Semi-automatic fruit packaging machine

A semi-automatic, packaging machine technology, applied in the mechanical field of packaging objects or materials, can solve the problems of troublesome operation of the net sleeve, increase the difficulty of manual operation, and cumbersome process, and achieve the effect of solving low efficiency, improving packaging efficiency and packaging accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

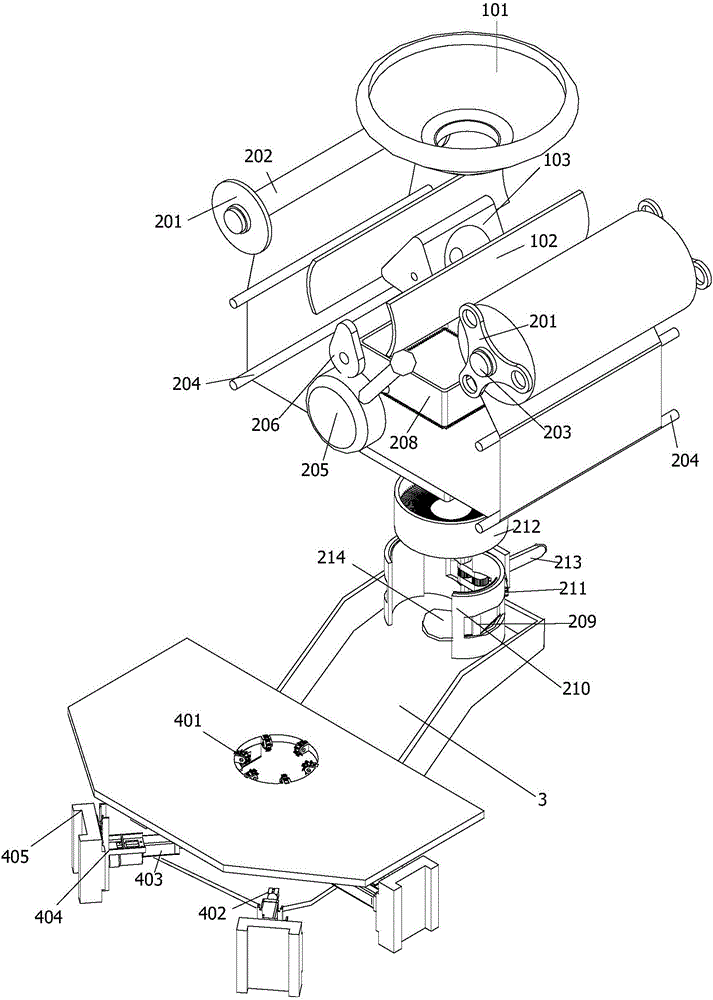

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] As shown in Figures 1 and 2, this embodiment provides a semi-automatic fruit packaging machine, including a frame on which a fruit conveying device 1, a paper wrapping device 2, a connecting slideway 3, and a sleeve are arranged along the fruit packaging path. Net packing device 4, control device. The wrapping device 2 includes a paper feeding mechanism, a paper cutting mechanism, and a clamping and kink mechanism. The wrapping device 4 includes a mesh wrapping mechanism, a mesh stretching mechanism, and a mesh cutting mechanism. The conveyed wrapping paper is installed under the fruit conveying device. The paper cutting mechanism is used to cut the wrapping paper of a certain shape and size. After the slideway, it enters under the netting of the netting shaping conveying mechanism, controls the stretching mechanism of the netting to stretch the netting and puts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com