Built-in horizontal brace reinforced concrete shear wall

A reinforced concrete and shear wall technology, applied in the treatment of walls, building materials, construction, etc., can solve the problems of easy cracking of concrete, decreased seismic performance, difficult construction technology, etc., and achieve small prestress loss and energy consumption. The effect of improving, lightness of the floor structure system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

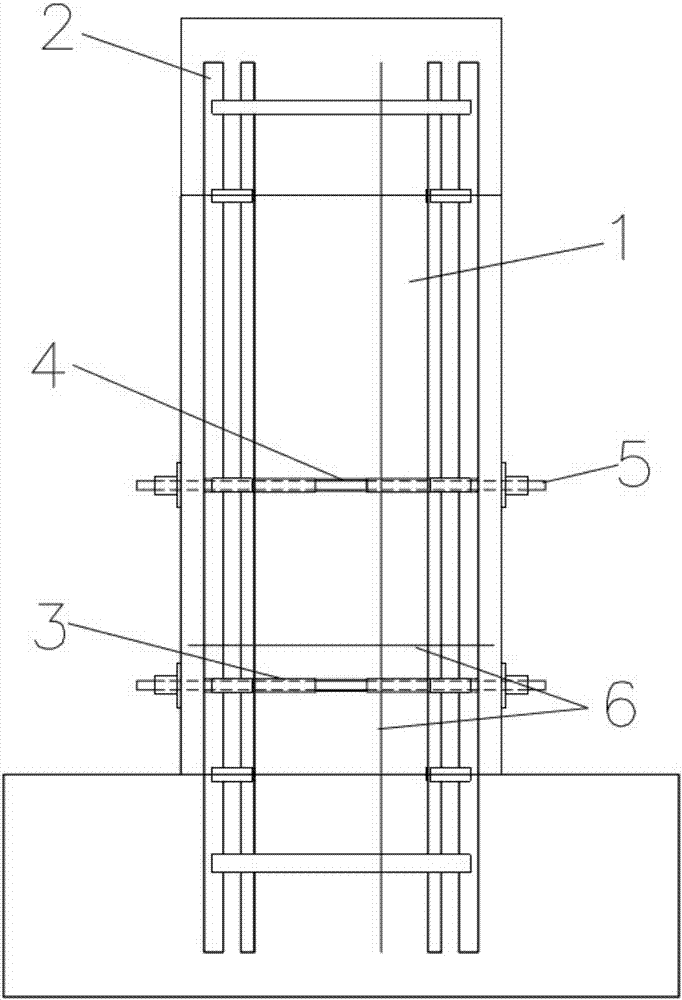

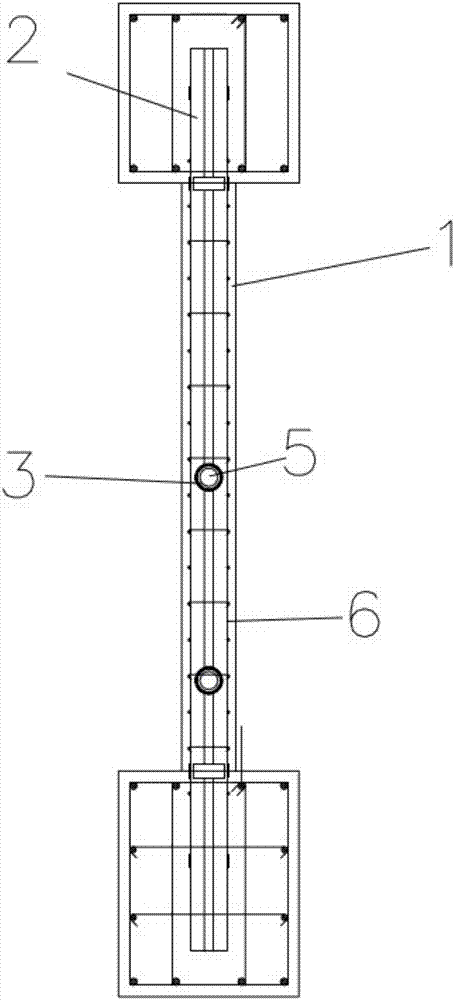

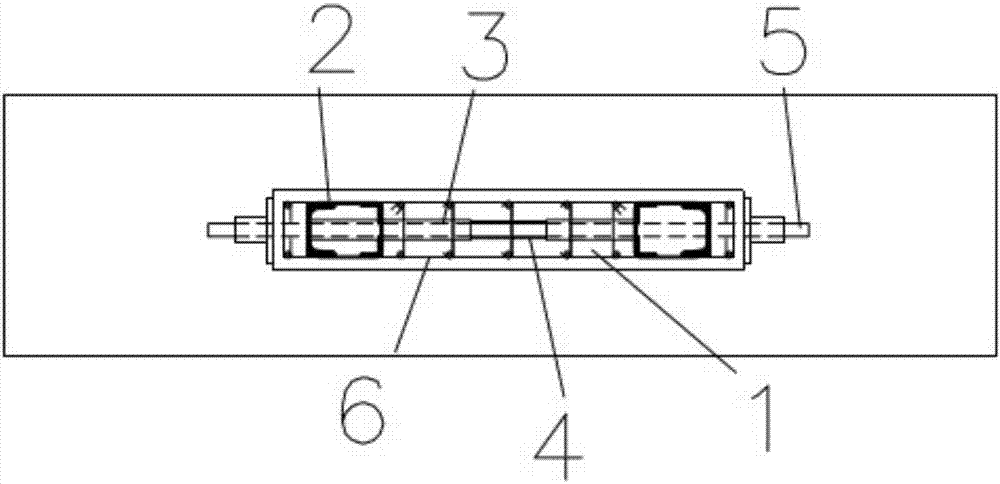

[0030] as attached Figure 1-3 As shown, the steel concrete shear wall of this embodiment includes a concrete wall support 1, a steel truss 2 built in the concrete wall support 1 and a prestressed horizontal diagonal brace. The prestressed horizontal diagonal brace includes a horizontal steel casing 3, a hose 4 and prestressed steel bars 5, wherein preferably, the hose 4 adopts a steel wire hose, and the prestressed steel bars 5 adopts precision-rolled rebar.

[0031] Such as Figure 4 As shown, it is a three-dimensional view of the built-in steel truss 2 in this embodiment, and the steel truss 2 is welded by channel steel, angle steel and flat steel.

[0032] Circular through holes are reserved at the corresponding positions on both sides of the steel truss 2 to form tunnels, and horizontal steel casings 3 are inserted into the two sides of the tunne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com