Non-intermittent motion three-dimensional packaging machine

A three-dimensional packaging, non-intermittent technology, applied in the directions of transportation and packaging, packaging, packaging/bundling items, etc., can solve the problems of slow packaging speed and poor packaging accuracy of three-dimensional packaging machines, to improve efficiency, improve packaging accuracy, and improve packaging. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

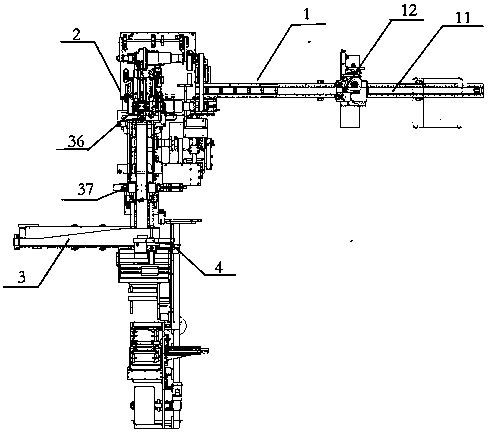

[0026] Such as figure 1 and figure 2 As shown, a non-intermittent motion three-dimensional packaging machine includes a feeding device 1, a packaging device 2 and a discharging device 3, the packaging device 2 is connected to the feeding device 1 and the discharging device 3 respectively, and the feeding device 1 includes a first incoming conveyor belt 11 and the first equidistant distribution device 12 located at one end of the first incoming material conveyor belt 11, the first incoming material conveyor belt 11 is connected to the packaging device 2, and the connection between the packaging device 2 and the discharging device 3 is provided with a material pulling device 4 .

[0027] The packaging device 2 comprises an upward movement channel 21 and a lateral movement channel 31. The lower end of the upward movement channel 21 is provided with a push-up mechanism 22, and between the upward push mechanism 23 and the upward movement channel 21, a paper feeding gap 23 is arra...

Embodiment 2

[0032] The general structure of embodiment 2 and embodiment 1 is the same, and its difference is, as Figure 4 As shown, the feeding device 1 includes a second incoming material conveyor belt 13, a second equidistant material distribution device 14, a synchronous pushing device 15 and a stacking device 16, and the second equidistant material distribution device 14 is located on the second incoming material conveyor belt 13 At one end, the synchronous pushing device 15 is respectively connected to the equidistant material distribution device 14 and the stacking device 16 , and the stacking device 16 is connected to the packaging device 2 .

[0033] The non-intermittent motion three-dimensional packaging machine of this embodiment is suitable for packaging two or more pieces of soap.

[0034] The second equidistant dispensing device 14 adjusts the distance between every two adjacent soaps to be consistent, and the soap is divided into equidistant upper and lower columns through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com