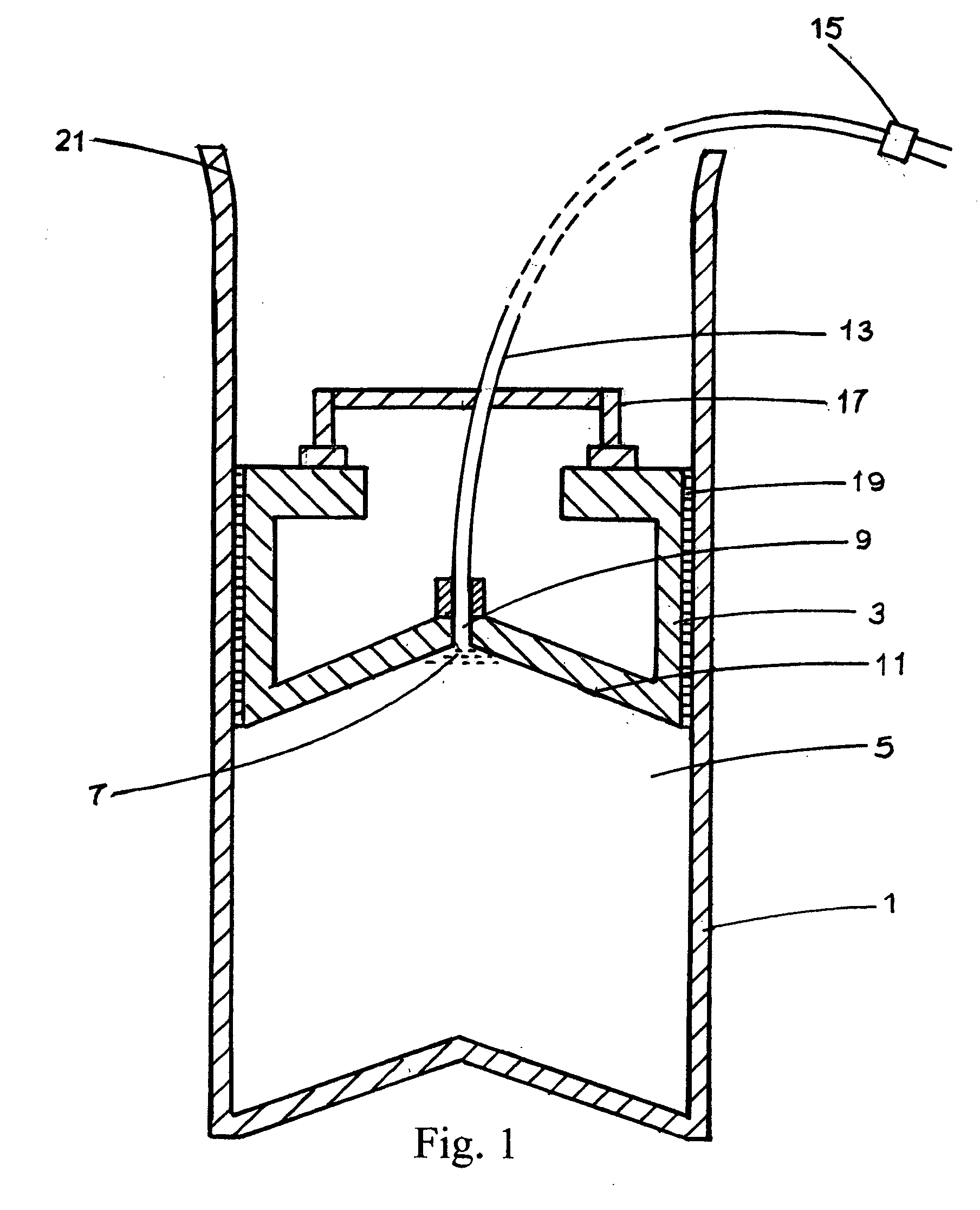

Container closure with biased closed valve

ActiveUS20070045356A1Increase liquid pressureIncrease pressureClosuresLiquid flow controllersEngineeringMechanical engineering

Owner:WESTROCK DISPENSING SYST

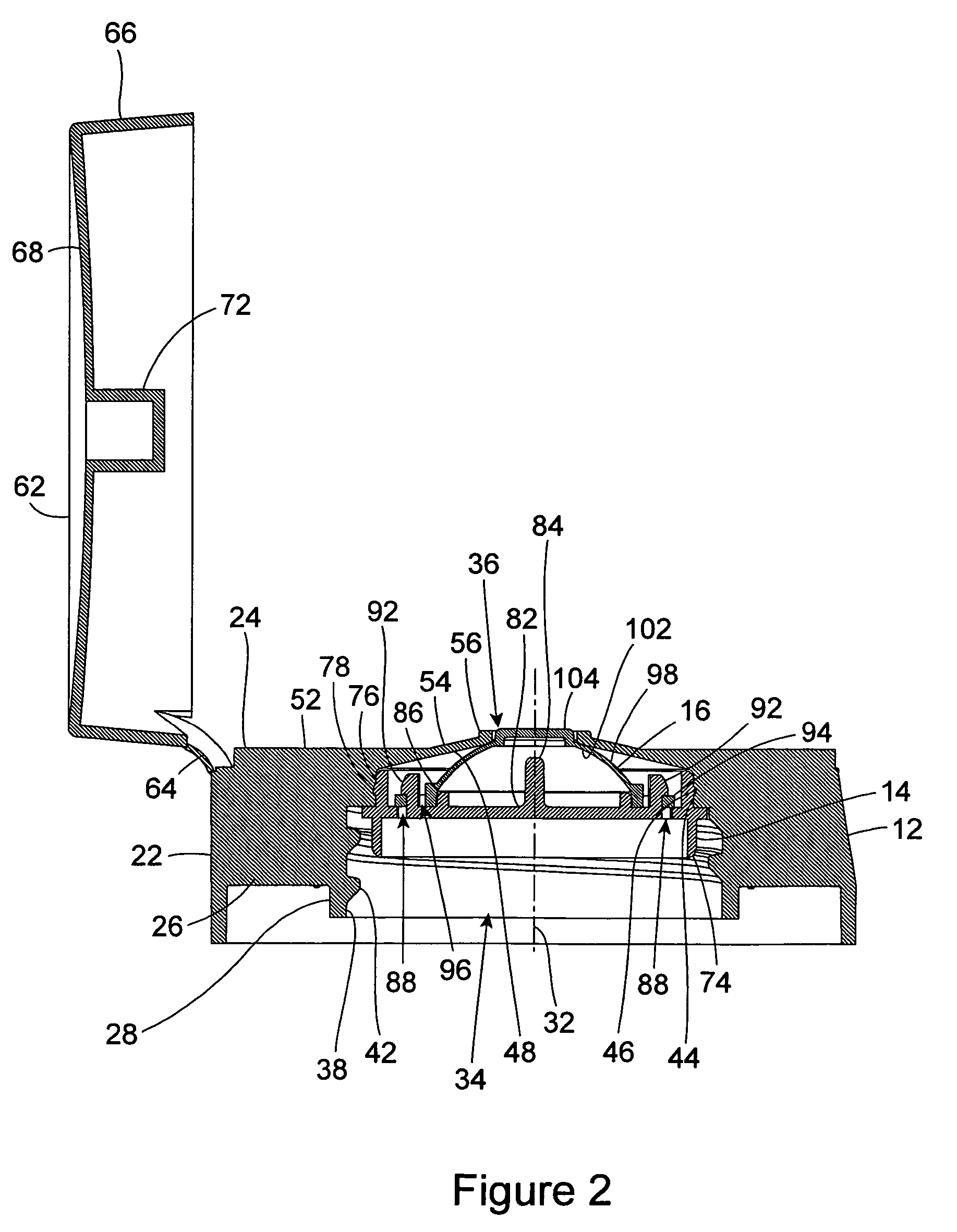

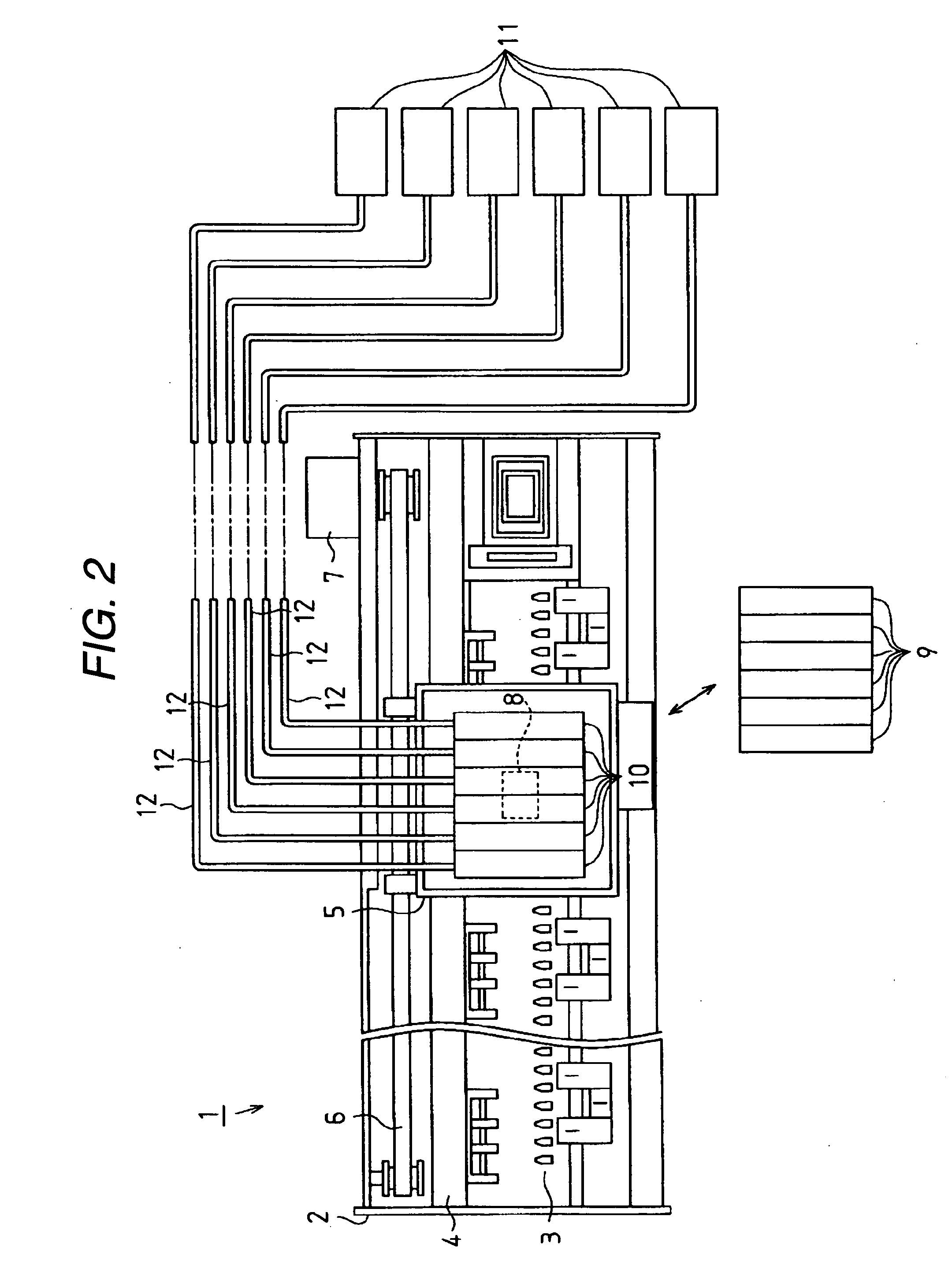

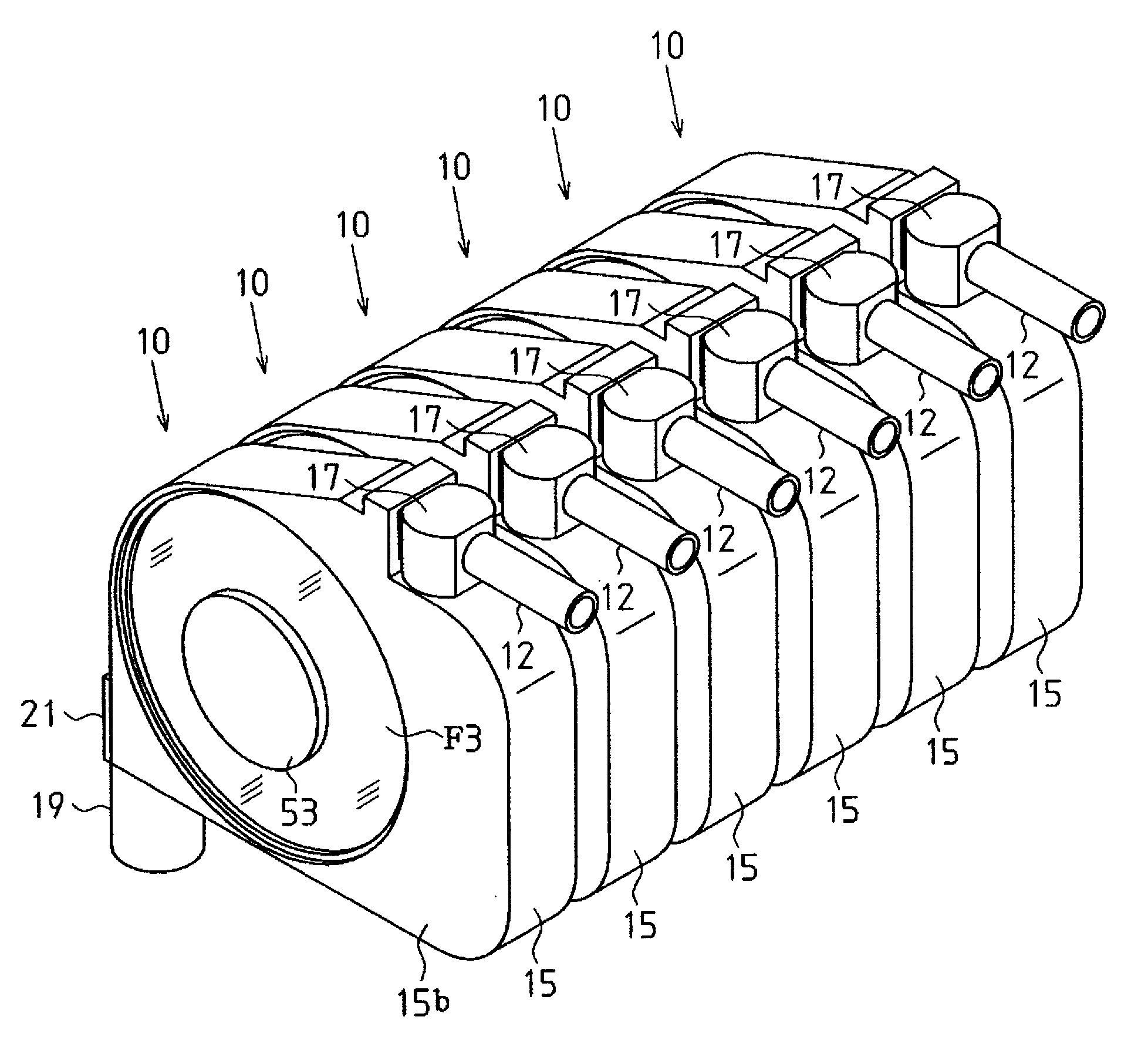

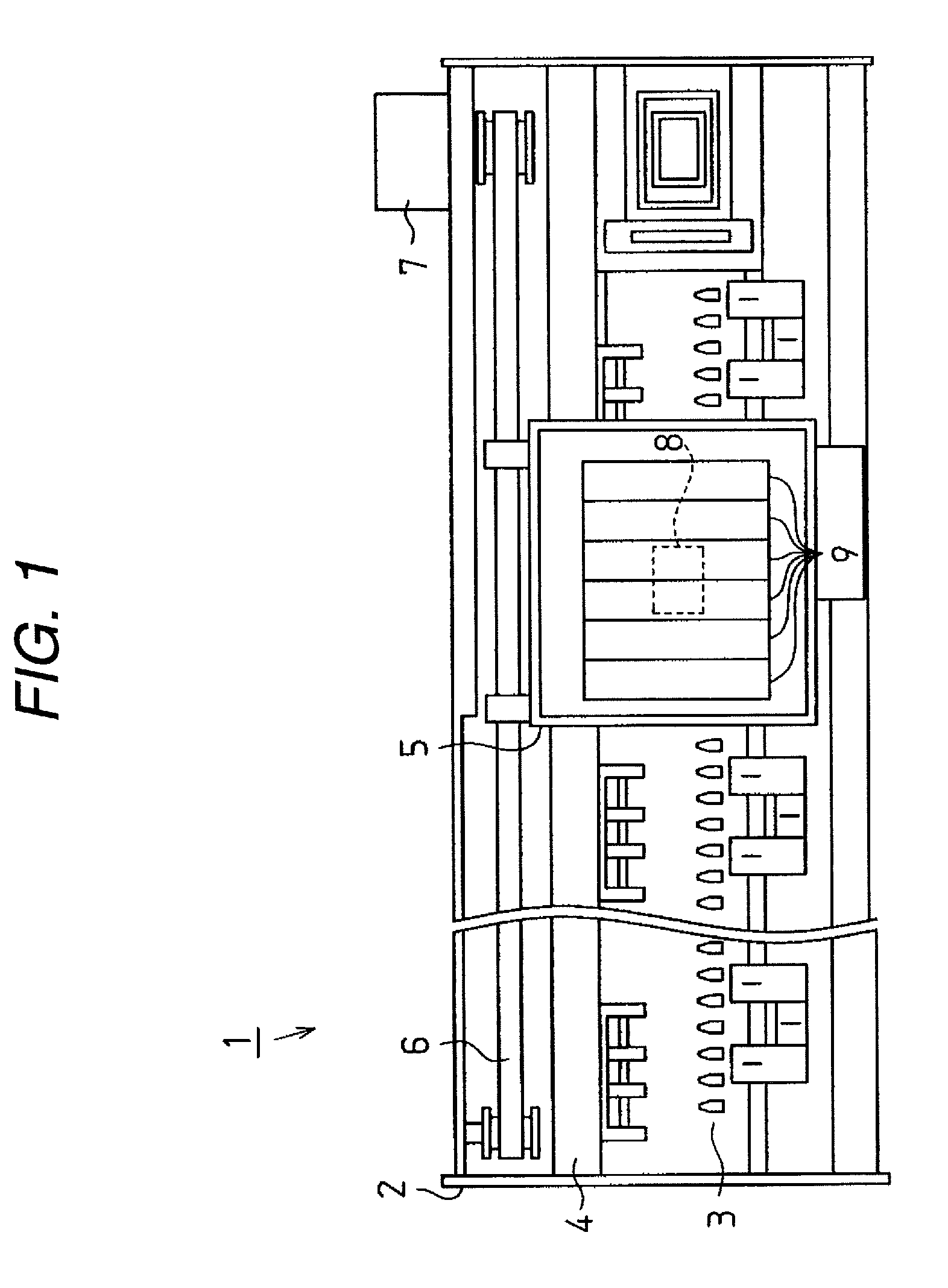

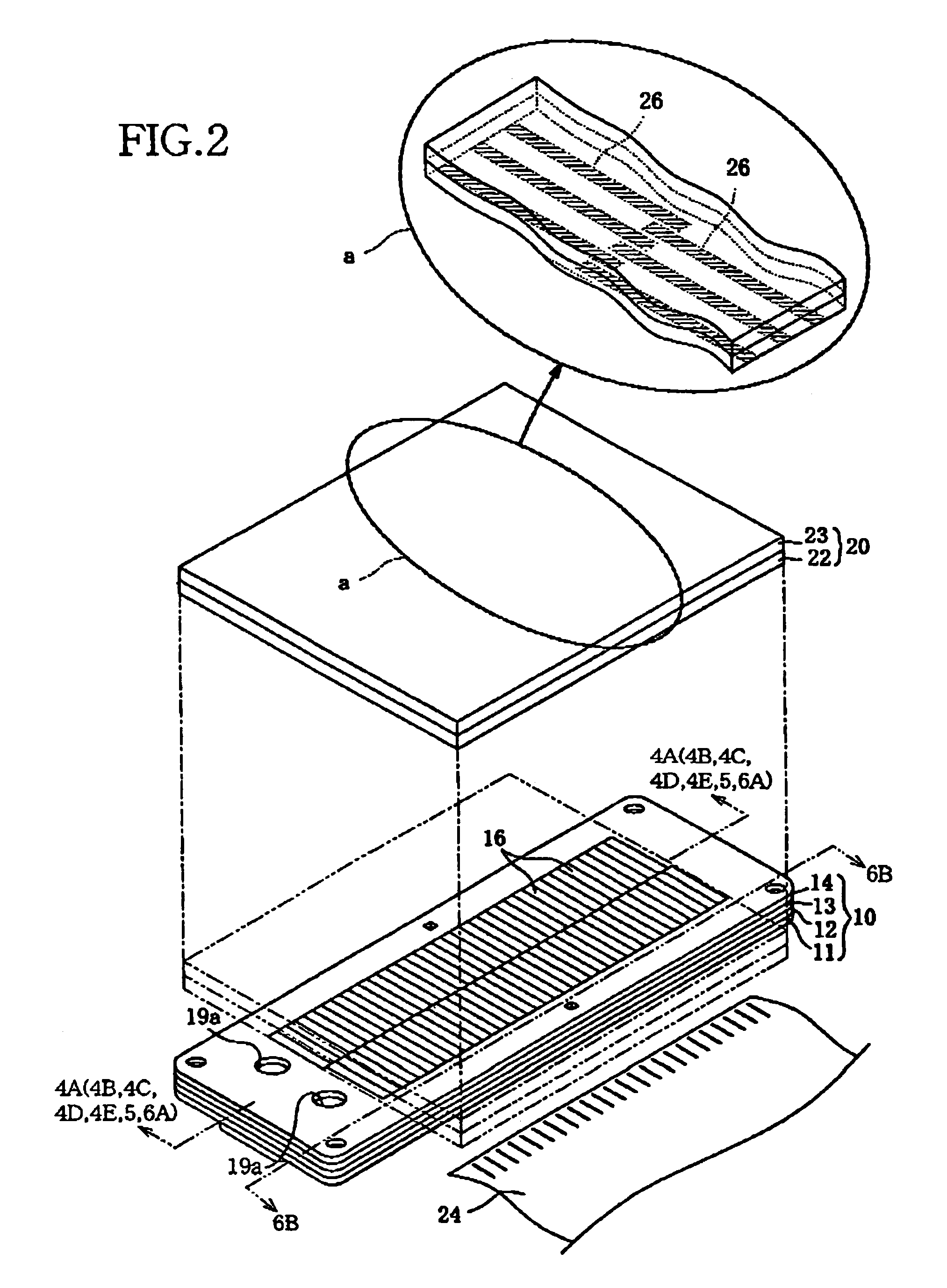

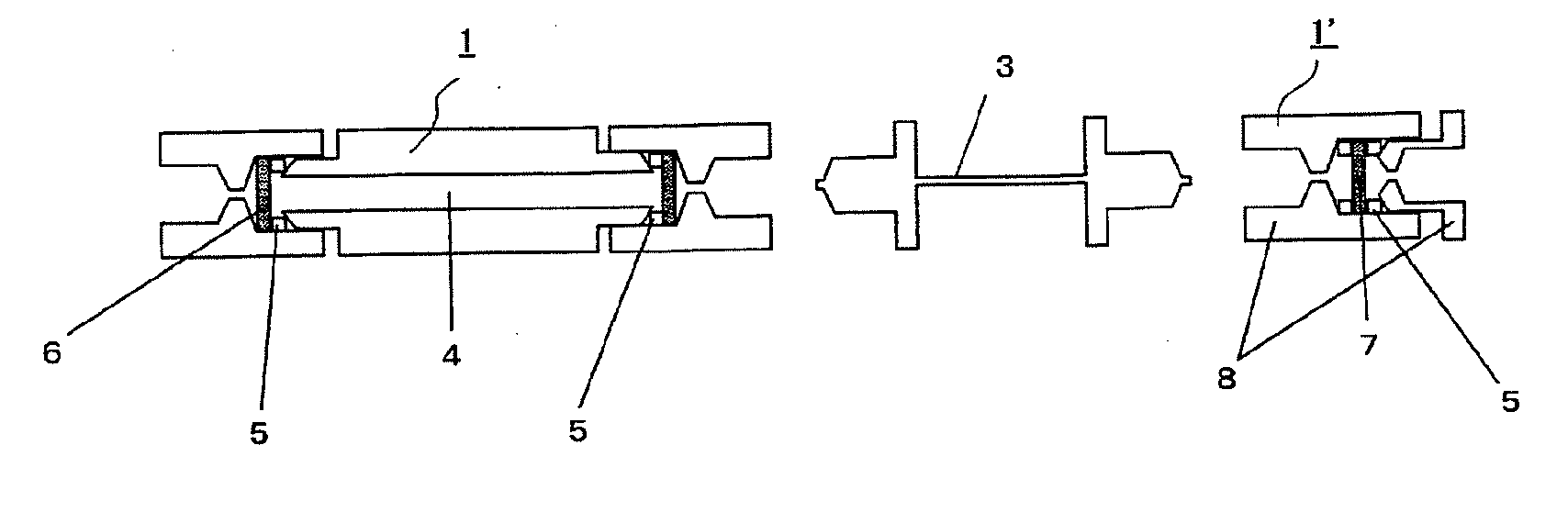

Attachment and liquid supplying

InactiveUS20050219281A1Uniform liquid jet qualityIncrease liquid pressureOther printing apparatusLiquid jetEngineering

An attachment is mountable on a carriage in place of a liquid container that contains liquid and that is mounted on the carriage having a liquid jet head for jetting liquid, so that the attachment can supply liquid introduced from outside to the liquid jet head. The attachment has a pressure control means provided in a flow passage which is formed in an attachment body and through which the liquid introduced from the outside is supplied to the liquid jet head.

Owner:SEIKO EPSON CORP

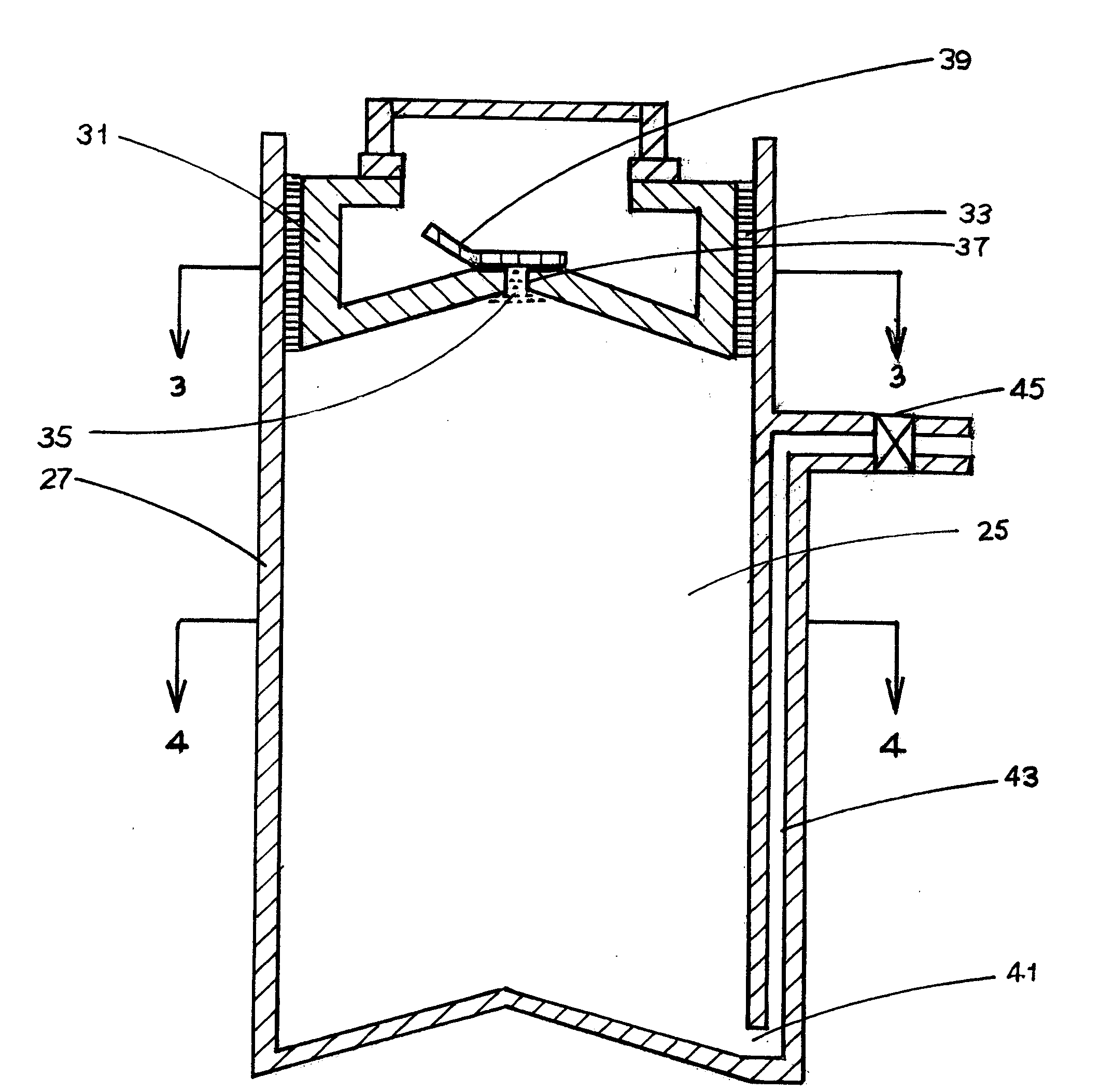

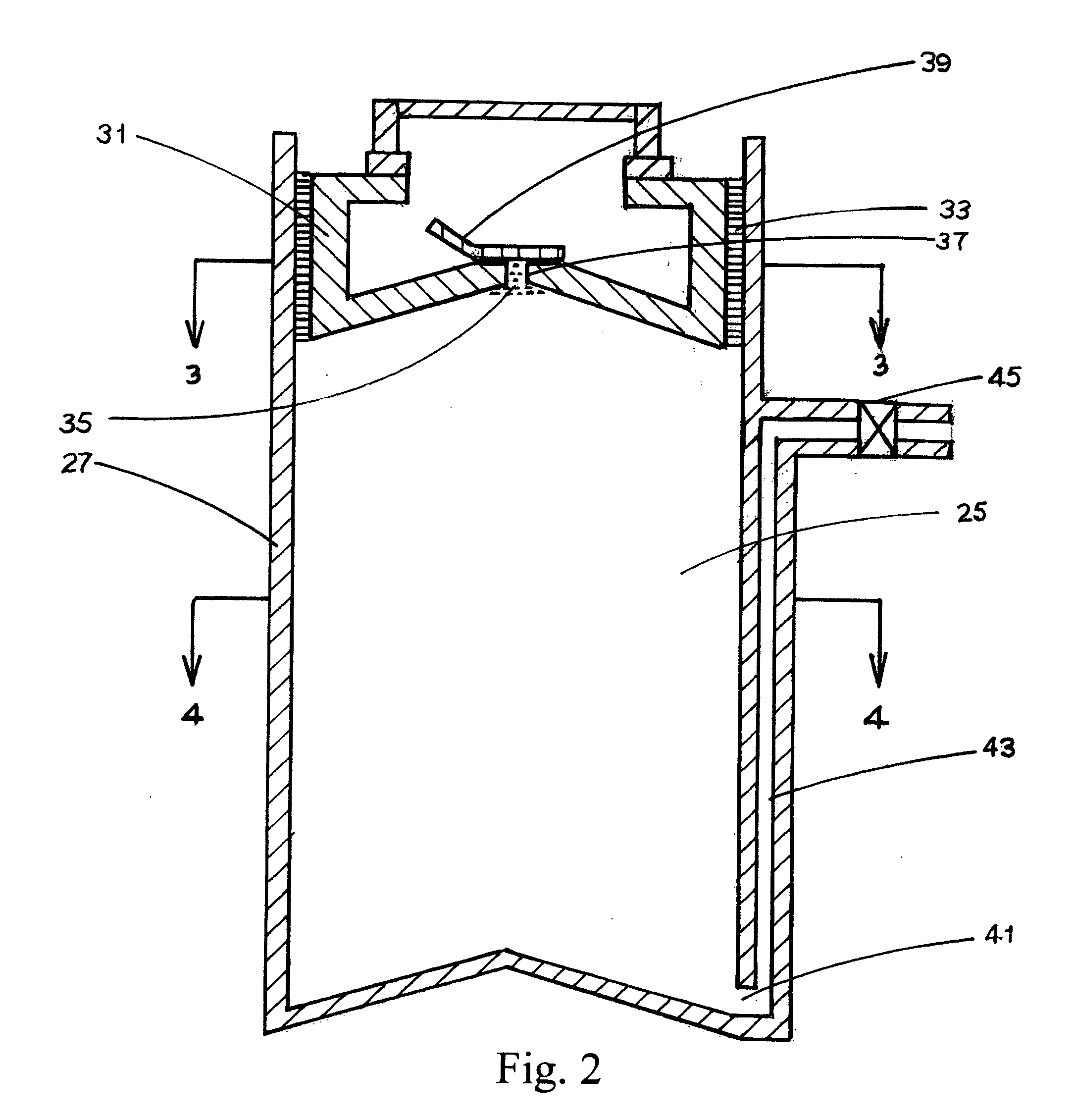

Container closure with biased closed tube valve

ActiveUS20070051755A1Increase pressure of liquidEasy constructionClosuresLiquid flow controllersEngineeringVALVE PORT

Owner:WESTROCK DISPENSING SYST

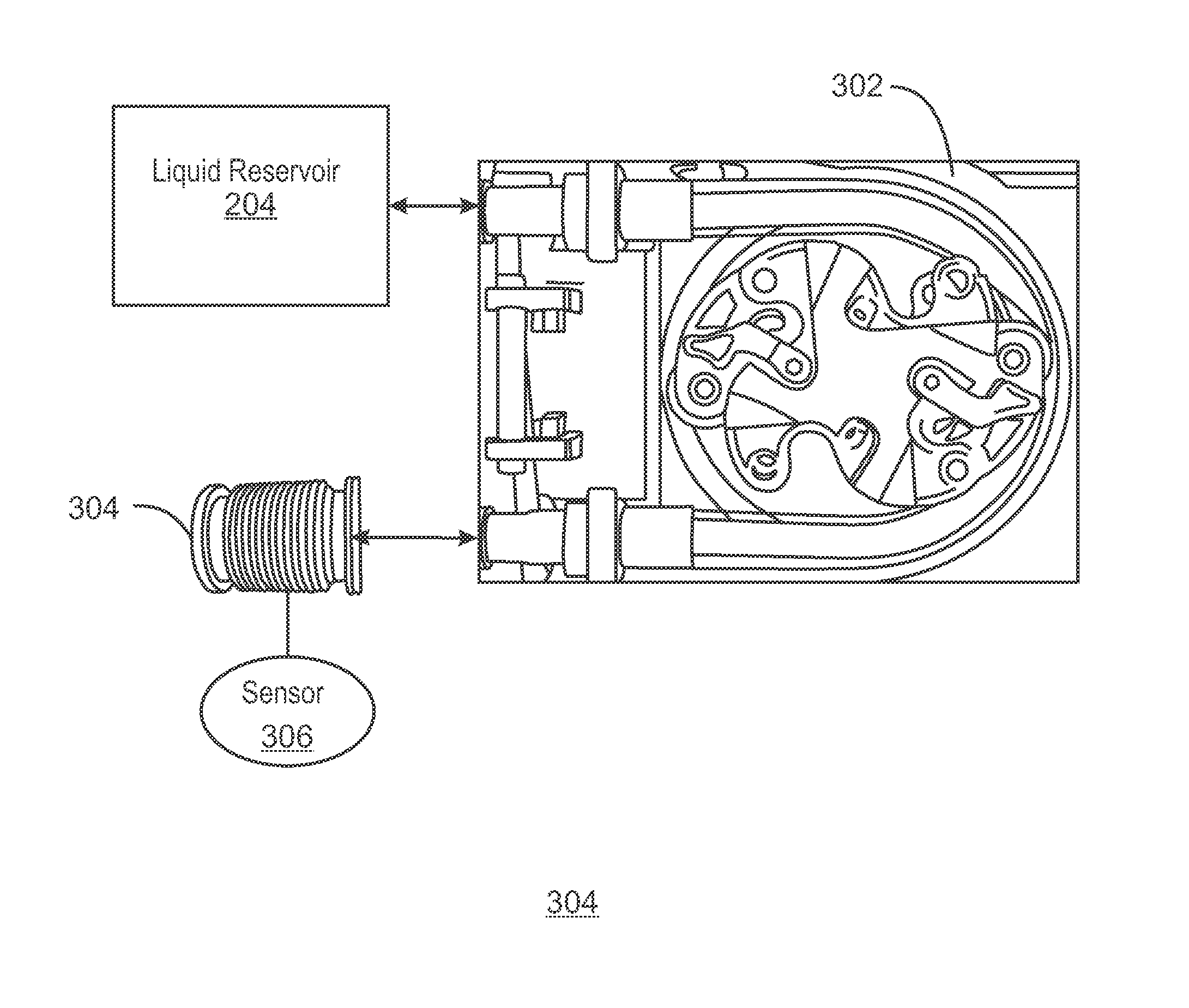

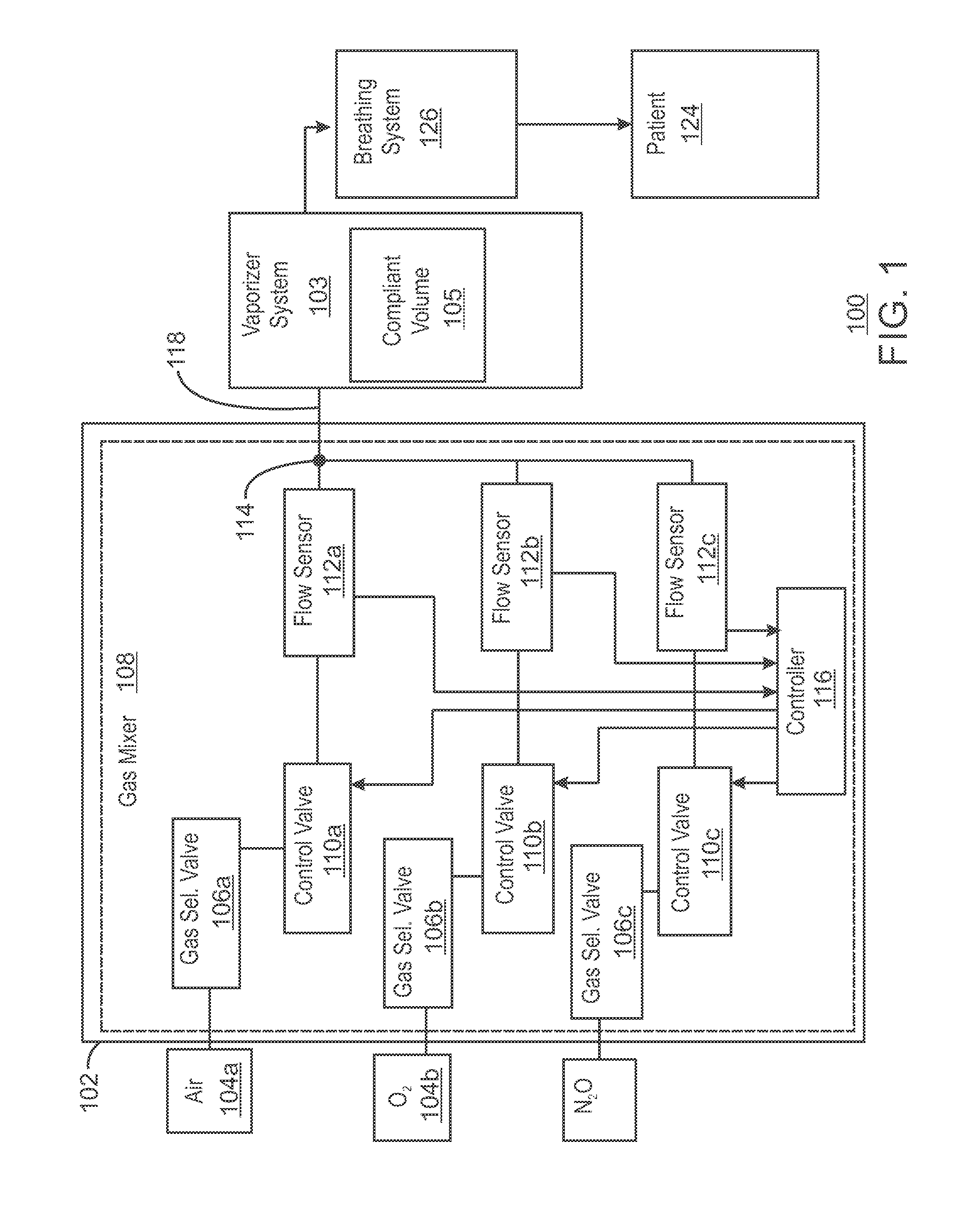

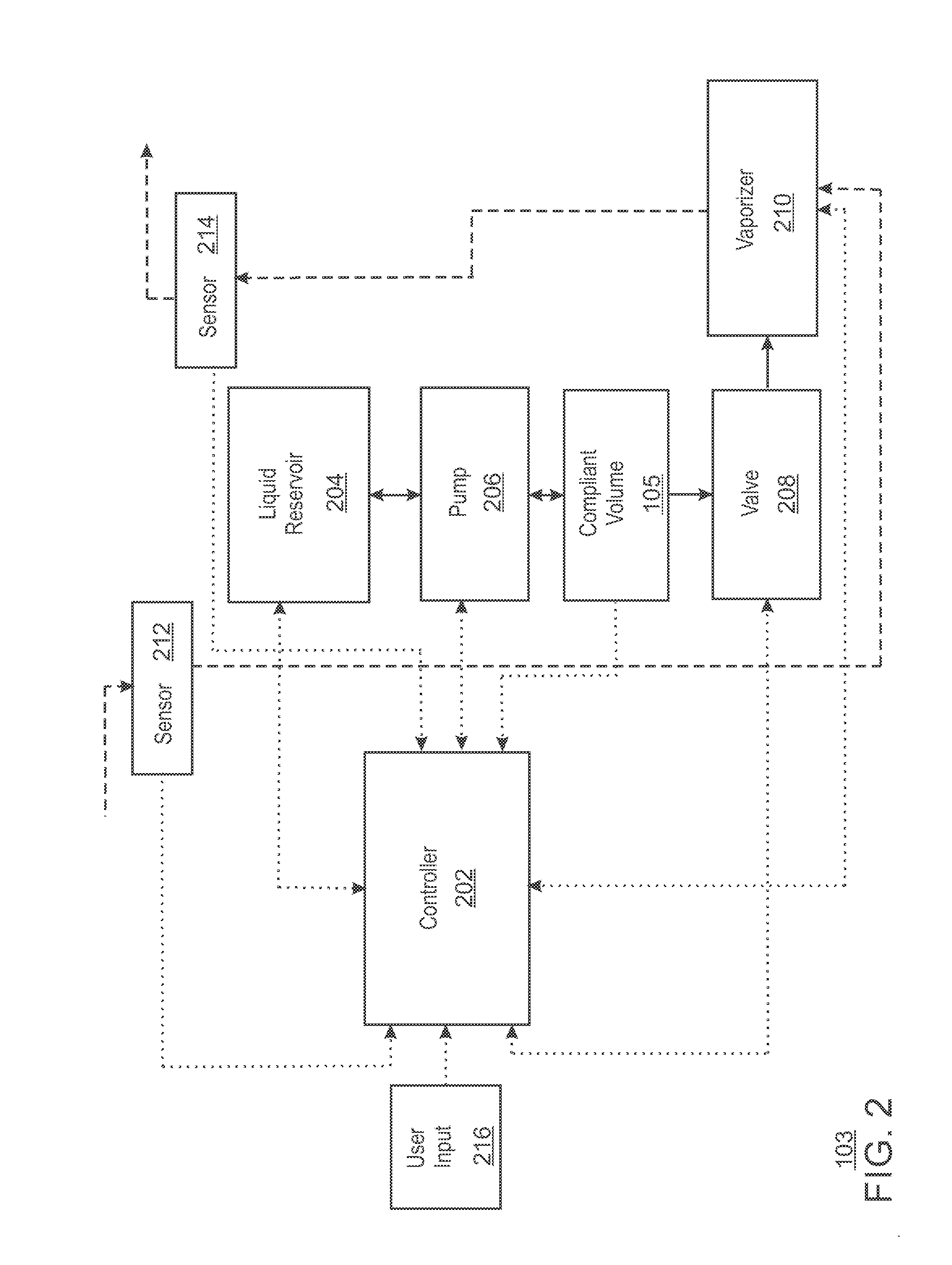

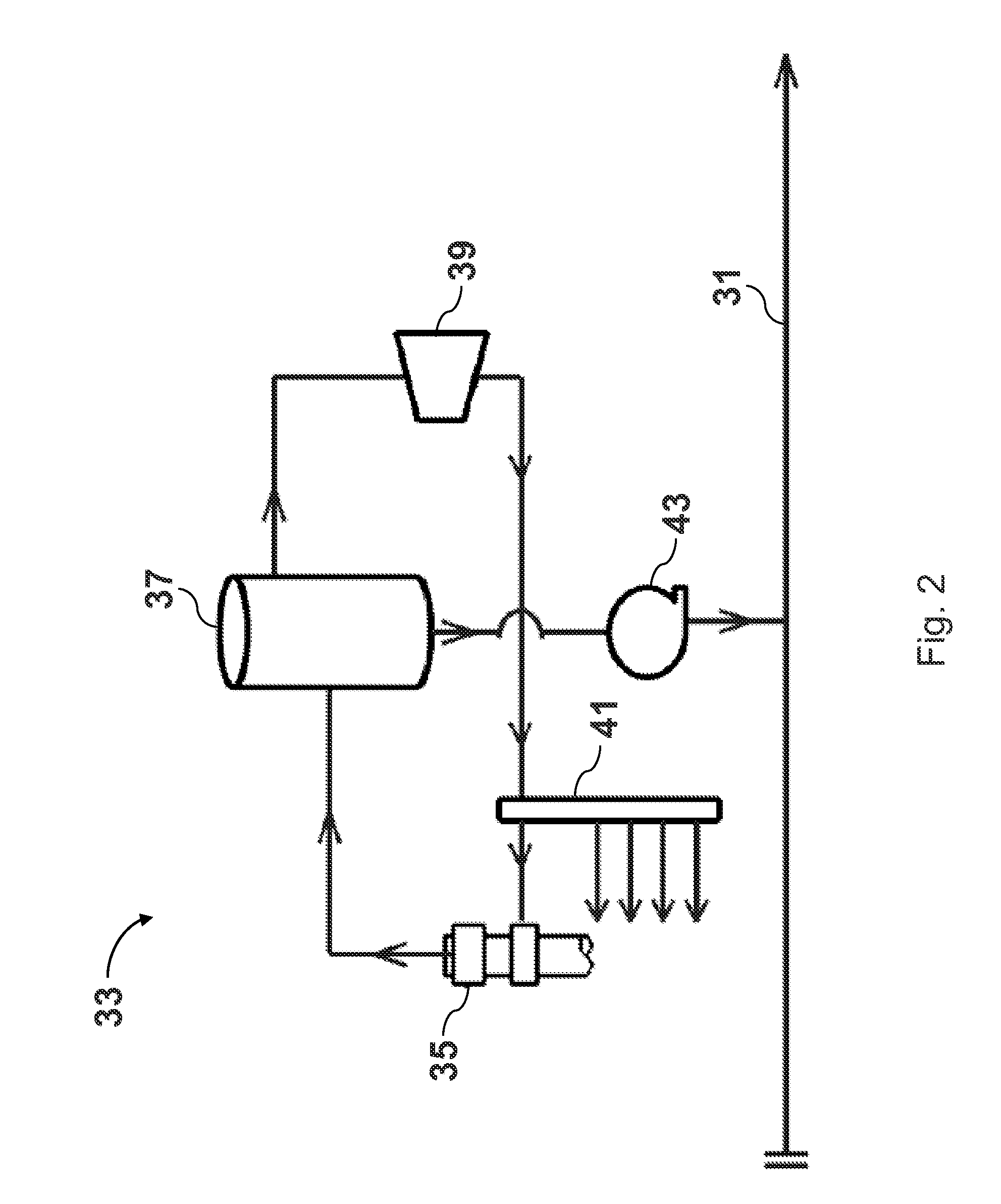

Anesthesia Compliant Volume System and Method

ActiveUS20160008567A1Increase pressureIncrease liquid pressureRespiratorsMedical devicesEngineeringVALVE PORT

A system for pressurizing liquid is described herein. The system may include a liquid reservoir and a pump coupled to the liquid reservoir, the pump to draw liquid from the liquid reservoir. A compliant volume coupled to the pump receives liquid from pump. The compliant volume is composed of an elastic material to increase pressure of the liquid. A valve coupled to the compliant volume receives pressurized liquid from the compliant volume.

Owner:GENERAL ELECTRIC CO

Attachment and attachment system

InactiveUS20100201762A1Uniform liquid jet qualityIncrease liquid pressureOther printing apparatusLiquid jetEngineering

Owner:SEIKO EPSON CORP

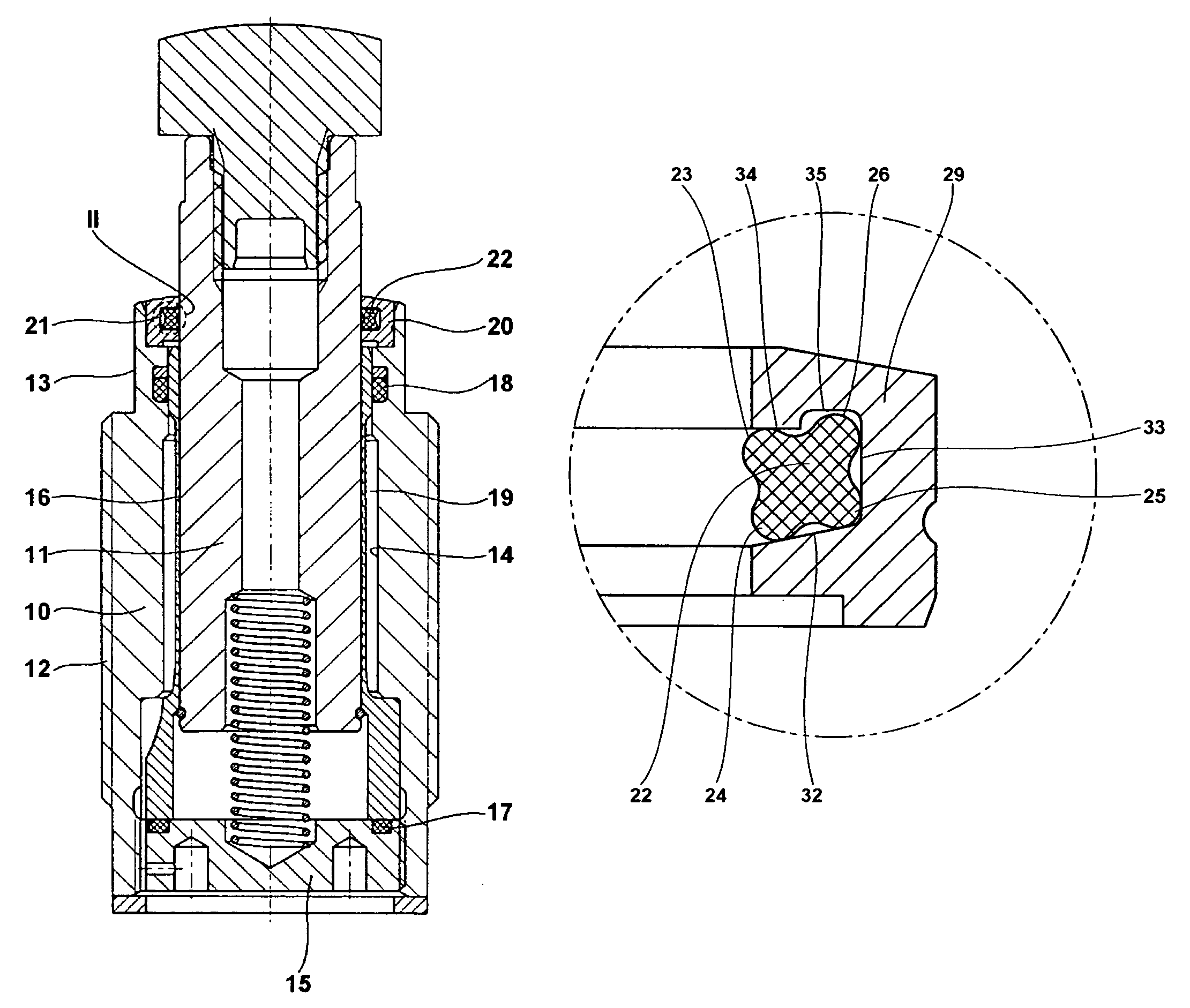

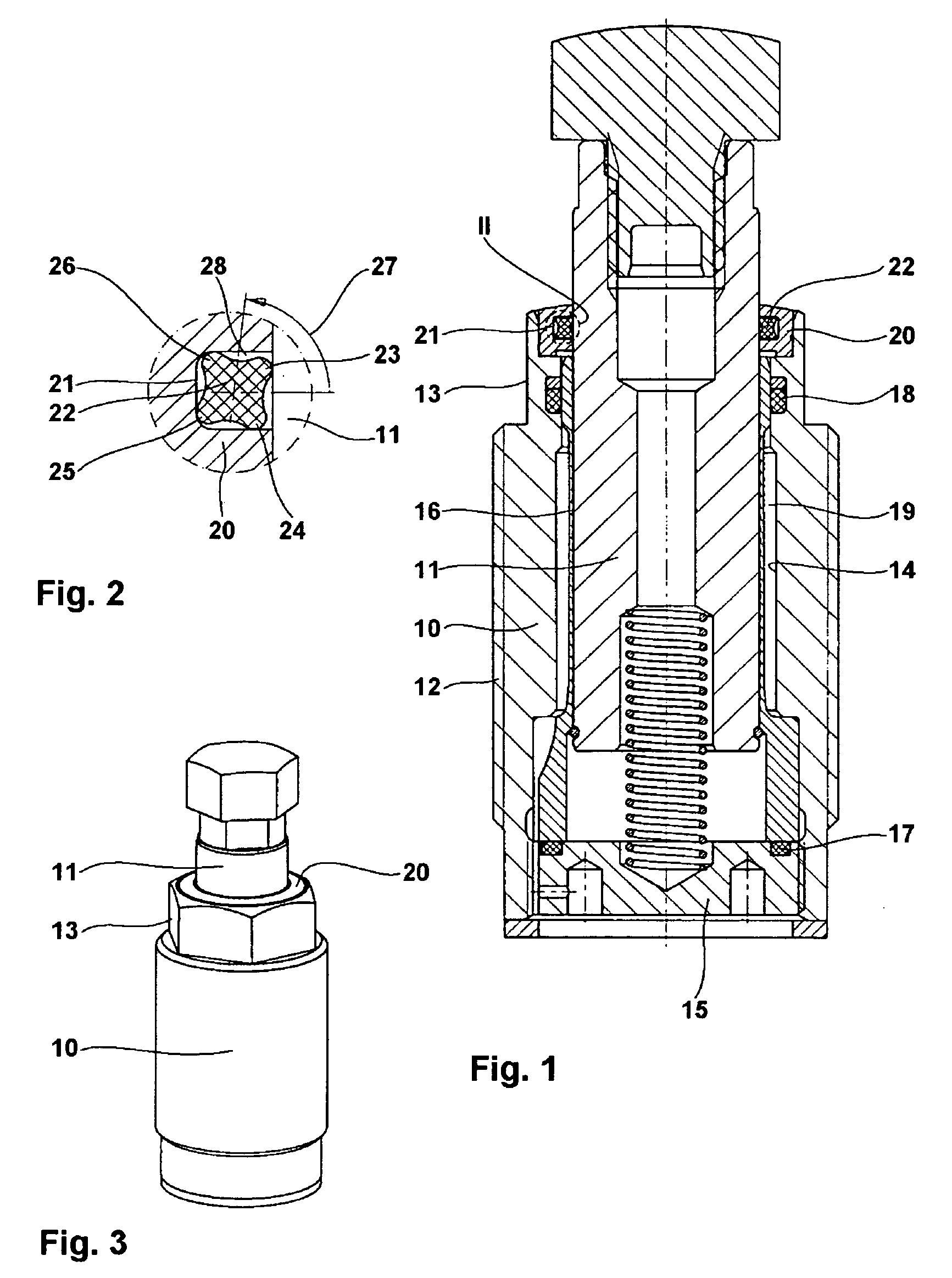

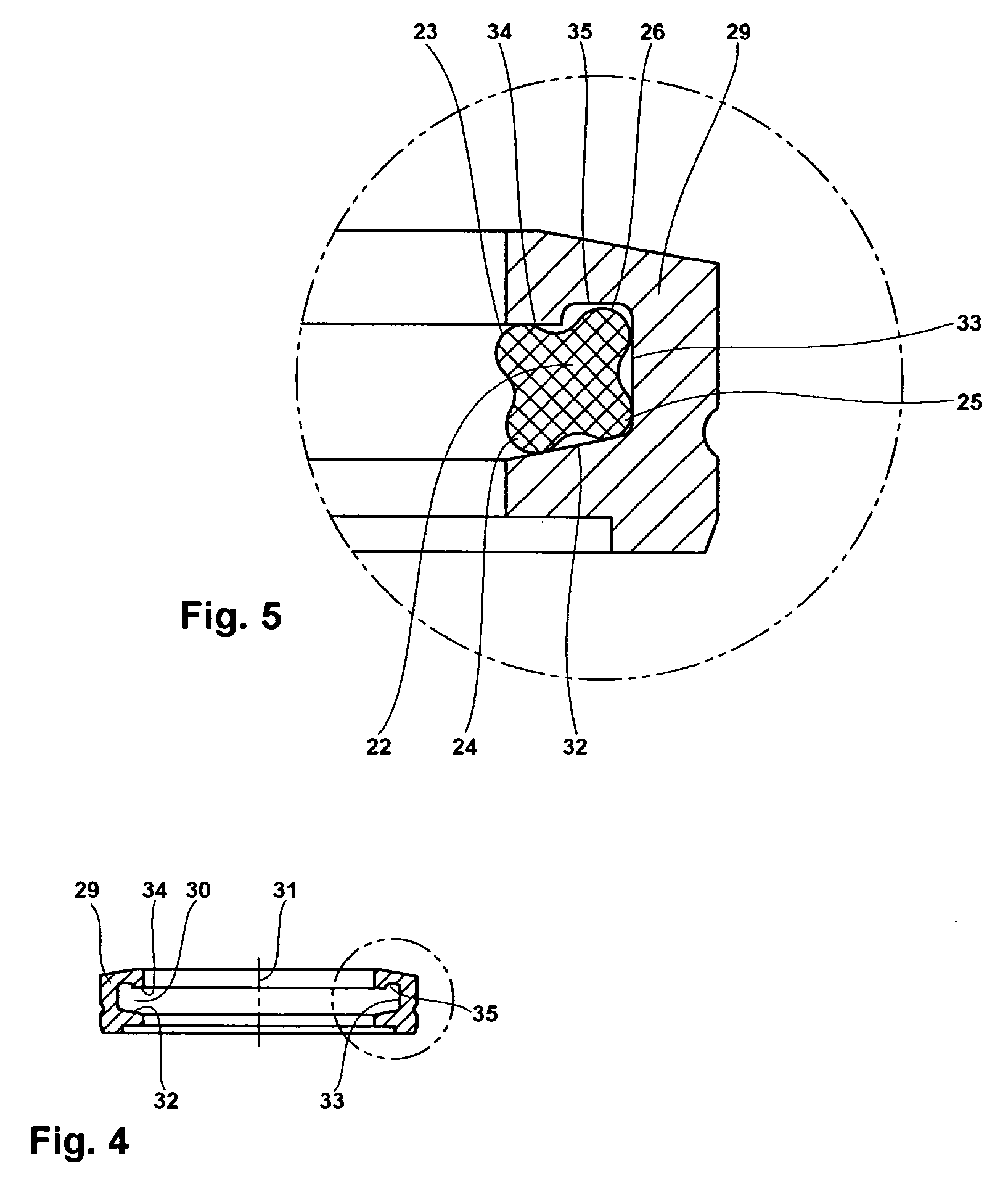

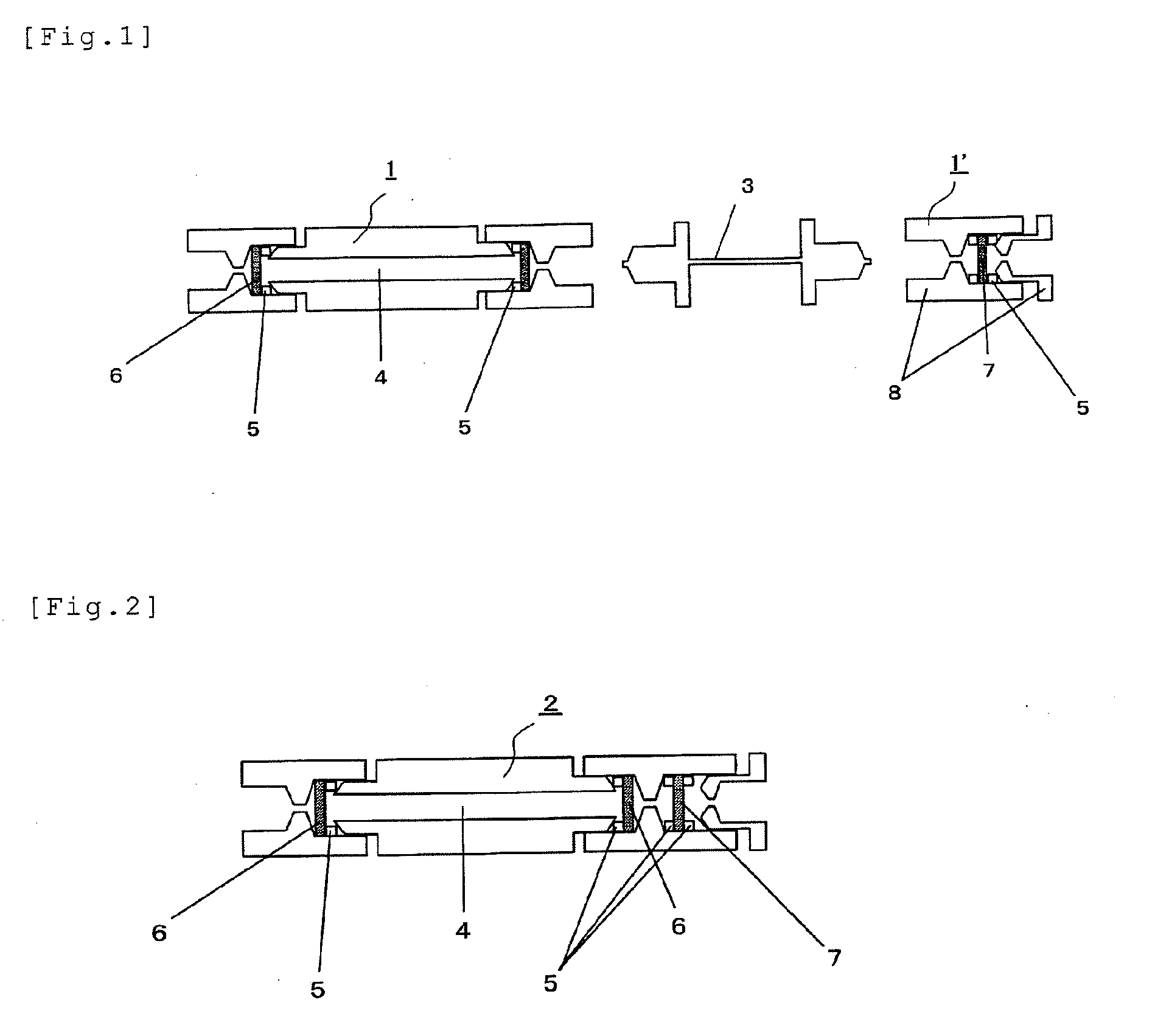

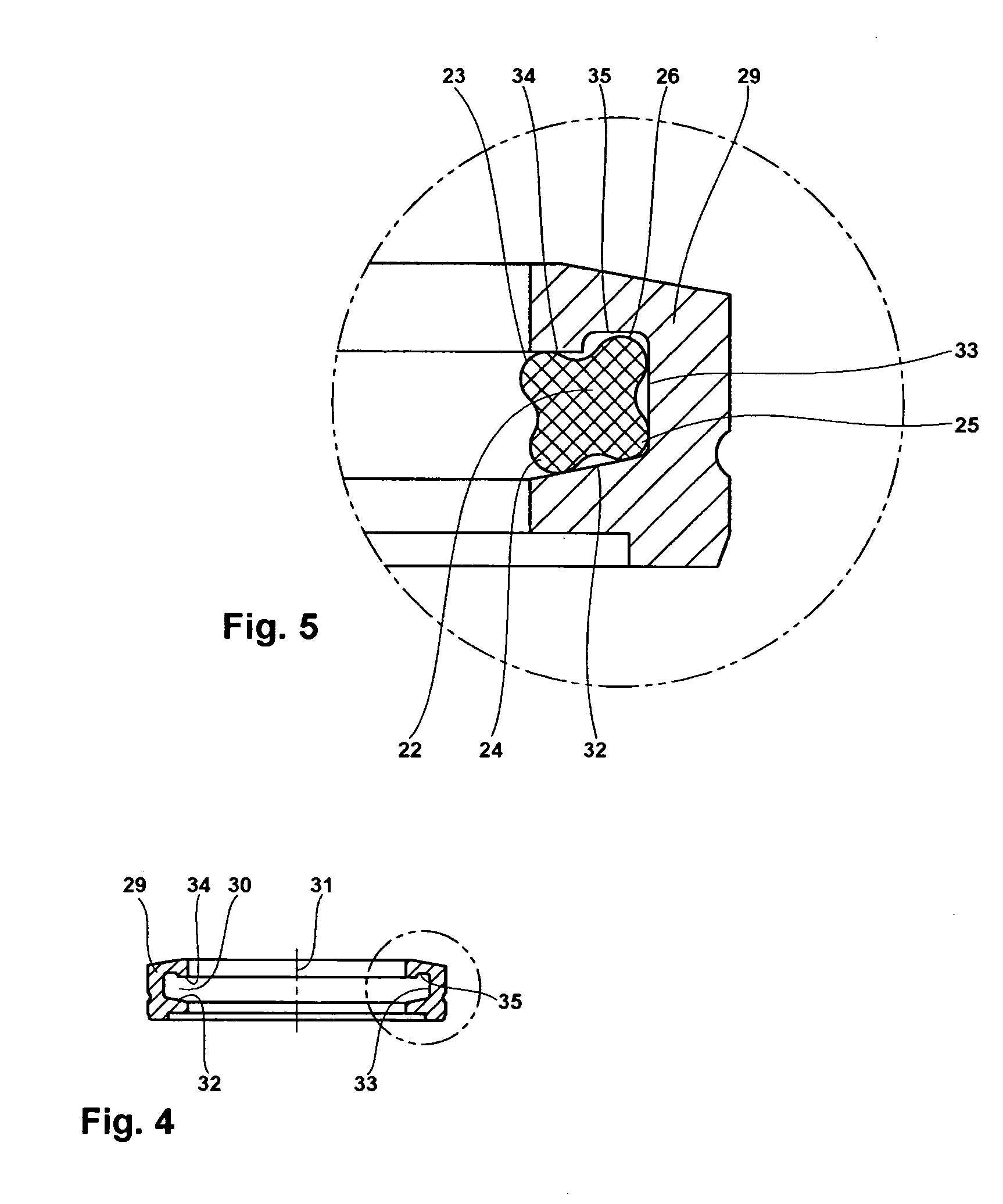

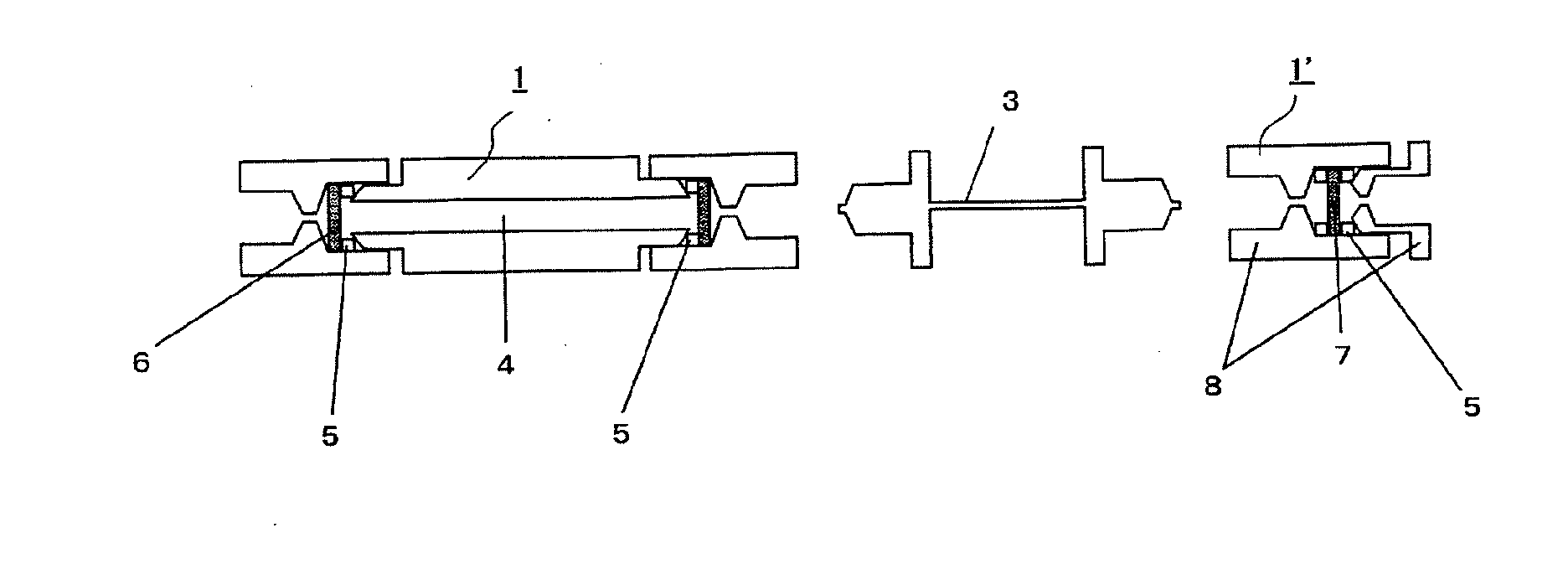

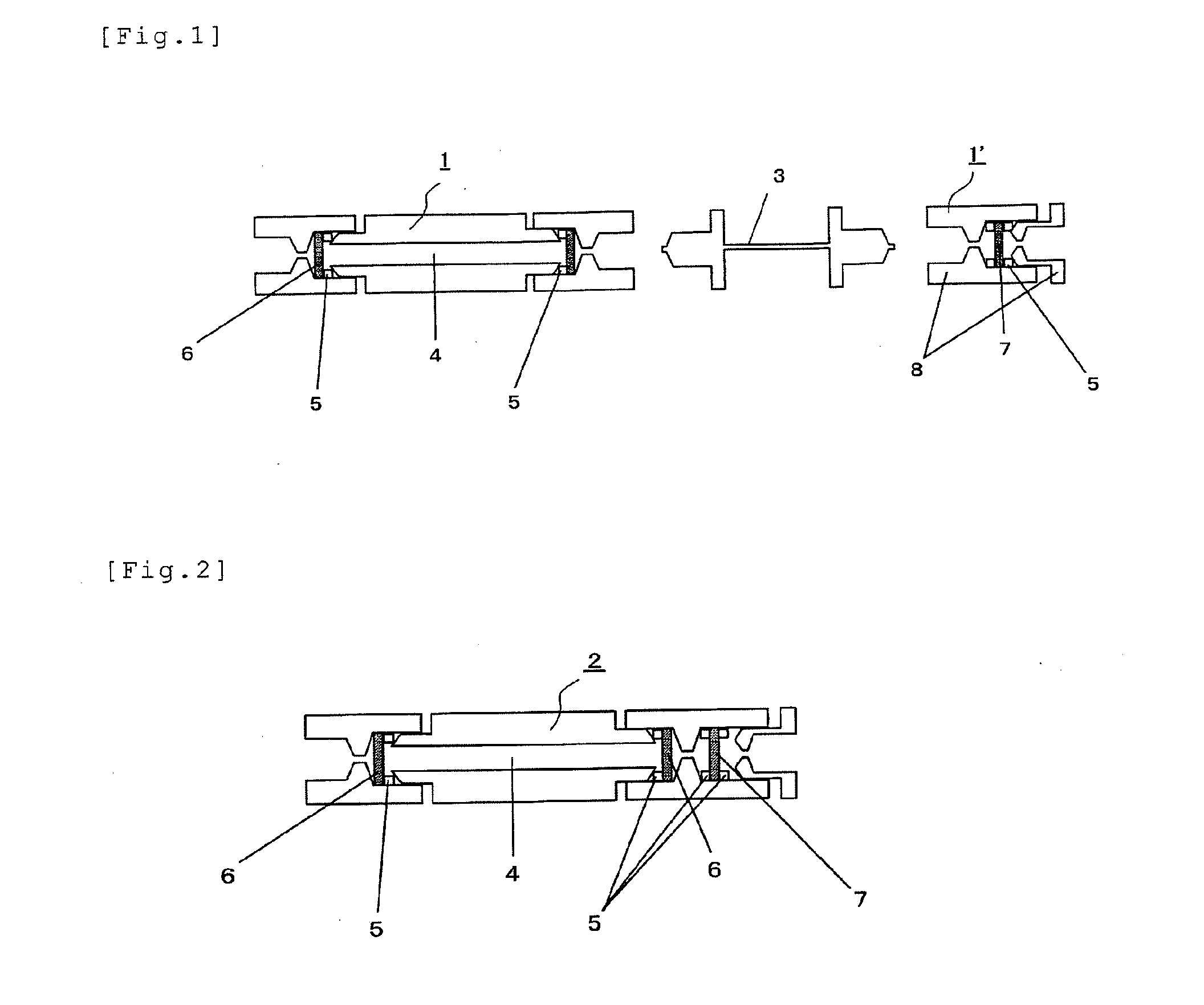

Wiping and/or sealing element as well as process for sealing a piston and clamping and/or support element

InactiveUS7234704B2Strong forceIncrease liquid pressureEngine sealsPiston ringsSquare cross sectionEngineering

The present invention pertains to a wiping and / or sealing element for sealing a piston (11) guided movably in a housing (10) with a seal held in a groove (21, 30). The present invention pertains, furthermore, to a process for sealing a movable piston (11) by means of a seal inserted into a groove (21, 30) and a clamping and / or support element with a piston (21), which is guided in a housing (10) such that it can be withdrawn and extended, wherein the piston (11) is sealed by means of a seal arranged in a groove (21). To achieve sealing of the piston (11) with a high sealing force for high liquid pressures at low friction, the wiping and / or sealing element according to the present invention as well as the clamping and / or support element according to the present invention are wherein the seal is a quad ring (22) with a square cross section.

Owner:LUGWIG EHRHARDT GMBH

Container closure with biased closed tube valve

ActiveUS7198180B2Easy constructionIncrease liquid pressureClosuresLiquid flow controllersMechanical engineeringLiquid content

Owner:WESTROCK DISPENSING SYST

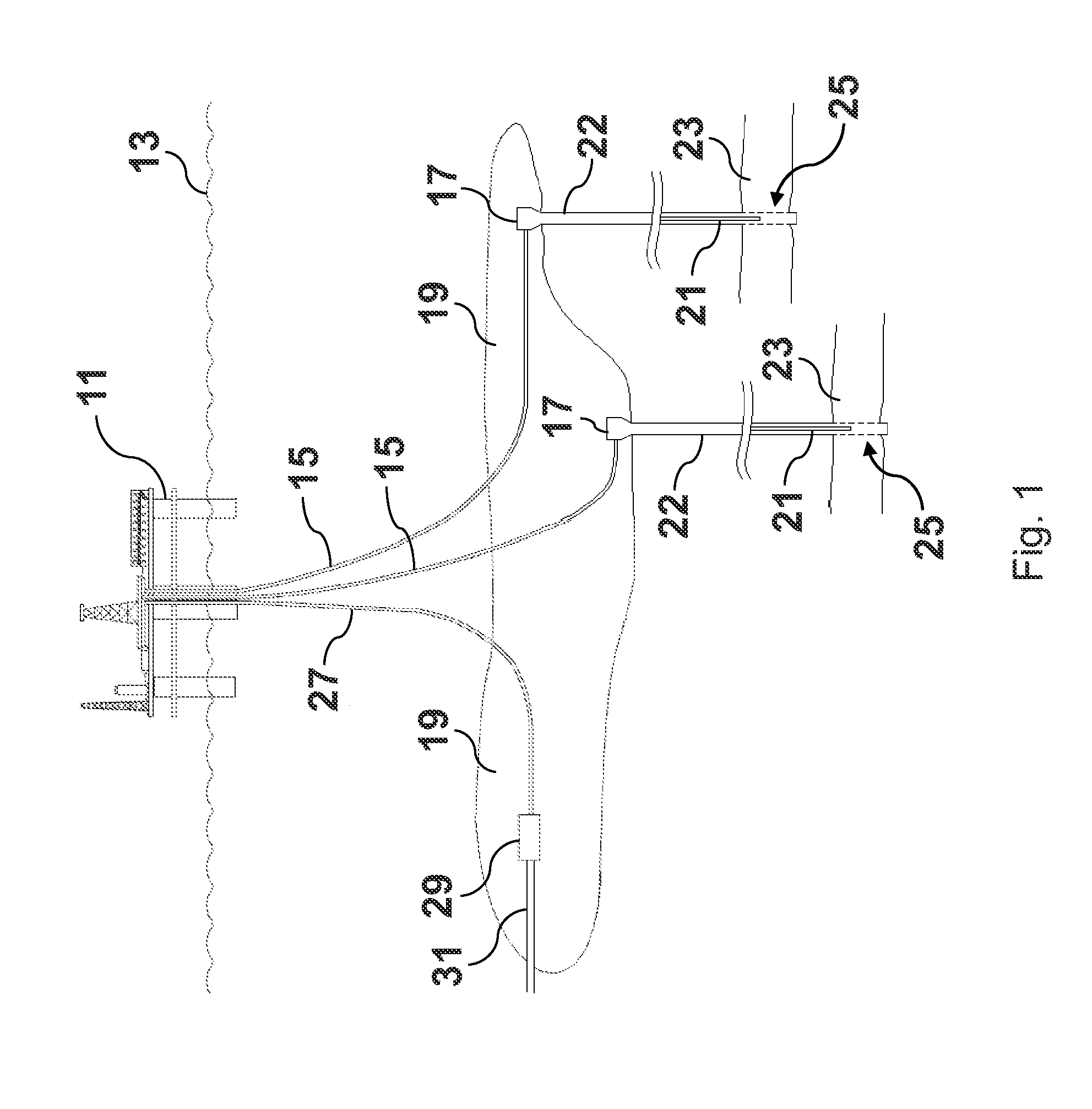

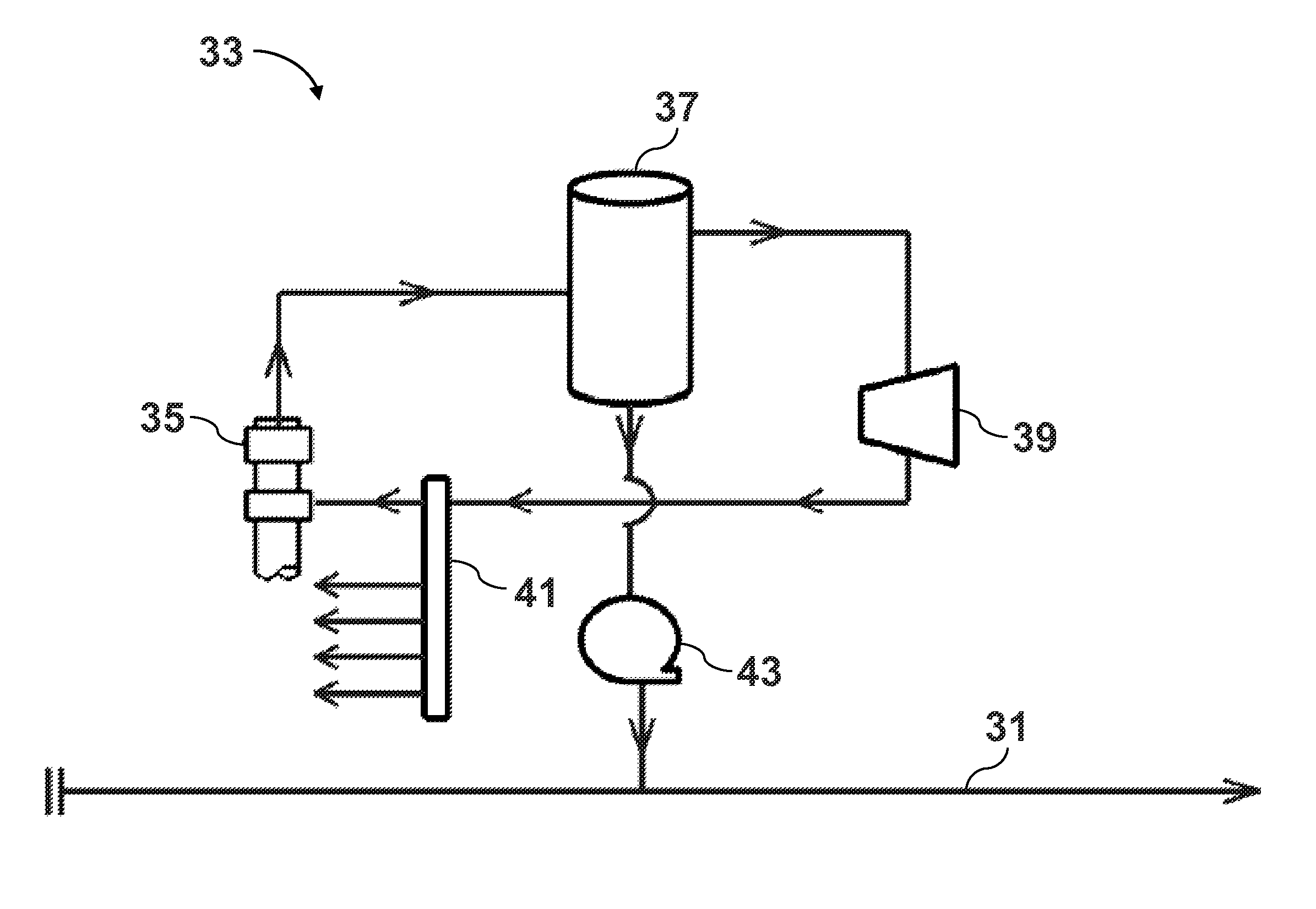

System and method for producing hydrocarbons from a well

ActiveUS20120000668A1Easy to transportReduce back pressureFluid removalHydrocotyle bowlesioidesProcess engineering

A system for producing hydrocarbons from a well includes an unloading unit that receives fluids from a wellhead. The unloading unit separates the oil and gas, and the oil is pumped to a pipeline. Using the unloading unit and the pump helps to reduce the pressure at the wellhead which helps increase production. The gas separated by the unloading unit is compressed and re-injected into the well to create a gas lift which further helps increase production. Capturing and reinjecting the separated gas for gas lift operations reduces environmental damages associated with conventional unloading unit and pump assemblies. The unloading unit, compressor, and pump are modular for quicker installation and a smaller footprint. After increasing the productive life of a first reservoir, the system can be broken down and reassembled for use at another reservoir.

Owner:CHEVROU USA INC

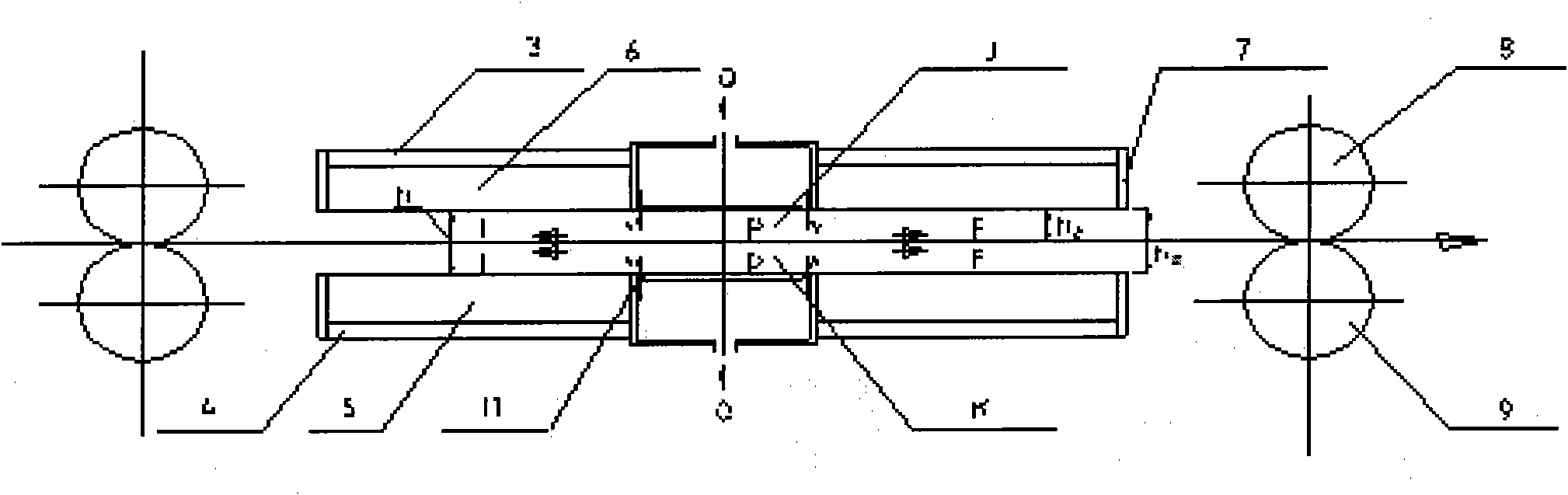

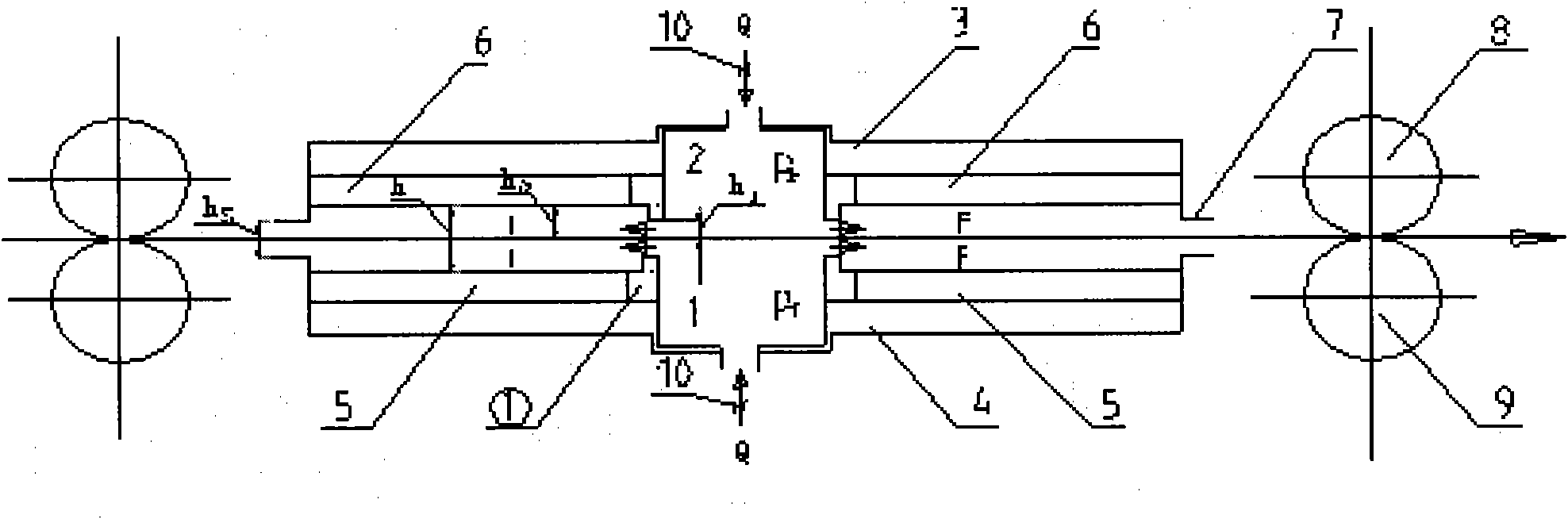

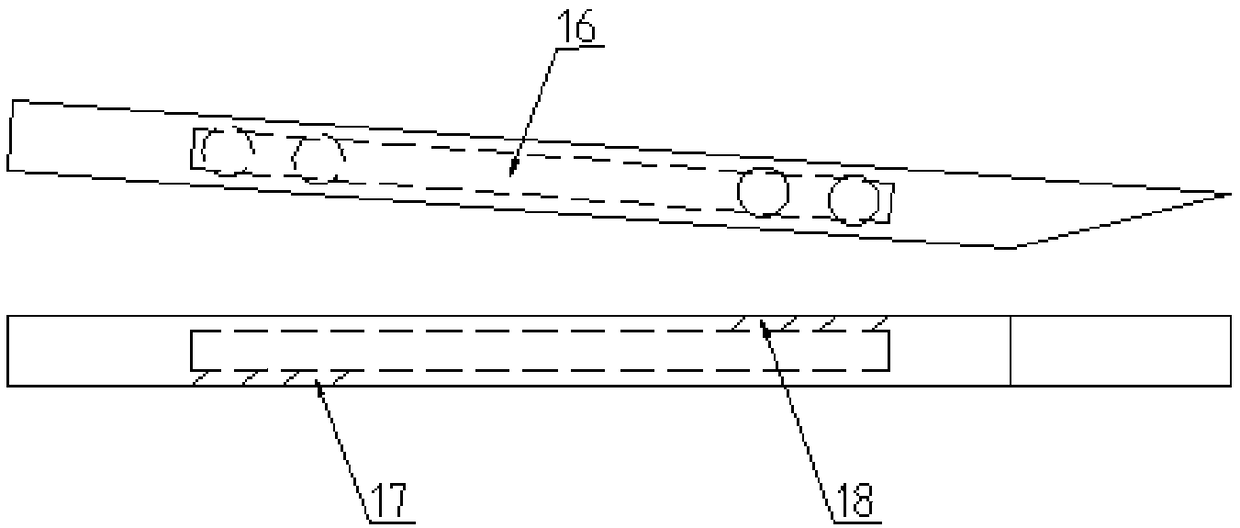

Static-pressure horizontal electroplating bath

ActiveCN101775637AImprove the exhaust effectImprove plating efficiencyTanksHigh current densityStrip steel

The invention provides a static-pressure horizontal electroplating bath, which consists of an upper frame, a lower frame, a lower anode, an upper anode, liquid blocking plates, a conductive roller, a supporting roller, an edge cap and an automatic tracking system, and is characterized in that: a double-cavity lower static-pressure cavity and an upper static-pressure cavity are formed between electroplating regions I and F in the middle of the electroplating bath; and plating solution is input into the upper and lower static-pressure cavities and horizontally sprayed into the electroplating regions I and F through a gap between band steel and a cavity head of the upper static-pressure cavity and a gap between the band steel and a cavity head of the lower static-pressure cavity. The gap between the band steel and the cavity head of the static-pressure cavity is smaller than the distance between the band steel and the anode; the transverse width of a main cavity of the static-pressure cavity is slightly smaller than the width of the band steel; and the distance between the upper and lower liquid blocking plates is smaller than the anode distance. High liquid static-pressure band steel clamping capacity and liquid static-pressure anti-band steel deflection capacity are established in the bath, so bidirectional horizontal injection of the plating solution in the middle of the bath is realized, and short circuit and burning problems of the band steel and the anode in a horizontal electroplating bath are solved. The static-pressure horizontal electroplating bath has the advantages of stable and reliable running, high coating quality, high current density, low power consumption, simple and compact device structure and the like.

Owner:北京中冶设备研究设计总院有限公司

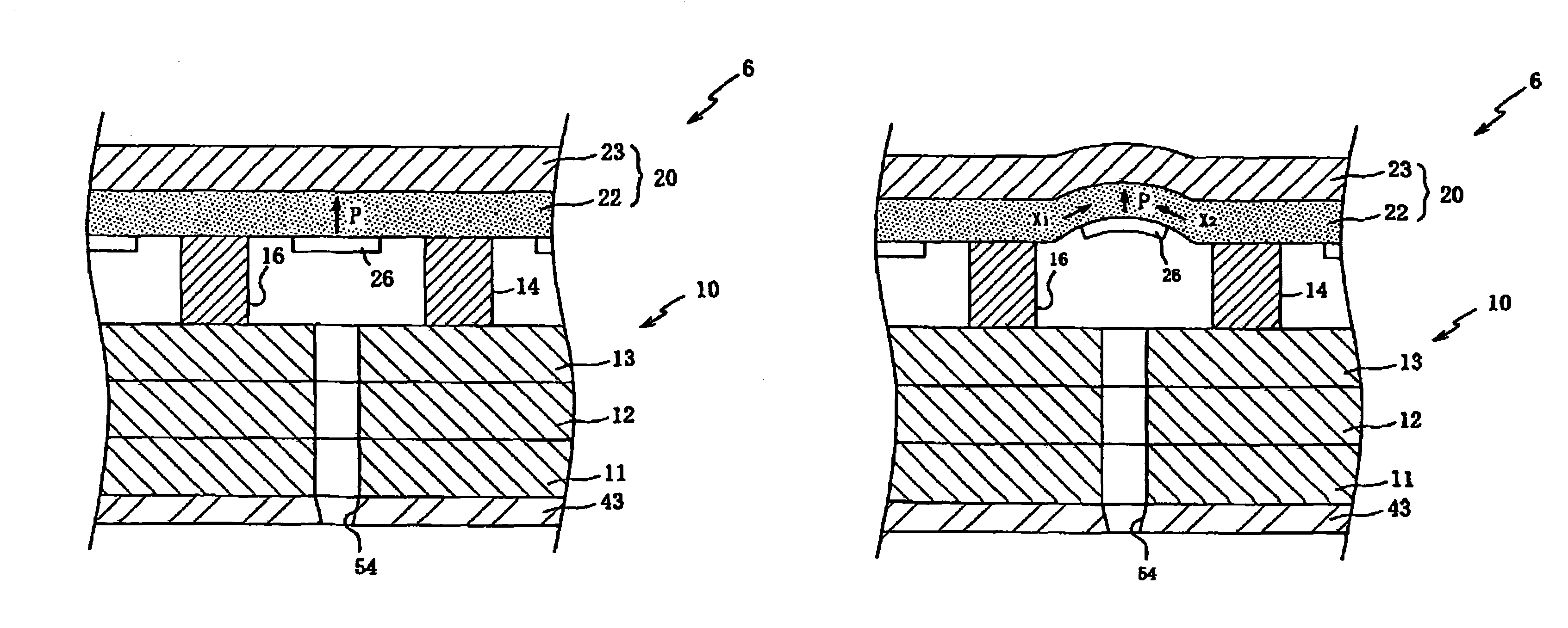

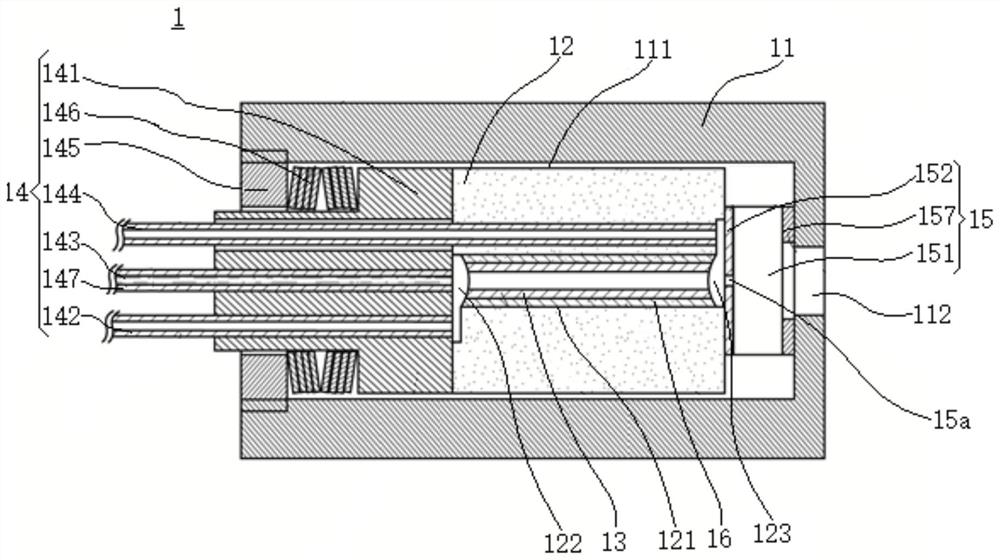

Liquid delivering apparatus

ActiveUS7240996B2Efficiently applies pressureIncrease liquid volumePiezoelectric/electrostrictive device manufacture/assemblyInking apparatusEngineeringMechanical engineering

A liquid delivering apparatus including a piezoelectric sheet which is opposed to liquid chambers and is polarized in a direction of thickness thereof; a restrictor sheet which is opposed to the liquid chambers, restricts a deformation of the piezoelectric sheet, and functions as a first electrode; and second electrodes which are opposed, via active portions of the piezoelectric sheet, to restrictive portions of the restrictor sheet, respectively, and are opposed to the liquid chambers, respectively. When an arbitrary one of the active portions of the piezoelectric sheet is deformed by an electric field which is generated in a direction substantially parallel to the direction of polarization of the piezoelectric sheet, the arbitrary one of the active portions of the piezoelectric sheet and a corresponding one of the restrictive portions of the restrictor sheet are curved in a direction to increase a volume of a corresponding one of the liquid chambers.

Owner:BROTHER KOGYO KK

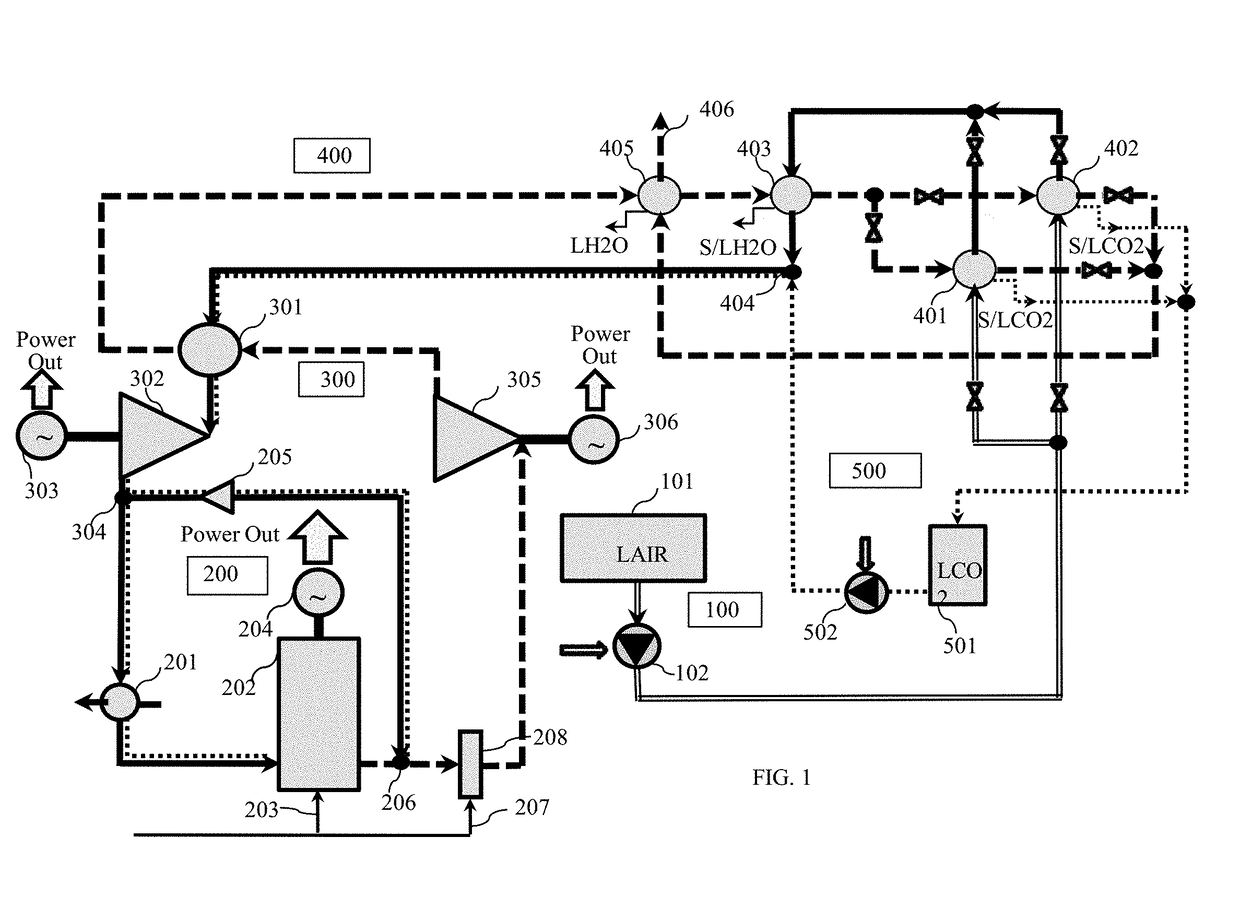

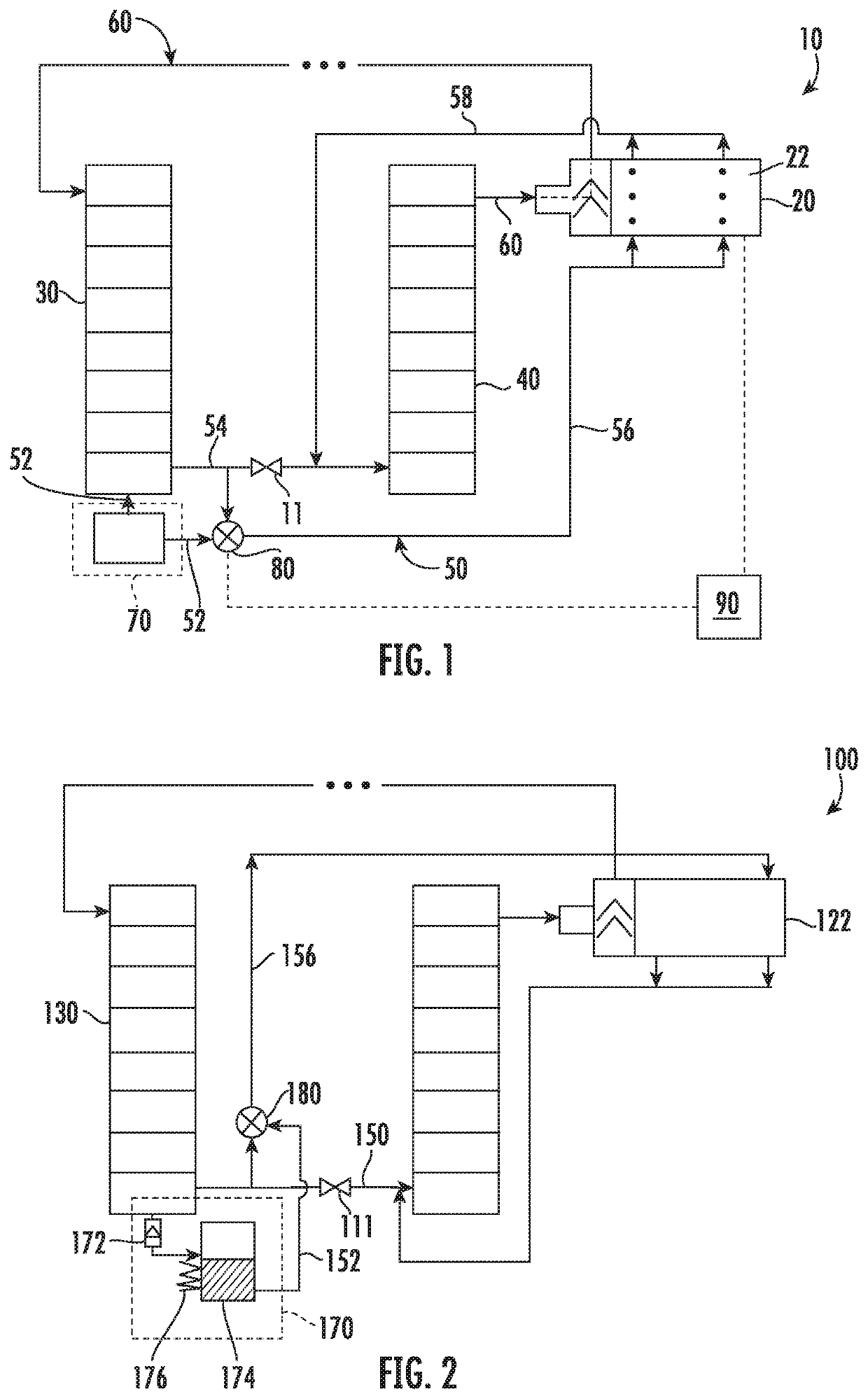

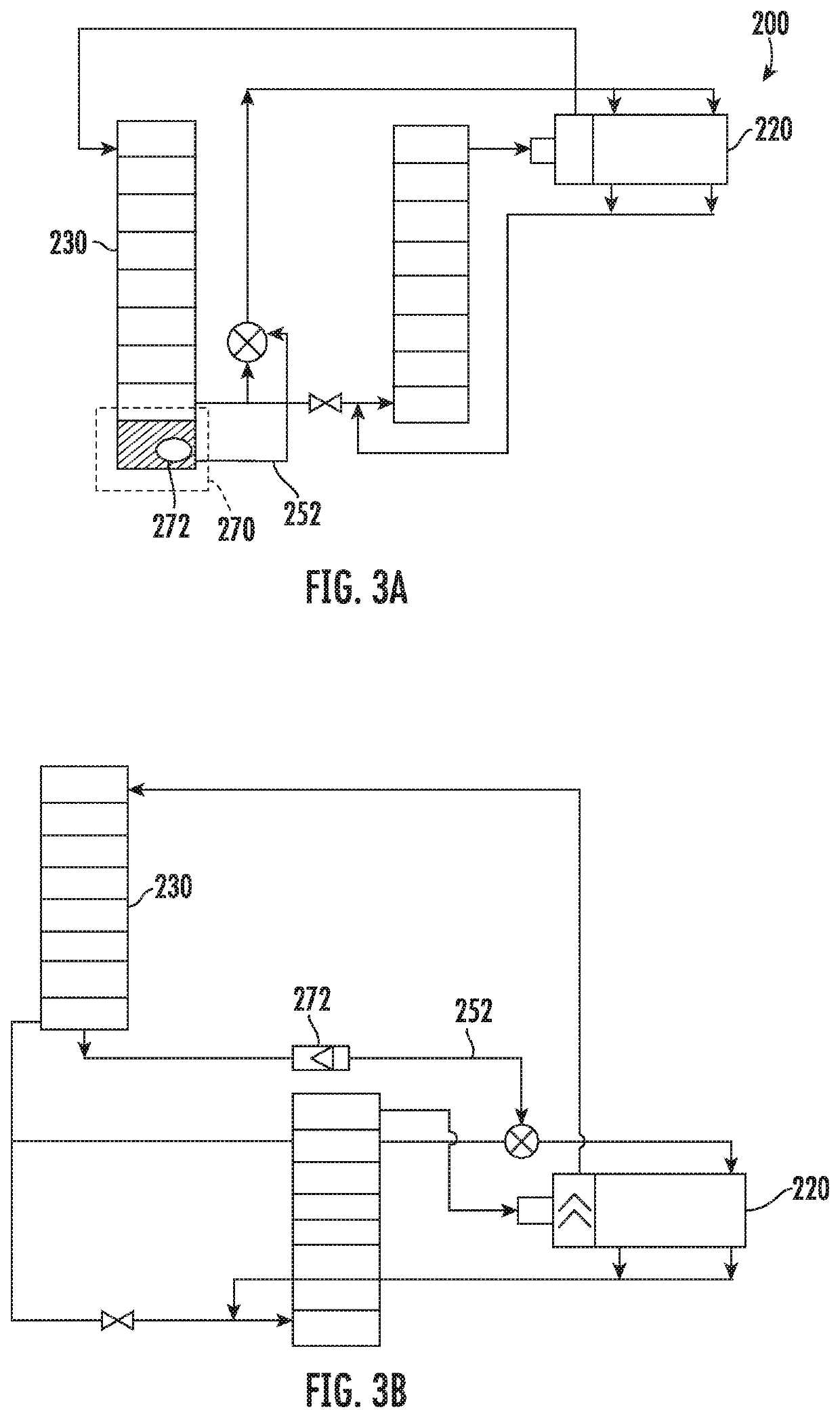

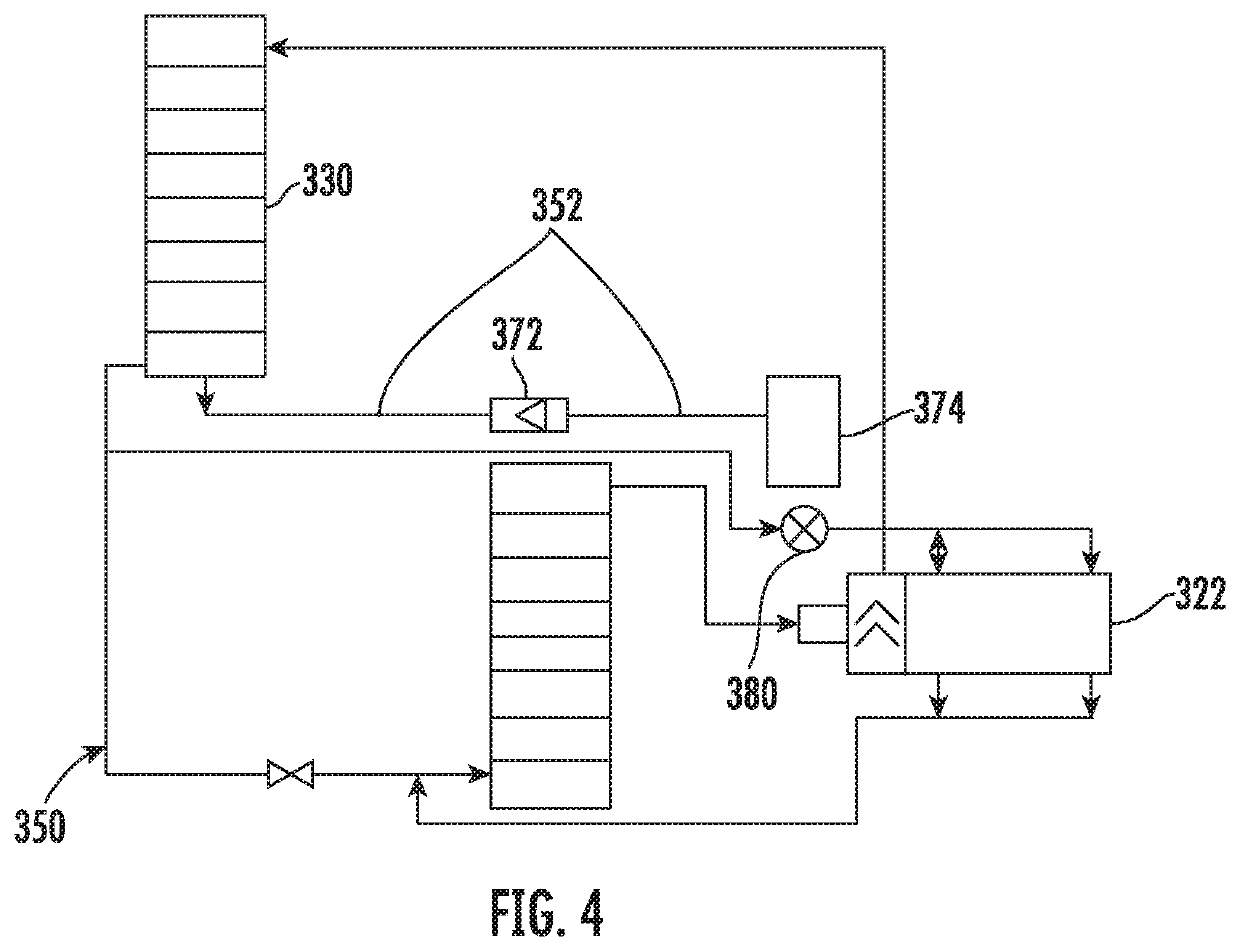

Method for Liquid Air Energy Storage with Semi-Closed CO2 Bottoming Cycle

A proposed method provides a highly efficient fueled power output augmentation of the liquid air energy storage (LAES) through its integration with the semi-closed CO2 bottoming cycle. It combines the production of liquid air in air liquefier during LAES charge using excessive power from the grid and an effective recovery of stored air for production of on-demand power in the fueled supercharged reciprocating internal combustion engine (ICE) and associated expanders of the power block during LAES discharge. A cold thermal energy of liquid air being re-gasified is recovered for cryogenic capturing most of CO2 emissions from the facility exhaust with following use of the captured CO2 in the semi-closed bottoming cycle, resulting in enhancement of total LAES facility discharge power output and suppressing the thermal NOx formation in the ICE.

Owner:SINATOV STANISLAV

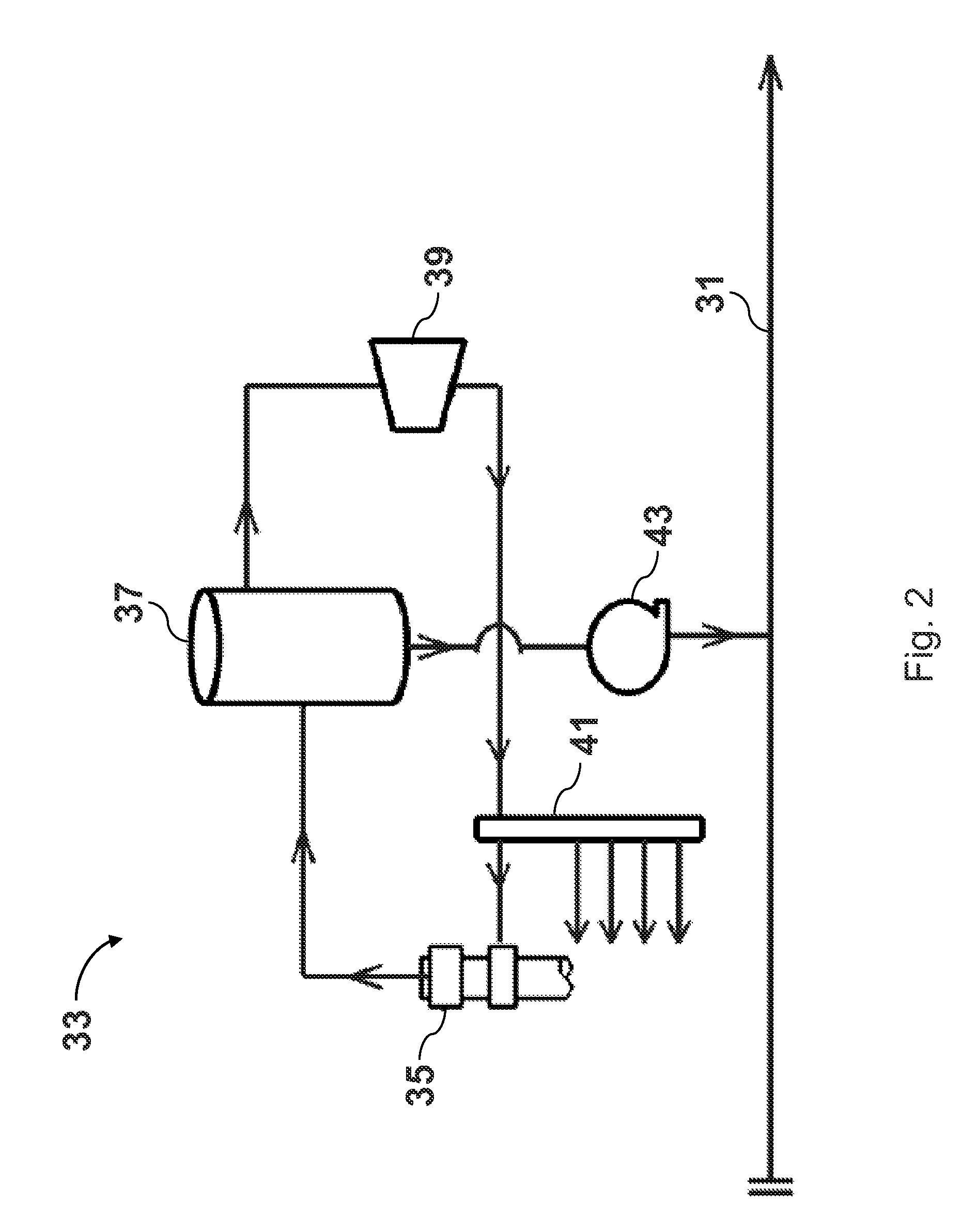

System and method for producing hydrocarbons from a well

ActiveUS9140106B2Easy to transportIncrease liquid pressureFluid removalProcess engineeringEngineering

A system for producing hydrocarbons from a well includes an unloading unit that receives fluids from a wellhead. The unloading unit separates the oil and gas, and the oil is pumped to a pipeline. Using the unloading unit and the pump helps to reduce the pressure at the wellhead which helps increase production. The gas separated by the unloading unit is compressed and re-injected into the well to create a gas lift which further helps increase production. Capturing and reinjecting the separated gas for gas lift operations reduces environmental damages associated with conventional unloading unit and pump assemblies. The unloading unit, compressor, and pump are modular for quicker installation and a smaller footprint. After increasing the productive life of a first reservoir, the system can be broken down and reassembled for use at another reservoir.

Owner:CHEVROU USA INC

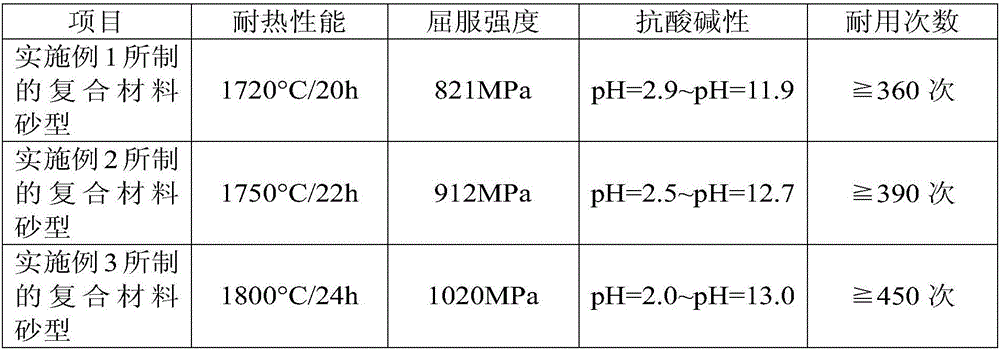

Cast iron pot with composite material as sand mould and casting method thereof

InactiveCN105855454AAdjustable thermal conductivitySmall overall thermal resistanceFoundry mouldsFoundry coresCast ironBall mill

The invention discloses a cast iron pot with a composite material as a sand mould and a casting method thereof. The casting method includes the steps that sand mould raw materials are weighed quantitatively and mixed evenly, then the materials are ball-milled and dried, a composite material sand mould is obtained, and the composite material sand mould is placed in a high-pressure container; cast iron blocks are fully heated and completely melted into molten iron, the molten iron is poured into the composite material sand mould, pressure in the pressure container is high pressure, a staged cooling means is adopted till the molten iron is completely cooled to room temperature to form castings, pressure continues to be maintained, and high pressure is relieved; the mould is taken out, the composite material sand mould is slowly removed by means of a metal tool, and the cast iron pot is obtained. Casting technologies, especially the improved casting technologies of improving a sand mould formula, improving pressure in a sand box, adopting the staged cooling means and the like, can greatly improve product quality of the cast iron pot and has certain economic and social meaning.

Owner:惠州市旲桥科技有限公司

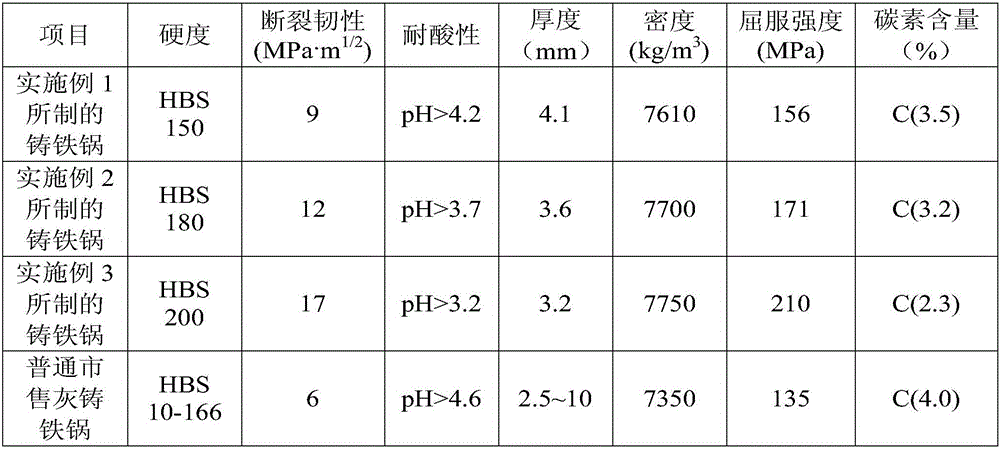

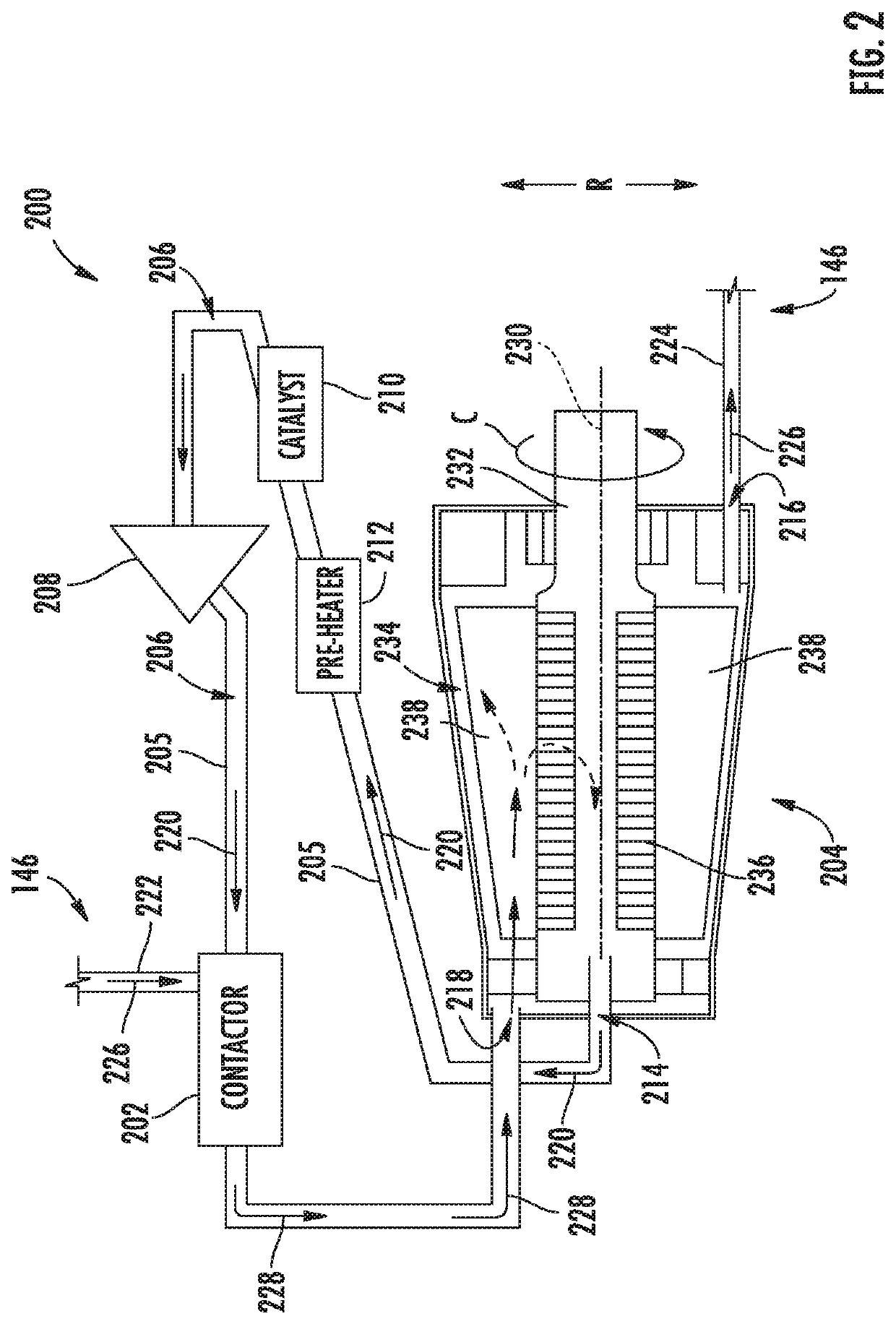

Fuel Oxygen Conversion Unit With A Dual Separator Pump

PendingUS20200140111A1Increase pressureIncrease liquid pressureLiquid degasification with auxillary substancesTurbine/propulsion fuel flow conduitsThermodynamicsFuel tank

A fuel delivery system for a gas turbine engine includes a fuel tank; a draw pump downstream of the fuel tank for generating a liquid fuel flow from the fuel tank; a main fuel pump downstream of the draw pump; and a fuel oxygen conversion unit downstream of the draw pump and upstream of the main fuel pump. The fuel oxygen conversion unit includes a stripping gas line; a contactor in fluid communication with the stripping gas line and the draw pump for forming a fuel / gas mixture; and a dual separator pump in fluid communication with the contactor for receiving the fuel / gas mixture and separating the fuel / gas mixture into a stripping gas flow and the liquid fuel flow at a location upstream of the main fuel pump.

Owner:GENERAL ELECTRIC CO

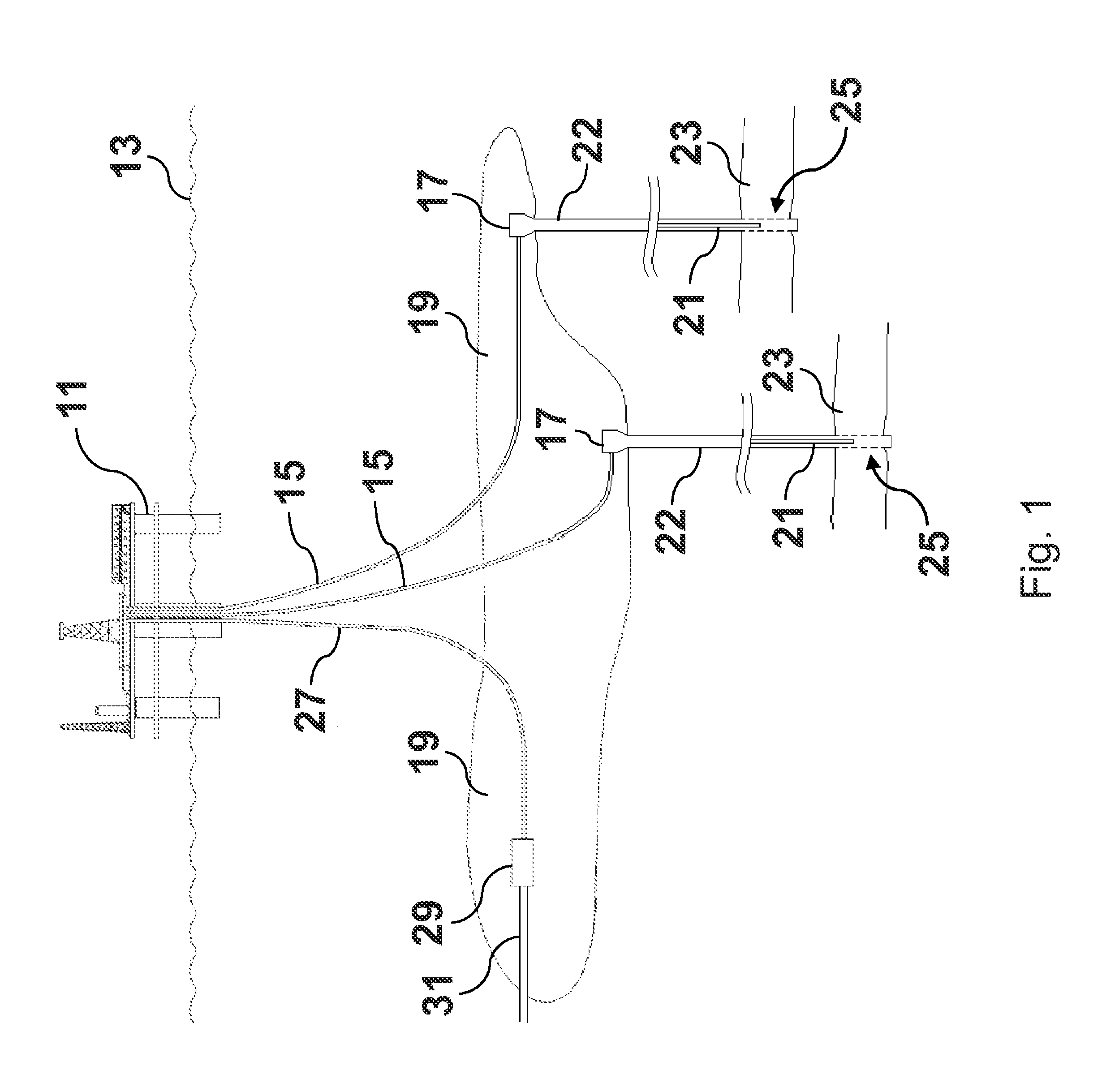

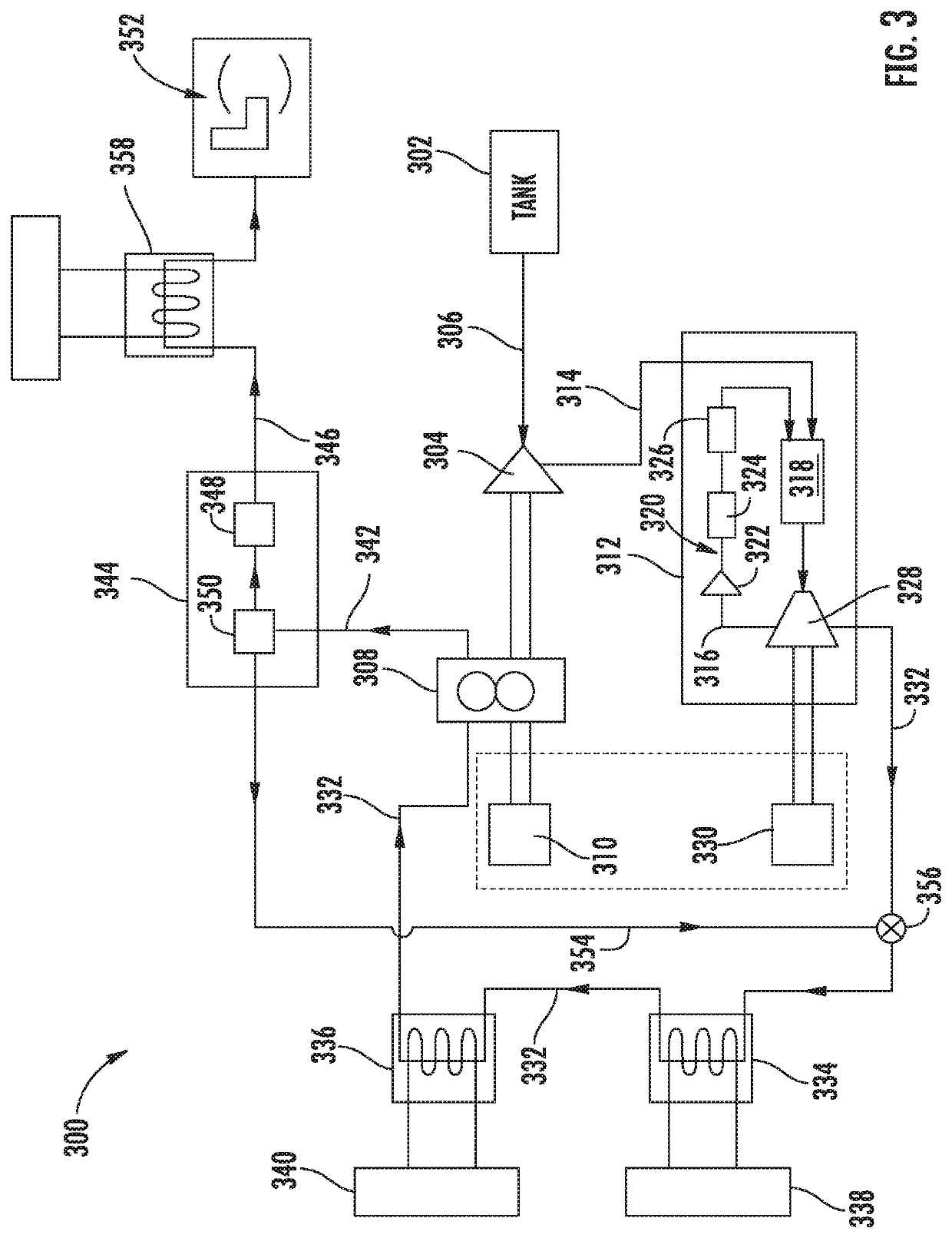

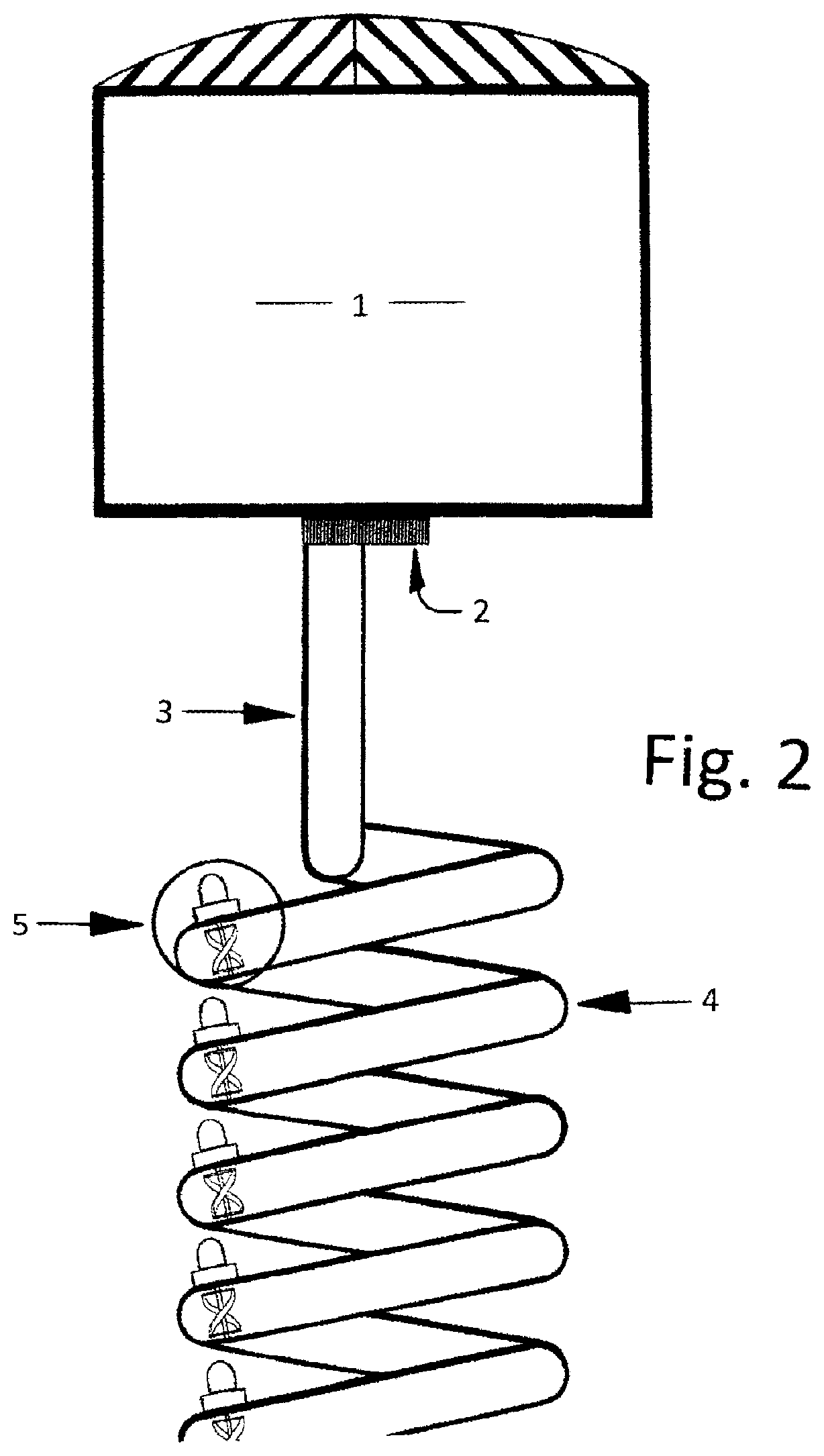

Ffwn clean energy power plant

PendingUS20220010763A1Improve efficiencyIncrease power outputHydro energy generationMachines/enginesWater storage tankHigh pressure water

Gravity and hydrostatic pressure are natural forces that have considerable force generating capabilities which can make significant contributions during the operation of a FFWN 24 / 7 / 365, baseload, 100% clean energy power plant. When these natural forces are combined with compressed air in the upper part of an elevated storage tank containing a liquid and the partial vacuum created by powerful pumps to produce a targeted water flow rate velocity of about 31.3 m / s through the entire length of a coiled section of pipe containing one or more helical turbines in each coil that are connected to an external generator, the electricity produced during a power producing cycle by all the turbines / generators when combined will be considerably more than the power ultimately consumed by the pumps to return the highly pressurized water in a ground level tank back to the storage tank utilizing a return tank and simple water displacement.

Owner:VON BARGEN EDWARD

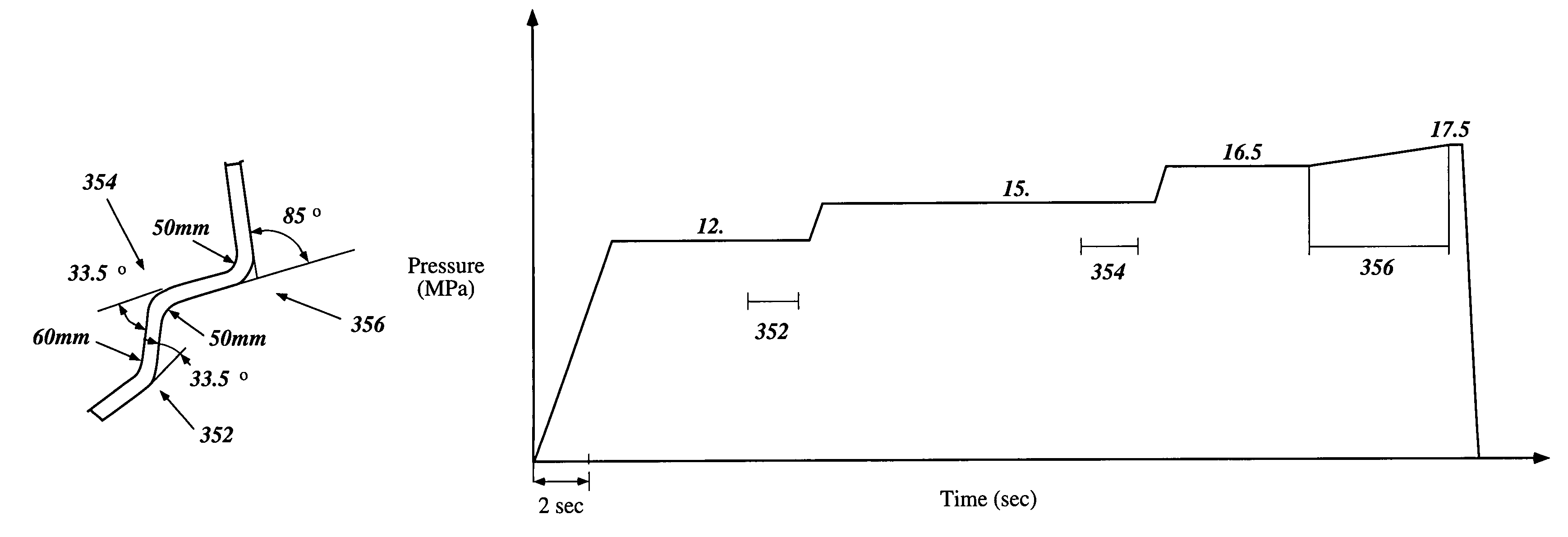

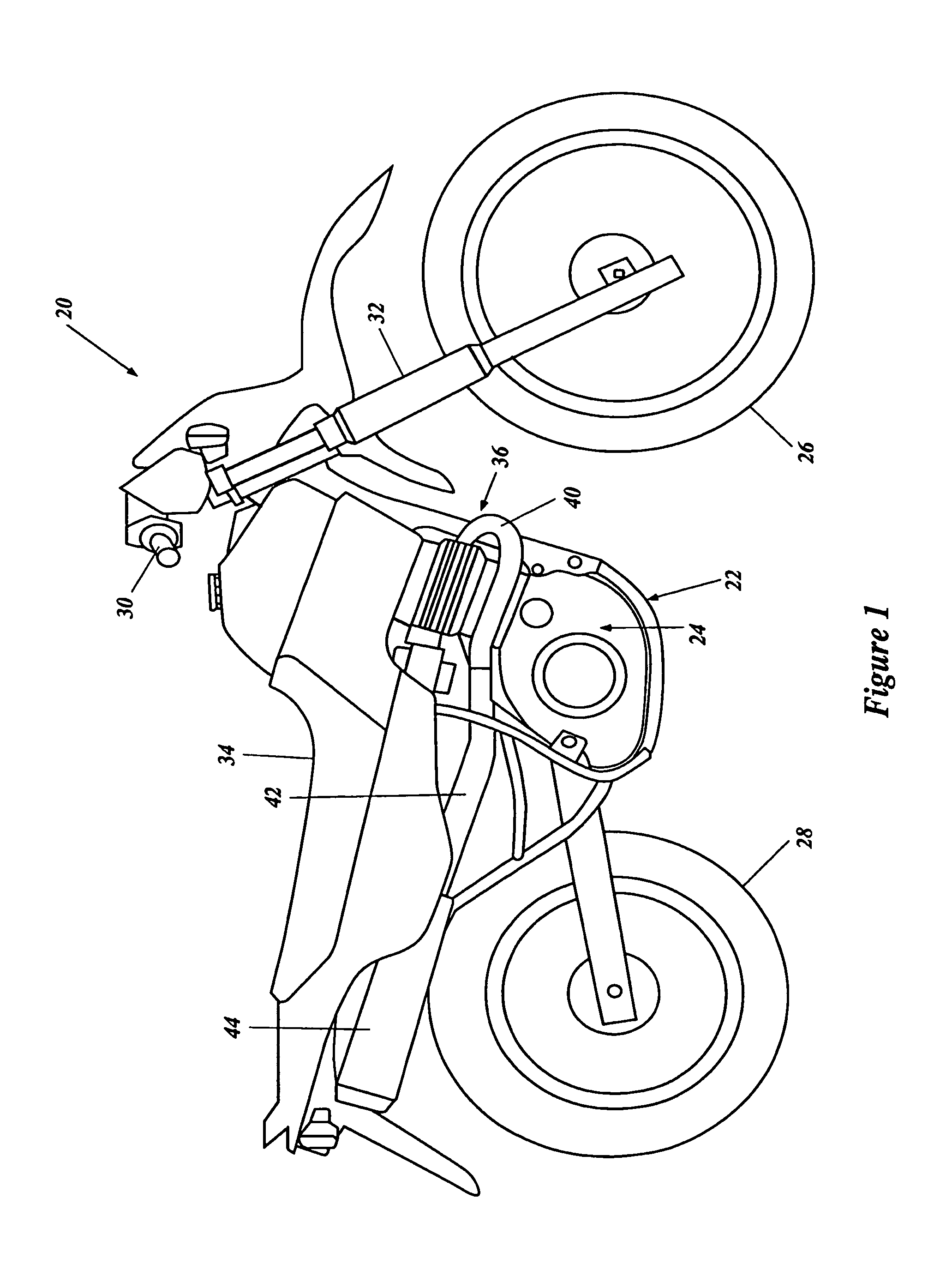

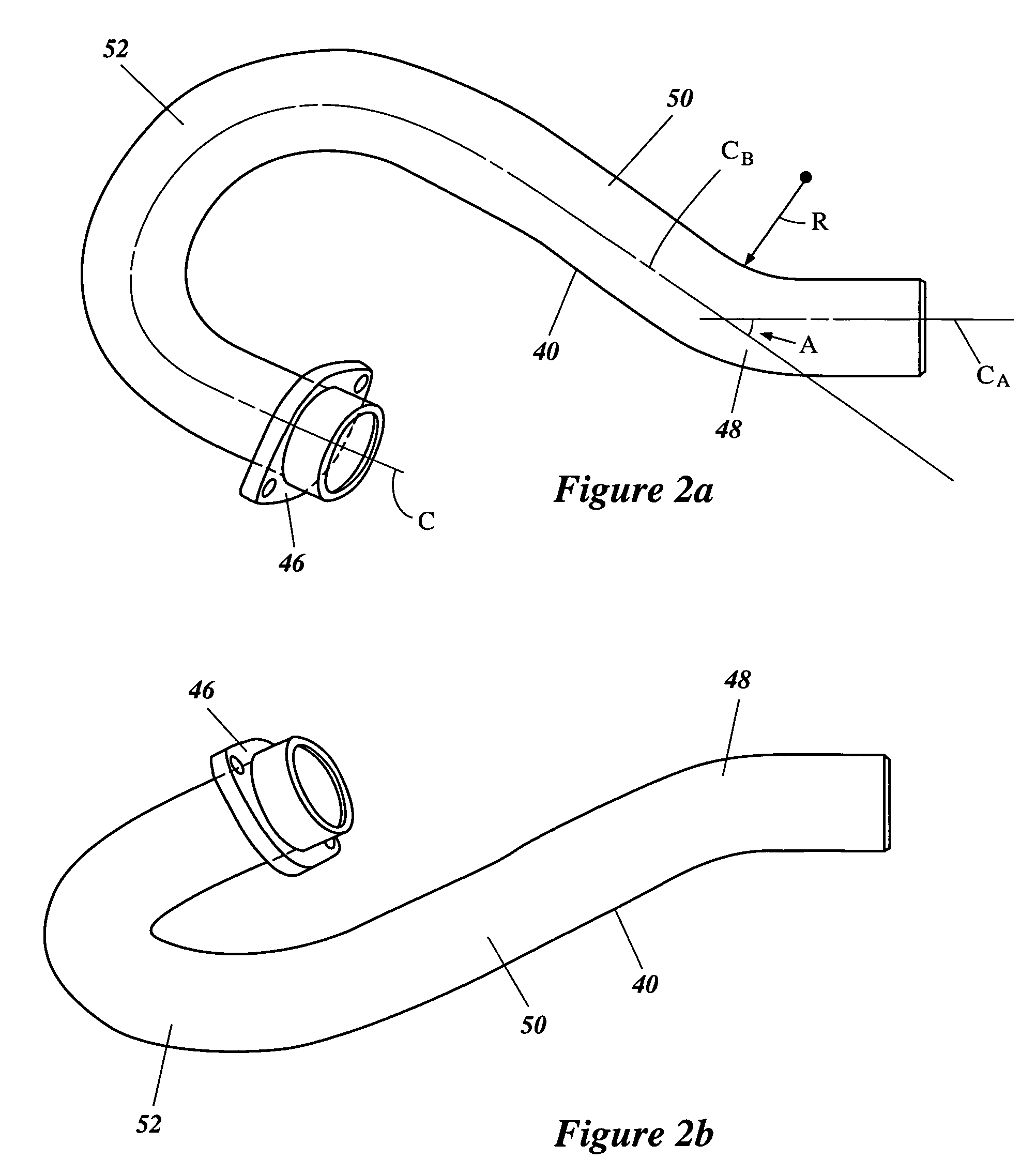

Pipe bending apparatus and method

A pipe bending apparatus for performing a pipe bending method, wherein the method includes filling a workpiece with a liquid, pressurizing the liquid to a target pressure level, and bending the workpiece to create a bent pipe. Preferably, the pressure level is inversely proportional to the radius of the bend in the pipe. Furthermore, preferably the pressure is directly proportional to the bending angle of the pipe. Preferably, the pressure is maintained substantially at the target pressure during the bending process. Optionally, the pressure level can be increased during the bending process.

Owner:YAMAHA MOTOR CO LTD

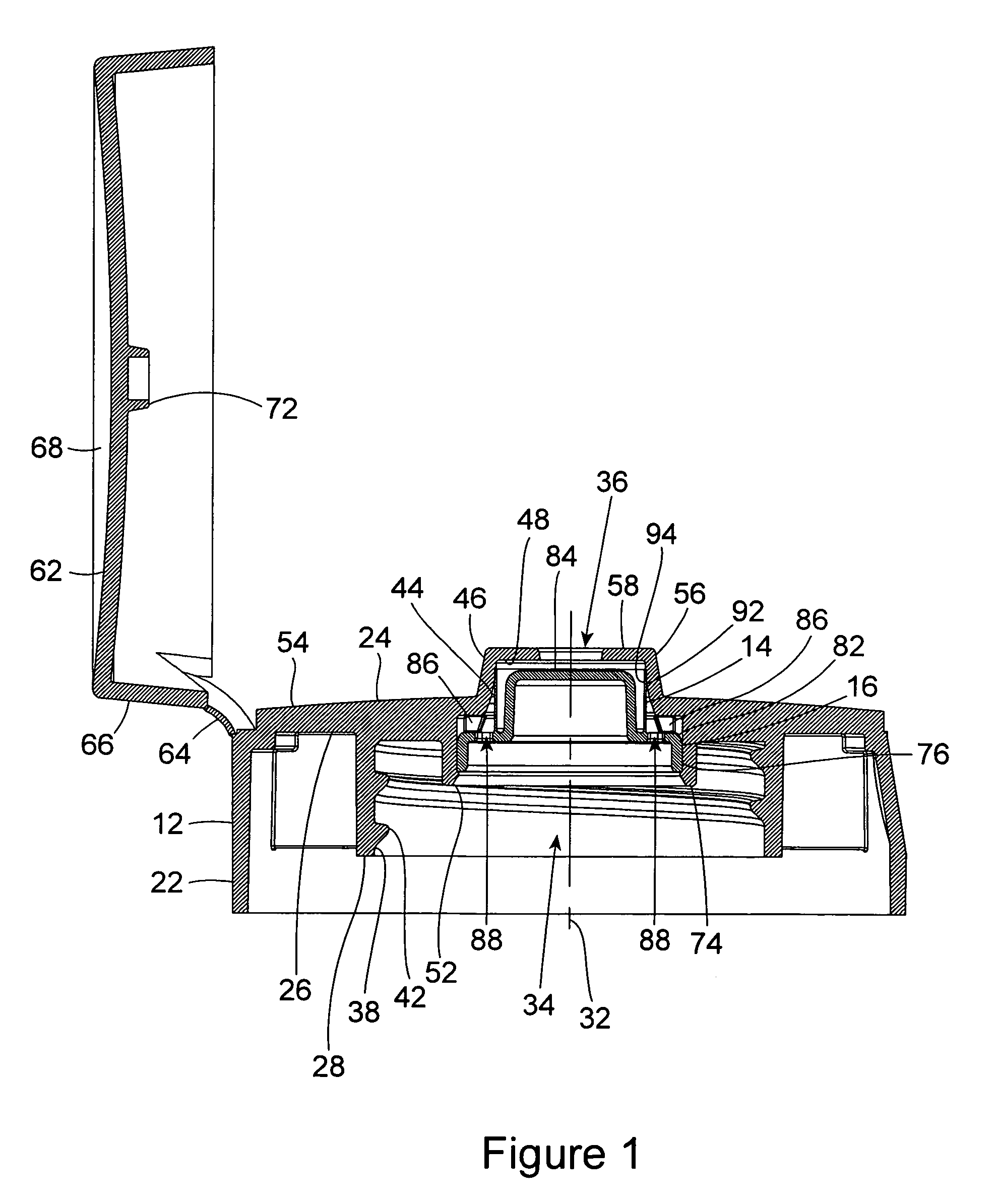

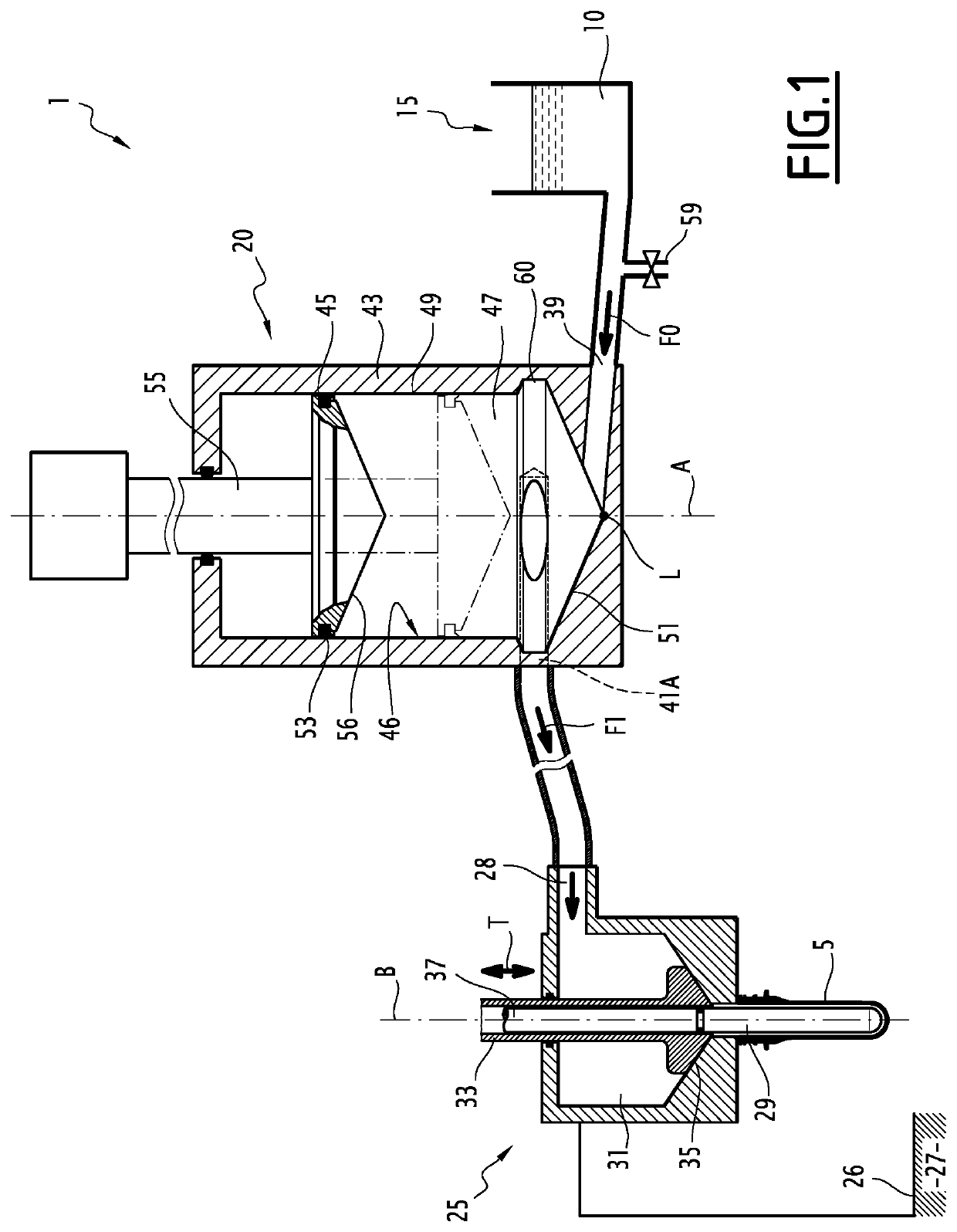

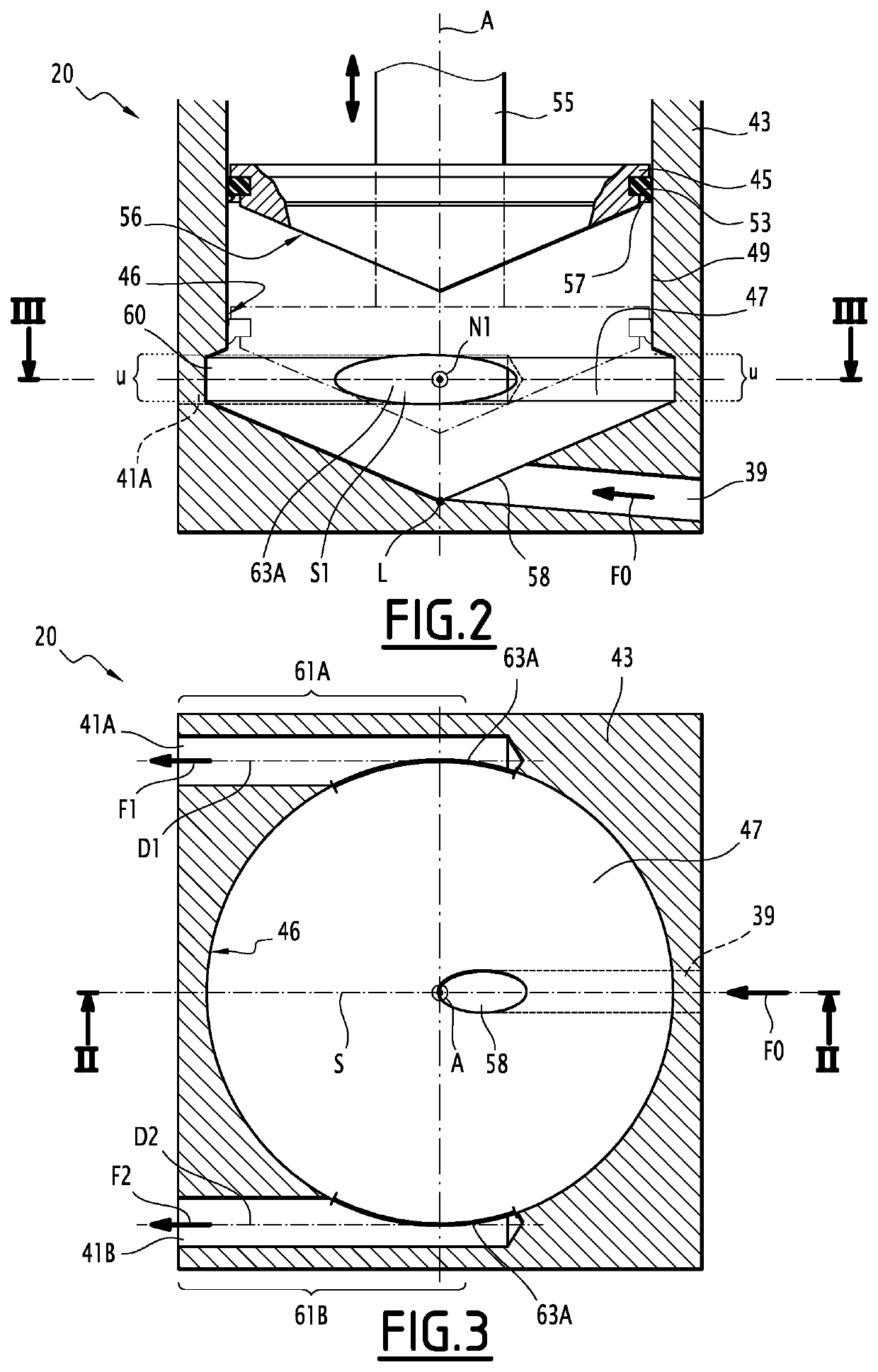

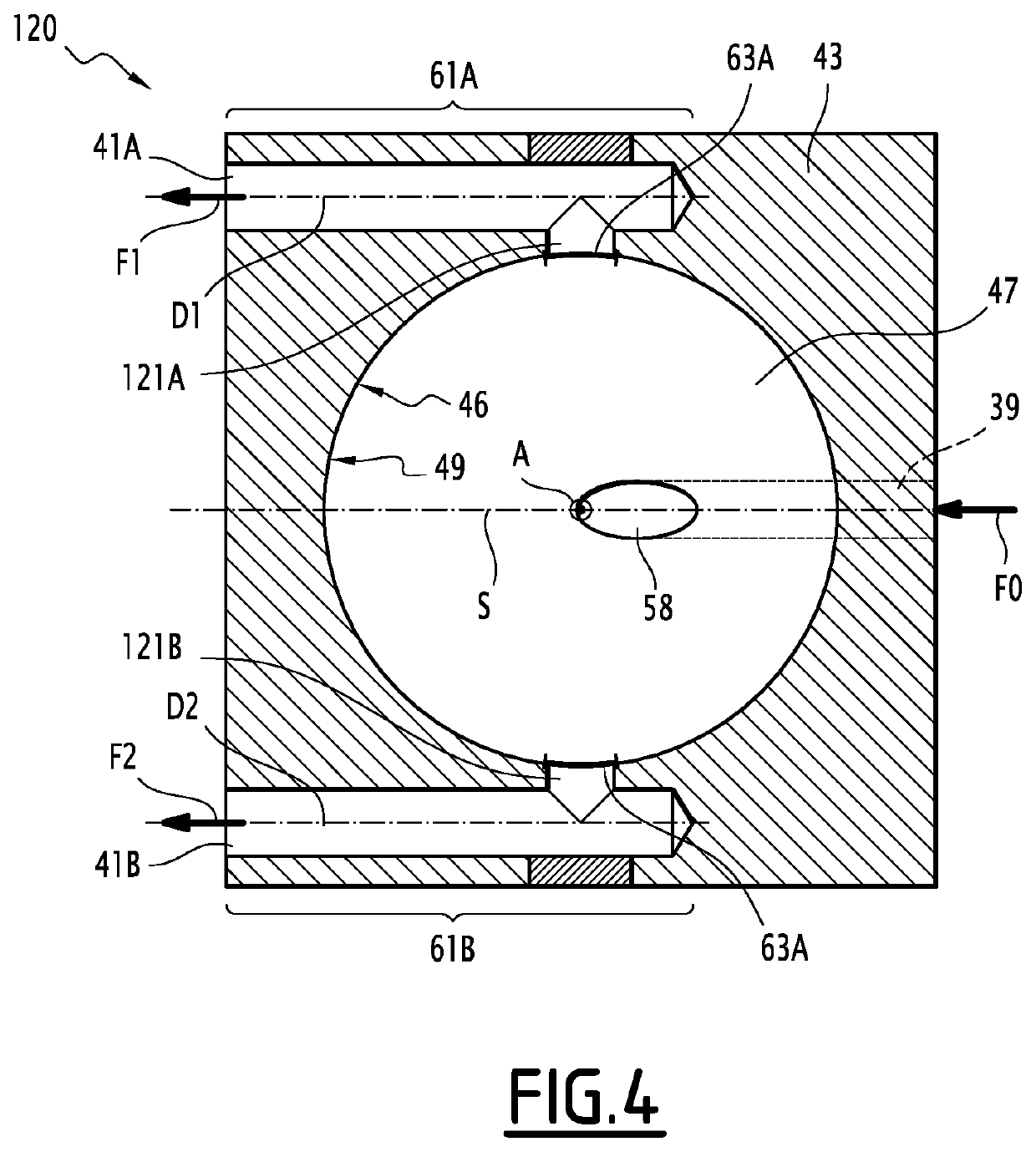

Injection device comprising at least one flexible diaphragm

An injection device having at least one flexible diaphragm The injection device for forming a preform into a container and filling the container, and further including a main housing having an inlet, an outlet and an injection chamber, a closing body movable relative to the outlet between a closed position and an opened position, a closing diaphragm attached at least to the closing body, the injection chamber being delimited at least by an inner surface of the closing diaphragm, the closing diaphragm having an outer surface defining an outside area, a bearing surface against which a supported portion of the outer surface of the closing diaphragm is applied. The closing diaphragm further includes a free portion forming with the supported portion the whole outer surface of the closing diaphragm. The bearing surface is arranged such that the surface of the free portion decreases when the closing body moves from the closed position to the opened position.

Owner:DISCMA

Liquid chromatography component

InactiveUS20110073539A1Easy to separateIncrease liquid pressureComponent separationPreparing sample for investigationLiquid phaseChemistry

The present invention aims to provide a liquid chromatography component including a column and a prefilter, which is hard to cause an increase of supplied liquid pressure even when the measurement of a sample is repeated. The present invention is a liquid chromatography component, which includes: a column with filler particles filled therein; and a prefilter, the filler particles having an average particle size in the range of 2 to 20 μm, the prefilter having a filtering particle size in the range of ⅙ to ⅓ of the average particle size of the filler particles.

Owner:SEKISUI CHEM CO LTD

Wiping and/or sealing element as well as process for sealing a piston and clamping and/or support element

InactiveUS20050173867A1Strong sealing forceLow frictionEngine sealsPiston ringsPistonLiquid pressure

The present invention pertains to a wiping and / or sealing element for sealing a piston (11) guided movably in a housing (10) with a seal held in a groove (21, 30). The present invention pertains, furthermore, to a process for sealing a movable piston (11) by means of a seal inserted into a groove (21, 30) and a clamping and / or support element with a piston (21), which is guided in a housing (10) such that it can be withdrawn and extended, wherein the piston (11) is sealed by means of a seal arranged in a groove (21). To achieve sealing of the piston (11) with a high sealing force for high liquid pressures at low friction, the wiping and / or sealing element according to the present invention as well as the clamping and / or support element according to the present invention are wherein the seal is a quad ring (22) with a square cross section.

Owner:LUGWIG EHRHARDT GMBH

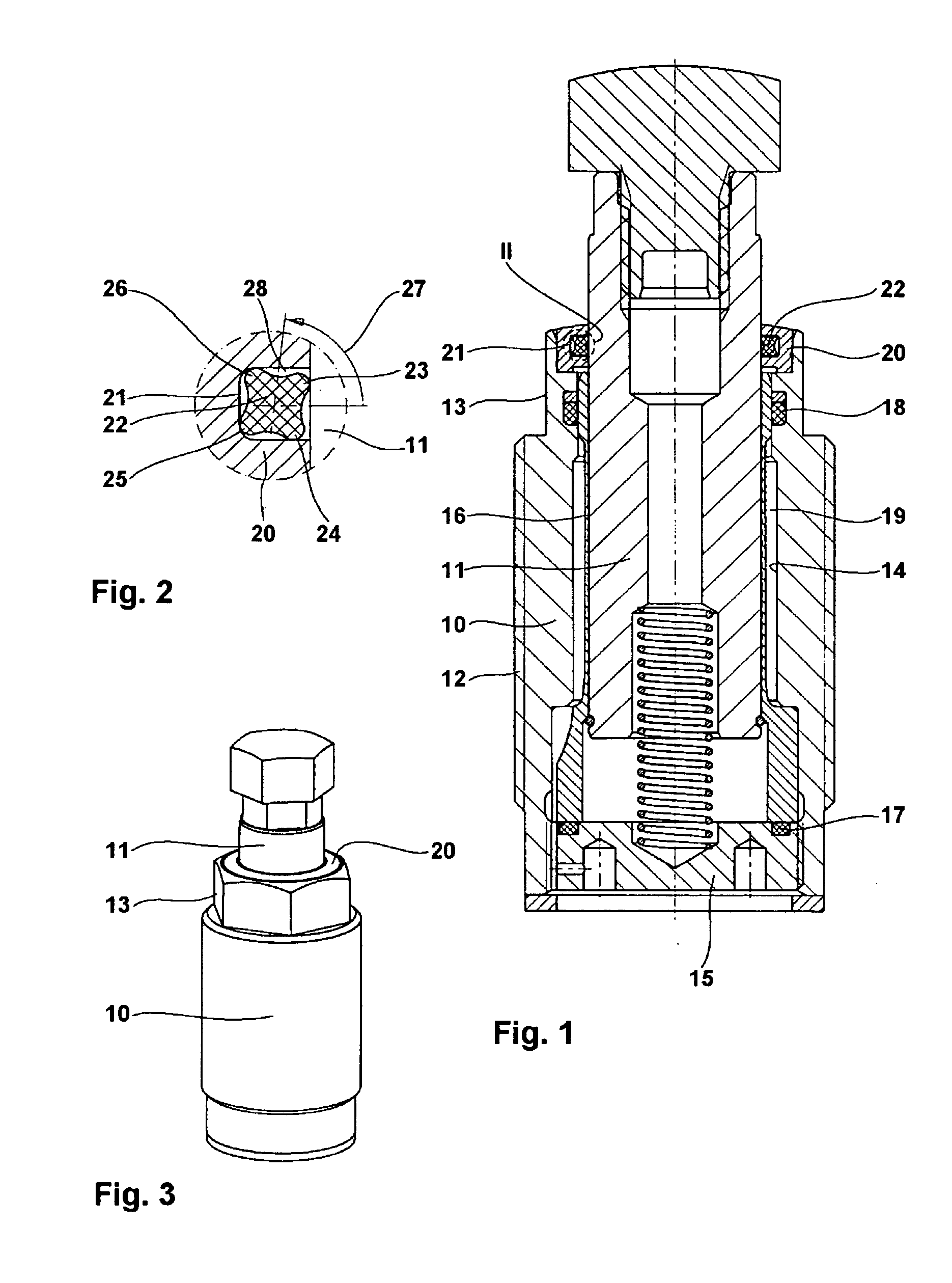

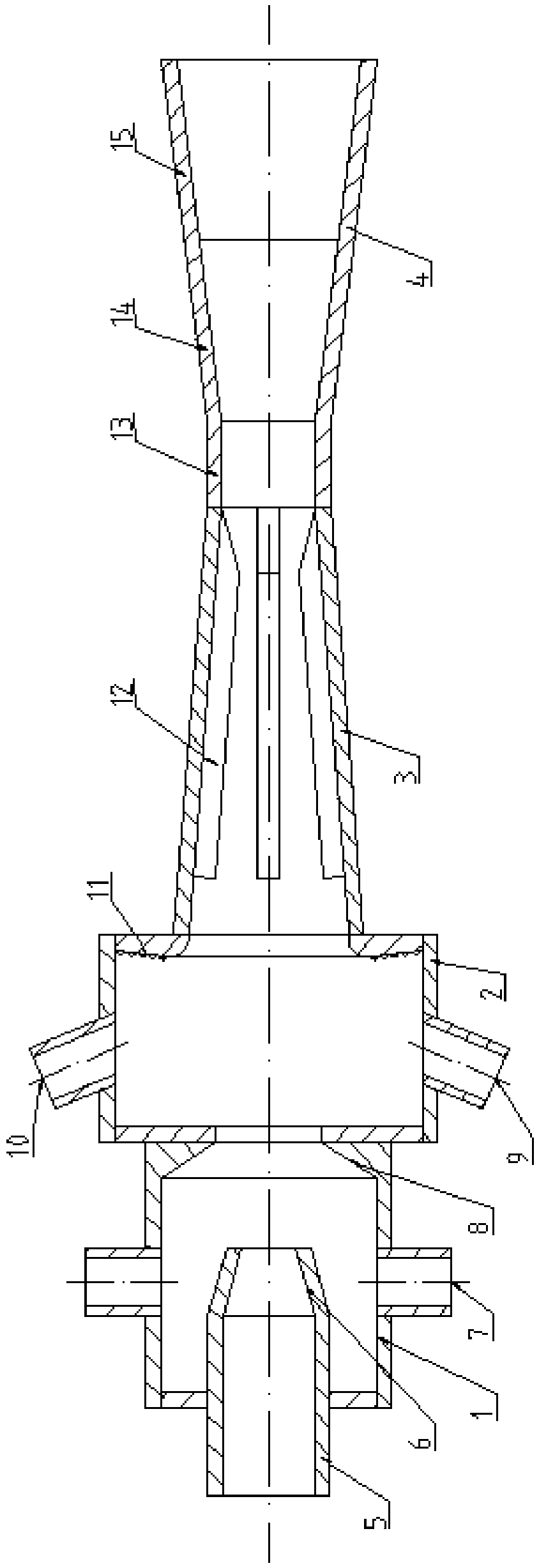

Gas-liquid mixing type jet injection device

PendingCN108970825AReduce shockReduces liquid build-up problemsLiquid spraying apparatusSustainable biological treatmentLiquid pressureEngineering

A gas-liquid mixing type jet injection device comprises a first mixing cavity (1), a second mixing cavity (2), a tapered shrinkage portion (3) and a diffusion portion (4) in sequentially adjacent connection. The first mixing cavity is peripherally provided with one or more gas suction inlets (7), and a water inlet (5) is positioned in the center of the first mixing cavity. The second mixing cavity(2) is peripherally provided with one or more treating fluid inlets (9) and a compressed gas inlet (10). The gas-liquid mixing type jet injection device is characterized in that a plurality of rectifying plates (12) are arranged on the inner peripheral wall of the tapered shrinkage portion (3) and internally provided with buffer cavities (16), and one side of each rectifying plate is provided with one or more inlet holes (17) while the other side is provided with one or more outlet holes (18). The gas-liquid mixing type jet injection device has advantages that problems of liquid impact and wall attachment of liquid in flow gathering of the tapered shrinkage portion can be reduced, design of the buffer cavities enables appropriate increasing of the pressure of liquid in a cavity of the tapered shrinkage portion during flow gathering, and a certain pressure increasing effect is achieved.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

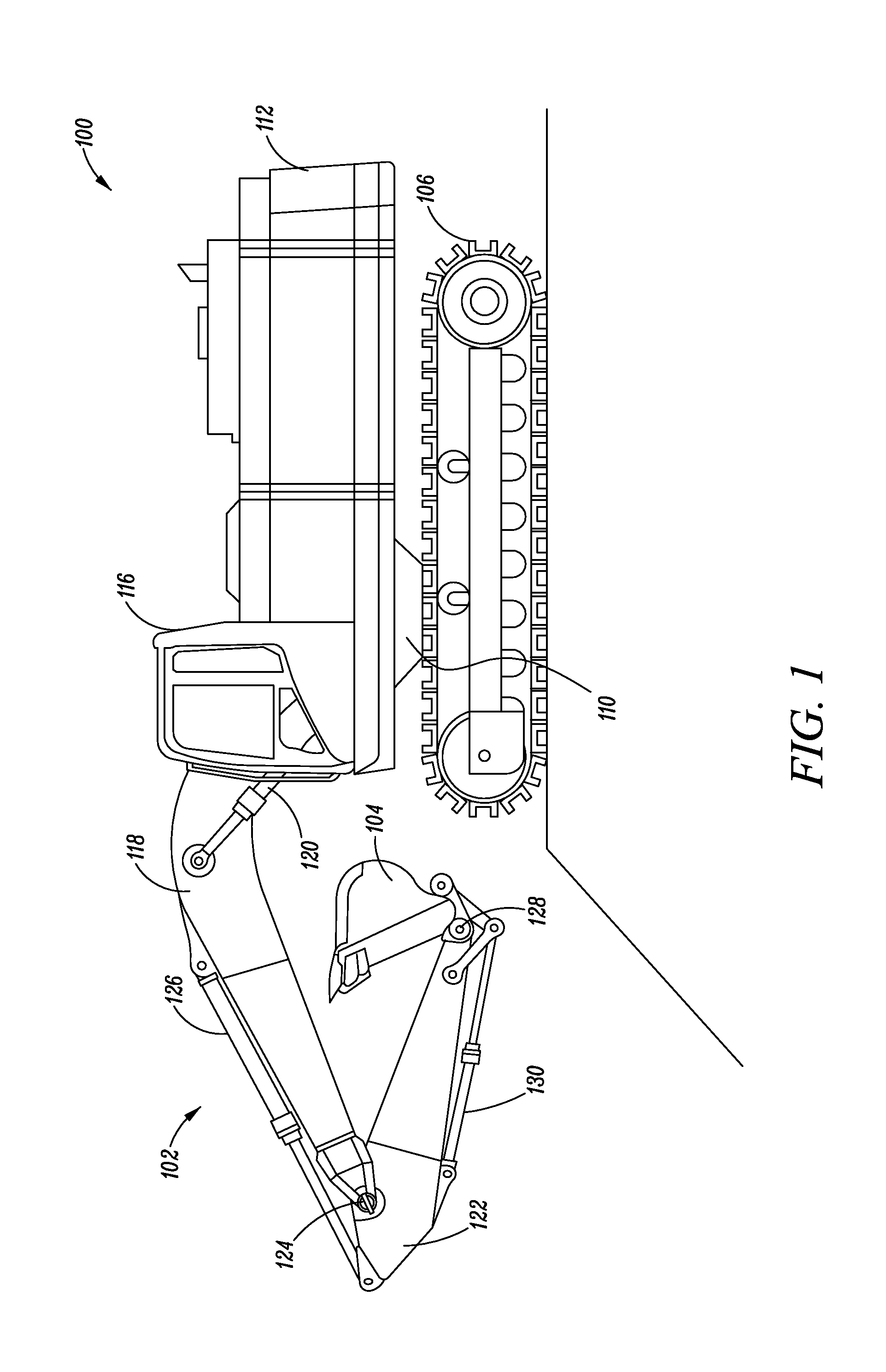

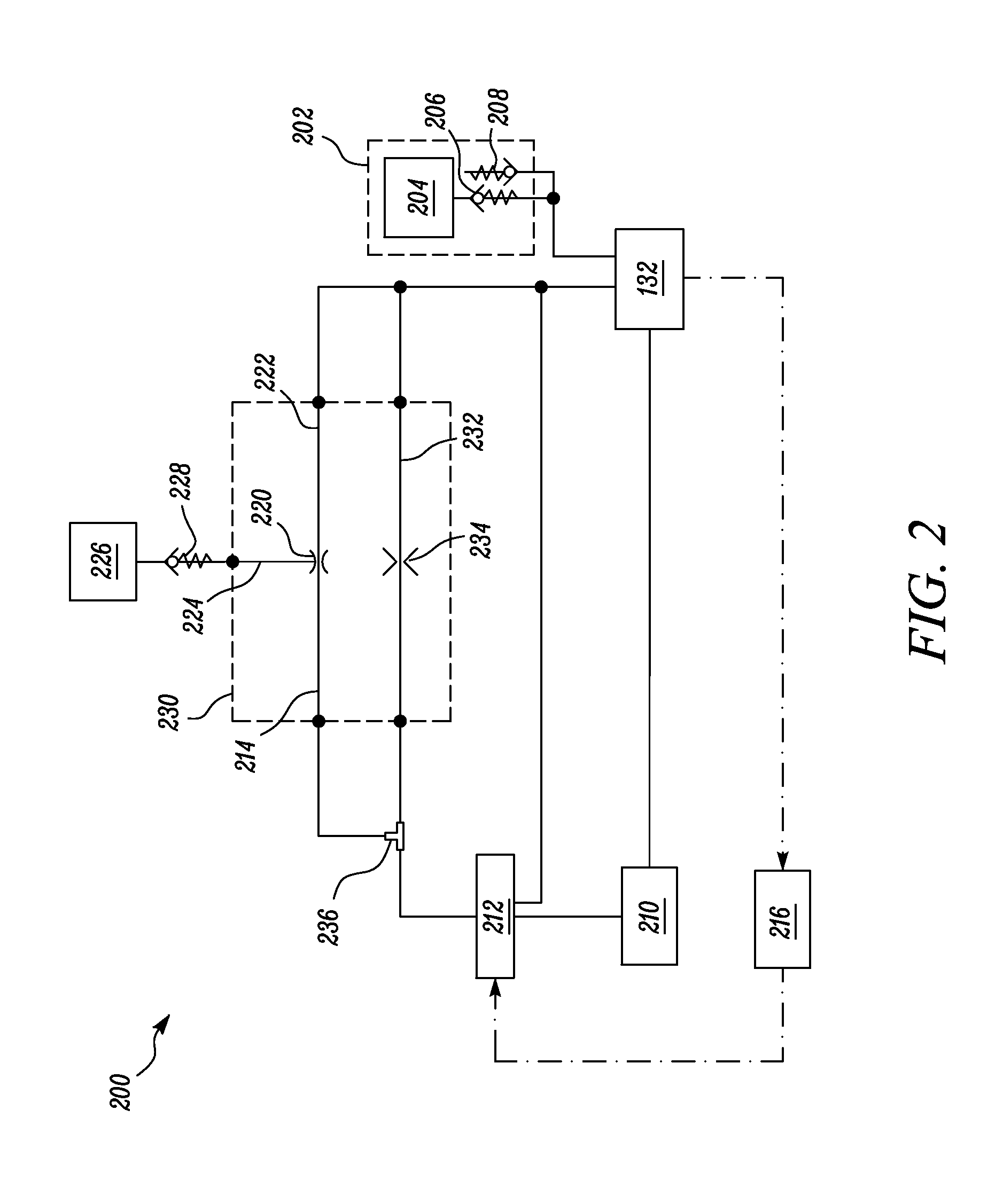

Hydraulic system for machine

ActiveUS20160025097A1Reduce pressureIncrease liquid pressureAccumulator installationsSoil-shifting machines/dredgersEngineering

A hydraulic system for a machine is disclosed. The hydraulic system includes a hydraulic tank configured to store a liquid therein. The hydraulic system also includes a first conduit, a venturi, a fluid conduit and a second conduit. The first conduit is in fluid communication with the hydraulic tank and configured to receive the liquid from the hydraulic tank. The venturi is in fluid communication with the first conduit and configured to reduce a pressure of the liquid flowing therethrough. The fluid conduit is in fluid communication with the venturi and configured to supply a gaseous fluid into the venturi. The second conduit is in fluid communication with the venturi and configured to supply a mixture of the liquid and the gaseous fluid into the hydraulic tank in order to increase a pressure of the liquid in the hydraulic tank.

Owner:CATERPILLAR GLOBAL MINING LLC

Flow cell and liquid chromatograph having same

ActiveCN109932450AReduce the output intensityImprove detection accuracyComponent separationColor/spectral properties measurementsLiquid coreEngineering

The present invention discloses a flow cell and a liquid chromatograph having the same. The flow cell comprises a housing, a cell core, a liquid core waveguide, an inlet connection module and an outlet connection module. The housing is configured to limit an installation cavity, and the cell core is arranged in the installation cavity and is internally provided with a liquid channel, a liquid inlet tank and a liquid outlet tank. The two ends of the liquid channel respectively communicate with the liquid inlet tank and the liquid outlet tank, the liquid inlet tank penetrates an inlet pressing block, the liquid inlet tank communicates with the liquid outlet tank, an incident light tube penetrates the inlet pressing block, the incident light tube communicates with the liquid inlet tank, and the outlet connection module is butted against one end, provide with the liquid outlet tank, of the cell core. The outlet connection module is provided with a light emitting hole directly facing the liquid outlet tank. According to the embodiment of the invention, the flow cell can reduce the possibility of energy loss and generation of stray light so as to improve the detection precision of the liquid concentration.

Owner:ANHUI WAYEE SCI & TECH CO LTD

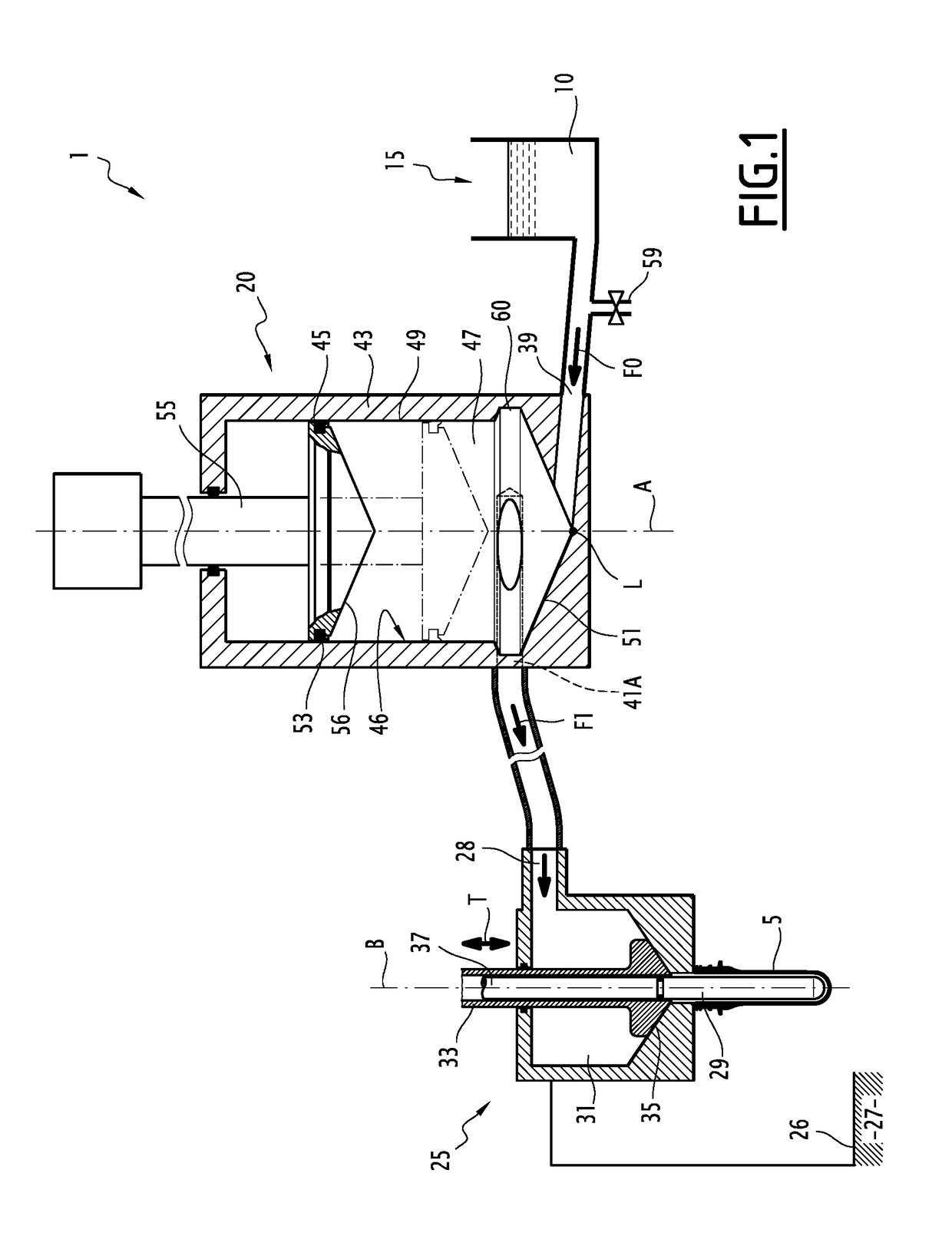

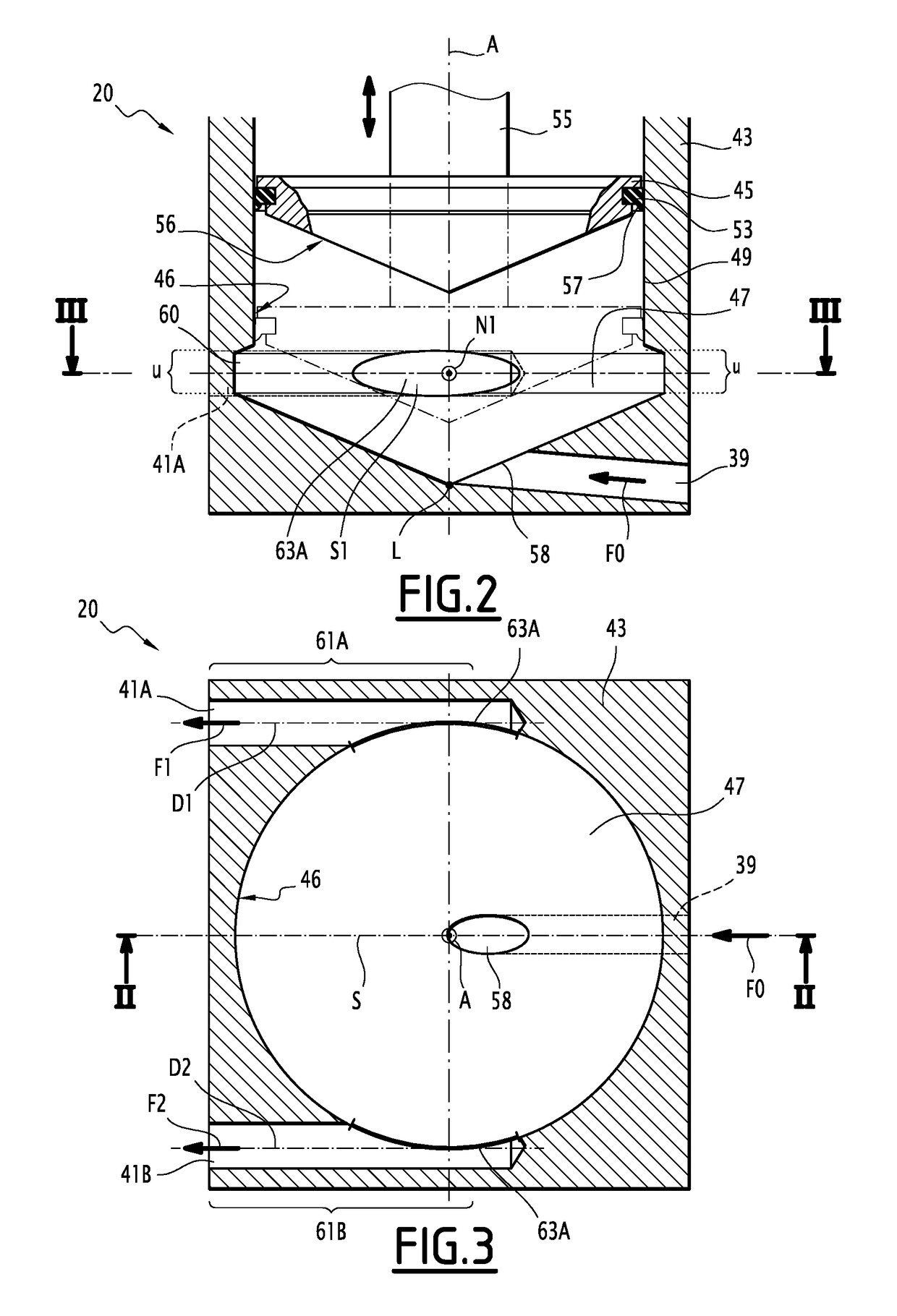

Injection device for a forming and filing a container using a pressurized liquid

ActiveUS10625460B2Reduce riskIncrease chanceDomestic articlesLiquid materialRadial planeReciprocating motion

Owner:DISCMA

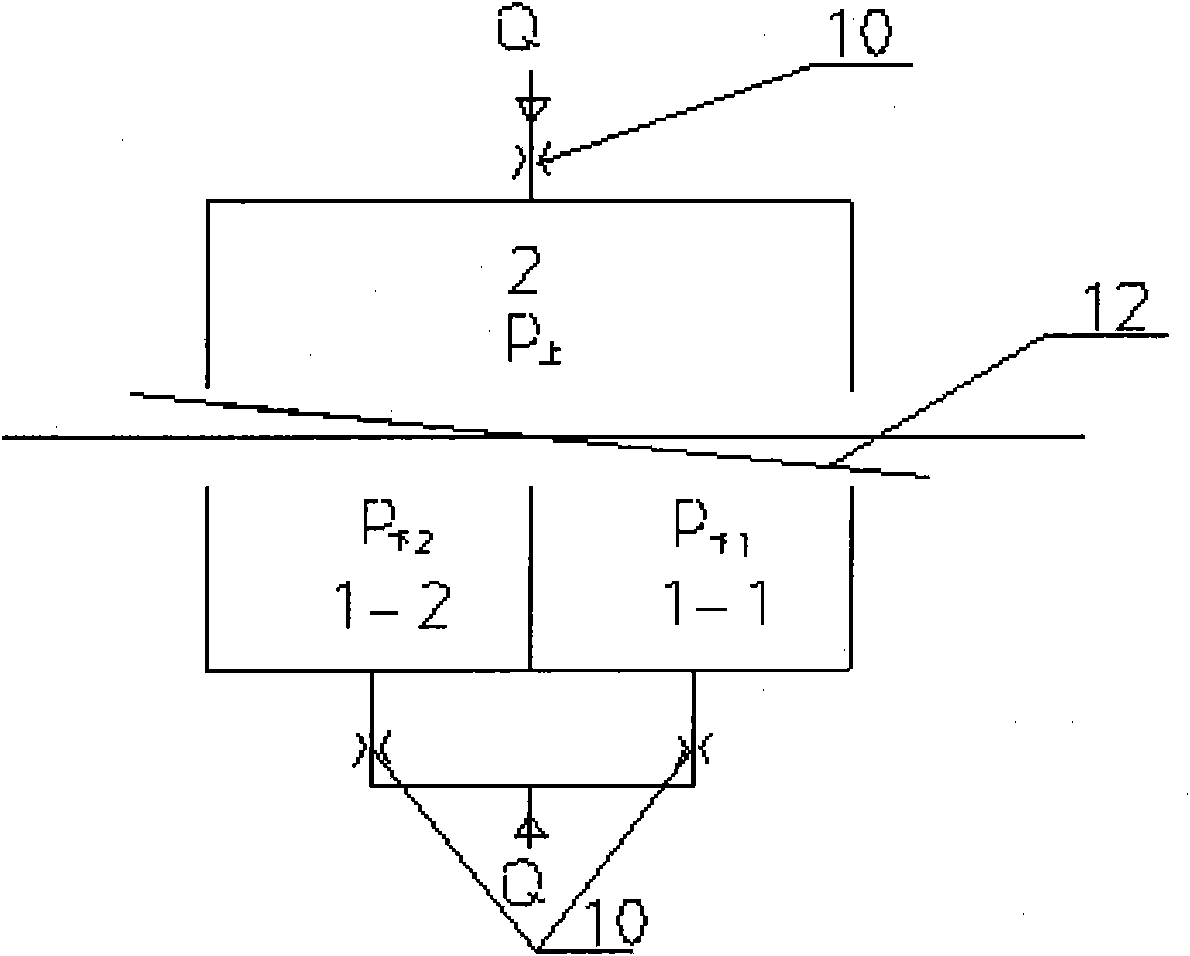

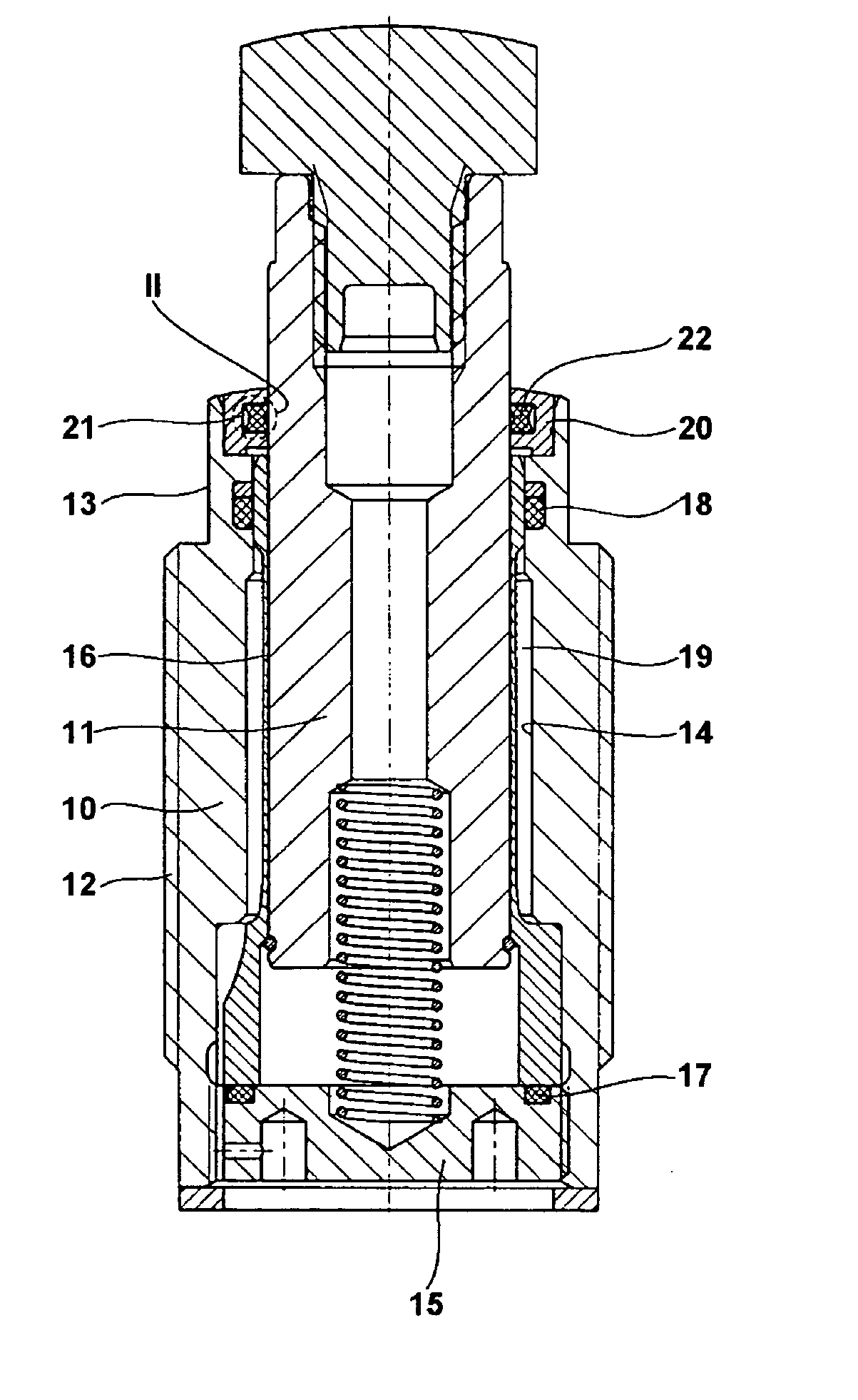

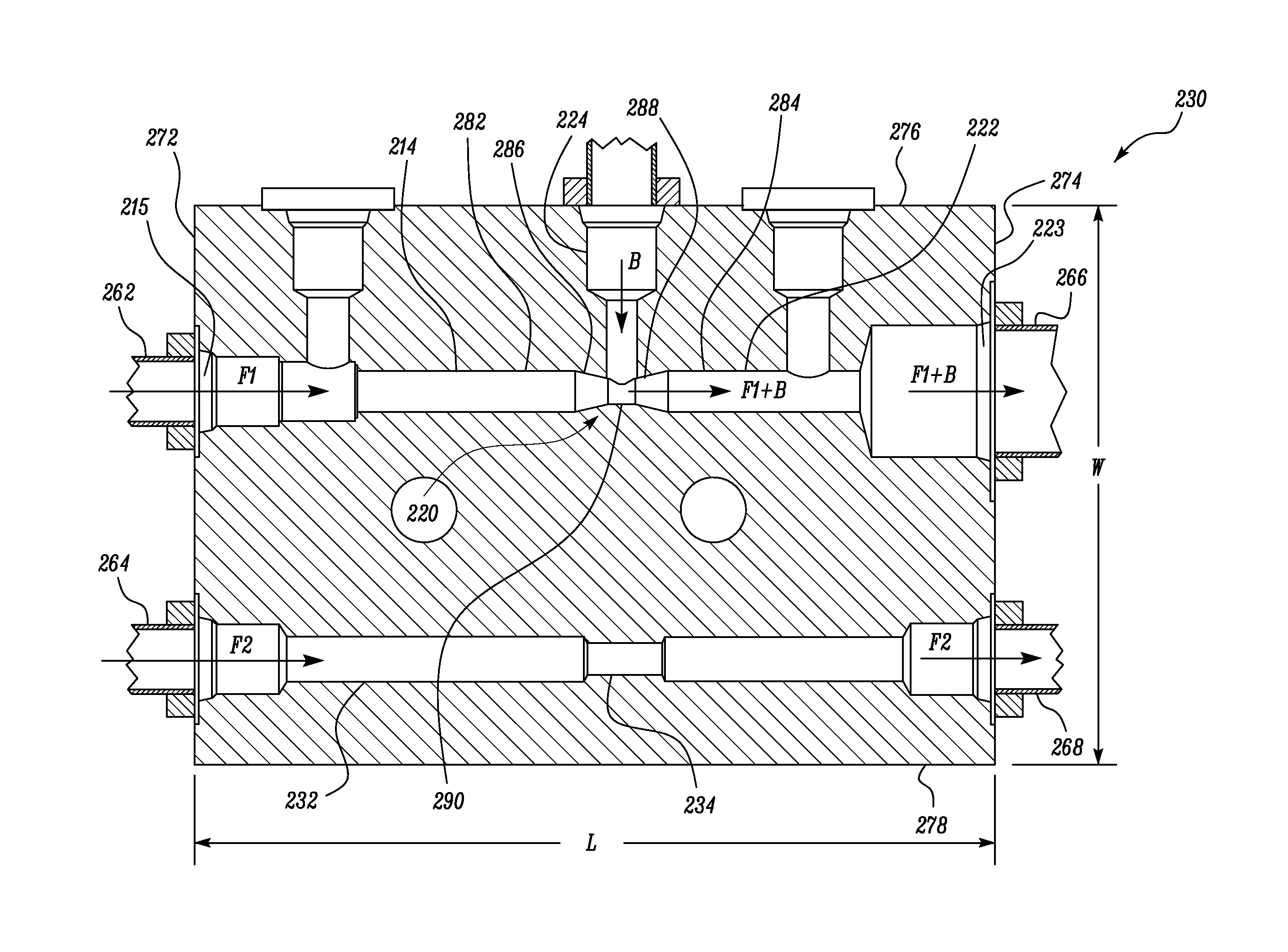

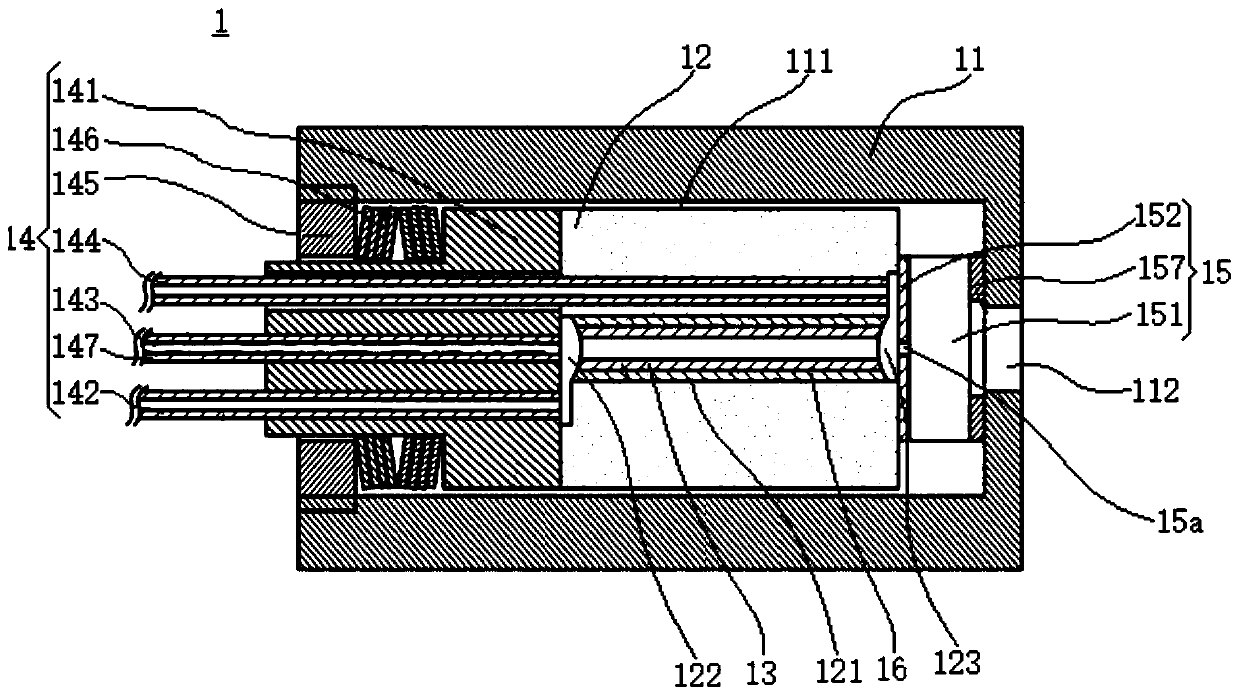

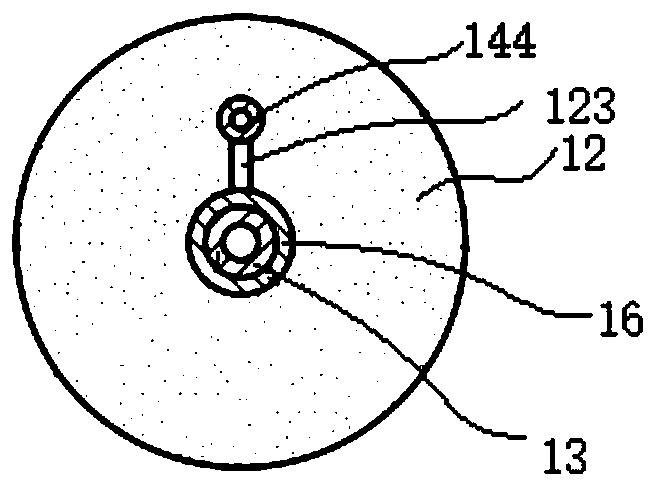

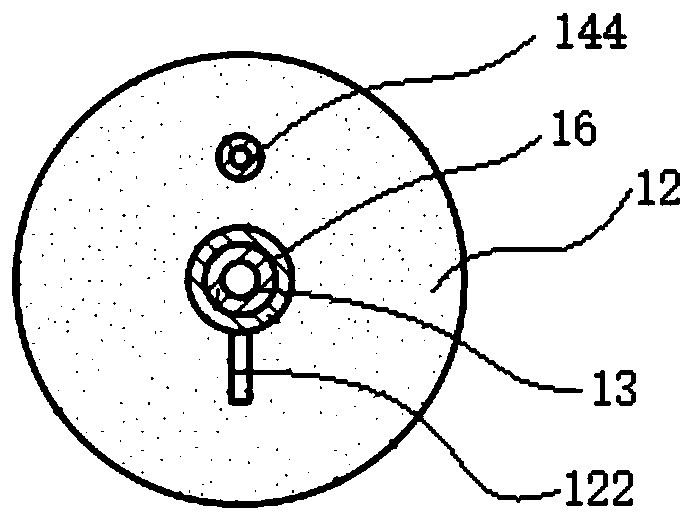

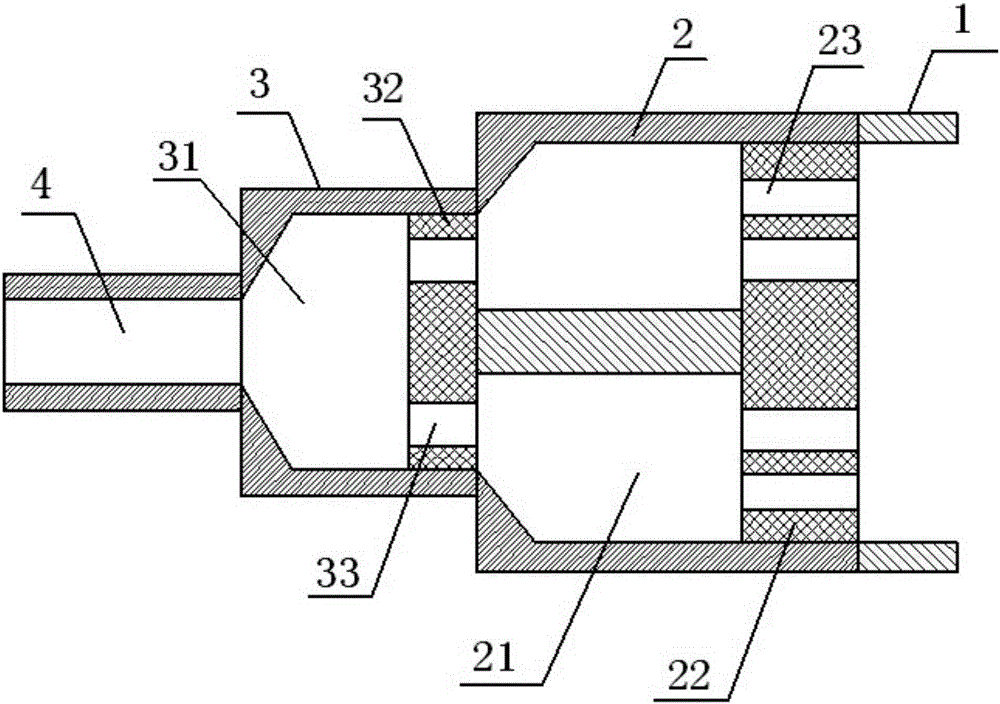

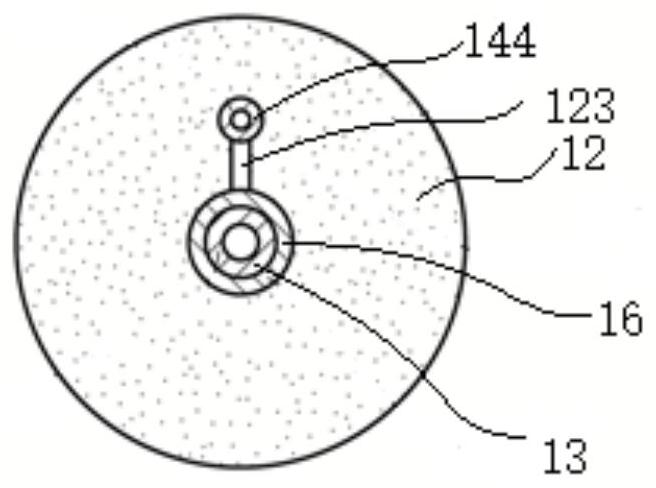

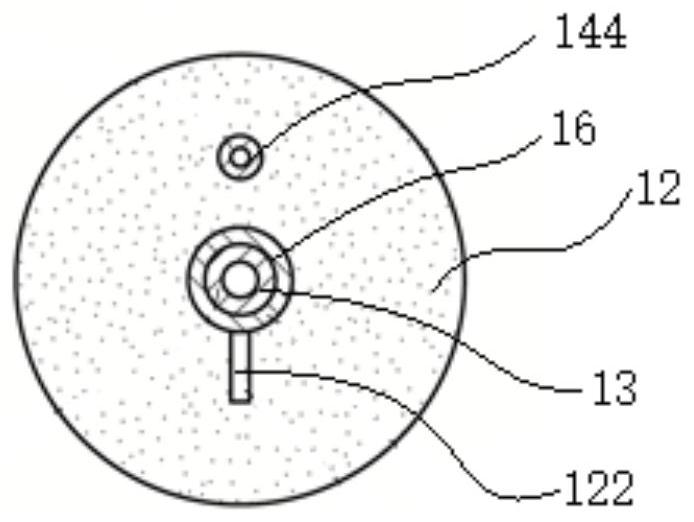

Double-cavity pressurization connector

InactiveCN105156787AIncrease flow rateIncrease liquid pressureSleeve/socket jointsLiquid storage tankEngineering

The invention discloses a double-cavity pressurization connector. The double-cavity pressurization connector comprises a liquid inlet pipe, a primary pressurization chamber, a secondary pressurization chamber and a liquid outlet pipe which are communicated together in sequence, wherein a primary pressurization cavity is arranged in the primary pressurization chamber; a primary baffle is arranged between the primary pressurization cavity and the liquid inlet pipe and provided with a primary liquid inlet; a secondary pressurization cavity is arranged in the secondary pressurization chamber; a secondary baffle is arranged between the secondary pressurization cavity and the primary pressurization cavity and provided with a secondary liquid inlet; the liquid inlet pipe and a liquid storage tank are communicated with the liquid outlet pipe sequentially through the primary liquid inlet, the primary pressurization cavity, the secondary liquid inlet and the secondary pressurization cavity. According to the technical scheme, liquid is pressurized through the primary pressurization cavity and the secondary pressurization cavity and then enters a small-diameter pipeline after being pressurized, stress is not increased suddenly in the radial direction of the small-diameter pipeline, the stress is relatively balanced, and the service life is prolonged.

Owner:ANHUI YINENG MACHINERY

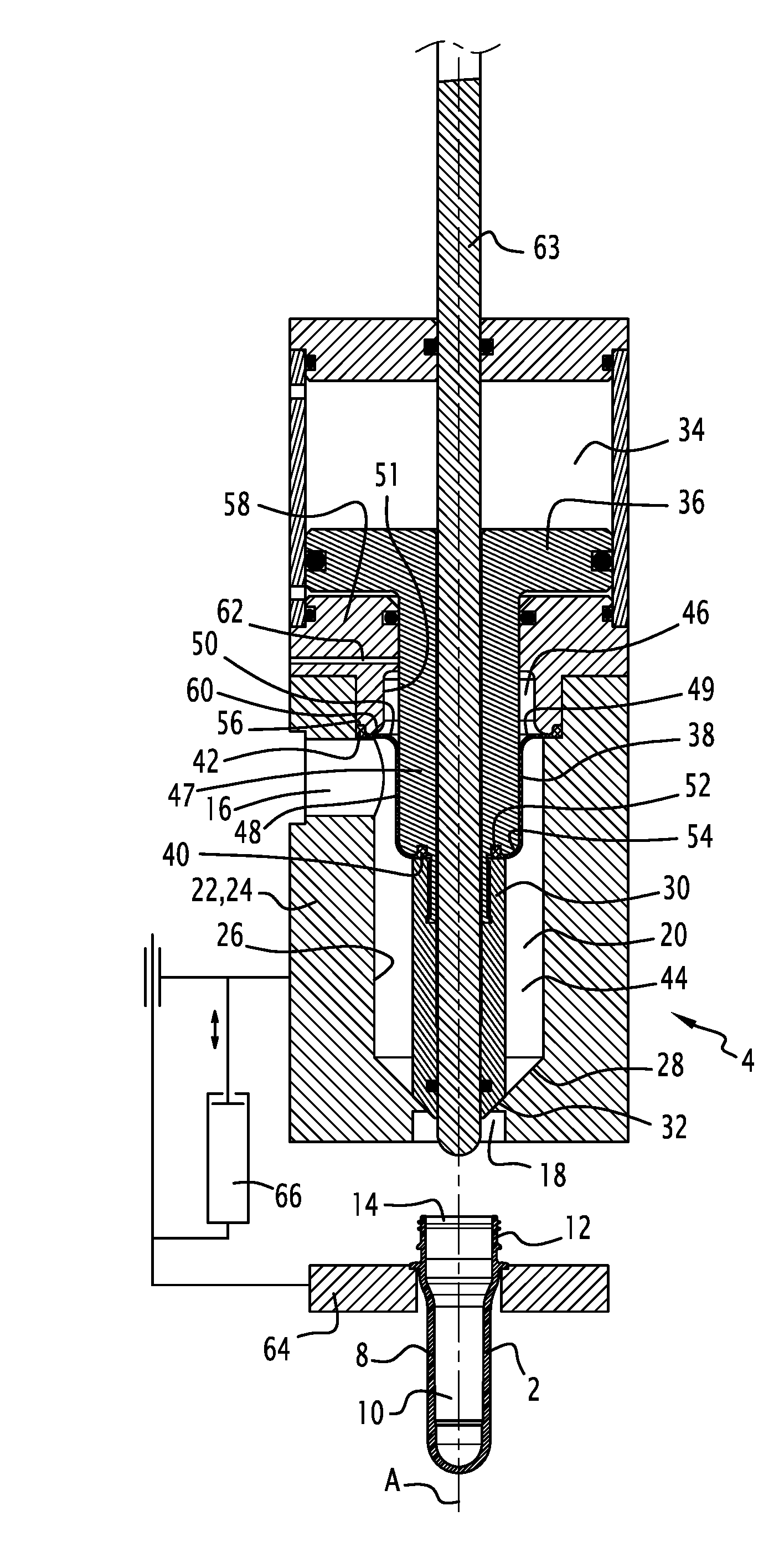

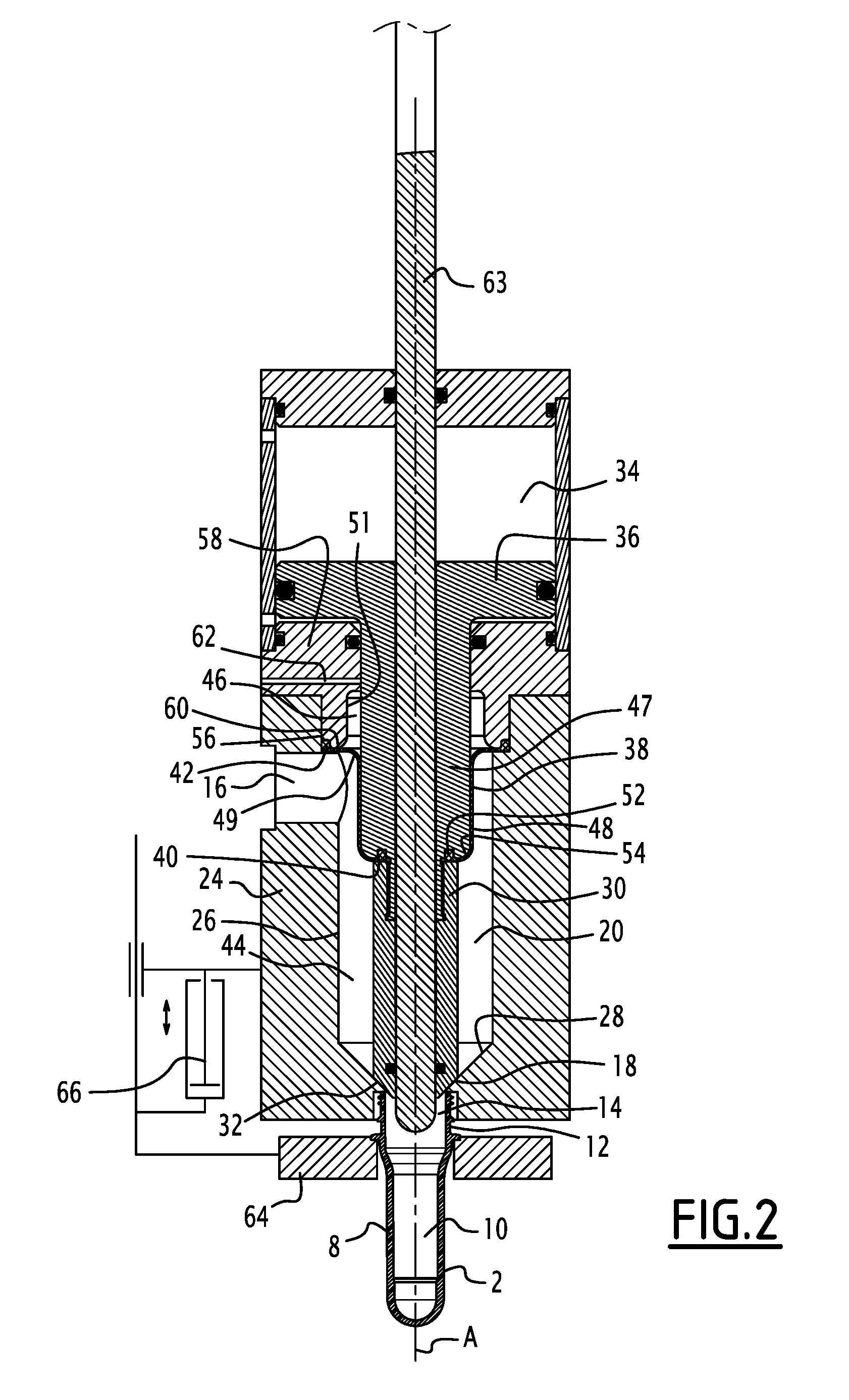

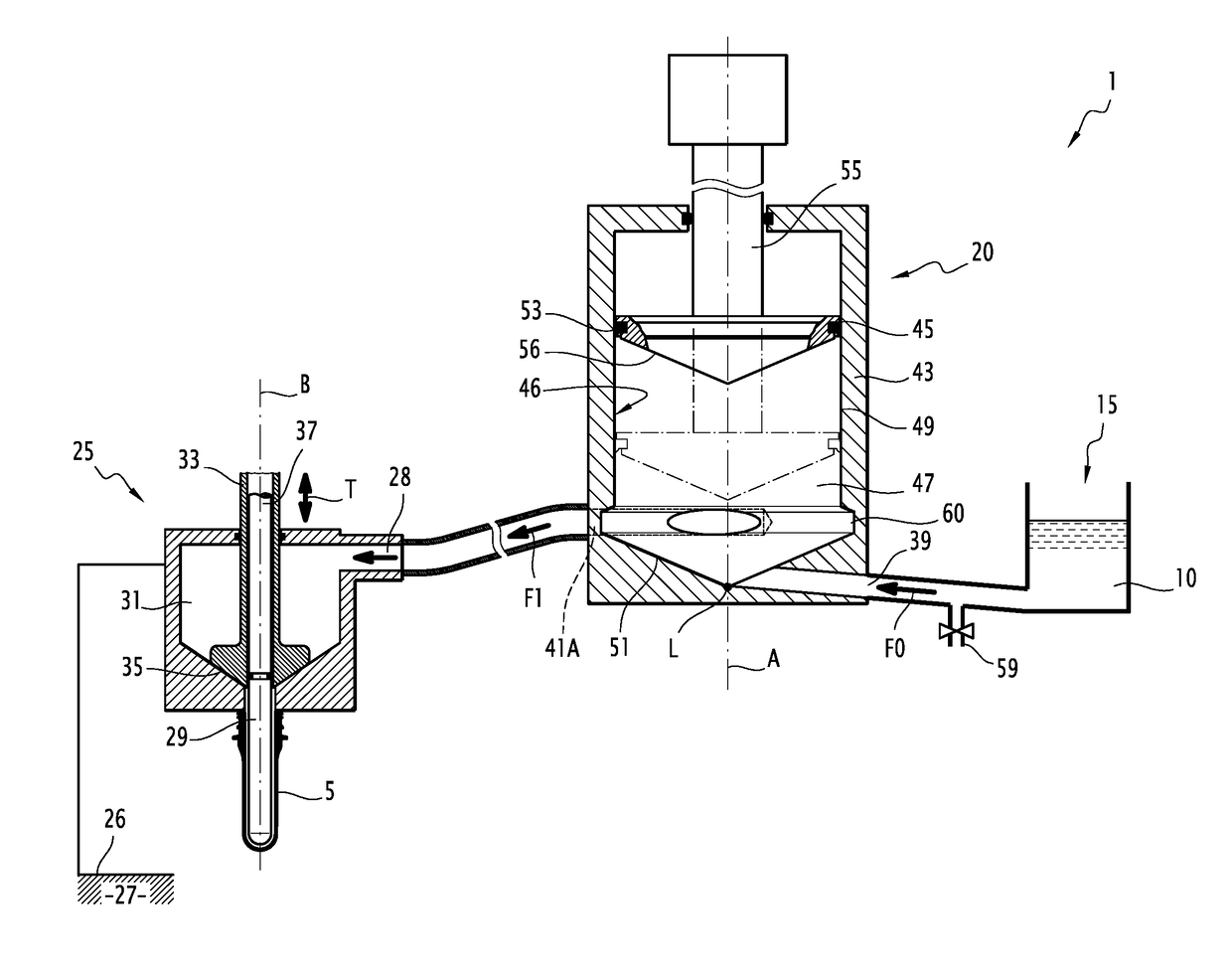

Injection Device for a Forming and Filing a Container using a Pressurized Liquid

ActiveUS20170232655A1Reduce riskIncrease chanceDomestic articlesLiquid materialRadial planeReciprocating motion

An injection device for injecting a pressurized liquid into the preform. The injection device includes a piston device having a piston body with a piston head arranged to reciprocate therein. The piston head cooperates with a sealing portion of the piston body to fluidicly isolate an inner chamber of the piston device. The piston body being in fluidic communication with a liquid source for admitting liquid into the inner chamber. The piston body including at least two outlet ducts for delivering pressurized liquid to the injection head. Each outlet duct opening defining an outlet port in a wall of the inner chamber. Each outlet port being centered on an outlet port center, wherein all the outlet port centers extend in the same radial planes of the inner chamber, are at the same distance from the piston axis and are arranged angularly in a regular manner around the piston axis.

Owner:DISCMA

Liquid chromatography component

InactiveUS20120067823A1Easy to separateIncrease liquid pressureIon-exchange process apparatusComponent separationLiquid phaseChemistry

The present invention aims to provide a liquid chromatography component including a column and a prefilter, which is hard to cause an increase of supplied liquid pressure even when the measurement of a sample is repeated. The present invention is a liquid chromatography component, which includes: a column with filler particles filled therein; and a prefilter, the filler particles having an average particle size in the range of 2 to 20 μm, the prefilter having a filtering particle size in the range of ⅙ to ⅓ of the average particle size of the filler particles.

Owner:YOTANI TAKUYA

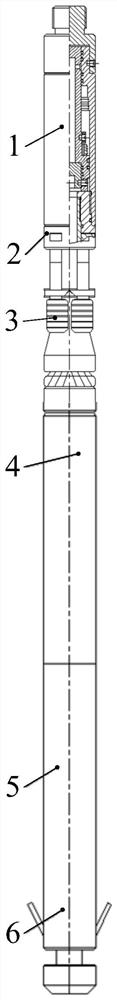

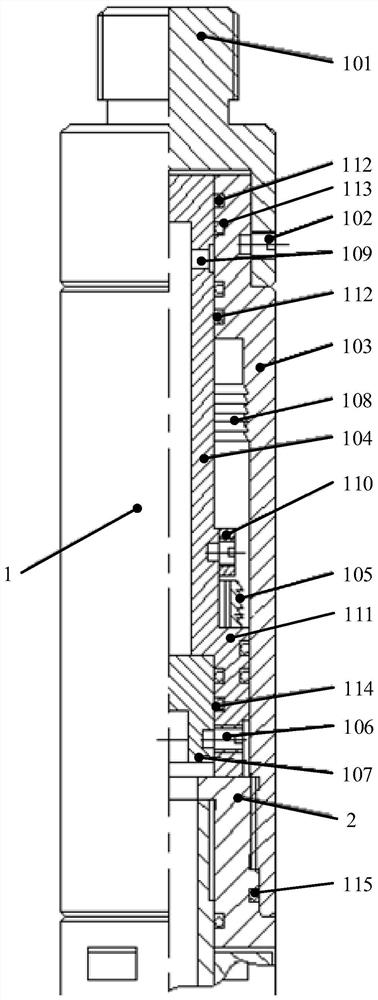

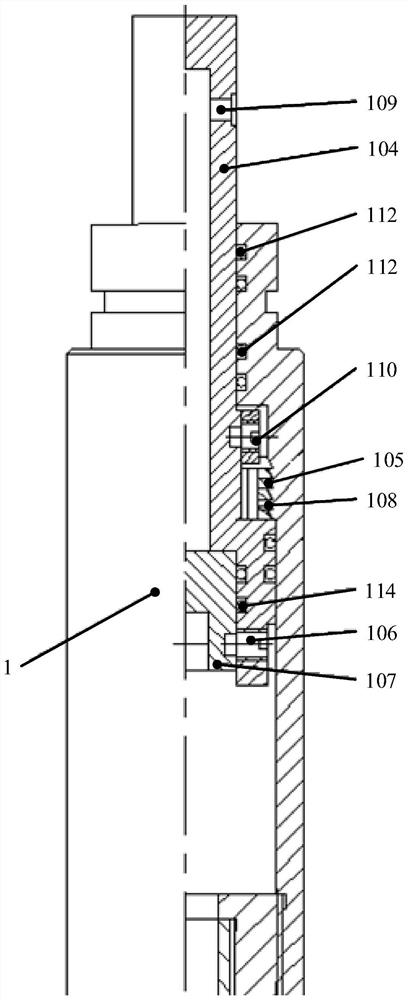

plug

ActiveCN111749645BIncrease liquid pressureIncrease productivityWell/borehole valve arrangementsSealing/packingThermodynamicsUpper joint

The invention discloses a plug, belonging to the technical field of oil well maintenance. The communicable mechanism in the occluder includes: an upper joint, a piston sleeve whose upper end is fixed in the lower end of the upper joint through first scissors, a first piston slidably arranged in the piston sleeve, and a first piston sleeved in the first The sawtooth ring on the piston and the second piston arranged in the lower end of the first piston through the second scissors. After the plug is installed in the pipe string, if the pipe string is stuck, liquid can be injected through the wellhead to increase the liquid pressure above the plug, and the liquid pressure is applied to the top wall of the second piston to make the first The two scissors are cut, the second piston moves downward, and the first piston and the second piston are separated, thereby conducting the plug, so that the liquid above and below the plug can flow through the plug, so as to further Provide conditions for maintenance or production, thereby improving production efficiency.

Owner:PETROCHINA CO LTD

Method and system for cooling a motor during motor startup

InactiveUS20210247107A1Increase liquid pressureCompressorMechanical apparatusElectric machineControl theory

A HVAC system includes a compressor having a low pressure input and a high pressure output. The compressor is driven by a motor having a liquid coolant flowpath configured to cool and lubricate the motor. The motor has a coolant input and a coolant output. An evaporator is in communication with the compressor, and includes a coolant input and a coolant output. A condenser is in fluid communication with the evaporator and the compressor. A first coolant flowpath, includes a coolant drive system connecting the output of the condenser to a valve switching device. A second coolant flowpath connects the output of the condenser to the input of the evaporator and to a second input of the valve switching device. A third coolant flowpath connects the valve switching device to the inputs of the motor. A fourth coolant flowpath connects outputs of the motor to the input of the evaporator.

Owner:CARRIER CORP

Liquid distribution

InactiveUS20100096404A1Minimize degradationIncrease pressureOpening closed containersBottle/container closureEngineeringMechanical engineering

A method for expelling gas and distributing liquid from a container is disclosed. A piston on which an outlet is formed is positioned in a container holding gas and liquid. The piston and cylinder are so formed that movements of the piston can increase the pressure of the gas and the liquid. This pressure increase can be used to expel gas from the container via the piston outlet and to distribute liquid from the container via the piston outlet and / or another outlet. Expelling the gas minimizes degradation of liquid remaining in the container due to an interaction with the gas.

Owner:COOK MELVIN SEYMOUR

Flow cell and liquid chromatograph having same

ActiveCN109932450BReduce the output intensityImprove detection accuracyComponent separationColor/spectral properties measurementsFlow cellLight pipe

Owner:ANHUI WAYEE SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com