Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Improve packaging accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

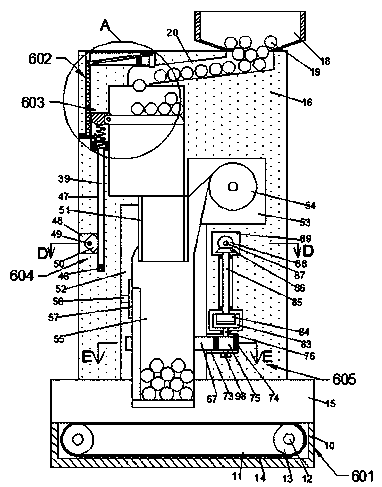

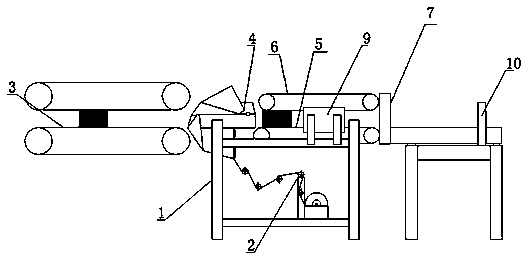

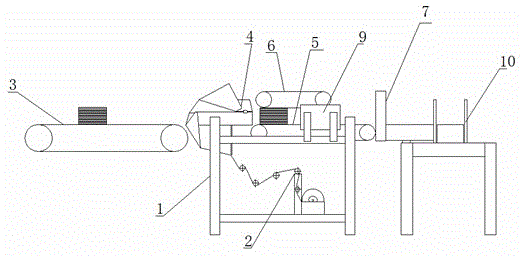

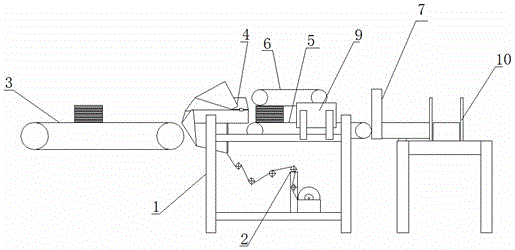

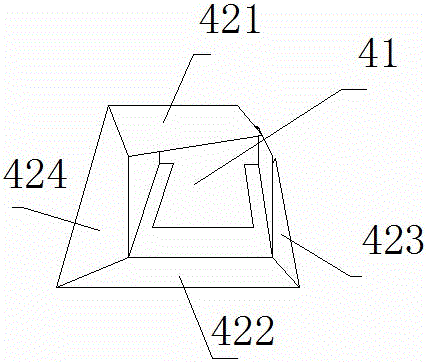

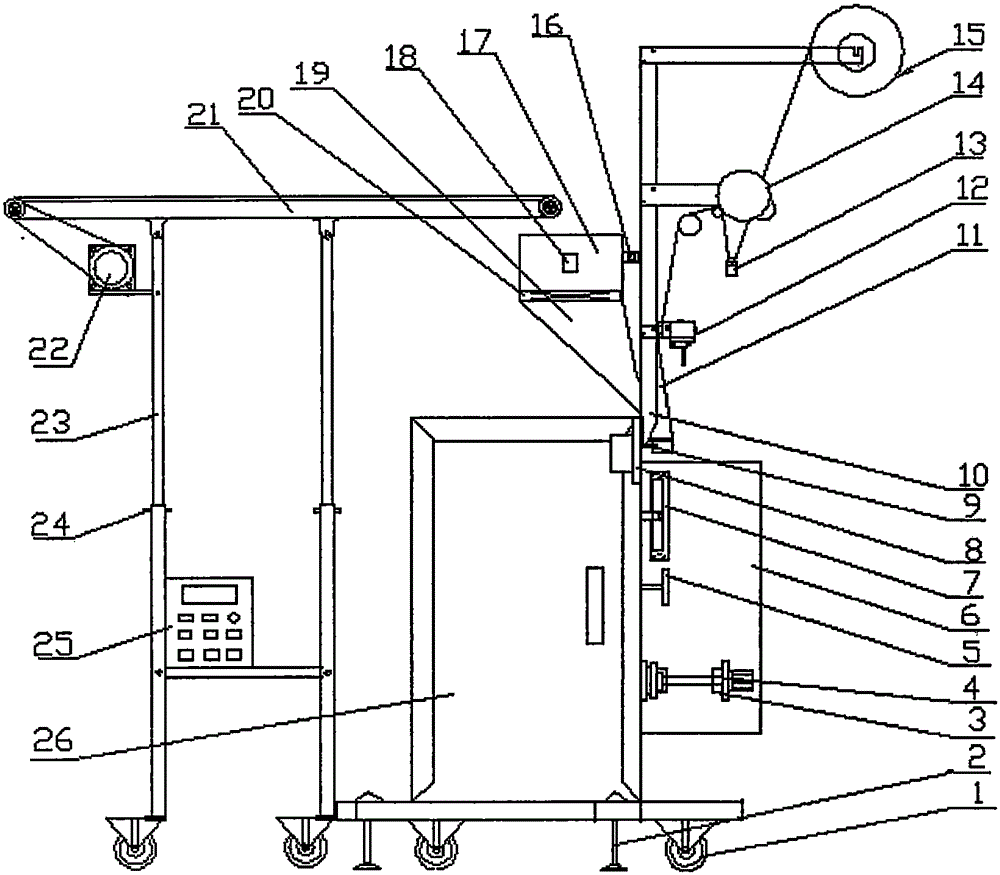

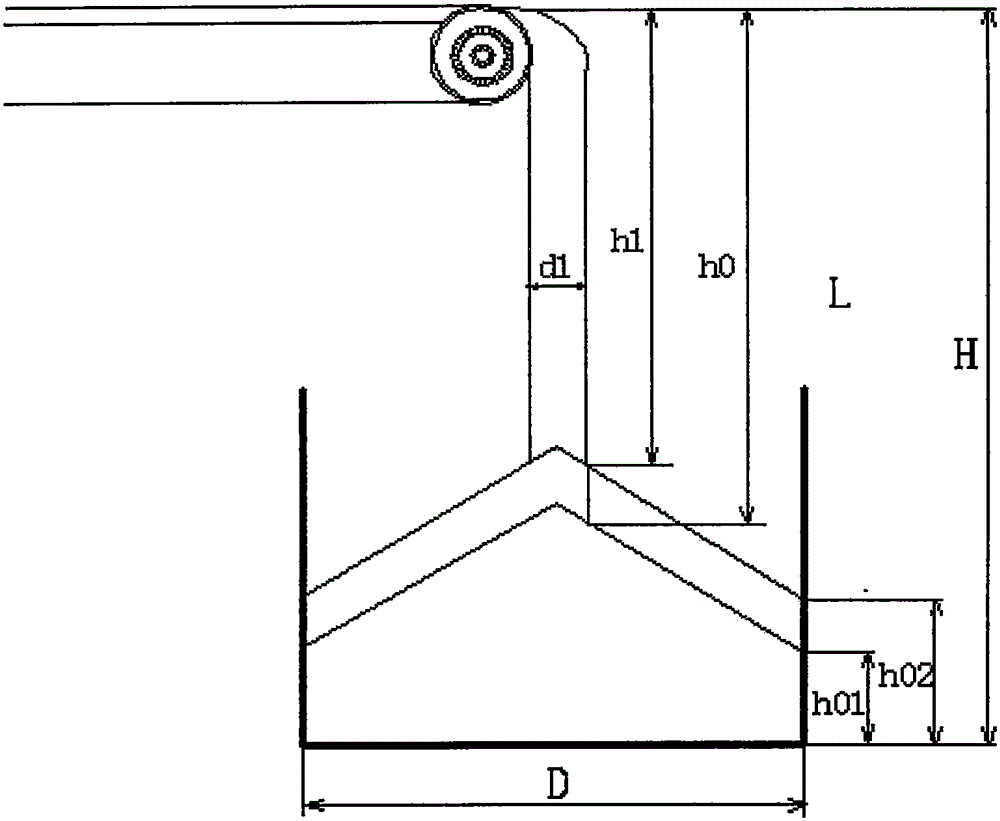

Semi-automatic fruit packaging machine

InactiveCN105752387ASolve efficiency problemsSolve the workloadWrappingPackaging fruits/vegetablesPulp and paper industryPackaging machine

The invention discloses a semi-automatic fruit packaging machine which comprises a rack, the rack is provided with a fruit conveying device, a paper packaging device, a linking slide way and a cover net packaging device which are arranged in the fruit packaging path; the paper packaging device comprises a paper conveying mechanism, a paper cutting mechanism and a clamping and twisting mechanism; the cover net packaging device comprises a net cover shaping and conveying mechanism, a cover net stretching mechanism and a cover net cutting mechanism; conveyed fruits and packaging paper pass through the linking slide way and enter the position below a cover net of the net cover shaping and conveying mechanism after falling into the clamping and twisting mechanism for integral packaging and twisting, the cover net stretching mechanism is controlled to unfold a cover net and arrange the cover net on a fruit in a sleeved mode, and then the cover net is cut through the cover net packaging device.The semi-automatic fruit packaging machine has the functions of automatically packaging the fruits with fruit preservative film / paper and fruit packaging net covers, fruits can be packaged and output automatically, the problem that manual fruit packaging is low in efficiency and large in workload is solved, and packaging efficiency and precision are improved completely.

Owner:WUHAN UNIV OF TECH

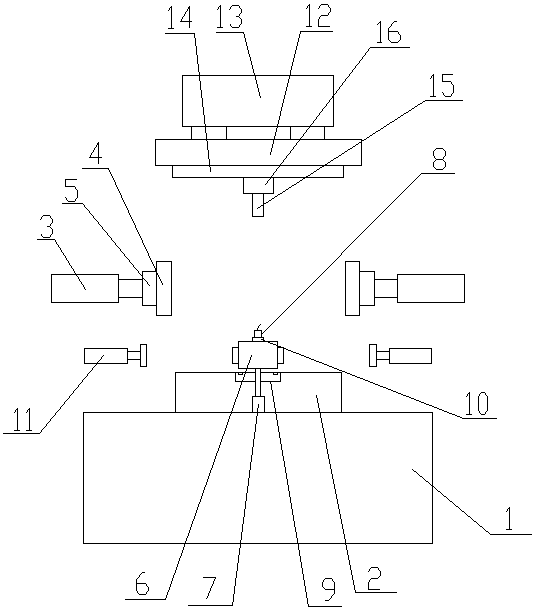

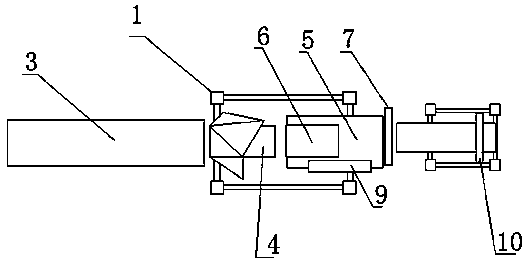

Automatic packing device

InactiveCN108482759AImprove accuracyImprove packaging accuracyWrapper twisting/gatheringPackaging automatic controlElectric machineryEngineering

The invention provides an automatic packing device which comprises a base, wherein a carton placement table is arranged on the base; carton clamping air cylinders are arranged above the carton placement table; clamping plates are arranged on the carton clamping air cylinders; rotating motors are arranged between the carton clamping air cylinders and the clamping plates; an adhesive tape storage rack is arranged on the base; a position adjusting rod is arranged between the adhesive storage rack and the base; an adhesive tape head fixing clamp is arranged on the adhesive tape storage rack; and aposition detecting sensor is arranged on the carton placement table. According to the automatic packing device, the clamping plates are driven by the carton clamping air cylinders to clamp a carton and the carton is driven by the rotating motor to rotate; the adhesive tape encapsulation operation is performed through the adhesive tape head fixing clamp on the adhesive tape storage rack, and the position of the carton is detected through the position detecting sensor, so that the accurate degree of encapsulation can be improved; and the position of the carton on the carton placement table is adjusted through position adjustment air cylinders, so that the encapsulation accuracy can be improved.

Owner:WUHU JINMAO PACKAGE PROD

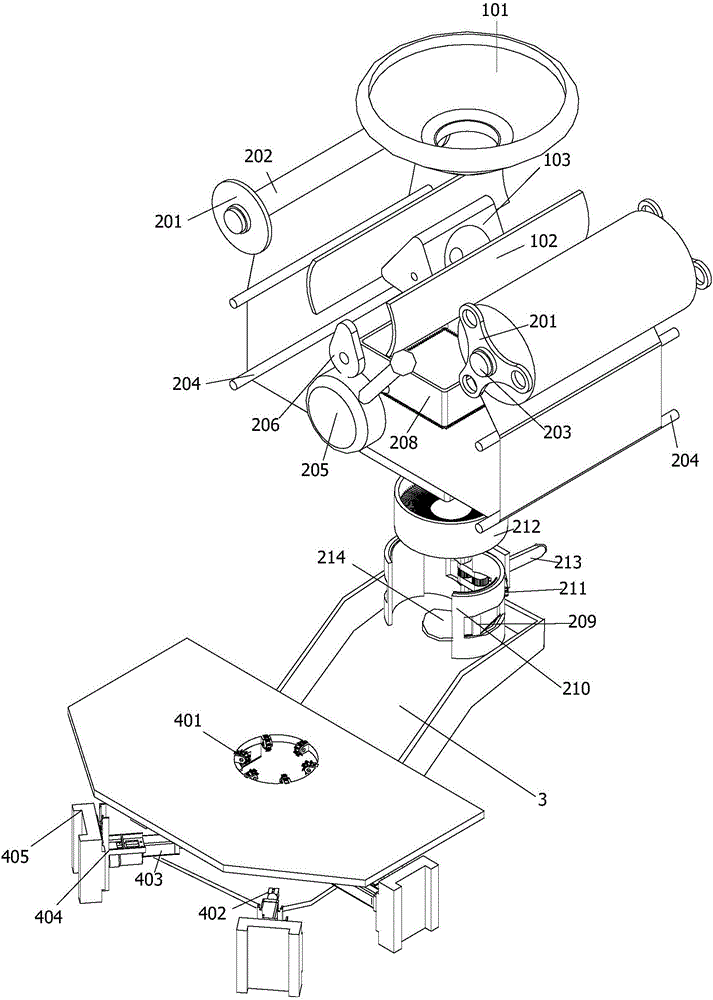

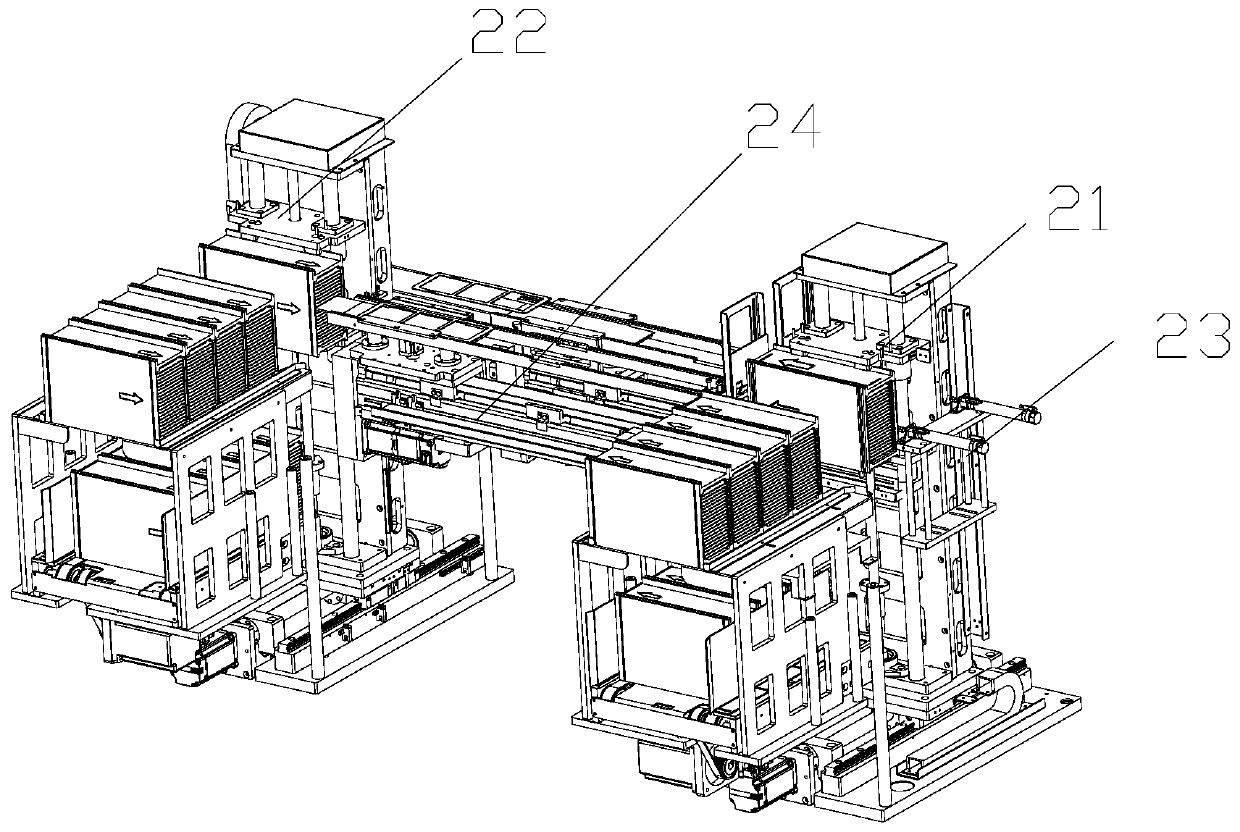

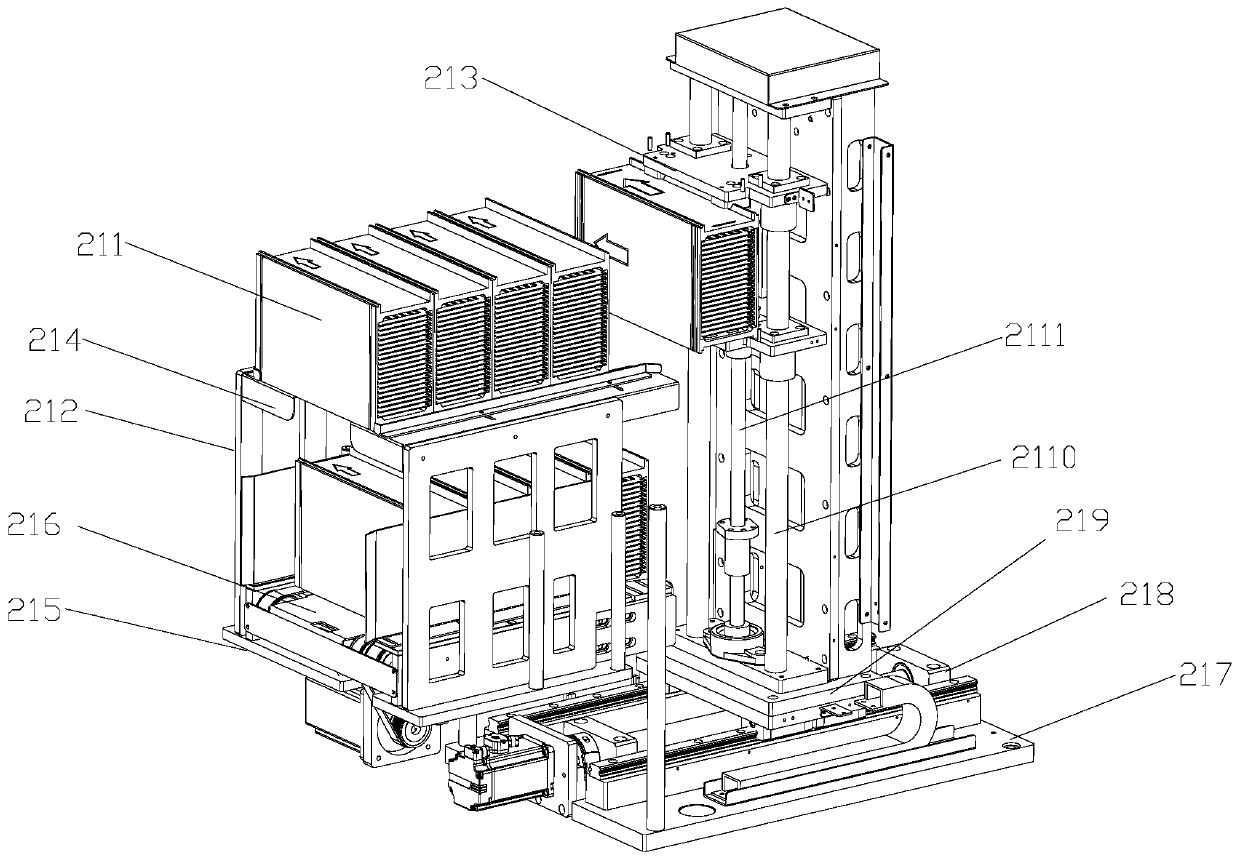

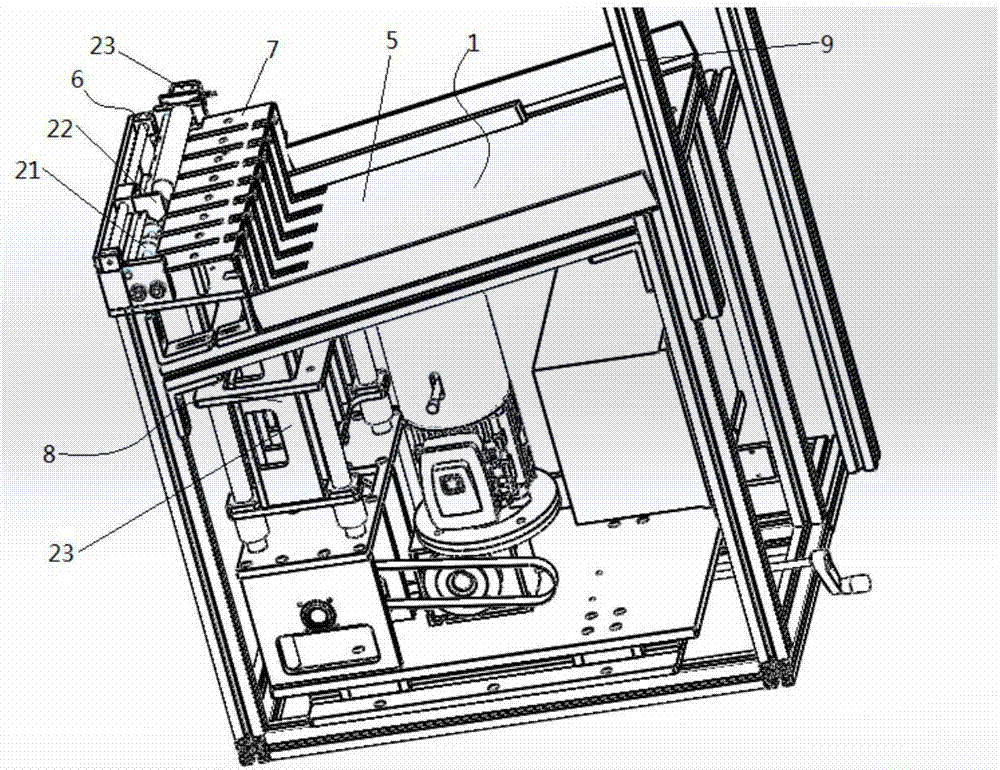

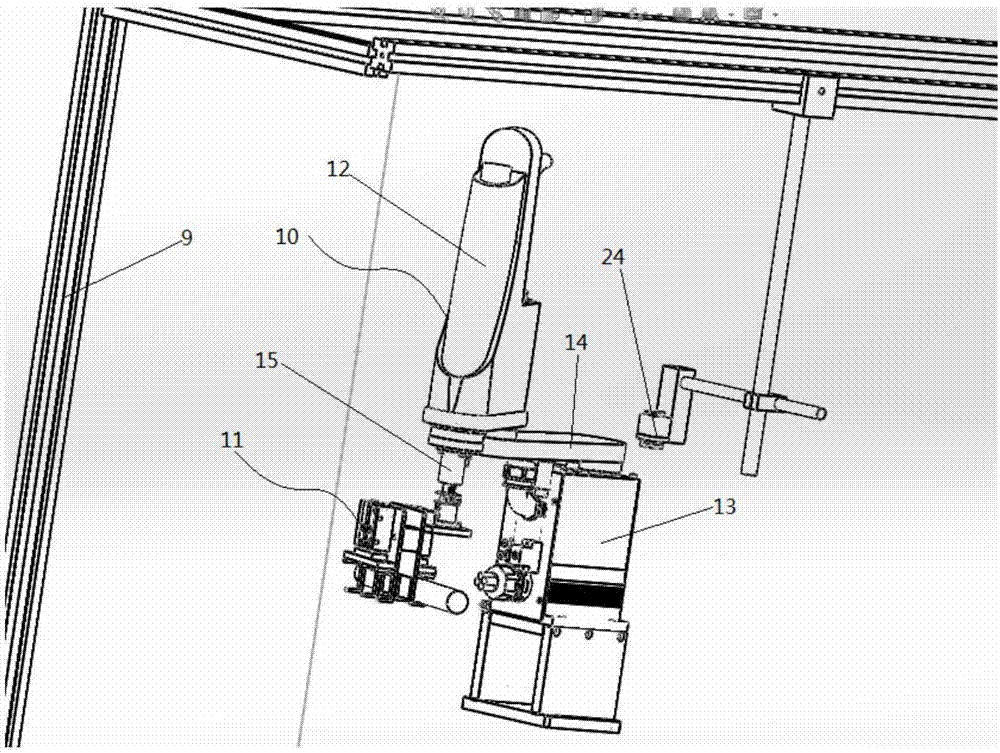

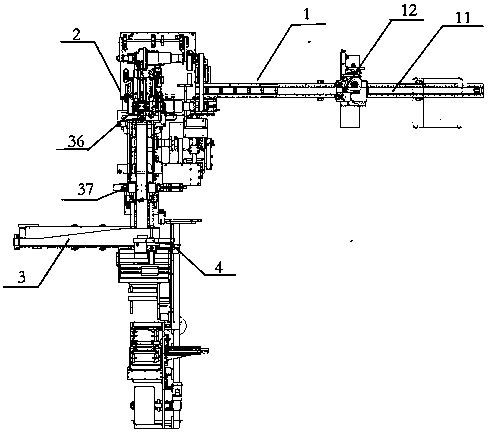

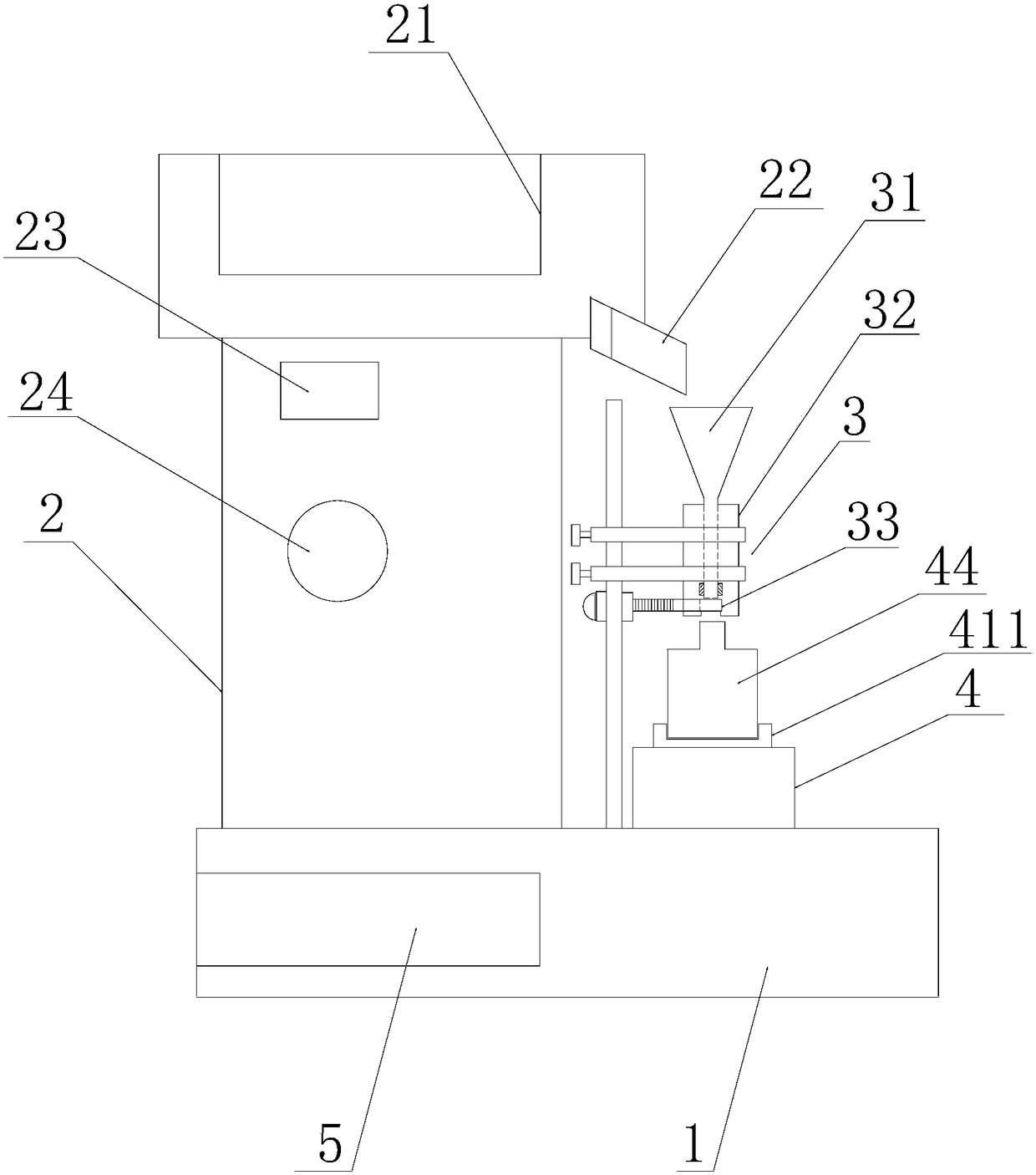

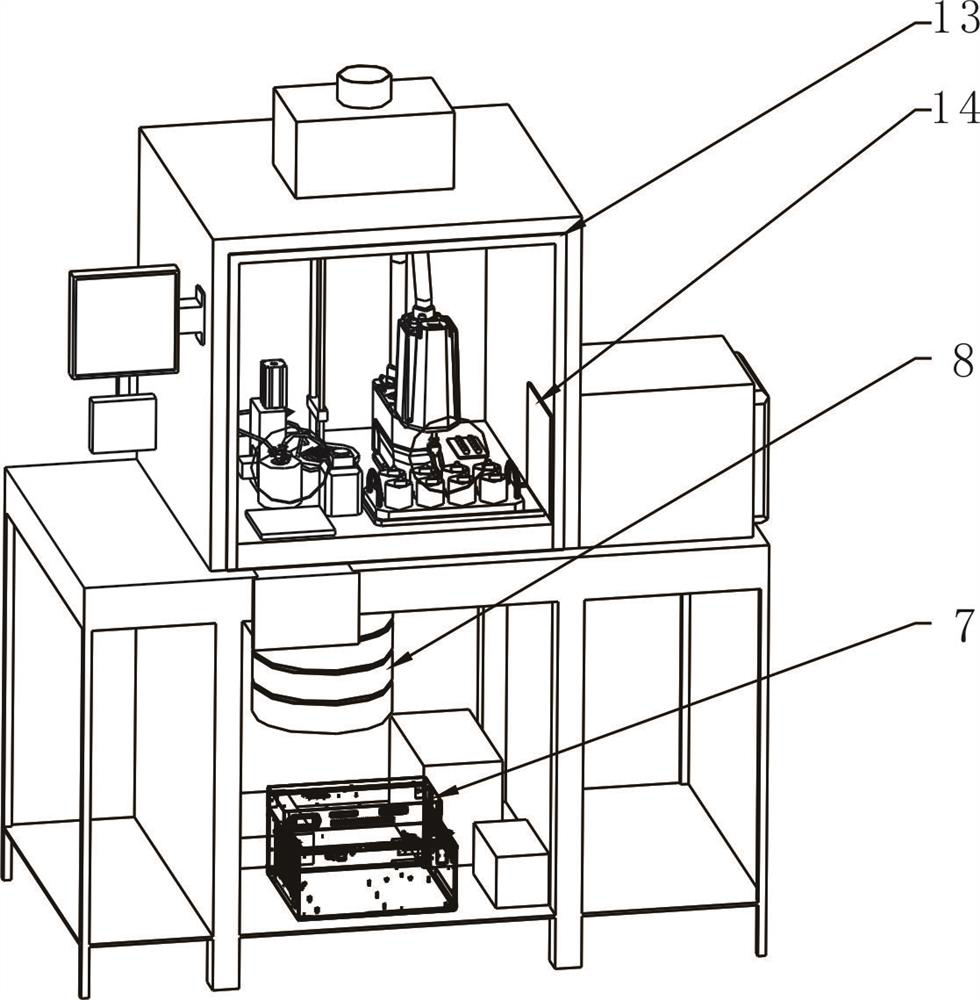

Automatic loading system and method for radio isotope liquid medicine capsules

ActiveCN107744468AFully automatedRealize flexible productionCapsule deliveryEngineeringPower apparatus

The invention relates to an automatic loading system and method for radio isotope liquid medicine capsules. The system comprises a supporting bench and a shielding heat chamber mounted on the supporting bench, wherein a loading platform is disposed in the heat chamber; a robot, a loading device, a pre-filling capsule tray assembly and a mother solution circulating device connected with the loadingdevice via a power device are arranged on the loading platform; the robot, the loading device and the power device are connected with a controller; and the controller can automatically quantitativelyload the liquid medicine capsules according to the liquid medicine capsules and a patient condition. The automatic loading system and method for radio isotope liquid medicine capsules have great automation degree and production efficiency, great loading precision and simple operation as well as excellent shielding performance; the system has an economic mode or a high-efficient mode, so bigger selection space can be provided for users with different demands; and great application value is provided.

Owner:类彦威

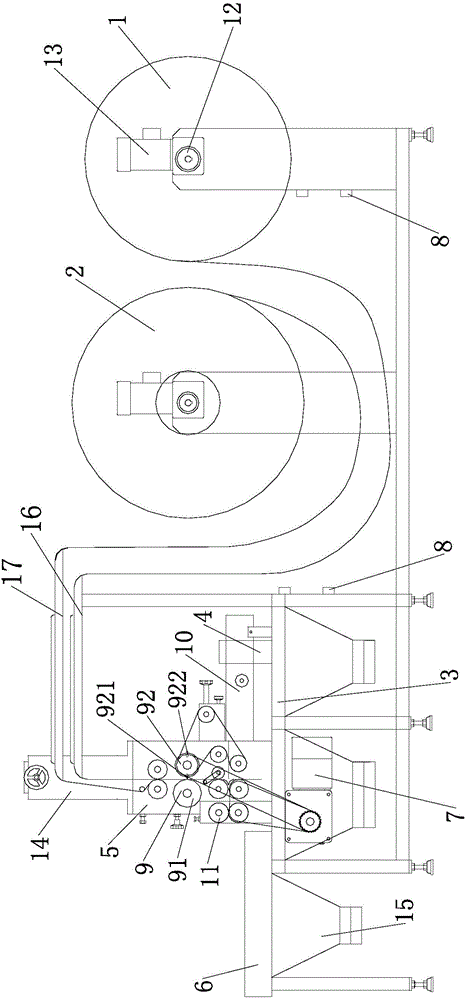

Paper towel packaging machine adopting whole-roll film packaging

The invention discloses a paper towel packaging machine adopting whole-roll film packaging and relates to the technical field of paper towel packager machinery. According to the packaging machine, a material and a packaging film are conveyed simultaneously, the material is packaged by the packaging film while being conveyed, and the packaging process is uninterrupted, so that the packaging efficiency is increased; during packaging, locations of grains and patterns on the packaging film can be excellently controlled, so that the grains and the patterns are packaged to specific locations of the material, and packaged paper towels are more attractive, thereby meeting the demands of people in daily lives.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

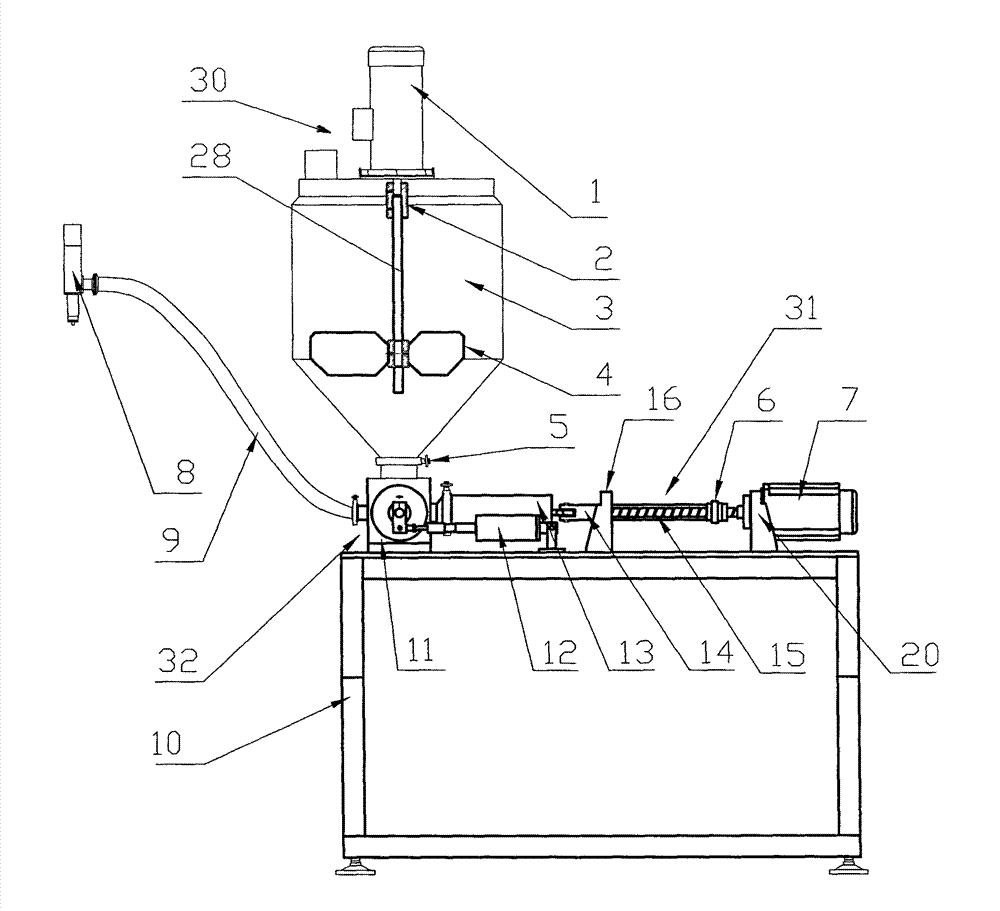

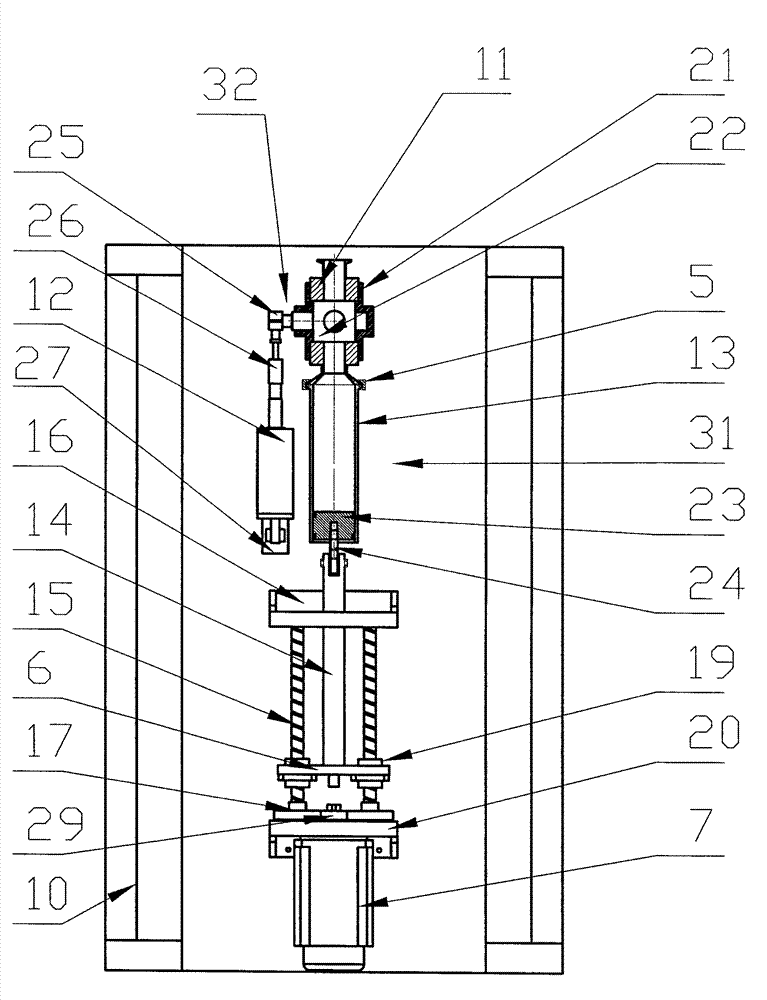

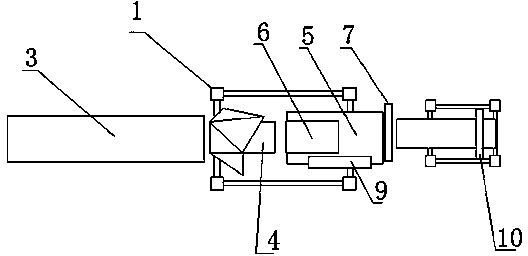

Capacity-adjustable liquid filling mechanism

ActiveCN102923333ANormal operating speedNormal packing qualityLiquid materialMotor driveElectric machinery

The invention discloses a capacity-adjustable liquid filling mechanism which comprises a frame (10), a liquid input device (30), a liquid pushing device (31) and a valve switching device (32). The liquid pushing device comprises a cylinder barrel (13) and a piston (23). The outer end of the piston of the liquid pushing device is connected with a connection rod (14) which is connected with a feeding lead screw (15) through a guide block (6) with a nut (19), and the feeding lead screw is connected with a pushing motor (7) through an intermediate conveying assembly. The pushing motor drives the intermediate conveying assembly to enable the feeding lead screw to rotate, and accordingly, the guide block with the nut and the connection rod are pushed to drive the piston to push liquid in the cylinder barrel and a valve body out of the valve body. The capacity for pushing liquid is adjusted through rotation speed and time (namely, stroke of the connection rod) of the pushing motor. The capacity-adjustable liquid filling mechanism works stably, is high in adjustment precise, improves packing precision and yield accordingly, and ensures normal operation speed and packing quality of a packing machine.

Owner:WENZHOU KEDI MACHINERY

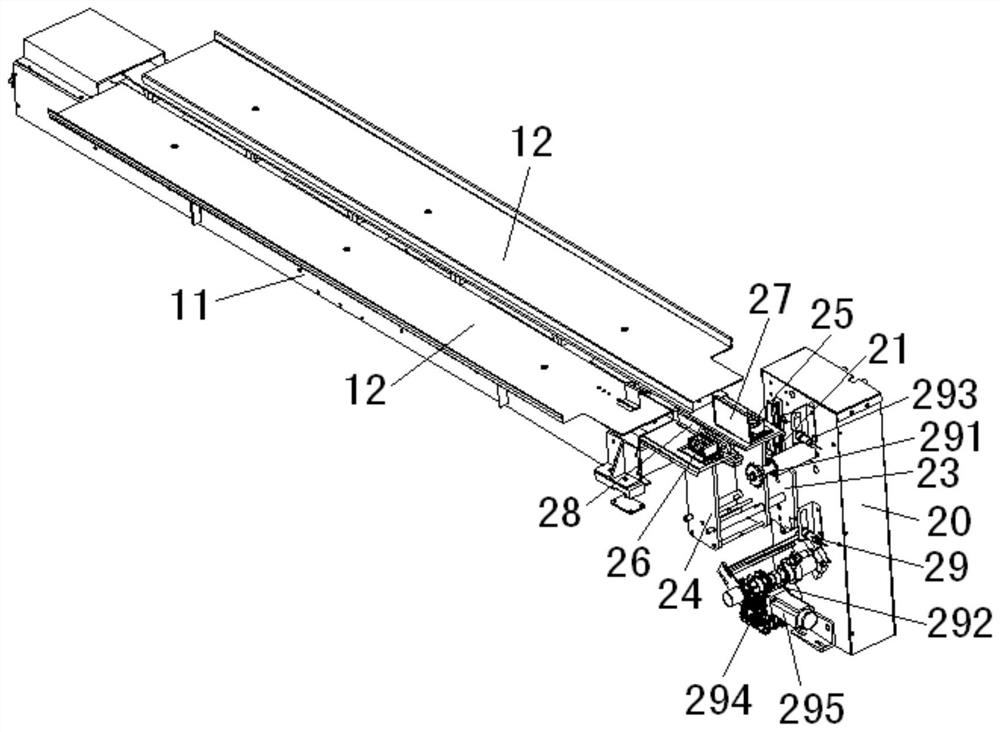

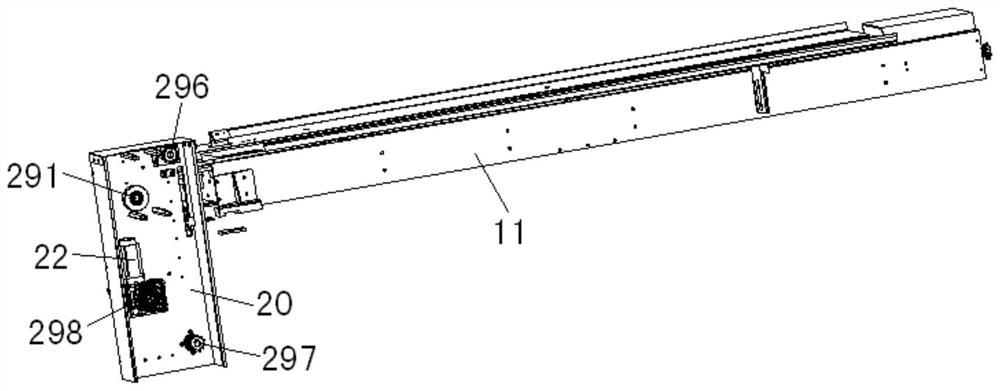

Chip mounting equipment based on mobile phone camera chip

PendingCN111223802ANo manual workImprove packaging efficiencySemiconductor/solid-state device manufacturingConveyor partsEmbedded systemElectrical and Electronics engineering

The invention discloses chip mounting equipment based on a mobile phone camera chip, which comprises a steel sheet carrier tape receiving and discharging circulating mechanism, a chip product carryingmechanism, a chip product feeding mechanism and a camera positioning detection mechanism, wherein the steel sheet carrier tape receiving and discharging circulating mechanism comprises a steel sheetcarrier tape discharging device, a steel sheet carrier tape receiving device, a steel sheet carrier tape pushing device and a steel sheet carrier tape conveying device; the chip product carrying mechanism comprises a suction device and a moving device; and the chip product feeding mechanism comprises a Tray, two Tray stacking devices which are correspondingly arranged front and back, and a Tray transfer device. The equipment is used for carrying out steel sheet carrier tape packaging on the mobile phone camera chip, a mobile phone camera chip product is placed on an insulating carrier tape ofa steel sheet and is protected through the insulating carrier tape, the whole equipment runs in a full-automatic mode, the packaging precision is high, and the working efficiency can be greatly improved.

Owner:苏州美仪自动化设备有限公司

Bag sealing device for packaging granular medicine

InactiveCN110712776AImprove packaging efficiencySave volumeWrapper twisting/gatheringSolid materialPharmacy medicineEngineering

The invention discloses a bag sealing device for packaging granular medicine. The bag sealing device comprises a base, wherein a conveying device is arranged in the base; the conveying device comprises a rotatable conveying belt; a packaging block is fixedly arranged on the upper end surface of the base; a feeding hopper is fixedly arranged on the upper end surface of the packaging block; medicineparticles are placed in the feeding hopper; a flowing groove is formed in the lower end of the feeding hopper in a communicating mode; and a blocking device is arranged on the upper side of the flowing groove. According to the bag sealing device, the granular medicine can be packaged in a fixed weight mode through a constant weight device, moreover, forming and sealing of a packaging bag are synchronously carried out, so that the overall size and the space size of the device are saved, and the device is low in energy consumption and high in medicine packaging efficiency during operation; secondly, side sealing work and a traction device are synchronously carried out, transverse sealing work and cutting-off work are synchronously carried out, so that the forming time of the packaging bag is saved; and in addition, automatic constant weight packaging can be carried out during medicine packaging, and the packaging precision is high.

Owner:宁波鄞州梦绕箱包有限公司

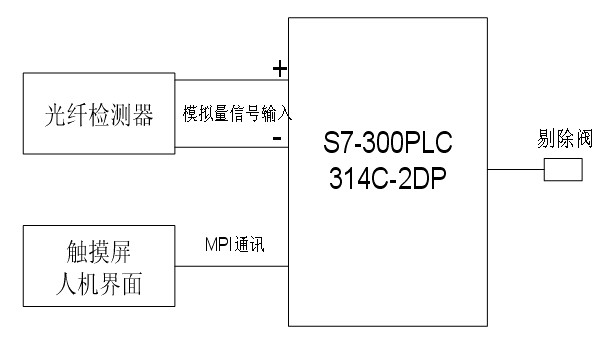

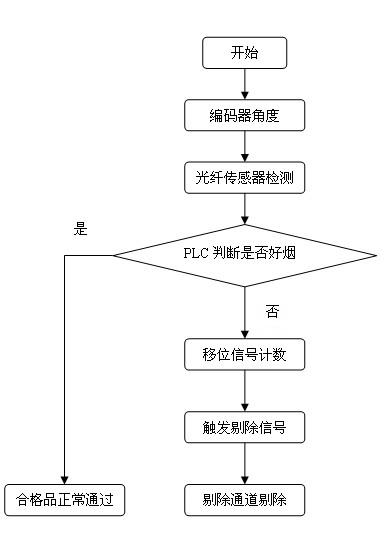

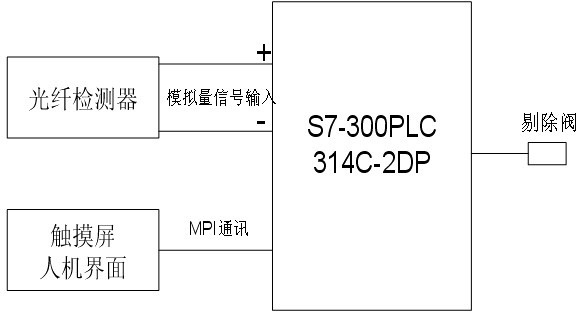

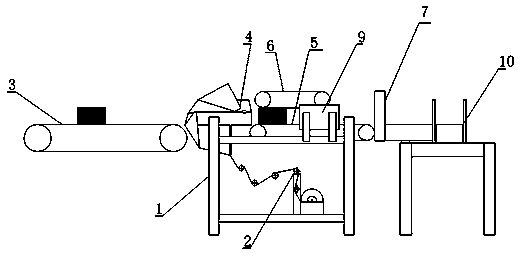

Automatic control device and control method for loose package detection of cigarette box transparent wrapping paper

ActiveCN102275645AImprove packaging accuracyReduce labor intensityPackaging cigarettePackaging cigarsAutomatic controlProgrammable logic controller

The invention relates to a detection automatic control device and a control method for a loose cigarette packet of a transparent package paper for a cigarette box, an optical fiber probe of an optical fiber detector is fixedly installed at a cigarette packet turret outlet of a cigarette box package set, an optical fiber amplifier of the optical fiber detector is fixedly installed at a main wallboard position of the cigarette box package set, the optical fiber detector is connected with a PLC (Programmable Logic Controller) in a remote terminal of the cigarette box package set via a signal connection line, a loose cigarette packet detecting function module is disposed in the PLC, the PLC is connected with a touch screen via an MPI communication input port, and a removing valve is connectedon a PLC output port, the automatic control device and the control method are advantaged by capability of realizing automatic detection of a loose cigarette packet of a transparent package paper for a cigarette box, improving detection speed and accuracy, reaching beneficial effect of improving package precision of transparent paper for a cigarette box, and replacing original manual examination and detection, reduction of manual labor intensity, improvement of working efficiency, and guarantee of production quality.

Owner:CHINA TOBACCO HENAN IND

Soft tissue packaging machine using whole film rolls for packaging

ActiveCN104249825AShorten the timeImprove packaging efficiencyWrappingWell controlBiomedical engineering

The invention discloses a soft tissue packaging machine using whole film rolls for packaging and relates to the technical field of tissue packaging machinery. Materials and packaging films are conveyed at the same time, the materials are packaged with the packaging films during conveying, and accordingly packaging is uninterrupted, and packaging efficiency is improved. In addition, positions of textures and patterns on the packaging films can be well controlled during packaging to enable the textures and the patterns to be packaged at specific positions of the materials, so that packaged tissues can be more attractive to meet daily life demands.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Combustion apparatus

ActiveUS20190186784A1Low costImprove workabilityHeat exhanger finsStationary tubular conduit assembliesCombustorEngineering

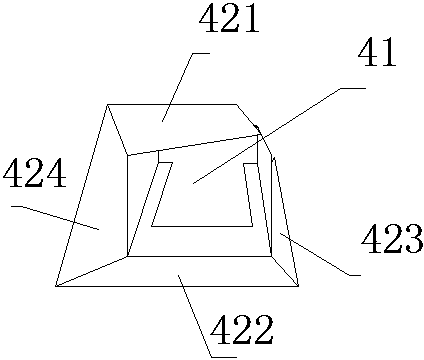

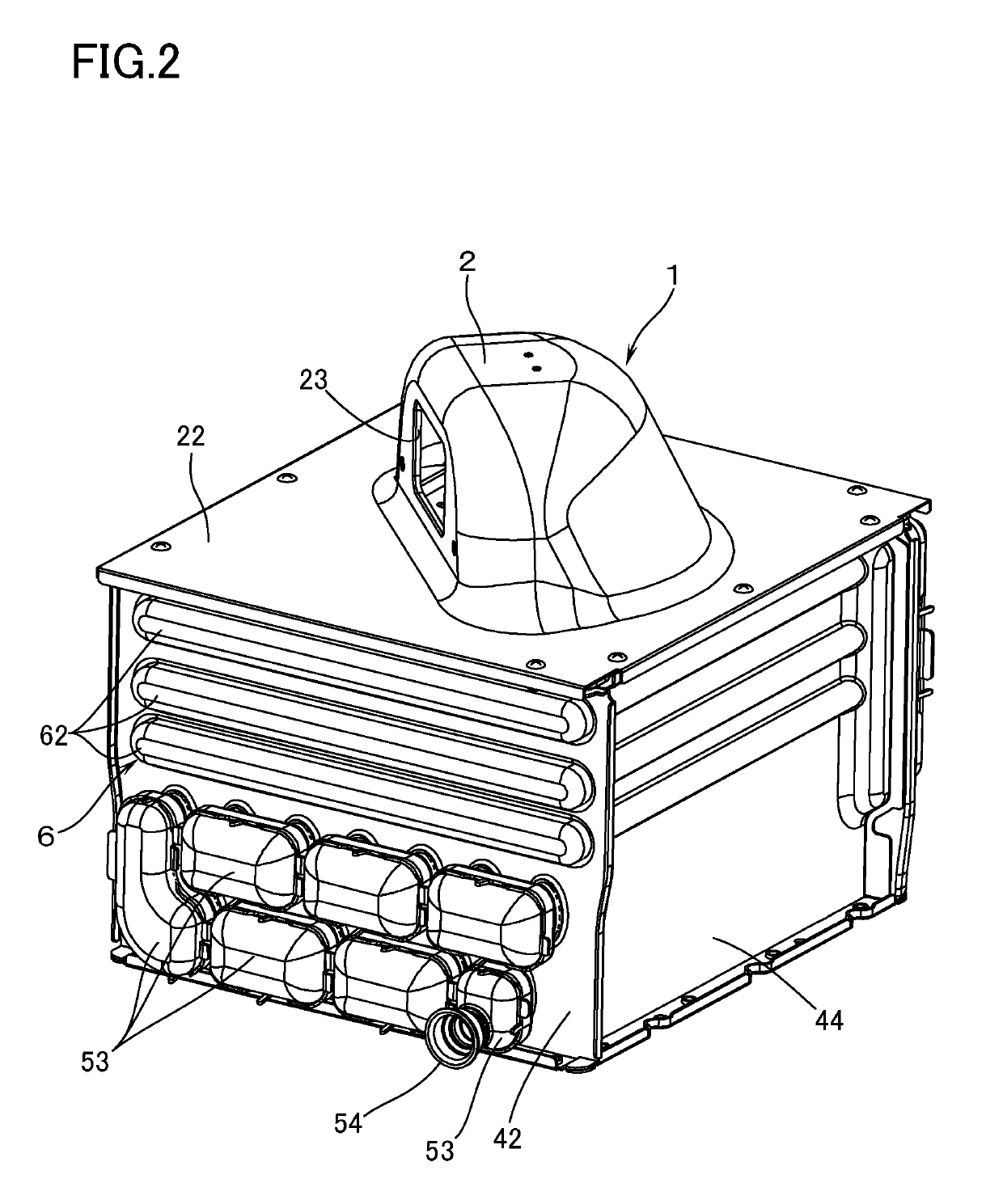

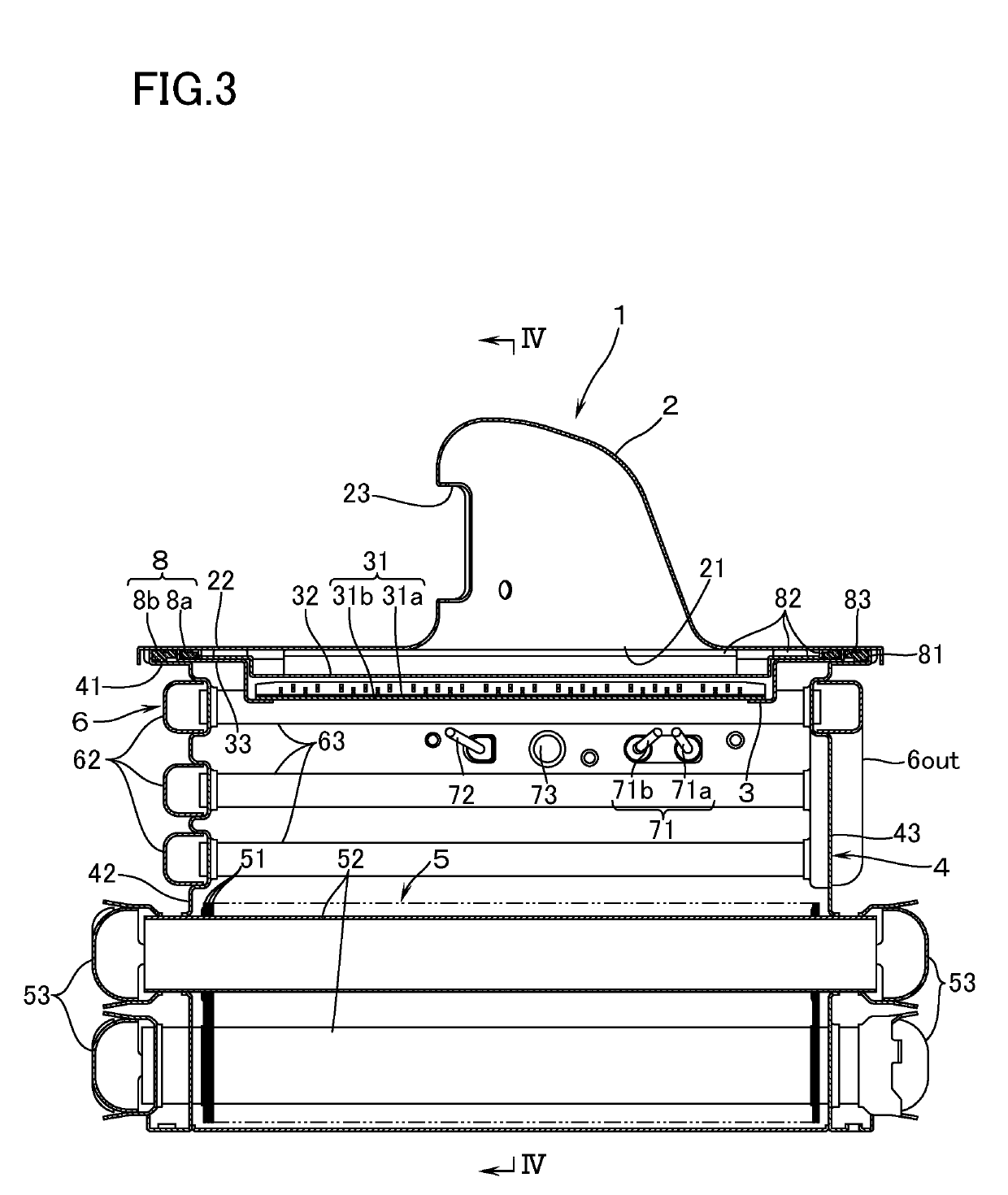

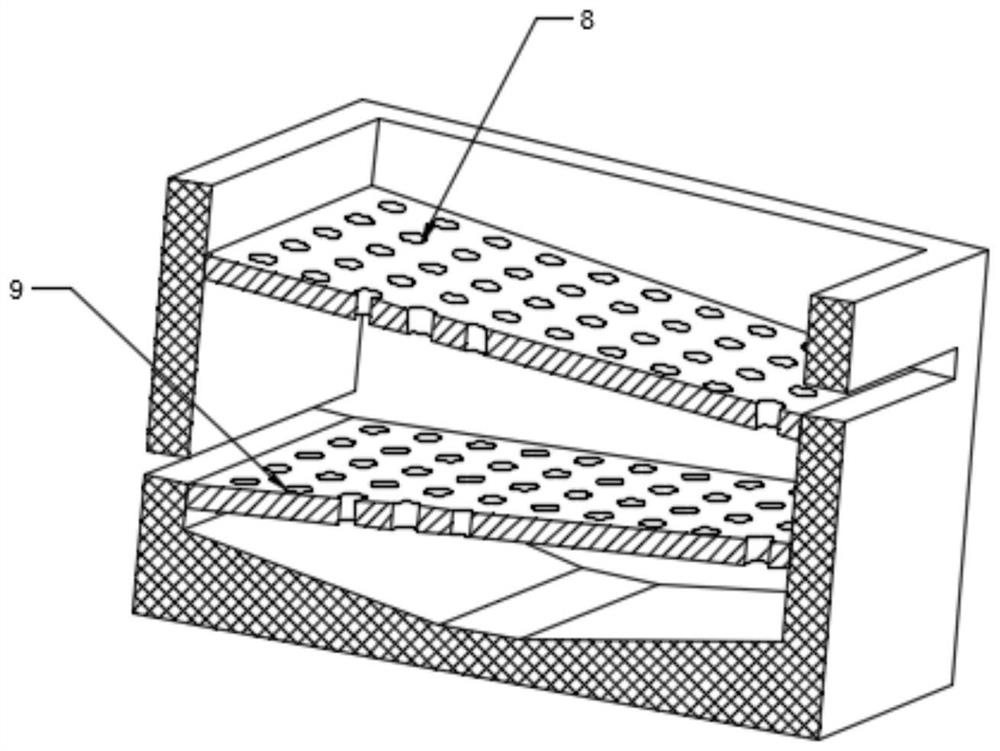

A combustion apparatus has a burner including a burner body and a combustion plate, as well as a combustion box. A combustion plate flange part projects outward beyond an inner rim of a body flange part and beyond an inner rim of a combustion box flange part. The combustion box has, on a perimeter of one end, the combustion box flange part, adapted to be connected to the body flange part enclosing an open surface of the burner body. The combustion plate is provided with an inside projection which is erected, by bending, toward the body flange part so as to face the inner rim of the packing such that, in a state in which the combustion box flange part is connected to the body flange part, the outside projection and the inside projection are in contact with the body flange part.

Owner:RINNAI CORP

Traditional Chinese medicine decoction piece screening and packaging equipment and method thereof

InactiveCN112156970AImprove accuracy and packaging efficiencyImprove packaging efficiencySievingScreeningElectric machineryDrive motor

Owner:广东龙晟制药有限公司

Cooling and drying device for biomass briquette fuel and method thereof

InactiveCN105423730ARapid temperature dropIncrease productivityDrying gas arrangementsDrying machines with progressive movementsBiomassEngineering

The invention discloses a cooling and drying device for biomass briquette fuel and a method thereof, and belongs to the field of energy technicalization. The cooling and drying device comprises a box body and a material conveyor arranged below the box body. Holes are formed in a conveyer belt of the material conveyor. An input opening and an output opening are formed in the two ends of the box body. The box body is separated into at least two cooling and drying chambers through partition plates. The upper portions of the cooling and drying chambers are communicated through an air exhausting pipe and an induced draft fan. The method comprises the steps that 1, the fuel is conveyed into a first cooling and drying chamber through the material conveyor, drying air enters the first cooling and drying chamber from the lower portion of a fuel bed, and after the drying air penetrates through the fuel bed, the drying air is exhausted out through the upper portion of the fuel bed; and 2, the primary cooled fuel is conveyed into a second cooling and drying chamber, fuel of which the temperature is close to the room temperature is obtained, and finally the fuel is packed. According to the cooling and drying device for the biomass briquette fuel, the structure is simple and practical; relative movement between the fuel is avoided in the conveying process of the fuel, and thus the broken rate of the fuel is reduced; the drying rate of the fuel can be adjusted according to the actual operational needs, so that energy consumption is reduced; the device is especially suitable for lower-density biomass briquette fuel with the diameter being greater than 20 mm.

Owner:深圳市燕化石油有限公司 +2

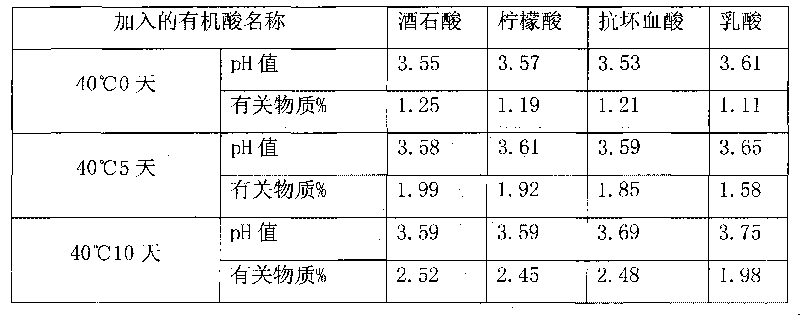

Medicine composition containing docetaxel and preparation method thereof

InactiveCN101708177AShort dissolution and dispersion timeThe main drug is stableOrganic active ingredientsPharmaceutical non-active ingredientsAlcoholDocetaxel

The invention relates to a medicine composition containing docetaxel and a preparation method thereof. The medicine composition is characterized by comprising the following components according to the mixture ratio (in parts by weight): 10-100 parts of docetaxel, 260-2600 parts of polysorbate 80, 1-20 parts of stabilizing agent and 0-11 parts of anhydrous alcohol; The preparation method comprises the following steps: (1) adding the stabilizing agent which regulates the pH into the polysorbate 80, dispersing, dissolving and adding medicinal carbon for refining the polysorbate 80; (2) taking part of the refined polysorbate 80, adding the docetaxel and the anhydrous alcohol, dissolving the medicine by the dissolution-aiding means of ultrasonic, stirring and the like and stirring the mixture evenly; (3) after removing the anhydrous alcohol, adding the remanent refined polysorbate 80, stirring and mixing the mixture evenly; and (4) after sterilizing and filtering, filling the obtained solution into a sterile container by filling equipment.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

Dead weight type double scale wet ammonium packaging machine and packaging process

InactiveCN102424123AImprove packaging accuracyGuaranteed speed and precisionSolid materialWater contentEngineering

The invention provides a dead weight type double scale wet ammonium packaging machine, comprising a feeding mechanism, a weighing mechanism, a blanking mechanism, a bag sewing mechanism, a transmission mechanism and a main control box. The feeding mechanism comprises a feeding bin, a stirring motor as well as a big auger and a small auger; the weighing mechanism comprises a scale body and a scale body cylinder; a sensor is arranged between the weighing mechanism and the feeding mechanism; and the blanking mechanism comprises a blanking hopper, the blanking hopper is provided with an air vibration device to prevent material from being bonded on the weighing mechanism and the blanking hopper. The invention also provides a wet ammonia packaging process. By adopting the wet ammonia packaging equipment and packaging process provided by the invention, the problems that wet ammonia is easy to be bonded on the inner wall of a scale bucket in an actual packaging process as moisture content of material is high, flowability is poor and corrosivity is strong and a wet ammonia material can be easily adhered on bin wall after the wet ammonia material enters into a container, especially the wet ammonia material is bonded at a dead angle and blanking can not be normal can be solved, and the technological problem that automatic quantitative packaging can not be realized on wet ammonia is solved.

Owner:周海南

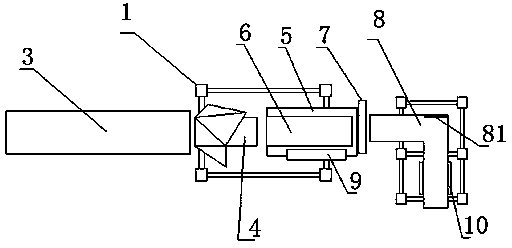

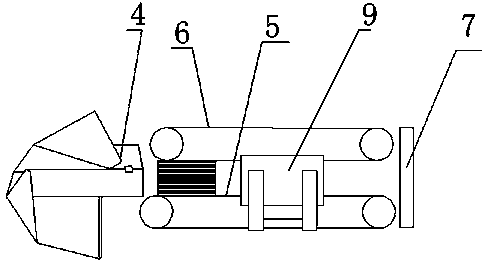

Semi-finished product forming structure applicable to roll paper packaging machine

InactiveCN104210703AImprove accuracySave packing timePaper article packagingWrapping material feeding apparatusRolling paperPaper towel

The invention provides a semi-finished product forming structure applicable to a roll paper packaging machine, and relates to the technical field of tissue packaging machinery. According to the semi-finished product forming structure provided by the invention, a conveyed packaging film covers a conveyed material to form a columnar packaging bag with a side opening in the packaging bag, and then the side opening of the columnar packaging bag is thermally sealed, and finally a semi-finished packaging bag with openings in the two ends of the same are formed by cutting off the columnar packaging bag. According to the semi-finished product forming structure provided by the invention, the material is packaged by the entire roll of film, therefore the packaging efficiency can be improved; furthermore, in the process of packaging, the positions of figures and patterns on the packaging film can be controlled well to package the figures and patterns on the special positions of the material, therefore the packaged tissue is more beautiful, and the daily demands of living of people can be met.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Spiral detecting machine

The invention discloses a spiral detecting machine. The spiral detecting machine comprises a feeding mechanism, a spiral detecting mechanism, a discharging mechanism and multipurpose mechanical arm mechanisms arranged on the upper portions of the mechanisms. The feeding mechanism comprises a feeding slope and a rotating device, the feeding slope and the rotating device are provided with a sliding material slope, a feeding pushing hand is arranged at the lowest inclined downward position of the feeding slope, the feeding pushing hand can push materials to the sliding material slope from the feeding slope, the rotating device is arranged at the lowest inclined downward position of the sliding material slope, the spiral detecting mechanism is arranged at one end of the feeding mechanism, and the discharging mechanism is arranged on one side of the spiral detecting mechanism. Materials are automatically fed one by one from the feeding mechanism, the rotating device is arranged on the feeding mechanism and carries out automatic rotary positioning on materials, the multipurpose mechanical arm mechanisms automatically carry the materials to the spiral detecting mechanism to be automatically detected, after detection is finished, the multipurpose mechanical arm mechanisms automatically put the materials into the discharging mechanism, and the discharging mechanism carries out split packaging on the materials according to the detection result.

Owner:南京三智视觉科技有限公司

Non-intermittent motion three-dimensional packaging machine

PendingCN108216732AStable Transition Package StructureImprove packaging accuracyWrappingIntermittent motionActive force

The invention discloses a non-intermittent motion three-dimensional packaging machine. The non-intermittent motion three-dimensional packaging machine comprises a packaging device, and the packaging device is connected with a feeding device and a discharge device; the packaging device comprises an upward moving channel and a lateral moving channel; an upward pushing mechanism is arranged at the lower end of the upward moving channel; the upper end of the upward moving channel is connected with the lateral moving channel; a lateral pushing mechanism is arranged at one end of the lateral movingchannel; a paper supporting mechanism is arranged next to the lateral pushing mechanism; and an upward pressing chute and a downward pressing chute are formed in the two side walls of the lateral moving channel separately. According to the non-intermittent motion three-dimensional packaging machine, packaging of an entire material is achieved by controlling motion of the to-be-packaged material inall directions, packaging of different stages can be carried out on multiple materials at the same time, and packaging efficiency is improved; the entire packaging machine is in a continuous motion mode, so that the acceleration, deceleration and waiting time of the machine during intermittent motion is shortened; and besides, the entire machine can achieve multi-dimensional action through one active force, packaging precision is improved, and packaging cost is greatly reduced.

Owner:QUANSTAR PRECISION MACHINERY SHANGHAI

Plate packaging machine for pole plates of lead-acid batteries

InactiveCN104091970AEliminate pollutionIncrease productivityFinal product manufactureLead-acid accumulators constructionGlass fiberLead–acid battery

The invention belongs to the technical field of packaging equipment of battery pole plates and particularly relates to a plate packaging machine for pole plates of lead-acid batteries. The plate packaging machine comprises a glass-fiber feeding mechanism, a PE (Polyethylene) partitioning-plate feeding mechanism, a glass-fiber feeding platform, a PE partitioning-plate feeding platform, a working platform, a plate feeding mechanism, a belt cutting machine head, a plate receiving mechanism and a motor, wherein the glass-fiber feeding mechanism and the PE partitioning-plate feeding mechanism are arranged at the right side of the working platform; the positions under the glass-fiber feeding mechanism and the PE partitioning-plate feeding mechanism are respectively provided with a photoelectric switch; the glass-fiber feeding platform is arranged under the PE partitioning-plate feeding platform; the plate feeding mechanism is arranged at the rear side of the working platform; the belt cutting machine head consists of a belt cutting mechanism, a folding mechanism and a laminating mechanism which are arranged on the working platform in sequence; the plate receiving platform is arranged at the left side of the working platform; the belt cutting mechanism comprises a cut-off shaft and a belt cutting shaft group; the belt cutting shaft group is provided with a cutting knife and a mark pressing knife; the motor is arranged under the working platform. The plate packaging machine has the advantages that the packaging accuracy is high, and the procedure and the cost for using glue solution to bond PE partitioning plates and glass-fiber partitioning plates are omitted, so that the production efficiency and the benefit of enterprises are improved.

Owner:HUBEI JUNZHENG ELECTROMECHANICAL SCI & TECH CO LTD

Semi-finished product forming structure applicable to handkerchief paper packaging machine

ActiveCN104210702AImprove accuracySave packing timePaper article packagingWrapping material feeding apparatusPaper towelEngineering

The invention provides a semi-finished product forming structure applicable to a handkerchief paper packaging machine, and relates to the technical field of tissue packaging machinery. According to the semi-finished product forming structure provided by the invention, a conveyed packaging film covers a conveyed material to form a columnar packaging bag with a side opening in the packaging bag, and then the side opening of the columnar packaging bag is thermally sealed, and finally a semi-finished packaging bag with openings in the two ends are formed by cutting off the columnar packaging bag. According to the semi-finished product forming structure provided by the invention, the material is packaged by the entire roll of film, therefore the packaging efficiency can be improved; furthermore, in the process of packaging, the positions of figures and patterns on the packaging film can be controlled well to package the figures and patterns on the special positions of the material, therefore the packaged tissue is more beautiful, and the daily demands of living of people can be met.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Automatic packaging equipment for disposable set tableware

InactiveCN111824495AImprove packaging accuracyImprove fitWrappers shrinkagePackaging by pressurising/gasifyingStructural engineeringMechanical engineering

The invention belongs to the technical field of packaging equipment, and particularly discloses automatic packaging equipment for disposable set tableware. The automatic packaging equipment comprisesa rack; a conveying belt for conveying tableware is arranged on the rack; a first unwinding roller and a first guiding roller are rotatably connected to one side of the rack through a bracket, and thefirst unwinding roller is matched with the first guiding roller for releasing an upper cover film; a second unwinding roller and a second guiding roller which are used for releasing a lower cover film is arranged below the first unwinding roller; a cutting roller is rotatably connected to the middle of the rack through a pair of brackets, a group of grooves are uniformly formed in the periphery of the cutting roller, and heating rings are arranged on the edges of the grooves; a hot air bin for heating the upper cover film and the lower cover film is arranged on the side, away from the first unwinding roller, of the rack; and an exhaust pipe is fixedly connected between the first unwinding roller and the second unwinding roller through a bracket, and the exhaust pipe communicates with an exhaust fan through a pipeline. According to the automatic packaging equipment, air exhausting is conducted between the upper cover film and the lower cover film through the exhaust pipe, the fitting degree of a packaging film and the tableware is further increased, and the packaging quality of the tableware is improved.

Owner:安徽新多旺智能包装科技有限公司

Automatic bagging machine

InactiveCN111942665AGood transmission accuracyGood transmission effectPackagingProcess engineeringIndustrial engineering

The invention provides an automatic bagging machine. The machine comprises a product feeding mechanism, a product lifting mechanism, a pushing mechanism, a bagging mechanism, a bag sleeving mechanism,a bag distributing and conveying mechanism and a discharging mechanism. According to the overall structural design of the machine, products can be automatically conveyed, positioned and lifted; a series of operations such as distributing, code spraying, detecting, limiting pressing, sleeving of packaging bags after bag distribution on the periphery of a bag opening palm in the bagging mechanism,loading of the products into the packaging bags, and pushing and discharging of the packaging bags loaded with the products can be automatically carried out; the automatic bagging machine has the advantages of being capable of reducing labor intensity of workers and labor cost of enterprises, high in packing efficiency, high in packing precision and good in packing effect; and the problems of poorpackaging effect, low packaging efficiency, low packaging precision, high labor intensity of workers and high labor cost of enterprises due to the fact that products are packaged in a traditional manual operation mode are effectively solved.

Owner:东莞市欧立包装设备有限公司

A kind of soft pumping paper packaging machine with whole roll film packaging

ActiveCN104249825BShorten the timeImprove packaging efficiencyWrappingBiomedical engineeringWell control

The invention discloses a soft-pumping paper packaging machine that adopts full roll film packaging, and relates to the technical field of paper towel packaging machines. The present invention transports the material and the packaging film at the same time, and the packaging film packs the material while conveying, the packaging process is uninterrupted, and the packaging efficiency is improved; and the present invention can well control the patterns and patterns on the packaging film during the packaging process The location makes the patterns and patterns packaged at the specific position of the material, making the packaged tissue more aesthetically pleasing and meeting people's daily needs.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

A handkerchief paper packaging machine with whole roll film packaging

ActiveCN104210686BShorten the timeImprove packaging efficiencyWrappingPaper towelPulp and paper industry

The invention discloses a paper towel packaging machine adopting whole-roll film packaging and relates to the technical field of paper towel packager machinery. According to the packaging machine, a material and a packaging film are conveyed simultaneously, the material is packaged by the packaging film while being conveyed, and the packaging process is uninterrupted, so that the packaging efficiency is increased; during packaging, locations of grains and patterns on the packaging film can be excellently controlled, so that the grains and the patterns are packaged to specific locations of the material, and packaged paper towels are more attractive, thereby meeting the demands of people in daily lives.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Capsule dust removing and bottling device

PendingCN108128501AImprove hygieneEasy to cleanPackaging automatic controlSolid materialEngineeringBottle

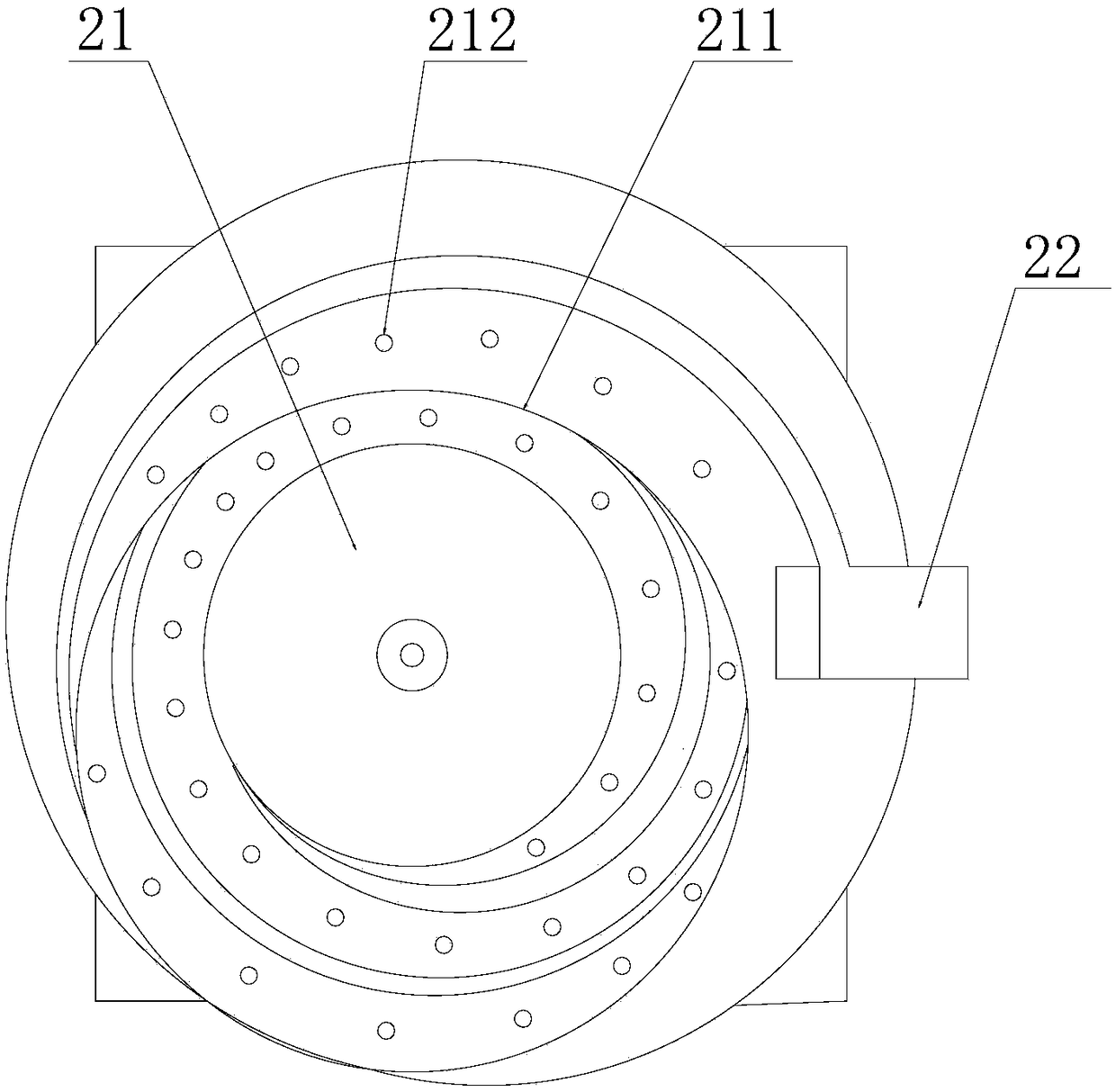

The invention discloses a capsule dust removing and bottling device. The device comprises a base, a dust removing mechanism, a grain counting mechanism, a conveying mechanism and a control mechanism.The dust removing mechanism comprises a vibration disc and a feeding plate, dust removing holes are formed in the disc wall of the vibration disc, the vibration disc is connected to the feeding plate,and the vibration disc and the feeding plate cooperate with each other to transport capsules to the grain counting mechanism. The grain counting mechanism comprises a feeding funnel, a filter cylinder and a discharging plate, the feeding funnel and the filter cylinder cooperate with each other, and the discharging plate is arranged below the feeding funnel. The conveying mechanism is arranged below the grain counting mechanism and provided with a plurality of capsule bottles. Through mutual cooperation of the dust removing mechanism, the grain counting mechanism and the conveying mechanism, the dust removing operation, gain counting operation and bottling operations of the capsules are automatically completed. According to the device, the working efficiency is improved, the production cost is reduced at the same time, the labor intensity of workers is greatly reduced, hygiene and cleanliness of the capsules are ensured, secondary pollution of the capsules in manual operation is avoided, and the bottling accuracy is improved.

Owner:潘金槐

Rear suspension line lower adjusting tool structure

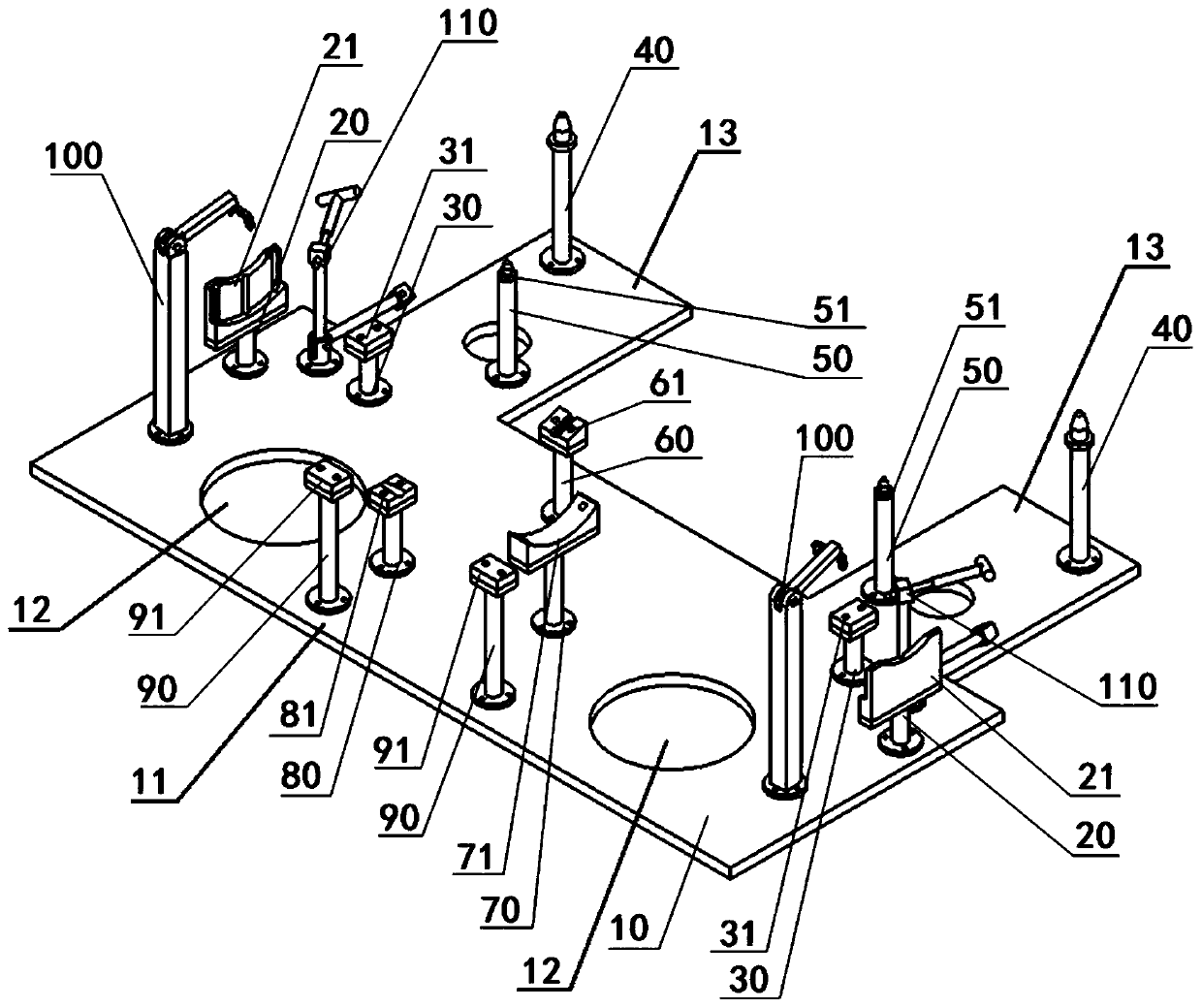

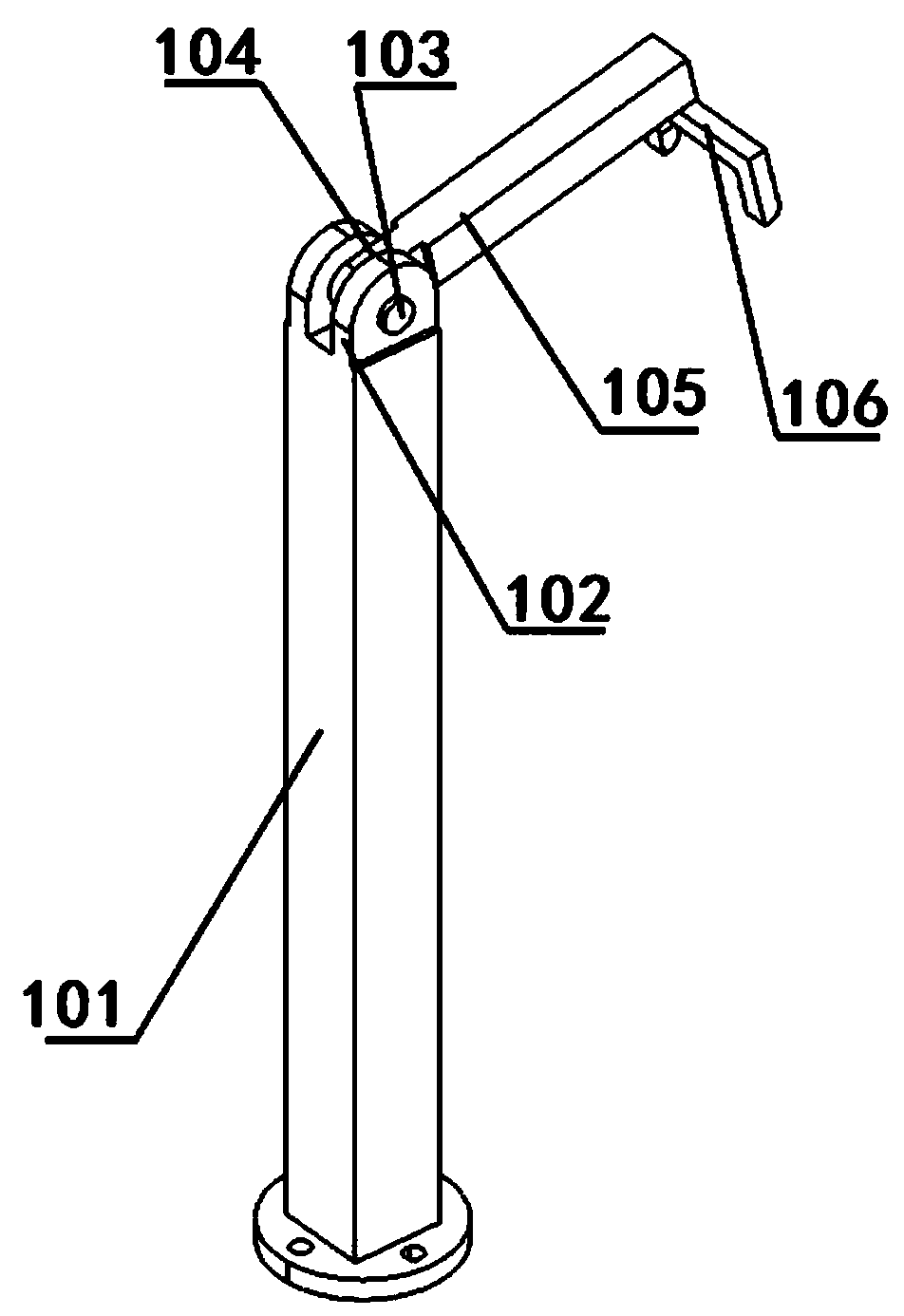

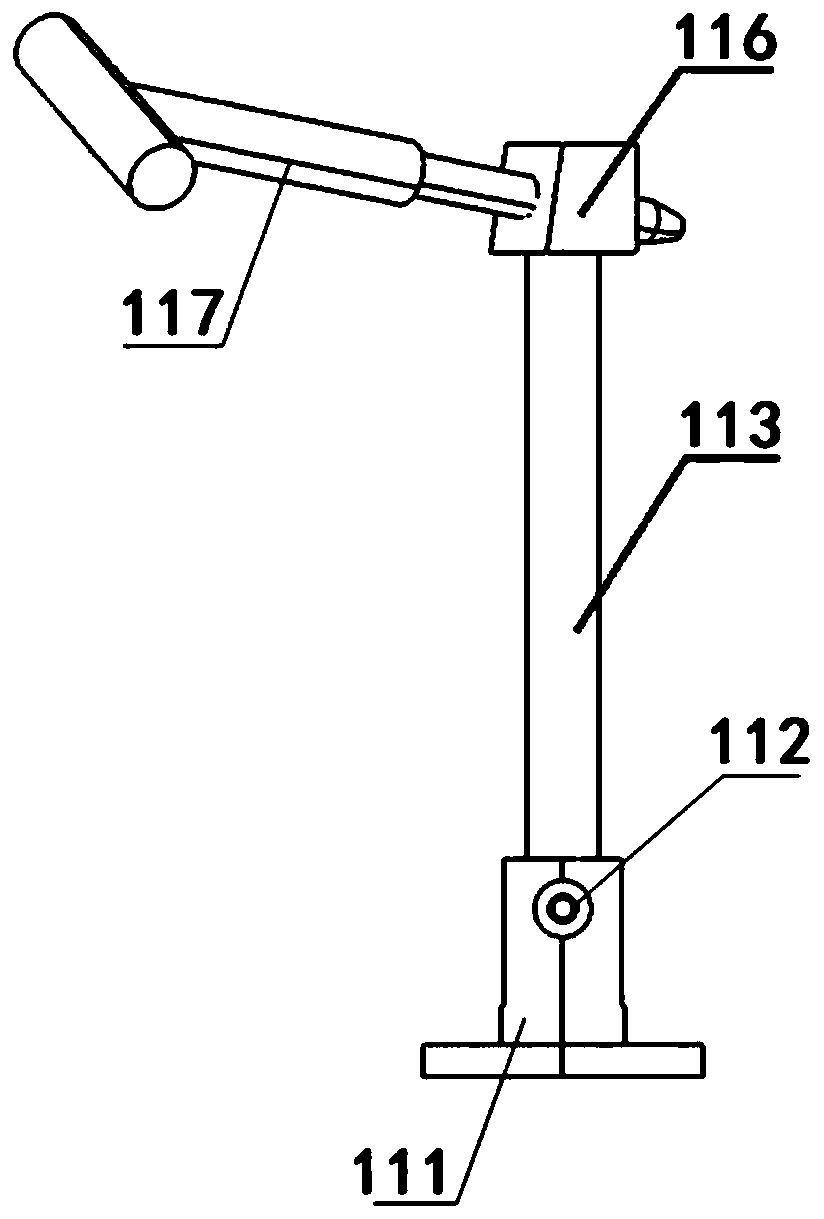

PendingCN111422282ARealize offline adjustmentImprove packaging accuracyVehiclesCamber angleVehicle frame

The invention relates to a rear suspension line lower adjusting tool structure, which belongs to the technical field of automobile production and manufacturing. The rear suspension line lower adjusting tool structure comprises a rear auxiliary frame positioning pin structure, a rear auxiliary frame auxiliary supporting structure, a rear brake disc supporting structure, a swing arm supporting structure, a swing arm supporting structure, a motor supporting structure, a rear wheel toe-in positioning structure, a rear wheel camber angle positioning structure and a vehicle body assembling positioning structure which are arranged on a base plate. The rear suspension line lower adjusting tool structure is a tool structure integrating rear suspension sub-assembly, rear suspension combined assemblyand rear suspension adjustment, what is guaranteed is that the camber angle and toe-in of the rear wheel are consistent with the design state and are assembled in place at a time by designing a positioning structure on the tool, and the procedure of adjusting the camber angle and toe-in of the rear wheel on a detection line is omitted.

Owner:IAT AUTOMOBILE TECH

High-precision low-damage automatic filling machine

PendingCN109625357AHigh filling accuracyImprove packaging accuracySolid materialEngineeringMechanical construction

The invention relates to the field of mechanical structures, in particular to a high-precision low-damage automatic filling machine. The high-precision low-damage automatic filling machine comprises afeeding module, a material distribution module, a detecting module, a recovering module and a packaging module which are mounted in sequence, wherein the detecting module is used for detecting whether materials are qualified or not, the recovering module is used for recovering the unqualified materials, and the packaging module is used for packaging the qualified materials; and the high-precisionlow-damage automatic filling machine further comprises a controller used for controlling the whole work progress of the automatic filling machine. According to the high-precision low-damage automaticfilling machine, by arranging the feeding module, the material distribution module, the detecting module, the recovering module for recovering the unqualified materials, the packaging module and thecontroller, the filling precision is high, operation is convenient, material processing damage is small, and safety and reliability are high.

Owner:SOUTH CHINA AGRI UNIV

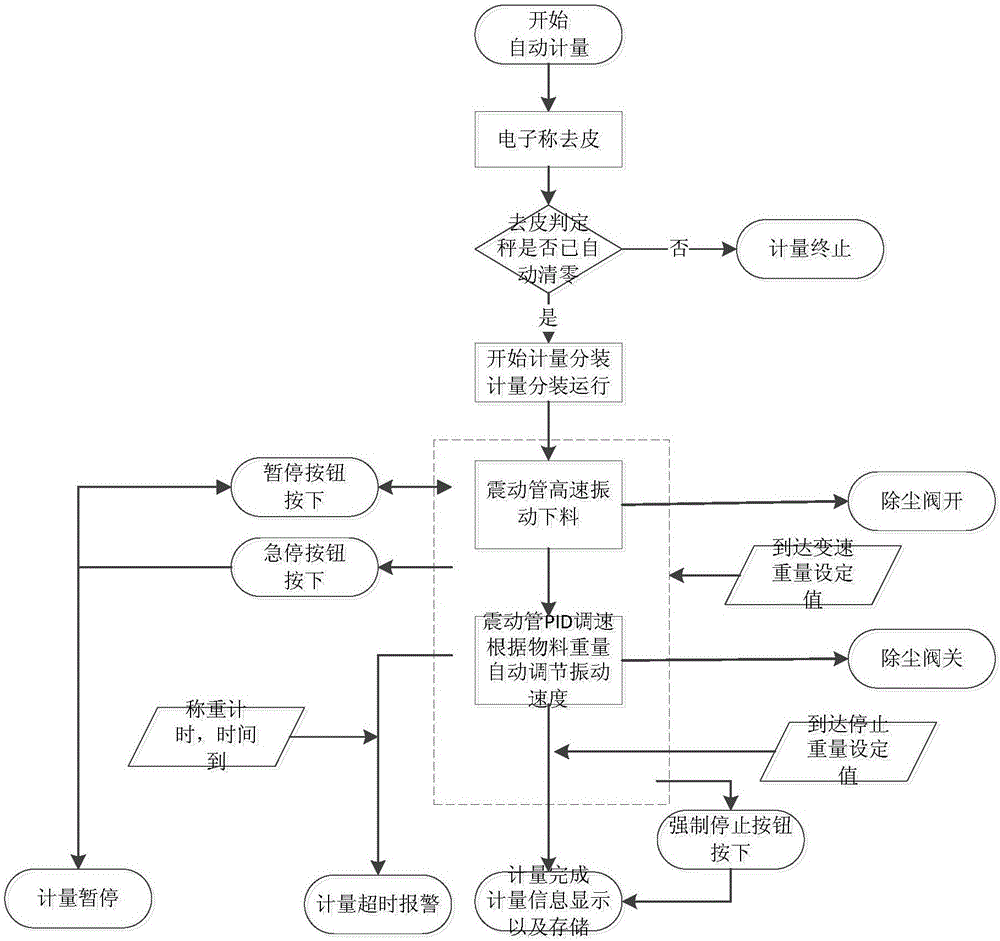

Automatic powder control subpackaging device and method

InactiveCN106240857AReal-time acquisitionRealize automatic dispensing controlSolid materialAutomatic train controlAutomatic control

The invention discloses an automatic powder control subpackaging device and method and relates to the technical field of powder subpackaging. With adoption of the automatic powder control subpackaging device and method, real-time acquisition of feeding amount is realized, and the feeding speed is controlled in real time according to the feeding amount, so that automatic subpackaging control of a material is realized, manual operation is avoided, manual participation and labor cost are reduced, and subpackaging precision is improved; in addition, the entire subpackaging process can be finished in a sealed equipment system without being exposed to the environment, so that the sterile requirement to the environment is lowered, and the sterile treatment cost is also greatly reduced; and moreover, dust drug is prevented from leaking in quantity and is prevented from causing greater harm to a human body.

Owner:北京诚益通科技有限公司

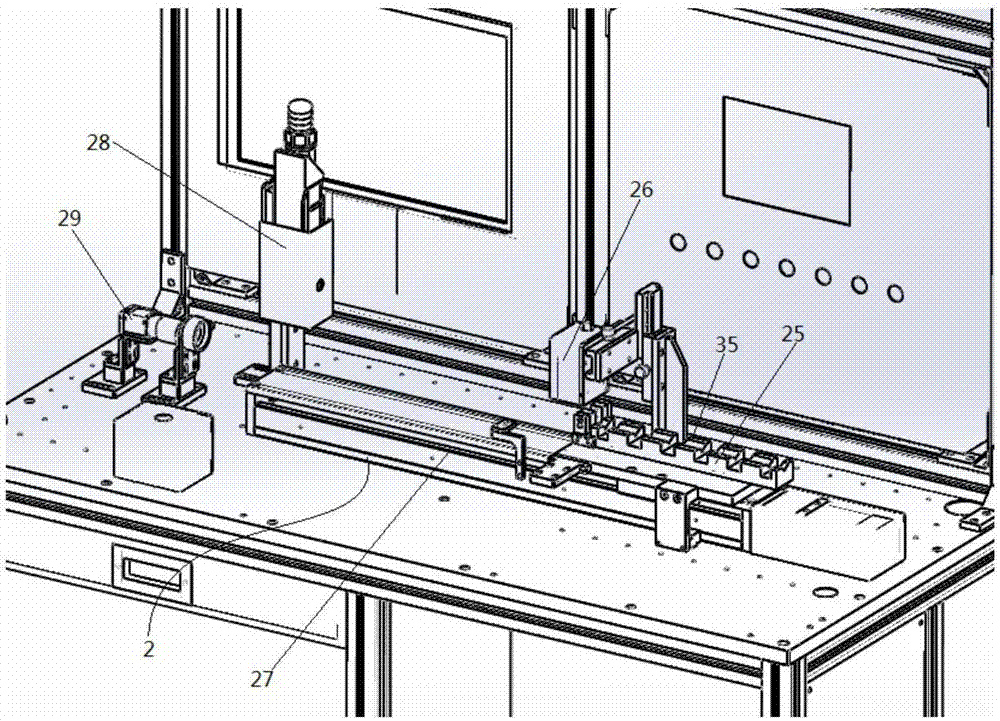

Automatic dispensing system and dispensing method for radioisotope medicine liquid capsules

ActiveCN107744468BFully automatedRealize flexible productionCapsule deliveryProcess engineeringPower apparatus

The invention relates to an automatic packaging system and automatic packaging method for radioisotope medicine liquid capsules. The system includes a support platform and a shielded thermal chamber installed on the support platform; a dispensing platform is provided in the thermal chamber, and a robot, dispensing device, and pre-filled capsule tray assembly are installed on the dispensing platform, and are connected to the dispensing device through a power unit The mother liquid circulation device; the robot, the dispensing device and the power unit are all connected to the controller, and the controller controls the above-mentioned components to move according to the liquid medicine and the patient's condition to realize the automatic quantitative dispensing of the medicine liquid capsule. The invention has high degree of automation, high production efficiency, high packaging precision, simple operation, and good shielding performance. The automatic packaging system and packaging method of isotope medicinal liquid capsules. At the same time, this set of systems can choose economical mode or high-efficiency mode to meet different needs. It provides users with more choices and has great application value.

Owner:类彦威

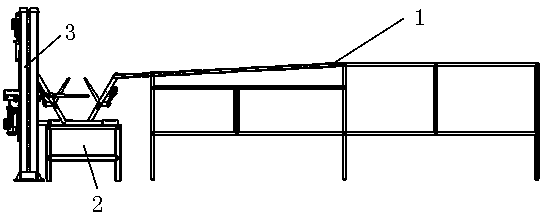

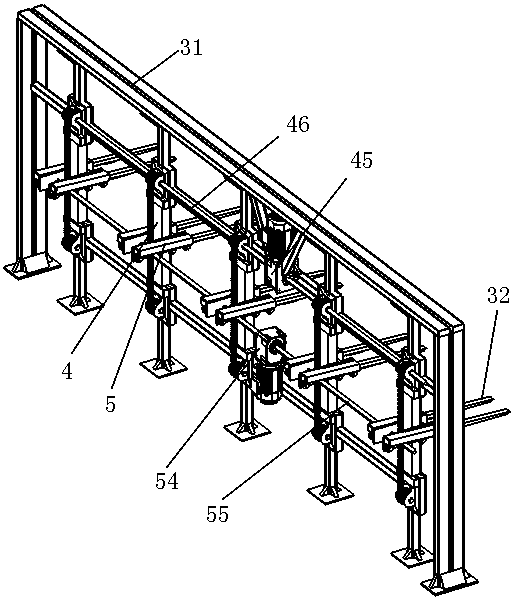

Steel pipe packaging automatic forming equipment

PendingCN109018497AImprove packaging efficiencyImprove packaging accuracyPackagingEngineeringMechanical engineering

The invention relates to the technical field of steel pipe packaging equipment, in particular to steel pipe packaging automatic forming equipment. The steel pipe packaging automatic forming equipmentcomprises a feeding frame, a binding mechanism, a forming mechanism and a PLC, wherein the binding mechanism is arranged at the outlet of the feeding frame, the forming mechanism is arranged on the other side of the binding mechanism, and the PLC is connected with the binding mechanism and the forming mechanism. The forming mechanism comprises a plurality of pairs of supporting fork bodies horizontally arranged on a gantry, wherein a pair of the supporting fork bodies is correspondingly arranged on a supporting fork translation mounting frame; and the gantry is further provided with supportingfork lifting mounting frames, and the supporting fork translation mounting frames are slidably connected with the supporting fork lifting mounting frames. According to the steel pipe packaging automatic forming equipment, steel pipes can be automatically stacked into standard regular hexagons through the bundling mechanism and the forming mechanism, so that time and labor are saved, and the packaging efficiency and the packaging accuracy of the steel pipes are greatly improved.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

High-precision packaging machine capable of predicating overhead feed column mass and compensating feeding delay in real time

ActiveCN105151340AAccurately measure falling speedAccurate packaging accuracySolid materialPackaging automatic controlControl circuitPackaging machine

The invention provides a high-precision packaging machine capable of predicating overhead feed column mass and compensating feeding delay in real time. The high-precision packaging machine comprises a sealing mechanism, a SMART700-IE touch screen, a former regulating mechanism, an unloading hopper, a film drawing mechanism, a weighing mechanism, a feeding and executing mechanism, a servo motor, a frequency converter, a PLC control circuit system, an upper computer and the like, wherein the sealing mechanism is arranged on the lower part of the former regulating mechanism; the SMART700-IE touch screen is arranged at the side of the former regulating mechanism; the film-drawing mechanism is arranged on the upper part of the former regulating mechanism; a PLC control case is arranged at the side of the sealing mechanism. The high-precision packaging machine can predicate packaging quality and packaging precision in real time, budgets out amount of materials which are finally dropped into a bag at different moments, finds out the optimal cutting-off and feeding moment, and accurately measures material mass, material dropping speed and material precision. The high-precision packaging machine is high in packaging precision, high in working efficiency, accurate in weighing and high in practicability, and saves labor power.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com