Negative bending moment area UHPC treatment steel-concrete composite structure and preparation method thereof

A technology of negative bending moment area and combined structure, which is applied to bridge parts, bridge materials, bridges, etc., to achieve the effects of being easy to promote and use, enhancing integrity, and solving cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as Figure 1~4 , the laying process is as follows in the present embodiment:

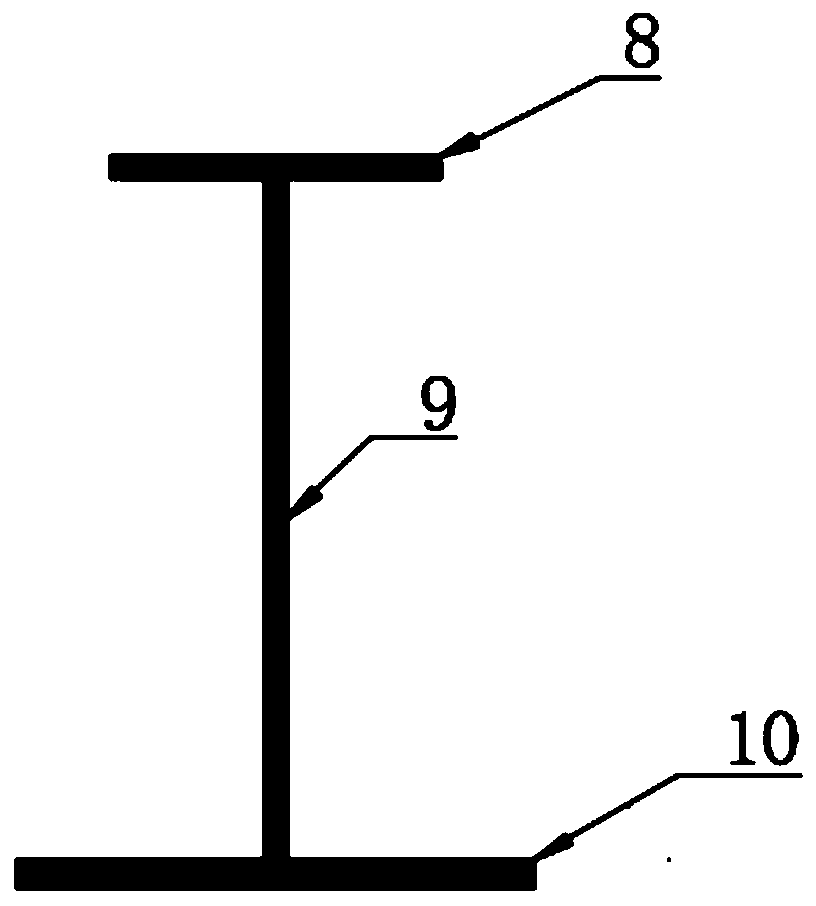

[0041] Steel girders 5 are erected at equidistant intervals within a section of span L formed by every two piers 7, the steel girders 5 are I-shaped steel girders, and the steel girder webs 9 are equidistantly arranged with steel girder stiffeners 6 along the length direction , at the negative bending moment zone on the pier 7, use steel plate 3 to bolt or weld the upper flange 8 of the steel girder in the adjacent span L, and the pier 7 is arranged according to the span L being 30-60m;

[0042] Then weld the shear nail 4 on the upper surface of the steel plate 3 and the upper flange 8 of the steel beam;

[0043] A continuous prefabricated ordinary concrete bridge deck 1 is laid on the upper surface of the steel plate 3 and the upper flange 8 of the steel beam. The negative bending moment zone of the ordinary concrete bridge deck 1 on the pier 7 has a concave cavity, and the UHPC bridg...

Embodiment 2

[0049] Such as Figure 1~5 , the laying process is as follows in the present embodiment:

[0050] Steel girders 5 are erected at equidistant intervals within a span L formed by every two piers 7, the steel girders 5 are I-shaped steel girders, and steel plates 3 are bolted or welded at the negative moment zone on the pier 7 The upper flange 8 of the steel girder adjacent to the span L, and the piers 7 are arranged according to the span L being 30-60m;

[0051] Then weld the shear nail 4 on the upper surface of the steel plate 3 and the upper flange 8 of the steel beam;

[0052] The steel girder stiffeners 6 are welded and fixed equidistantly along the length direction of the steel girder web, and a continuous ordinary concrete bridge deck 1 is laid on the upper surface of the steel plate 3 and the upper flange 8 of the steel girder by template method, and the ordinary concrete bridge deck 1 The negative bending moment zone on the pier 7 has an inner cavity, and the UHPC brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com