Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increase cracking load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

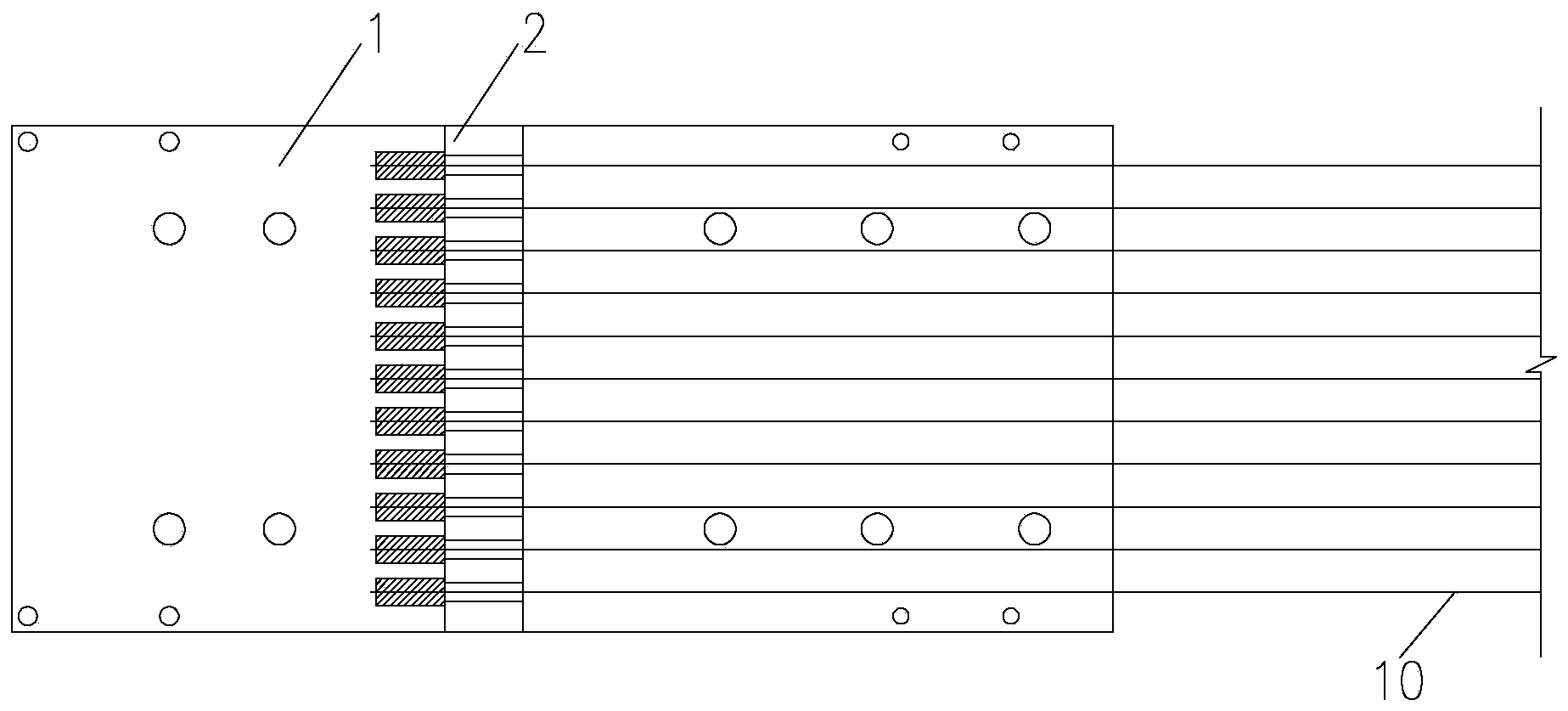

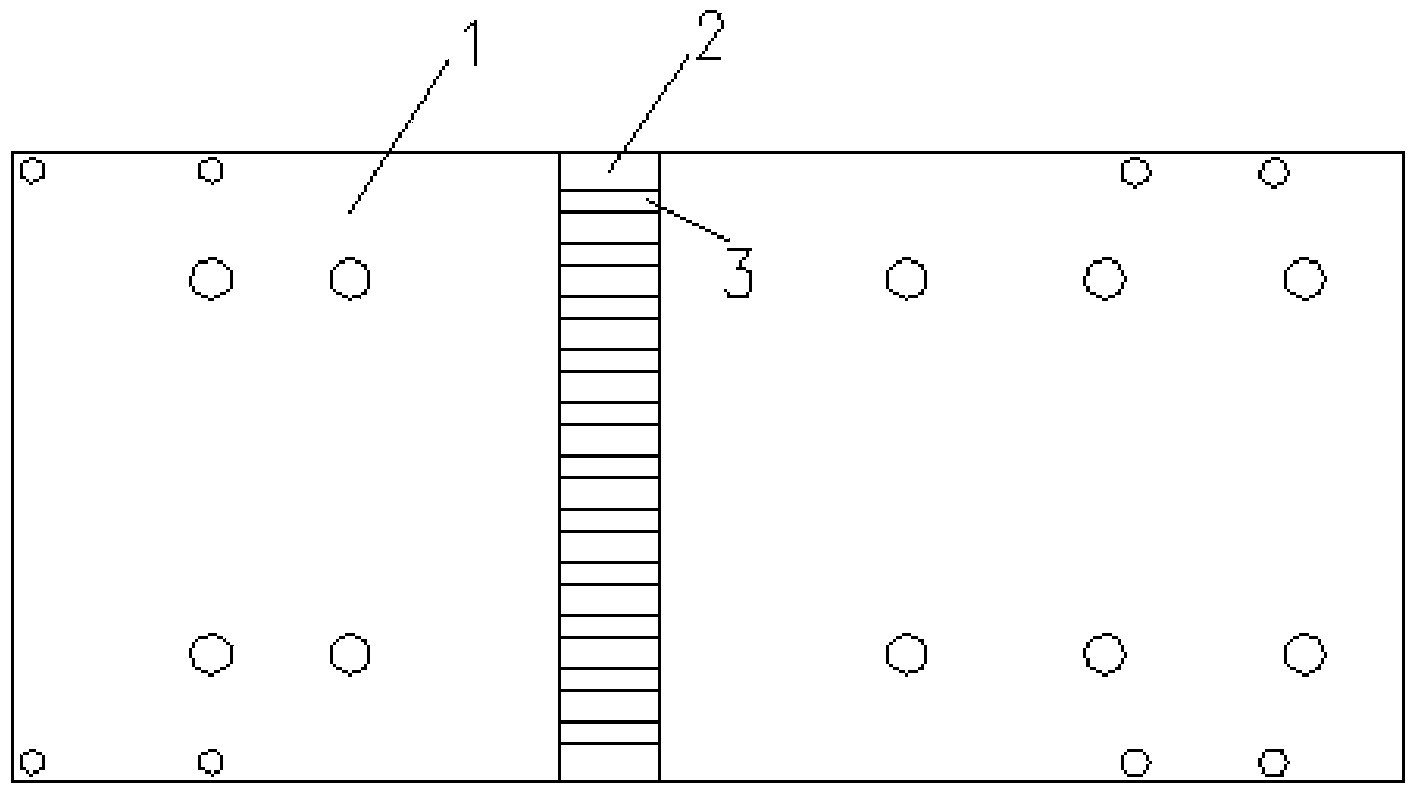

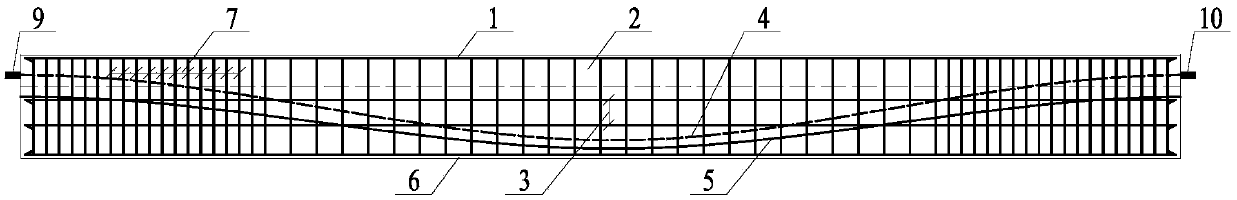

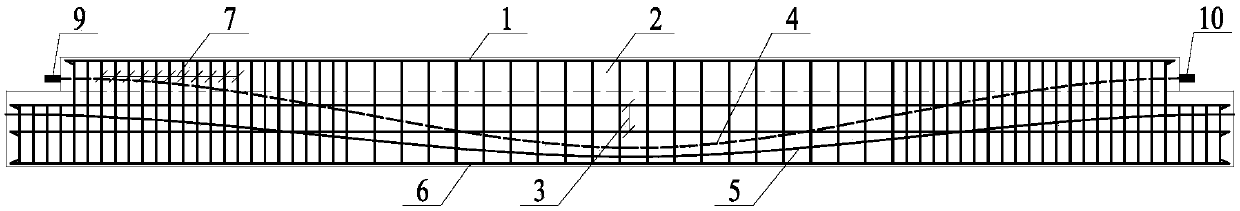

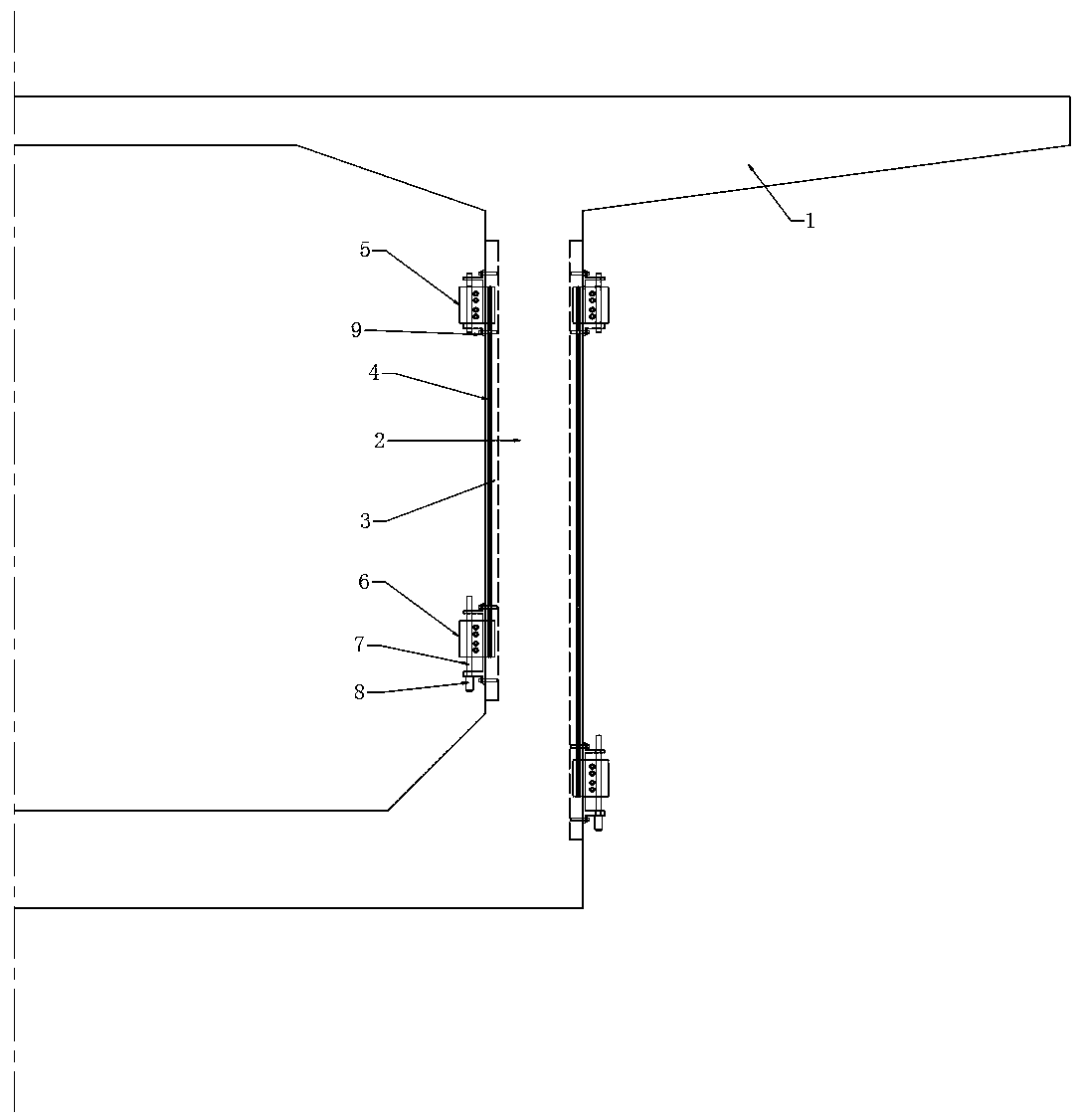

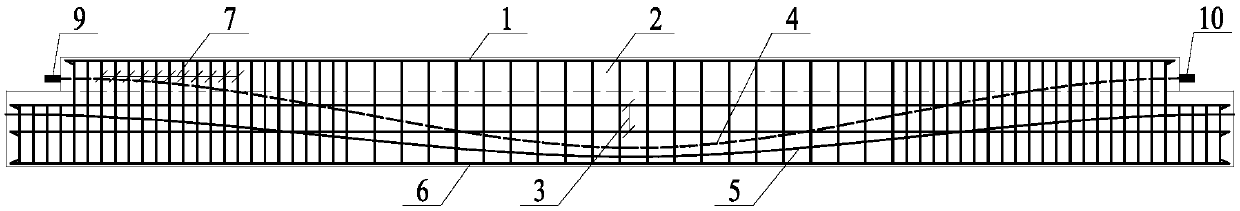

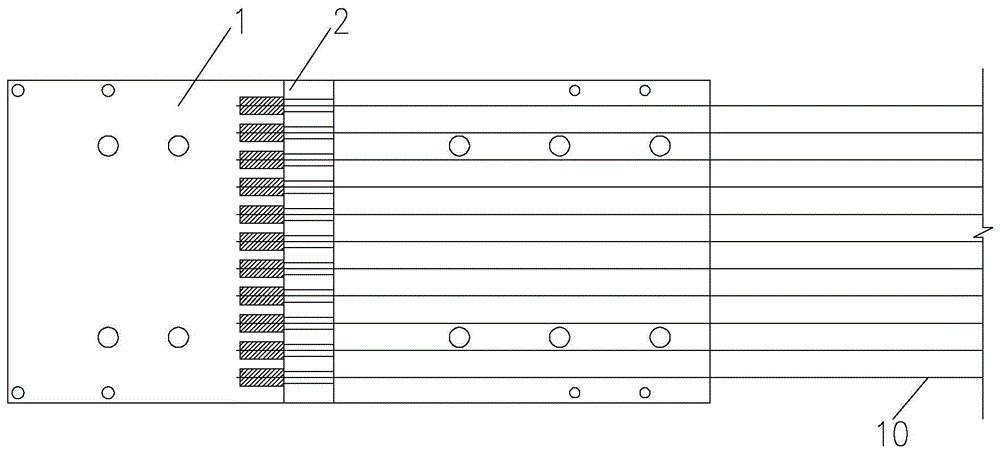

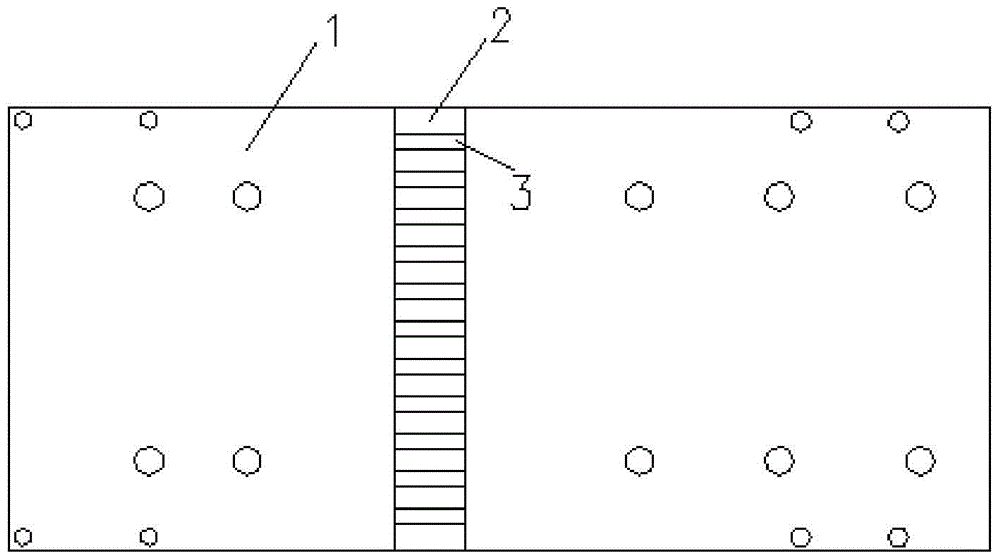

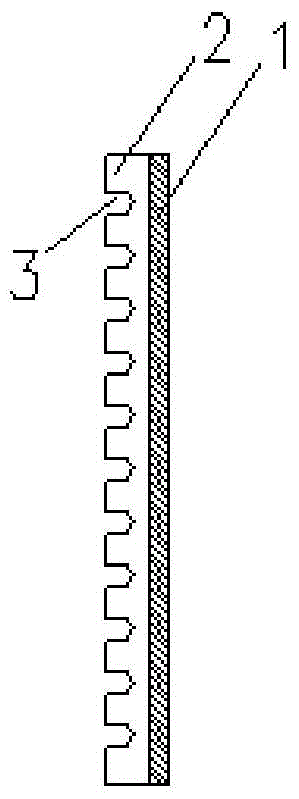

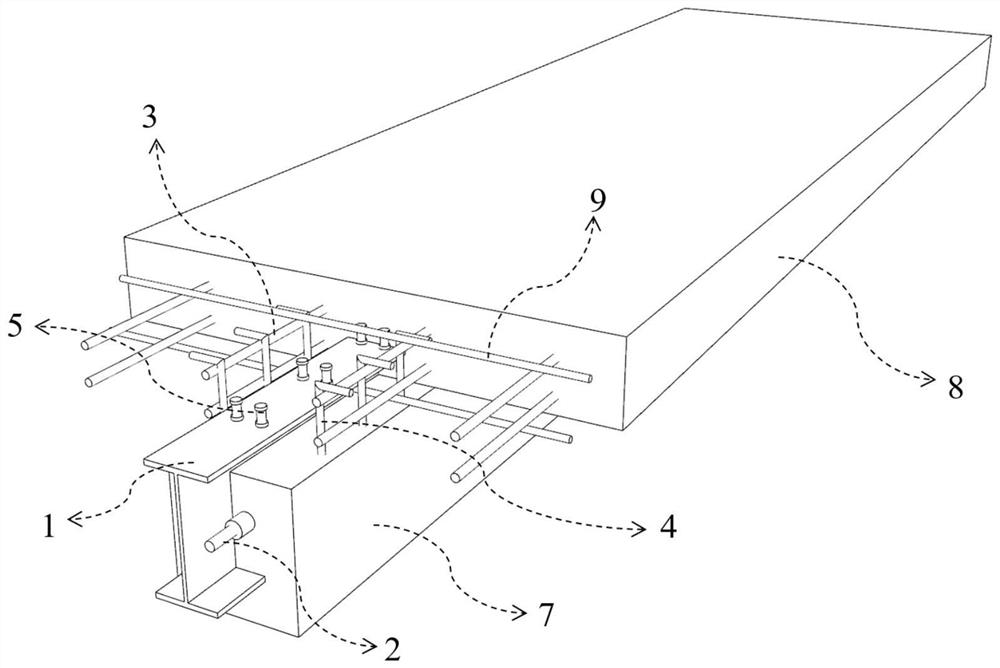

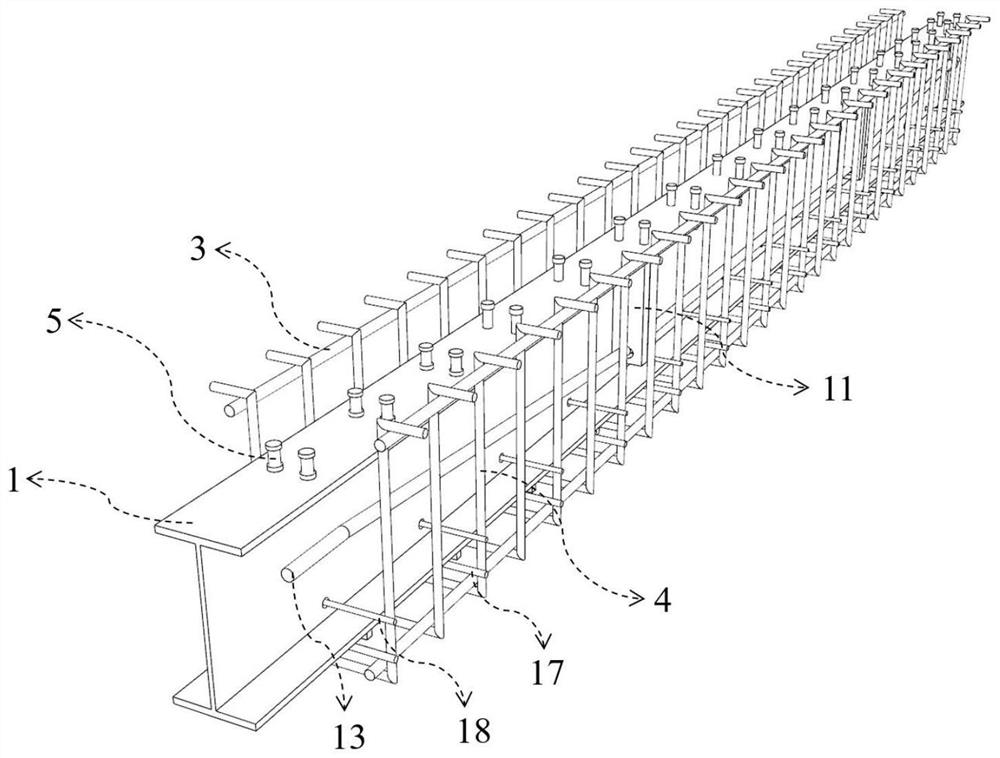

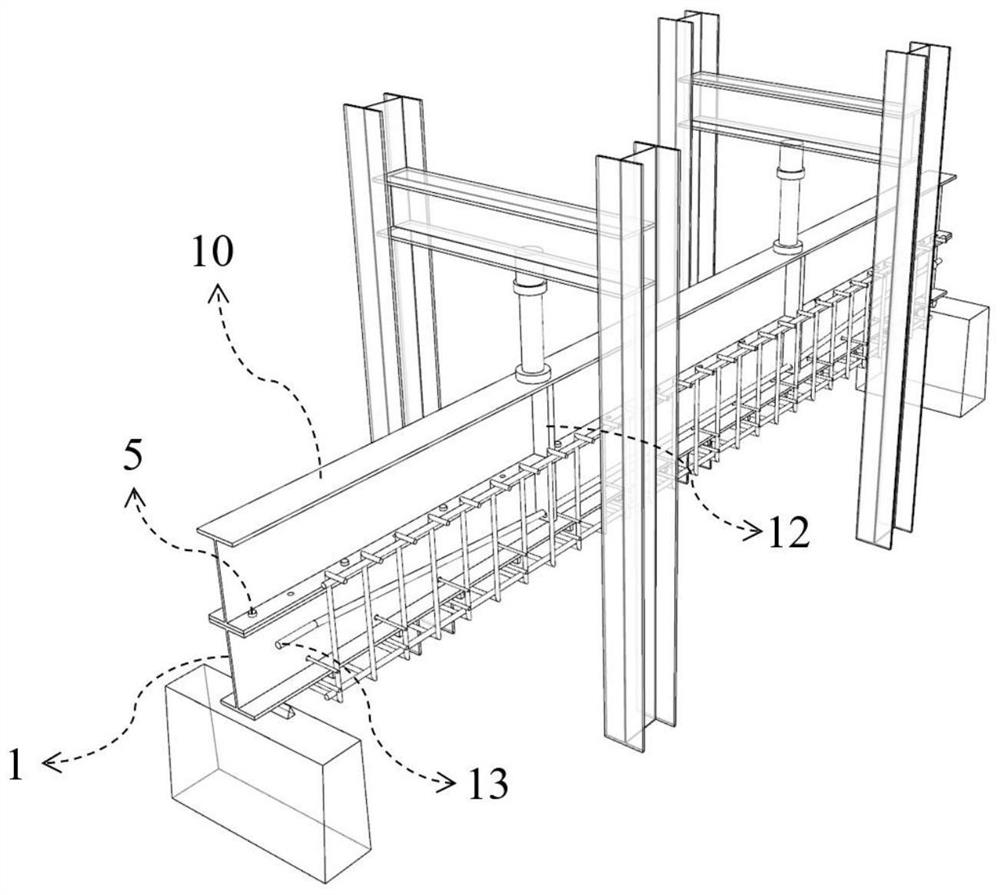

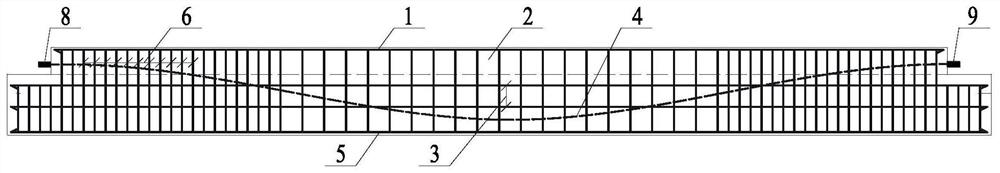

Concrete structure reinforcing method, self-anchored prestress assembly, assembled tensioning assembly

InactiveCN104074368AIncrease cracking loadIncrease stiffnessBuilding repairsBuilding reinforcementsPre stressFastener

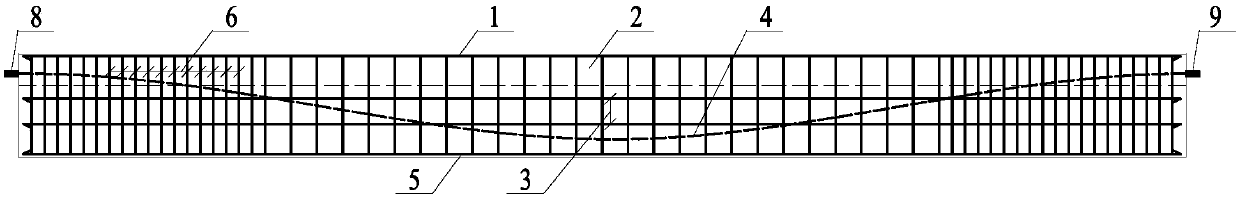

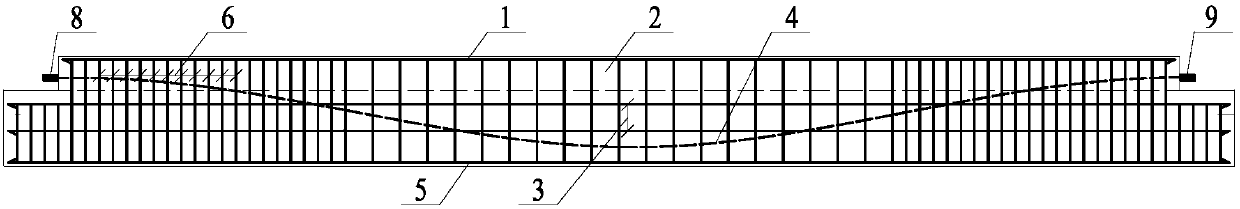

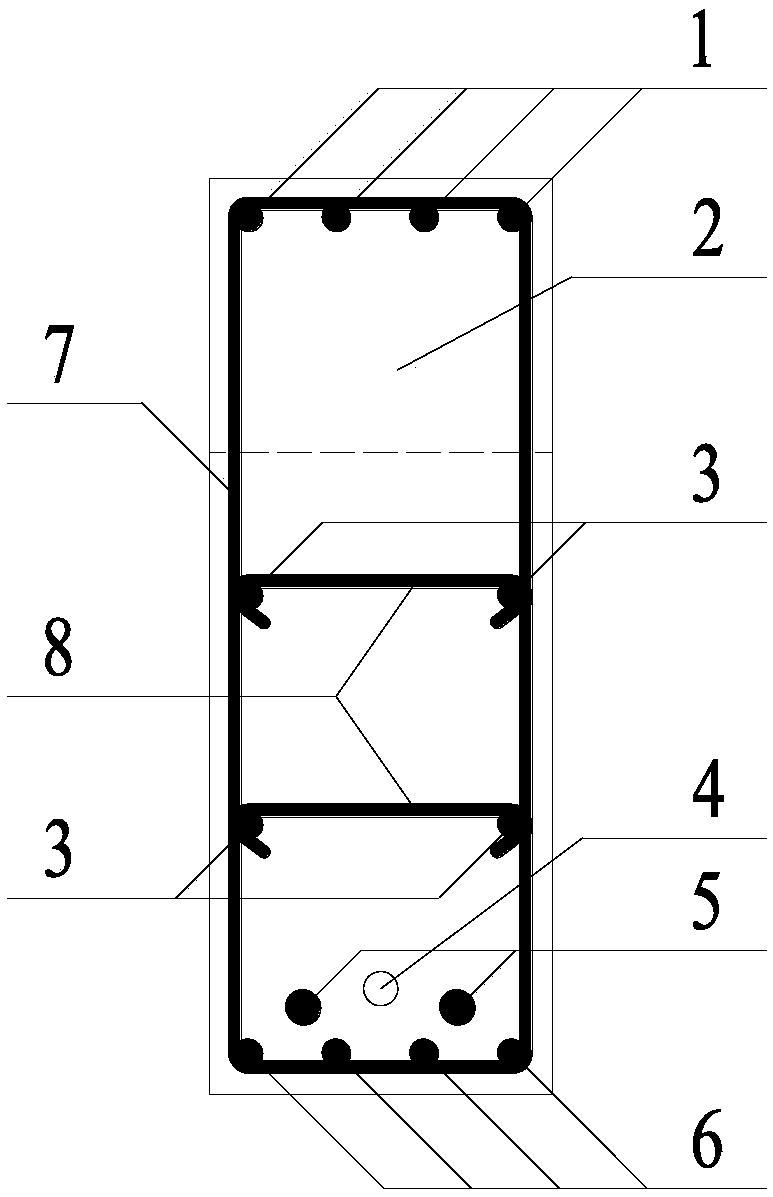

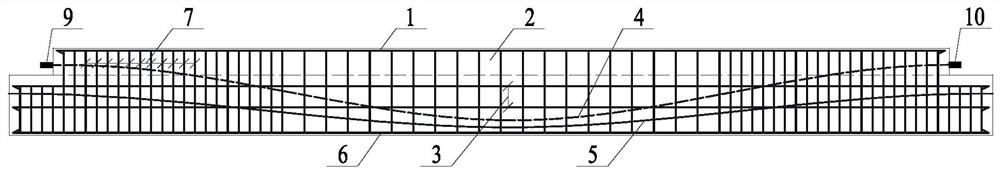

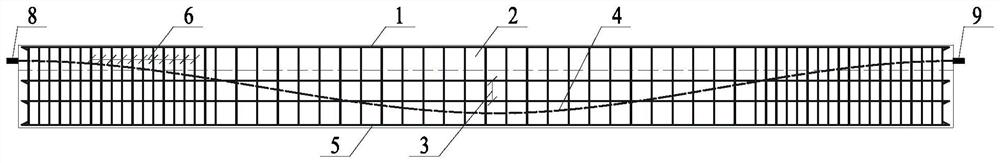

The invention relates to a concrete structure reinforcing method, a self-anchored prestress assembly and an assembled tensioning assembly. The concrete structure reinforcing method comprises the following steps including: an anchor seat installation step: an anchor seat is fixed on a concrete structure, wherein the anchor seat is pasted by adopting a pouring method, and fastening elements are chemically buried; a prestress cable manufacturing and installation step: a prestress cable is manufactured and is arranged in the assembled tensioning assembly; a prestress tensioning step: the prestress tensioning step includes a single prestress cable pre-tensioning sub step and a whole prestress cable tensioning sub step, so that the single prestress cables can be sequentially tensioned, and all of the prestress cables can be subsequently tensioned integrally; and a mortar spraying reinforcing step: the mortar spraying is at least carried out on regions covered by the prestress cables of the concrete structure, so that the reinforcement on the concrete structure is realized. The invention aims at providing the method of obviously improving the bearing force of the concrete structure.

Owner:湖南省交通科学研究院有限公司 +1

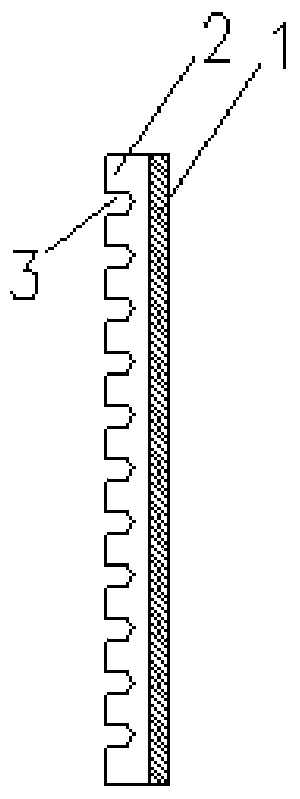

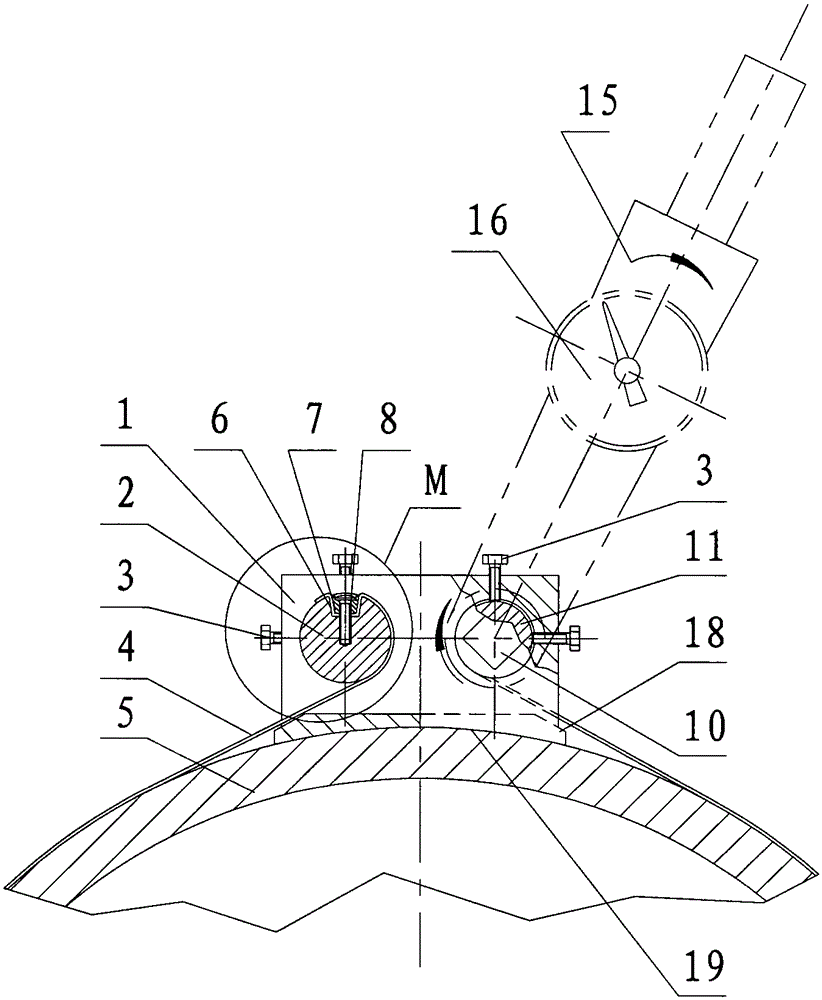

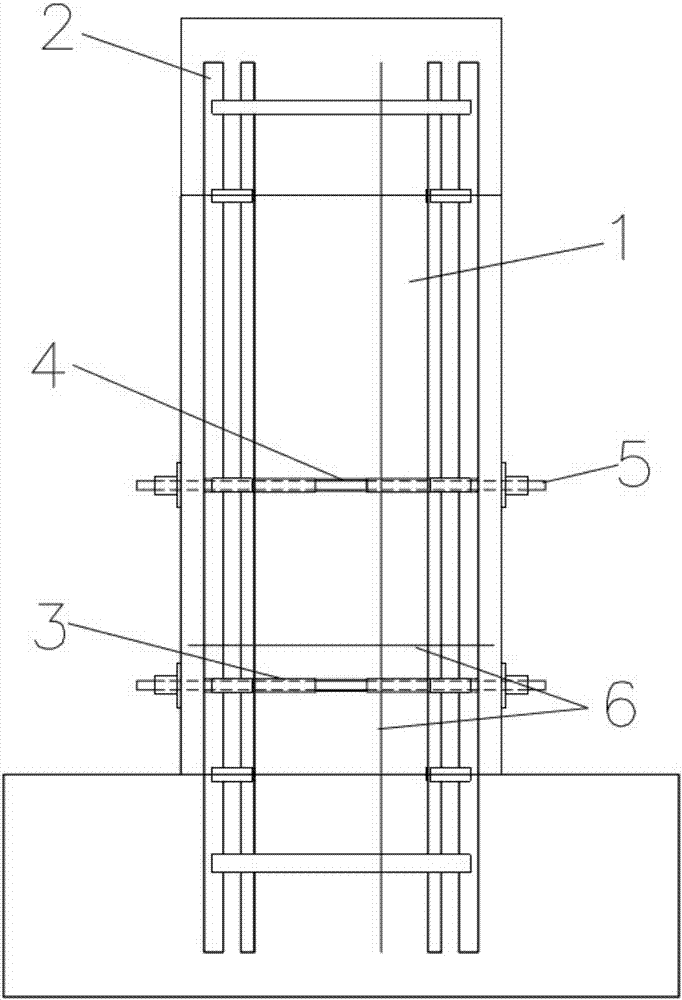

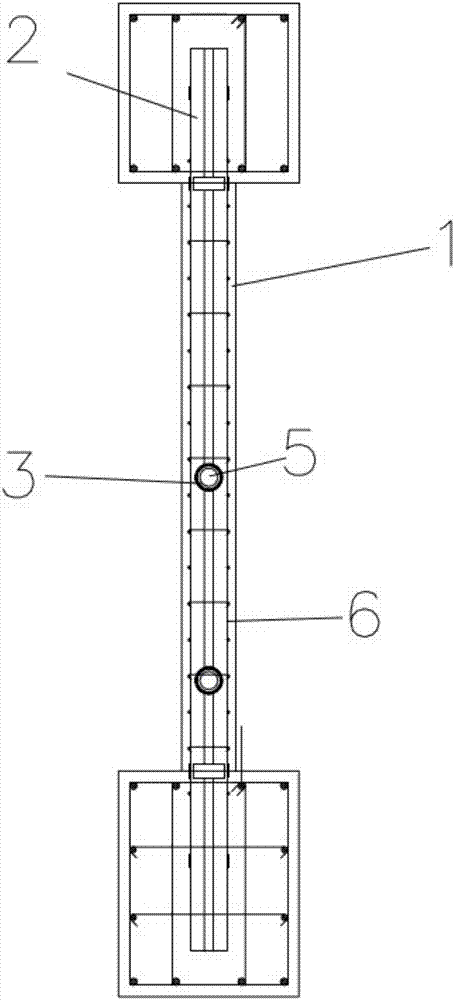

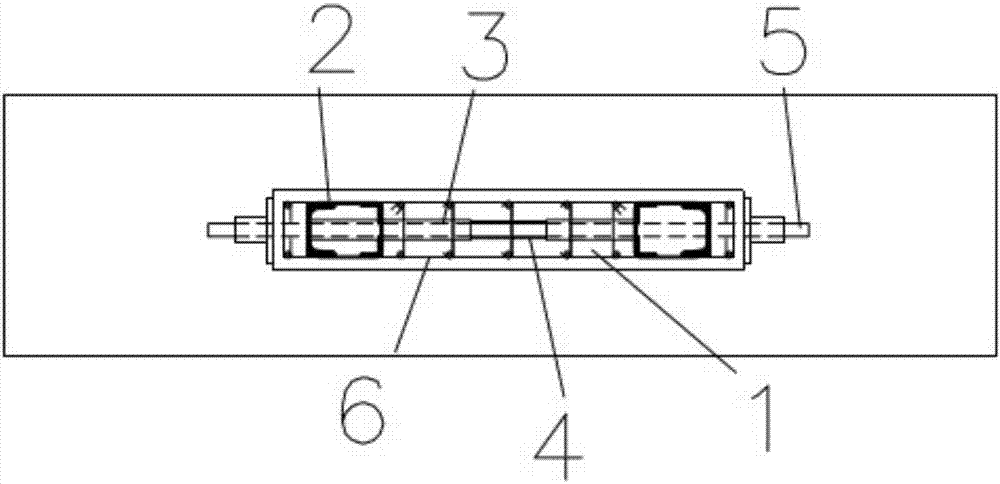

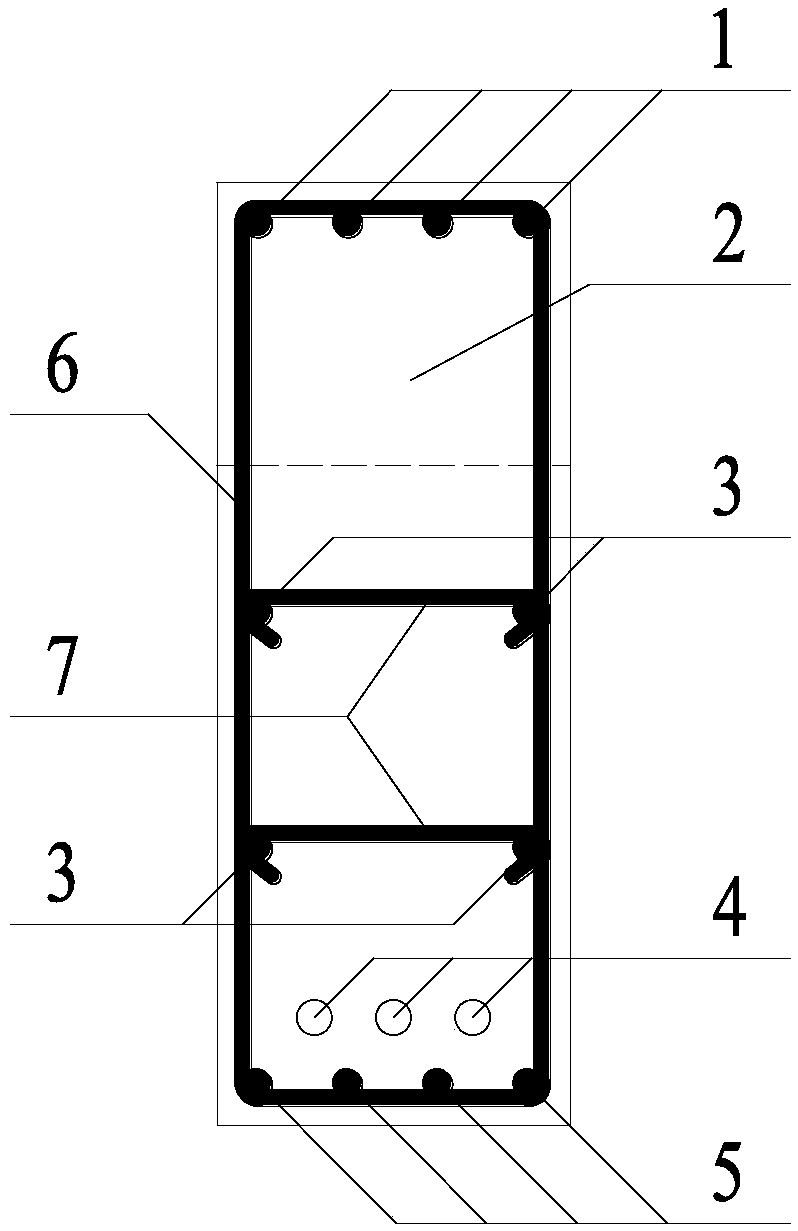

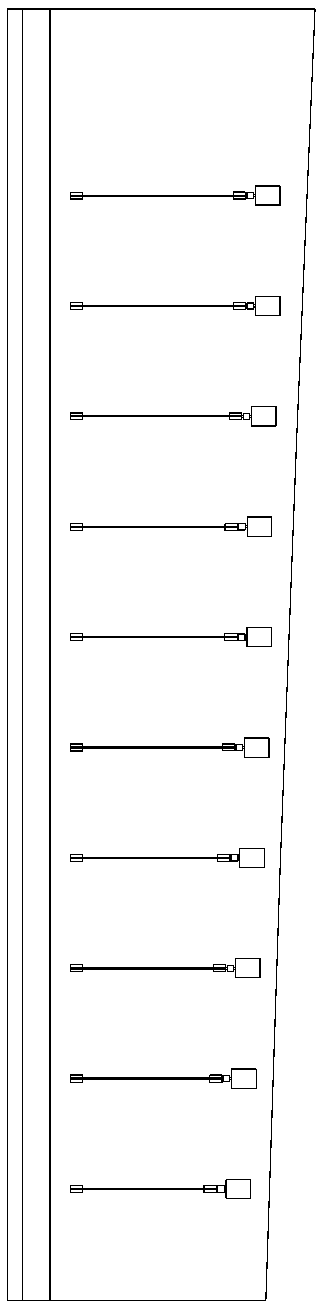

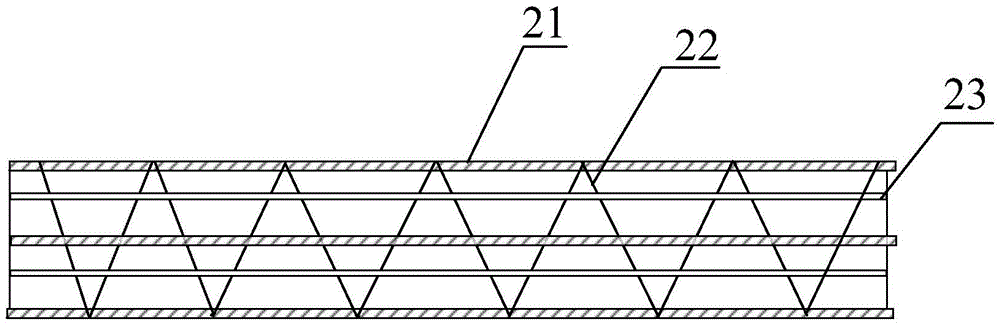

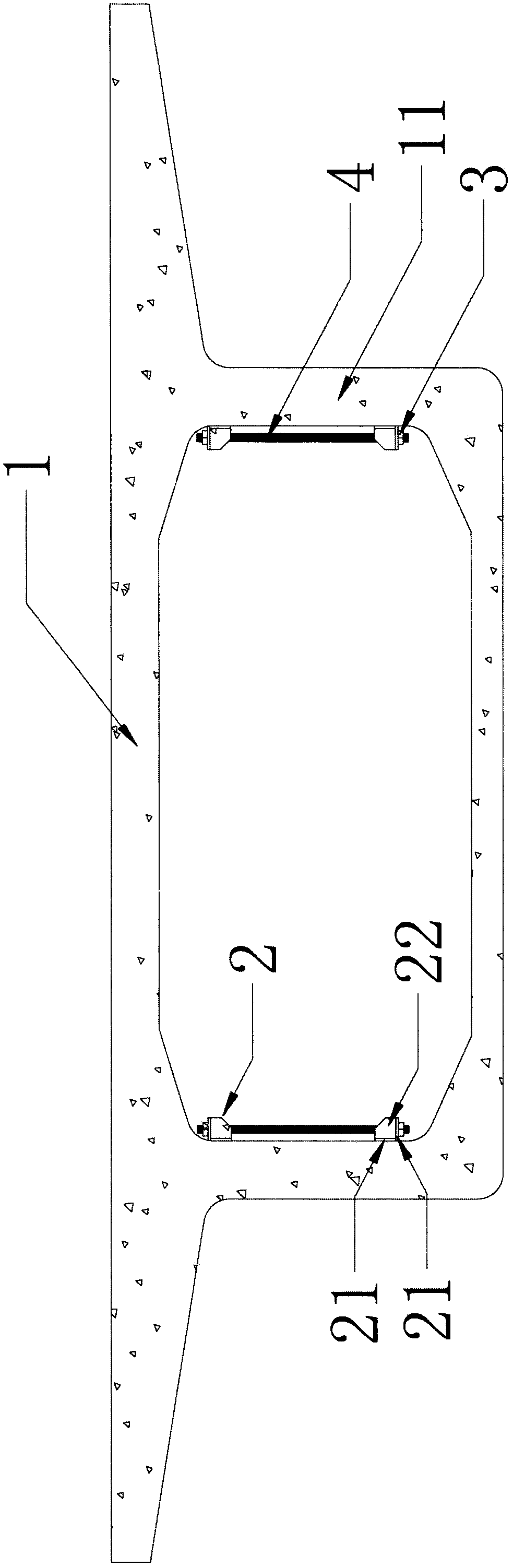

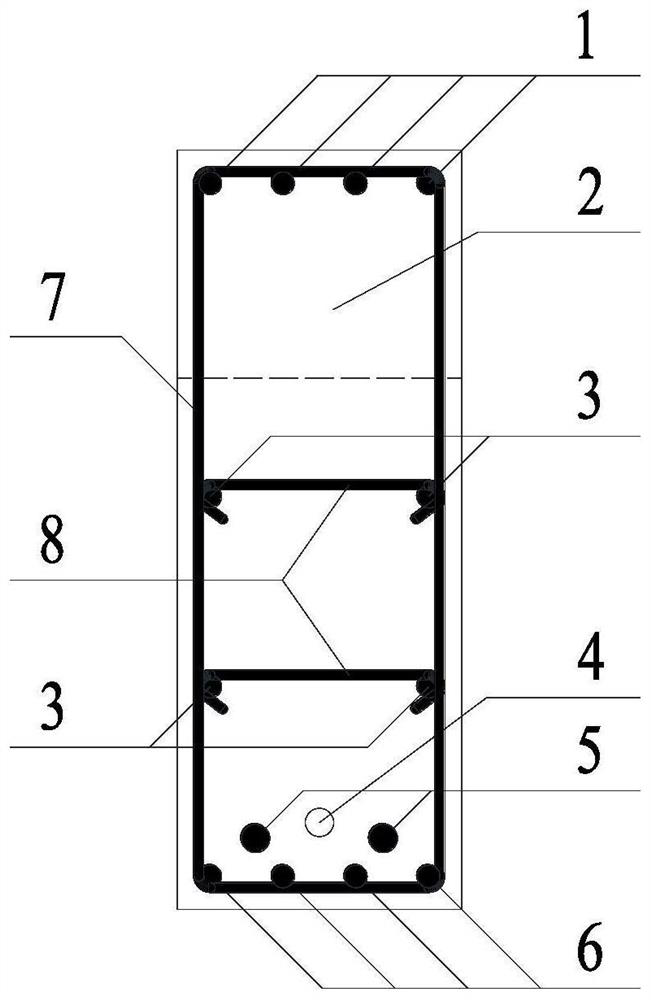

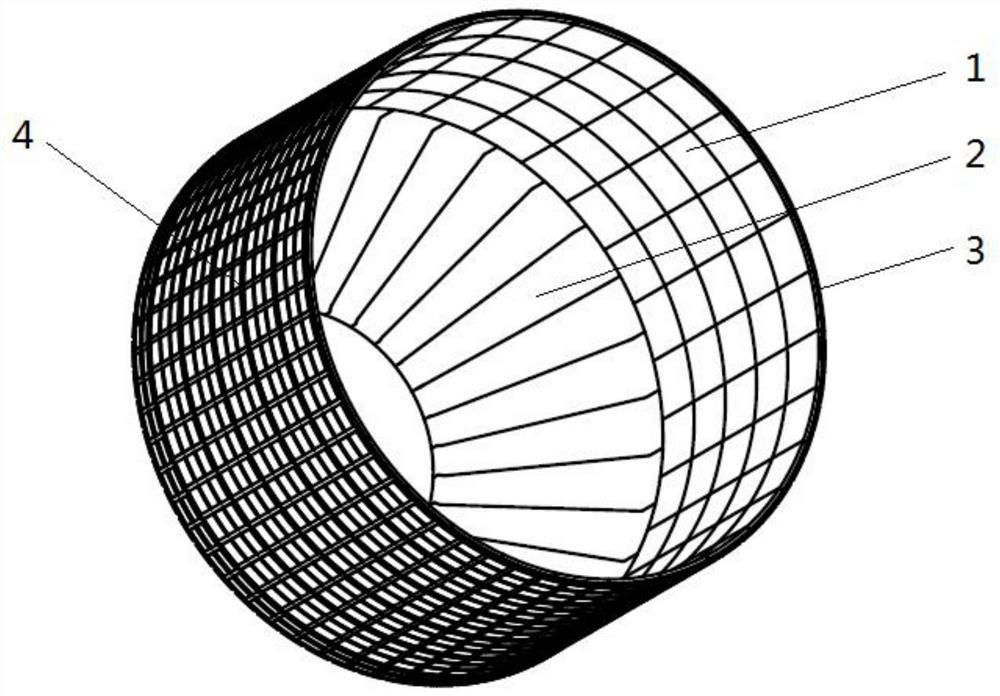

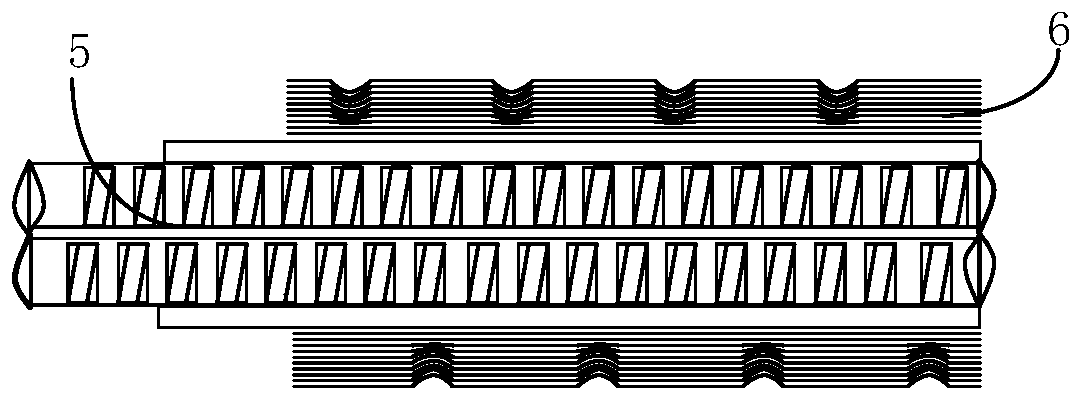

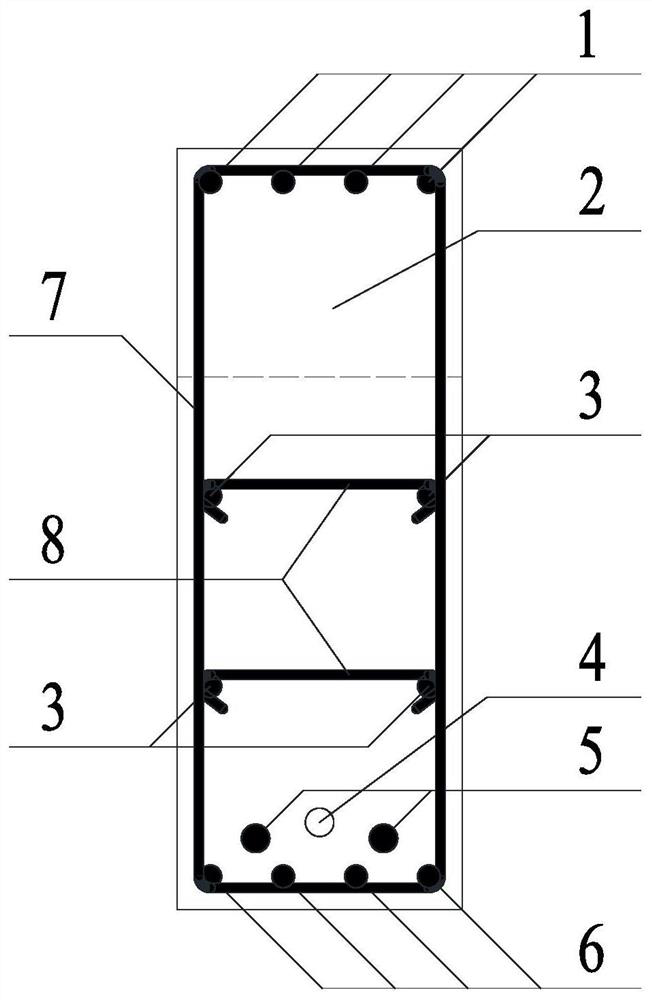

Pressure bearing pipe damage repair process

InactiveCN105090676AIncrease cracking loadIncreased bending stiffnessPipe elementsFiberForeign matter

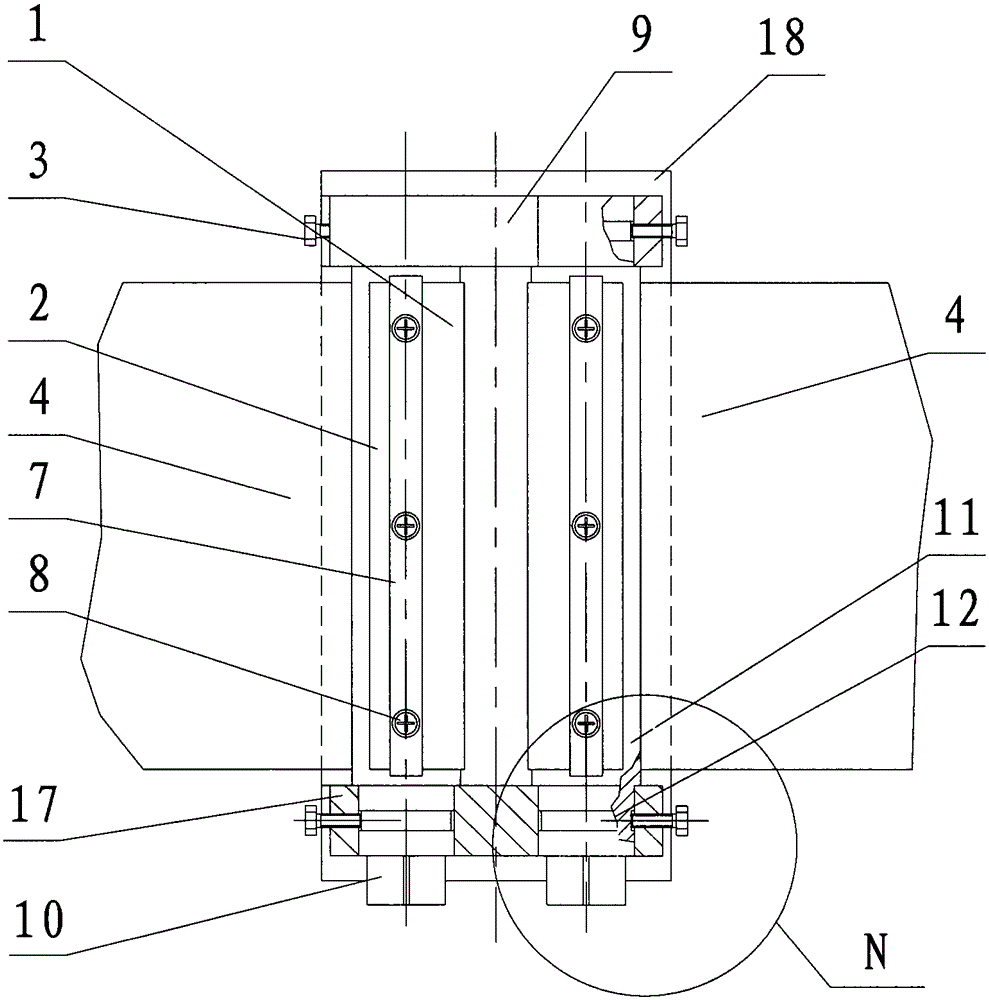

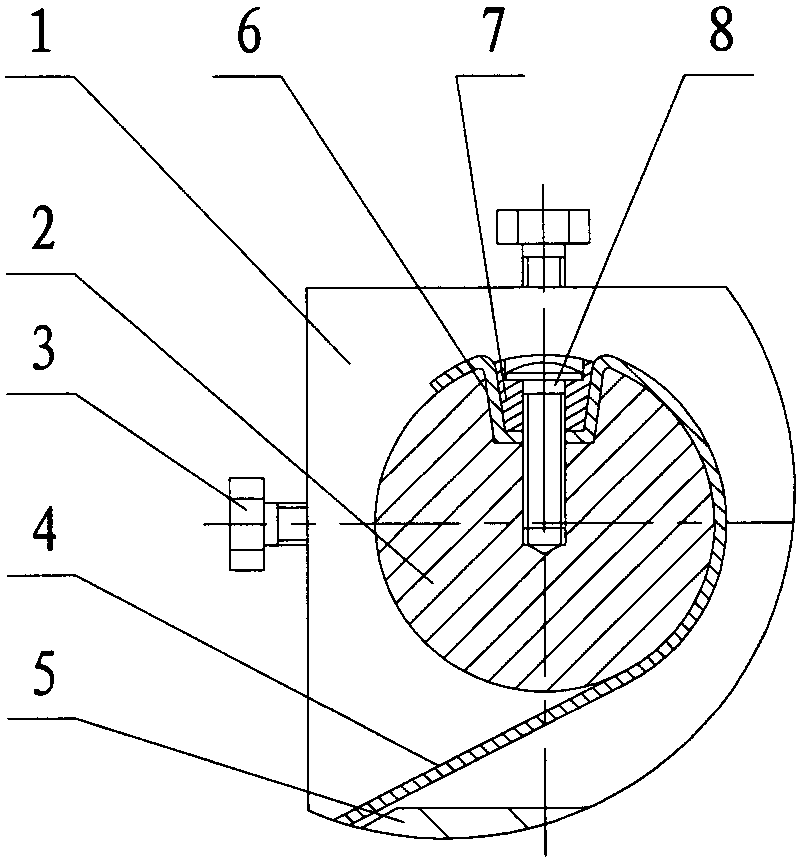

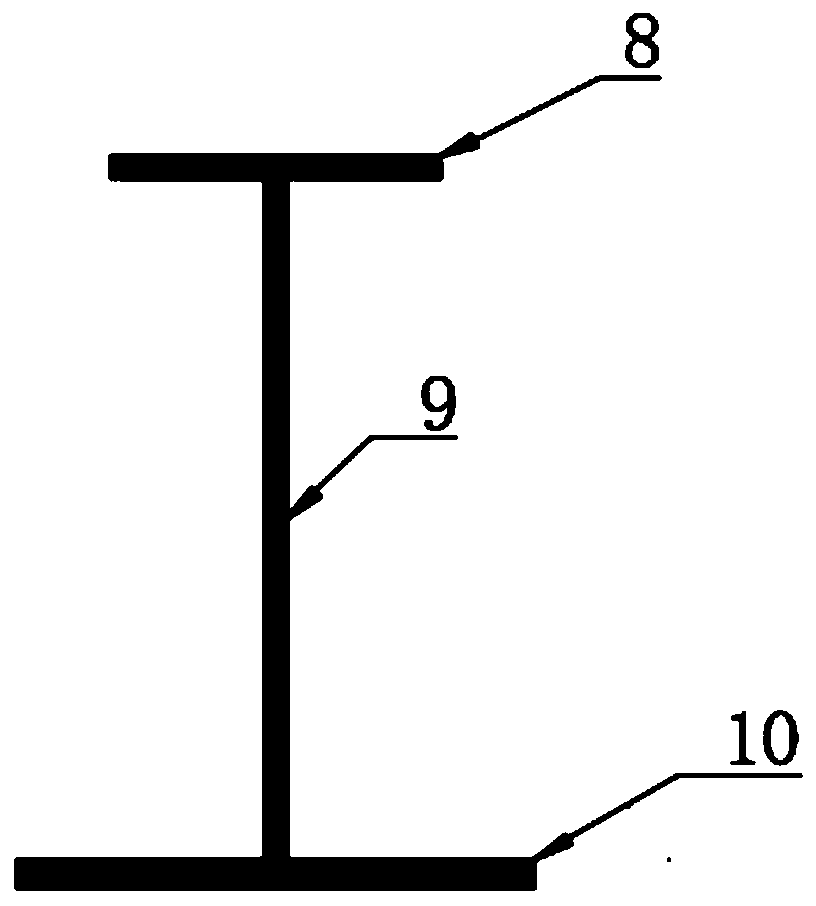

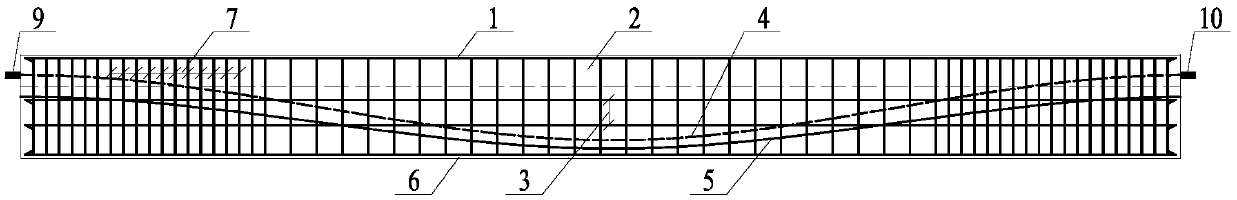

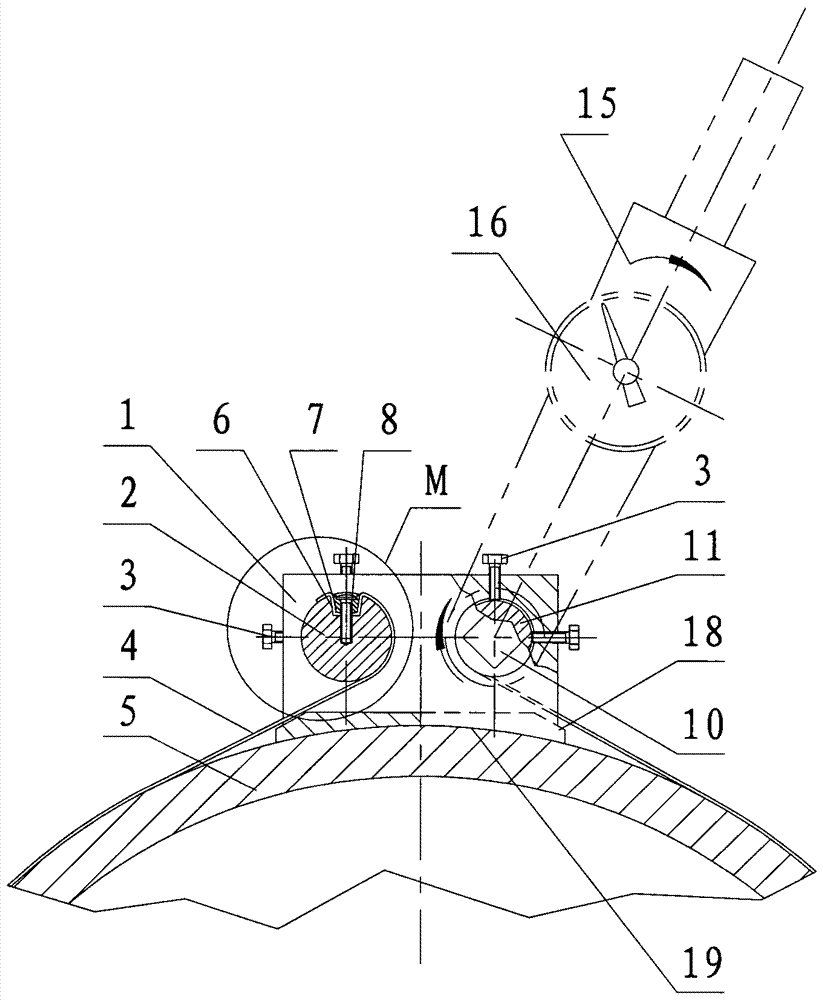

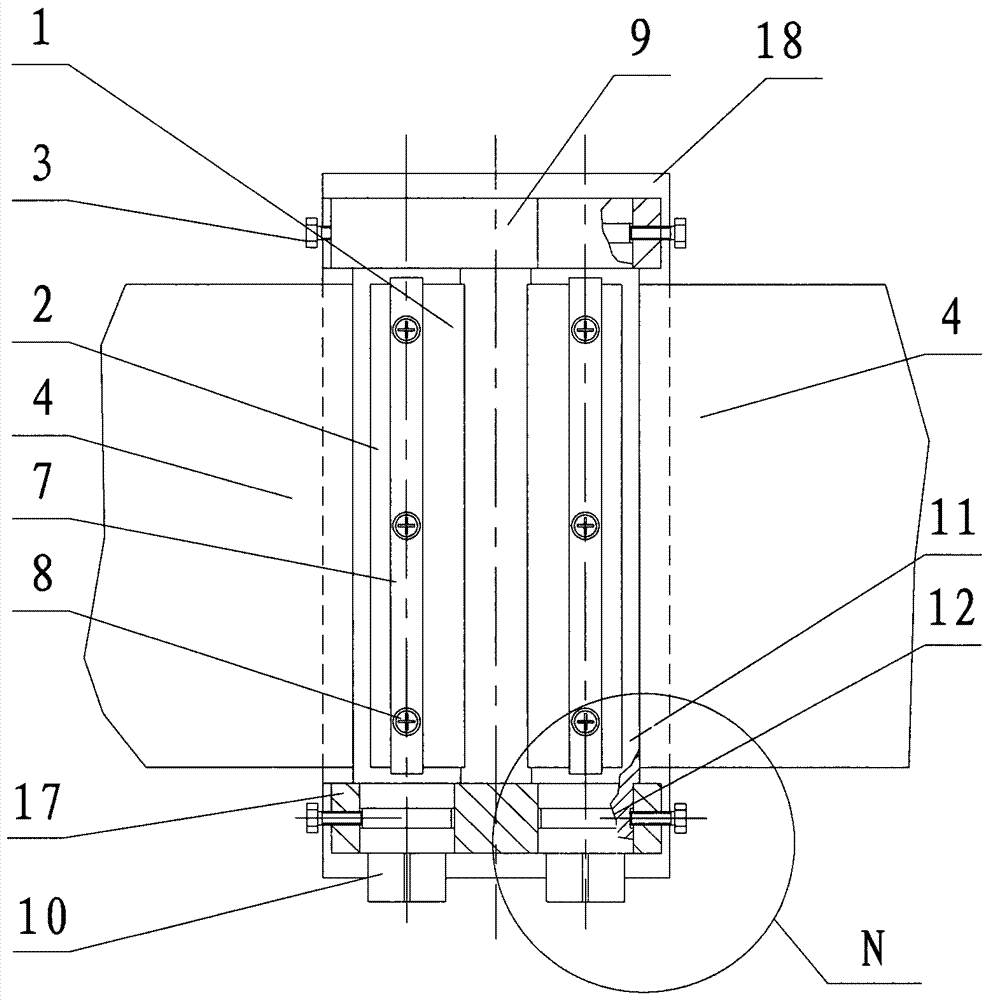

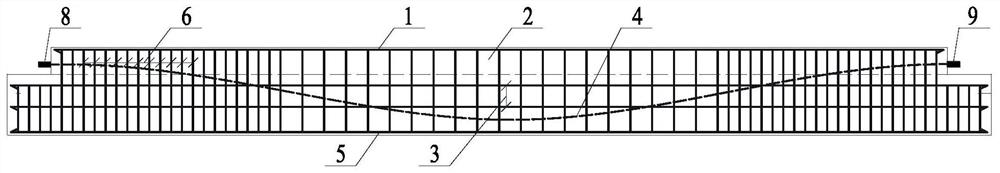

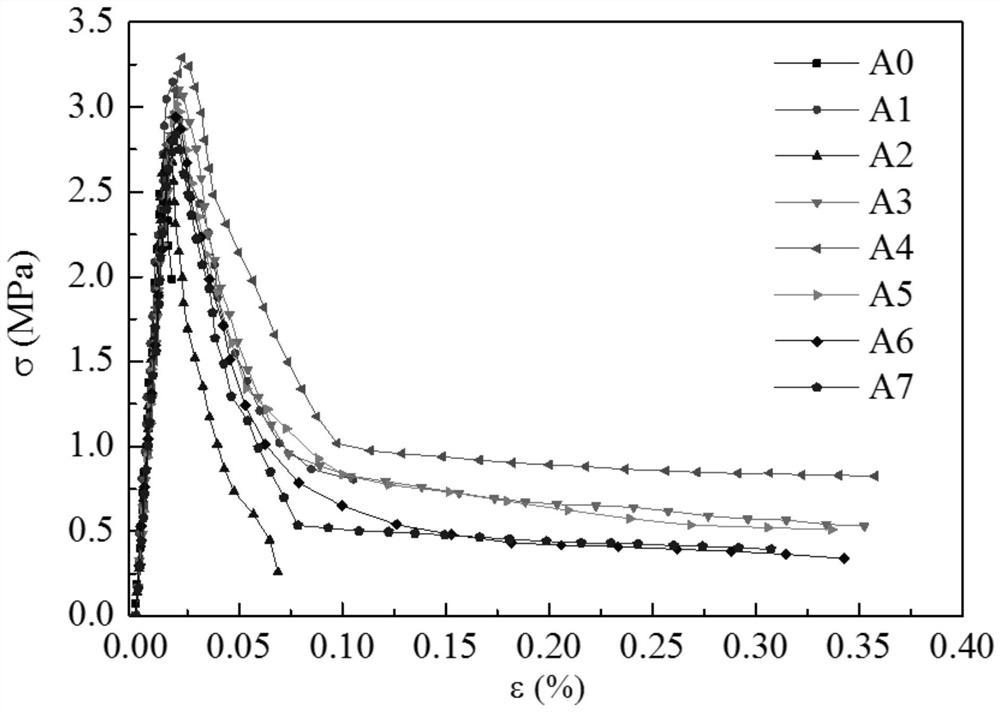

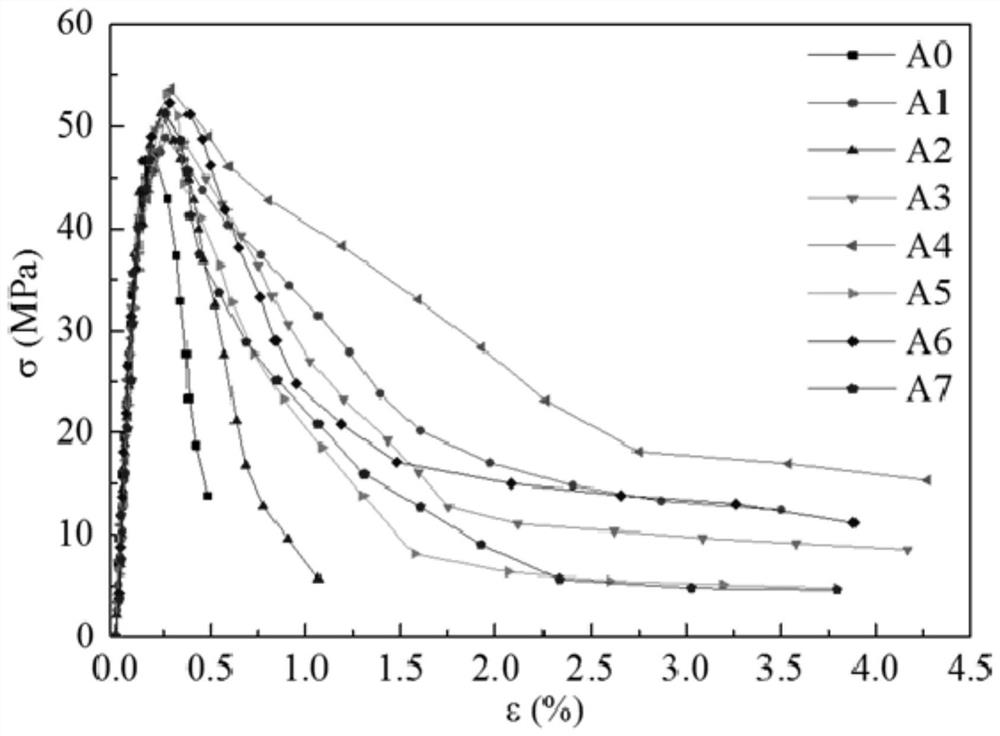

The invention discloses a pressure bearing pipe damage repair process. The process is performed by the following steps: a carbon fiber fabric (4), a repair agent, adhesive, a torque spanner (15) and a tensioning device (1) are prepared; the damage positioning is performed for a pressure bearing pipe (5), and an obstacle is removed; a foreign matter at a damage part is removed, and an area to be repaired is determined; after the repair agent is coated on the area to be repaired, the adhesive is coated; the carbon fiber fabric (4) is bonded on the adhesive, and the left and right ends of the carbon fiber fabric (4) are tightened by the tensioning device (1); the torque spanner (15) is clamped on a shaft head (10), and is wrenched to enable a finger of a dial (16) to reach preset torsion; all locking screws (3) are tightened, and the prestress of the carbon fiber fabric (4) is constant; the adhesive is uniformly coated on the surface of the carbon fiber fabric (4); and after the adhesive reaches the stated condensation period, the tensioning device (1) is disassembled to finish one-time repair process.

Owner:SOUTHWEAT UNIV OF SCI & TECH

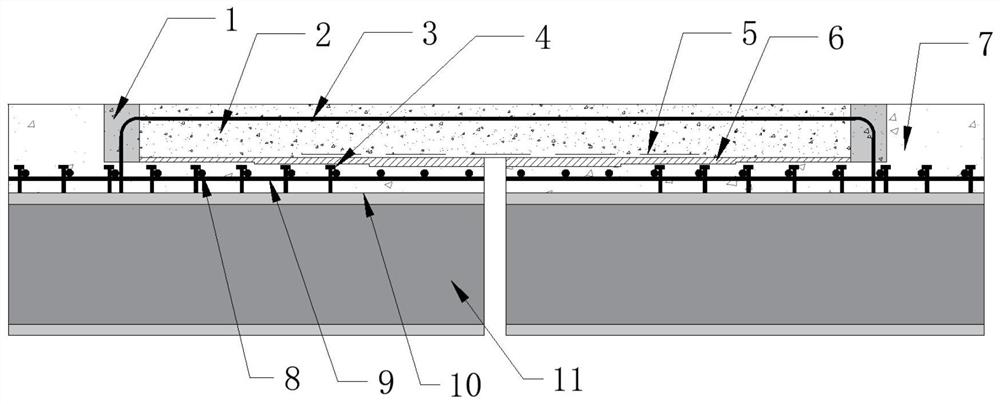

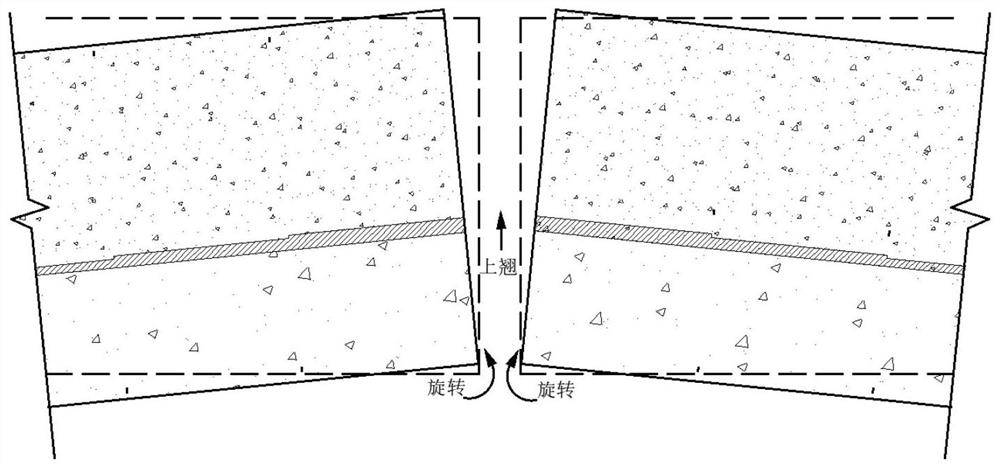

Negative bending moment area UHPC treatment steel-concrete composite structure and preparation method thereof

PendingCN110241724AIncrease cracking loadSolve crackingBridge structural detailsBridge materialsBridge deckComposite beams

The invention discloses a negative bending moment area UHPC treatment steel-concrete composite structure and a preparation method thereof. An UHPC bridge deck slab is adopted within a segment length of a steel-concrete composite structure negative bending moment area; and a top flange of an adjacent steel girder is welded (bolted) to a pier top. For a steel-concrete simply supported bridge deck continuous composite structural beam, the negative bending moment area UHPC treatment steel-concrete composite structure has the advantages that the cracking load of the negative bending moment area composite beam can be obviously increased; and due to smaller fracture interval, the development of a concrete crack can be obviously suppressed; and the excellent anti-cracking performance can effectively solve the cracking problem of the negative bending moment area.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Fibre reinforced plastic and concrete composite arc structure and construction method

InactiveCN1609379AAccelerated corrosionImprove airtightnessArched structuresVaulted structuresPolyesterEngineering

The present invention relates to building member and its construction process and is especially composite arched structure of fiber reinforced plastic and concrete. The present invention proposes one kind of arced structure with laminated fiber reinforced plastic adhered to the surface of concrete and its construction process. The construction process includes forming concrete arch, milling surface with grinding wheel to eliminate floated surface mortar and roughen the surface, smearing epoxy resin-cement putty to flat the surface, painting primer with structural glue, coating with fiber fabric, soaking the fiber fabric with resin adhesive, covering with polyester film, extruding with scraper the excessive resin adhesive, curing and taking down the polyester film. The composite arched structure is corrosion resistant and durable, and has doubled bearing capacity and simple construction.

Owner:杨庆国 +3

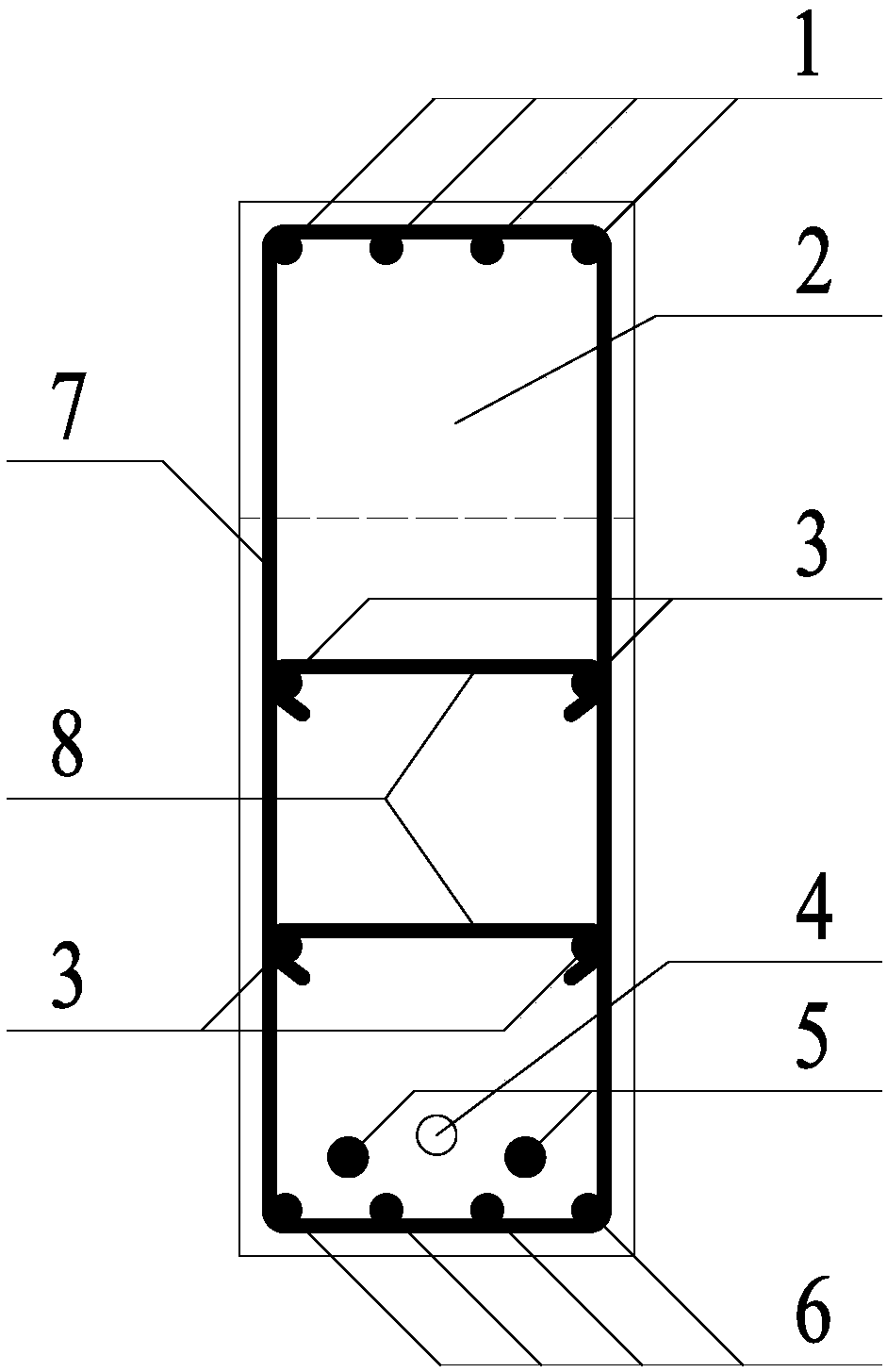

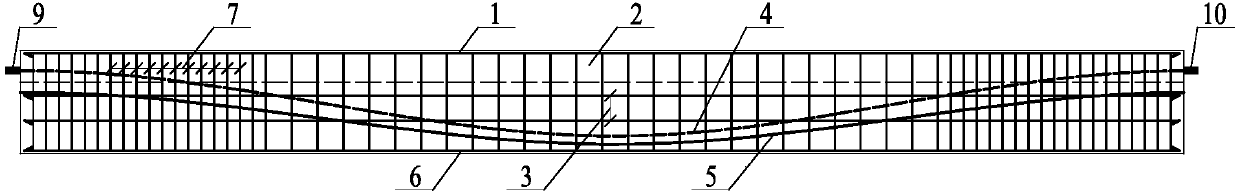

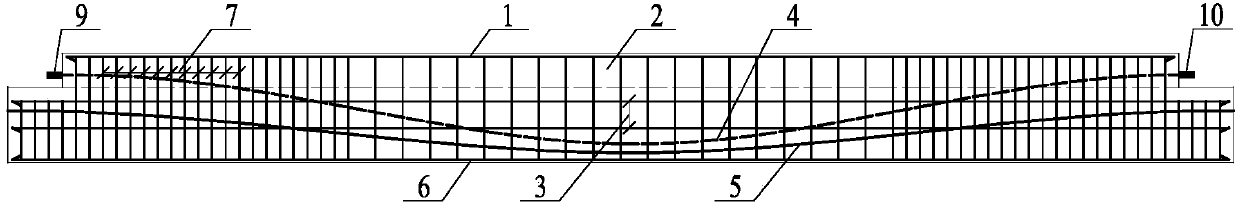

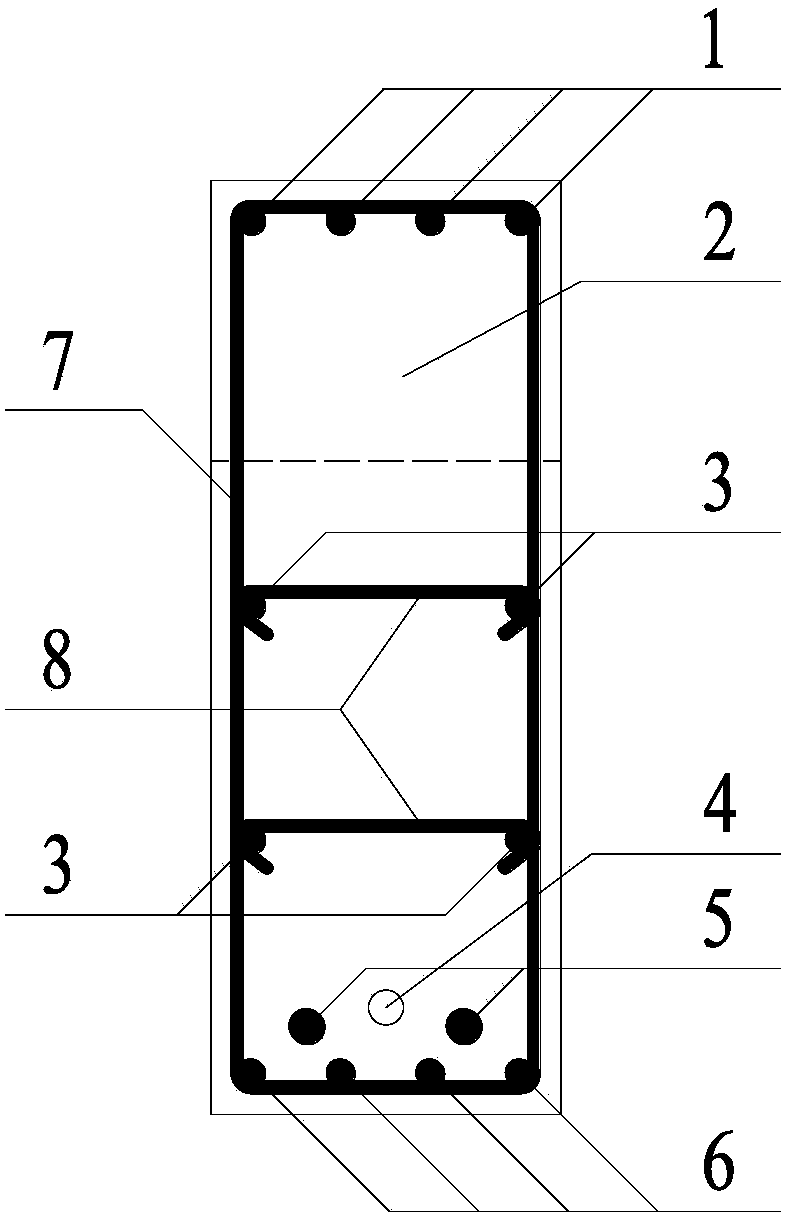

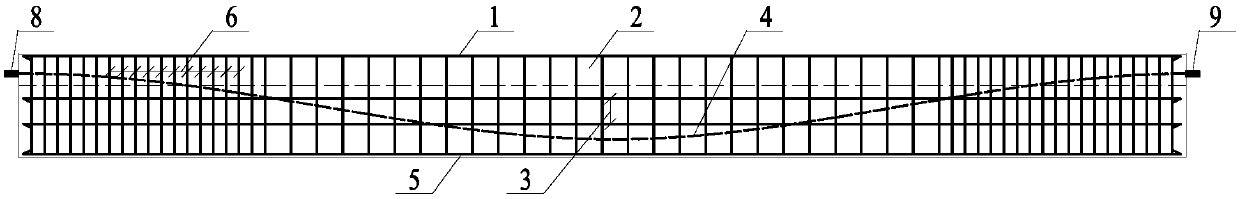

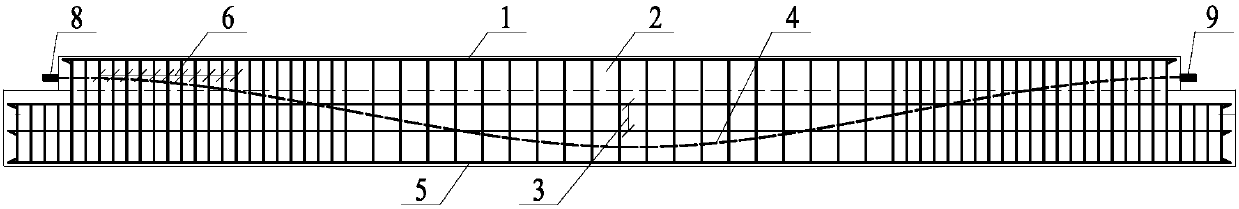

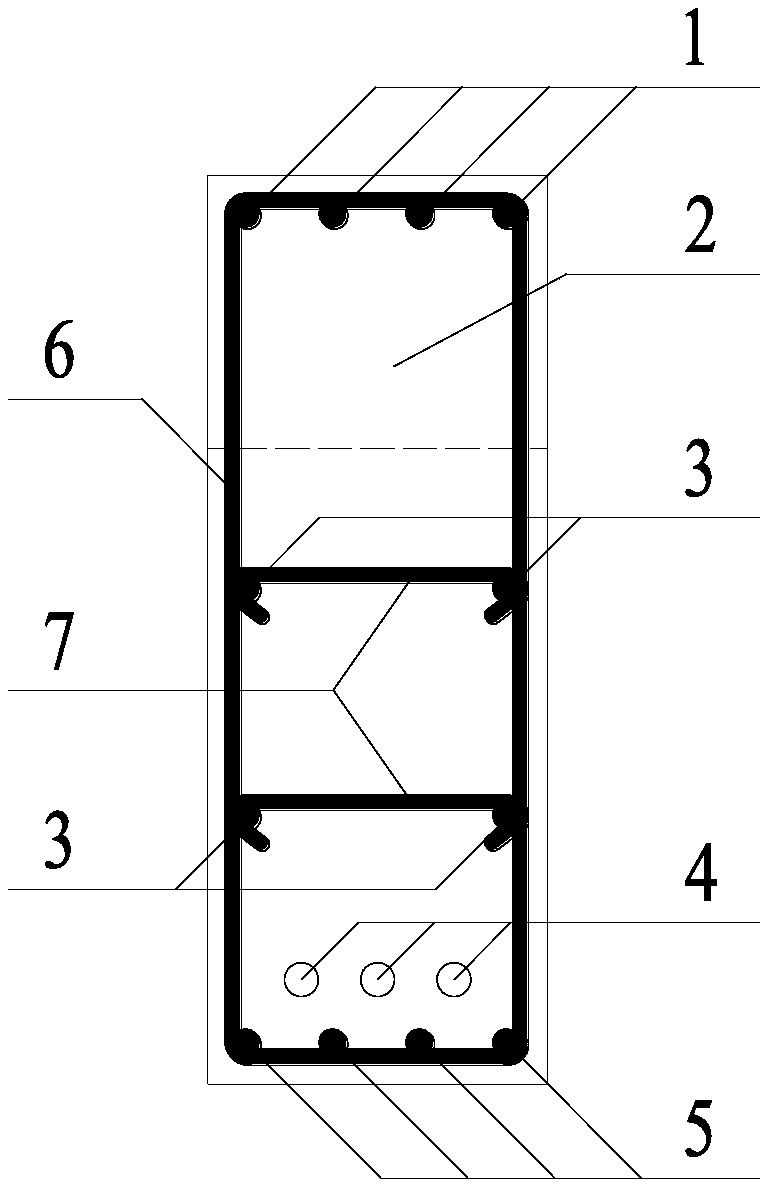

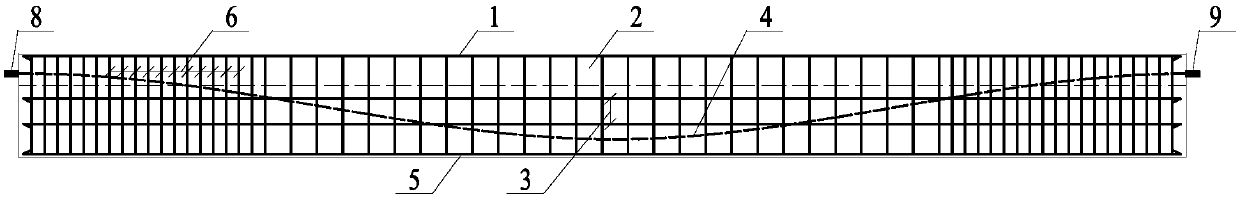

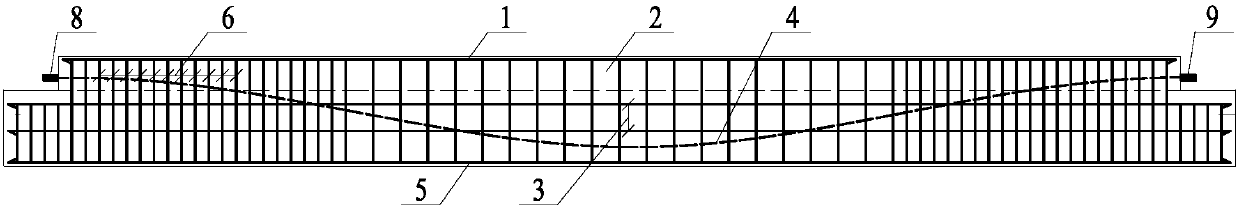

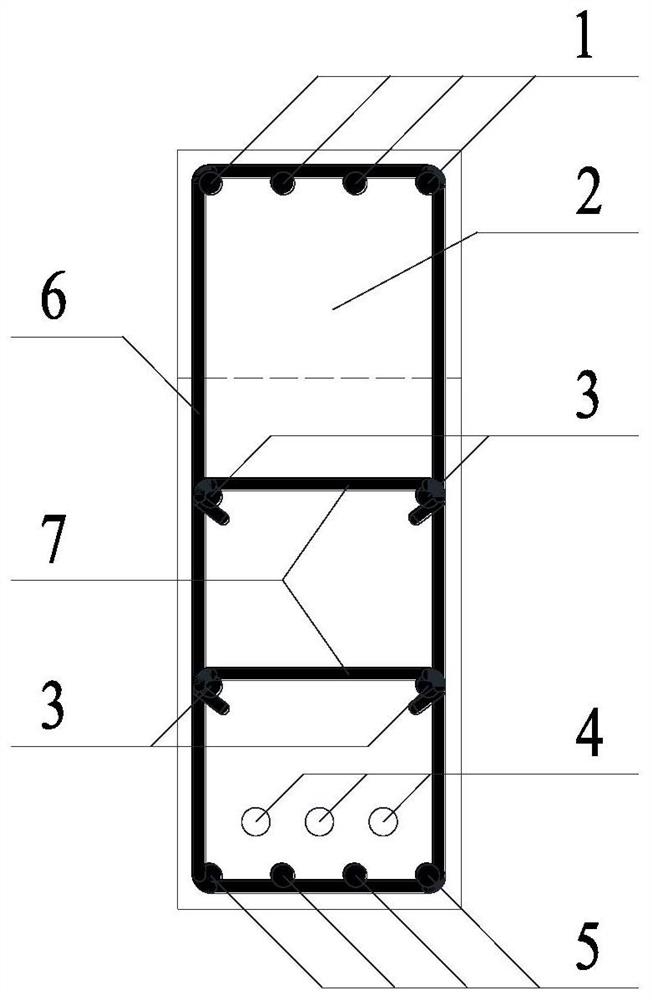

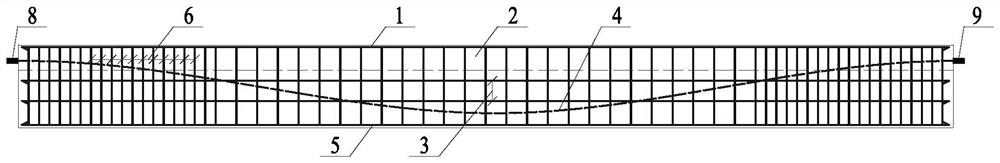

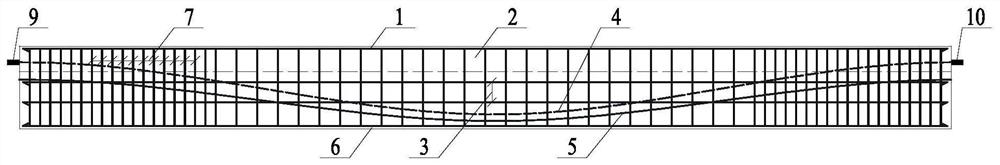

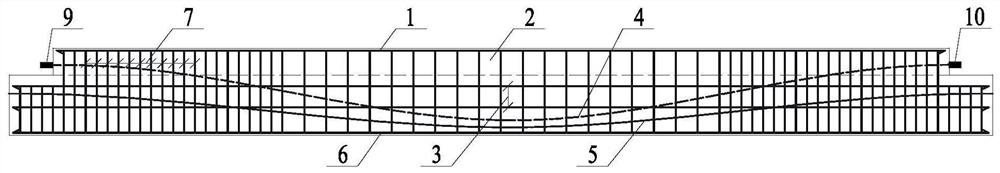

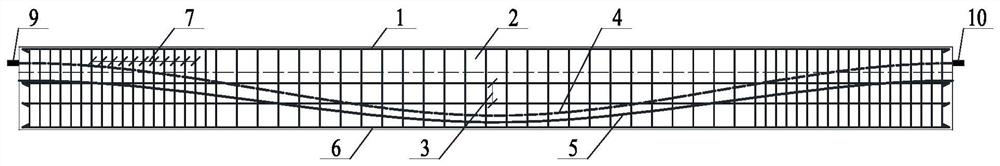

Post-tensioning retard-bonded co-tensioning prestress concrete composite beam and design and construction methods thereof

ActiveCN109868939AImprove crack resistanceImprove bending abilityGirdersJoistsPre stressDeformation control

The invention relates to a post-tensioning retard-bonded co-tensioning prestress concrete composite beam and design and construction methods thereof. The post-tensioning retard-bonded co-tensioning prestress concrete composite beam is a novel prestressed composite beam for applying bonded prestress and retard-bonded prestress to a precast beam and the composite beam through pre-tensioning method and post-tensioning method processes in stages in order to meet the construction and use demands. Compared with a traditional prestress composite beam, the post-tensioning retard-bonded prestress technology is adopted in the post-tensioning retard-bonded co-tensioning prestress concrete composite beam, the characteristics of high prefabrication degree, convenient and fast construction and the likeof a lower composite structure are achieved, and the anti-crack and anti-bending properties of a member can be further improved. Configuration of prestressed tendons is relatively more flexible, and the post-tensioning retard-bonded prestress tendons have the good anti-corrosion property, so that the post-tensioning retard-bonded co-tensioning prestress concrete composite beam is especially suitable for structures which have the high-property requirements such as the large span and the heavy load and have the high requirements for deformation control, bearing capacity and the weather-proof property, and the superiority of the fabricated structures can also be embodied while the design requirements are met.

Owner:上海同吉建筑工程设计有限公司 +1

Post-tensioning unbonded co-tensioning prestressed concrete composite beam and design and construction methods thereof

The invention relates to a post-tensioning unbonded co-tensioning prestressed concrete composite beam and design and construction methods thereof. The post-tensioning unbonded co-tensioning prestressed concrete composite beam is a novel prestressed composite beam for applying bonded and unbonded prestress to a precast beam and the composite beam in stages by adopting a pre-tensioning method and apost-tensioning method in order to meet the construction and use demands. Compared with a traditional prestressed composite beam, the post-tensioning unbonded prestressed technology is adopted in thepost-tensioning unbonded co-tensioning prestressed concrete composite beam, the characteristics of high prefabricated degree, convenient and fast construction and the like of a lower composite structure are upheld, the unique advantages are also possessed, thus the anti-crack and anti-bending properties of a member can be improved, the structure demands at different stages are met through batchedtensioning, the integrity and the anti-seismic property of the structure can be enhanced by cooperating with the design of fabricated integrated prestress joint connection, thus the post-tensioning unbonded co-tensioning prestressed concrete composite beam is especially suitable for structures which have the high-property requirements such as the large span and the heavy load and have the high requirements for deformation control, and bearing capacity, and the superiority of the fabricated structure can also be embodied while the design requirements are met.

Owner:上海同吉建筑工程设计有限公司 +1

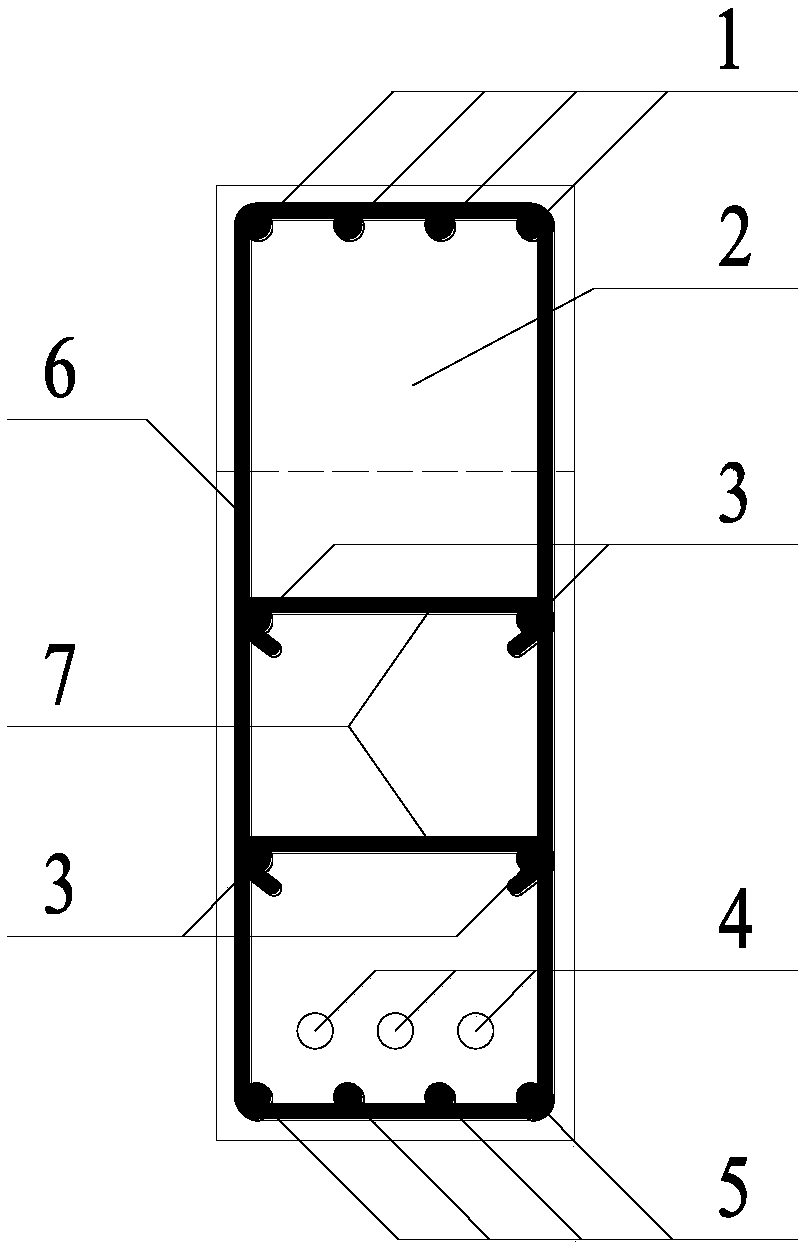

Built-in horizontal brace reinforced concrete shear wall

ActiveCN106930437AIncrease cracking loadAvoid damageWallsBuilding material handlingReinforced concretePre stress

The invention relates to the technical field of concrete buildings, in particular to a built-in horizontal brace reinforced concrete shear wall. The built-in horizontal brace reinforced concrete shear wall comprises a concrete wall support, a steel truss arranged in the concrete wall support, and a prestressed horizontal brace. The built-in horizontal brace reinforced concrete shear wall is characterized in that the prestressed horizontal brace comprises horizontal steel casing pipes, hoses and prestressed steel bars; directly facing through holes are reserved in the two sides of the steel truss; the horizontal steel casing pipes penetrate into the through holes correspondingly; directly facing horizontal steel casing pipes communicate with each other through the hoses; the same prestressed steel bar penetrates into the interiors of the penetrating horizontal steel casing pipes and the hose; one end of each prestressed steel bar is anchored through a gasket nut; and after extending to the outside of the concrete wall support, the other end of each prestressed steel bar is applied with prestress and anchored through a gasket nut. The prestressing technology and the steel reinforced concrete composite structure technology are combined together, and the novel built-in horizontal brace reinforced concrete shear wall which limits crack development, improves the anti-seismic property of the shear wall component and is optimized in structure and easy to operate is provided.

Owner:GUANGXI UNIV

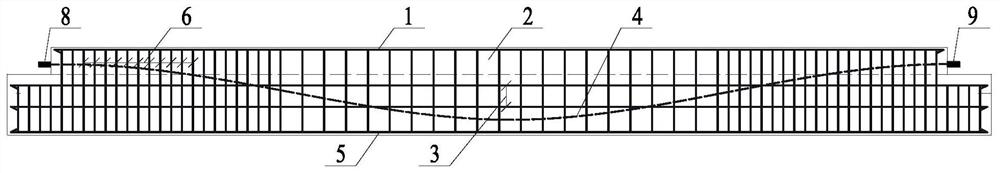

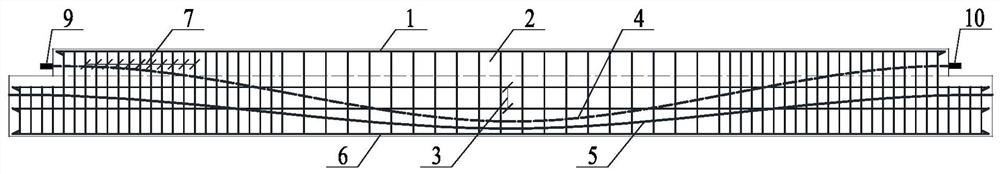

Post-tensioning retard-bonded prestress concrete composite beam and design and construction methods thereof

ActiveCN109868936AImprove weather resistanceReduce widthGirdersJoistsWeather resistanceComposite structure

The invention relates to a post-tensioning retard-bonded prestress concrete composite beam and design and construction methods thereof. A layer of top longitudinal bars is arranged at the top of the composite beam, a layer of bottom longitudinal bars is arranged at the bottom of the composite beam; the composite beam is further provided with a plurality of stirrups, a plurality of post-tensioningretard-bonded prestress bars are further arranged on the lower part of the composite beam, and the two ends of the post-tensioning retard-bonded prestress bars extend out of the composite beam and arefixedly provided with anchorage devices and clamps correspondingly. The post-tensioning retard-bonded prestress concrete composite beam adopts a post-tensioning retard-bonded prestress technology, the characteristics that a lower composite structure is high in prefabricating degree and fast and convenient to construct are accorded, and the anti-cracking and anti-bending performance of componentscan also be improved. The post-tensioning prestress can be applied to the post-tensioning retard-bonded prestress concrete composite beam after whole construction, post-tensioning unbounded prestresstendons also have good anti-corrosion performance, thus the post-tensioning retard-bonded prestress concrete composite beam is particularly suitable for structures with the high requirements for deformation control, bearing capacity and weather resistance and with the high-performance requirements for the large span and the heavy load, and the superiority of the fabricated structure can also be reflected while the design requirements are met.

Owner:上海同吉建筑工程设计有限公司 +1

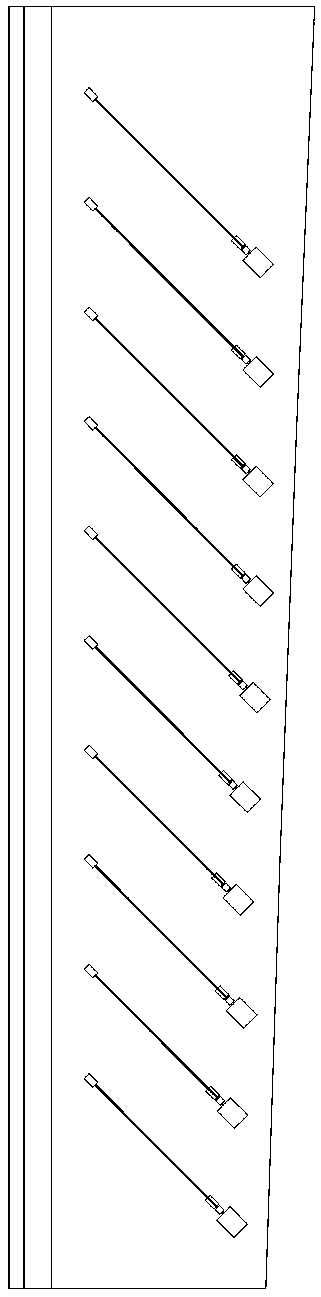

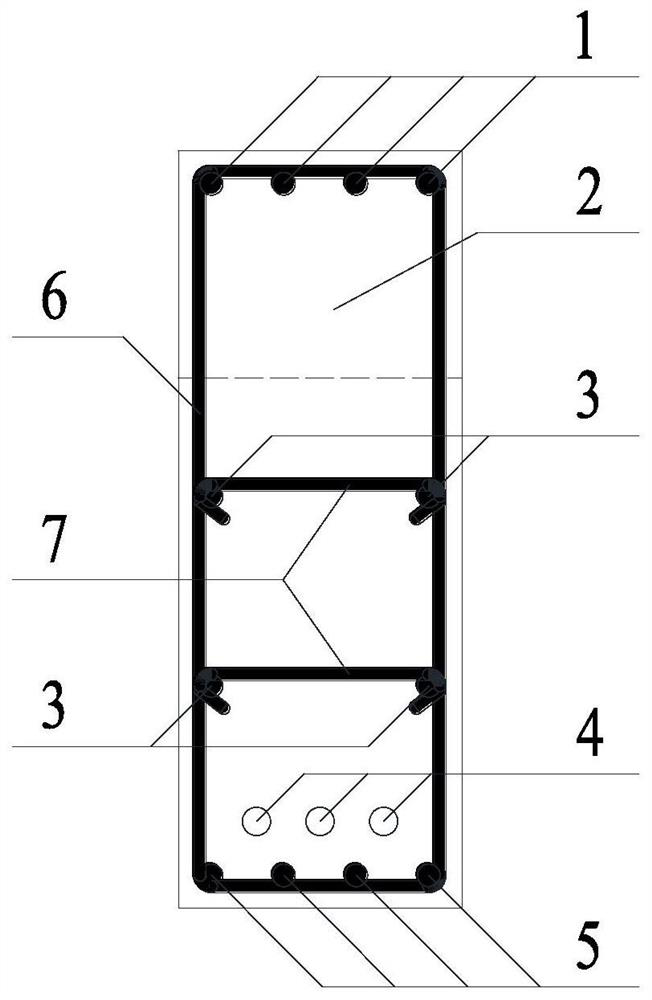

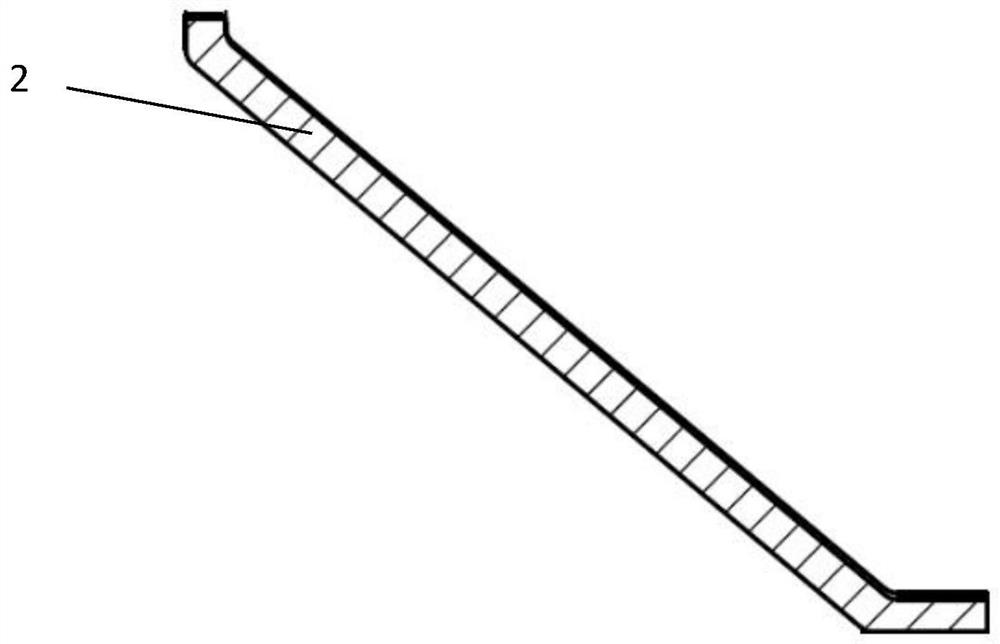

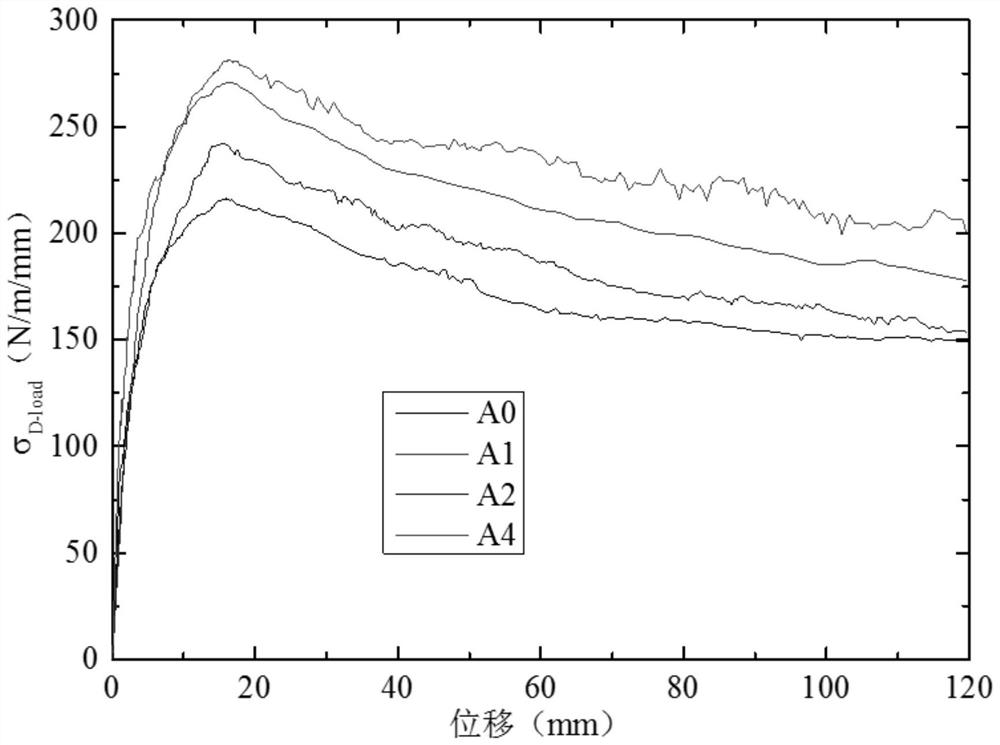

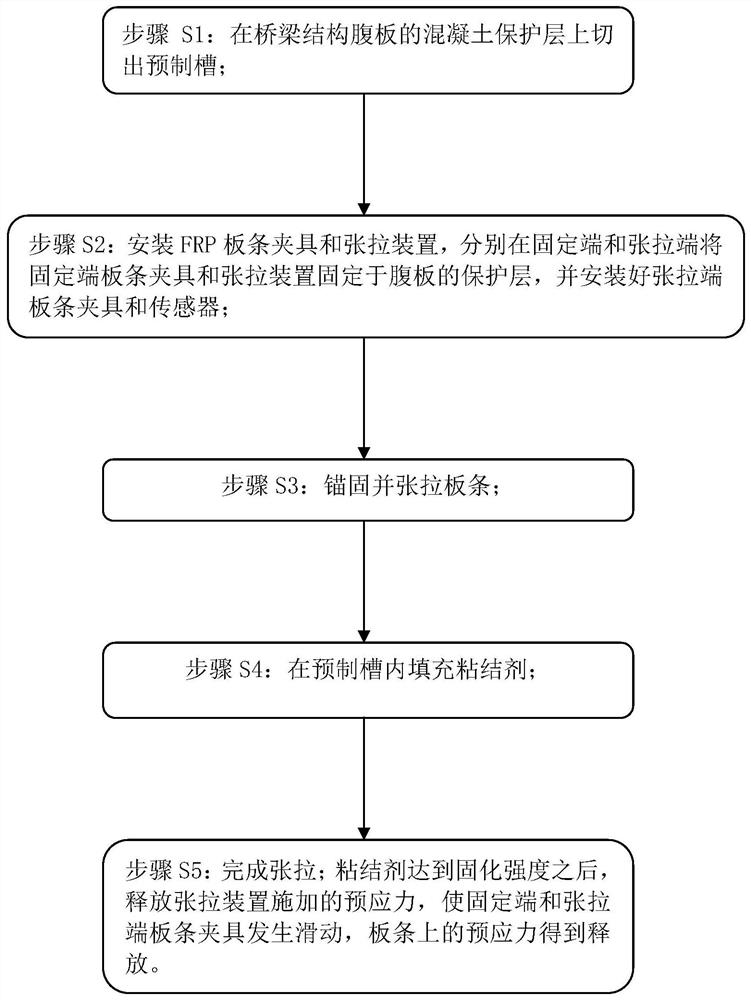

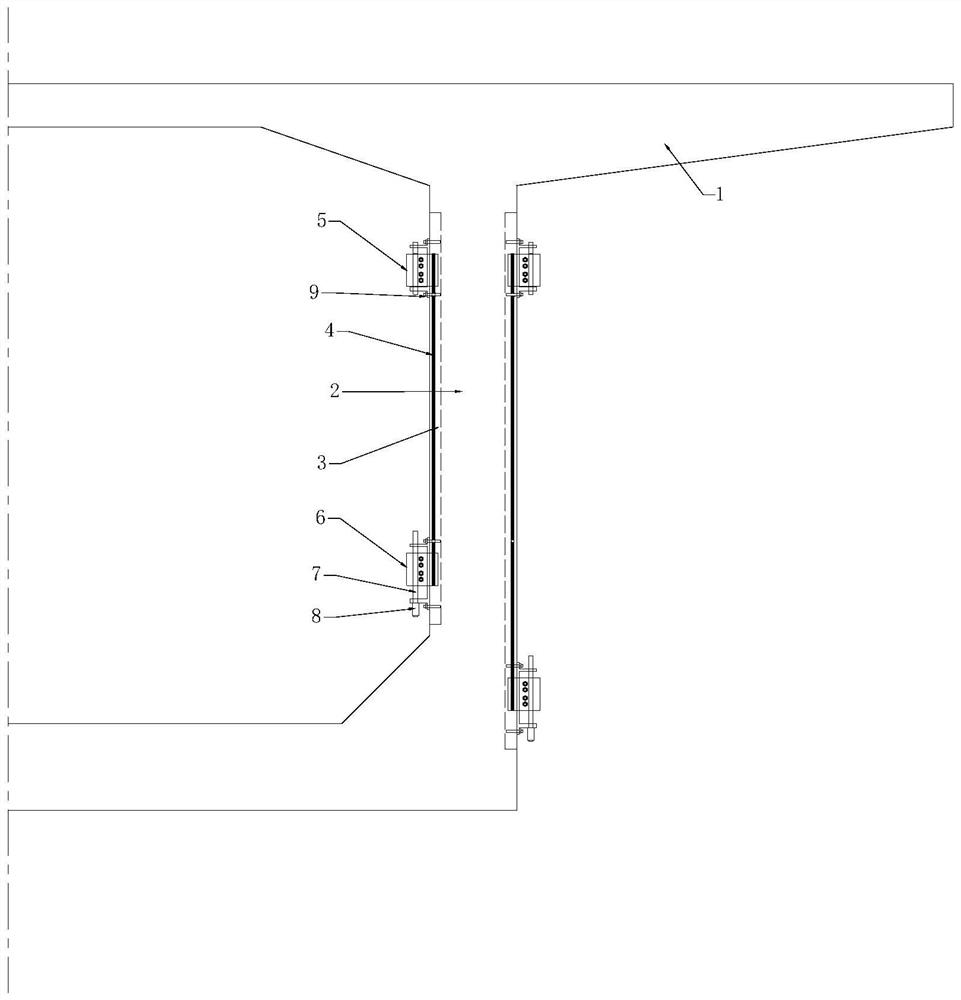

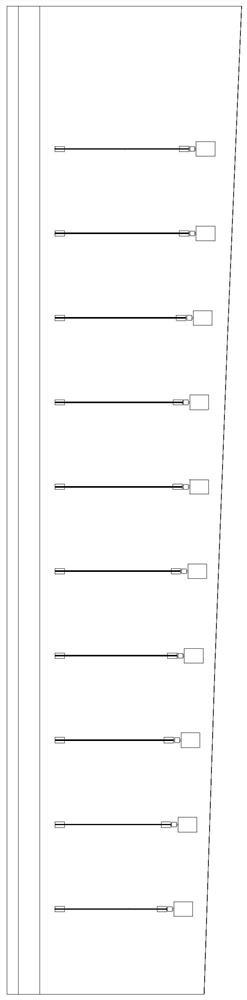

Bridge vertical prestress loss compensation method based on embedding and pasting of prestress batten in surface layer

ActiveCN110820603AIncrease cracking loadIncreased shear capacityBridge erection/assemblyBridge strengtheningPre stressArchitectural engineering

The invention discloses a bridge vertical prestress loss compensation method based on embedding and pasting of prestress batten in a surface layer. The bridge vertical prestress loss compensation method comprises the steps that firstly, a prefabrication groove is cut in a concrete protection layer of a bridge structure web; secondly, batten clamps and a tensioning device are installed, the fixed end batten clamp and the tensioning device are fixed to the protection layer of the web at the fixed end and the tensioning end correspondingly, and the tensioning end batten clamp and a sensor are installed; thirdly, the batten is anchored and tensioned; fourthly, the prefabrication groove is filled with a bonding agent; and fifthly, tensioning is finished, and after the bonding agent reaches thecuring strength, the prestress applied by the tensioning device is released, the tensioning end clamp and the fixed end clamp slide, and the prestress on the batten is released. The bridge vertical prestress loss compensation method has the advantages that durability is good, construction convenience and simpleness are good, and web cracking load and anti-shearing bearing capacity can be improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-ductility prefabricated vibration-resistant concrete pile

InactiveCN105603968AIncreased cracking and ultimate loadsImprove seismic performanceBulkheads/pilesRebarBending moment

The invention provides a high-ductility prefabricated vibration-resistant concrete pile. The concrete pile comprises concrete, a steel reinforcement cage, end plates and pile hoops, and the steel reinforcement cage is arranged inside the concrete; the end plates are arranged at the two ends of the steel reinforcement cage; each pile hoop is arranged outside the corresponding end plate; the steel reinforcement cage comprises prestressed steel reinforcements, a stirrup and high-ductility non-prestressed steel reinforcements, and the steel reinforcement cage is formed by roll-welding the prestressed steel reinforcements and the spiral stirrup; the high-ductility non-prestressed steel reinforcements are longitudinally fixed to the stirrup. By means of the high-ductility prefabricated vibration-resistant concrete pile, the defects that existing prefabricated concrete piles are poor in bending performance and ductility, the failure is brittle failure, ductility is poor, cracks appearing in the prefabricated concrete piles spread rapidly, steel reinforcements in a tensile area are yielded and tightened quickly till fracture, and the difference between ultimate bending moment and the cracking bending moment is not large are overcome, ductility of a tube pile is improved well, it is helpful to improve vibration resistance, maintenance cost can be lowered, the service life is prolonged, and the high-ductility prefabricated vibration-resistant concrete pile has the advantages of being simple in process, high in cost performance, wide in application scope and the like.

Owner:TIANJIN BAOFENG BUILDING MATERIALS CO LTD

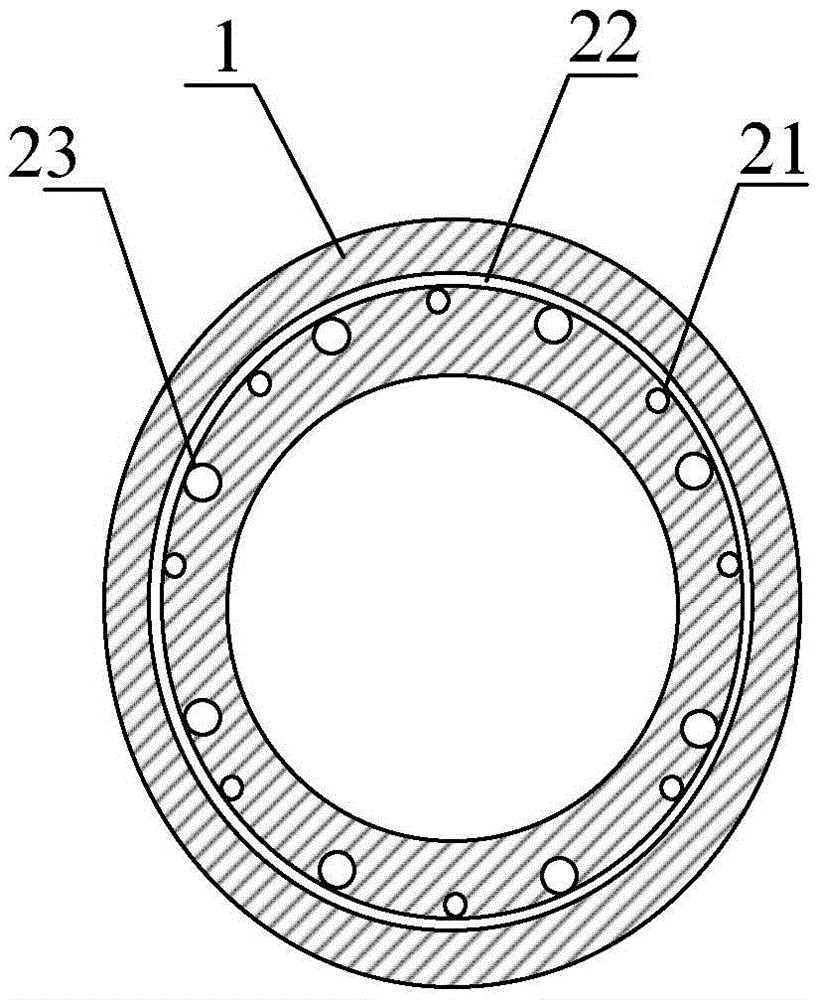

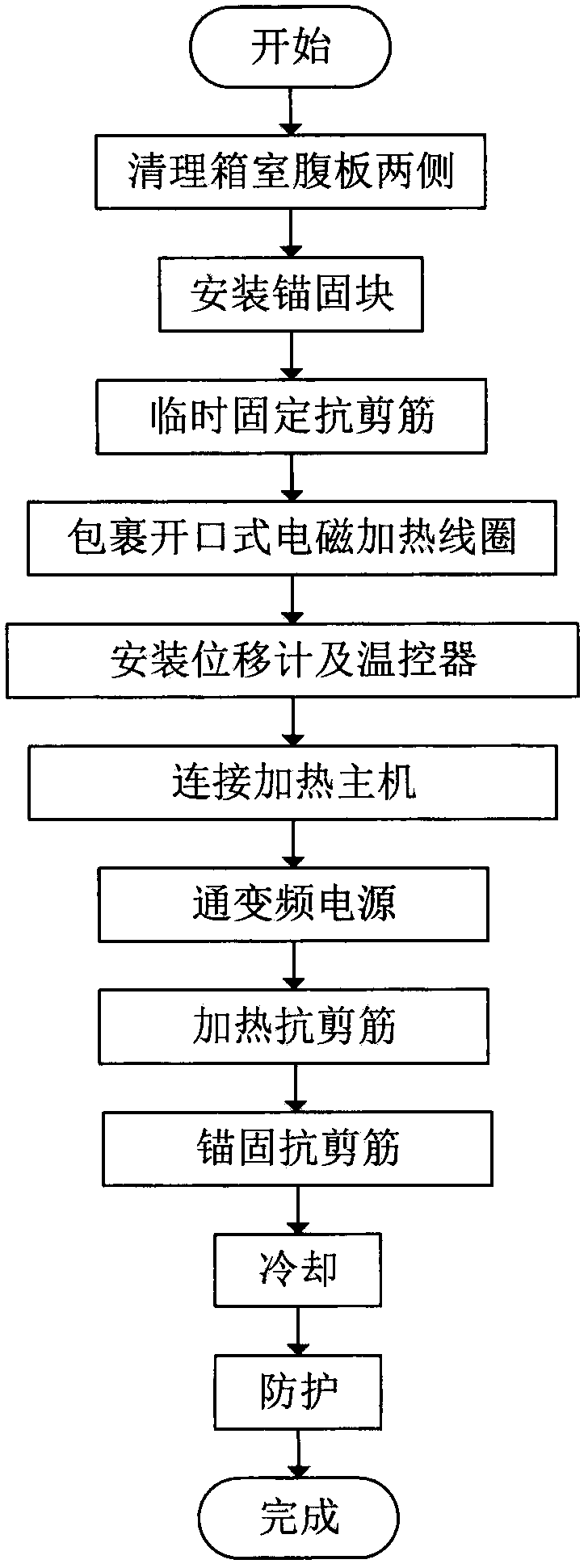

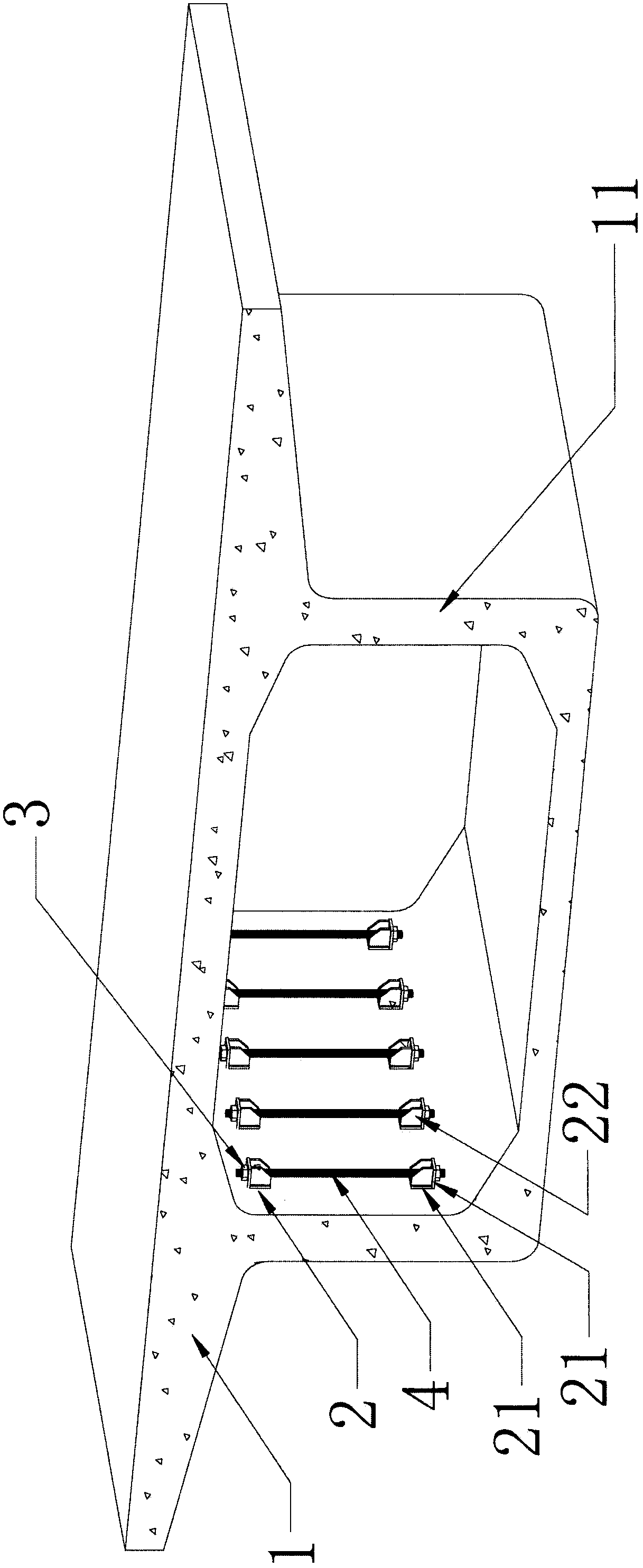

Method for reinforcing box girder by pre-stress shear-resistance

ActiveCN108301335AImprove shear resistanceEasy to operateBridge erection/assemblyBridge strengtheningPre stressingEngineering

The invention provides a method for reinforcing a box girder by pre-stress shear-resistance. Anchorage blocks are correspondingly installed on both sides of a web plate of a box chamber of the box girder up and down, a shear-resistance bar is temporarily fixed between the two anchorage blocks; a precast open type electromagnetic heating coil is used for wrapping the periphery of the shear-resistance bar, and the electromagnetic heating coil is connected with a heating main machine; and a high-frequency magnetic field generated by variable-frequency power supply enables the shear-resistance barto carry out self-heating rapidly, a temperature control device controls the electromagnetic heating temperature, a displacement meter controls the elongation of the shear-resistance bar, and at thesame time, two ends of the shear-resistance bar are anchored by an anchorage, so that the disposal of the pre-stress shear-resistance reinforcement box girder is achieved. According to the method forreinforcing box girder by pre-stress shear-resistance, the initiative is strong, the cracking load of the web plate of the box girder is effectively improved, and the shear-resistance bearing capacityof the web plate is improved; and through the novel construction process, large tensile equipment is not required, the operation is simple, easy control is achieved, the accuracy is high, the safetyis high, and the construction efficiency is greatly improved.

Owner:NANJING FORESTRY UNIV

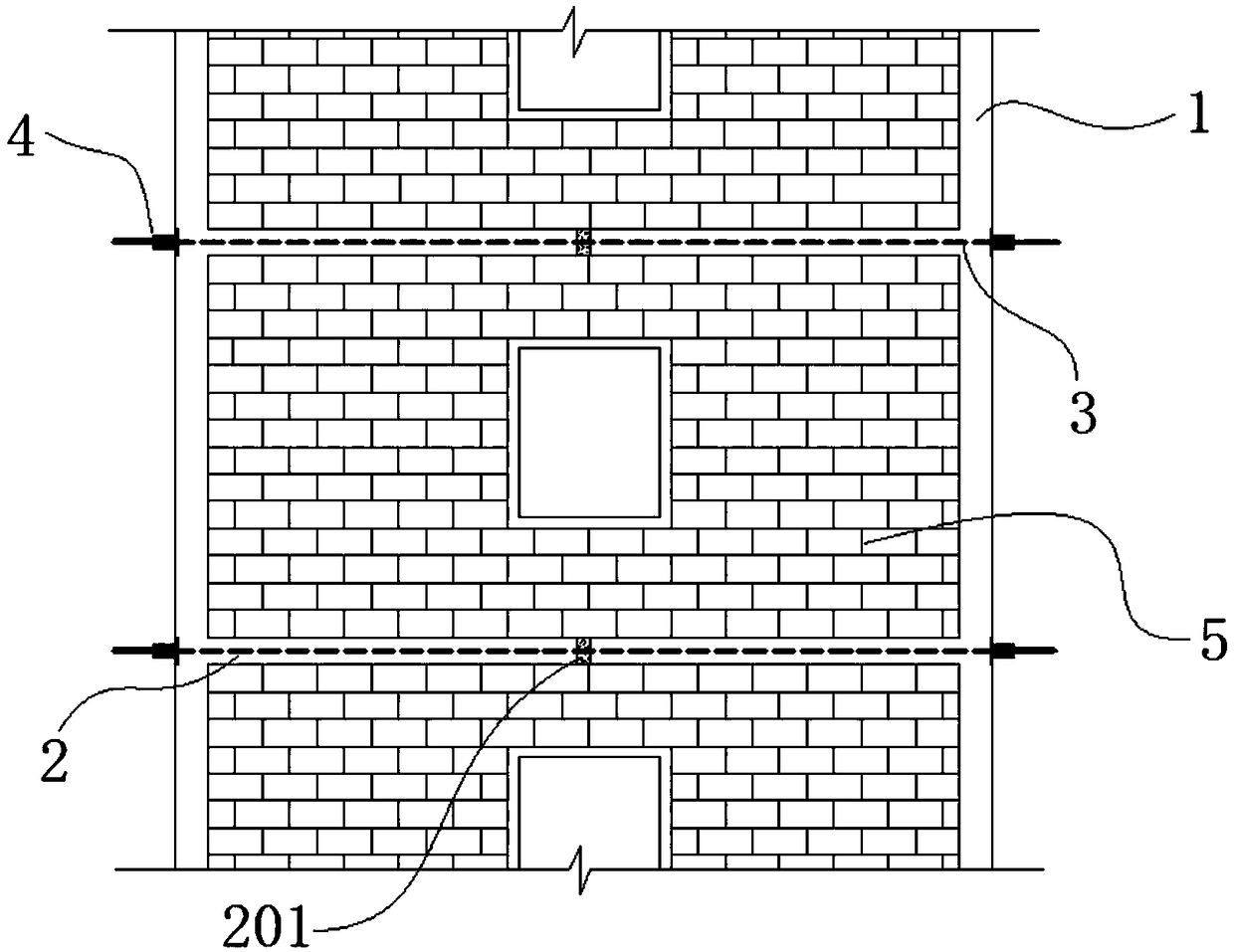

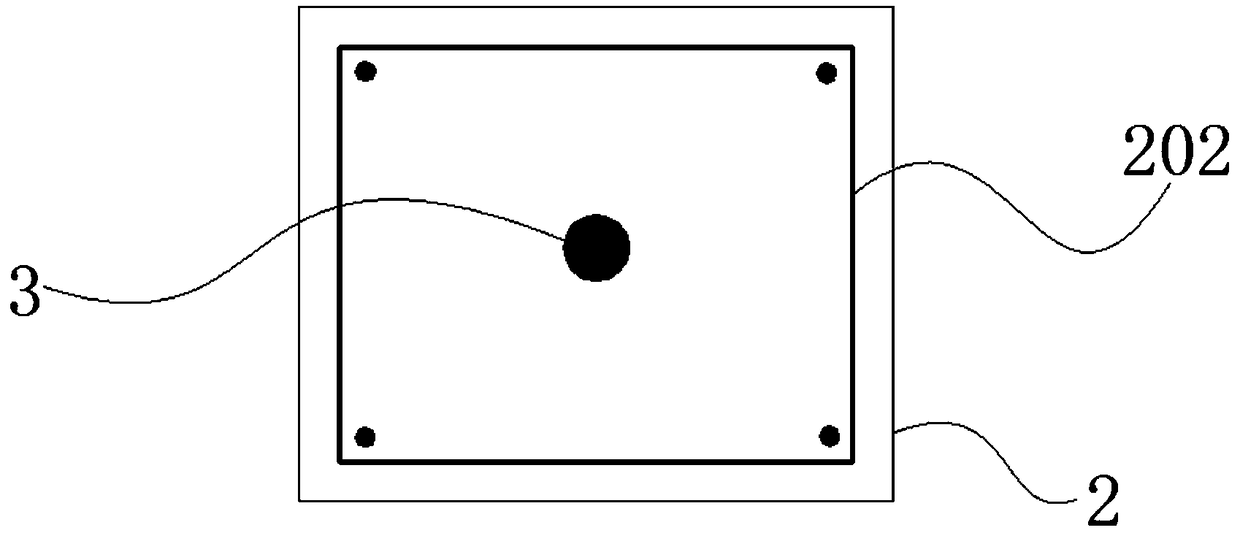

Internal centralized transverse prestress restraint masonry and prestress applying method thereof

InactiveCN109296116ASufficient supplyEasy constructionWallsBuilding material handlingPre stressRebar

The invention provides internal centralized transverse prestress restraint masonry and a prestress applying method thereof. The internal centralized transverse prestress restraint masonry comprises house masonry provided with concrete structural columns and concrete horizontal ring beams. Unbonded prestressing tendons are arranged in reinforcement cages of the concrete horizontal ring beams, applyprestress at the tension ends and are anchored by prestressed anchorage devices. The prestress applying method of the internal centralized transverse prestress restraint masonry comprises the steps that the unbonded prestressing tendons are arranged, concrete of the horizontal ring beams is poured, and the unbonded prestressing tendons are tensioned. A prestress transmitting route of the transverse prestress restraint masonry is clear, and the action mechanism is facilitated to be clear. The cracking load, the ultimate deformation capability and the energy dissipation capability of a house masonry wall are improved significantly, when damaged, the house masonry wall cracks but is not scattered, and thus good integrity and good collapse resistance are maintained.

Owner:CHONGQING UNIV

Post-tensioned unbonded prestressed concrete composite beam and design and construction method thereof.

ActiveCN109868937AGood weather resistanceImprove crack resistanceGirdersJoistsCrack resistancePre stress

The invention relates to a post-tensioned unbonded prestressed concrete composite beam and a construction method thereof. According to the post-tensioned unbonded prestressed concrete composite beam,post-tensioned unbonded prestress is applied to a whole beam after the composite beam is composited and formed to meet the use requirement. Compared with a traditional composite beam, post-tensioned unbonded prestressed technology is adopted, the characteristics of a lower composite structure, such as high prefabricated fabricated degree and convenient construction are inherited, the crack resistance and bending resistance of the elements are improved. Due to ability to apply post-tensioned prestress after overall construction, the post-tensioned unbonded prestressed concrete composite beam isespecially suitable for structures with high performance requirements such as large span and heavy load which require high deformation control and bearing capacity, and can further embody the advantages of fabricated structures while meeting the design requirements.

Owner:上海同吉建筑工程设计有限公司 +1

Post-tensioned bonded co-tensioned prestressed concrete composite beam and design and construction method thereof

ActiveCN109868940AImprove crack resistanceImprove bending abilityGirdersJoistsCrack resistancePre stress

The invention relates to a post-tensioned bonded co-tensioned prestressed concrete composite beam and a design and construction method thereof. The composite beam is a novel prestressed composite beamwhich applies bonded prestress to a prefabricated beam and the composite beam by adopting a pretensioning method and a post-tensioning method in stages in order to meet construction and use requirements. Compared with a traditional prestressed composite beam, post-tensioned bonded prestressed technology is adopted, the characteristics of the lower composite structure such as high prefabrication and fabricating degree and convenient construction are inherited, unique advantages are achieved, the crack resistance and bending resistance of elements can be improved, the structural requirements ofdifferent stages are met by batch tensioning, and the integrity and seismic resistance of the structure can be enhanced by matching with the design of fabricated integral prestressed joint connection. The post-tensioned bonded co-tensioned prestressed concrete composite beam is especially suitable for structures with high performance requirements such as large span and heavy load which require high deformation control and bearing capacity, and can further embody the advantages of the fabricated structure while meeting the design requirements.

Owner:上海同吉建筑工程设计有限公司 +1

Methods of strengthening concrete structures, self-anchoring prestressed components, prefabricated tensioned components

InactiveCN104074368BIncrease cracking loadIncrease stiffnessBuilding repairsBuilding reinforcementsReinforced concretePre stress

The invention relates to a concrete structure reinforcing method, a self-anchored prestress assembly and an assembled tensioning assembly. The concrete structure reinforcing method comprises the following steps including: an anchor seat installation step: an anchor seat is fixed on a concrete structure, wherein the anchor seat is pasted by adopting a pouring method, and fastening elements are chemically buried; a prestress cable manufacturing and installation step: a prestress cable is manufactured and is arranged in the assembled tensioning assembly; a prestress tensioning step: the prestress tensioning step includes a single prestress cable pre-tensioning sub step and a whole prestress cable tensioning sub step, so that the single prestress cables can be sequentially tensioned, and all of the prestress cables can be subsequently tensioned integrally; and a mortar spraying reinforcing step: the mortar spraying is at least carried out on regions covered by the prestress cables of the concrete structure, so that the reinforcement on the concrete structure is realized. The invention aims at providing the method of obviously improving the bearing force of the concrete structure.

Owner:湖南省交通科学研究院有限公司 +1

Post-tensioning bonded prestress concrete composite beam and design and construction methods thereof

ActiveCN109868935AImprove crack resistanceImprove bending abilityGirdersJoistsHeavy loadComposite beams

The invention relates to a post-tensioning bonded prestress concrete composite beam and a construction method thereof. According to the composite beam, in order to meet the use demands, post-tensioning unbounded prestress is applied to the whole beam after the composite beam is composited and formed. Compared with a traditional composite beam, a post-tensioning bonded prestress technology is adopted by the post-tensioning bonded prestress concrete composite beam, the characteristics that a lower composite structure is high in prefabricating degree and fast and convenient to construct are accorded, and the anti-cracking and anti-bending performance of components can also be improved. The post-tensioning prestress can be applied to the post-tensioning bonded prestress concrete composite beamafter whole construction, post-tensioning unbounded prestress tendons also have good anti-corrosion performance, thus the post-tensioning bonded prestress concrete composite beam is particularly suitable for structures with the high requirements for deformation control, bearing capacity and weather resistance and with the high-performance requirements for the large span and the heavy load, and the superiority of the fabricated structure can also be reflected while the design requirements are met.

Owner:上海同吉建筑工程设计有限公司 +1

Post-tensioned bonded prestressed concrete composite beam and its design and construction method

ActiveCN109868935BImprove crack resistanceImprove bending abilityGirdersJoistsCrack resistanceWeather resistance

The invention relates to a post-tensioned prestressed concrete composite beam and a construction method thereof. The composite beam is a kind of post-tensioned non-post-tensioned beam applied to the entire beam after the composite beam is laminated and formed to meet the requirements of use. Bonded prestress. Compared with the traditional composite beam, it adopts post-tensioned bonded prestressing technology, which not only inherits the characteristics of high prefabrication and convenient construction of the lower composite structure, but also improves the crack resistance and bending resistance of the components. Because post-tensioned prestress can be applied after the overall construction and the post-tensioned unbonded prestressed tendons have good anti-corrosion performance, it is especially suitable for large-span and heavy-duty structures that require high deformation control, bearing capacity and weather resistance. In the structure with high performance requirements such as loading, it can also reflect the superiority of the assembled structure while meeting the design requirements.

Owner:上海同吉建筑工程设计有限公司 +1

Post-tensioned co-tensioned prestressed concrete composite beams with bonding and their design and construction methods

ActiveCN109868940BImprove crack resistanceImprove bending abilityGeometric CADGirdersEarthquake resistancePre stress

The invention relates to a co-tensioned prestressed concrete composite beam with post-tensioning and bonding and its design and construction method. A new type of prestressed composite beam with bonded and bonded prestress applied by pre-tensioning and post-tensioning processes. Compared with the traditional prestressed composite beam, it adopts post-tensioned bonded prestressing technology, which not only inherits the characteristics of high prefabrication and convenient construction of the lower composite structure, but also has its unique advantages, which can improve the crack resistance of components Bending performance, stretching in batches to meet the structural needs of different periods, and can cooperate with the design of assembled integral prestressed node connections to enhance the integrity and seismic performance of the structure, especially suitable for large spans with high requirements for deformation control and bearing capacity In structures with high performance requirements such as heavy loads and heavy loads, it can also reflect the superiority of assembled structures while meeting the design requirements.

Owner:上海同吉建筑工程设计有限公司 +1

Damage repair technology of pressure pipeline

InactiveCN105090676BIncrease cracking loadIncreased bending stiffnessPipe elementsFiberForeign matter

Owner:SOUTHWEAT UNIV OF SCI & TECH

Post-tensioned slow bonded prestressed concrete composite beam and its design and construction method

The invention relates to a prestressed concrete composite beam with post-tensioning and slow bonding and its design and construction method. The top of the composite beam is provided with a layer of top longitudinal reinforcement, and the bottom is provided with a layer of bottom longitudinal reinforcement; it also has several stirrups A number of post-tensioned slow bonded prestressed tendons are also arranged at the lower part of the composite beam, and the two ends of the composite beam protrude out of the composite beam and are respectively fixed with anchors and clamps. The composite beam adopts post-tensioning slow bonded prestressing technology, which not only inherits the characteristics of high prefabrication and convenient construction of the lower composite structure, but also improves the crack resistance and bending resistance of the components. Because post-tensioning prestressing can be applied after the overall construction and post-tensioning slow bonded prestressing tendons have good anti-corrosion properties, it is especially suitable for large-span and heavy-duty structures that require high deformation control, bearing capacity and weather resistance. In the structure with high performance requirements such as loading, it can also reflect the superiority of the assembled structure while meeting the design requirements.

Owner:上海同吉建筑工程设计有限公司 +1

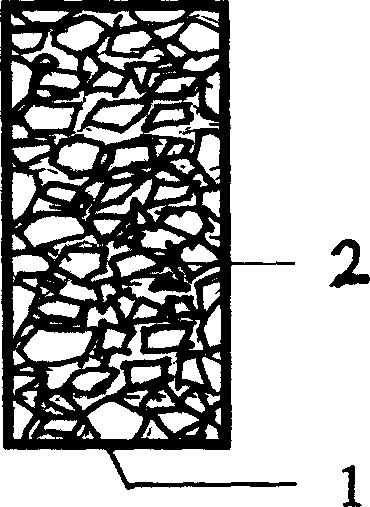

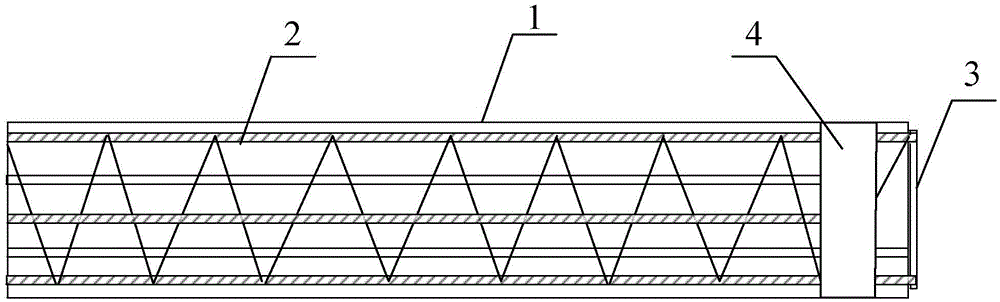

A dry quenching coke tank and production method

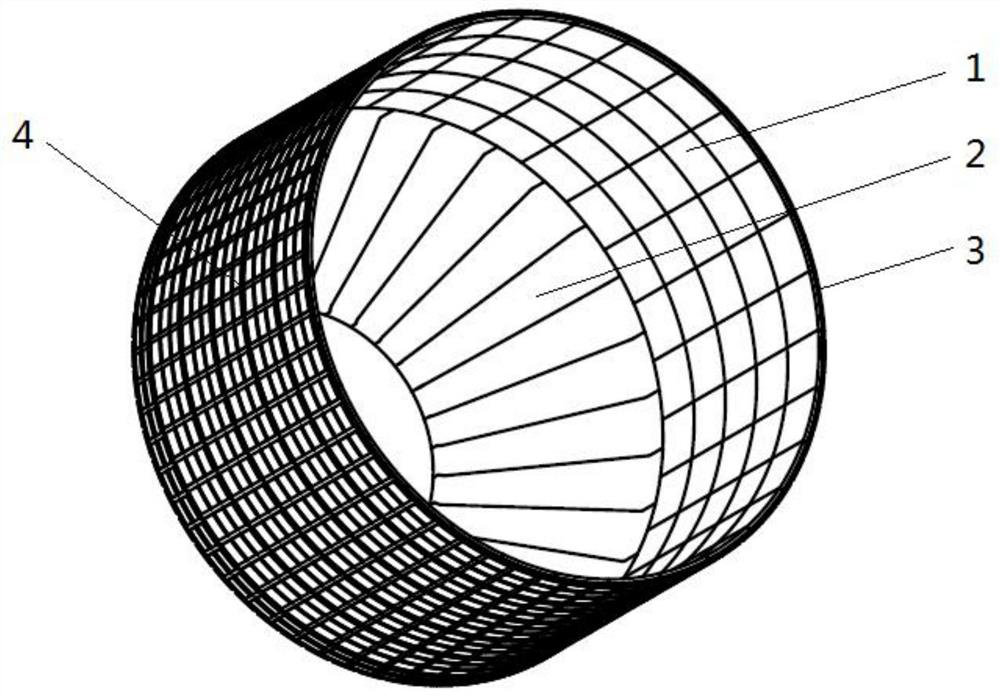

ActiveCN112552934BIncrease cracking loadIncrease ultimate loadCoke quenchingCoke oven brickworkFiberCoke

The invention discloses a CDQ coke tank and a production method thereof. A CDQ coke tank comprises a coke tank body, the coke tank body includes a tank body, a refractory fiber felt and a grid; the tank body consists of The liner is formed by masonry and splicing of prefabricated blocks; the refractory fiber felt is arranged on the outer surface of the tank body; the grid is wrapped on the outer surface of the refractory fiber felt in a stretched state. By stretching the grid, the coke tank is prestressed, so that the stress is evenly transmitted to the refractory working layer, which offsets the tensile stress generated by the side wall of the coke coke tank, avoids the defect that the inner lining is easy to crack and peel off, and can effectively improve the coke. The service life of the tank.

Owner:SHOUGANG CORPORATION +1

Post-tensioned unbonded co-tensioned prestressed concrete composite beam and its design and construction method

ActiveCN109868938BImprove crack resistanceImprove bending abilityGeometric CADDesign optimisation/simulationEarthquake resistanceCrack resistance

Owner:上海同吉建筑工程设计有限公司 +1

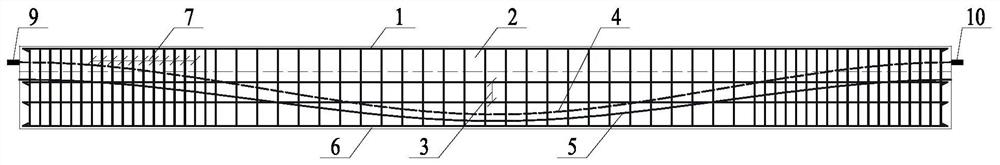

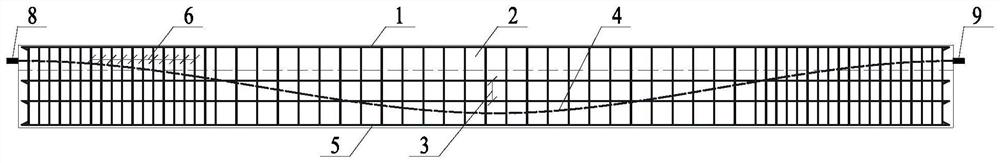

Dual prestressed beam and construction method thereof

PendingCN114293709AReduce the number of prestressed tendonsSimple processLoad-supporting elementsBuilding material handlingPre stressArchitectural engineering

A double prestressed beam mainly comprises a prefabricated part and a cast-in-place part. Wherein the prefabricated part is manufactured in a factory and comprises profile steel, prestressed tendons, longitudinal bars, stirrups, shear bolts, H-shaped perforated steel plate connecting pieces and prefabricated concrete. In the manufacturing process, a vertical load is firstly applied to the profile steel to enable the profile steel to be bent and deformed to a certain degree, then prefabricated part concrete is poured and cured, when the concrete reaches certain strength, unloading is conducted, auxiliary profile steel is dismantled, and the profile steel on the lower portion contracts to apply first prestress to the concrete; however, deformation of the profile steel on the lower portion cannot be completely recovered due to constraint of the concrete, the profile steel still bends to a certain degree, at the moment, the prestressed tendons are tensioned to completely recover the deformation, and second prestress is applied to the concrete due to the action of the prestressed tendons. According to the method, the double prestressing force is applied to the concrete in sequence only by changing the construction process, and the cracking load and the durability in the use stage are greatly improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Dry quenching coke tank and production method

ActiveCN112552934AIncrease cracking loadIncrease ultimate loadCoke quenchingCoke oven brickworkFiberCoke

The invention discloses a dry quenching coke tank and a production method thereof. The dry quenching coke tank comprises a coke tank body, the coke tank body comprises a tank body, a refractory fiberfelt and grids; the tank body is formed by laying and splicing lining plate precast blocks; the refractory fiber felt is arranged on the outer surface of the tank body; and the grids are coated on theouter surface of the refractory fiber felt in a stretching state. The grids are tensioned, and prestress is applied to the coke tank, so that the stress is uniformly transferred to a refractory working layer, the tensile stress generated by coke on the side wall of the coke tank is counteracted, the defect that the lining is easy to crack and peel off is avoided, and the service life of the coketank can be effectively prolonged.

Owner:SHOUGANG CORPORATION +1

A kind of coarse polypropylene-basalt hybrid fiber prefabricated dry hard fiber concrete, pipe jacking and manufacturing method

InactiveCN110642564BImprove corrosion resistanceIncrease cracking loadUnderground chambersTunnel liningPolymer scienceBasalt fiber

The invention relates to a crude polypropylene-basalt hybrid fiber prefabricated dry hard fiber concrete, a pipe jacking, and a manufacturing method, comprising: containing basalt fiber and crude polypropylene fiber in the concrete, wherein the mass ratio of crude polypropylene to basalt is 1 :1~4:1; more preferably, each cubic meter of concrete contains: cement 375kg, sand 850kg, coarse aggregate 545kg, fine aggregate 545kg, coarse polypropylene 4kg, basalt fiber 2kg, water reducer 3.75kg. By adopting the crude polypropylene-basalt hybrid fiber prefabricated dry hard fiber concrete, pipe jacking, and manufacturing method of the present invention, a high-strength pipe jacking with fewer cracks in use can be obtained, and the problem of low pipe jacking production efficiency can be solved.

Owner:CHONGQING UNIV +2

Compensation method for bridge vertical prestress loss based on surface embedding prestress slats

ActiveCN110820603BIncrease cracking loadIncreased shear capacityBridge erection/assemblyBridge strengtheningAdhesivePre stress

The invention discloses a method for compensating the vertical prestress loss of bridges based on embedding prestressed slats on the surface. The steps are as follows: step S1: cutting out prefabricated grooves on the concrete protective layer of the web of the bridge structure; step S2: installing the plates The strip clamp and the tensioning device are fixed to the protective layer of the web at the fixed end and the tensioning end respectively, and the tensioning end strip clamp and the sensor are installed; Step S3: Anchoring and Stretching the slats; step S4: filling the prefabricated groove with adhesive; step S5: completing the stretching; after the adhesive reaches the curing strength, release the prestress applied by the tensioning device, so that the tensioning end and the fixed end clamp occur Sliding, the prestress on the slats is released. The invention has the advantages of good durability, good construction convenience, and can increase web cracking load and shear bearing capacity.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

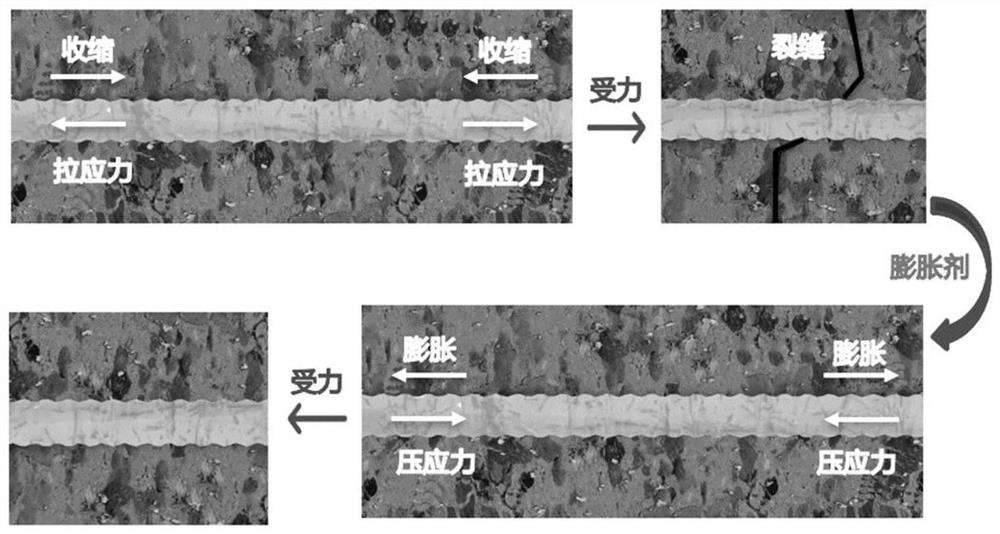

Self-stress bridge continuous construction structure based on simply supported steel beams and construction method thereof

PendingCN114775435AReduce lossIncrease the amount of expansion deformationBridge structural detailsBridge erection/assemblyBridge engineeringEnergy absorption

The invention relates to a self-stress bridge continuous construction structure based on simply supported steel beams and a construction method thereof, and belongs to the field of bridge engineering structures and civil engineering materials, the self-stress bridge continuous construction structure comprises a self-stress connecting plate, an elastic deformation layer, a bridge deck pavement layer, a buffer energy absorption layer and a connecting structure; the self-stress connecting plate is made of a self-stress concrete material; the elastic deformation layers are arranged at the two ends of the self-stress connecting plate and are made of elastic concrete materials. An interface binder is smeared between the H-shaped steel beam and the bridge deck pavement layer, and the buffer energy absorption layer is a polytetrafluoroethylene rubber gasket; the connecting structure comprises inverted-U-shaped steel bars, shear nails, longitudinal steel bars and constructional steel bars, and the longitudinal parts of the inverted-U-shaped steel bars transversely penetrate through the self-stress connecting plates, are bent downwards in an arc shape in the elastic deformation layer and penetrate through the bridge deck pavement layer to be welded to the H-shaped steel beams. The connecting plate is made of a self-stress concrete material, and the self-stress bridge continuous construction structure is reasonable, so that the self-stress concrete connecting plate is better applied to the bridge connection construction structure.

Owner:SHANDONG UNIV

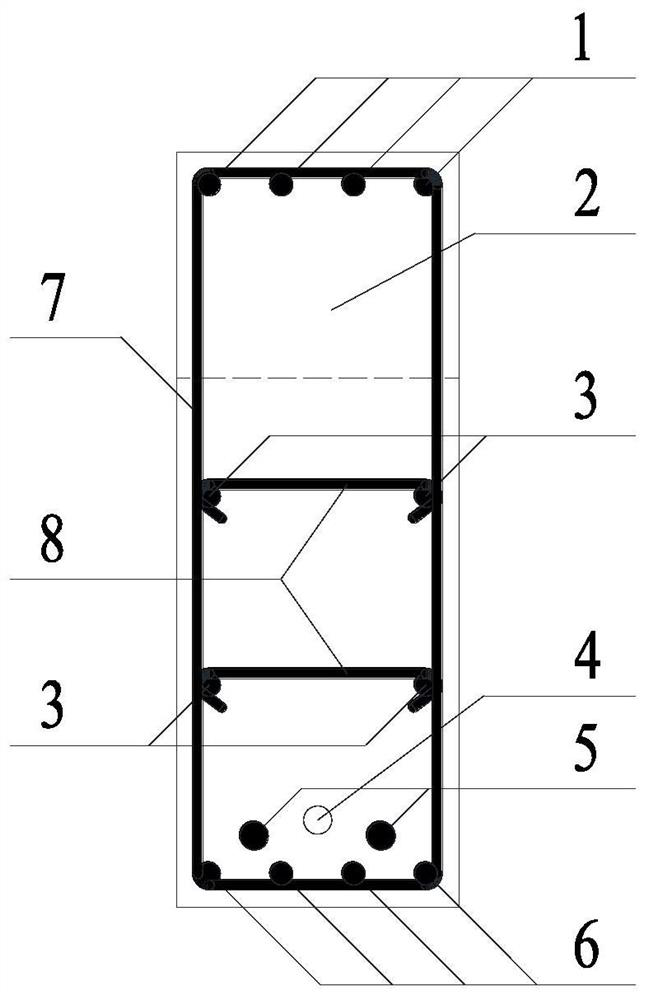

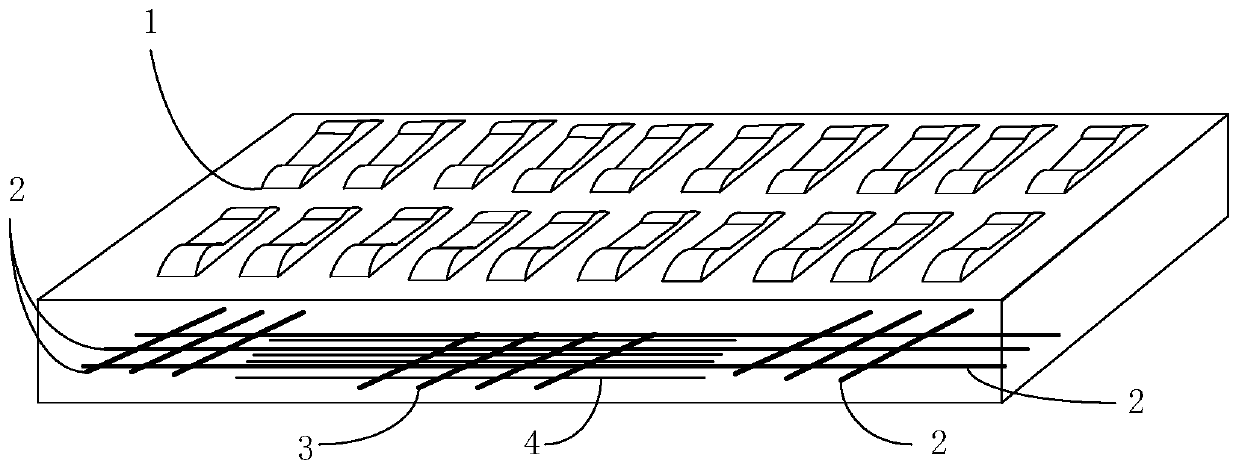

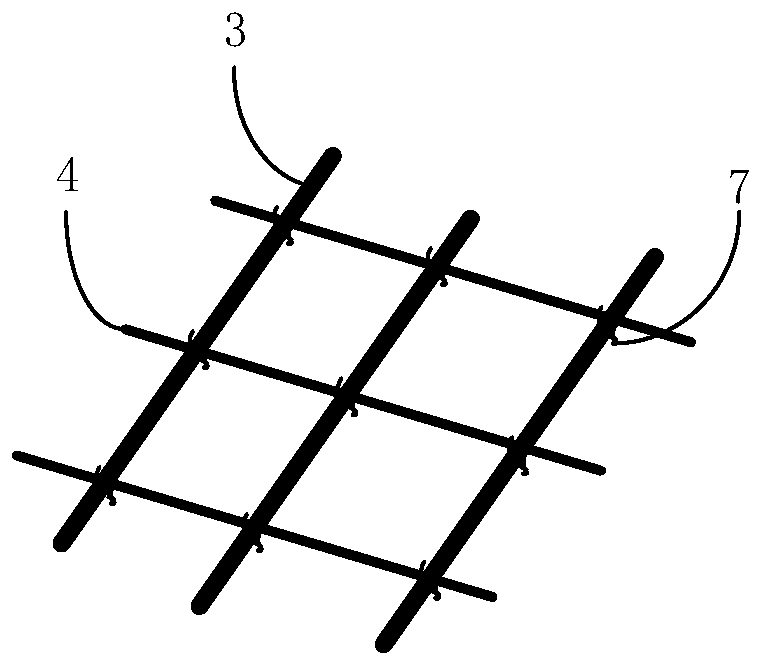

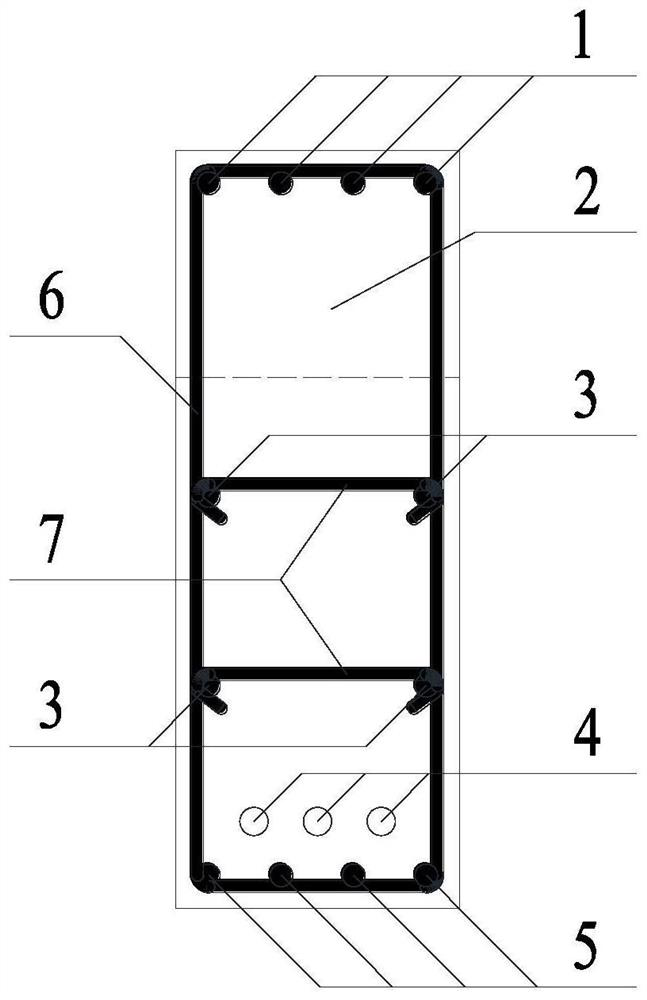

A kind of FRP prestressed tendon ballastless track slab and preparation method thereof

ActiveCN107443542BImprove insulation performanceImprove fatigue resistanceBallastwayFiberEngineering

The invention discloses an FRP prestressed reinforcement ballastless track. The FRP prestressed reinforcement ballastless track comprises a plate body extending in the lengthwise direction, a plurality of layers of stress reinforcement meshes are arranged in the thickness direction of the plate body, are horizontally arranged in the plate body, and comprise a plurality of steel-continuous filament composite reinforcements extending in the transverse direction of the plate body and a plurality of high-strength steel bars extending in the lengthwise direction of the plate body, and the steel-continuous filament composite reinforcements and the high-strength steel bars are arranged in an orthogonal manner; and the plate body is further internally provided with a plurality of FRP prestressed reinforcements arranged in the lengthwise direction and the transverse direction, and the FRP prestressed reinforcements are located between the two layers of adjacent stress reinforcement meshes. The invention further discloses a manufacturing method of the FRP prestressed reinforcement ballastless track; the steel-continuous filament composite reinforcements and the traditional high-strength steel bars form the stress reinforcement meshes, and the insulating property of a track plate is improved; the FRP prestressed reinforcements are adopted for increasing cracking loads, and the fatigue durability and the endurance quality of the track plate are improved; and by means of the method, other insulating measures are not needed, and the production cost can be effectively reduced.

Owner:SOUTHEAST UNIV

Post-tensioned unbonded prestressed concrete composite beam and its design and construction method

ActiveCN109868937BImprove crack resistanceImprove bending abilityGirdersJoistsPre stressArchitectural engineering

The invention relates to a post-tensioned non-bonded prestressed concrete composite beam and a construction method thereof. The composite beam is a kind of post-tensioned non-bonded beam applied to the entire beam after the composite beam is laminated and formed to meet the requirements of use. Bonded prestress. Compared with the traditional composite beam, it adopts post-tensioning unbonded prestressing technology, which not only inherits the characteristics of high prefabrication and convenient construction of the lower composite structure, but also improves the crack resistance and bending resistance of the components. Because it can apply post-tensioned prestress after the overall construction, it is especially suitable for structures with high performance requirements such as large spans and heavy loads that require high deformation control and bearing capacity, and can also reflect the design requirements while meeting the design requirements. Advantages of prefabricated structures.

Owner:上海同吉建筑工程设计有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com