Pressure bearing pipe damage repair process

A damage repair and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of weak anti-corrosion ability of plastic pipes, limited service life of pipes, and lack of rigidity, etc., to achieve the construction period. Short, ensure no loss of prestress, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to the following embodiments, and corresponding equivalent replacement measures can be taken due to specific engineering examples.

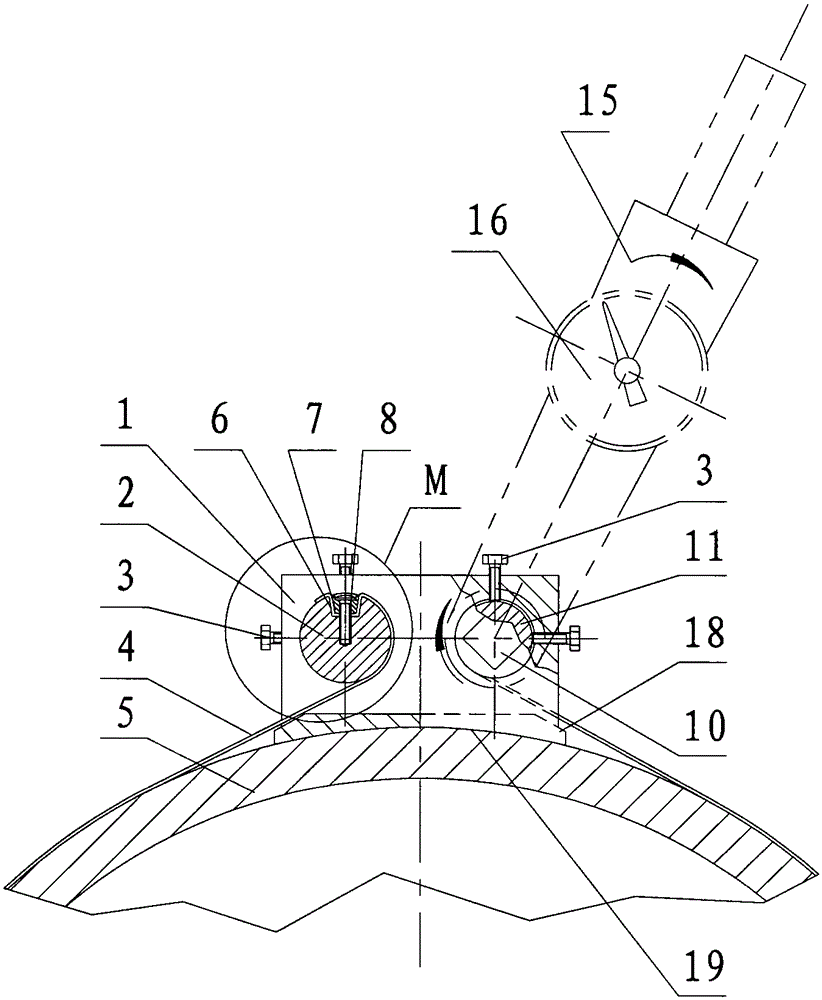

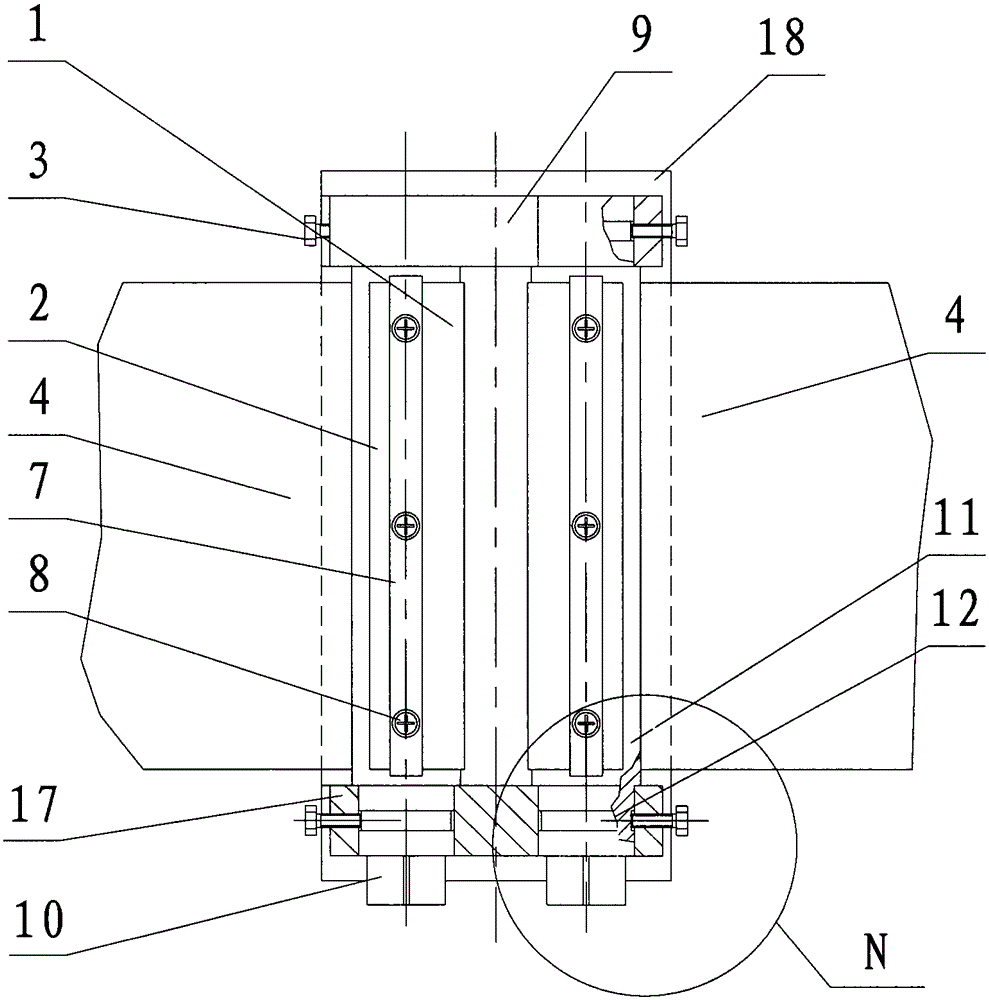

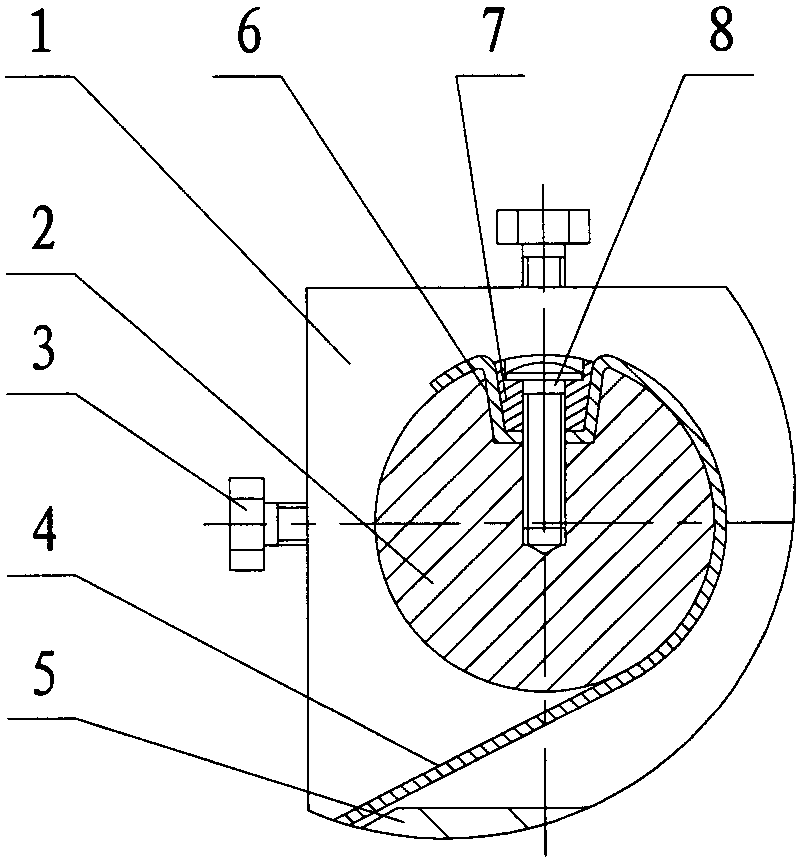

[0040]Such as figure 1 , figure 2 , image 3 with Figure 4 , a pressure-bearing pipeline damage repair process is characterized in that the process is carried out in the following steps:

[0041] A. Prepare carbon fiber cloth 4 of appropriate length according to the diameter of pressure-bearing pipeline 5, prepare enough repair agent, prepare enough adhesive, prepare torque wrench 15 with pointer disc 16, and prepare tensioning device 1;

[0042] The tensioning device 1 comprises: a base 18 with an arc-shaped bottom surface 19, a front axle sleeve 17 is fixed on the front of the top surface of the base 18, a rear axle sleeve 9 is fixed on the back of the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com