Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve labor utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

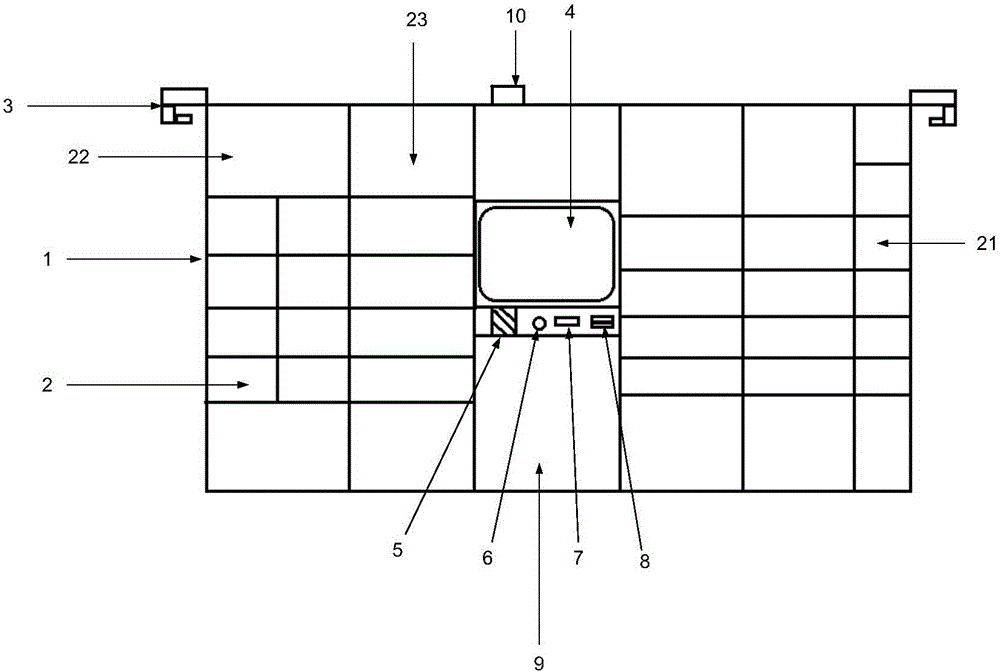

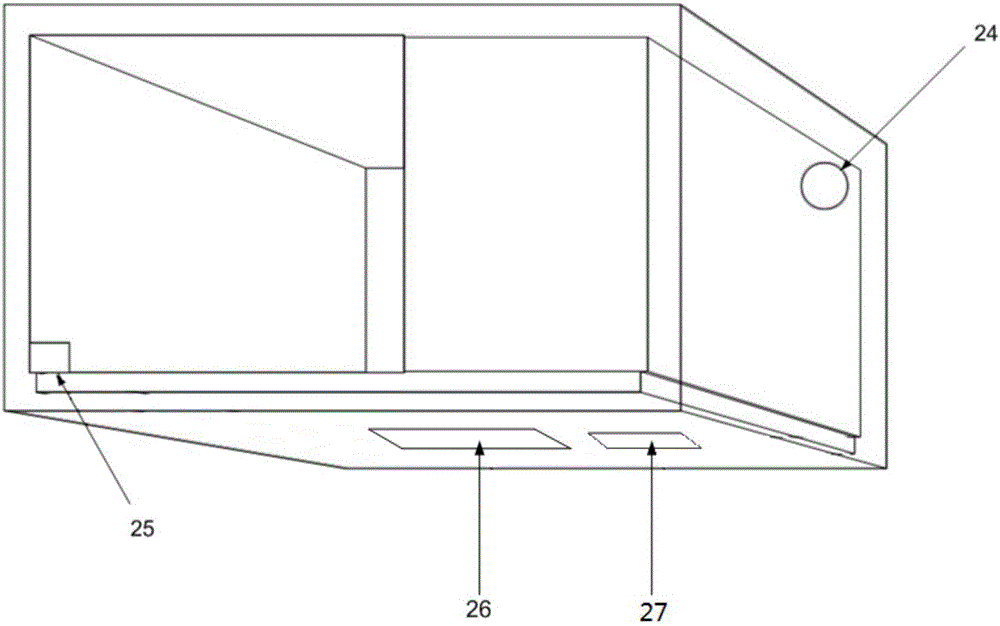

Multifunctional express delivery send-receive cabinet and application method thereof

ActiveCN105957266AFunction increaseImprove adaptabilityApparatus for meter-controlled dispensingThe InternetComputer terminal

The invention provides a multifunctional express delivery send-receive cabinet and an application method thereof, and belongs to the intelligent express delivery technical field; the express delivery send-receive cabinet comprises a cabinet body, a box group, cameras, a touch screen, an ID card sensor, a fingerprint recognizer, a bar-code scanner, a bar code generator, an intelligent control box, an alarm, a matching ID card, an internet mobile communication device, and a client end; the box group is nested in the cabinet body; the cameras are respectively fixed on two sides of the top of the cabinet body; the touch screen is nested in the cabinet body center, and fixedly arranged on the intelligent control box; the ID card sensor, the fingerprint recognizer, the bar-code scanner, and the bar code generator are fixed on the intelligent control box, and positioned below the touch screen; the internet mobile communication device is arranged in the intelligent control box; the alarm is fixedly arranged on the cabinet body. The multifunctional express delivery send-receive cabinet is various in functions, suitable for various express piece kinds, can improve express delivery send-receive efficiency, and can save space.

Owner:南通西科瑞智能科技有限公司

Novel technology for twice production of grapes in one year

The invention relates to the technical field of grape production, in particular to novel technology for twice production of grapes in one year. The technology comprises production period normal management, normal technological management of a sunny greenhouse, normal technological management of a sunny greenhouse, nutritive water management and comprehensive control of diseases and insects, fruiting of winter buds of annual-growth grape plants, twice planting of annual-growth grape plants in one year and twice production of fresh grapes in one year. The production steps comprise: selecting a good-quality grape variety, planting annual-growth grape seedlings in a soil accommodating container, placing the container in a corrugation, performing the production period normal management, trimming before protection against cold, disc-fixing grape braches, covering the grape braches by sand, taking the container out, transferring the container to a temperature regulation room, controlling the temperature and the moisture of the temperature regulation room, performing the before-planting temperature rise twice in one year, taking out the container, placing the container in the corrugation, performing the normal management, and simultaneously placing an ozone generator to control the growth of braches, leaves, flowers and fruits. By adopting new technology, the grape yield is improved by three times, the utilization rate of land is doubled, the profit is raised by three times and the labor efficiency is improved.

Owner:鞍山绿泰佳葡萄主题公园有限公司

Grape-cuttage orchard-construction ecological culturing method

InactiveCN105210791AIncrease productionImprove qualityCultivating equipmentsDiseaseEconomic benefits

The invention discloses a grape-cuttage orchard-construction ecological culturing method. The grape-cuttage orchard-construction ecological culturing method includes the following steps of seed branch collecting and treatment, wherein seed branches are collected, stored, treated and subjected to root promotion, and the seed branches with the cracked surfaces of base portions and adventive roots are obtained; orchard construction preparing work, wherein the preparing work includes good orchard planning, deep-ploughing land preparation, fertilizing, planting ditch excavating and supporting column fixing; seed branch planting, wherein the root-promoted branches are planted; after-planting management in the year, wherein the management includes soil fertilizer and water management, disease and pest control, summer pruning, winter pruning, foliage fertilizer spraying and winter orchard cleaning; after-planting management in the next year, wherein the management includes soil fertilizer and water management, summer pruning, flower promoting measure taking, disease and pest control, picking in proper time, timely thinning, and winter pruning and orchard cleaning. By means of the grape-cuttage orchard-construction ecological culturing method, grapes are high in yield and good in quality, and economic benefits are good; the soil use rate is high; the labor use rate is increased.

Owner:李佰峰

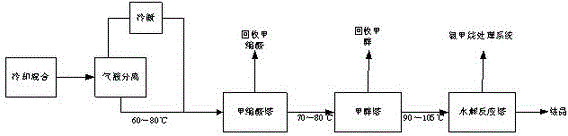

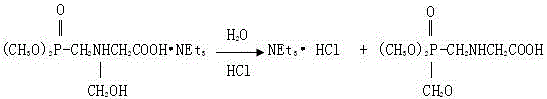

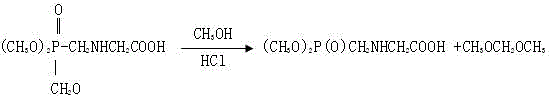

Continuous hydrolysis process for preparing glyphosate by glycine method

ActiveCN103739625BGuaranteed hydrolysis effectLess side effectsGroup 5/15 element organic compoundsGlycineHydrolysis

The invention provides a continuous hydrolysis process for preparing glyphosate by a glycine method. The process comprises following specific steps: (A) conveying a condensation reaction synthetic solution into a mixing reactor by a pump and controlling a material temperature to be lower than 55 DEG C to finish an acid adding and neutralizing process; (B) carrying out gas-liquid separation on materials discharged by a heat exchanger and enabling condensed gas and liquid to respectively enter a methylal recycling tower to recycle methylal; (C) enabling kettle bottom liquid discharged from the methylal recycling tower to enter a methanol recycling tower to recycle methanol; enabling kettle bottom liquid discharged from the methanol recycling tower to enter a hydrolysis tower to finish a hydrolysis reaction; and (D) carrying out flash evaporation on kettle bottom liquid discharged from hydrolysis tower; removing water and acid and enabling the kettle bottom liquid enter a crystallization kettle; and cooling and crystallizing under agitation to obtain the glyphosate.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

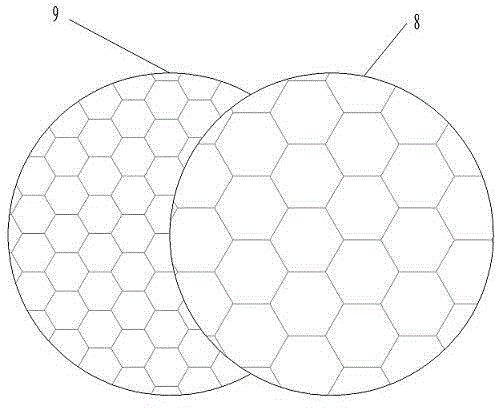

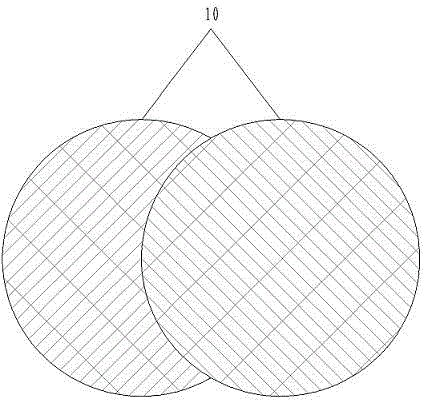

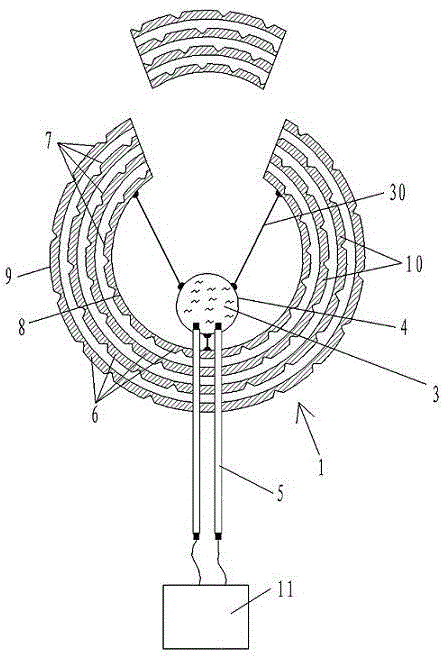

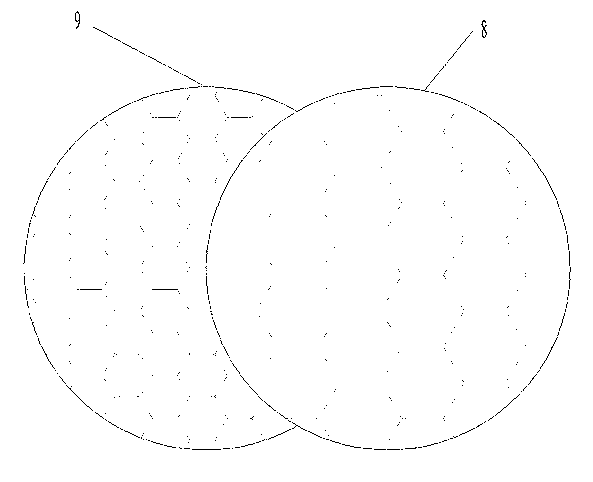

High-energy liquid blasting separated type farm-oriented material throwing device and throwing method

InactiveCN102696313ASimple operation techniqueImprove labor utilizationFertiliser distributersBlastingVoltage generatorAgricultural engineering

The invention relates to a high-energy liquid blasting separated type farm-oriented material throwing device and a throwing method, belongs to a material throwing device by blasting and a throwing method. Interior of an open container which can be blasted is divided into a plurality of small strip-shaped tubes which are arranged in a central radial shape by virtue of a plurality of partition boards which can not be blasted and are radially arranged, and each small strip-shaped tube is internally filled with farm-oriented material; one side of a bottom cover of a container which can not be blasted is provided with a liquid sac provided with an electrode, the liquid sac is arranged at the center of a radial shape, the bottom cover is used for sealing an opening of the container, and a safe device to be blasted is formed; and when a high-energy liquid blasting impact voltage generator is used for detonating the liquid sac, the sealed container is blasted out, and the farm-oriented material is uniformly thrown. The invention has the advantages that: operation is easy when the device disclosed by the invention is used for blasting and throwing the farm-oriented material, operation is safe, rapid and efficient, the phenomenon that farming season sowing is delayed is thoroughly solved, low temperature blasting is adopted while no farm-oriented material is damaged, agricultural labour force is liberated, the existing time-consuming agricultural operation is replaced, and a great agricultural technical revolution can be caused in future.

Owner:黄强 +1

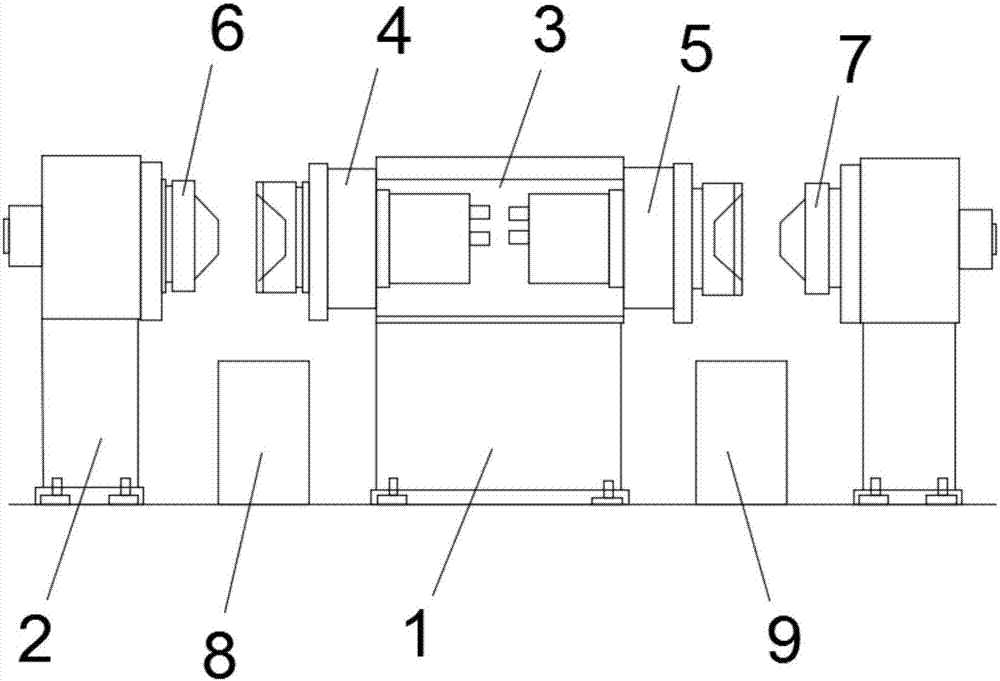

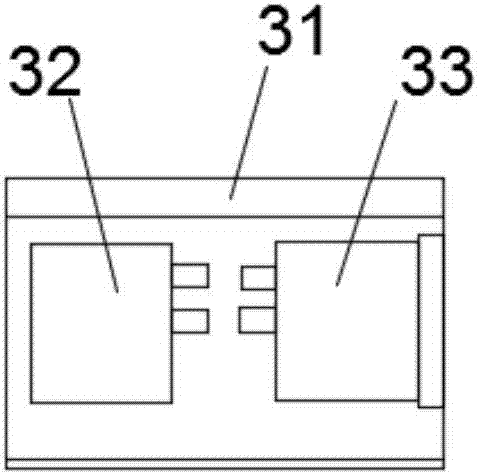

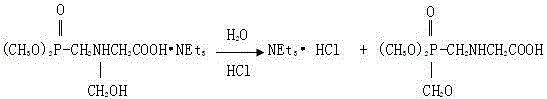

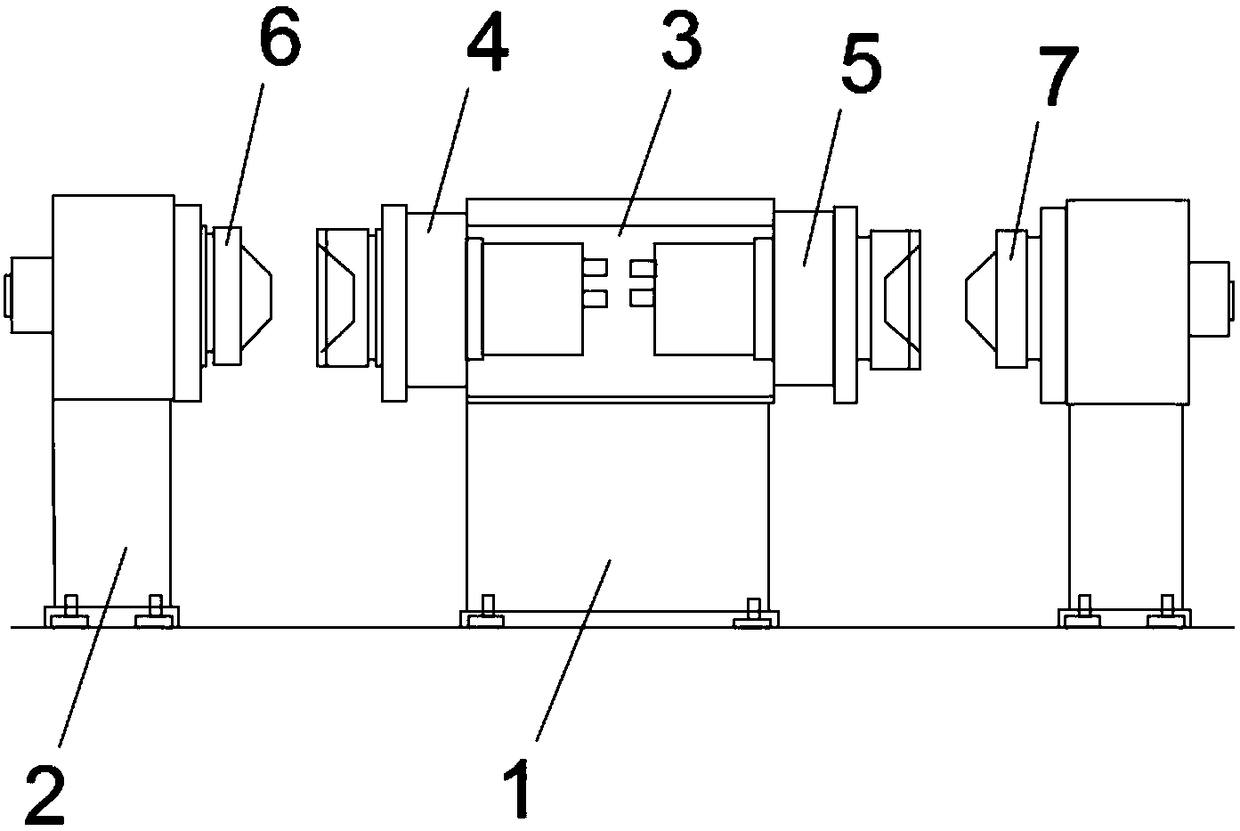

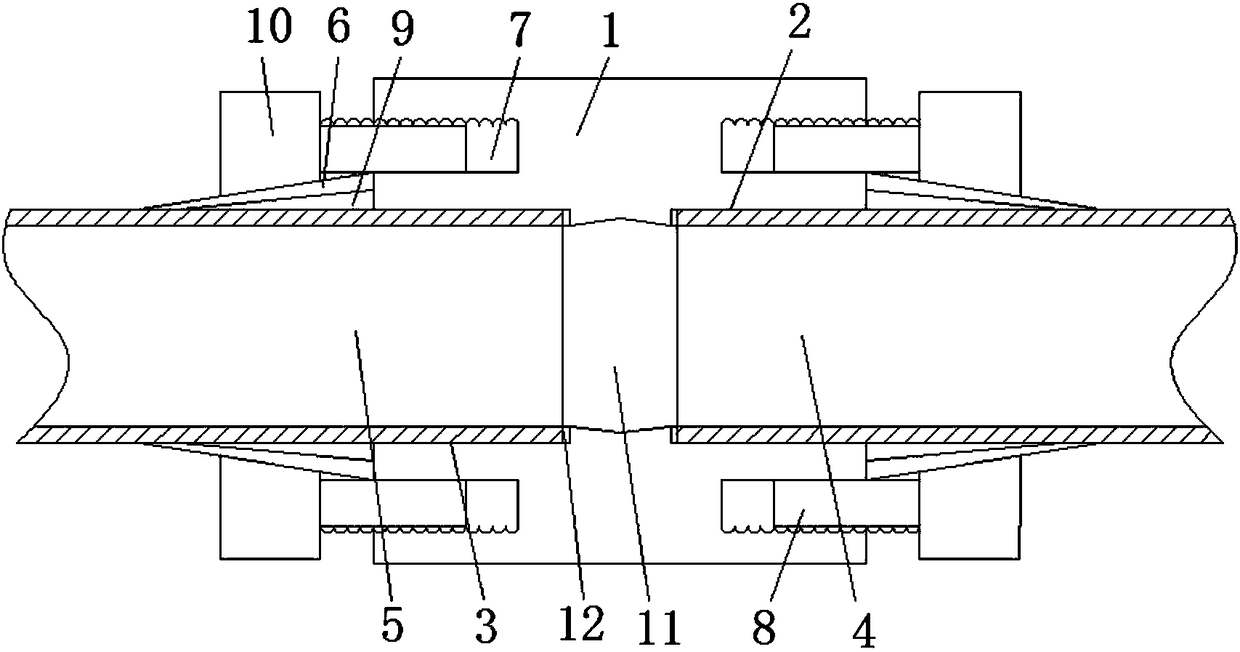

Pressure device for production of casting

The invention relates to a pressure device for production of a casting. The pressure device comprises a primary base and secondary bases. The primary base is in a cuboid shape, and is made of stainless steel materials. The bottom of the primary base is bent outwards and fixed through bolts. The number of the secondary bases is two, the secondary bases are arranged on the two sides of the primary base, the primary base and the secondary bases are located on the same straight line, and the secondary bases are kept symmetrical about the primary base. The secondary bases are in a cuboid shape, the length of each secondary base is smaller than that of the primary base, and the bottom of each secondary base is bent outwards and fixed through bolts. A power assembly is arranged on the upper portion of the primary base, a first press mold assembly and a second press mold assembly are arranged on the two sides of the power assembly, and a first fixing assembly and a second fixing assembly are arranged on the upper portions of the secondary bases.

Owner:JIASHAN YONGJIN METAL PROD

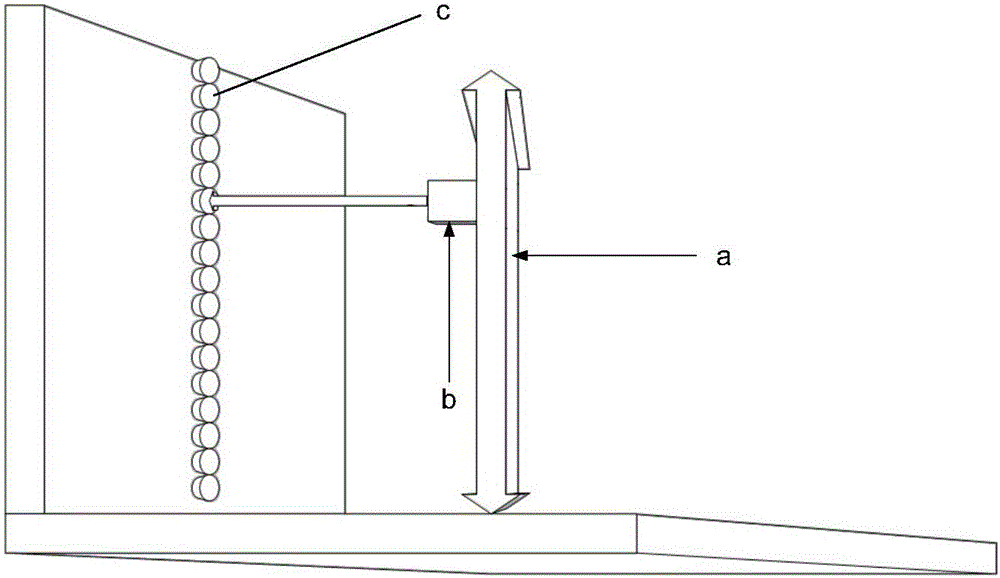

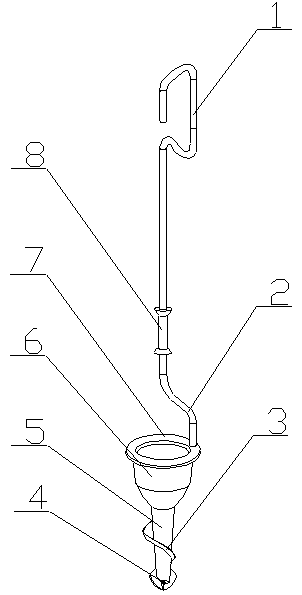

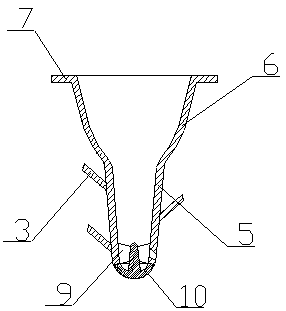

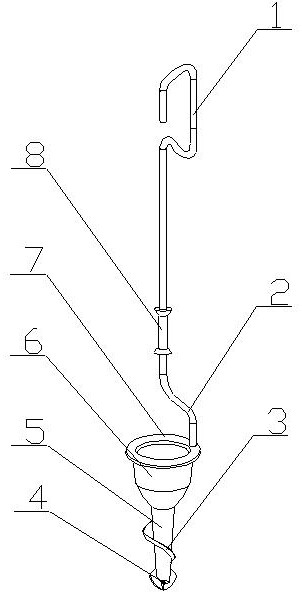

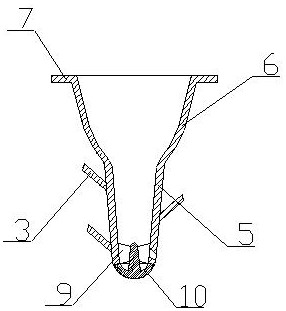

Agricultural-planting deep root fertilizing device

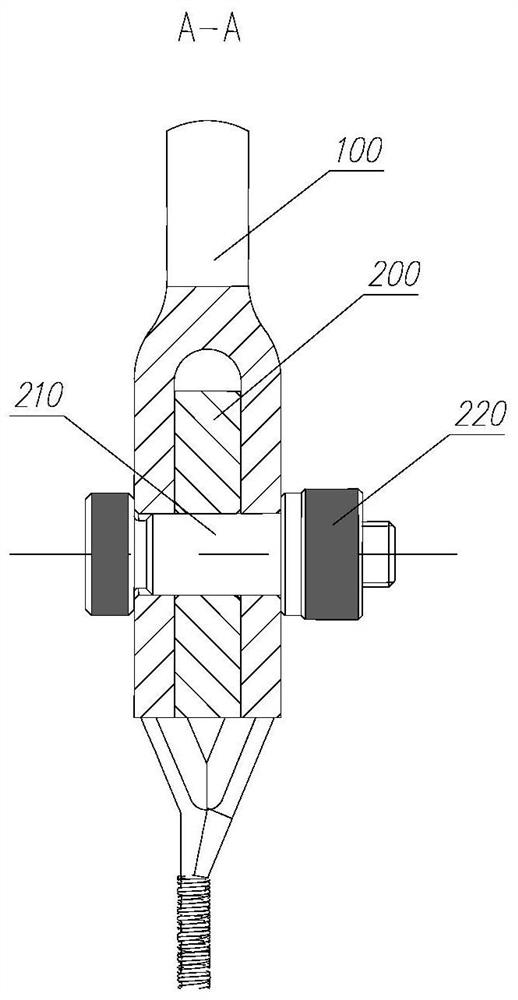

ActiveCN109275404AImprove labor utilizationImprove fertilization efficiencyManure treatmentFertiliser distributersBlade plateSpiral blade

The invention discloses an agricultural-planting deep root fertilizing device. According to the fertilizing device, rotary cutting is carried out on a soil layer through an spiral blade at the outer side, and a fertilizer is pushed into soil through relative rotation between a guide pipe and blade plates. The fertilizing device can be operated by a single person, soil filling is not needed, and fertilization operation efficiency is effectively improved. The fertilizing device is characterized in that one end of the guide pipe is arranged at the bottom of a hopper and communicates with the hopper, the diameter of the bottom of the hopper is gradually reduced, the diameter of the guide pipe is gradually increased from the other end to one end, and the diameter of the other end of the guide pipe is one half of the diameter of one end of the guide pipe; a rotating block is rotatably arranged at the other end of the guide pipe, the rotating block is of an arc-shaped cover structure, the middle of the rotating block extends towards the inner part of the guide pipe to form a rotating shaft, and a plurality of the blade plates are arranged on the rotating shaft at equal intervals; a gap isformed between the blade plate and the inner wall of the guide pipe, a blanking hole is formed in the guide pipe and corresponds to the bade plates, and the diameter of the blanking hole is graduallyreduced from inside to outside; and the spiral blade is arranged on the outer wall of the guide pipe.

Owner:滁州禾田农业机械有限公司

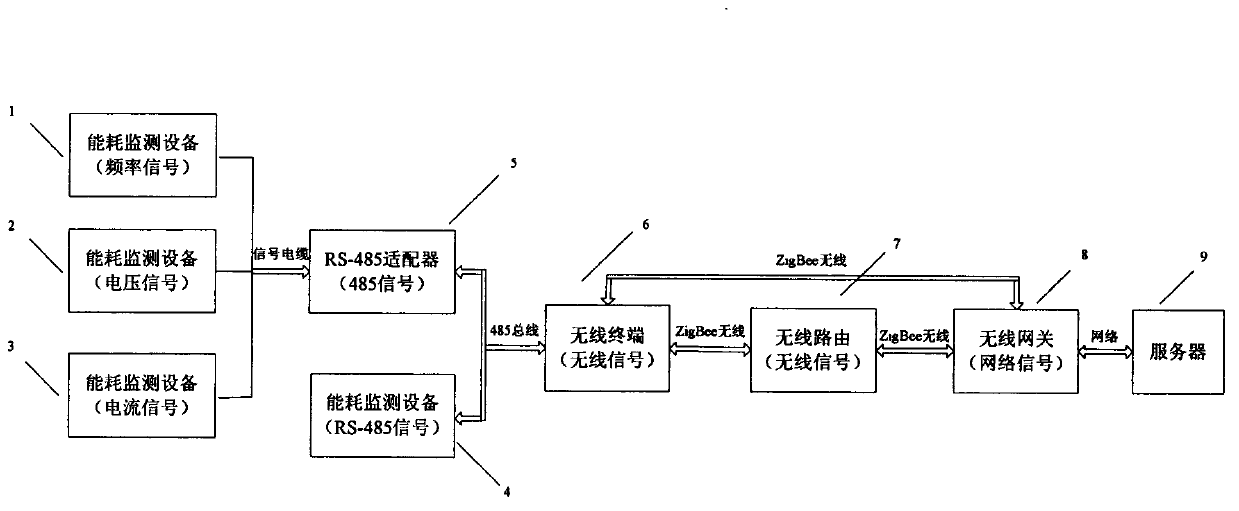

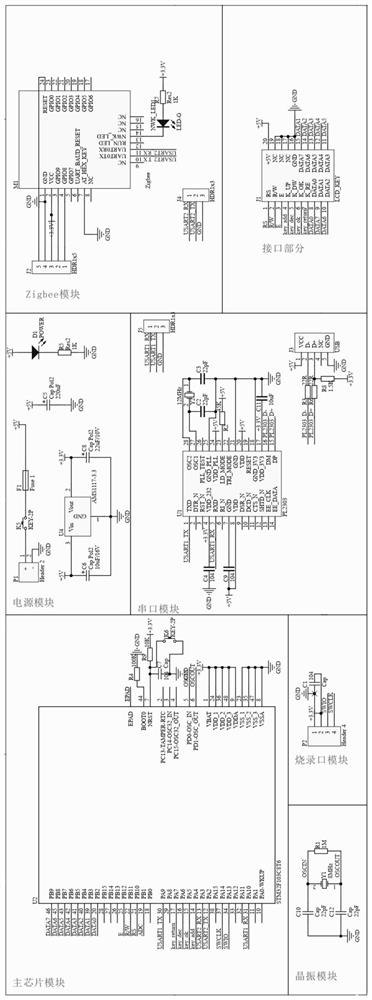

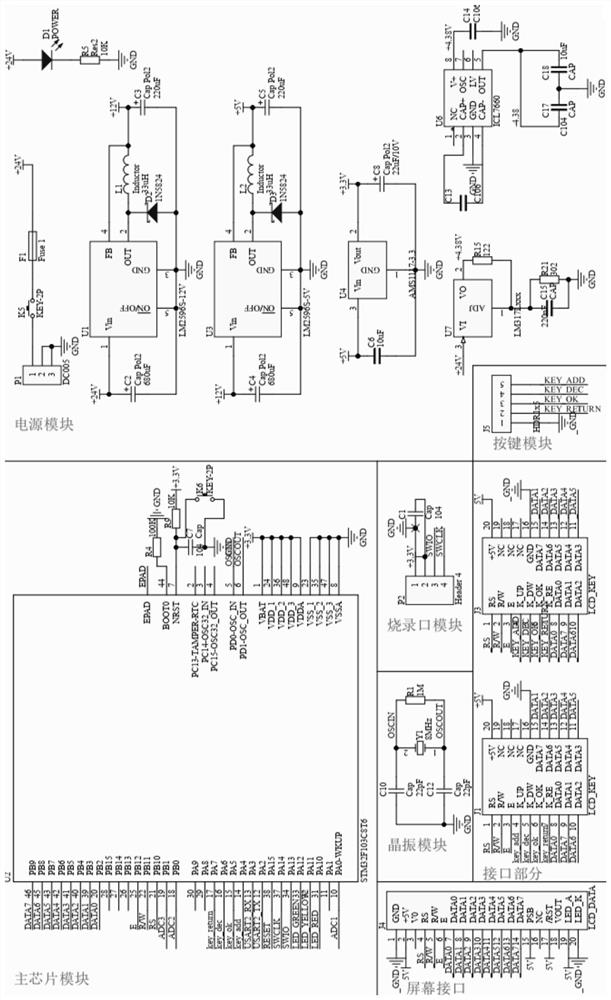

Wireless sensing communication system and wireless sensing communication method for monitoring energy consumption

InactiveCN103680093AIncrease the number ofReal-time grasp of energy consumptionTransmission systemsNetwork topologiesHysteresisEngineering

The invention relates to a wireless sensing communication system for monitoring energy consumption. The system consists of energy consumption monitoring devices, and has the difference that the energy consumption monitoring devices are connected with an RS-485 adapter (5) by a signal cable; the RS-485 adapter (5) is connected with a wireless terminal (6) by an RS-485 bus; a wireless router (7) is connected with a wireless gateway (8) by the wireless terminal (6) through a Zigbee in a wireless way; the wireless gateway (8) is connected with a server (9); a wireless transmission communication method is provided by the invention. Therefore, energy consumption monitoring communication of industrial and mining enterprises can be realized, the problems that the energy consumption monitoring data has hysteresis, the traditional monitoring method is limited by wiring condition, the transmission bandwidth is narrow and is not stable, the signal attenuation is high, and the like can be solved, the wireless sensing communication system is suitable for acquiring and transmitting the energy consumption data in the environment with complicated mine geological conditions.

Owner:SHANDONG GOLDSOFT TECH LTD

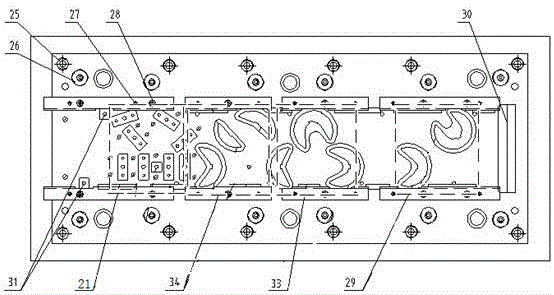

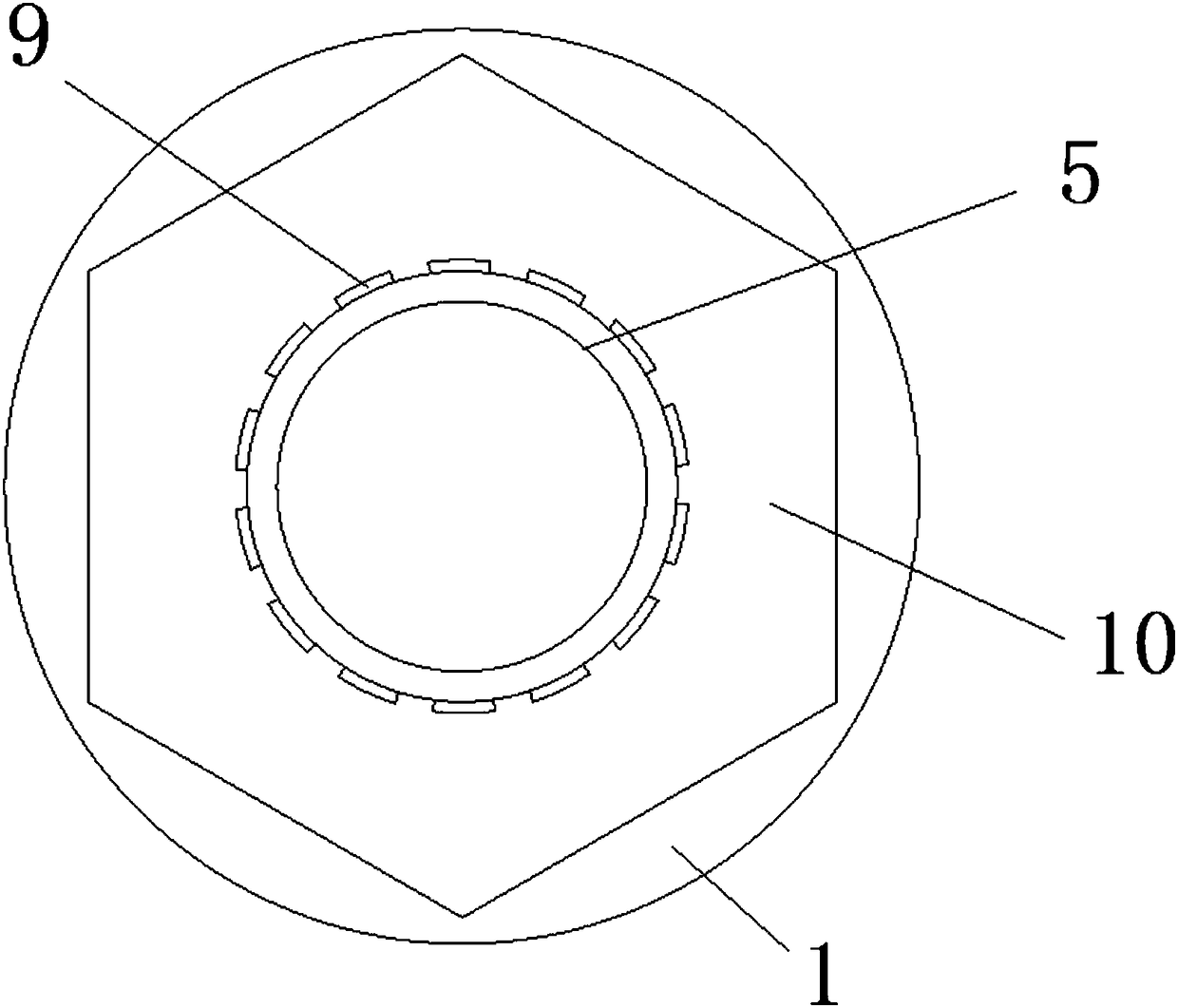

C-shaped pole shoe one-die eight-element continuous manufacturing method and continuous die

PendingCN106270159AImprove productivityPromote safe productionShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a C-shaped pole shoe one-die eight-element continuous manufacturing method and a continuous die. Eight groups of convex hulls and through holes are stamped in a strip by means of convex hull stamping male die inserts, and then C-shaped pole shoes corresponding to the eight groups of convex hulls and through holes are subjected to blanking and die stripping sequentially through blanking female die inserts and special-shaped male dies in the strip moving process. The continuous die comprises a female die fixing plate, the convex hull stamping male die inserts and the eight blanking female die inserts different in shape are sequentially arranged on the female die fixing plate, and each convex hull stamping male die insert is provided with a convex hull stamping male die and a punching female die; an upper die base is arranged above the female die fixing plate, the special-shaped male dies corresponding to the blanking female die inserts and convex hull stamping female die inserts corresponding to the convex hull stamping male die inserts are arranged below the upper die base, and each convex hull stamping female die insert is provided with a convex hull stamping female die and a punching male die. The method and the continuous die have the advantages that production efficiency is high, machining time is short, and manpower resources are saved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

Method for recycling negative material from waste lithium ion battery

ActiveCN103346365BSolve the technical problems of recyclingImprove electrical performanceWaste accumulators reclaimingBattery recyclingOrganic solventProcess engineering

The invention discloses a method for recycling a negative material from a waste lithium ion battery. The method comprises the following steps of detecting the voltage of the waste lithium ion battery, disassembling the battery, taking out a cell, thoroughly separating the negative material on a negative pole piece from a copper foil, and carrying out the high-temperature impurity removal treatment on the recycled graphite negative material so as to finally obtain the graphite negative material of an original state. The method is simple and feasible, the cost is lower than that of the negative material which is sold in the market, no organic solvent is used in the recycling process, no dust is produced, and the method is environment-friendly compared with the production process of a normal negative material. Meanwhile, the recycling of the waste resource favors the protection of the existing resource and can guarantee the long-term development of the lithium ion battery industry.

Owner:信骅(上海)器材有限公司

A method for reclaiming and separating positive pole pieces from waste lithium-ion batteries

ActiveCN103367839BSolve the technical problems of recyclingSimple methodWaste accumulators reclaimingBattery recyclingOrganic solventEngineering

The invention discloses a method for recovering and separating an anode pole piece from a waste and old lithium ion battery. The method comprises the steps: carrying out voltage detection of the waste and old lithium ionic battery, dismantling the battery, removing an electric core of the battery, and completely separating an anode material of the anode pole piece from an aluminum foil by high temperature treatment. The method is the simple and easy method, does not require any organic solvents in the treatment process, cannot produce dust, and is more environmentally friendly compared with a conventional separation process. At the same time, waste and old resource recycling is a way of protection of existing resources, and ensures long-term development of lithium ion battery industries.

Owner:内蒙古斯诺新材料科技有限公司

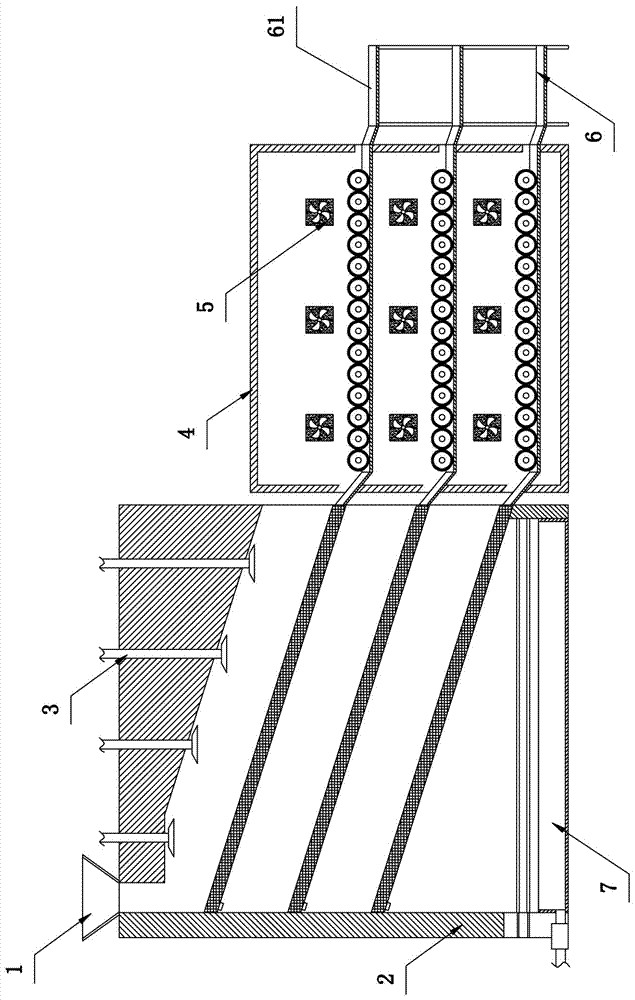

Plastic grain transmission equipment and use method thereof

PendingCN107053520APromote healthy developmentSimple structureGas current separationDrying gas arrangementsAgricultural engineeringTransmission equipment

The invention provides plastic grain transmission equipment and a use method thereof. The plastic grain transmission equipment comprises a feeding hopper, a screening transmission device, a cleaning device, a drying transmission device, a hot air device, a material collection device and a filtering device. Through the arrangement of the screening transmission device, the cleaning device, the drying transmission device and the hot air device, plastic grains are transmitted while screening and classifying, cleaning and drying can also be achieved, operation is simplified, the utilization rate of labor is greatly increased, and benign development of enterprises is facilitated.

Owner:福建汇利丰环保科技有限公司

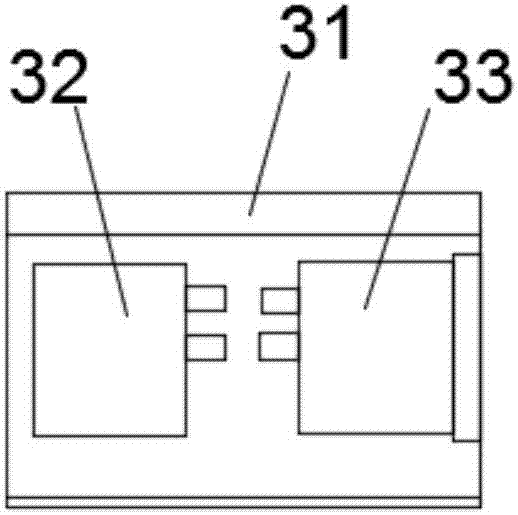

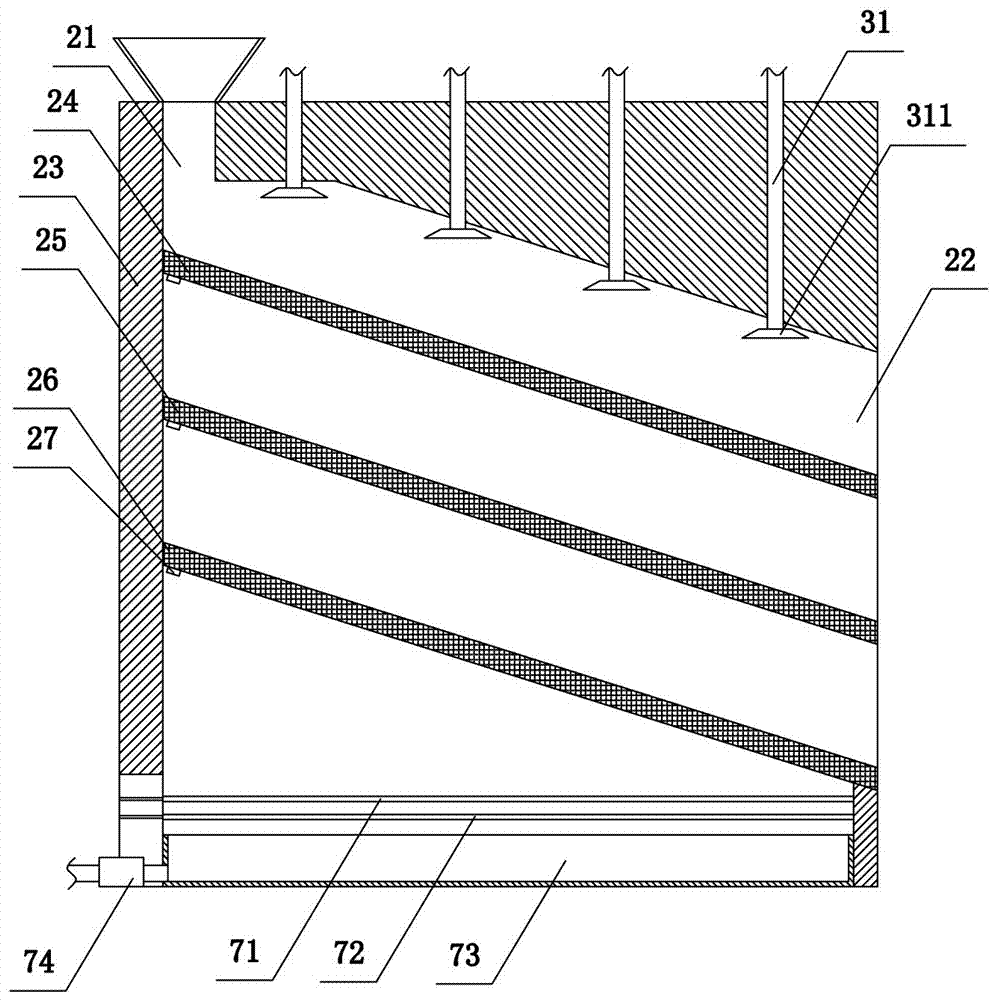

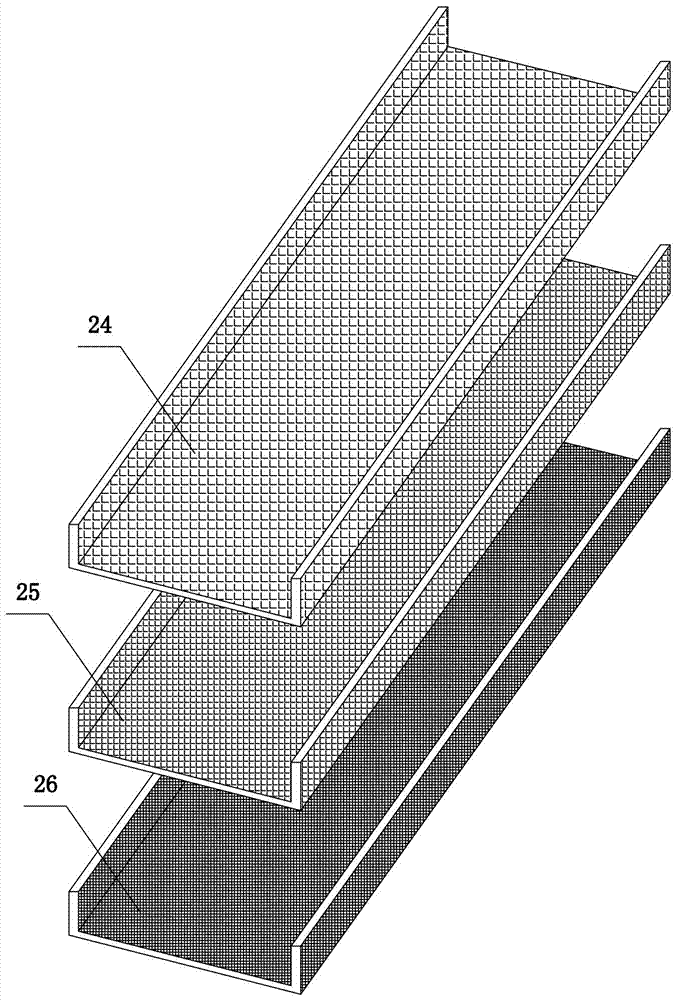

Utilization rate monitoring system

InactiveCN113391148AEasy to operateImprove labor utilizationElectrical testingMachine utilizationMonitoring system

The invention relates to a utilization rate monitoring system. According to the scheme, the utilization rate monitoring system comprises detection instruments, a coordinator and a server side. The detection instruments are arranged on machines and acquire the utilization rates of the machines, each machine is provided with a state display lamp in communication connection with the corresponding detection instrument, and an operator can check the states of the machines through the state display lamps. The coordinator is in communication connection with each detection instrument, collects and sorts machine utilization data on each detection instrument, and regularly uploads the machine utilization data to the server side. The coordinator is in communication connection with the server side, the utilization rate state data of each machine is generated through the server, and the scheduling data is generated according to the utilization rate state data and the production arrangement data. The system can remarkably improve the utilization rate of each machine in a workshop to maximize the utilization rate, and enable an operator to conveniently check and operate the machines. Meanwhile, performance assessment can be carried out on employees according to the utilization rate, and the number of equipment in each workshop can be increased or decreased to achieve machine supply and demand balance.

Owner:杭州捷配信息科技有限公司

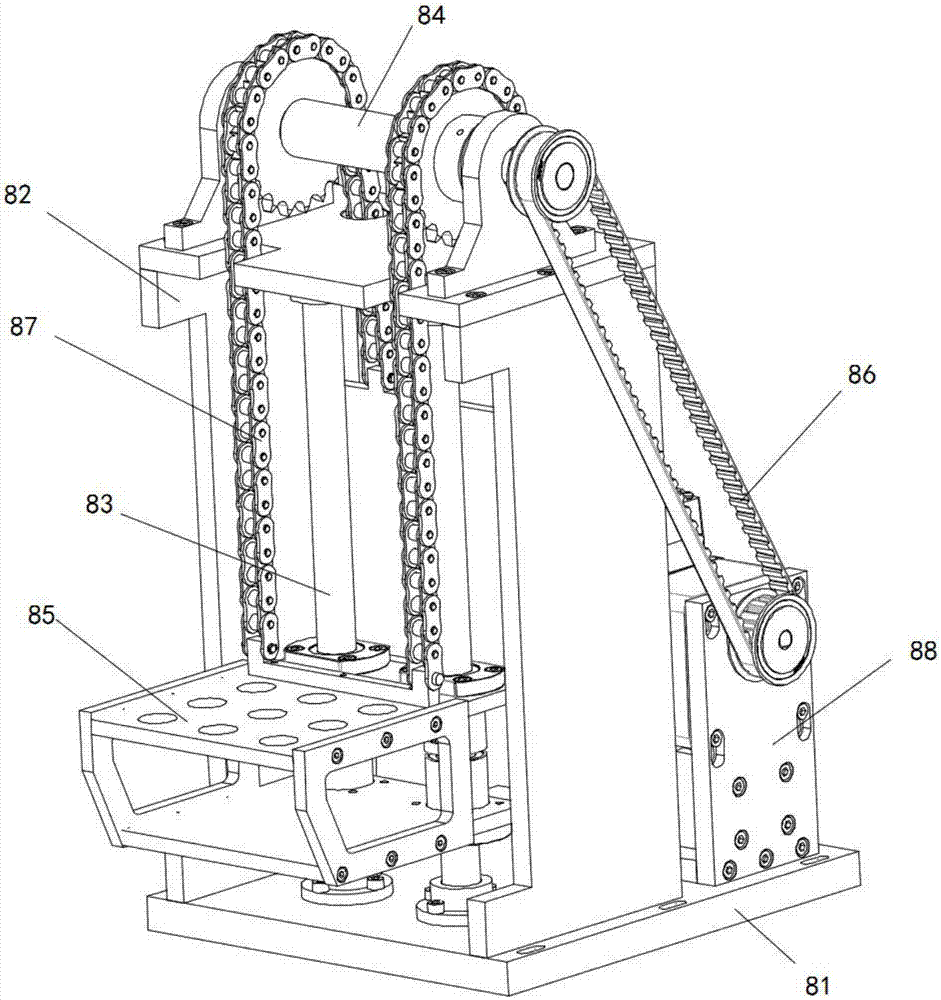

Casting pressure device with lifting function

The invention relates to a casting pressure device with a lifting function. The device comprises a main base and secondary bases; a power module is arranged at the upper part of the main base; a first pressing mold module and a second pressing mold module are respectively arranged on two sides of the power module; a first fixing module and a second fixing module are respectively arranged at the upper parts of the two secondary bases; a first lifting module and a second lifting module are respectively arranged on two sides of the main base; and the first lifting module includes a base, a lifting frame arranged at the upper end of the base, a lifting rod arranged in the lifting frame, a driving motor arranged on the side surface of the lifting frame, a transmission rod arranged at the upper end of the lifting frame, and a lifting base arranged on the side surface of the lifting frame.

Owner:JIASHAN YONGJIN METAL PROD

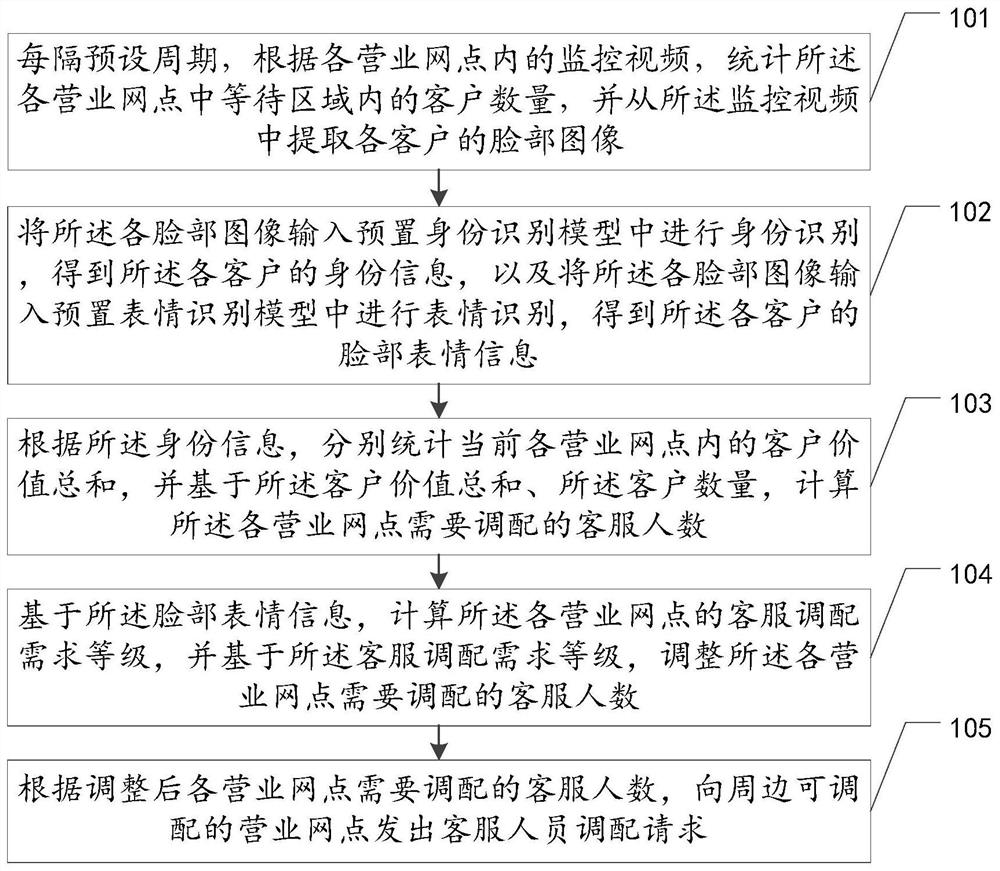

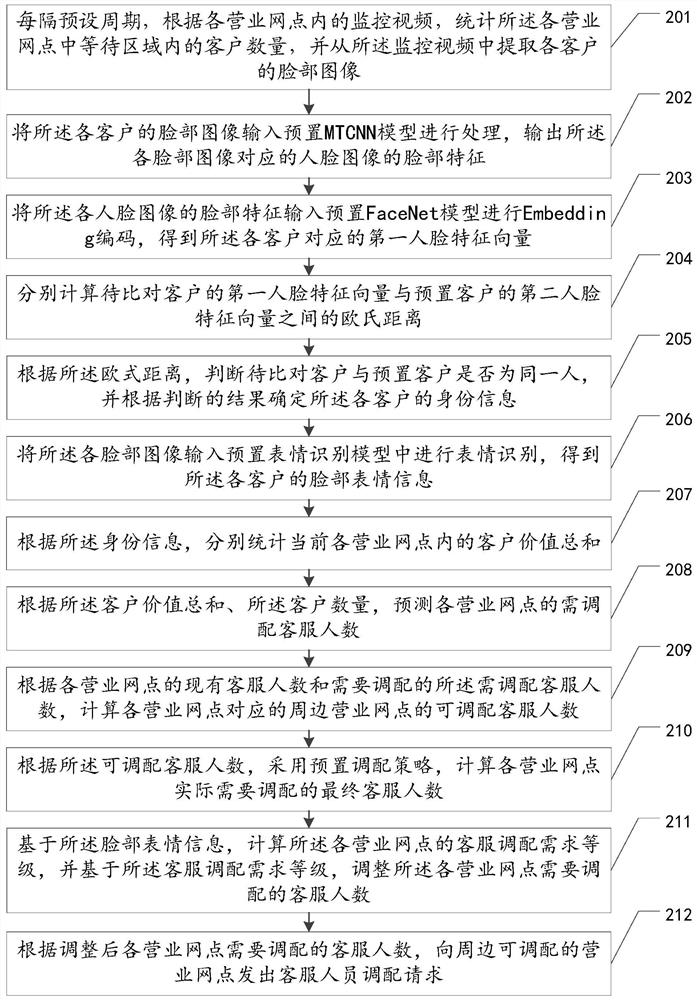

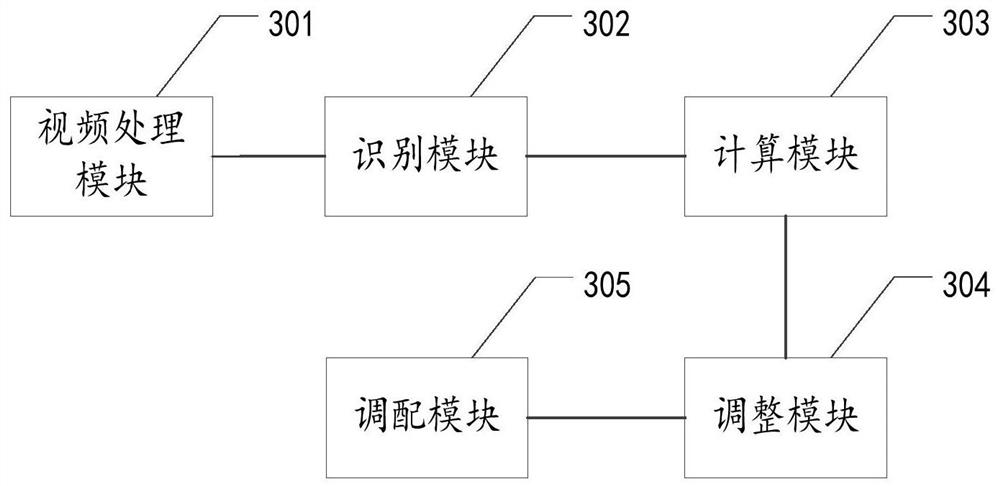

Customer service staff scheduling method, device and equipment and storage medium

PendingCN112580538AImprove service satisfactionReduce labor costsFinanceDigital data authenticationComputer networkIdentity recognition

The invention relates to the field of artificial intelligence, and discloses a customer service staff scheduling method, device and equipment and a storage medium. The method comprises the following steps: counting the number of clients according to monitoring videos in each business outlet, extracting face images of each client from the monitoring videos, respectively inputting the face images into a preset identity recognition model and a preset expression recognition model, and recognizing identity information and facial expression information of each client; according to the identity information, respectively counting the sum of customer values of each business outlet, and calculating the number of customer service staff needing to be allocated for each business outlet in combination with the counting number of the face images; and finally, according to the facial expression, adjusting the number of customer service staff needing to be allocated at each business outlet, and sendinga customer service staff allocation request to the business outlets which can be allocated around. The invention also relates to a blockchain technology, and the face image is stored in the blockchain. According to the invention, dynamic mobilization of customer service staff is realized, the manual utilization rate of customer service staff is improved, and the labor cost of enterprises is reduced.

Owner:PING AN BANK CO LTD

A deep root fertilizer applicator for agricultural planting

ActiveCN109275404BImprove labor utilizationImprove fertilization efficiencyManure treatmentFertiliser distributersSpiral bladeAgricultural engineering

The invention discloses an agricultural planting deep-root fertilizer which discloses a fertilizer which rotates the soil layer through the outer helical blade, and pushes the fertilizer into the soil through the relative rotation between the guide pipe and the leaf plate. Single-person operation, no need to fill soil, effectively improving the efficiency of fertilization operations. It is characterized in that one end of the guide pipe is placed at the bottom of the hopper and communicated with the hopper, the diameter of the bottom of the hopper gradually decreases, the diameter of the guide pipe gradually increases from the other end to one end, and the diameter of the other end of the guide pipe is the guide One-half of the diameter of one end of the tube, the rotary block is rotatably placed on the other end of the guide tube, the rotary block is an arc-shaped cover structure, the middle part of the rotary block extends to the inside of the guide tube to form a rotating shaft, a plurality of leaf plates, etc. The distance is placed on the rotating shaft, and there is a gap between the leaf plate and the inner wall of the guide tube. There is a blanking hole on the guide tube, which corresponds to the page plate. The diameter of the blanking hole gradually decreases from the inside to the outside. , the helical blade is placed on the outer wall of the guide tube.

Owner:滁州禾田农业机械有限公司

High-energy liquid-explosion separation-type material throwing stand-by device

InactiveCN102698917AGood quality statusGood production effectLiquid spraying apparatusVoltage generatorAgricultural science

The invention relates to a high-energy liquid-explosion separating-type material throwing stand-by device, which belongs to the field of explosive material throwing devices. The stand-by device is formed in a manner that an explosive open container is internally divided to a plurality of strip tubes which are arranged in a radial pattern from one center by virtue of numerous non-explosive clapboards arranged in a radial pattern, wherein if the strip tubes are filled with agricultural materials, a liquid container with an electrode on one surface of a bottom cover of a non-explosive container, and the opening of the container is sealed by the bottom cover; and when the liquid container is detonated by a high-energy liquid-explosion impulse voltage generator, the agricultural materials are uniformly thrown out after the sealed container is bombed out,. The stand-by device has the advantages that the agricultural materials are loaded in the container when an explosion occurs, and the agricultural materials are stored according to the conventional manner before the explosion occurs, therefore, the quality of the agricultural materials can be more favorably guaranteed; and when being used for exploding and throwing the agricultural materials, the stand-by device is simple to operate and safe, fast and efficient in operation, avoids the problem of sowing delay in farming seasons, allows agricultural labor force to be liberated and can substitute for the conventional time-wasting and labor-wasting agricultural operation, thus serving as great agricultural technical revolution.

Owner:黄强 +1

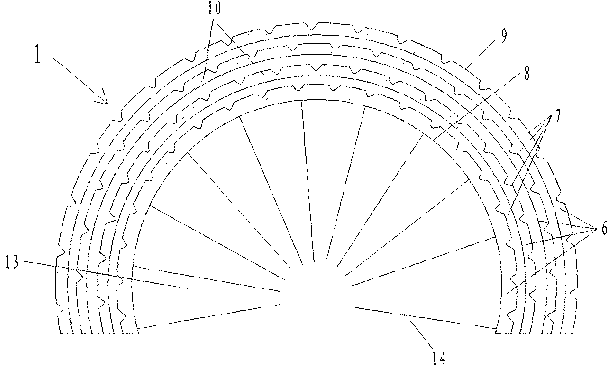

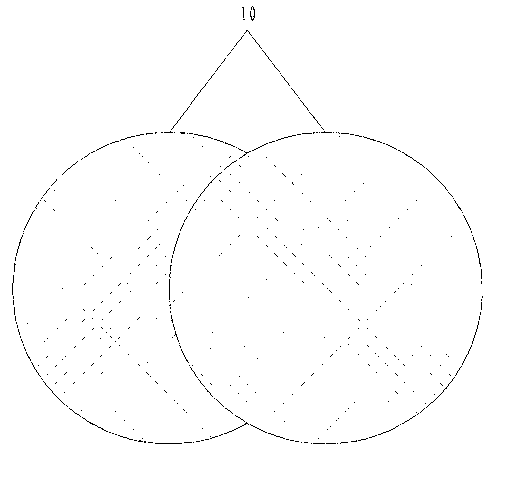

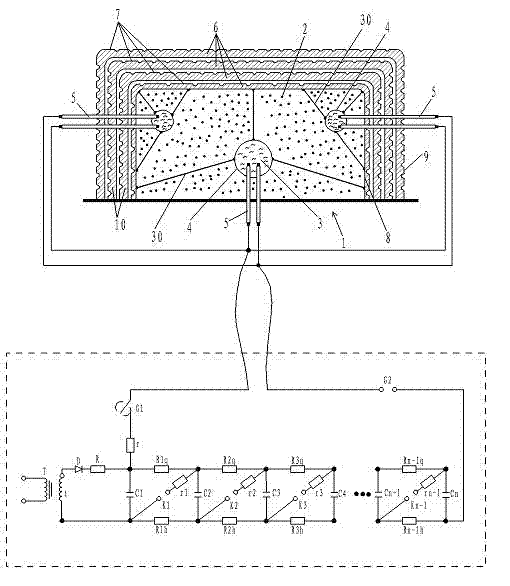

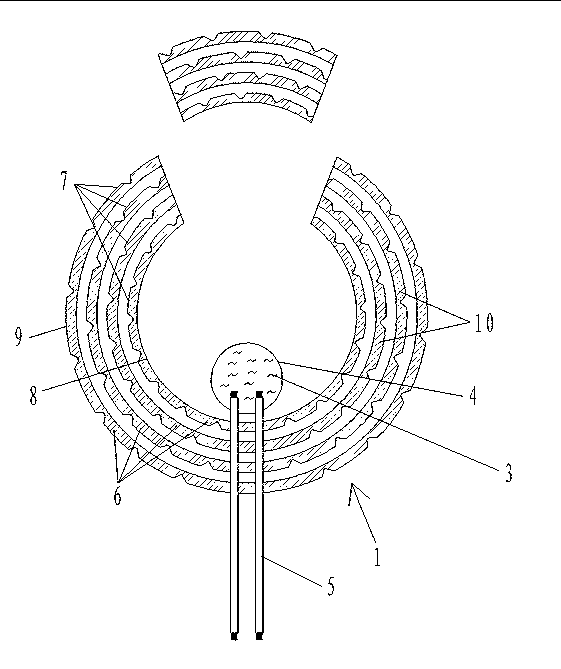

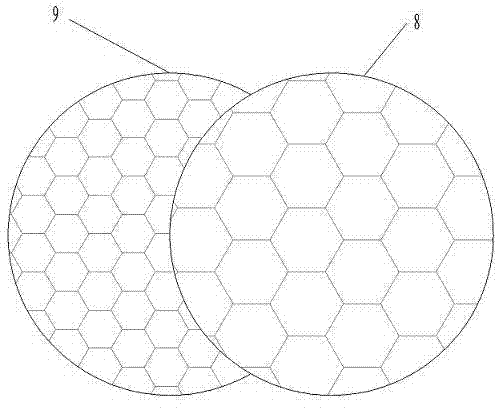

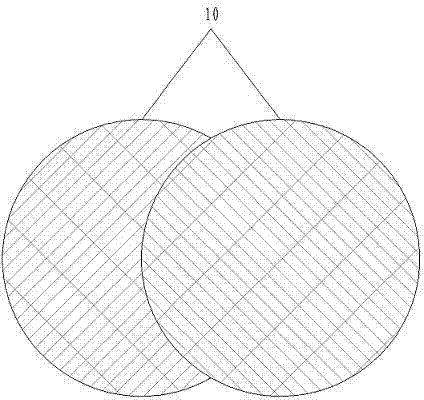

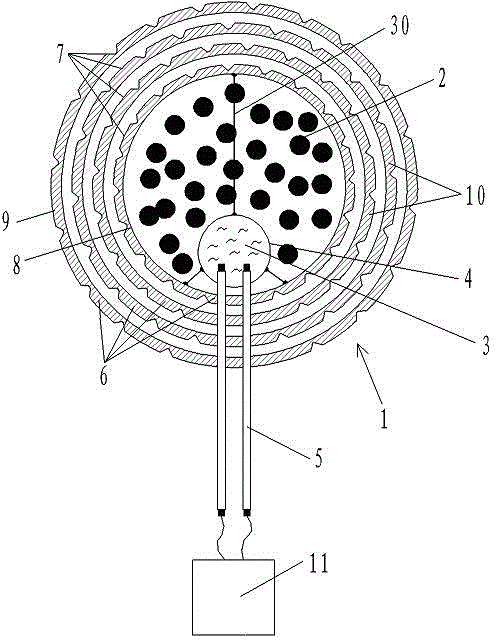

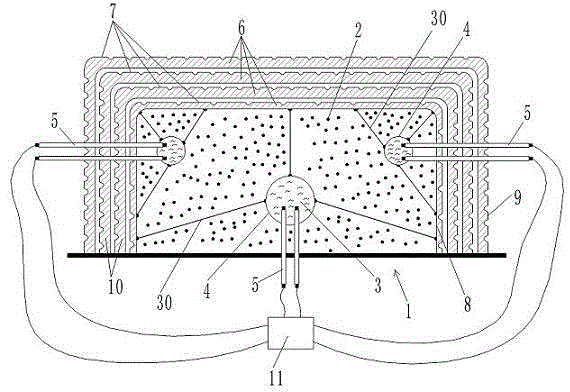

Dividing type agricultural material scattering device with high energy liquid detonation and scattering method

InactiveCN103111392BSimple operation techniqueImprove labor utilizationLiquid spraying apparatusLoad circuitVoltage generator

Owner:黄强 +1

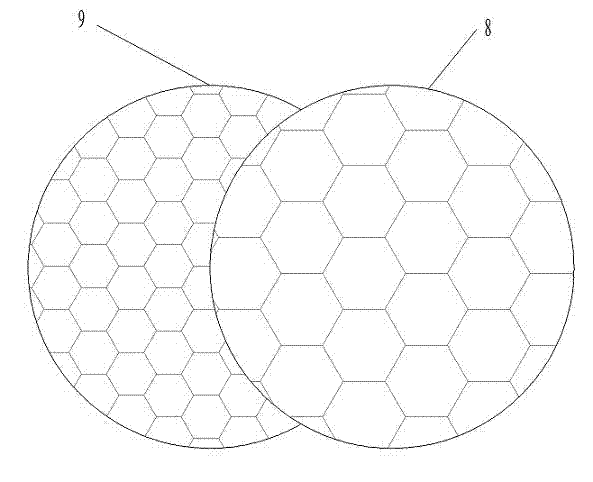

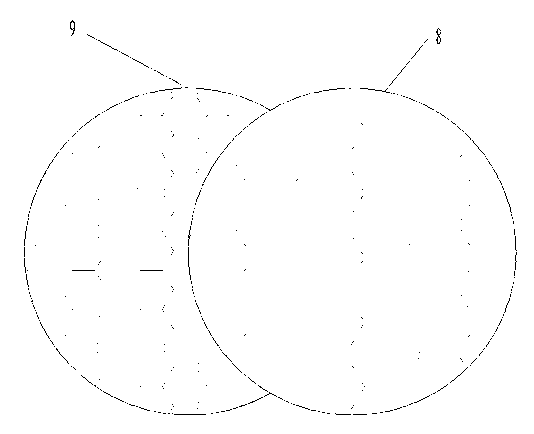

High-energy liquid explosion fixed-point blasting spare device for throwing agricultural materials

InactiveCN103111391BSimple operation techniqueImprove labor utilizationLiquid spraying apparatusVoltage generatorDetonation

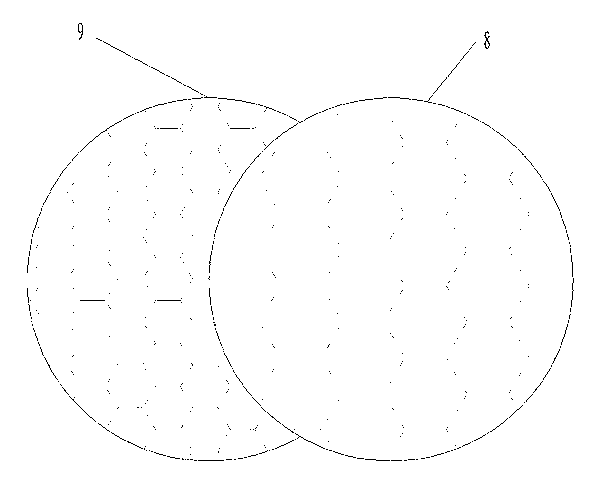

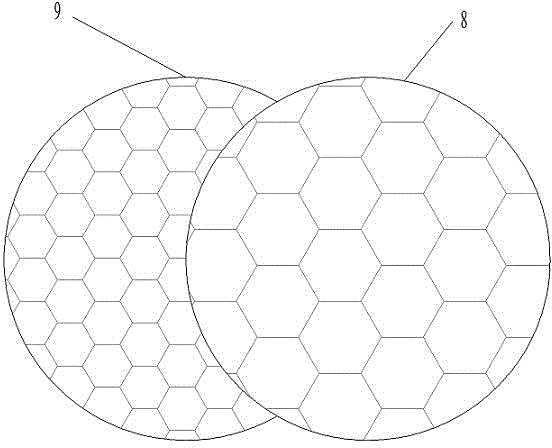

The invention relates to a high energy liquid detonation blob blasting agricultural-material scattering backup device and belongs to blasting material-scattering devices and scattering methods. Liquid bags with electrodes arranged in a container with an opening are taken as a safe to-be-blasted backup device, each of the liquid bags with the electrodes is connected on the inner wall of the container with the opening through a soft rope, and the liquid bags with the electrodes are respectively fixed on different positions in the container with the opening, a tortoise-plastron-shaped structure is formed on a container shell through partition of a ditch groove to improve the evenness of scattering, the liquid bags are blasted by an impulse voltage generator of high energy liquid detonation, and agricultural materials are evenly scattered by the container with the opening after the container with the opening is blasted. The high energy liquid detonation blob blasting agricultural-material scattering backup device has the advantages that the operation of scattering the agricultural materials is simple, various shapes of areas are formed by scattering according to different landforms, operation is safe, fast and efficient, the problem of farming season delaying seeding no longer exists, the high energy liquid detonation blob blasting agricultural-material scattering backup device belongs to low temperature blasting without damaging the agricultural materials, librates agricultural labor force, replaces existing time-and-labor-consuming agricultural operation, and is a great agricultural technology revolution.

Owner:黄强 +1

High-energy liquid-explosion partitioned spare agricultural material casting device and casting method

InactiveCN102698916AEasy to throwSimple operation techniqueLiquid spraying apparatusVoltage generatorHigh energy

The invention relates to a high-energy liquid-explosion partitioned spare agricultural material casting device and a casting method and belongs to explosion material casting devices and casting methods. The interior of an explosible open container is partitioned by multiple nonexplosible partitions in radial array to form a plurality of small strip tubes arrayed radially from a center, and the spare device is formed by filling the small strip tubes with agricultural materials. A sac with electrodes on one face of a bottom cover of an nonexplosible container is positioned at the radial center when explosion is needed, an opening of the container is sealed by the bottom cover, and the agricultural materials are cast uniformly after the sealed container is blown up when the sac is detonated by a high-energy liquid-explosion impulse voltage generator. The high-energy liquid-explosion partitioned spare agricultural material casting device and the casting method have the advantages that sacs can be provided according to types and quantity of the agricultural materials in the container, using the device for casting agricultural materials is simple in operation, safe in working, quick and efficient, and free of sowing in wrong farming seasons and damages to the agricultural materials because of belonging to low-temperature explosion, agricultural labor force is liberated, current agricultural operations which are time-wasting and labor-wasting are substituted, and the high-energy liquid-explosion partitioned spare agricultural material casting device and the casting method are a great agricultural technological revolution.

Owner:黄强 +1

High-energy liquid explosion separated-scattering device and high-energy liquid explosion separated-scattering method

InactiveCN102696315APrevent harmful seedsPrevent fertilizerFertiliser distributersBlastingVoltage generatorHigh energy

The invention relates to a high-energy liquid explosion separated-scattering device and a high-energy liquid explosion separated-scattering method, and belongs to blasting scattering devices and blasting scattering methods. The interior of an explosive open container is divided into a plurality of elongated tubules radially arranged at one center by a plurality of non-explosive partitions radially arranged at one center. Agricultural materials are filled into the elongated tubules; a liquid sac with electrodes on one side of a non-explosive bottom container cover is placed at the radial center, and an opening of the container is sealed by the bottom cover; and when the liquid sac is detonated by a high-energy liquid explosion impact voltage generator, the sealed container is exploded, and then the agricultural materials are scattered evenly. The high-energy liquid explosion separated-scattering device and the high-energy liquid explosion separated-scattering method have the advantages that the agricultural materials are filled into the container only when explosion is needed, storing the agricultural materials in existing ways before explosion more helps guarantee quality of the agricultural materials, the high-energy liquid explosion separated-scattering device is simple for explosive scattering of the agricultural materials, explosive scattering is safe, quick and efficient, the problem of missing seeding seasons is avoided, agricultural labor is freed, existing time-consuming and labor-consuming agricultural labor is replaced, and the high-energy liquid explosion separated-scattering device and the high-energy liquid explosion separated-scattering method can be great agricultural technological revolution.

Owner:黄强 +1

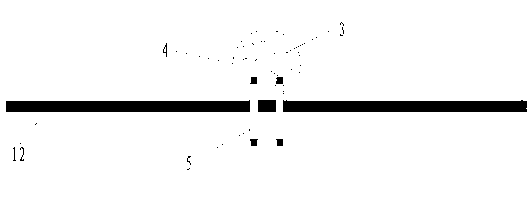

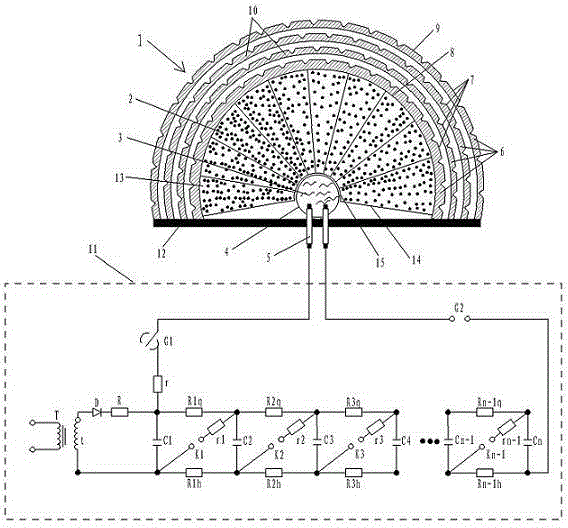

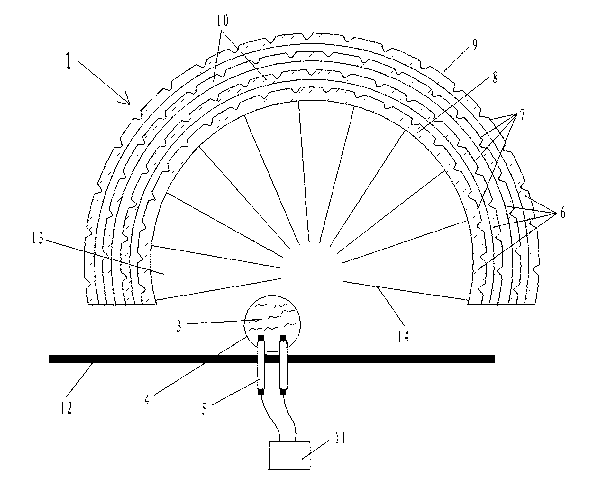

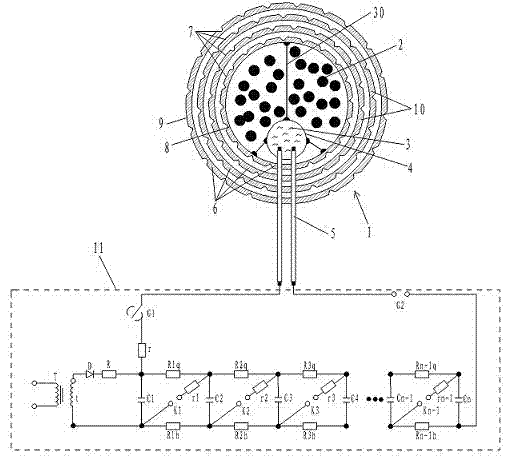

Material-dispersing device with high-energy liquid blast point blasting system and dispersion method

InactiveCN103111390AFang makes productionLiberate agricultural laborLiquid spraying apparatusCapacitanceHigh energy

The invention provides a material-dispersing device with a high-energy liquid blast point blasting system and a dispersion method, and belongs to blasting material-dispersing devices and dispersion methods. The dispersion method includes the following steps: firstly, placing materials to be dispersed and liquid bags in a material sealed container, and secondly, connecting each liquid bag with the inner wall of the material sealed container through a soft rope, wherein two mutual-insulating electrodes are arranged in each liquid bag, the other ends of the mutual-insulating electrodes penetrate through the material sealed container and are placed outside liquid bag shell bodies and are connected with an impulse voltage generator. The impulse voltage generator is a combinational circuit device formed by a plurality of capacitors which are charged in parallel and discharged in series. The combinational circuit comprises an A storing subcircuit, a B power supply and control subcircuit and a C load subcircuit. The dispersion method has the advantages that operation of dispersing materials to be dispersed is simple, operation is safe, fast and efficient, and the problem that seeding is not conducted according to farming seasons is solved. Besides, the blasting is conducted under low temperature, thus the materials to be dispersed are not damaged, agricultural labor force is liberated, the exiting time-consuming and laborsome agricultural operations are replaced, and a great agricultural technology revolution is conducted.

Owner:黄强 +1

Method for mechanically producing high-definition corundum patterned glass

InactiveCN101696090BHigh degree of mechanizationImprove labor utilizationHydrofluoric acidEngineering

Owner:HANGZHOU WEILI BUILDING MATERIALS

High-energy liquid-explosion material throwing stand-by device

InactiveCN102698918ALiberate agricultural laborSimple operation techniqueLiquid spraying apparatusHigh energyEngineering

The invention relates to a high-energy liquid-explosion material throwing stand-by device, which belongs to an explosive material throwing device. The stand-by device is characterized in that a container with an opening, which is internally provided with a liquid container with an electrode, serves as a safe device to be exploded; a shell of the container is divided to be in a tortoise-plastron-shaped structure by grooves, thereby improving the uniformity of throwing; and before an explosion, materials to be thrown, such as agricultural materials, are loaded into the container with the opening as required, the container is sealed, the liquid container is detonated by a high-energy liquid-explosion impulse voltage generator, and the agricultural materials are uniformly thrown out after the sealed container is bombed out. The stand-by device has the advantages that the agricultural materials are loaded in the container when the explosion occurs, and the agricultural materials are stored in the conventional manner before the explosion occurs, therefore, the quality of the agricultural materials can be favorably guaranteed; and when being used for throwing the agricultural materials, the stand-by device is simple to operate and safe, fast and efficient in operation, avoids the problem of sowing delay in farming seasons, does not damage the agricultural materials by virtue of the low-temperature explosion, allows agricultural labor force to be liberated, and can substitute for the conventional time-wasting and labor-wasting agricultural operation, thus serving as great agricultural technical revolution.

Owner:黄强 +1

Continuous hydrolysis system for preparation of glyphosate by glycine method

ActiveCN103788127BAvoid rushingGuaranteed hydrolysis effectGroup 5/15 element organic compoundsHydrolysisHybrid reactor

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

A pressure device for the production of castings

The invention relates to a pressure device for production of a casting. The pressure device comprises a primary base and secondary bases. The primary base is in a cuboid shape, and is made of stainless steel materials. The bottom of the primary base is bent outwards and fixed through bolts. The number of the secondary bases is two, the secondary bases are arranged on the two sides of the primary base, the primary base and the secondary bases are located on the same straight line, and the secondary bases are kept symmetrical about the primary base. The secondary bases are in a cuboid shape, the length of each secondary base is smaller than that of the primary base, and the bottom of each secondary base is bent outwards and fixed through bolts. A power assembly is arranged on the upper portion of the primary base, a first press mold assembly and a second press mold assembly are arranged on the two sides of the power assembly, and a first fixing assembly and a second fixing assembly are arranged on the upper portions of the secondary bases.

Owner:JIASHAN YONGJIN METAL PROD

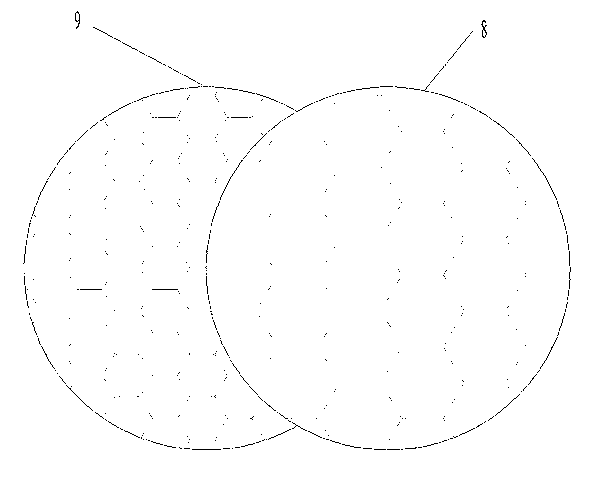

Dividing type agricultural material scattering device with high energy liquid detonation and scattering method

InactiveCN103111392ASimple operation techniqueImprove labor utilizationLiquid spraying apparatusLoad circuitSowing

The invention relates to a dividing type agricultural material scattering device with high energy liquid detonation and a scattering method and belongs to a material blasting and scattering device and the scattering method. A plurality of anti-detonation dividing plates which are arrayed in radial shape are divided into a plurality of strip-shaped small pipes which are arrayed in a central radial shape in an container which can be detonated and is provided with an opening, agricultural materials are filled in the strip-shaped small pipes, one face of a bottom cover of the anti-denotation container is provided with a liquid bag with electrodes, the liquid bag is arranged in the radial-shaped center, the opening of the container is sealed by the bottom cover, and the electrodes are connected with an impulse voltage generator which is provided with three branch circuits, namely a charge and discharge circuit, a power supply circuit and a load circuit, and the agricultural materials are evenly thrown after the sealed container is blown up when the liquid bag is detonated by the impulse voltage generator. The dividing type agricultural material scattering device with the high energy liquid detonation and the scattering method has the advantages of being simple in denotation and throwing operation of the agricultural materials, safe in operation, convenient and fast, high-efficiency, free from problems of delaying season sowing, free from damage on the agricultural materials due to low-temperature denotation, and capable of liberating agricultural labor force and substituting the existing agricultural operation which wastes time and labor. The dividing type agricultural material scattering device with the high energy liquid detonation and the scattering method is a great agricultural technology revolution.

Owner:黄强 +1

High energy liquid detonation blob blasting agricultural-material scattering device and scattering method

InactiveCN103111393BSimple operation techniqueImprove labor utilizationLiquid spraying apparatusVoltage generatorDetonation

The invention relates to a high energy liquid detonation blob blasting agricultural-material scattering device and a scattering method and belongs to blasting material scattering devices and scattering methods. Agricultural materials and liquid bags with electrodes arranged in a sealed container are taken as a safe to-be-blast device, each of the liquid bags with the electrodes is connected on the inner wall of the sealed container with the opening through a soft rope, and the liquid bags with the electrodes are respectively fixed on different positions in the sealed container with the opening, a tortoise-plastron-shaped structure is formed on a container shell through partition of a ditch groove to improve the evenness of scattering, the liquid bags are blasted by an impulse voltage generator of high energy liquid detonation, and agricultural materials are evenly scattered by the sealed container with the opening after the sealed container with the opening is blasted. The high energy liquid detonation blob blasting agricultural-material scattering backup device has the advantages that the operation of scattering materials is simple, various shapes of areas are formed by scattering according to different landforms, operation is safe, fast and efficient, the problem of farming season delaying seeding no longer exists, the high energy liquid detonation blob blasting agricultural-material scattering backup device belongs to low temperature blasting without damaging the agricultural materials, librates agricultural labor force, replaces existing time-and-labor-consuming agricultural operation, and is a great agricultural technology revolution.

Owner:黄强 +1

Optimization method for pulsating assembly line of small bypass ratio aeroengine

ActiveCN113059347BSimplify the process contentLow skill level requiredAircraft componentsAssembly machinesProcess engineeringAssembly line

The invention discloses a method for optimizing a pulsating assembly line of an aero-engine with a small bypass ratio, which includes optimizing the assembly process flow, determining the pulsating beat, determining the pulsating station, determining the product flow mode between the stations, configuring station resources, optimizing the process layout and Pilot run. The present invention breaks the original "big pot meal" mode in which multiple people work collectively, greatly reduces the number of workers at each station, realizes the fine management and operation of each station, eliminates the phenomenon of "slacker work", and improves the use of labor The process content of each station is simplified, the process division is more clear, the main body of quality responsibility is clear, and the requirements for the skill level of workers are reduced. As time goes by, the proficiency of workers will be greatly improved, and the consistency of assembly will be improved; The reform of engine assembly from "discrete mode" to "production line mode" has improved the on-site management level, assembly efficiency and assembly quality.

Owner:PLA NO 5719 FACTORY

Connector device for novel plastic polyvinyl chloride (PVC) pipes

InactiveCN108533857AQuick connectionSolve the leakSleeve/socket jointsWater leakagePolyvinyl chloride

The invention discloses a connector device for novel plastic polyvinyl chloride (PVC) pipes. The connector device for the novel plastic PVC pipes comprises a frame, wherein a first limiting groove anda second limiting groove are formed in the centers of two sides of the frame; a first PVC pipe is fixedly connected to an inner wall of the first limiting groove; a second PVC pipe is fixedly connected to an inner wall of the second limiting groove; fixing blocks are fixedly connected to two sides of the frame; first silicone pads are fixedly connected to the bottom part of the fixing blocks; thread grooves are formed in two sides of the frame; and a thread frame is in threaded connection to an inner wall of each thread groove. The connector device for the novel plastic PVC pipes provided bythe invention relates to the technical field of pipeline connectors, and solves the problems that according to a currently used PVC pipe connecting manner, a fuse machine is used for connecting so asto be difficult and require a certain skills during an operation process, water leakage is easy to cause due to improper connection, the fuse machine can produce a pungent smell during work so as to cause a harsh operation environment, and pipelines are not favorably replaced and maintained at the later period.

Owner:湖州吴兴旭诚塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com