Continuous hydrolysis process for preparing glyphosate by glycine method

A technology of glyphosate and glycine, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of failure to realize the continuous reaction of the whole process of hydrolysis, failure to achieve ideal results, etc. problems, to achieve remarkable energy-saving effects, easy control, and prolong the service life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

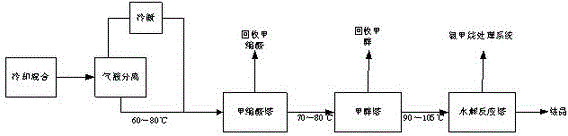

[0038] The continuous hydrolysis process for preparing glyphosate by glycine method, the specific steps of the process are:

[0039] A The condensation reaction synthesis liquid is fed into the mixing reactor through a pump, and the material temperature is controlled at 53°C to complete the acid neutralization process;

[0040] B. The material discharged from the heat exchanger is separated from gas and liquid, and the liquid and the condensed gas enter the methylal recovery tower respectively to recover the methylal;

[0041] C The bottom liquid discharged from the methylal recovery tower enters the methanol recovery tower to recover methanol; the bottom liquid discharged from the methanol recovery tower enters the hydrolysis tower to complete the hydrolysis reaction;

[0042] D The bottom liquid discharged from the hydrolysis tower is flashed to remove water and acid, and then enters the crystallization kettle, where it is cooled and crystallized under stirring to obtain glyphosate. ...

Embodiment 2

[0044] The continuous hydrolysis process for preparing glyphosate by glycine method, the specific steps of the process are:

[0045] A The condensation reaction synthesis liquid is fed into the mixing reactor through a pump, and the material temperature is controlled at 50°C to complete the acid neutralization process;

[0046] B. The material discharged from the heat exchanger is separated from gas and liquid, and the liquid and the condensed gas enter the methylal recovery tower respectively to recover the methylal;

[0047] C The bottom liquid discharged from the methylal recovery tower is controlled at 80℃ and enters the methanol recovery tower to recover methanol; the bottom liquid discharged from the methanol recovery tower is controlled at 105℃ and enters the hydrolysis tower to complete the hydrolysis reaction ;

[0048] D The bottom liquid discharged from the hydrolysis tower is flashed to remove water and acid, and then enters the crystallization kettle, where it is cooled a...

Embodiment 3

[0050] The continuous hydrolysis process for preparing glyphosate by glycine method, the specific steps of the process are:

[0051] A. Feed the condensation reaction synthesis liquid into the mixing reactor through a pump, and control the material temperature at 55°C to complete the acid neutralization process;

[0052] B. The material discharged from the heat exchanger is separated from gas and liquid, and the liquid and the condensed gas enter the methylal recovery tower respectively to recover the methylal;

[0053] C The bottom liquid discharged from the methylal recovery tower is controlled at 70°C and enters the methanol recovery tower to recover methanol; the bottom liquid discharged from the methanol recovery tower is controlled at 90°C and enters the hydrolysis tower to complete the hydrolysis reaction ;

[0054] D The bottom liquid discharged from the hydrolysis tower is flashed to remove water and acid, and then enters the crystallization kettle, where it is cooled and cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com