Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Improve optimization design efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

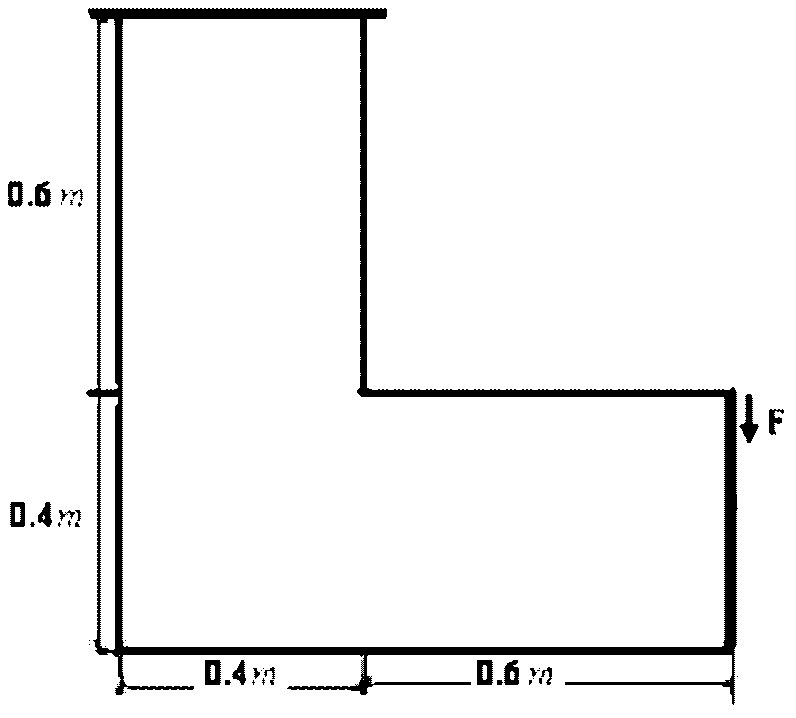

Material breakage constraint-based continuum structure topology design modeling and optimization design method

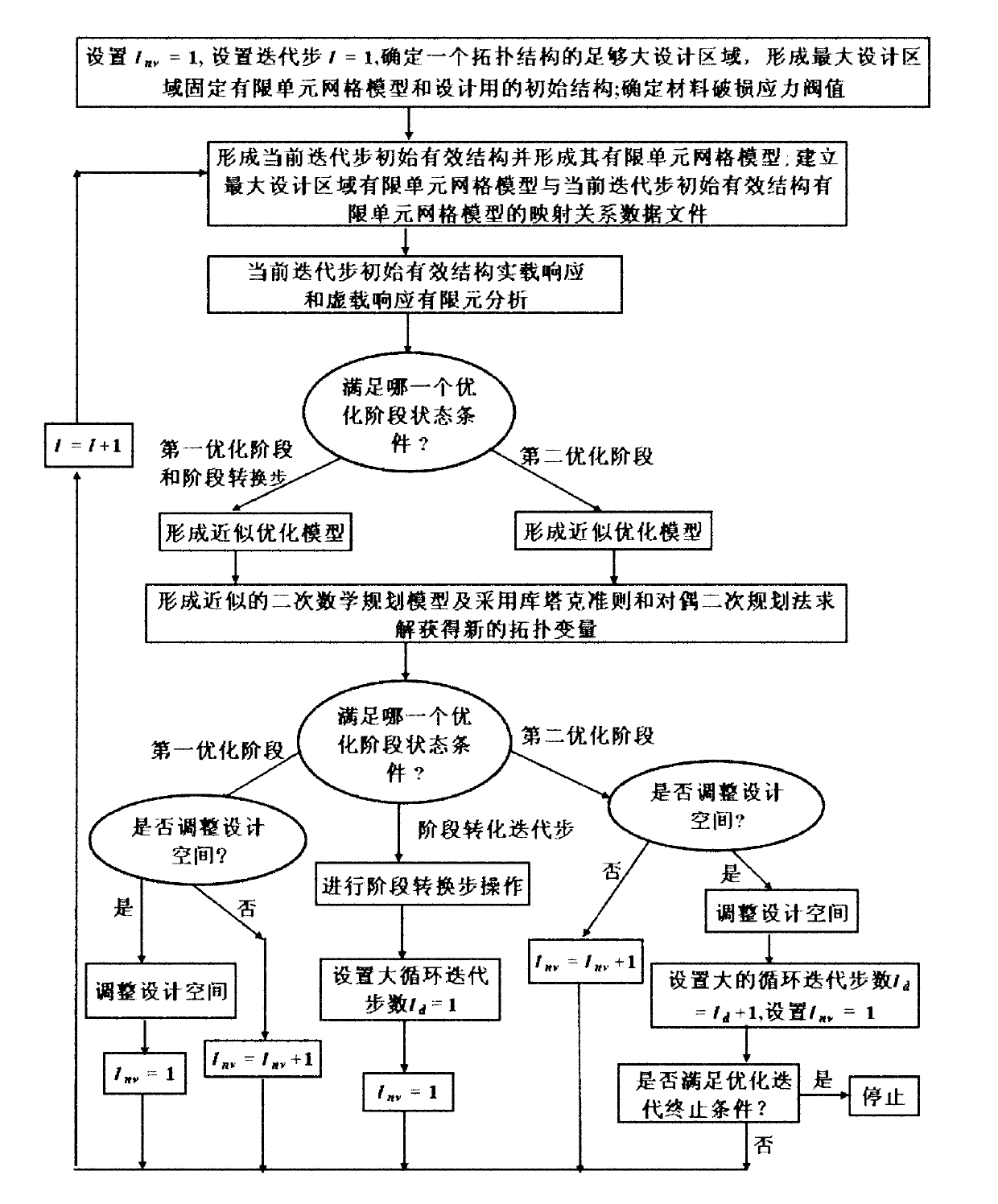

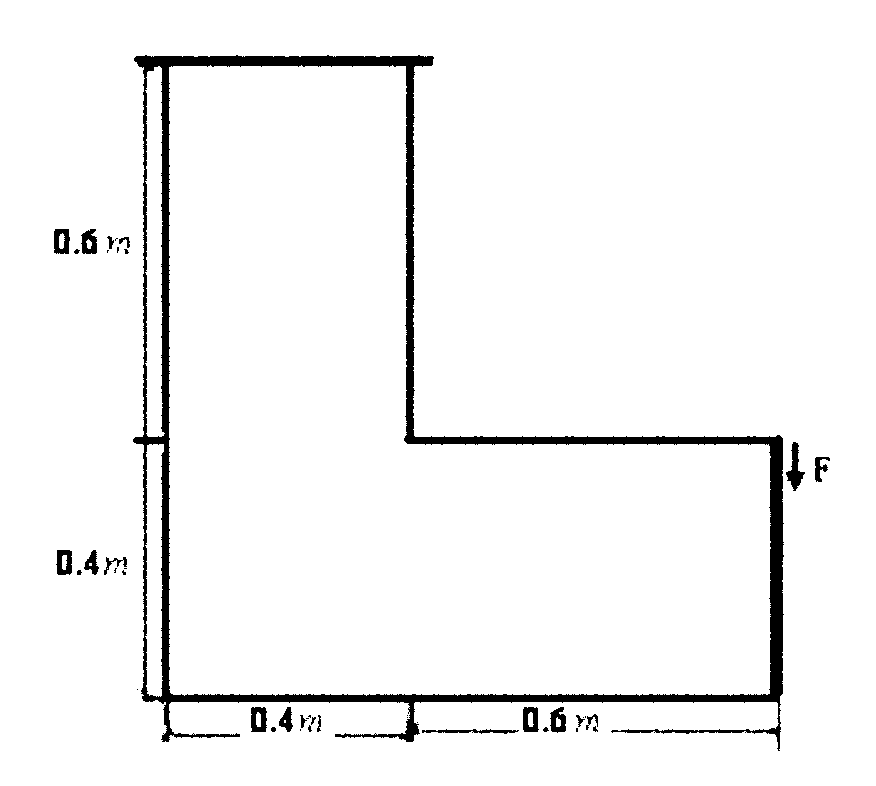

InactiveCN102043883AReduced maximum stress fluctuationsAddress stressSpecial data processing applicationsStress concentrationStress level

The invention discloses a material breakage constraint-based continuum structure topology design modeling and optimization design method, which is used for solving (a) problems of stress concentration and singularity, and (b) a problem of maximum stress fluctuation and a problem of high analyzed and calculated quantity in different degrees in the prior art. In the method, effective stress constraint relaxation is adopted to treat the phenomenon of stress singularity. In the process of optimizing problem approximation modeling, a q1 norm metrical function of the structural stress serves as a penalty function, all unit stress constraints are replaced by q2 norm metrical function constraint of the structural stress, the most potential active unit stress constraints and the introduced volume constraints, and the local stress level is controlled by combining variable constraint limit. The optimization process of the method is divided into two optimization stages and a conversion stage, and the design space is automatically expanded and reduced. A quadratic programming method is utilized to solve each stage, a pure optimized structural topology in black / white distribution can be obtained, and the method has high optimization design efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Optimum design method for aircraft system based on sequence radial basis function surrogate model

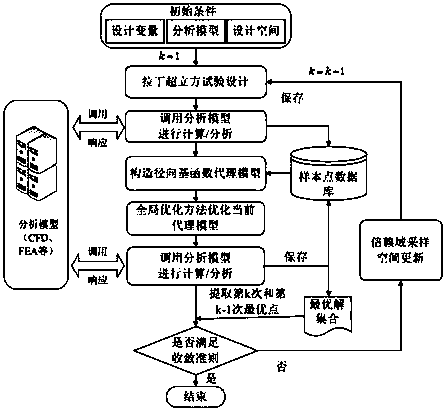

ActiveCN103473424AImprove the optimization design meansMeet the needs of multidisciplinary optimization designSpecial data processing applicationsSurrogate modelEngineering

The invention relates to an optimum design method for an aircraft system based on a sequence radial basis function surrogate model and belongs to the technical field of optimum design of the aircraft system. According to the optimum design method, the thought of searching step range of trust domain solving high-dimensional optimization problem is applied to a supervisory sequence surrogate model, the sample space is gradually updated and the approximate precision of the surrogate model is promoted, so that the optimizing strategy convergence is guided to the globally optimal solution and the optimum design method provided by the invention has better global optimization capacity and optimization efficiency. The method is strong in universality. According to the method, the program development is conveniently realized, the optimum design means for the aircraft system is improved, the design cost is lowered and the requirement for multidisciplinary optimum design of the present aircraft system is met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

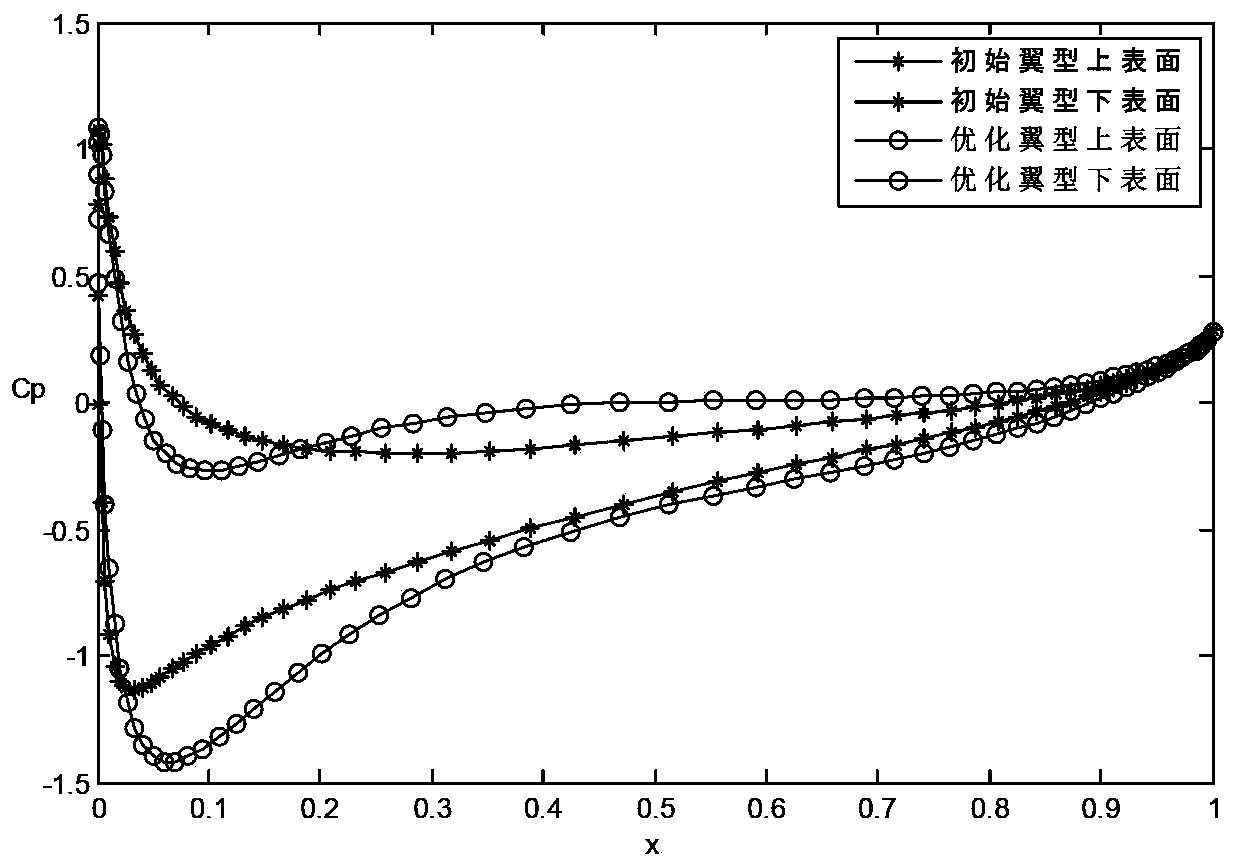

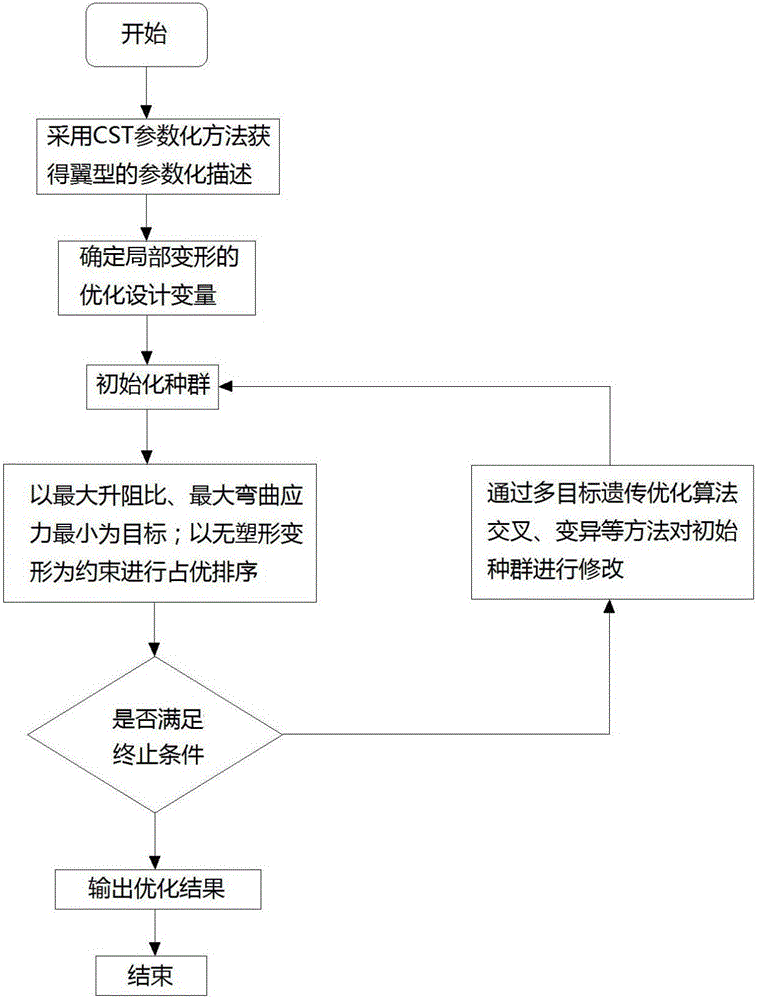

Design method of self-adaptive wing profile

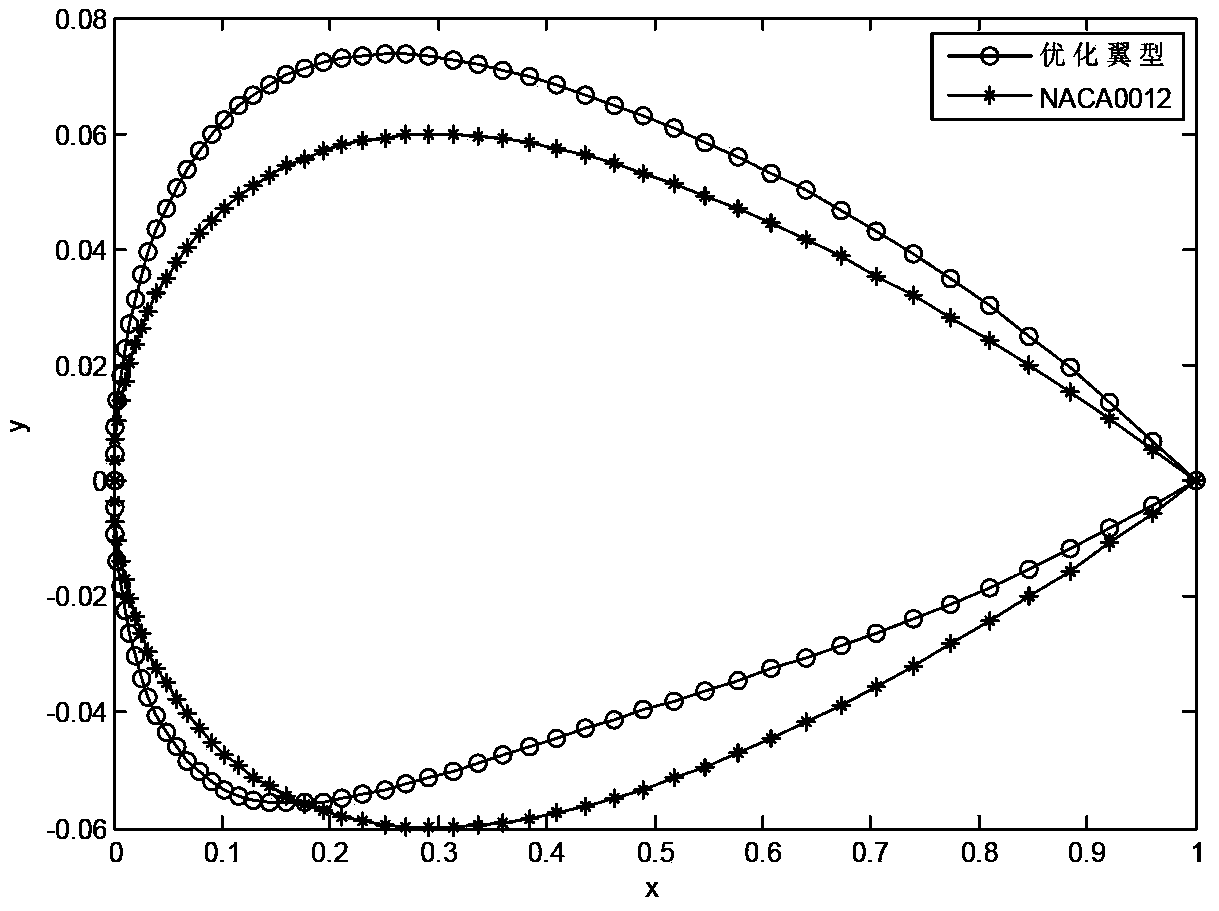

ActiveCN106845019AImprove engineering realizabilityImprove performanceGeometric CADSustainable transportationLeading edgeSelf adaptive

The invention discloses a design method of a self-adaptive wing profile. Firstly, parameterized description of a selected initial wing profile is obtained with a CST parameterization method, an optimal design variable of local deformation is determined, populations are initialized with a selected optimization algorithm, domination sequencing is performed on the populations under the conditions that the lift-to-drag ratio reaching the maximum when the lift coefficient CL is equal to 0.9 and the maximum bending stress reaching the minimum after change of leading edge camber are taken as optimization objects and non-plastic deformation is taken as a constraint, and finally, an optimized wing profile meeting the terminal conditions is selected. With pneumatic characteristics expected by the wing profile as the design objects, a constraint relation between the self-adaptive wing profile and an original wing profile is established, a reasonable target wing profile can be provided for design of a deformation driving technology, the engineering implementability is improved, and the design optimization efficiency is further improved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

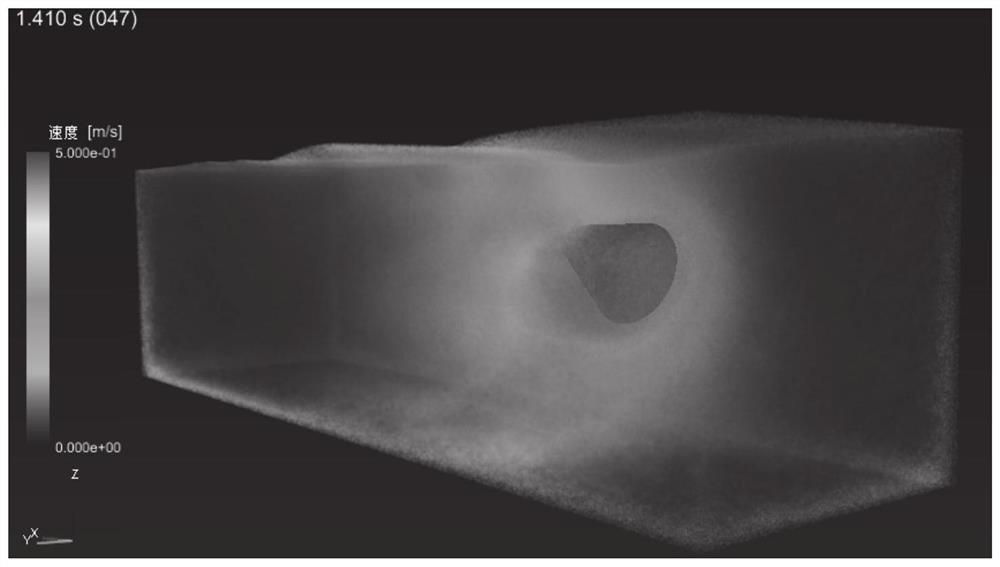

Noise simulating calculation method for automotive alternating current generator

InactiveCN104361174AAchieve automatic optimizationSmall amount of calculationSpecial data processing applicationsExperimental researchNoise reduction

The invention relates to a noise simulating calculation method for an automotive alternating current generator. The method comprises the following steps of initializing basic data, performing setting and grid division on a simulating calculation area, calculating an unsteady aerodynamic characteristic equation set of the generator at specific rotating speed by adopting finite volume method-based commercial CFD (computational fluid dynamics) software, verifying correctness, verifying the correctness of a simulating numerical value calculation result, testing and measuring the aerodynamic performance and the noise of the alternating current generator, and performing noise reduction structure optimization design on the alternating current generator according to a comparison result of the simulating numerical value calculation result and a practical verification result. According to the method, the far-field radiation aerodynamic noise characteristics of a main aerodynamic noise source part, different turbulence model for predicting the nose of the alternating current generator, aerodynamic noise time-frequency characteristics under different working conditions and the like are researched and analyzed; an experimental research method is adopted for verifying the aerodynamic noise characteristics of the alternating current generator; on such a basis, the noise reduction structure of the alternating current generator is optimized.

Owner:芜湖杰诺瑞汽车电器系统有限公司

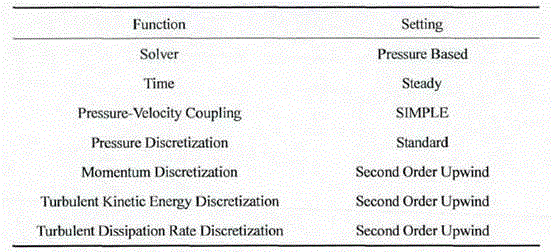

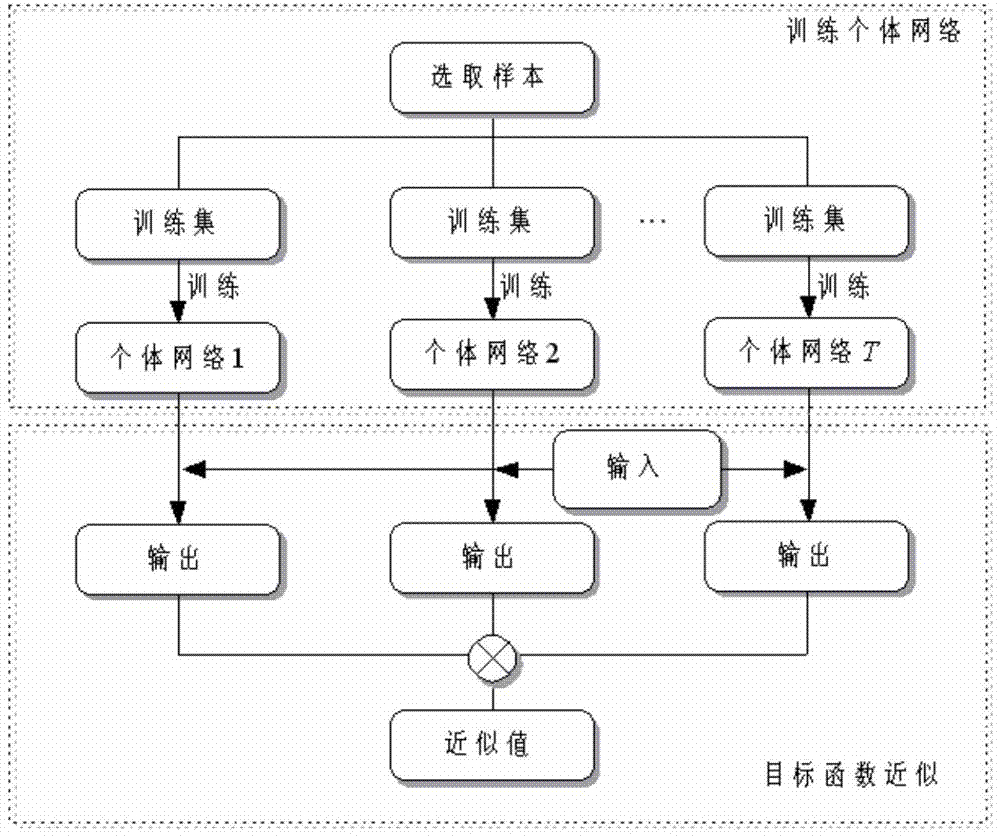

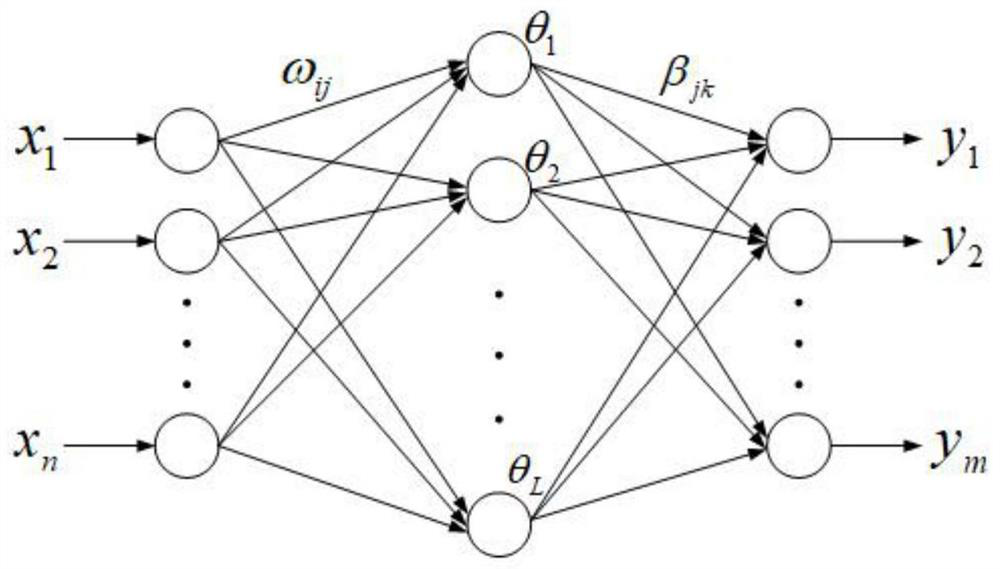

Aerodynamic shape optimization method based on neural network integration

InactiveCN103488847ASmall amount of calculationImprove optimization design efficiencySpecial data processing applicationsNerve networkAlgorithm

The invention provides an aerodynamic shape optimization method based on neural network integration, and aims to solve the aircraft aerodynamic shape optimization problem. The method includes the steps that firstly, multiple aerodynamic shapes are constructed as samples according to different aerodynamic shape parameters, and the objective function of each sample is acquired by the adoption of a numeric analysis method; based on sample data, an objective function approximate model is constructed by the adoption of a neural network integration method; compared with a numeric analysis method, the approximate model is low in accuracy but much smaller in calculated amount; the objective function approximate model and a direct search algorithm are combined for optimization search, and the numeric analysis method or the approximate model is called based on a certain strategy in the search process to acquire the objective functions until the optimal aerodynamic shape is acquired. According to the method, on the premise that the optimization effect is guaranteed, times of numeric analysis can be effectively reduced in the optimization process, optimization design efficiency and quality can be improved, and the method is very suitable for the aircraft aerodynamic shape optimization design and relevant engineering problems.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

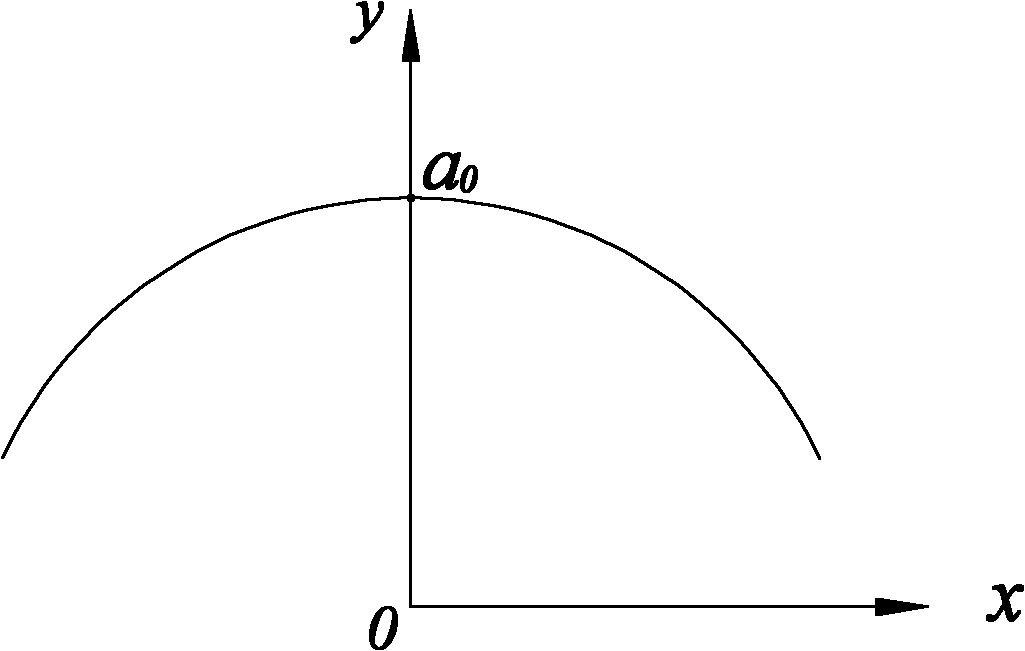

Roll groove design method for seamless steel pipe stretch reducing machine set

InactiveCN102172630AImprove optimization design efficiencyImprove product qualityRollsMetal rolling arrangementsOptimal designEngineering

The invention discloses a roll groove design method for a seamless steel pipe stretch reducing machine set, which can reduce difficulty in optimal design and satisfy needs for product pipe profile and wall thickness control, and comprises the following steps: 1, collecting equipment parameters and variety specification ranges of a seamless steel pipe stretch reducing machine set; 2, selecting products of steel pipe representative specifications and determining the weighting coefficient of every specification; 3, setting a groove curve equation(Y=a0+a1*2+a2*4+,..., +an*2n) by using a0, a1, a2,..., and an as the groove curve parameters of the machine frames of the seamless steel pipe stretch reducing machine set; 4, setting a target function for optimizing groove curves, and determining the optimal values of the groove curve parameters by using an optimal design method; and 5, substituting the optimal values of the groove curve parameters into the groove curve function to obtain the required groove curves of every machine frame of the seamless steel pipe stretch reducing machine set. When the method of the invention is used, the optimization process of the groove design can be simplified, and the designed groove can meet the pipe profile requirements of products and has uniform wall thickness.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

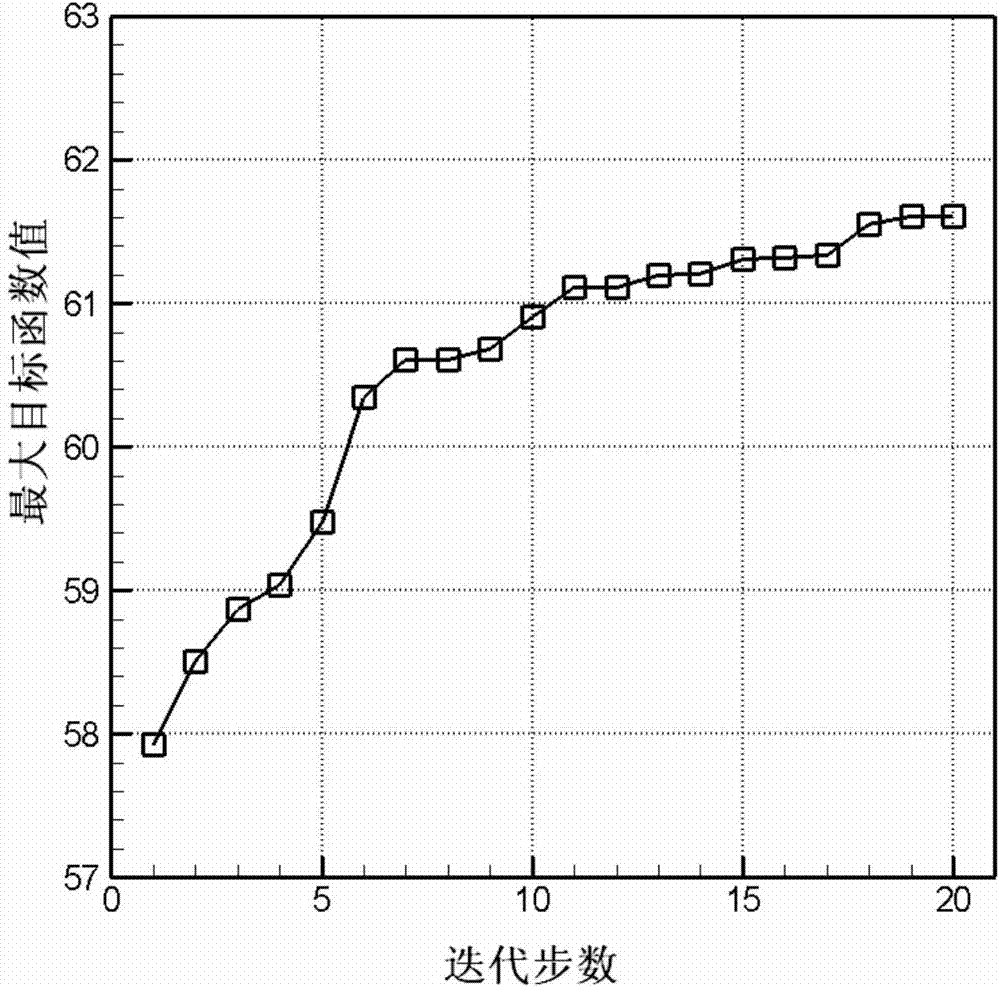

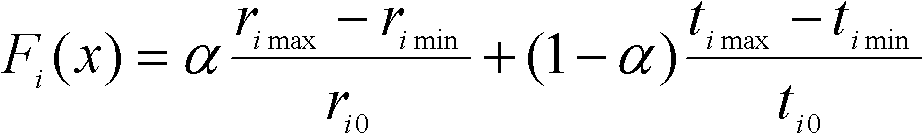

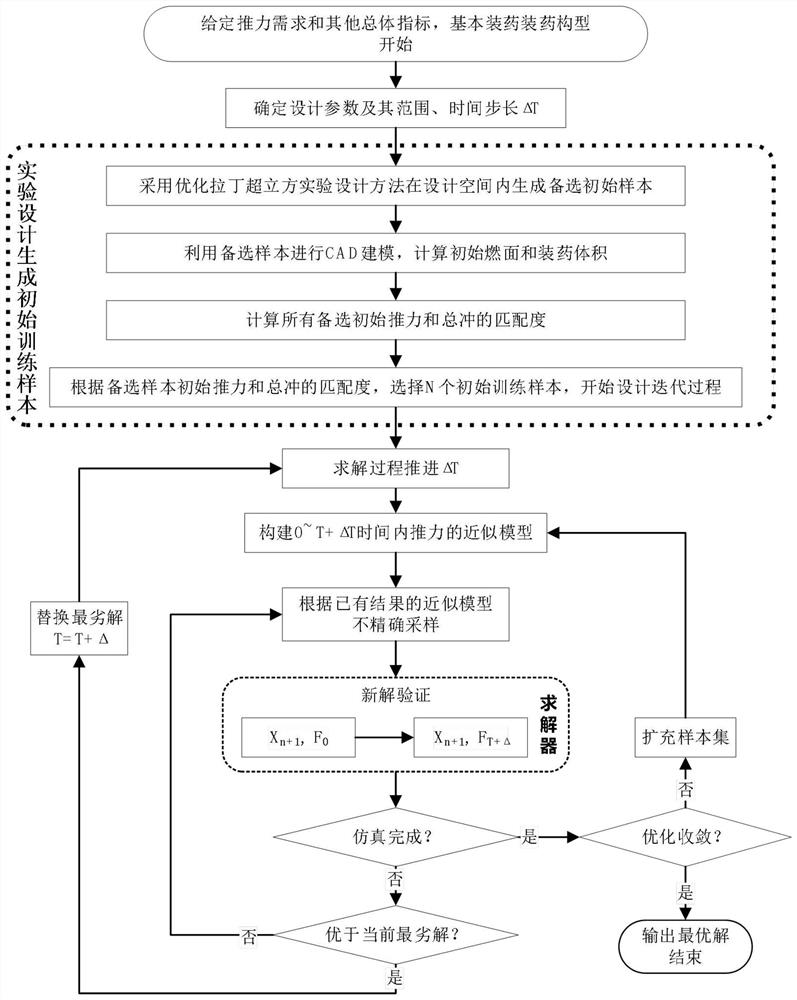

Solid rocket engine performance progressive matching design method

ActiveCN112149228ASmall amount of calculationImprove performanceGeometric CADDesign optimisation/simulationClassical mechanicsControl theory

The invention provides a solid rocket engine performance progressive matching design method. The solid rocket engine performance progressive matching design method comprises the steps of acquiring task objectives of total indexes of a solid rocket engine; determining a time interval division number according to the working time of a preset thrust demand in the task target; obtaining an initial training sample set of the preset thrust demand matching degree based on an initial balance pressure method; according to the initial training sample set, operating the combustion surface and internal ballistic trajectory calculation model in the initial time interval to obtain N thrust curves, and constructing a thrust approximation model according to the N thrust curves; carrying out inaccurate sampling to obtain alternative solutions; substituting the alternative solution into a combustion surface calculation and internal trajectory calculation model, and calculating the performance of the internal trajectory within simulation time to obtain an alternative thrust curve; when the simulation time is not less than the working time, adding the alternative solution as a new sample point into asample set to obtain an updated sample set; and when a preset convergence condition is reached, outputting the alternative thrust curve as an optimal solution.

Owner:NAT UNIV OF DEFENSE TECH

Structure and process integrated design method for FRP structural part

ActiveCN108829914ARealize integrated designImprove optimization design efficiencyGeometric CADDesign optimisation/simulationElement modelElement analysis

The invention relates to a structure and process integrated design method for an FRP structural part. The structure and process integrated design method for the FRP structural part comprises the stepsof: (1), establishing a finite element model of the FRP structural part, performing parameterization of layer angle and layer thickness design variables, and establishing a material interpolation model; (2), performing finite element analysis on the structural part, extracting parameters required for calculating the sensitivity, and establishing a target function and a constraint condition on layer angle and total thickness design variables; (3), calculating the sensitivity of the target function and the constraint condition; (4), according to the sensitivity, iterating to obtain the optimalsolution of the target function by adopting a mathematical programming method, and updating a parameterization model of the layer angle and total thickness design variables; and (5), repeating the steps (2) to (4) till the result is converged or is up to the maximum iteration number, so that the optimal layer structure of the FRP structural part is obtained. Compared with the prior art, the structure and process integrated design method for the FRP structural part in the invention has the advantages that: structure and process integrated design is realized; and, on the premise that performancerequirements and manufacturing constraints are satisfied, the material utilization rate and the optimization design efficiency of the FRP structural part are effectively increased.

Owner:TONGJI UNIV

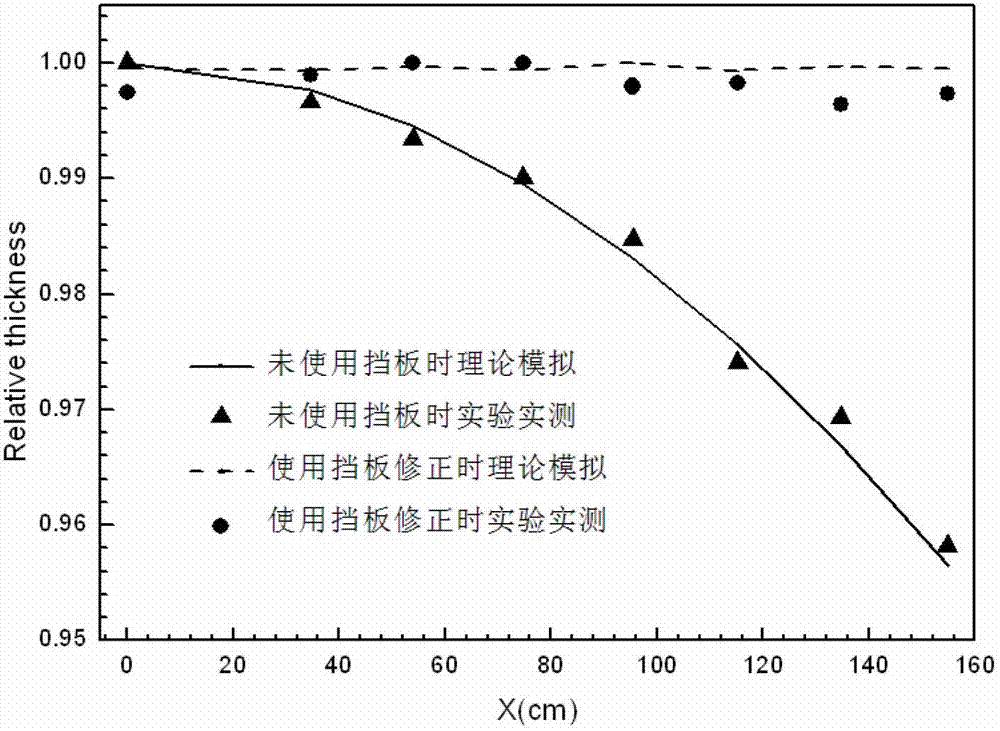

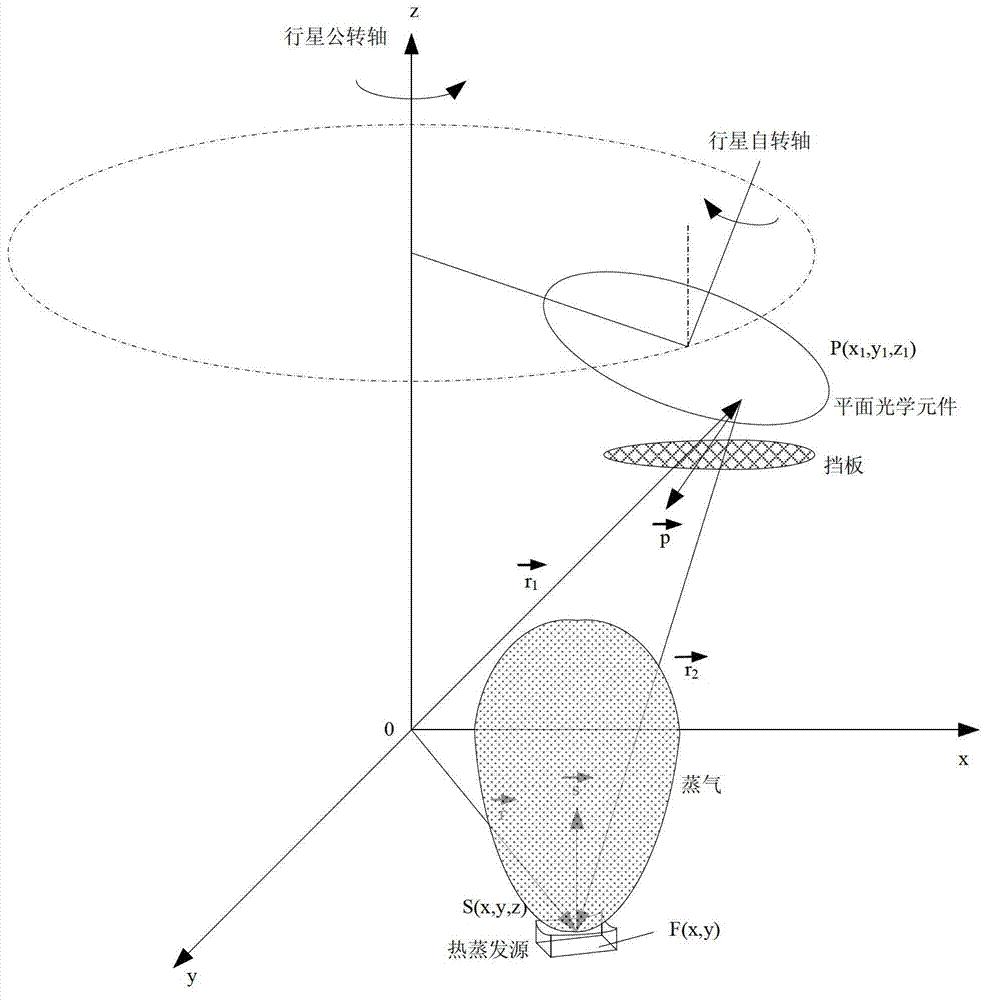

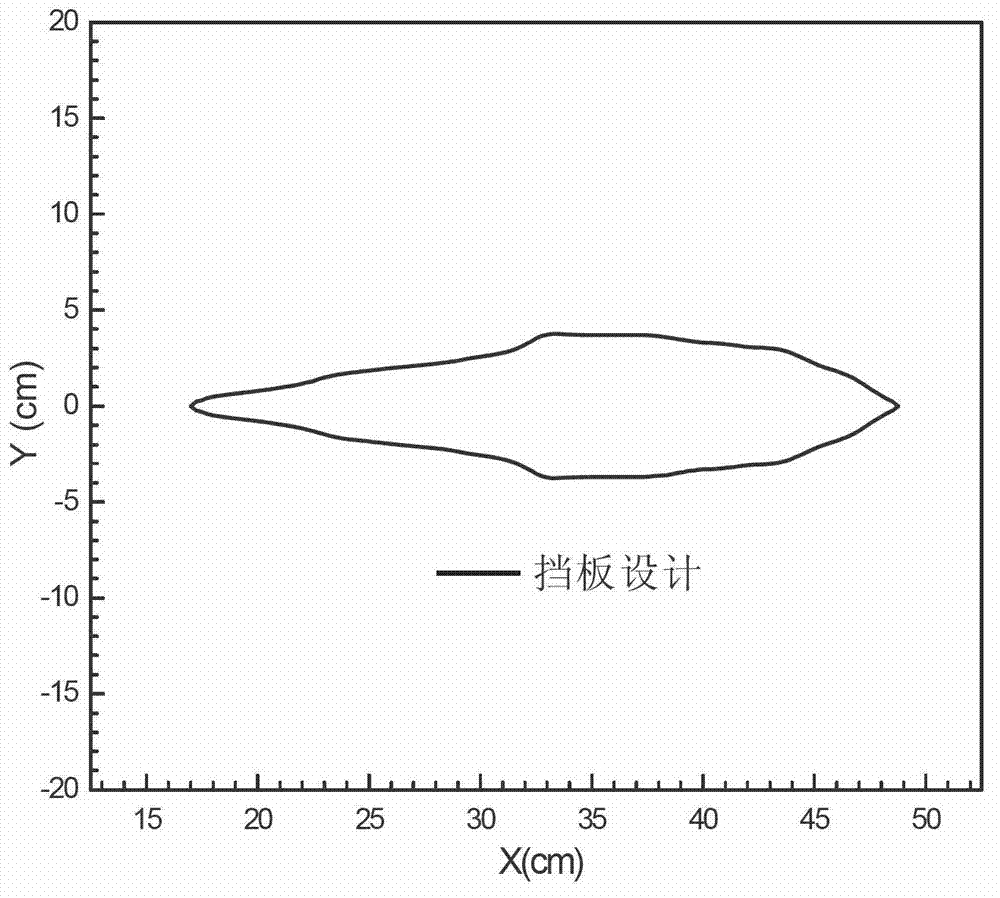

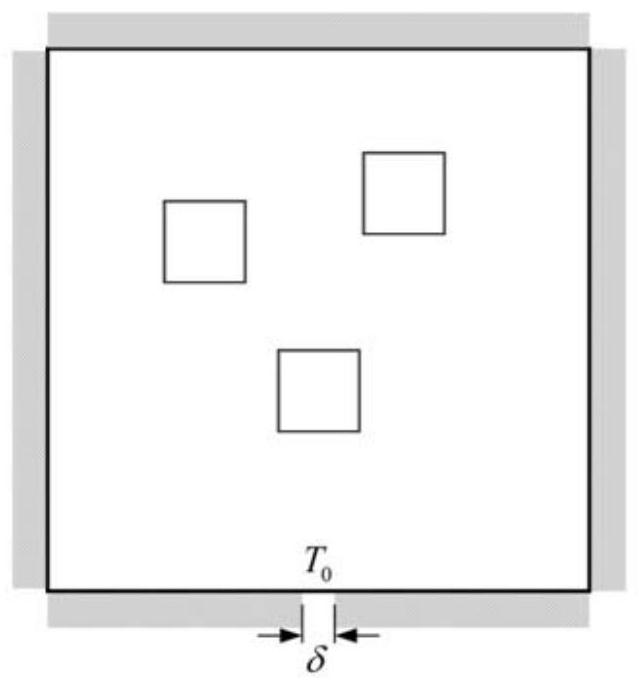

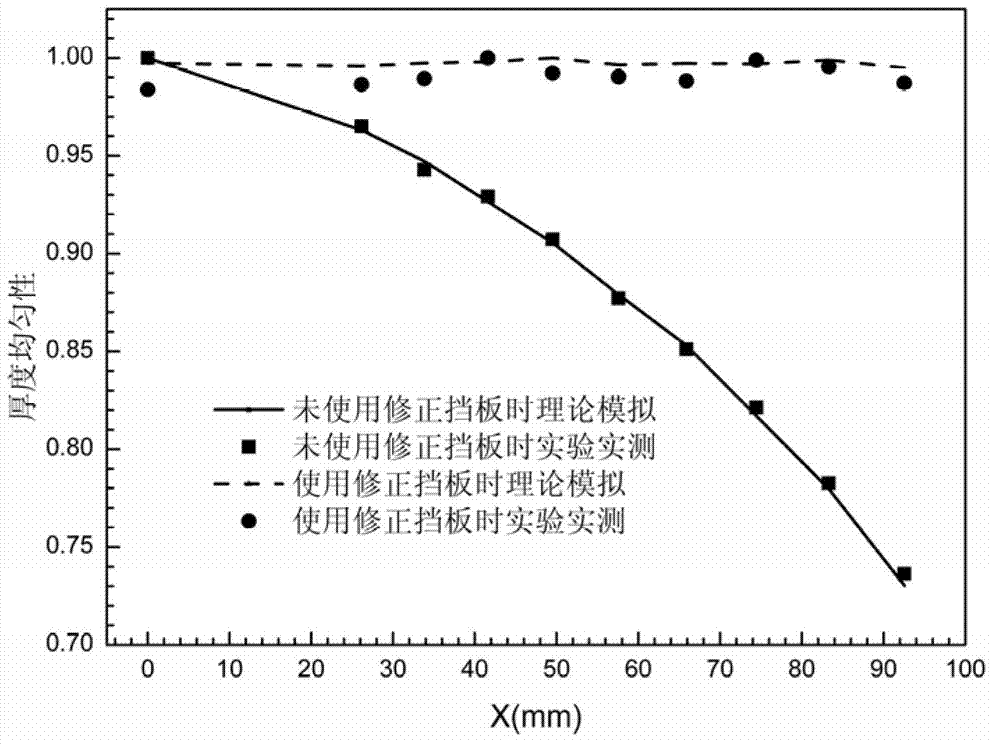

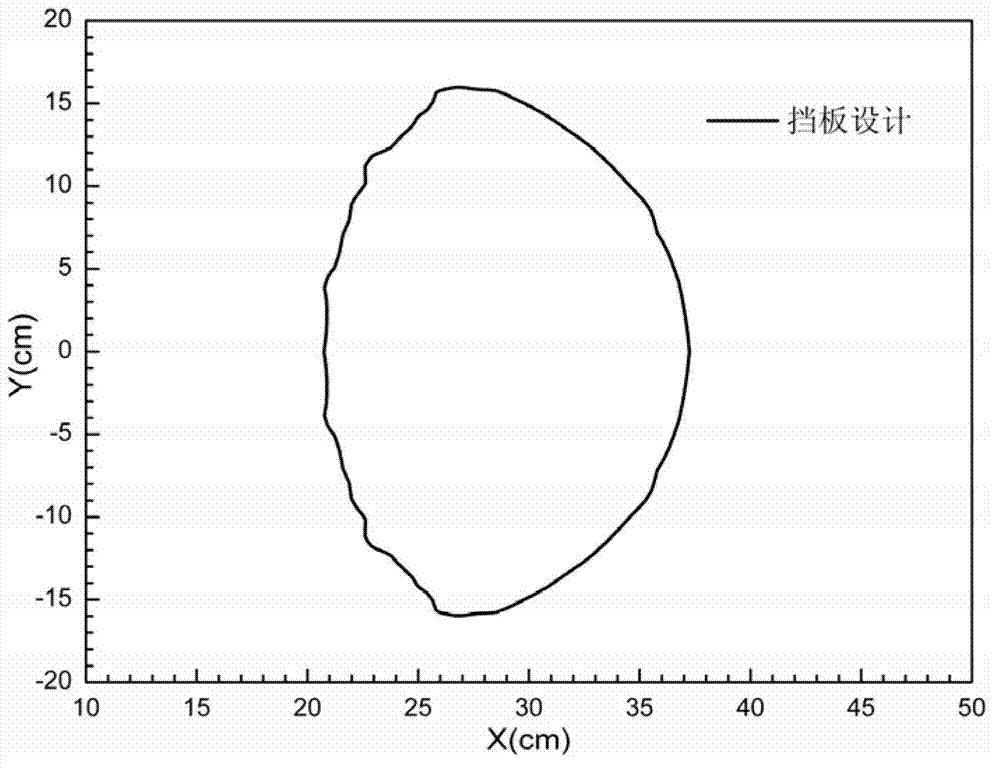

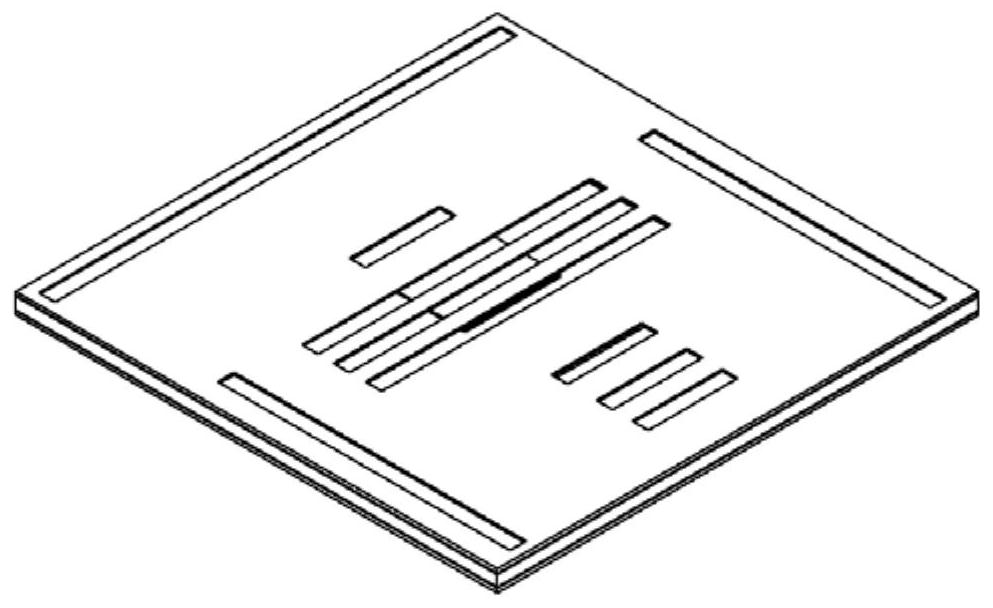

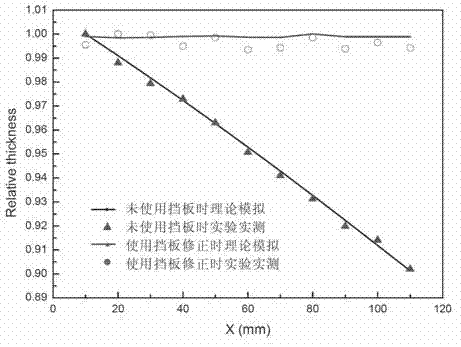

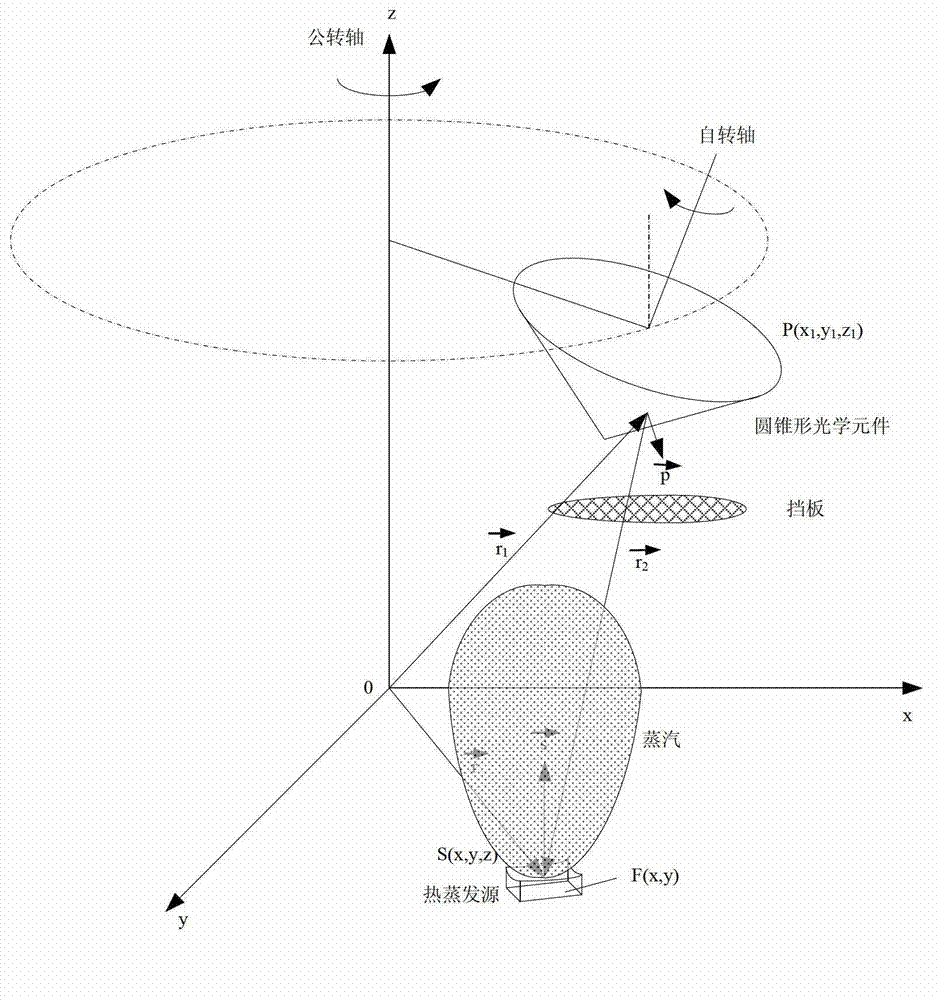

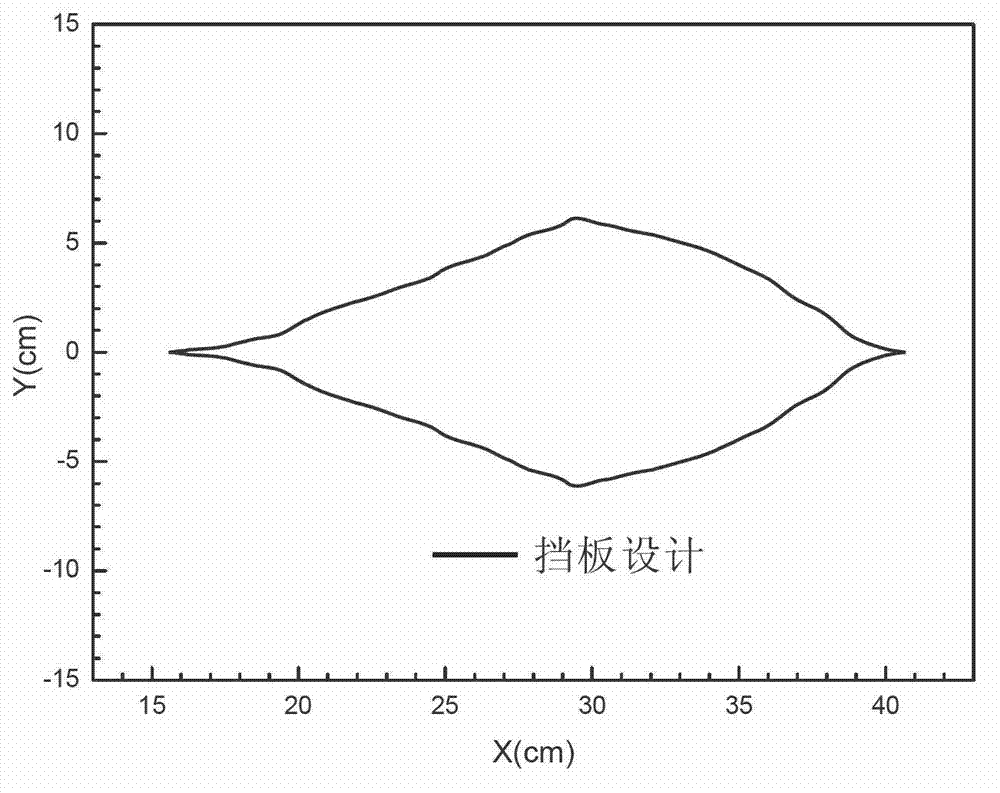

Design method of baffle for controlling distribution of film thickness of planar optical element in film coating planetary system

ActiveCN102776484AIn line with physical realityImprove optimization design efficiencyVacuum evaporation coatingSputtering coatingComputer optimizationEngineering

The invention provides a design method of a baffle for controlling distribution of film thickness of a planar optical element in a film coating planetary system. In a vacuum film coating process, the film material is delivered in a vacuum environment through an evaporating mode or a splashing mode, and forms a film with non-uniform thickness distribution on the surface of a planar optical element. Models are respectively established for really reflecting the distribution of the thickness of film deposited on the planar optical element in a planetary system of a vacuum film coating machine under the condition that a baffle is not used and the baffle is not used for correcting. The evaporating or splashing property of the film material in the vacuum film coating process is determined according to the film thickness distribution model under the condition that the baffle is not used, and then the distribution of the thickness of the film on the planar optical element in the planetary system of the vacuum film coating machine is simulated based on a film thickness distribution model theory in the presence of the correcting of the baffle. And finally the baffle design is optimized through a computer until the distribution of the thickness of the film on the planar optical element subject to the baffle correcting in the planetary system of the vacuum film coating machine meets the design requirement, so that the optimal baffle design is obtained. The design method can be applied to precisely controlling the distribution of the thickness of the film on the planar optical element.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Indoor optimization design method and system based on BIM

ActiveCN111428307AReduce wasteEasy to callGeometric CADDesign optimisation/simulationInteractive designConstruction management

Owner:广州高新工程顾问有限公司

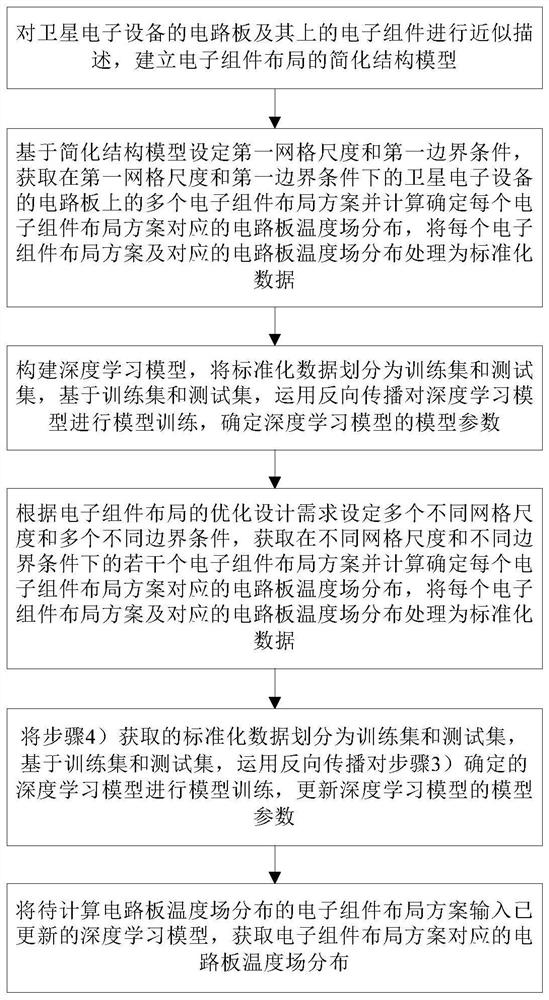

Transfer learning-based satellite part temperature field determination method

ActiveCN111783331AQuality improvementReduce computational workloadDesign optimisation/simulationNeural architecturesComputational scienceAlgorithm

The invention discloses a transfer learning-based satellite part temperature field determination method. The method comprises the steps of establishing a simplified structure model of electronic partlayout; acquiring a plurality of electronic part layout schemes under a first grid scale and a first boundary condition, calculating corresponding temperature field distribution, and processing the schemes and the temperature field distribution into standardized data; constructing a deep learning model, and determining model parameters of the deep learning model by utilizing the standardized data;acquiring a plurality of electronic part layout schemes under different grid scales and different boundary conditions, calculating corresponding temperature field distribution, and processing the schemes and the temperature field distribution into standardized data; updating model parameters of the deep learning model by utilizing the standardized data; and inputting the electronic part layout scheme of the temperature field distribution to be calculated into the deep learning model to obtain the temperature field distribution. The method can achieve the quick obtaining of the temperature field distribution corresponding to the electronic assembly layout under different grid scales and different boundary conditions.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

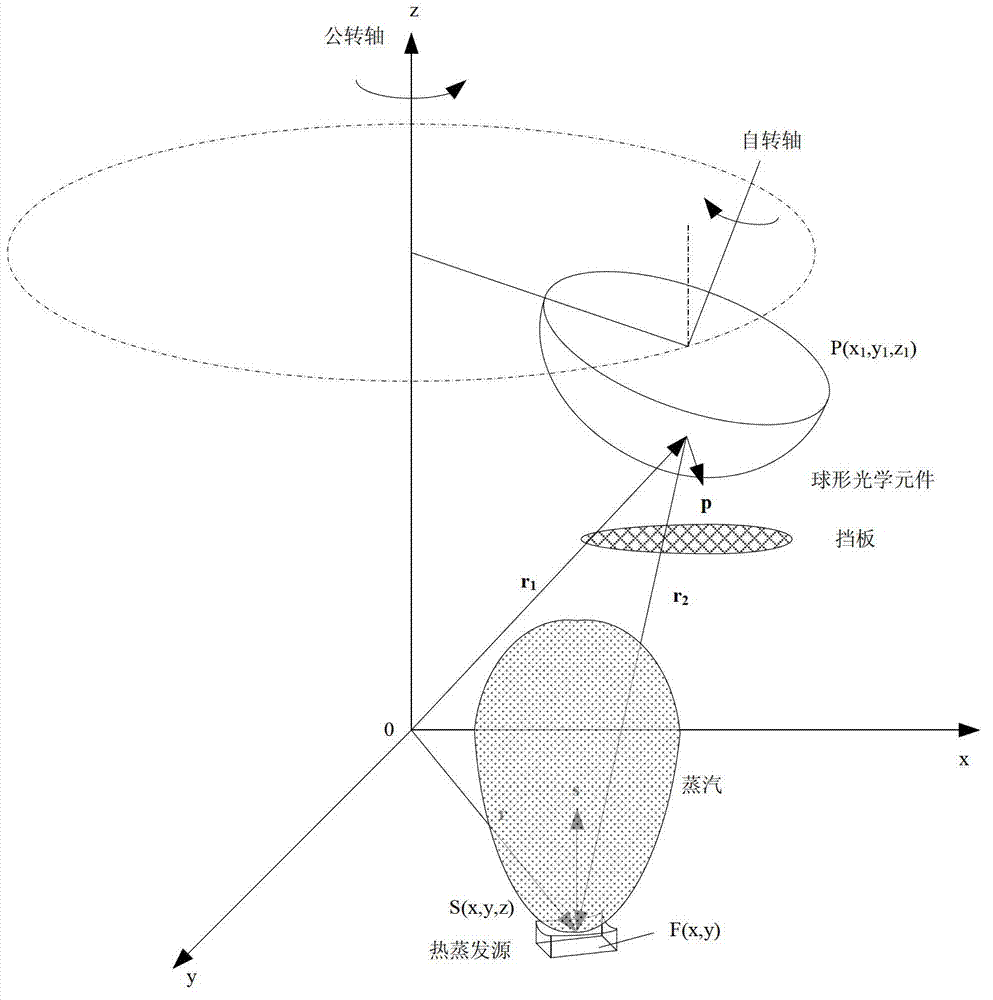

Baffle plate design method for controlling membrane thickness distribution of spherical optical element in coating machine planet system

ActiveCN102953041AImprove optimization design efficiencyVacuum evaporation coatingSputtering coatingComputer optimizationEvaporation

The invention discloses a baffle plate design method for controlling membrane thickness distribution of a spherical optical element in a coating machine planet system. In a vacuum coating process, a membrane material is transmitted in a vacuum environment in an evaporation or sputtering mode, and a membrane of which thickness distribution is not uniform is formed on the surface of the spherical optical element. Membrane thickness distribution models capable of actually reflecting thickness distributions of membranes deposited on the spherical optical element in the vacuum coating machine planet system when a baffle plate is not used and when the baffle plate is used for correction are respectively established. According to the membrane thickness distribution model when the baffle plate is not used, evaporating or sputtering characteristics of the membrane material are determined in the vacuum coating process; and then based on the characteristics, the membrane thickness distribution model when the baffle plate is used for correction is used to theoretically simulate the membrane thickness distribution on the spherical optical element in the vacuum coating machine planet system. The baffle plate design is optimized through a computer until the membrane thickness distribution on the spherical optical element in the vacuum coating machine planet system, which is corrected by the baffle plate, reaches the design demand, and thus the optimal baffle plate design is obtained. Compared with the traditional baffle plate design method, the baffle plate design method provided by the invention has the advantage that the baffle plate design is optimized by using the computer, so that the accurate control of the membrane thickness distribution on the spherical optical element can be realized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

SiC MOSFET packaging structure optimization design method, medium and equipment

ActiveCN112163355AImprove analysis efficiencyImprove accuracyDesign optimisation/simulationSpecial data processing applicationsMOSFETMathematical model

The invention relates to an embedded fan-out type SiC MOSFET packaging structure optimization design method, a medium and equipment, and the method comprises the steps: building a three-dimensional model of a SiC MOSFET device, determining a feasible region of chip distribution, carrying out the simulation parameter design based on the feasible region through employing a response surface method, and carrying out the finite element simulation based on simulation parameters; constructing a mathematical model between the distribution condition of the chips and the maximum heat dissipation temperature and the maximum stress according to a simulation result, thereby obtaining a chip distribution mode with optimal heat dissipation and stress, and realizing optimal design of the packaging structure. Compared with the prior art, the method has the advantages of high analysis efficiency, high optimization accuracy and the like.

Owner:FUDAN UNIV

Comprehensive energy source system of three-cell coupling type and optimization design method thereof

InactiveCN107425540ASystematizeAchieve high efficiencyBatteries circuit arrangementsSingle network parallel feeding arrangementsFuel cellsMathematical model

The invention relates to a comprehensive energy source system of a three-cell coupling type and an optimization design method thereof. The system includes a fuel cell, a photovoltaic cell and a storage cell. The optimization design method includes the following steps: taking minimization of an annual total cost of the energy source system as an objective function to establish an optimization mathematical model; acquiring input variable parameter values of the optimization mathematical model from a pre-constructed system optimization design database; carrying out solving on the optimization mathematical model to obtain decision variable output data; and obtaining optimal equipment capacity and an optimal operation strategy of the energy source system to output data according to the decision variable output data obtained by solving. Compared with the prior art, the optimization design method provided by the invention improves the overall energy efficiency of the system while the reliability and the stability of terminal load supply are improved, solves problems of disjointing between supply and demand and the like in prior methods, and provides a scientific basis for determining a reasonable design scheme and the reasonable operation strategy of the comprehensive energy source system.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

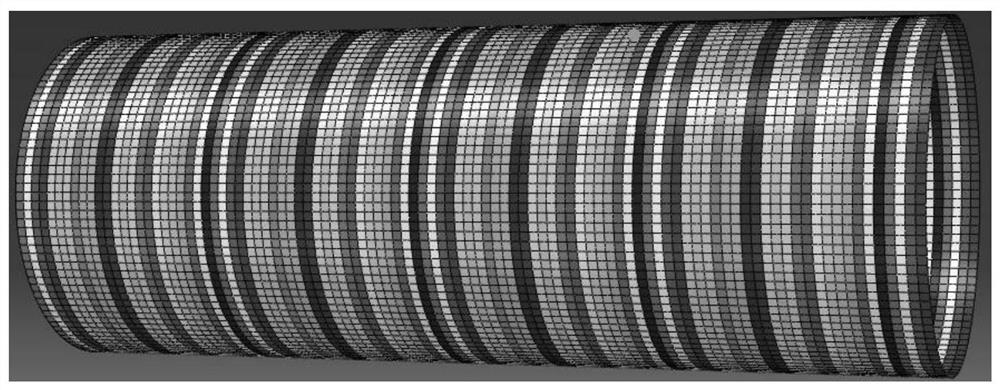

Modeling and optimization design method of variable stiffness composite cylindrical shell

PendingCN112182933AImprove design efficiencyImprove efficiencyDesign optimisation/simulationSpecial data processing applicationsAlgorithmElement analysis

The invention discloses a modeling and optimization design method of a variable stiffness composite cylindrical shell. The method comprises the following steps: performing unit discretization design on a geometric model of a cylindrical shell; endowing discrete units of the geometric model of the cylindrical shell with attributes of the variable stiffness composite material; carrying out variableangle parameter assignment on discrete units in the model, and establishing a finite element analysis model; and performing a small amount of finite element analysis on the parameterized analysis model of the discrete unit in the model, extracting sample points, and establishing an approximate model of buckling analysis and optimization design. According to the modeling and optimization design method, through a discrete finite element method and parametric programming, establishment of a simulation analysis model of the variable stiffness composite cylindrical shell is achieved, and a neural network approximation model is introduced in the design optimization process; rapid response analysis and optimization design of the mechanical property of the cylindrical shell are conducted with thefiber laying start-stop angle and the laying layer number sequence as variables, and the optimization design efficiency in application of the underwater pressure-resistant cylindrical shell is greatlyimproved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Design method for baffle plate used for controlling film thickness distribution on conical optical element in film plating planetary system

ActiveCN102787301AImprove optimization design efficiencyVacuum evaporation coatingSputtering coatingSputteringComputer optimization

The invention provides a design method for a baffle plate used for controlling film thickness distribution on a conical optical element in a film plating planetary system. According to the invention, in the process of vacuum plating, a film material is transmitted in a vacuum environment in a manner of evaporation or sputtering and forms a film with nonuniformly distributed thickness on the surface of the conical optical element, a film thickness distribution model capable of reflecting actual thickness distribution of the film deposited on the conical optical element in a vacuum plating machine planetary system when the baffle plate is not used and a film thickness distribution model capable of reflecting actual thickness distribution of the film on the conical optical element when baffle plate correction is used are respectively established; evaporation or sputtering characteristics of the film material during vacuum plating are determined based on the film thickness distribution model when the baffle plate is not used, then film thickness distribution on the conical optical element is simulated by using theories for the film thickness distribution model when baffle plate correction is used, designing of the baffle plate is optimized by using a computer until film thickness distribution on the conical optical element in the vacuum plating machine planetary system meets design demands after utilization of baffle plate correction, and therefore, an optimal baffle plate design is obtained. The method provided by the invention can realize accurate control of film thickness distribution on the conical optical element.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

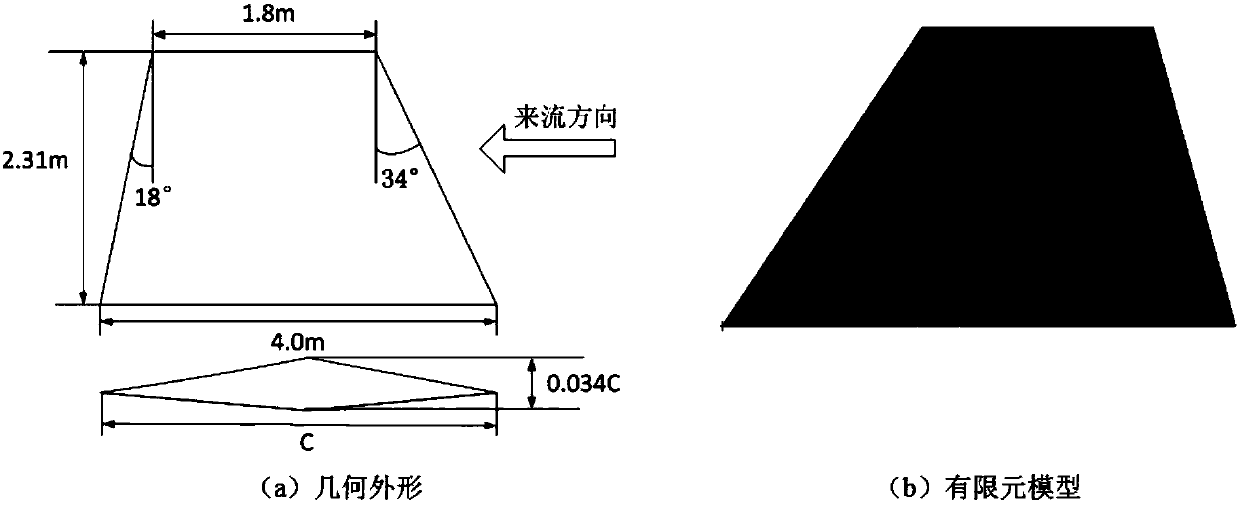

Reduced-order model-based aerodynamic-heat-structure optimization method

InactiveCN107766620AShorten the design cycleImprove performanceSustainable transportationSpecial data processing applicationsAviationAeroelasticity

The invention discloses a reduced-order model-based aerodynamic-heat-structure optimization method and belongs to the field of aerospace. The method comprises the steps of building an aircraft analysis model; building an initial aerodynamic heat reduced-order model; verifying an overall average relative error of the built aerodynamic heat reduced-order model; building an aerodynamic heat reduced-order model meeting a design precision requirement; obtaining a change condition of a structural internal temperature field of an aircraft in a whole ballistic flight process; performing aeroelasticityanalysis considering temperature influence in a whole ballistic trajectory for the aircraft; and by taking aircraft aeroelasticity characteristics obtained by analysis as constraints, optimizing design variables in the aircraft by adopting an optimization algorithm with a global optimization capability, thereby improving comprehensive performance of the hypersonic aircraft. The aerodynamic-heat-structure multidisciplinary optimization design efficiency of the hypersonic aircraft can be improved; the design cost can be reduced; the engineering practicality of the multidisciplinary design optimization method in hypersonic aircraft design can be improved; and the method has the advantage of high universality.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method and system for predicting hydrodynamic load of drag parachute

ActiveCN113919208AImprove optimization design efficiencyImprove accuracyGeometric CADSustainable transportationPrediction methodsSimulation software

The invention relates to a method and system for predicting the hydrodynamic load of a drag parachute, and the method comprises the following steps: screening influence factors affecting the load of a drag parachute to obtain a design variable; establishing a drag parachute simulation model in virtual simulation software according to the geometric parameters of the drag parachute; calibrating simulation parameters of the simulation model by means of a physical test; adjusting the design variables, carrying out virtual simulation to obtain different load variables, and and forming a database by the multiple sets of design variables and the corresponding load variables; obtaining an agent model of the design variable and the corresponding load variable through machine learning by utilizing data in the database; and inputting any design variable in a set range into the agent model to obtain a corresponding load variable prediction value.

Owner:SHANDONG UNIV

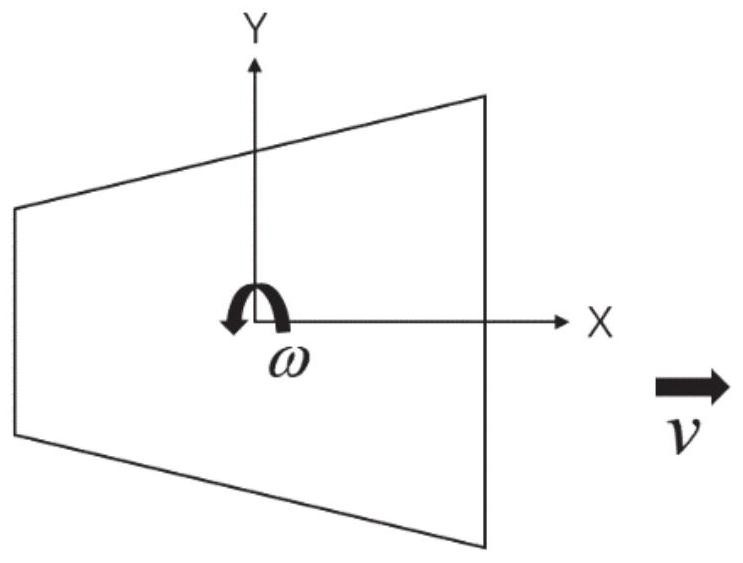

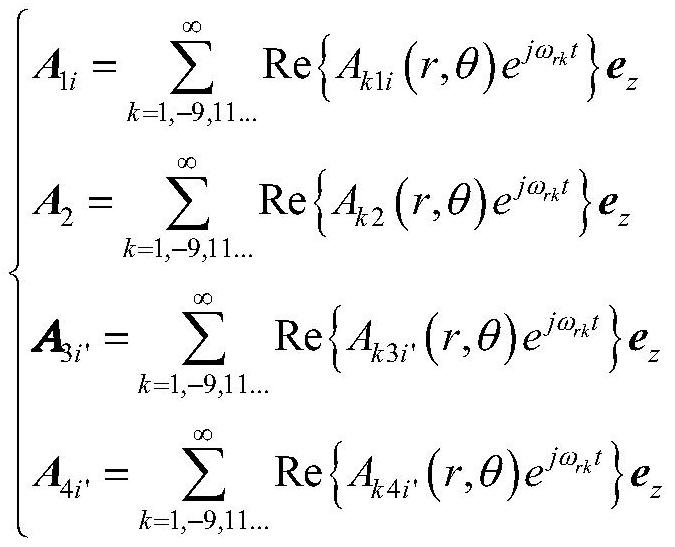

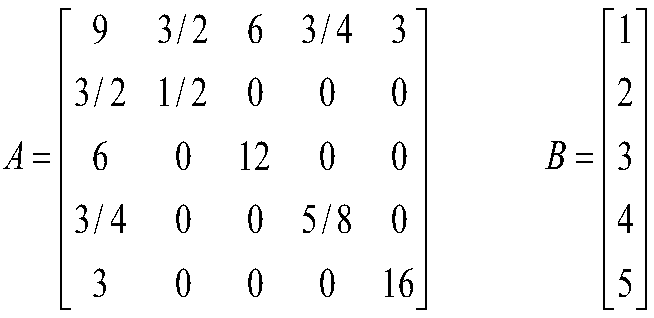

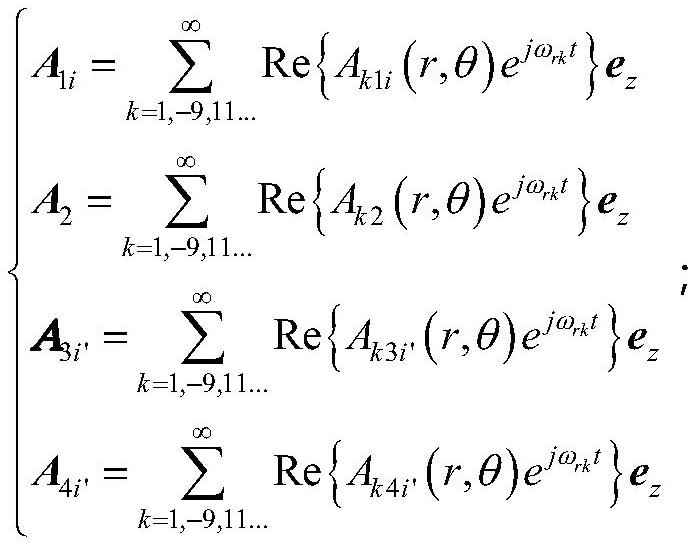

Multi-phase cage type induction motor magnetic field calculation method and system

ActiveCN113452209AWide applicabilityImprove optimization design efficiencyManufacturing dynamo-electric machinesDesign optimisation/simulationEngineeringMechanical engineering

The invention discloses a multi-phase cage type induction motor magnetic field calculation method and system, and the method comprises the steps: dividing a motor solving region according to the type of an excitation source, thereby obtaining a motor model, and obtaining a distribution function of the current density of a stator winding based on the motor model; aiming at the influence of the k current density harmonics, taking the vector magnetic potential in each sub-domain as a solving object of a control equation, respectively establishing a Laplace's equation, a Poisson equation and a Helmholtz equation, and solving a general solution of the vector magnetic potential according to boundary conditions among interfaces; based on the general solution of the vector magnetic potential of each sub-domain, solving the harmonic coefficient of each sub-domain; and based on the harmonic coefficient of each sub-domain, solving the radial and tangential components of the air gap flux density according to the vector magnetic potential expression of the air gap sub-domain, and solving the torque caused by the k space harmonics of the magnetomotive force and the total electromagnetic torque according to the radial and tangential components of the air gap flux density and the Maxwell tensor method.

Owner:NAVAL UNIV OF ENG PLA

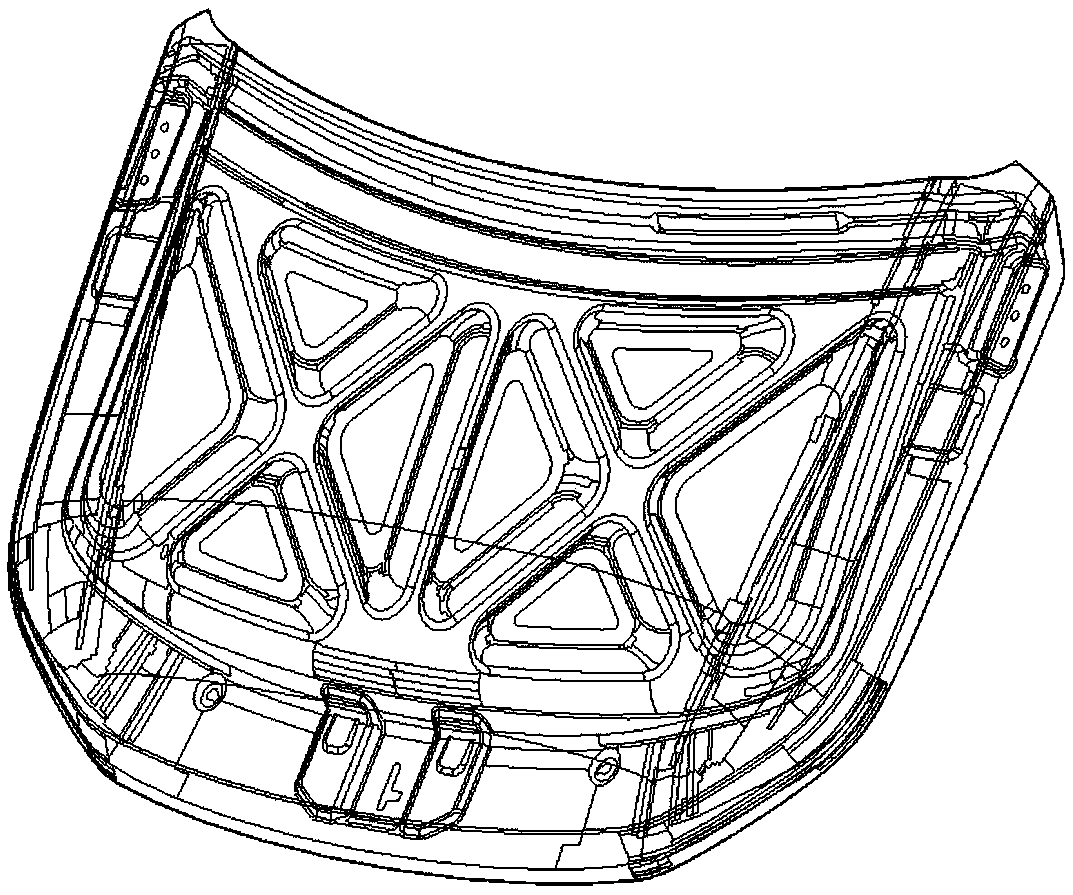

A lightweight implementation method and apparatus of a battery box

InactiveCN109359371AShorten the optimization design cycleOptimize Design EfficiencyDesign optimisation/simulationSpecial data processing applicationsQuality optimizationEngineering

The embodiment of the invention discloses a lightweight implementation method and a device of a battery box. The method comprises the following steps: determining a response surface approximation model of the battery box; According to the response surface approximation model, the quality of the battery box is optimized, and the calculation results which accord with the preset quality lightening verification standard are obtained as the quality of the battery box. As that response surface approximation model is adopted for quality optimization calculation, the optimization design period of thebattery box is shortened, and the optimization design efficiency is improve.

Owner:DONG HAN NEW ENERGY VEHICLE TECH CO LTD

An Aerodynamic Shape Optimization Method Based on Neural Network Integration

InactiveCN103488847BSmall amount of calculationImprove optimization design efficiencySpecial data processing applicationsAlgorithmNetwork integration

The invention provides an aerodynamic shape optimization method based on neural network integration, and aims to solve the aircraft aerodynamic shape optimization problem. The method includes the steps that firstly, multiple aerodynamic shapes are constructed as samples according to different aerodynamic shape parameters, and the objective function of each sample is acquired by the adoption of a numeric analysis method; based on sample data, an objective function approximate model is constructed by the adoption of a neural network integration method; compared with a numeric analysis method, the approximate model is low in accuracy but much smaller in calculated amount; the objective function approximate model and a direct search algorithm are combined for optimization search, and the numeric analysis method or the approximate model is called based on a certain strategy in the search process to acquire the objective functions until the optimal aerodynamic shape is acquired. According to the method, on the premise that the optimization effect is guaranteed, times of numeric analysis can be effectively reduced in the optimization process, optimization design efficiency and quality can be improved, and the method is very suitable for the aircraft aerodynamic shape optimization design and relevant engineering problems.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

Space filling optimal-design method for high flux combination experiment

InactiveCN101526968AImprove reliabilityMake up for the shortcomings of too much dependence on the initial valueMathematical modelsSpecial data processing applicationsMean squareData space

The invention provides a space filling optimal design method for a high flux combination experiment, which can effectively solve the problem that the optimal design of the high flux combination experiment in the prior art excessively depends on an initial value. The space filling optimal design method comprises the following steps: firstly, determining experiment data space dimensions (i.e. the number of experiment factors); establishing an optimal index model; and solving an optimal index (a mean square is approximate to an error) to obtain an optimal design structure of an experiment structure cell; then expanding a basic structure cell and also expanding a design result to a plurality of experiment design structure units in order to cover experiment data of a needed range; and finally carrying out self-adapting precise design for the basic structure cell to obtain an obvious experiment improved result. The invention provides the data space optimal method in the high flux combination experiment, thereby reducing the repetitiveness of design processing, enhancing the scientificalness and the reliability of design and being suitable for high and low dimensional data space optimal design; and in addition, the invention has substantive characteristics, thereby being an important link of the design of the high flux combination experiment in a materials science field, an engineering field, and the like.

Owner:JIANGNAN UNIV

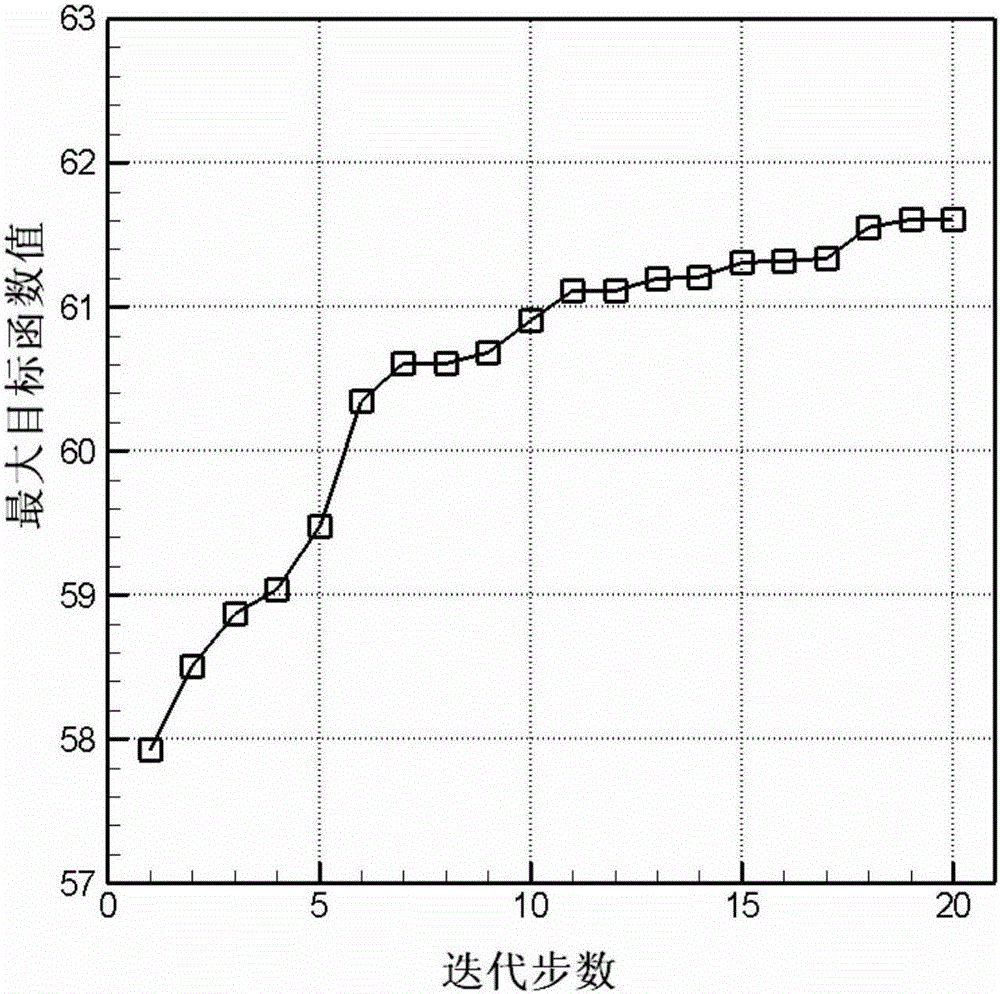

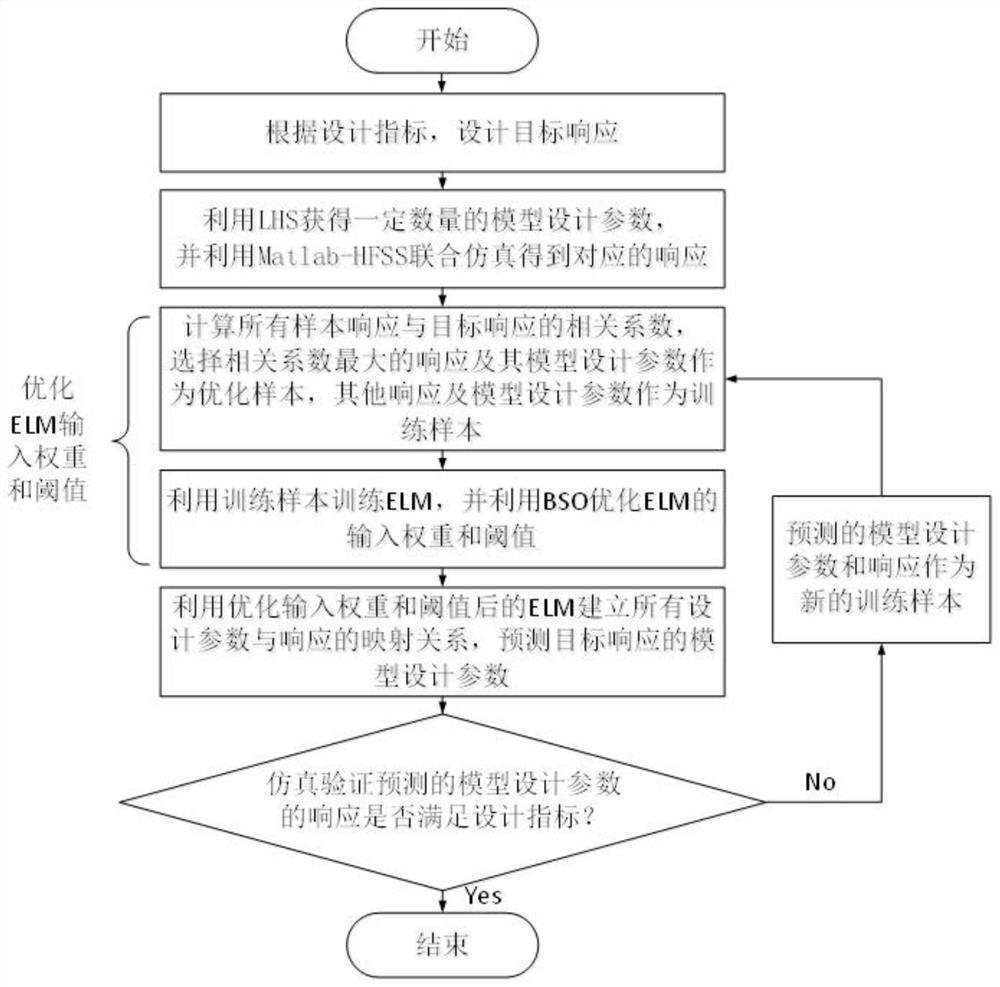

Optimization design method for microwave circuit

PendingCN113807040ASave time and labor costsImprove optimization design efficiencyArtificial lifeDesign optimisation/simulationOptimal designMicrowave

The invention discloses an optimization design method for a microwave circuit, and the method comprises the following steps: obtaining a sample model design parameter through LHS, and obtaining a corresponding sample response through a Matlab-HFSS joint simulation technology; calculating correlation coefficients of all sample responses and target responses, selecting the sample with the maximum correlation coefficient as an optimization sample, and other samples serving as training samples; training the ELM by using the training sample, predicting design parameters responding to the optimized sample, and optimizing an input weight and a threshold value of the ELM by using BSO; and establishing a mapping relationship between the microwave circuit model design parameters and the response by using the ELM after optimizing the input weight and the threshold, training by using all the training samples in the training process, and predicting the model design parameters corresponding to the target response in the prediction process. According to the method, the training and prediction quality of the neural network is improved, the number of required training samples is reduced, the time required for optimization design of the microwave circuit is shortened, the automation of the optimization design of the microwave circuit is realized, and the optimization design efficiency is improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Space filling optimal-design method for high flux combination experiment

InactiveCN101526968BImprove reliabilityMake up for the shortcomings of too much dependence on the initial valueMathematical modelsSpecial data processing applicationsMean squareData space

The invention provides a space filling optimal design method for a high flux combination experiment, which can effectively solve the problem that the optimal design of the high flux combination experiment in the prior art excessively depends on an initial value. The space filling optimal design method comprises the following steps: firstly, determining experiment data space dimensions (i.e. the number of experiment factors); establishing an optimal index model; and solving an optimal index (a mean square is approximate to an error) to obtain an optimal design structure of an experiment structure cell; then expanding a basic structure cell and also expanding a design result to a plurality of experiment design structure units in order to cover experiment data of a needed range; and finally carrying out self-adapting precise design for the basic structure cell to obtain an obvious experiment improved result. The invention provides the data space optimal method in the high flux combination experiment, thereby reducing the repetitiveness of design processing, enhancing the scientificalness and the reliability of design and being suitable for high and low dimensional data space optimal design; and in addition, the invention has substantive characteristics, thereby being an important link of the design of the high flux combination experiment in a materials science field, an engineering field, and the like.

Owner:JIANGNAN UNIV

Material breakage constraint-based continuum structure topology design modeling and optimization design method

InactiveCN102043883BReduced maximum stress fluctuationsAddress stressSpecial data processing applicationsStress concentrationStress level

The invention discloses a material breakage constraint-based continuum structure topology design modeling and optimization design method, which is used for solving (a) problems of stress concentration and singularity, and (b) a problem of maximum stress fluctuation and a problem of high analyzed and calculated quantity in different degrees in the prior art. In the method, effective stress constraint relaxation is adopted to treat the phenomenon of stress singularity. In the process of optimizing problem approximation modeling, a q1 norm metrical function of the structural stress serves as a penalty function, all unit stress constraints are replaced by q2 norm metrical function constraint of the structural stress, the most potential active unit stress constraints and the introduced volume constraints, and the local stress level is controlled by combining variable constraint limit. The optimization process of the method is divided into two optimization stages and a conversion stage, andthe design space is automatically expanded and reduced. A quadratic programming method is utilized to solve each stage, a pure optimized structural topology in black / white distribution can be obtained, and the method has high optimization design efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A Method for Optimizing Structural Parameters Based on Sparse Matrix Symbolic Operation Results

ActiveCN107944189BImprove optimization design efficiencyGeometric CADDesign optimisation/simulationMatrix decompositionAlgorithm

Owner:CHINA AIRPLANT STRENGTH RES INST

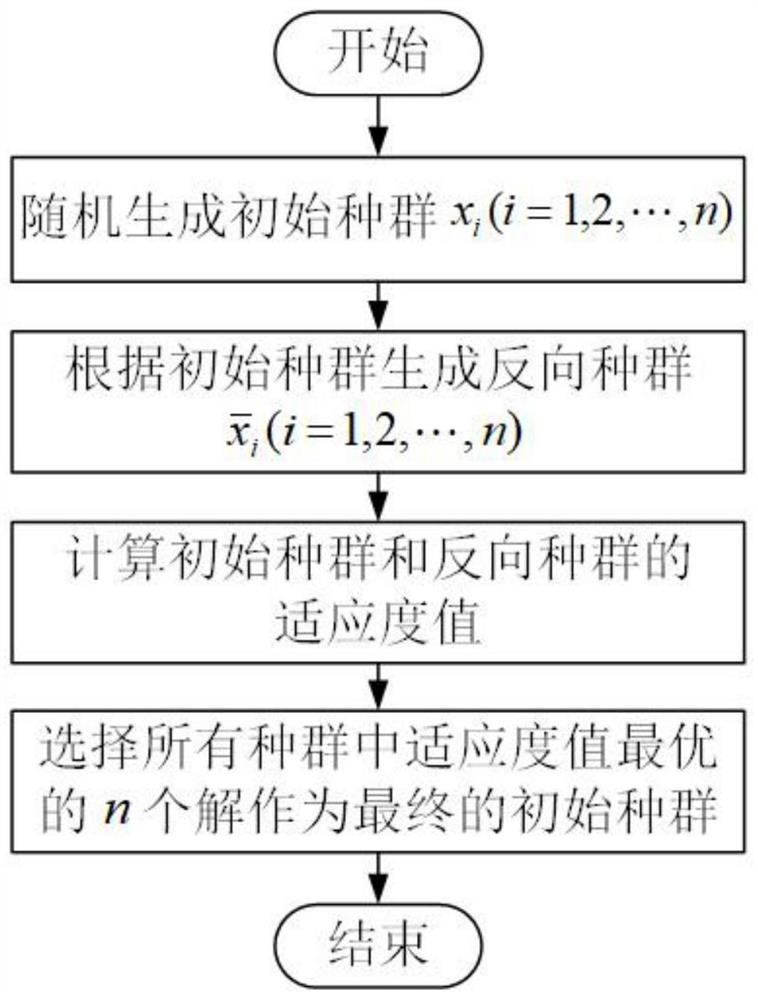

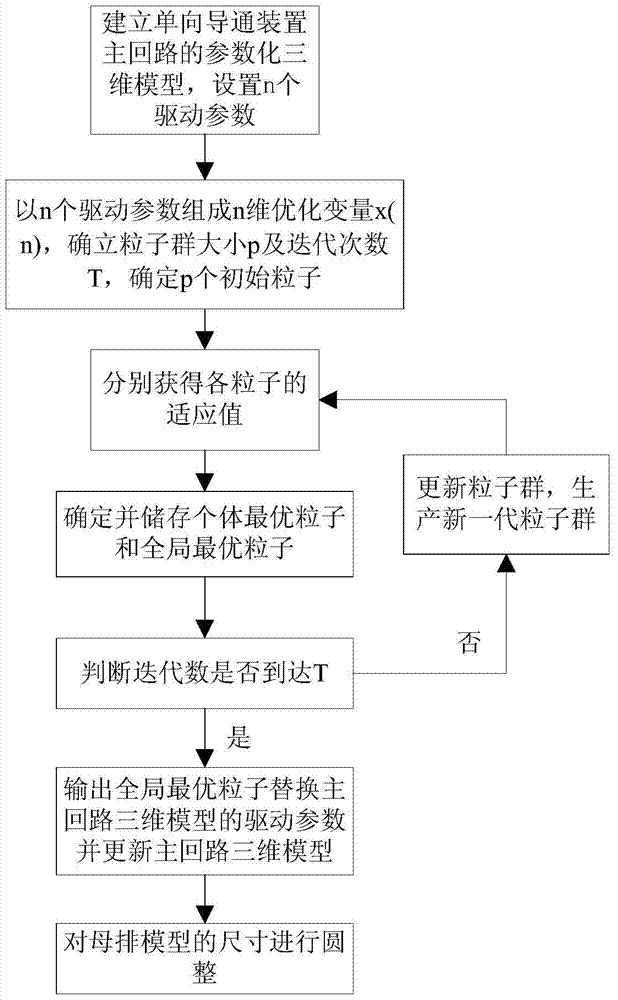

An Optimum Design Method for One-way Conductor Busbar

ActiveCN104573204BImprove optimization design efficiencyReduce manufacturing costSpecial data processing applicationsEngineeringDesign methods

Owner:CHINA UNIV OF MINING & TECH

Method for optimizing structural parameters based on symbolic operation results of sparse matrix

ActiveCN107944189AImprove optimization design efficiencyGeometric CADDesign optimisation/simulationMatrix decompositionElement analysis

The invention discloses a method for optimizing structural parameters based on symbolic operation results of a sparse matrix and belongs to the technical field of strength analysis of aircraft structures. The method mainly includes firstly generating a stiffness matrix through a finite element analysis method; secondly performing a matrix transformation on the stiffness matrix with a minimum filling element as a target, and establishing a mapping relationship; using the transformation to perform equivalent transformation on the right-end item of a load and then performing numerical decomposition, and forming a triangular decomposition matrix of a sparse matrix of linear equations; using results of matrix decomposition to perform finite element analysis to perform optimization calculation;using updated design variables to perform numerical item replacement operations by using the mapping relationship; and finally repeating the optimization process until the optimization converges. According to the method, the result of the first symbol operation is made full use of to perform the numerical decomposition operation. In the entire design process, only one symbolic operation needs to be performed. Compared with a traditional design process, theoretically the method shortens the design time by about 50%.

Owner:CHINA AIRPLANT STRENGTH RES INST

A method and system for calculating the magnetic field of a multi-phase cage induction motor

ActiveCN113452209BWide applicabilityImprove optimization design efficiencyManufacturing dynamo-electric machinesDesign optimisation/simulationGoverning equationHarmonics

A method and system for calculating the magnetic field of a multiphase cage induction motor. The method includes: dividing the solution area of the motor according to the type of excitation source to obtain a motor model, and obtaining the distribution function of the current density of the stator winding based on the motor model; for the first Influenced by the kth harmonic of the current density, the vector magnetic potential in each subdomain is taken as the solution object of the governing equation, and the Laplace equation, Poisson equation and Helmholtz equation are respectively established, and according to the The general solution of the vector magnetic potential is obtained based on the boundary conditions; based on the general solution of the vector magnetic potential of each subfield, the harmonic coefficients of each subfield are solved; based on the harmonic coefficients of each subfield, according to the expression of the vector magnetic potential of the air gap subfield Obtain the radial and tangential components of the air-gap magnetic density, according to the radial and tangential components of the air-gap magnetic density, and according to the Maxwell tensor method, obtain the torque caused by the kth space harmonic of the magnetomotive force and the total electromagnetic torque moment.

Owner:NAVAL UNIV OF ENG PLA

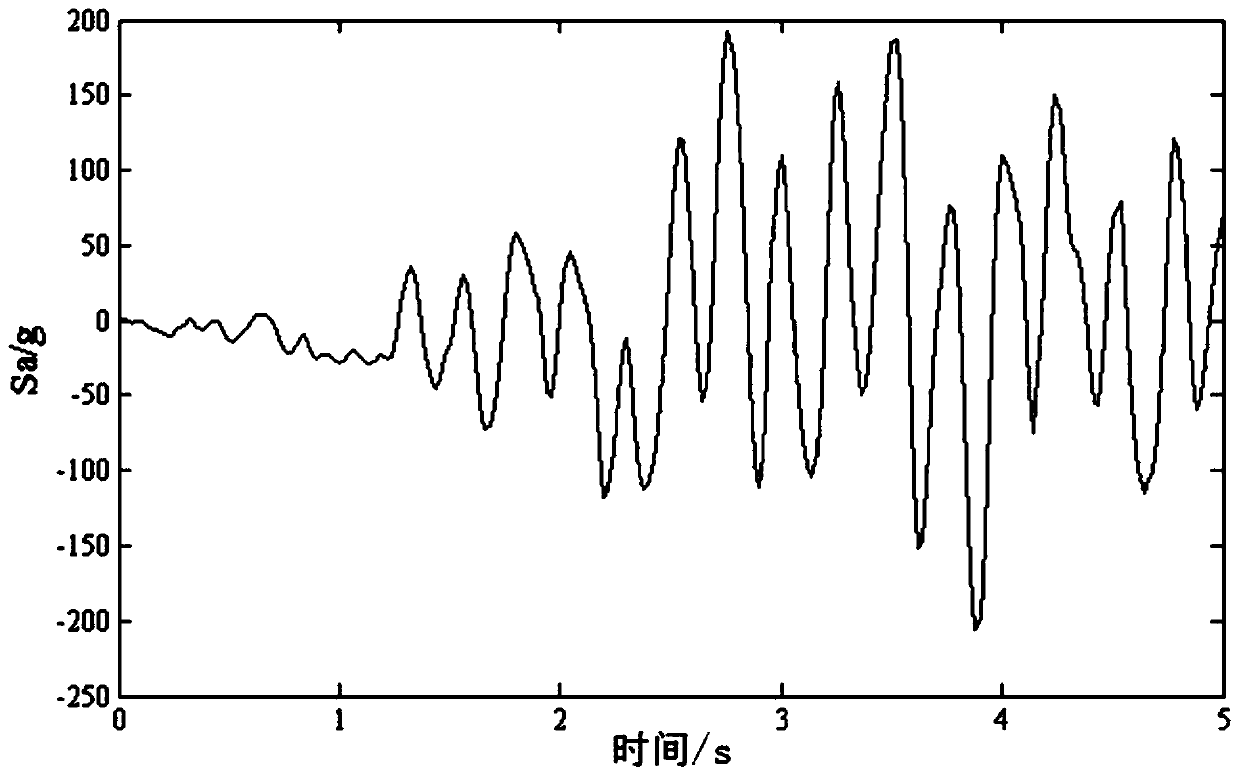

Seismic Optimal Design Method of Building Seismic Supports and Hangers

ActiveCN107798206BAvoid recalculationEasy to implementGeometric CADDesign optimisation/simulationThree-dimensional spacePolynomial regression model

The invention discloses an anti-seismic optimization design method of a building anti-seismic support-hanger. The method includes the steps: building a three-dimensional space analysis model of the building structure-anti-seismic support-hanger; selecting maximal space of the anti-seismic support-hanger and a minimum cross-sectional area of an inclined strut, and calculating maximum acceleration reaction of the anti-seismic support-hanger; calculating a floor response spectrum of a building structure, and correcting the floor response spectrum according to the maximum acceleration reaction toobtain a corrected floor response spectrum; building quadratic polynomial regression models among the maximum acceleration reaction of the anti-seismic support-hanger, the space of the support-hangerand the cross-sectional area of the inclined strut according to the corrected floor response spectrum; determining optimized design values of the space of the support-hanger and the cross-sectional area of the inclined strut. According to the method, polynomial regression models among earthquake actions of the anti-seismic support-hanger, the space of the support-hanger and the cross-sectional area and the support-hanger can be rapidly and accurately built, design parameters of the anti-seismic support-hanger are optimized, calculation result accuracy is ensured, and optimization design efficiency is greatly improved.

Owner:JIANGSU YIDINGGU ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com