Spiral detecting machine

A detection machine and detection mechanism technology, which is applied in the field of detection machines, can solve problems such as large differences in detection reference points, large detection error deviations, and backward detection methods, and achieve the effects of fast rotation speed, reduced errors, and stable push effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

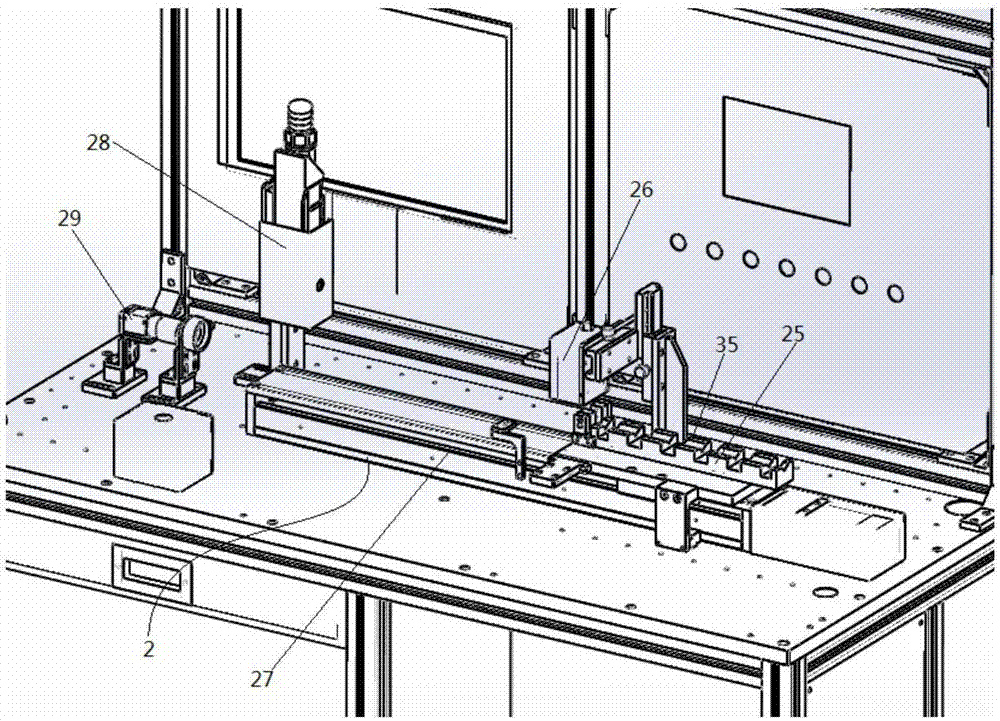

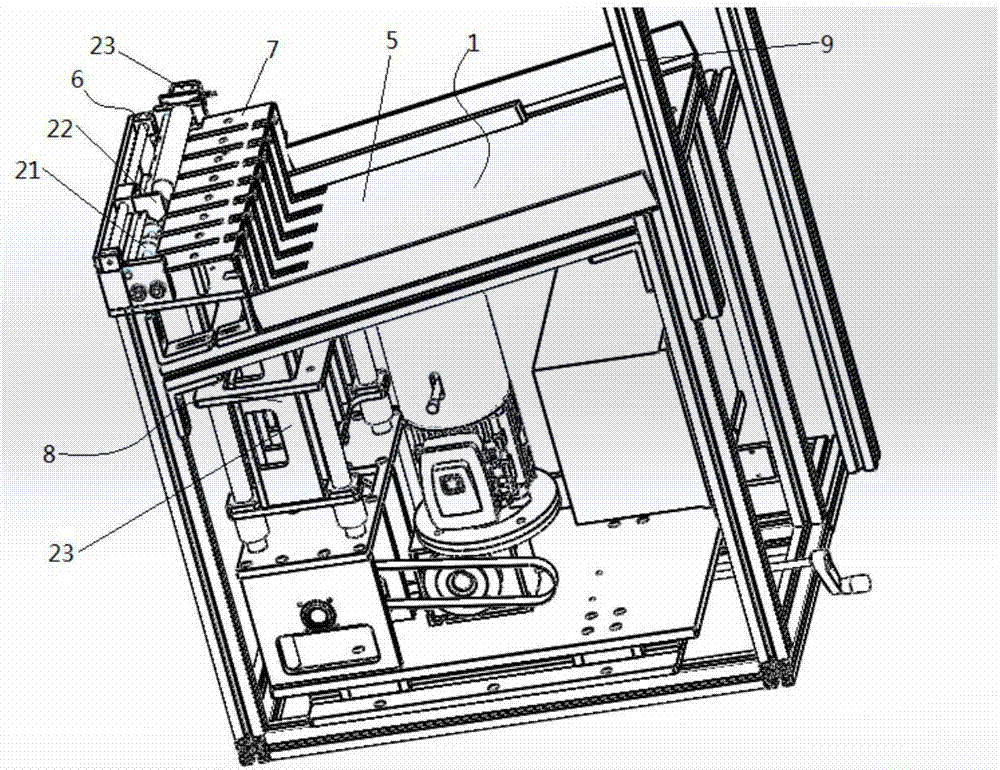

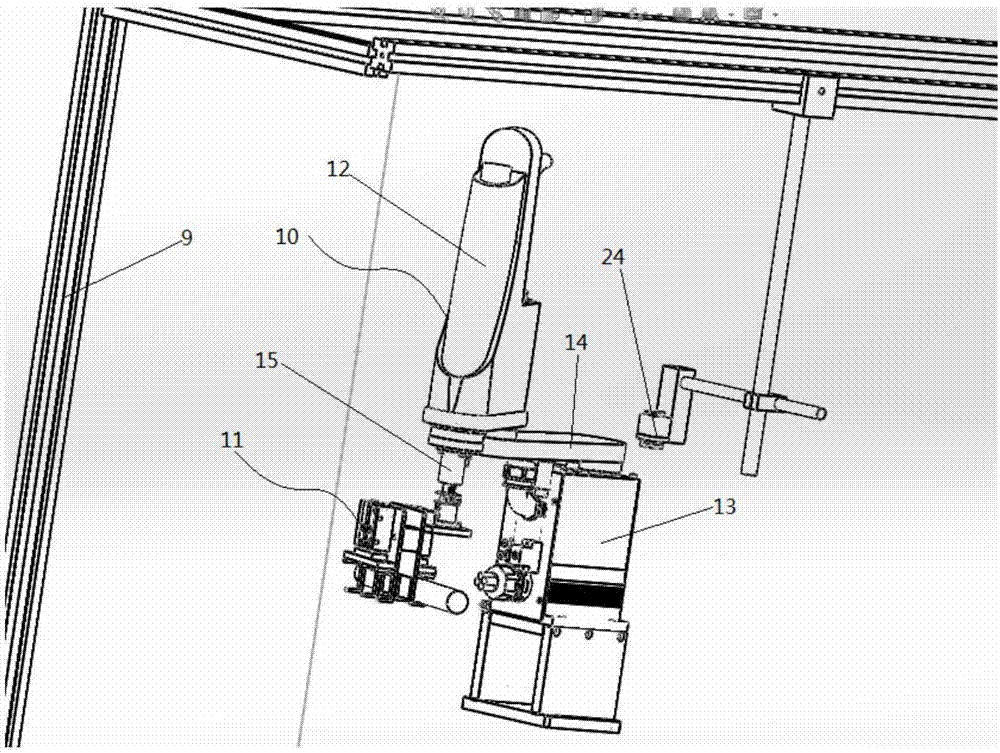

[0031] Such as Figure 1-5As shown, a screw detection machine is disclosed in this embodiment, which includes a feeding mechanism 1, a screw detection mechanism 2, a feeding mechanism 3 and a multi-purpose manipulator mechanism 4 arranged on the top of each mechanism. The feeding mechanism 1 includes a feeding slope 5 and the rotating device 6, the feeding slope 5 and the rotating device 6 are provided with a sliding material slope 7, the feeding slope 5 and the sliding material slope 7 are all inclined towards the rotation device 6, and the height of the feeding slope 5 is lower than the sliding material slope The height of 7, the lowermost part of the feeding slope 5 is provided with a feeding pusher 8, and the feeding pusher 8 can push the material from the feeding slope 5 onto the sliding material slope 7, and the sliding material slope 7 is inclined downward at the lowest point. Rotating device 6; one end of the feeding mechanism 1 is provided with a spiral detection mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com