High-energy liquid-explosion material throwing stand-by device

A backup device and liquid explosion technology, applied in the field of material throwing, can solve the problems of lack of practicability, complicated cannon operation, damage to seeds, etc., and achieve the effect of liberating agricultural labor and simple operation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, spare device for throwing material by high-energy liquid explosion

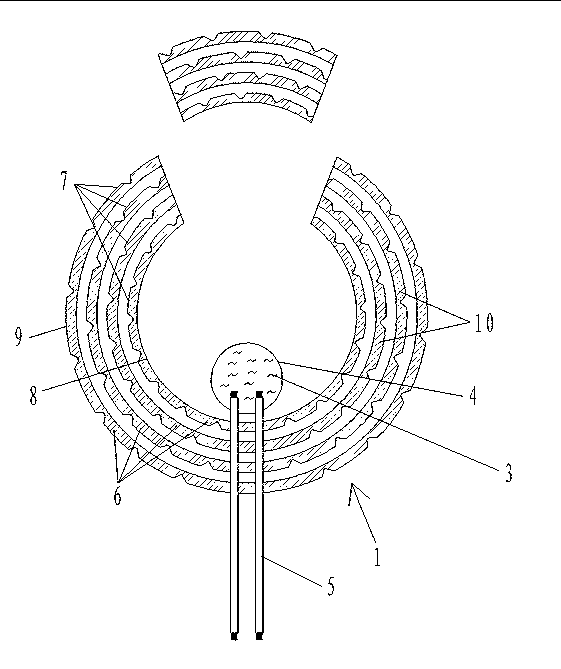

[0031] like figure 1 , 2 , 3, make the shell 6 of the container 1 with opening with cardboard material, also be provided with the rubber membrane liquid bag 4 that adorns general cleaning water liquid 3 in the container 1 that has opening, one end of two mutually insulated electrodes 5 penetrates respectively Among the liquid capsules 4, the liquid capsule 4 is airtight and watertight, and the other ends of the two mutually insulated electrodes 5 pass through the container 1 with the opening and are located outside the casing 6 of the container 1 with the opening. Two mutually insulated electrodes 5 and the gap around the hole passing through the container 1 shell 6 with opening are also sealed, so there is no air leakage. It becomes a spare device for throwing agricultural materials with high-energy liquid explosion.

Embodiment 2

[0032] Embodiment 2, the container shell with opening is a spare device for high-energy liquid explosion throwing materials with two layers inside and outside

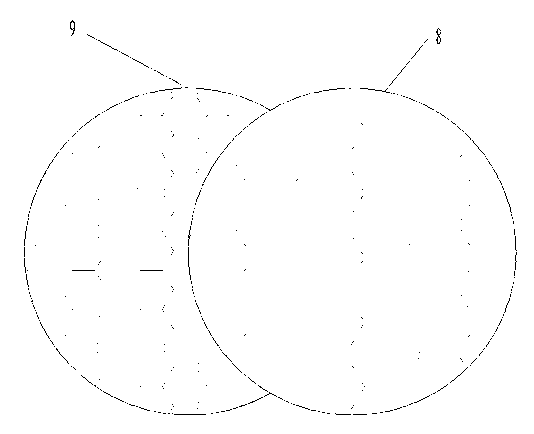

[0033] Like embodiment 1, the shell 6 of the container 1 with an opening has two inner and outer layers, and the inner and outer layers are respectively a tortoise-shaped structure with grooves between a plurality of small plates 7 . And all the tortoise shells of the inner layer 8 have the same shape and size, all the tortoise shells of the outer layer 9 have the same shape and size, and the tortoise shell shape area of the inner layer 8 is larger than the tortoise shell shape of the outer layer 9. This structure is conducive to evenly throwing agricultural materials around after blasting.

Embodiment 3

[0034] Embodiment 3, the container shell with opening is a backup device for high-energy liquid explosion throwing materials with four layers

[0035]As in embodiment 2, the shell 6 of the container 1 with an opening has four layers, and the inner and outer layers are respectively a tortoise-shaped structure with grooves between a plurality of small plates 7 . And all the tortoise shells of the inner layer 8 have the same shape and size, all the tortoise shells of the outer layer 9 have the same shape and size, and the tortoise shell shape area of the inner layer 8 is greater than the tortoise shell shape of the outer layer 9 . Also be provided with uniform distribution layer 10 between inner layer 8 and outer layer 9, uniform distribution layer 10 is two layers, and the platelet 7 of uniform distribution layer 10 is the bar shape that length and width are unequal; Its long sides of strip-shaped small plate 7 are perpendicular to each other. This structure is more conducive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com