Baffle plate design method for controlling membrane thickness distribution of spherical optical element in coating machine planet system

A technology of optical elements and planetary systems, which is applied in the field of baffle design to control the film thickness distribution of spherical optical elements, and can solve problems such as complex projection trajectories, several or even dozens of experiments, and difficult analytical solutions for baffle design. , to achieve the effect of improving design efficiency and high design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

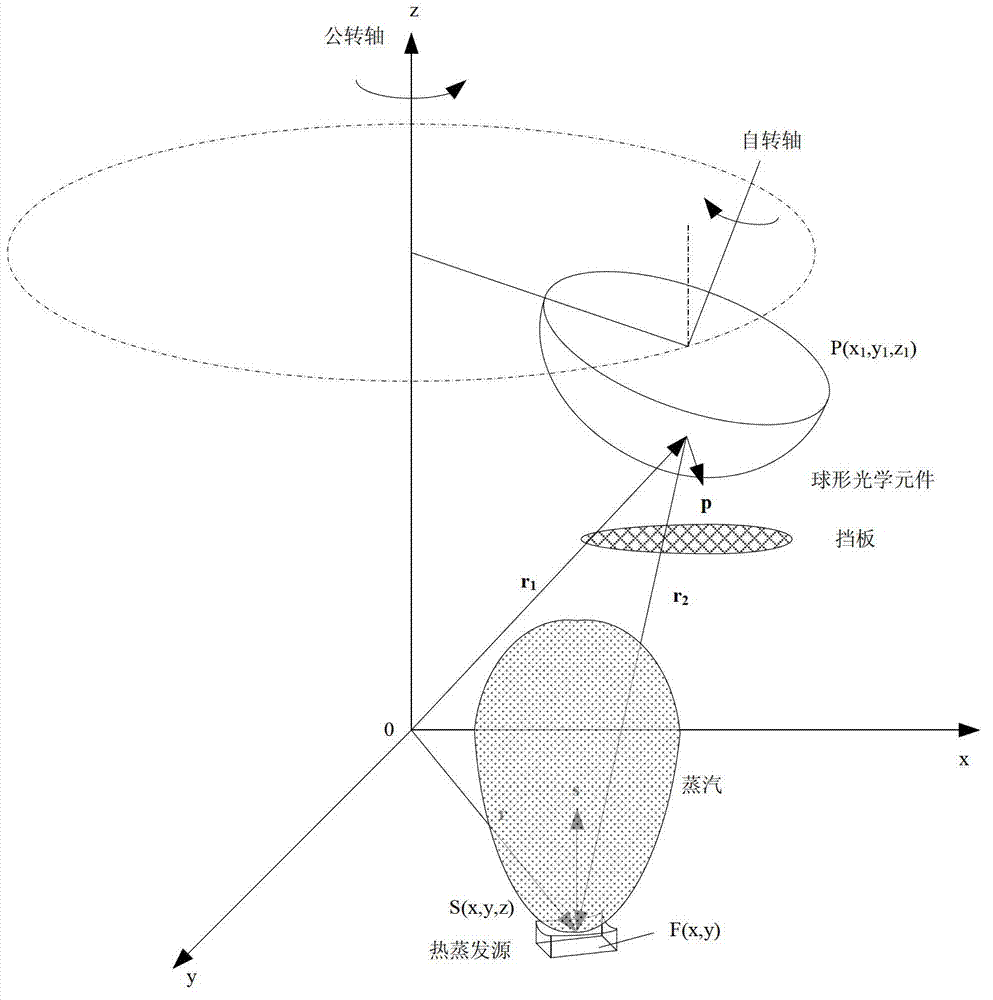

[0024] like figure 1 Shown is a schematic diagram of the thermal evaporation source-optical element-baffle combination system in a thermal evaporation vacuum coater equipped with a planetary system. In the thermal evaporation vacuum coating process, the evaporated thin film material is transported in a vacuum environment and deposited on the coating surface of the spherical optical element to form a thin film. In order to make the spherical optical thin film element meet the performance requirements of the optical system, it is necessary to control the film thickness distribution on the spherical optical element in the planetary system of the vacuum coating machine. The most common approach is to use baffles to control the film thickness distribution. The coated surface of the spherical optical element can be convex or concave. The specific computer optimization design process of the baffle used to control the film thickness distribution on the spherical optical element in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com