Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Improve installation work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

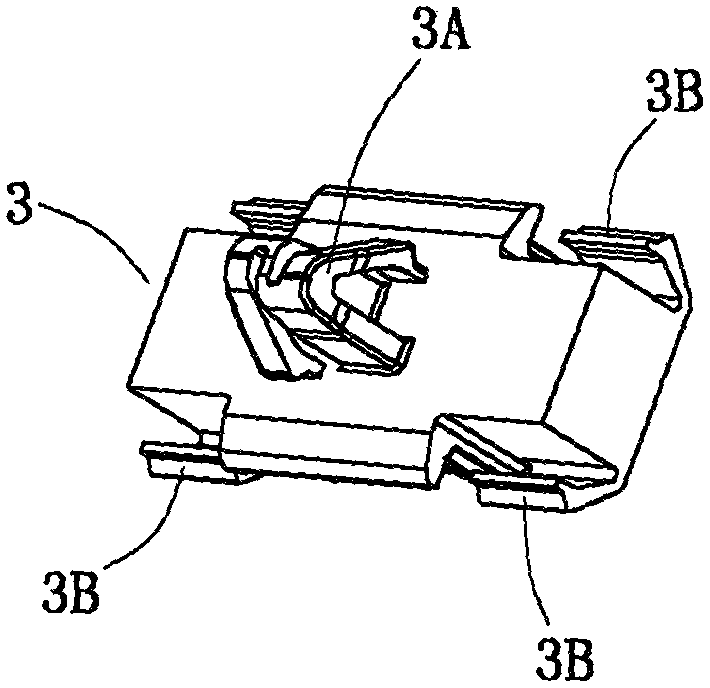

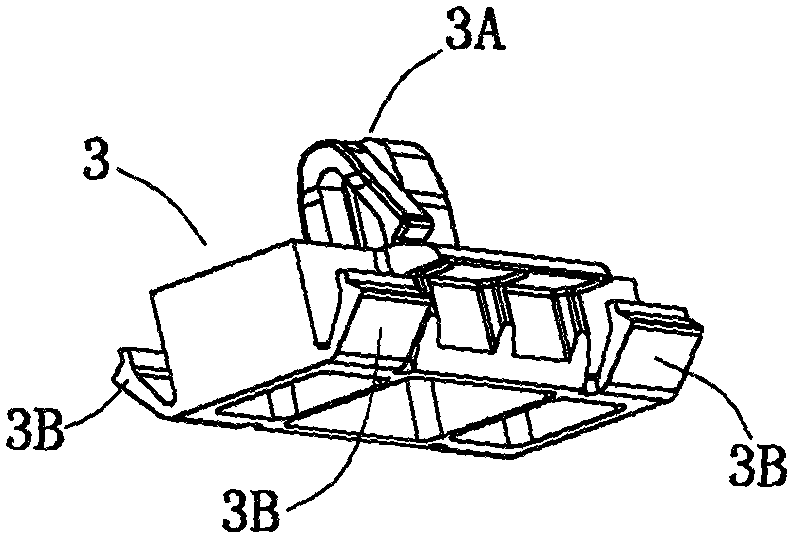

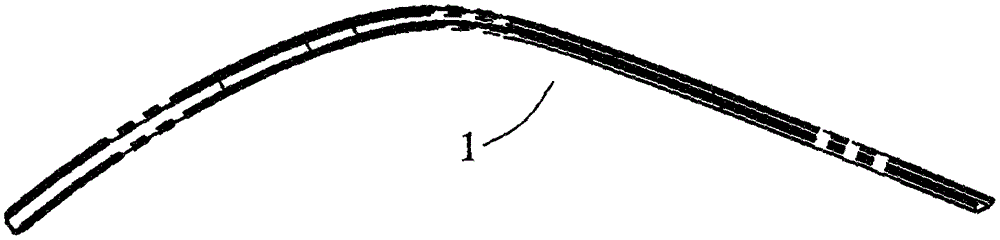

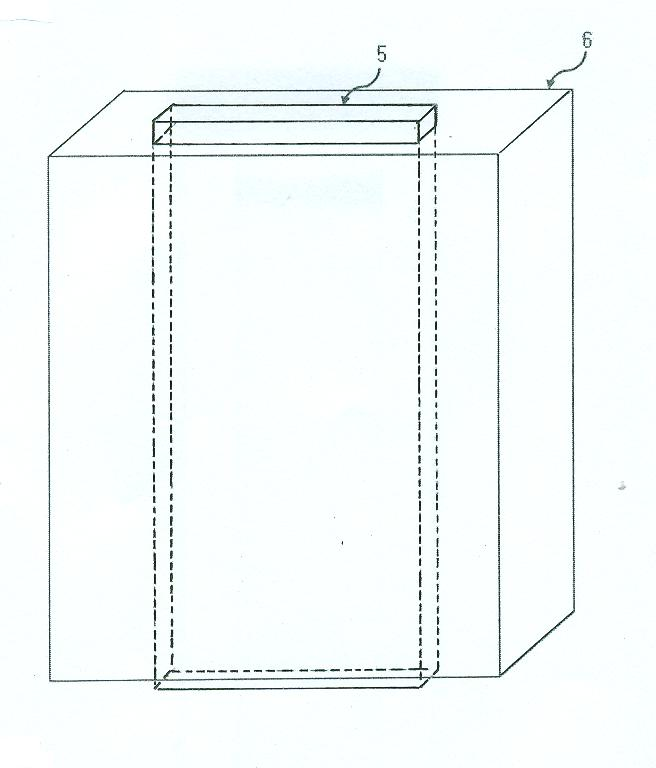

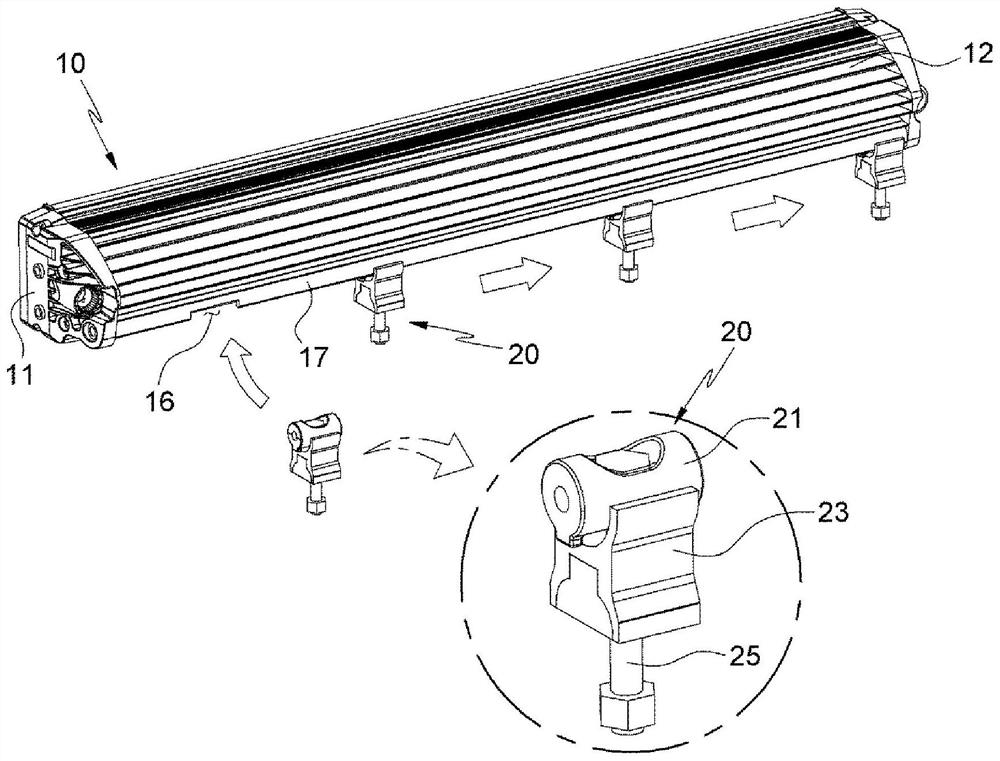

Automatic decoration strip and buckle mounting device and method

ActiveCN105269300AImprove installation work efficiencyHigh degree of automationVehicle componentsMetal working apparatusEngineeringAutomation

The invention provides an automatic decoration strip and buckle mounting device and method. The device comprises a workpiece carrying table (2), a robot (4) and a buckle vibrating disk (5), wherein the workpiece carrying table (2) is used for carrying decoration strip workpieces (1); the robot (4) is used for grabbing and mounting buckles (3) onto the decoration strip workpieces (1); the buckle vibrating disk (5) is used for automatically providing the buckles (3). The workpiece carrying table (2) comprises a table board (6). Workpiece carrying blocks (7) are arranged on the table board (6). A workpiece carrying groove (7A) matched with each decoration strip workpiece (1) in shape is formed in the upper surface of each workpiece carrying block (7). A plurality of workpiece hold-down mechanisms (8) are arranged at intervals beside the workpiece carrying blocks (7) in the extending direction of the workpiece carrying blocks (7). The two ends of each workpiece carrying block (7) are provided with extending direction workpiece positioning mechanisms. The end of a movable arm of the robot (4) is provided with a rotary disk (9). A plurality of buckle clamp holders (10) are evenly arranged in the circumferential direction of the rotary disk (9). The automatic decoration strip and buckle mounting device is high in automation degree and operating efficiency and good in product uniformity; the operation of mounting a plurality of buckles onto a decoration strip is completed in one step without midway manual operation and completed automatically and entirely by the device.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

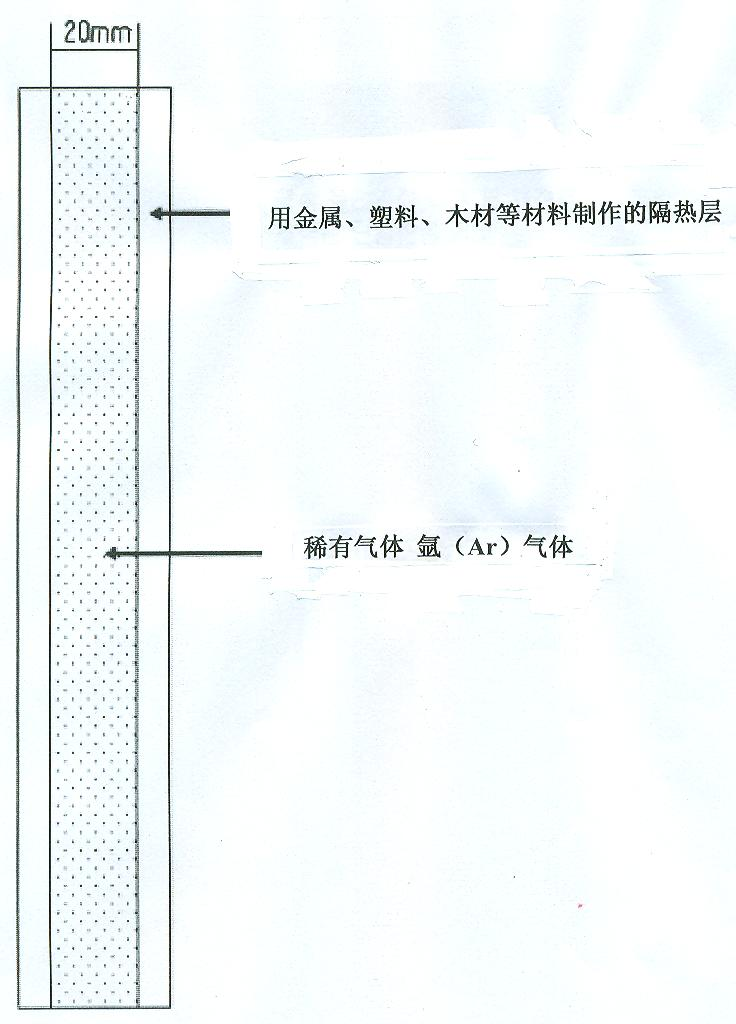

Multi cooling type phase-change material thermal storage system

InactiveCN102607308AChanging the way the natural air-conditioning is releasedAvoid frostHeat storage plantsVehicle heating/cooling devicesThermal energyAir cycle

A multi-cooling type PCM(Phase-Change Material) thermal storage system is provided to reduce heat loss through unnecessary heat exchange by employing insulating panels and maintain desired temperature of a storage container. A multi-cooling type PCM thermal storage system comprises a brine circulation heat exchange coil(10), an air circulation heat exchange tube(5), a circulating pump(9), and a blower(12). The brine circulation heat exchange coil is connected to the circulating pump and heat-exchanges with a low temperature latent heat PCM(11) stored in a thermal storage tank. The air circulation heat exchange tube heat-exchanges the low temperature latent heat PCM secondly. The circulating pump is installed in the upper part of the storage tank and circulates the brine, which is cooled by heat-exchange with the low temperature latent heat PCM, into the brine circulation heat exchange coil. The blower draws the internal air of the storage container, implements first and second heat-exchange with the brine circulation heat exchange coil and the air circulation heat exchange tube, and discharges the multi-cooled air into the storage container in order to maintain the required temperature.

Owner:KDPCM +1

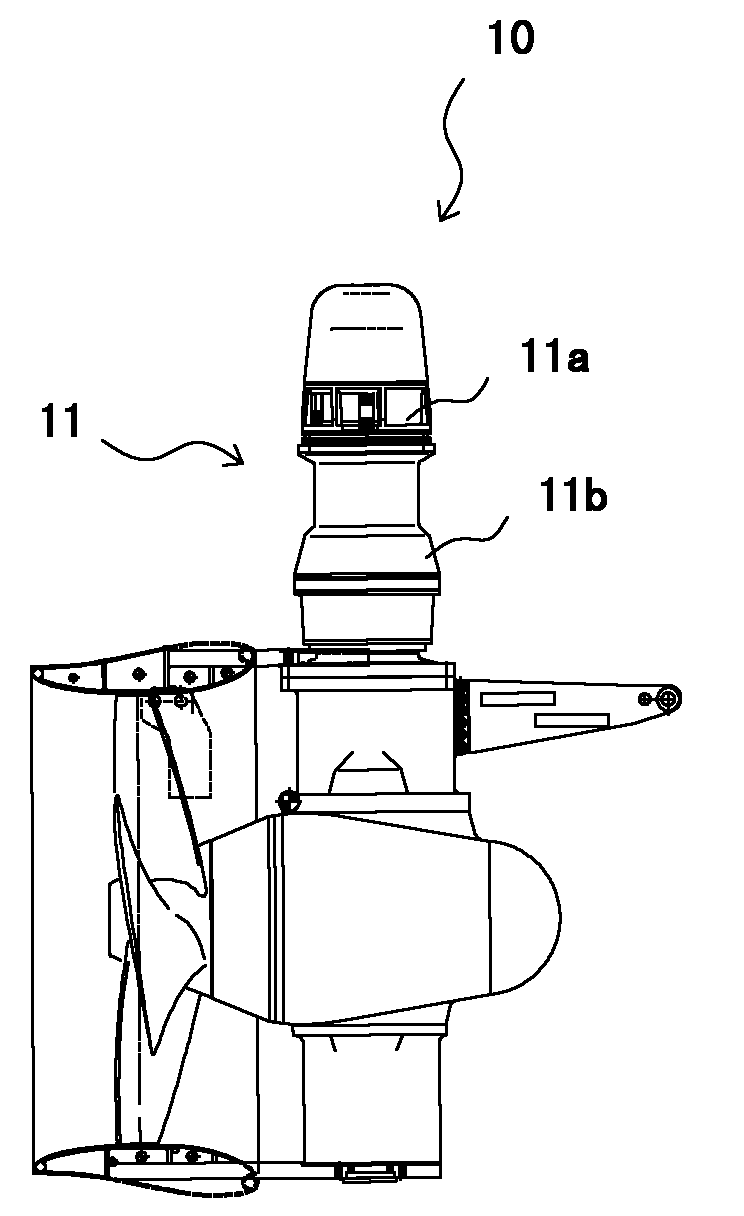

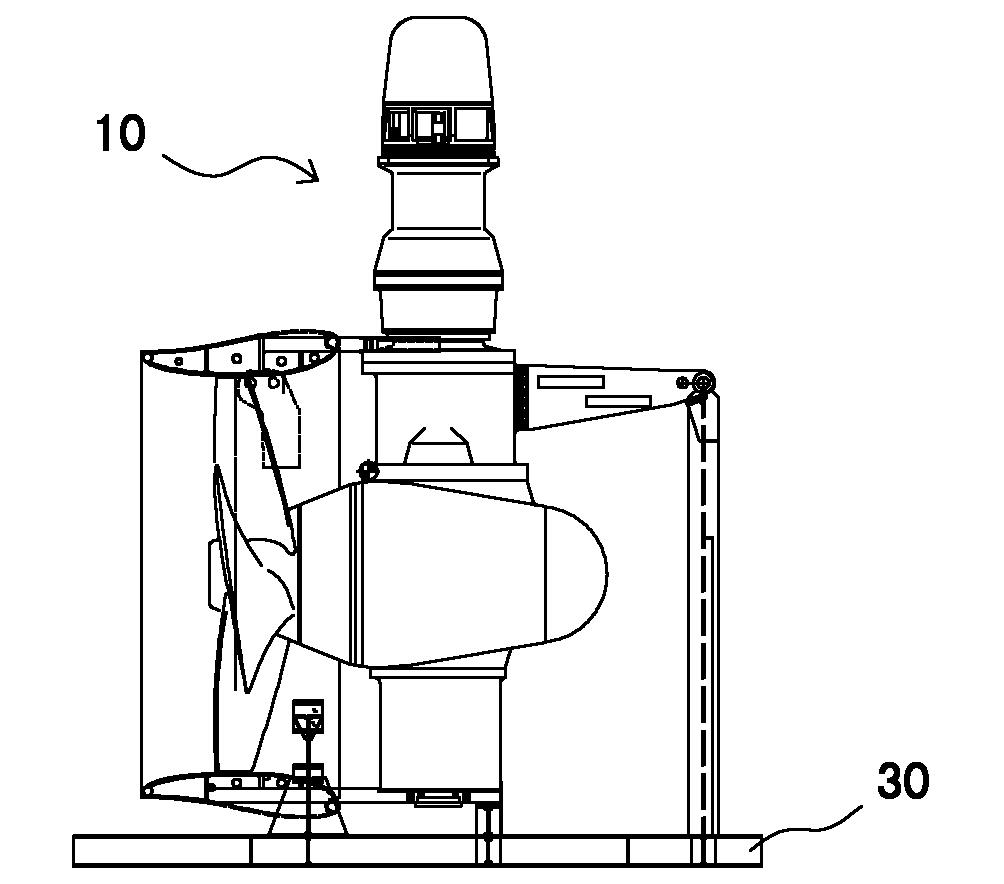

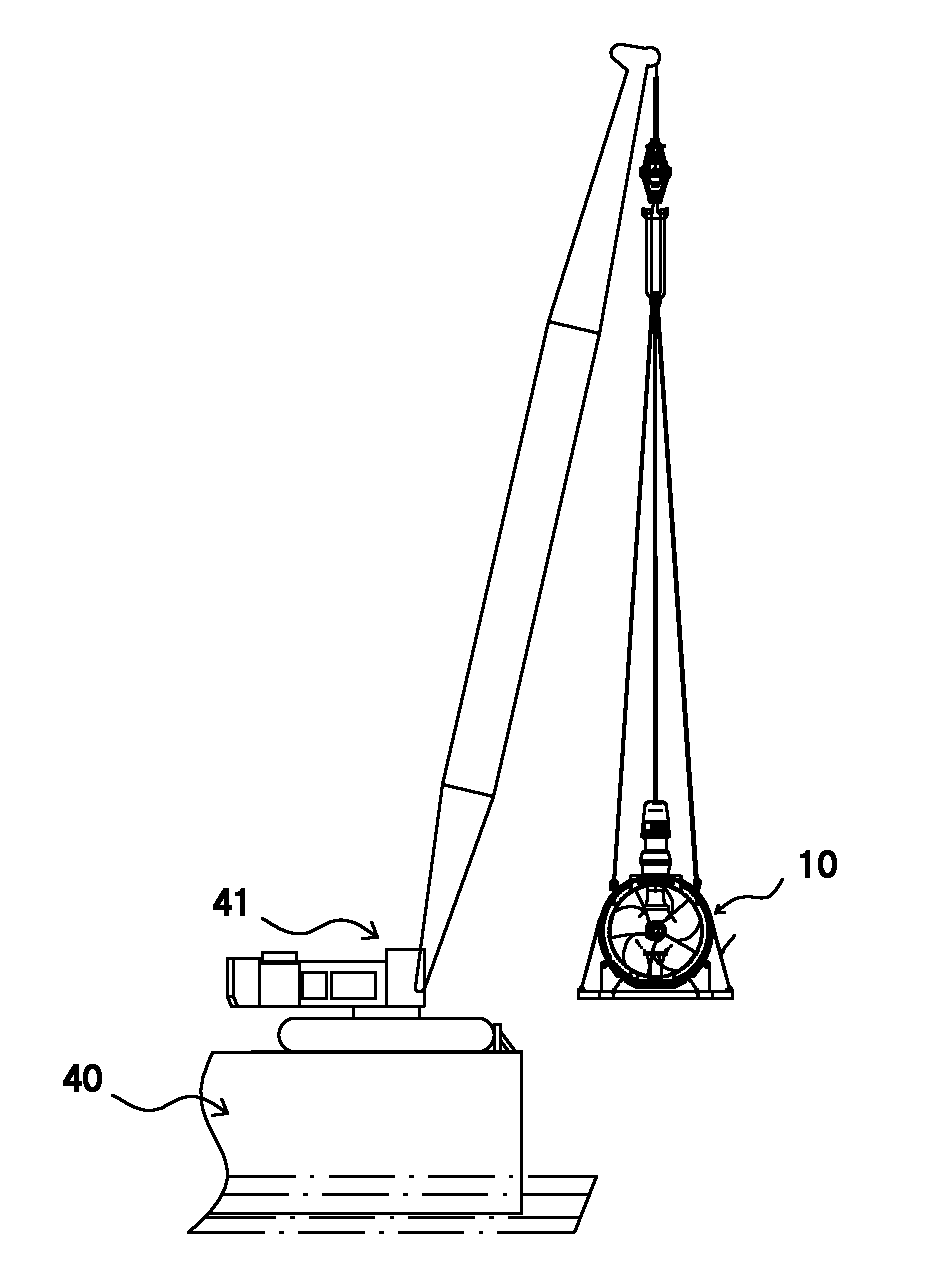

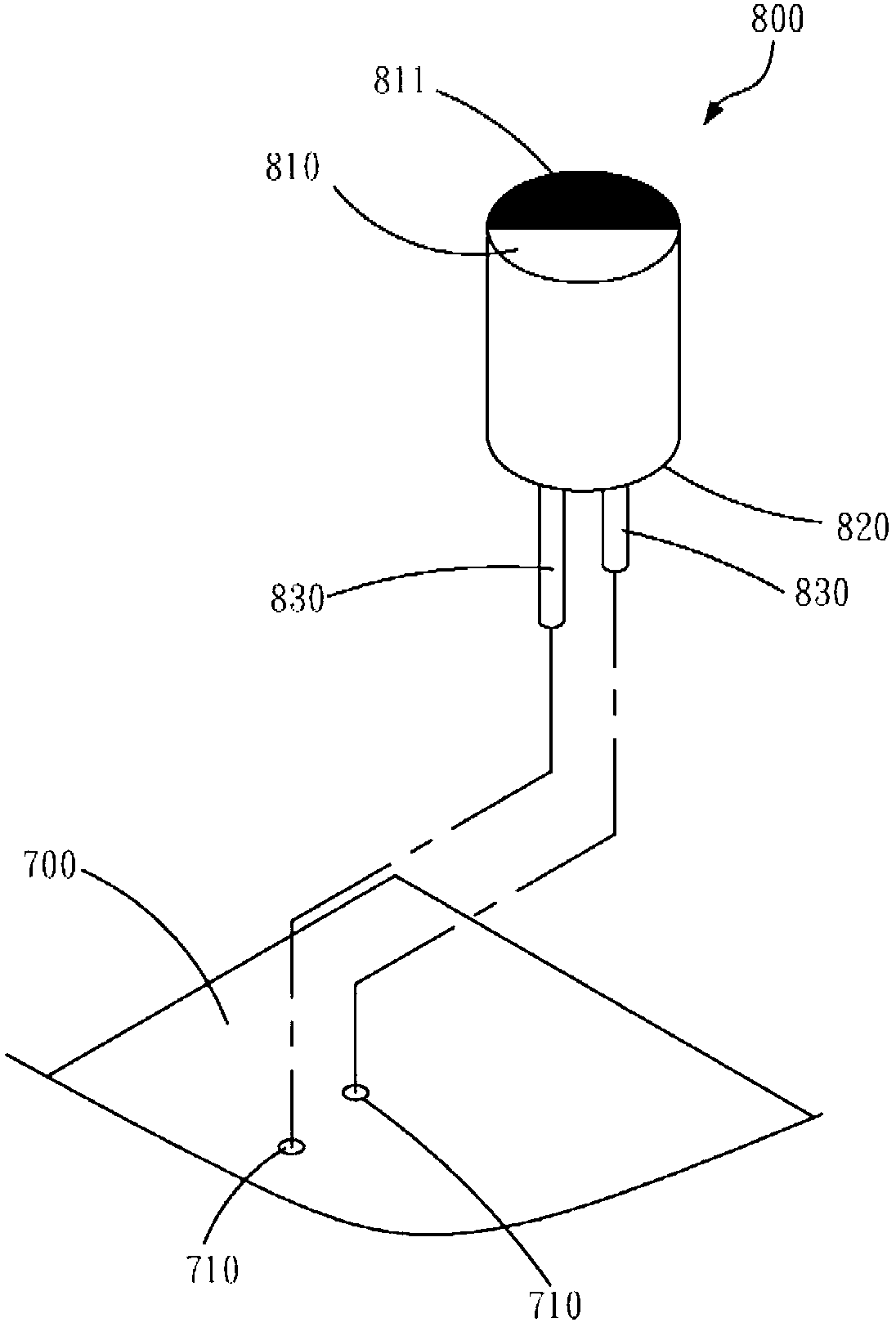

Method for installing thruster at bottom of drilling platform

ActiveCN102464088AEasy to adjustEasy alignmentVessel designingPropulsive elementsEngineeringOperability

The invention discloses a method for installing a thruster at the bottom of a drilling platform, wherein the drilling platform comprises a lower hull, the bottom of the lower hull is provided with a socket, and the socket is provided with an accommodating space (which is opened outwards and used for accommodating at least part of the thruster) and a sealing cover (for sealing the accommodating space). The method comprises the following steps of: providing a harbor basin, wherein water with a preset depth is provided in the harbor basin; placing the thruster in a designated area of the bottom of the harbor basin; enabling the drilling platform to float in the water in the harbor basin, and moving the drilling platform, so that the socket at the bottom of the drilling platform and the thruster at the bottom of the harbor basin are aligned in the vertical direction; and removing the sealing cover of the socket; and hoisting the thruster, so that at least part of the thruster is inserted in or jointed to the inside of the corresponding accommodating space of the socket. According to the installation method disclosed by the invention, the operability is strong.

Owner:YANTAI RAFFLES SHIPYARD

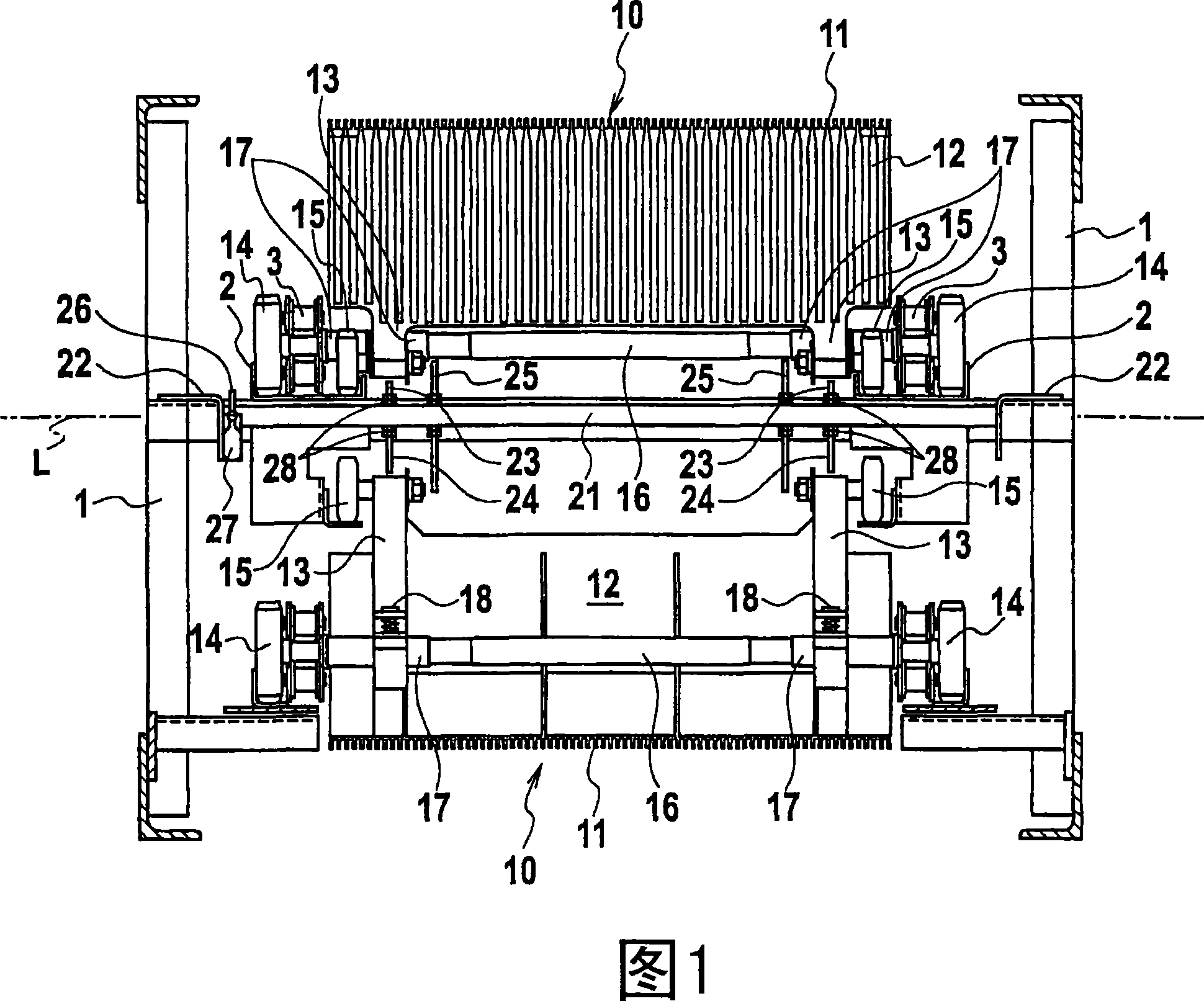

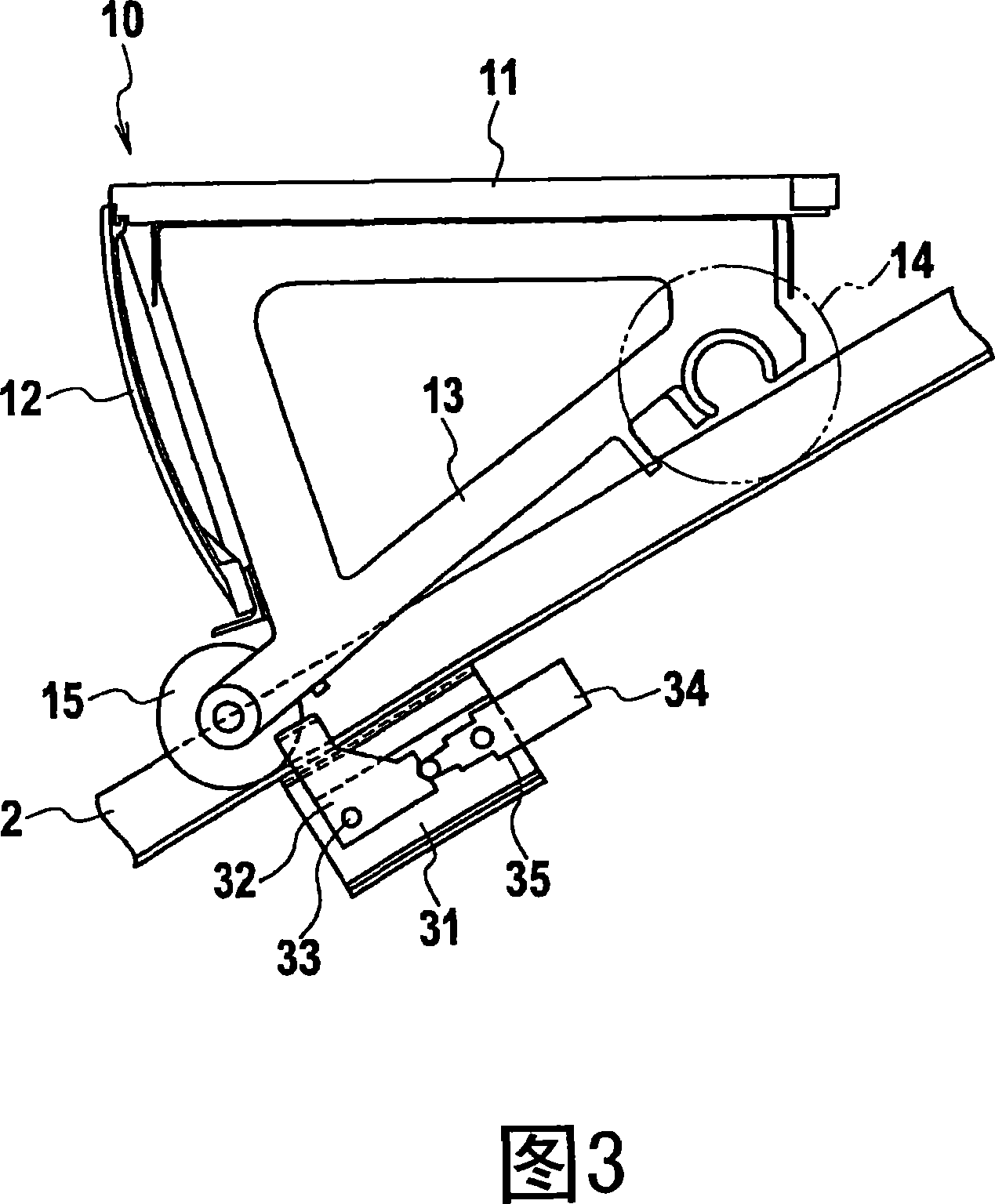

Abnormality detection device for step and passenger conveyor

The step abnormality detection device of the present invention comprises a detection shaft (21), detection sheets (23, 24, 25), a cam (26) and a limit switch (27). The detection shaft (21) is below the step (10) on the way in the truss (1), has a rod-like shape extending in a direction perpendicular to the direction of travel of the step (10), and can be wound around its length extend in the direction. The detection piece (23, 24, 25) is arranged on the outer surface of the above-mentioned detection shaft member (21), and its front end extends to a part of the component (13) as the above-mentioned step, and is provided with a movable support for the above-mentioned step ( 10) near the portion of the step rollers (14, 15). And, the cam (26) is installed coaxially with respect to the detection shaft member (21), and the working piece (27a) of the limit switch (27) is in contact with the cam (26).

Owner:TOSHIBA ELEVATOR KK

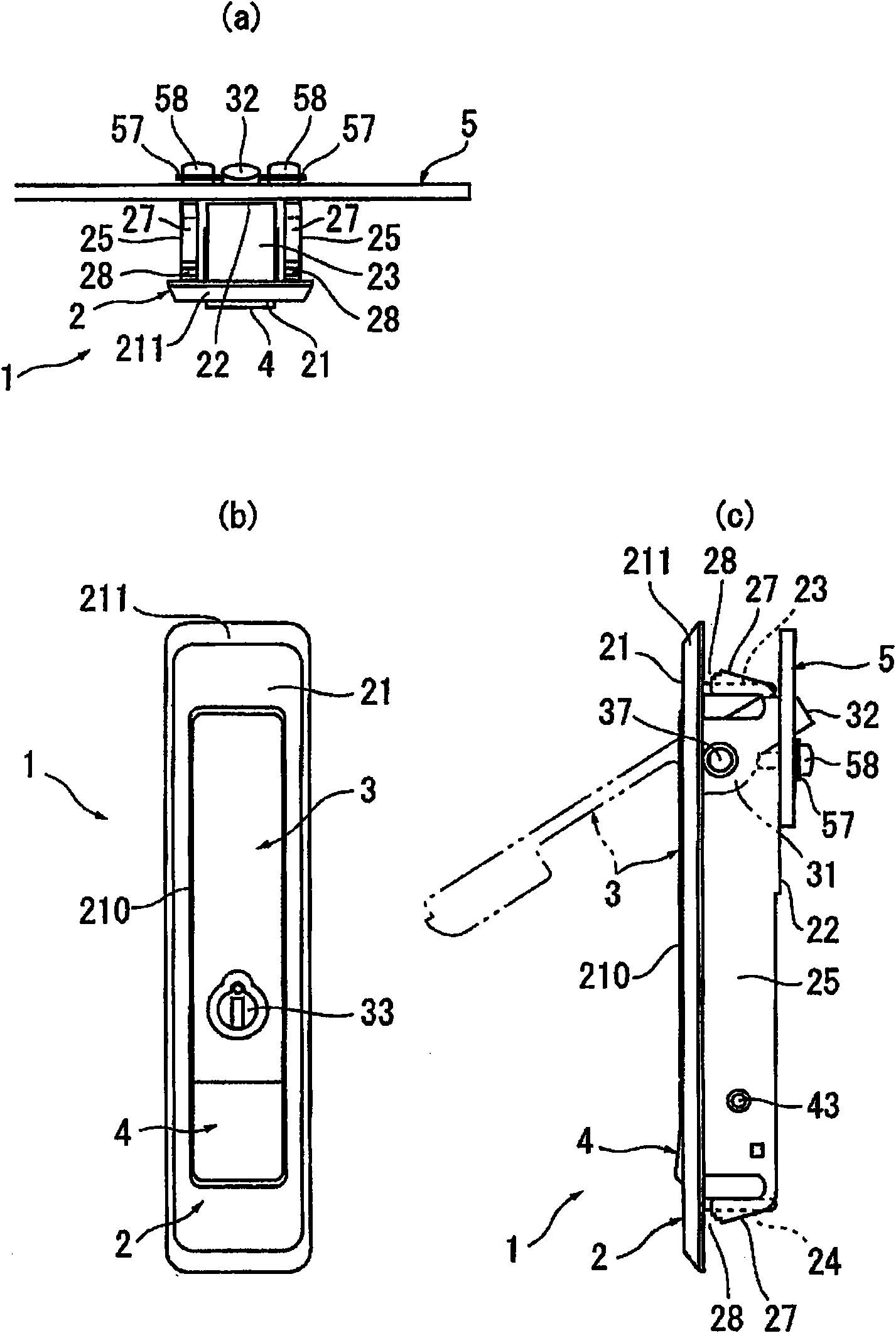

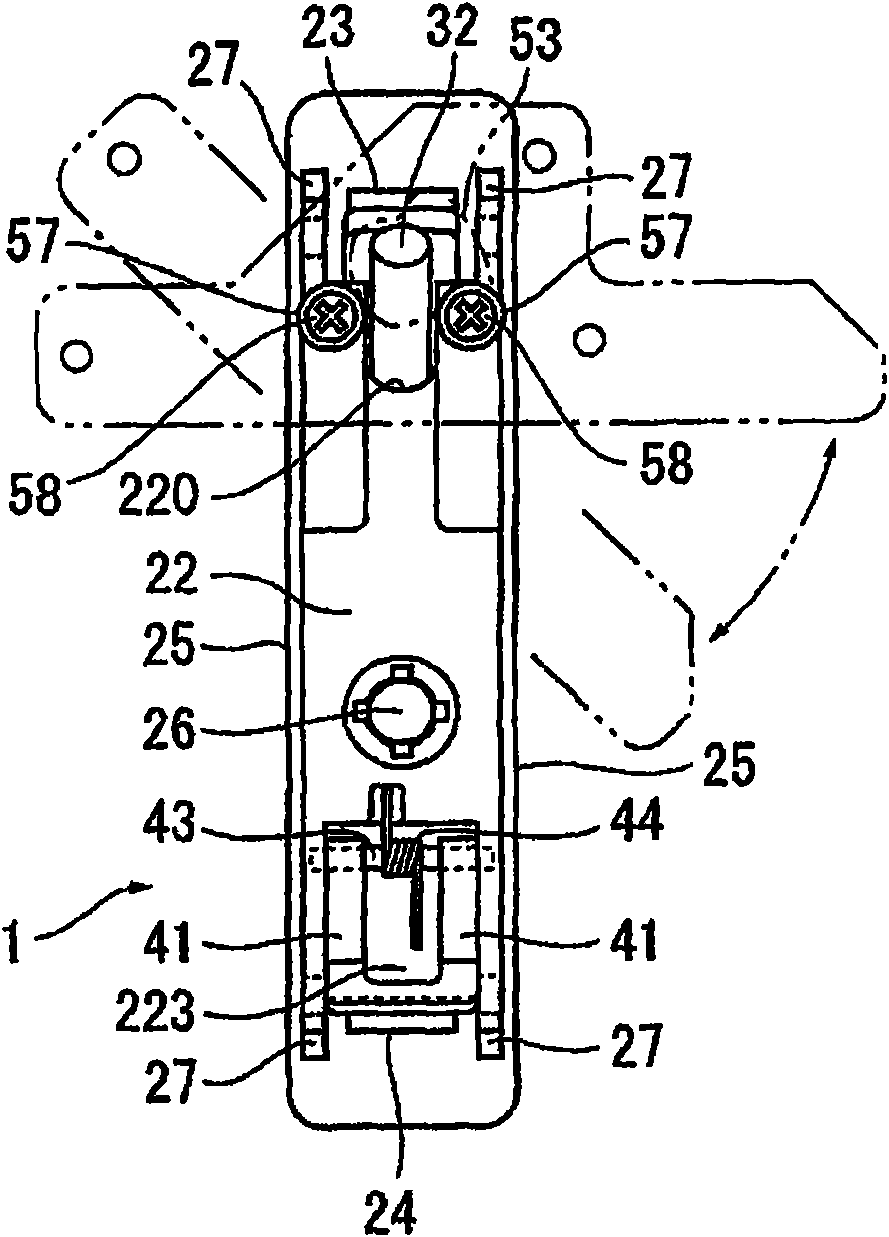

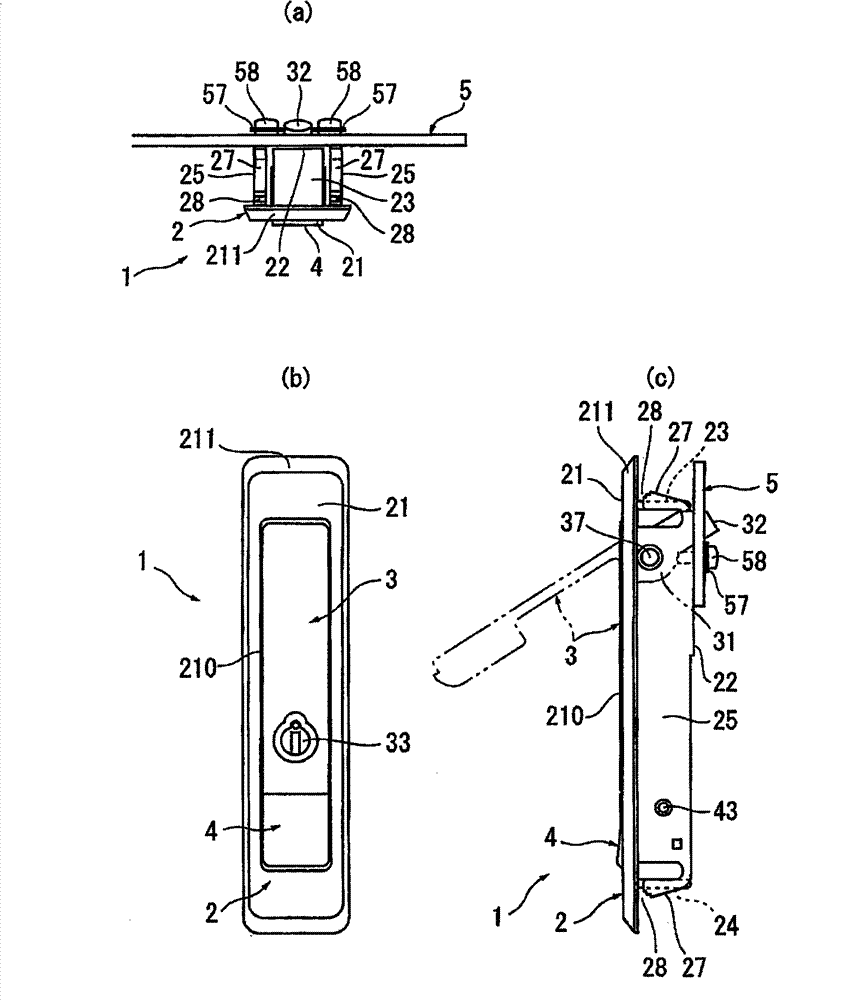

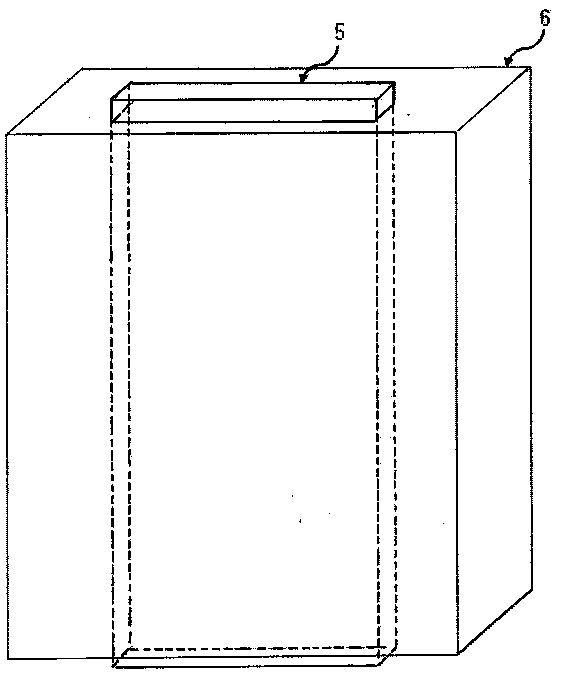

Handle device

ActiveCN101619631AImprove efficiencyEasy to installWing handlesCasings/cabinets/drawers detailsEngineeringFlange

A handle device is capable of being mounted on a door board by one step, which improves the mounting operation efficiency greatly. A casing (2) is formed by forming engineering plastics having prescribed rigidity and spring, the circumference surface of the casing (2) is provided with a casing locking member (27) which extends to a prescribed position in an opening (60) for mounting from a back face side of the casing (2), and then extends toward a flange (211) side that is a prescribed position outside the opening (60) from said position in the opening (60), the casing locking member (27) is provided with a fixation part (28) on its front end, the marginal part of the opening (60) is clipped between the fixation part (28) and the flange (211) by inserting the casing (2) in the opening (60), and the casing (2) is fixed by a reaction of the casing locking member (27).

Owner:TAKIGEN MFG CO LTD

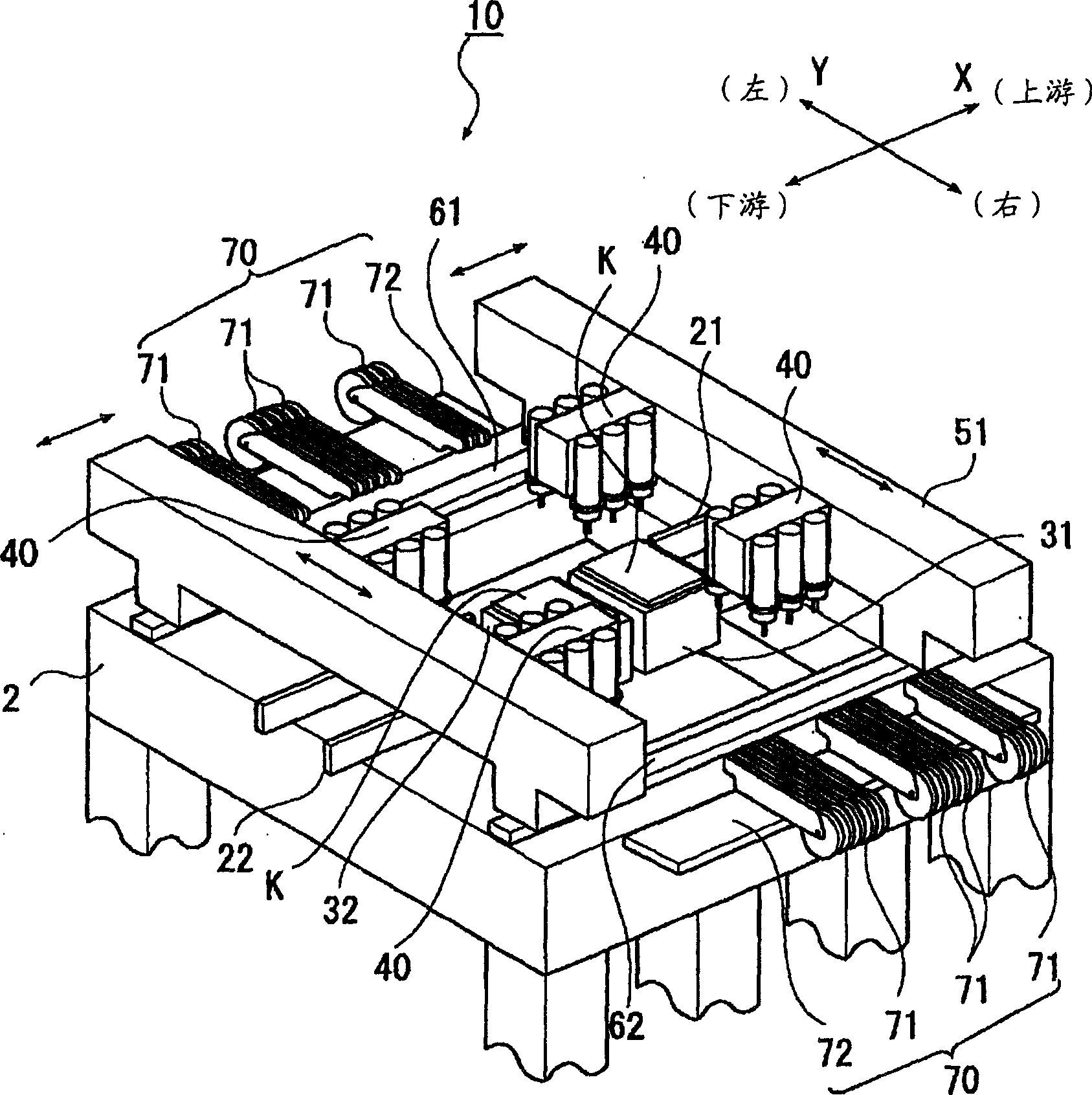

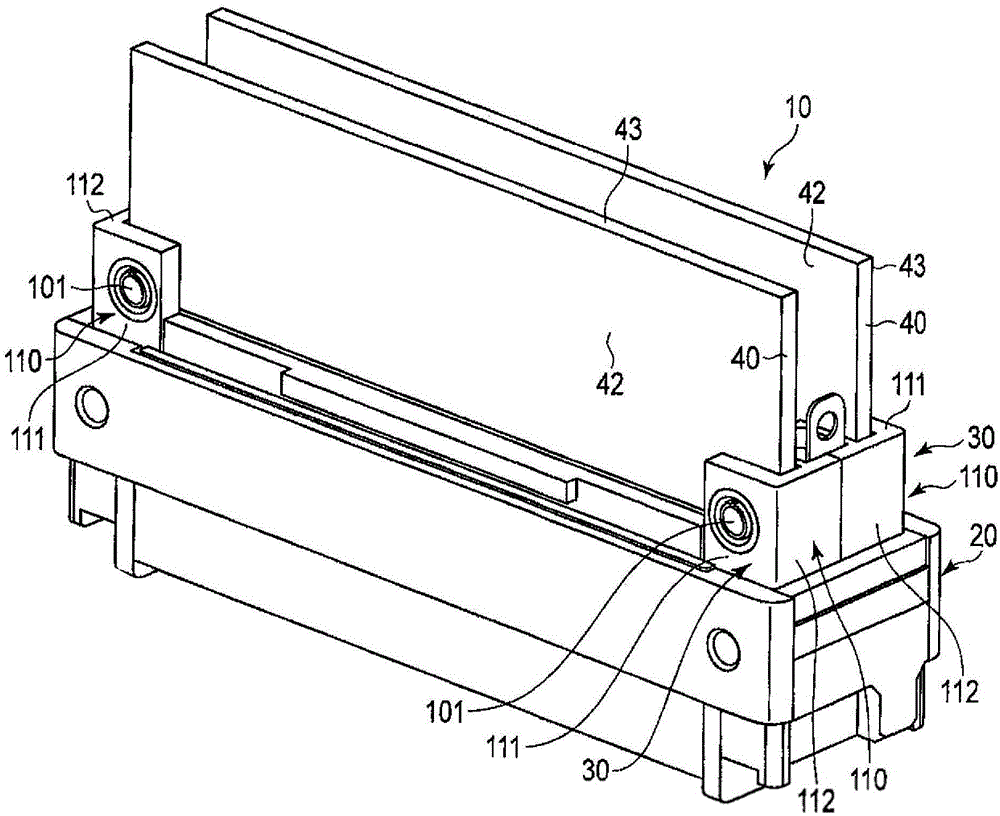

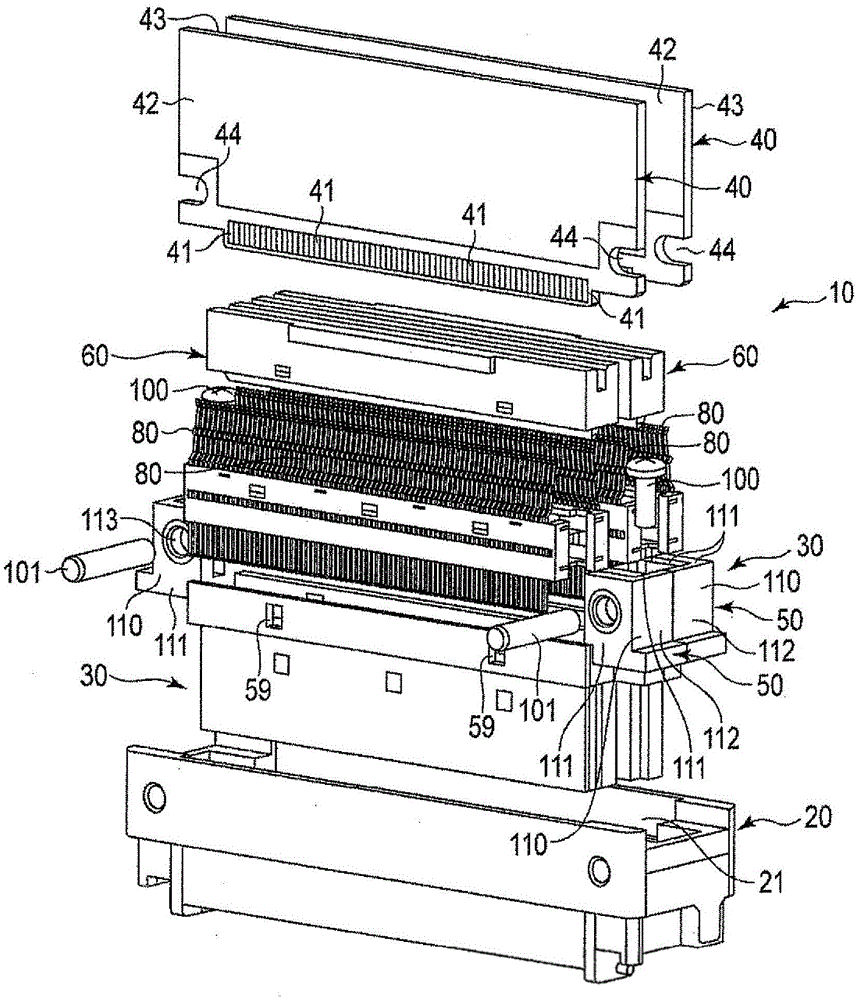

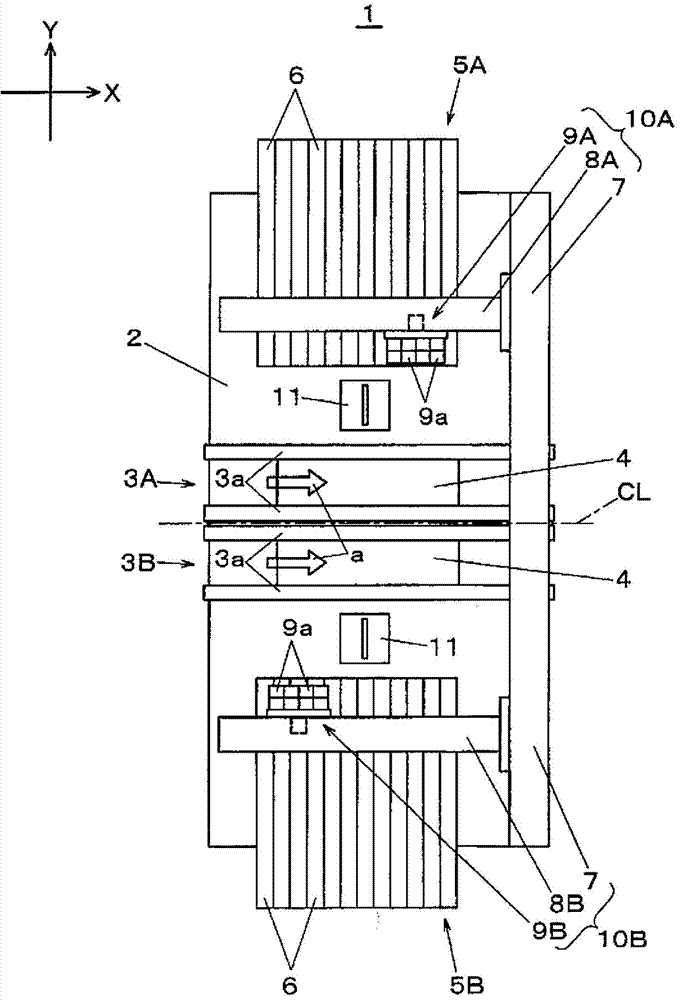

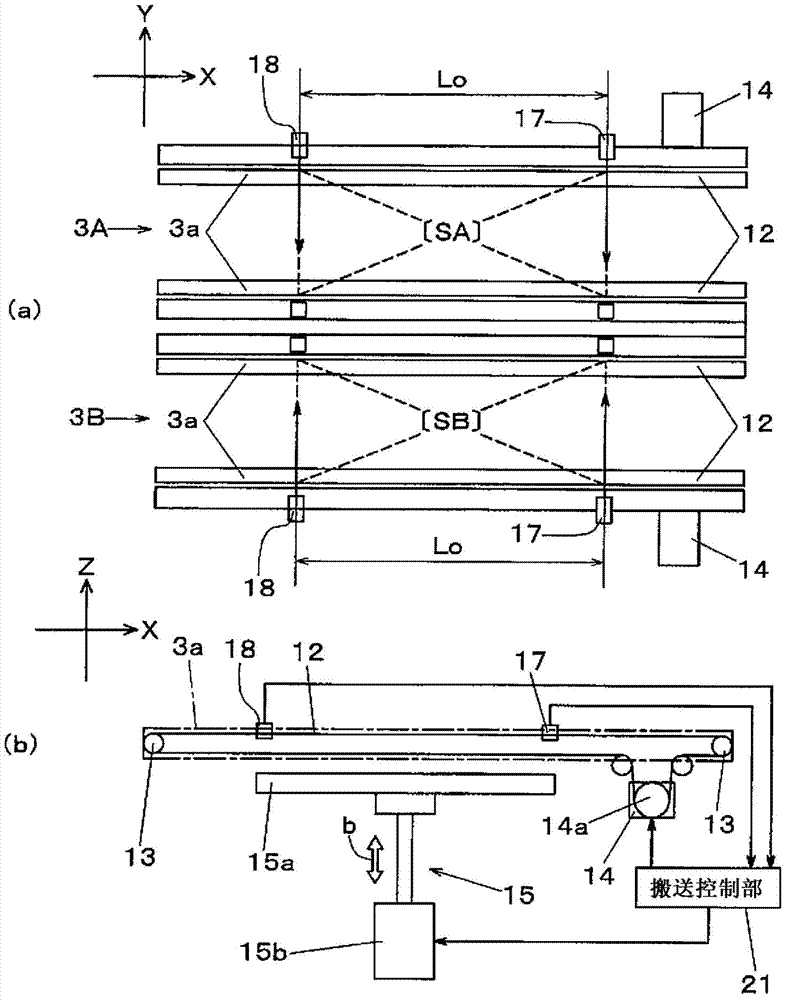

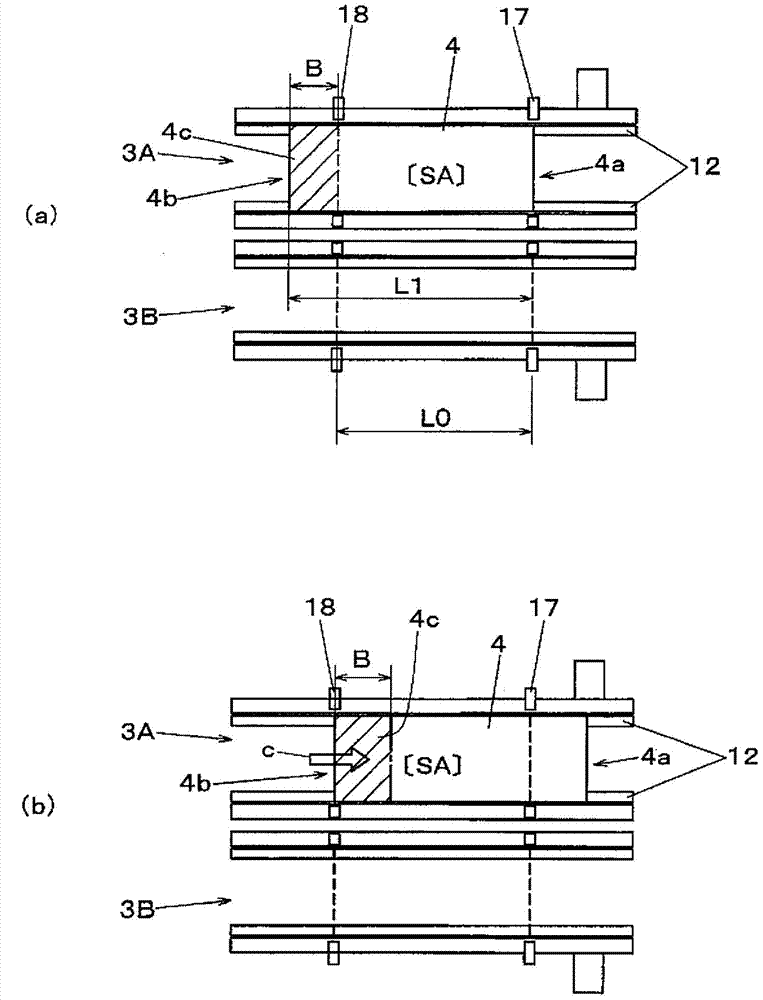

Electronic parts installation device

ActiveCN1662133ASave spaceEfficient installation workElectrical componentsElectronic componentEngineering

he objective of the invention is to provide an apparatus for mounting electronic components capable of improving efficiency in mounting work to a substrate. The electronic component mounting device is provided with substrate-holding means 31 and 32 in the middle of the transfer path by transfer means 21 and 22 of a substrate K, a first positioning mechanism that positions the head along the guide frame with the aid of head guide frames 51 and 52 arranged over the transfer path, and a second positioning mechanism that positions the head along the transfer direction. Each head 40 is arranged at the mutually opposite surface side of each guide frame. The heads held by one guide frame and the heads held by the other guide frame perform mounting operation only to the mutually different substrates held by the substrate-holding means.

Owner:JUKI CORP

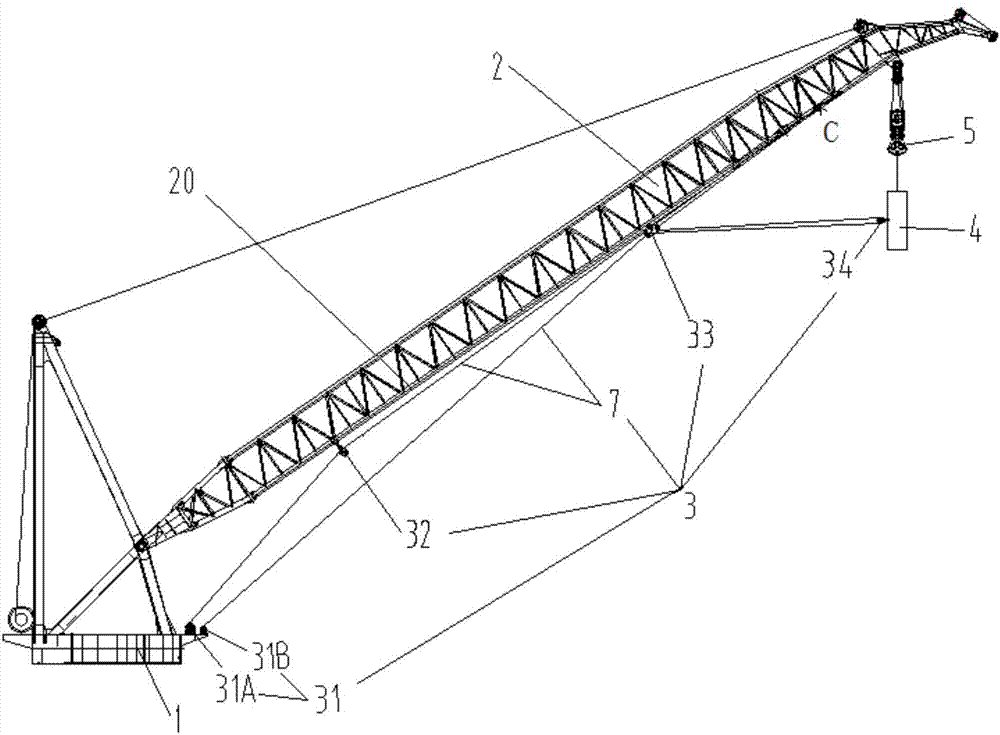

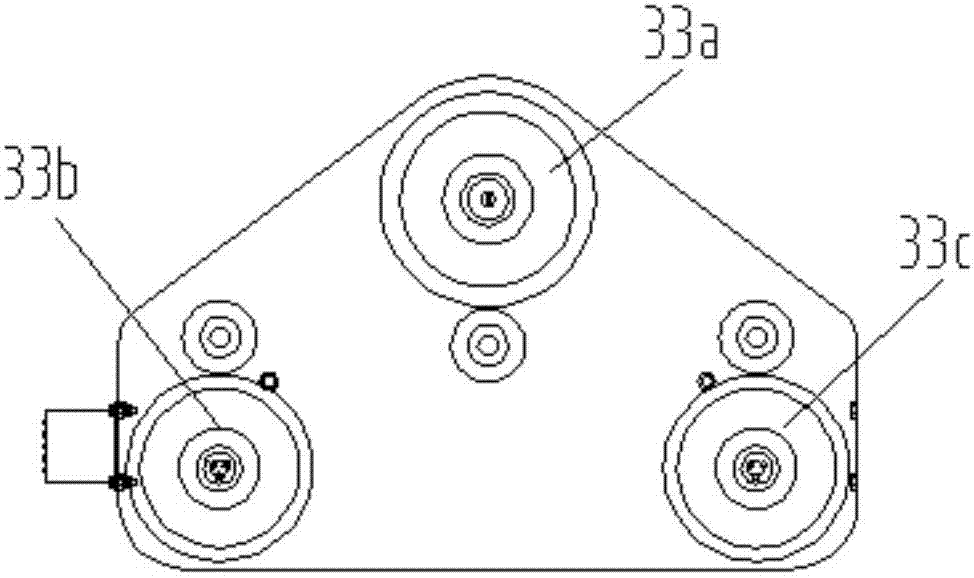

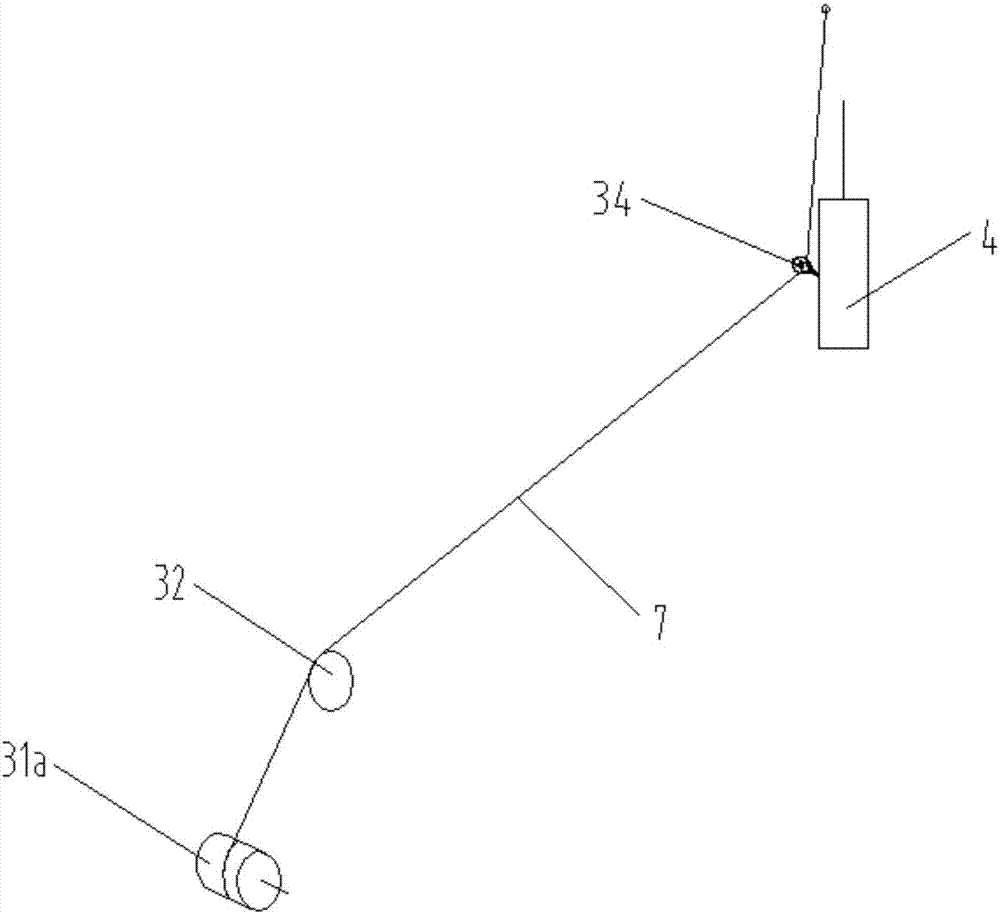

Floating crane cargo stabilizing device

The invention discloses a floating crane cargo stabilizing device which comprises a rotating platform, a cantilever crane supported on the rotating platform, and a cargo stabilizing mechanism arranged on the rotating platform and the cantilever crane. The cargo stabilizing mechanism comprises cargo stabilizing guide winches, a cargo stabilizing guide pulley, a cargo stabilizing pulley yoke, a cargo stabilizing guide cargo pulley and cargo stabilizing steel wire ropes, the cargo stabilizing guide winches are arranged on the rotating platform, the cargo stabilizing guide pulley is arranged in the position, close to the bottom, of a cantilever crane lower chord, a lifting hook is arranged on the lower side of the upper part of the cantilever crane, a sling load is tied in the lifting hook, the cargo stabilizing pulley yoke is arranged on the cantilever crane lower chord and located between the cargo stabilizing guide pulley and a fixing frame which is arranged in the position, close to the lifting hook, of the lower side of the upper part of the cantilever crane, the cargo stabilizing guide cargo pulley is arranged on the sling load, the cargo stabilizing steel wire ropes are arranged among the cargo stabilizing guide winches, the cargo stabilizing guide pulley, the cargo stabilizing pulley yoke and the cargo stabilizing guide cargo pulley optionally in a penetrating winding mode. According to the floating crane cargo stabilizing device provided by the invention, when sling loads of different sizes are lifted to different lift heights, cargo stabilizing can be achieved by converting different rope winding modes.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

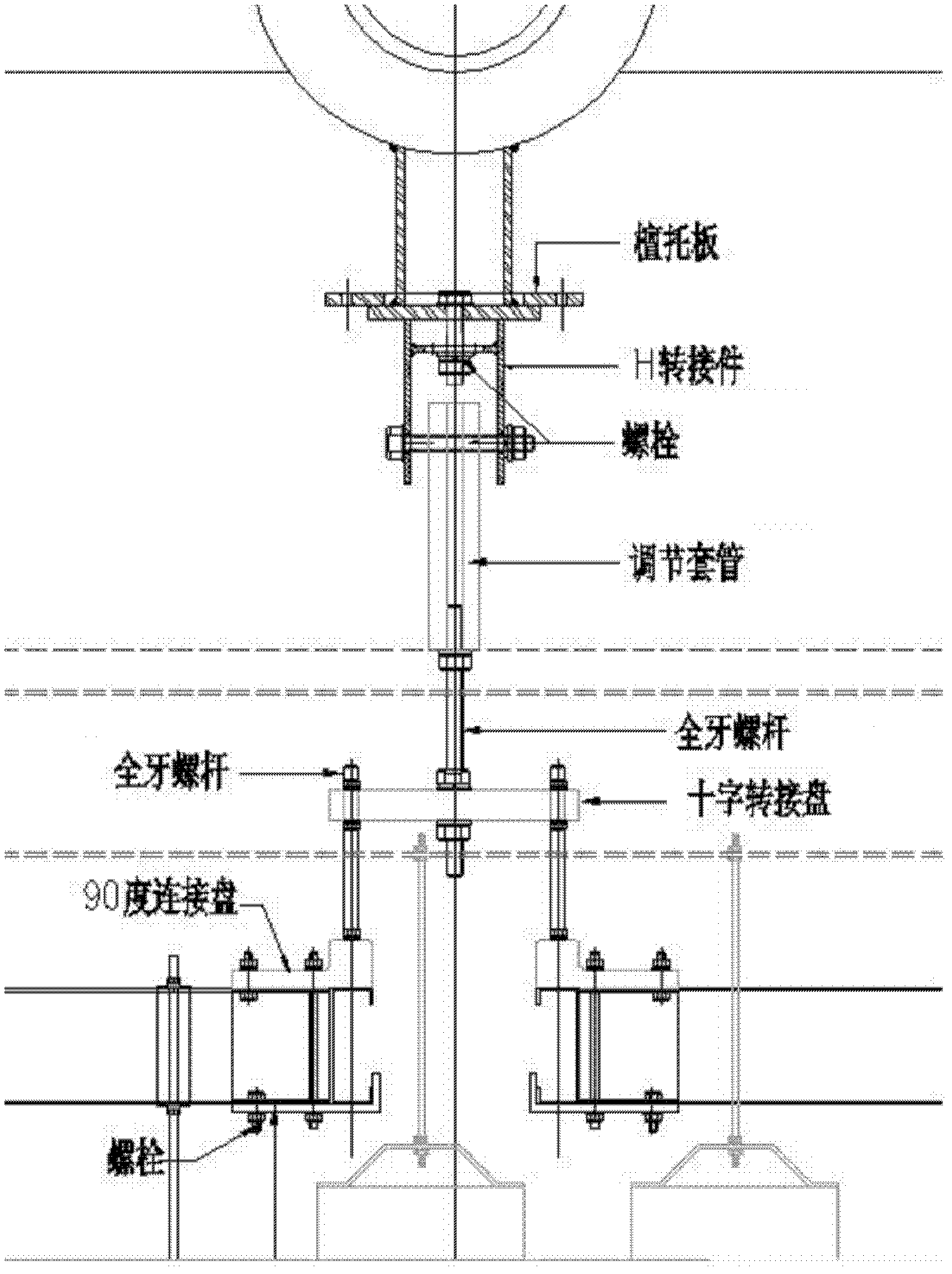

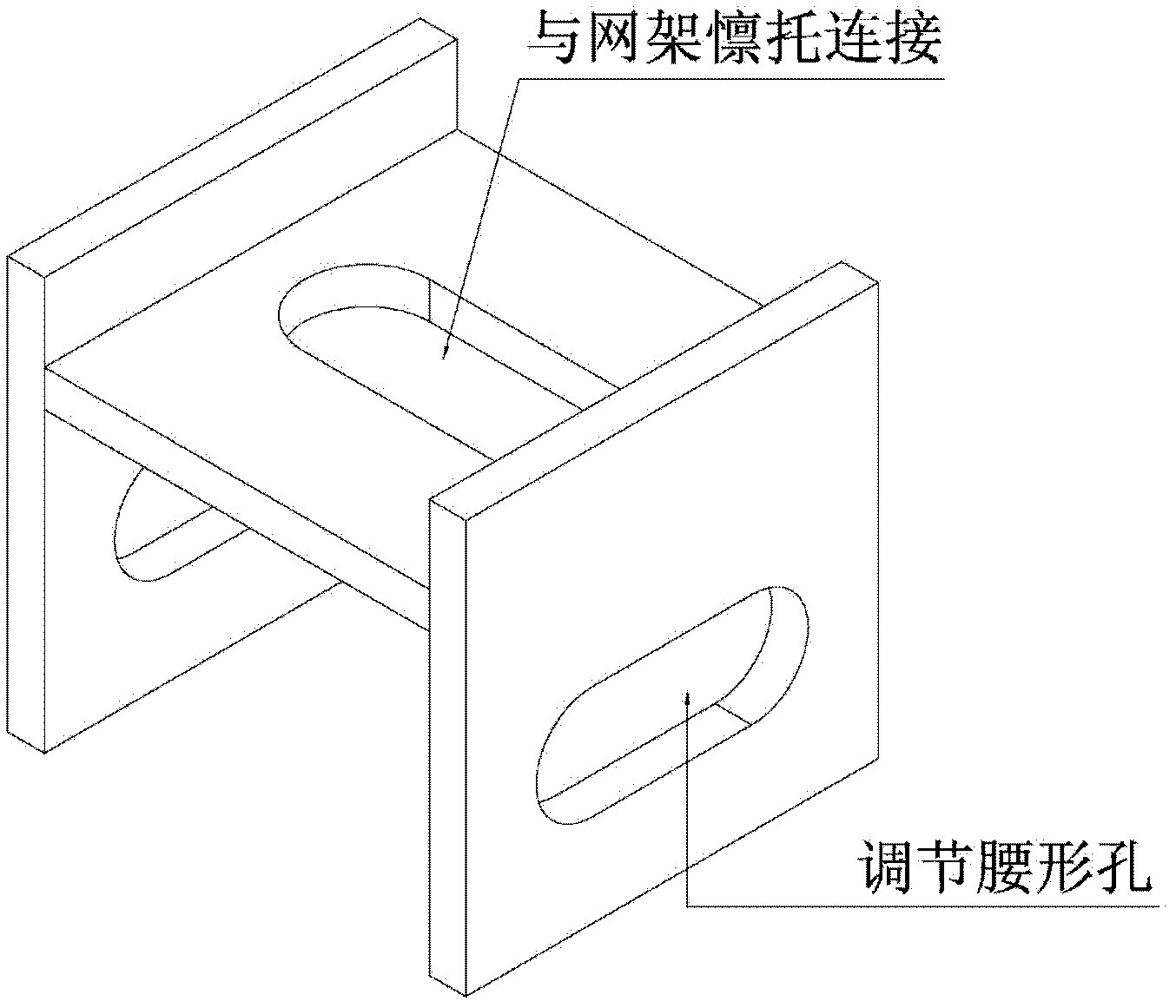

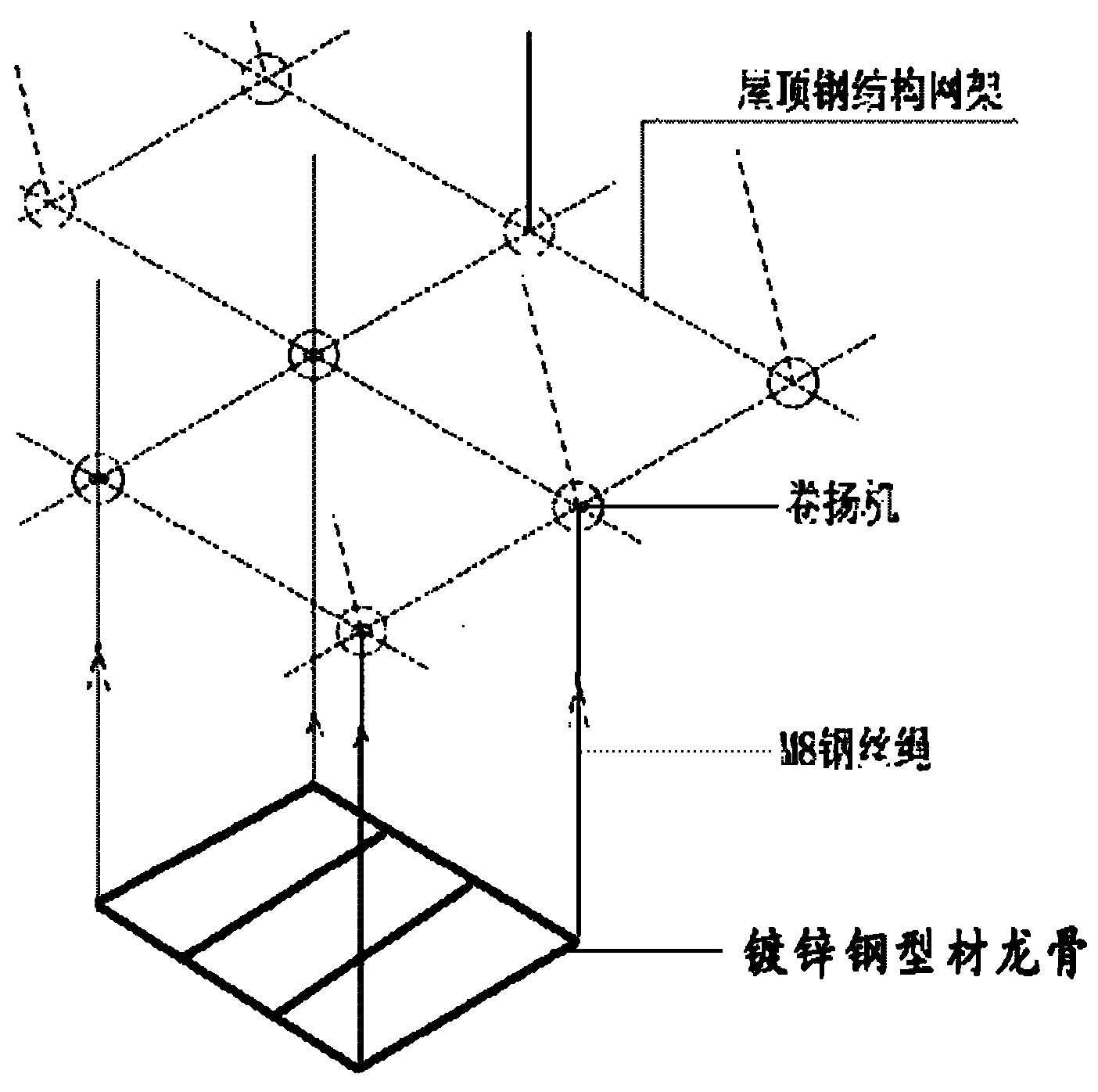

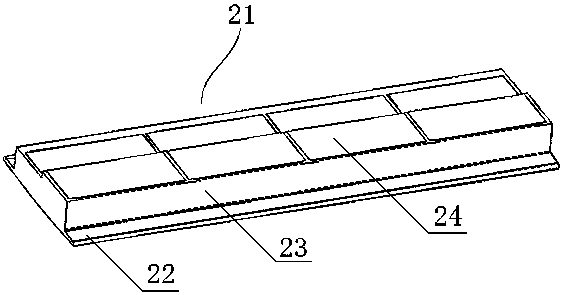

Assembled type unit framework installing method

ActiveCN102995907AReduce investmentImprove installation work efficiencyBuilding material handlingEconomic benefitsEngineering

The invention discloses an assembled type unit framework installing method which is characterized by comprising the following four steps of: measuring, paying off and positioning; installing a seamless steel tube lifting piece; installing an assembled type unit framework; and installing an aluminum panel. According to the assembled type unit framework installing method, the assembled type unit framework is wholly lifted and installed, so that the welding working is greatly reduced, the on-site manufacturing time is saved, the efficiency in large-span high altitude suspended ceiling installation working is improved, and the difficulty in vertical transportation is greatly reduced; by adopting a reversed installation process, the whole installation process is rapider and more convenient, and the erection and the detachment of a scaffold are avoided, so that time is greatly saved for construction on the ground, the labor investment is reduced, the cost is saved, and significant economic benefits are achieved; and moreover, the structure is more solid, the influence from the load of an adjacent region is small, the overall stress is more uniform, and the structure is safer; and meanwhile by utilizing the method, aspects such as on-site civilized construction, security production, construction quality and the like are all well ensured.

Owner:中建八局装饰工程有限公司

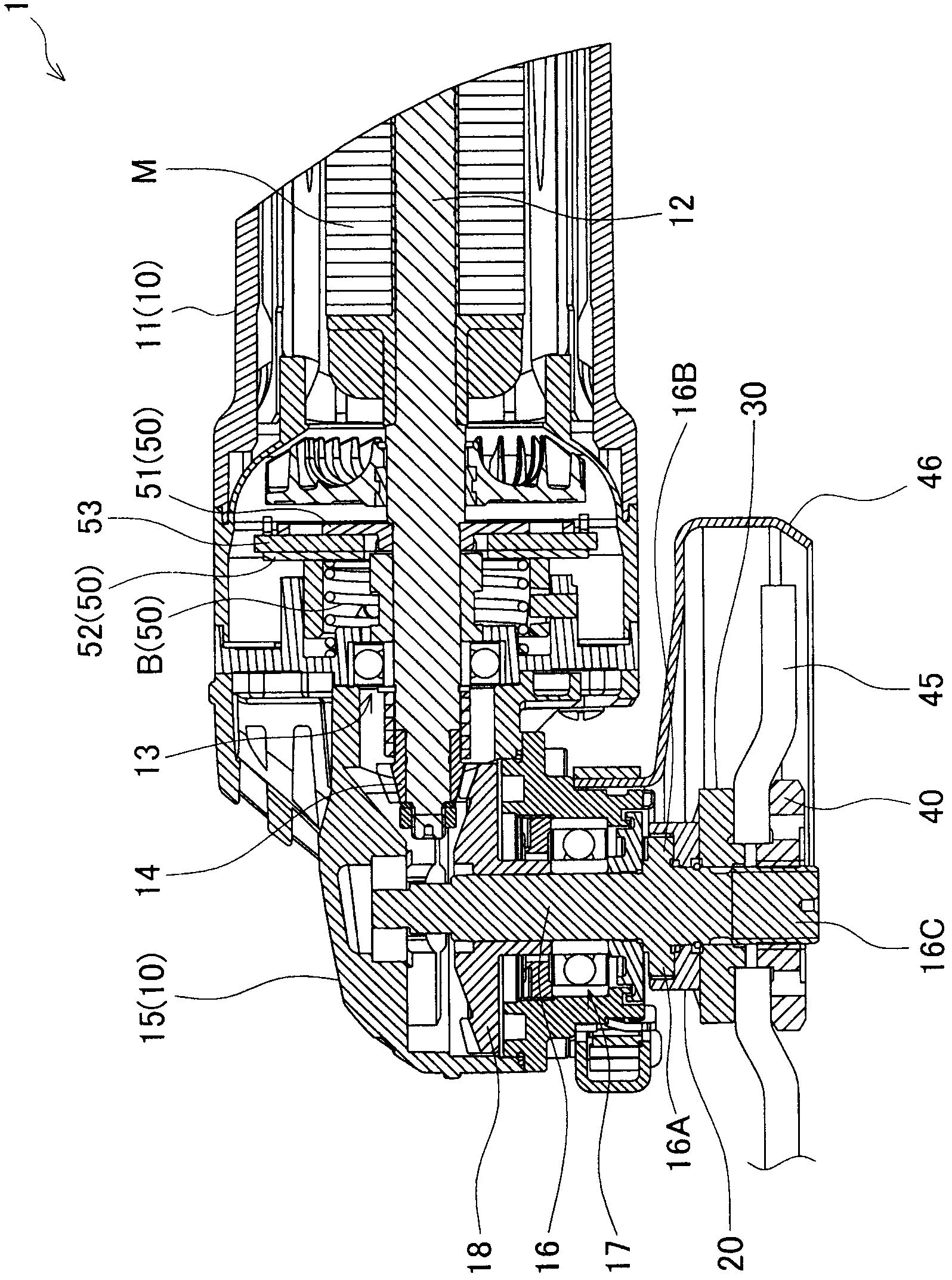

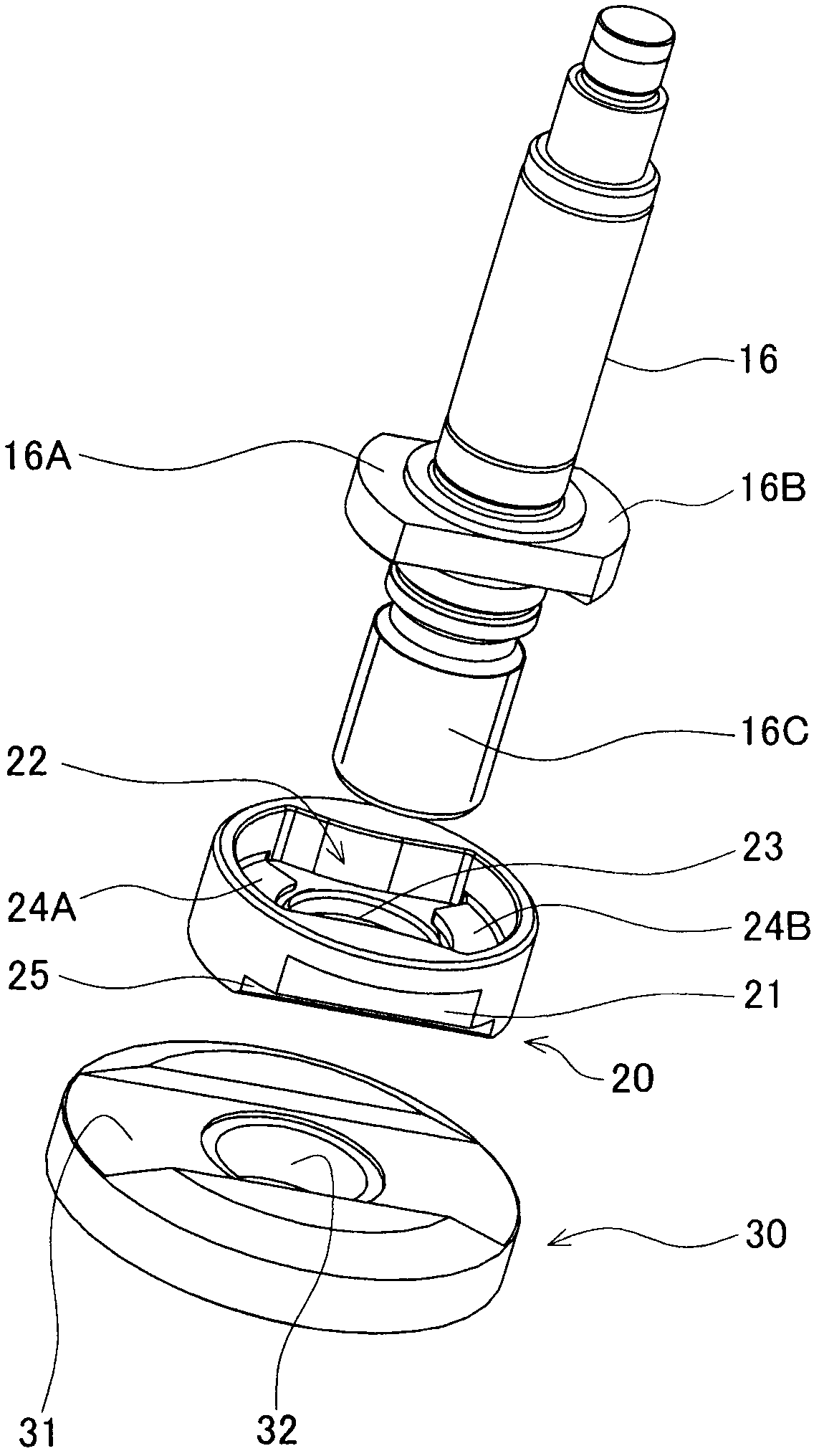

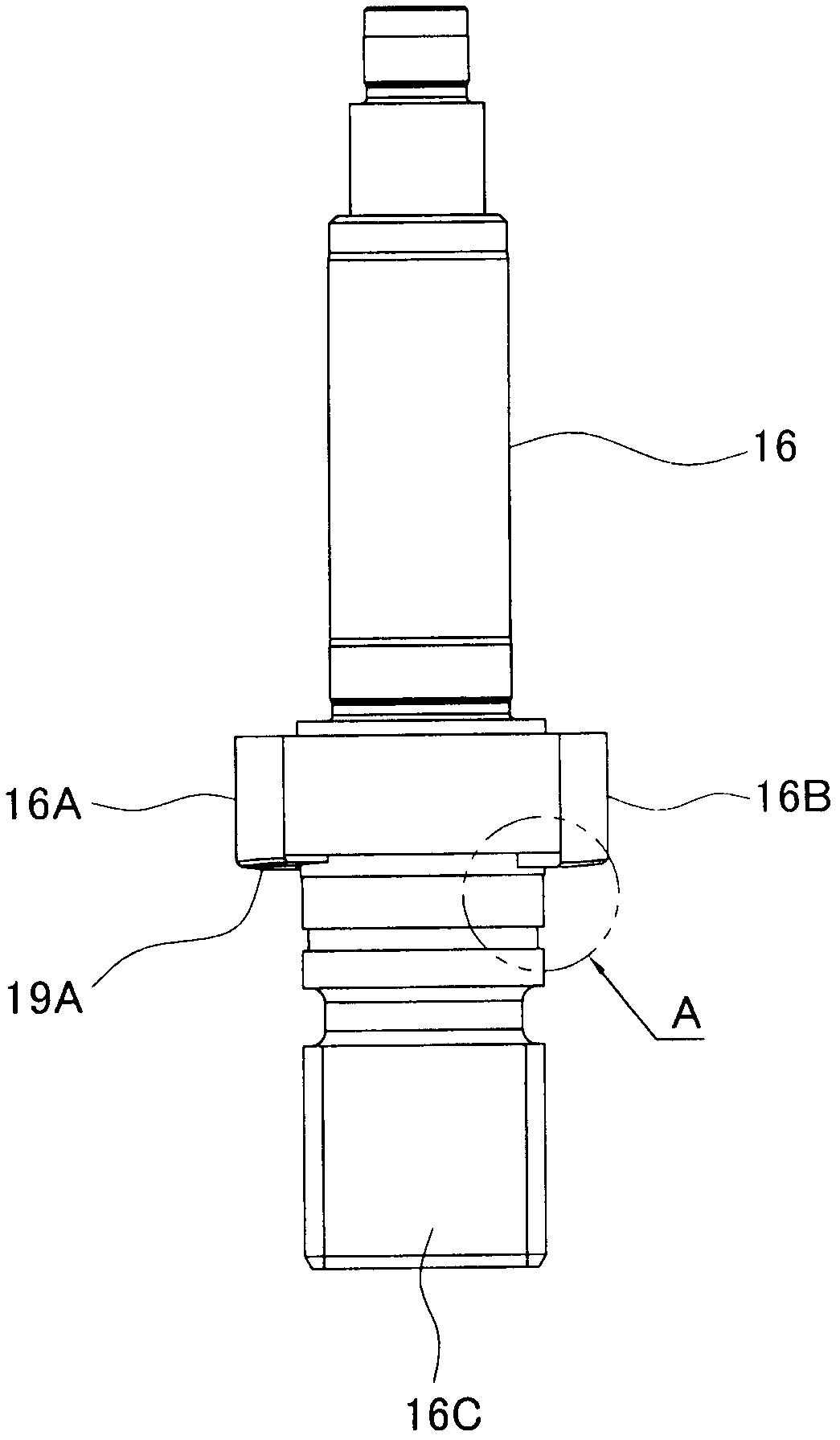

Power tool

InactiveCN102689293AEasy to identifyReliable anti-loosening functionGrinding wheel securing apparatusPortable grinding machinesEngineeringPower tool

It is an object of the present invention to provide a power tool which is configured to prevent a nut member screwed on the spindle from loosening during operation of a brake device, when an inner member is mounted on the spindle. A grinder 1 comprises a main body (10) with a brake device (50), a spindle (16) provided with an inner member, integrally formed into a pressing portion and protruding from the main body. When the spindle is braked by the brake device, the inner member is pressed toward a tip end of the spindle by the pressing portion. The inner member comprises a locking member (20) that contacts the pressing portion and is pressed toward the disc-like tool (45) when the brake device (50) is operated, and an inner flange (30) which is detachably attached to the locking member (20) so as to be rotatable together with the locking member (20) and the disc-like tool is clamped between the inner flange and the nut member.

Owner:MAKITA CORP

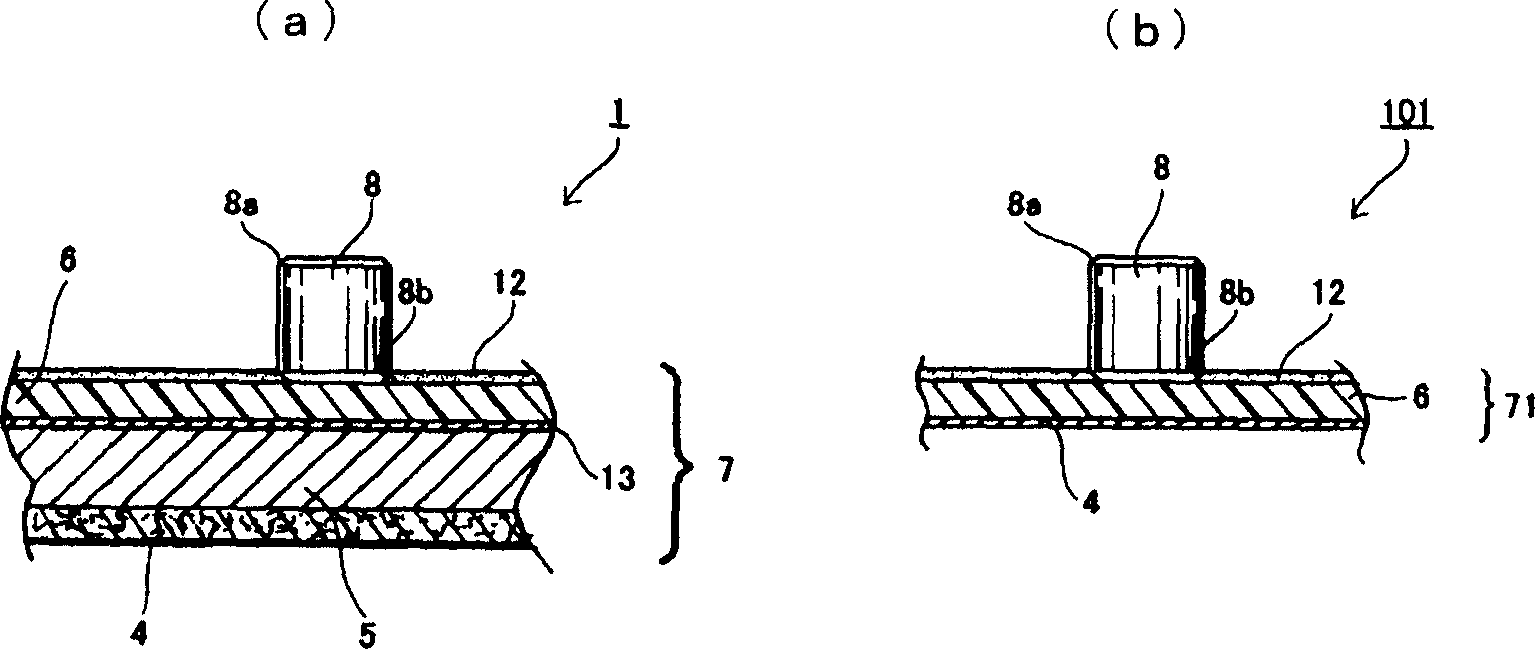

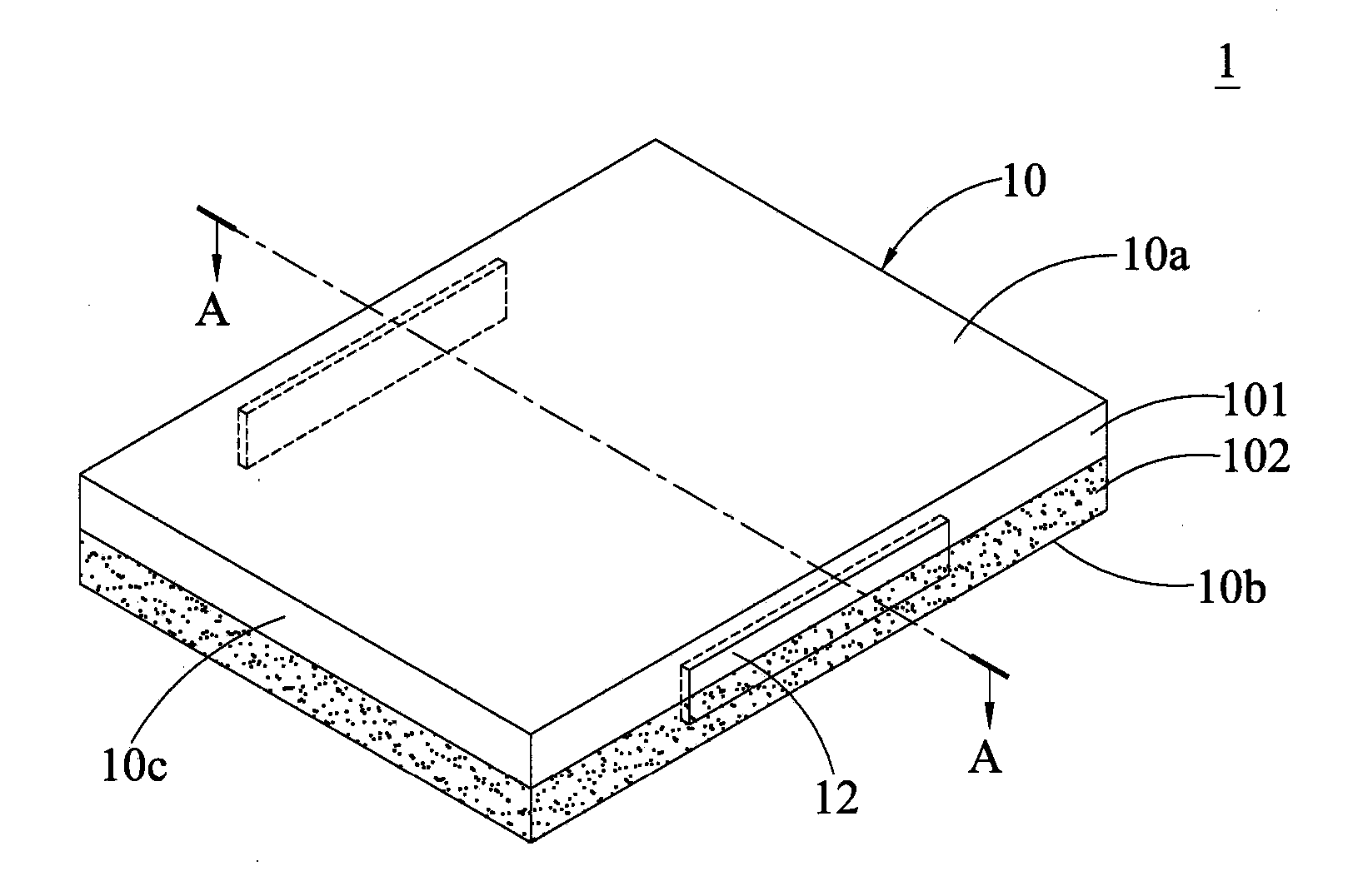

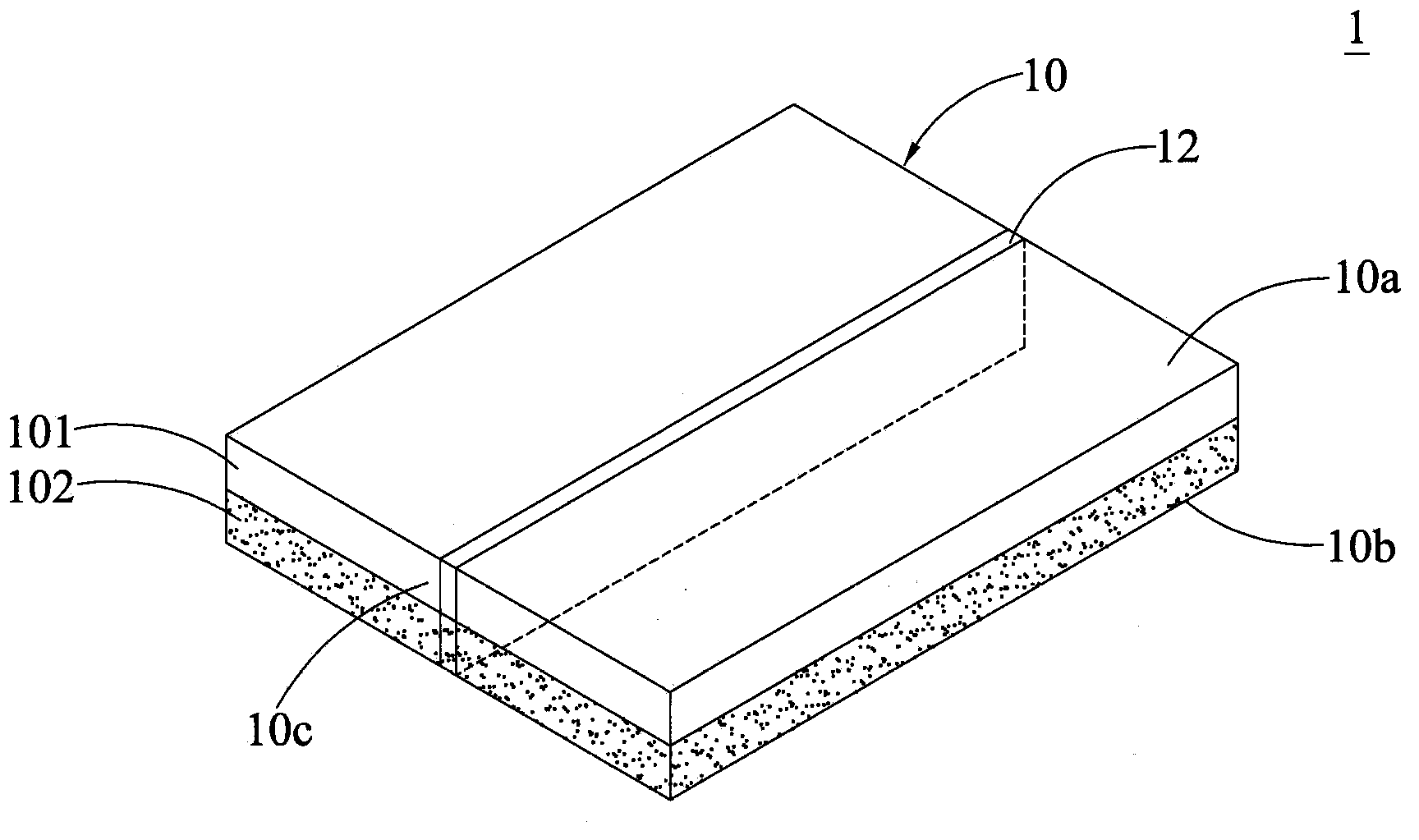

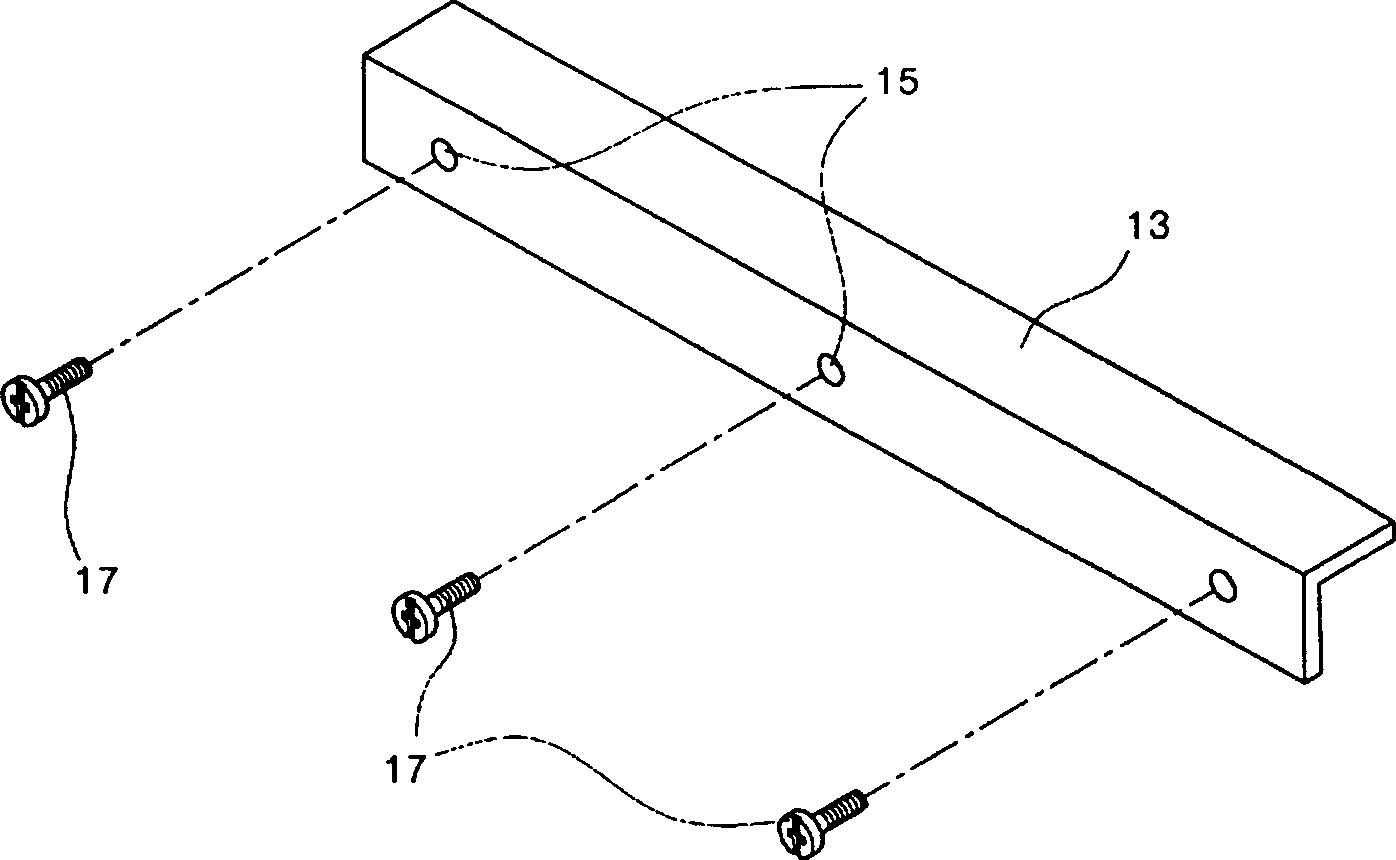

Polishing piece, polishing lap, and method of polishing glass panel for CRT

InactiveCN1684802AImprove installation work efficiencyNo lodgingBonded abrasive wheelsRubber materialEngineering

A method for manufacturing polishing lap capable of firmly fixing a polishing piece onto the upper surface of a base layer without using a vulcanized forming device and a vulcanized forming process for unvulcanized rubber material layer, comprising the steps of forming both end parts of the piece in a general flat or a general recessed curve surface without providing any irregular part for increasing an engagement force on the outer periphery of the polishing piece, and pressingly fixing the piece into an adhesive layer on the base layer at any end side of piece, whereby a working efficiency and an economic efficiency can be remarkably increased more than that of a system pressingly fixed into the unvulcanized rubber material layer and, since the polishing piece is firmly fixed to the base layer, and accidents such as falling down and falling during polishing operation can be prevented.

Owner:POBAALE INDS +1

Part recognition system and part recognition method

ActiveCN103313591AImprove installation work efficiencyReduce manpower requirementsPrinted circuit assemblingUsing optical meansData processingRecognition system

The invention relates to a part recognition system for driving an automatic device to pick up a part and adjust the pin of the part to a preset position, wherein the part comprises a top portion, a bottom portion and at least one set of pins, wherein the pins are arranged on the bottom portion and the top portion comprises at least one positioning characteristic. The part recognition system comprises a material conveying device, an optical sensor and a data processing device, wherein the material conveying device adjusts the part to a preset placing state for the automatic device to pick up, the optical sensor is arranged at one side of the material conveying device and acquires sampling data from the top of the part at a preset placing state and the data processing device electrically connects the optical sensor and the automatic device. The data processing device receives the sampling data, generates an instruction according to the positioning characteristic, sends the instruction to the automatic device and rotates the part according to the instruction after the automatic device is driven to pick up the part.

Owner:GIGA BYTE TECH CO LTD

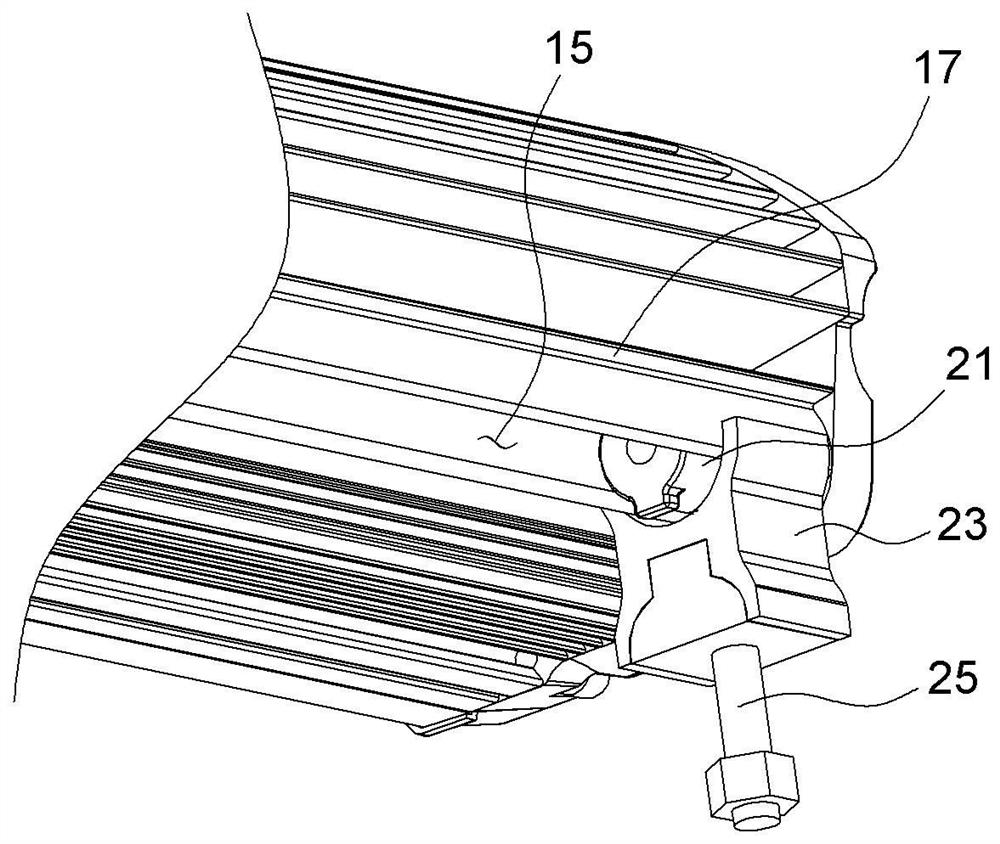

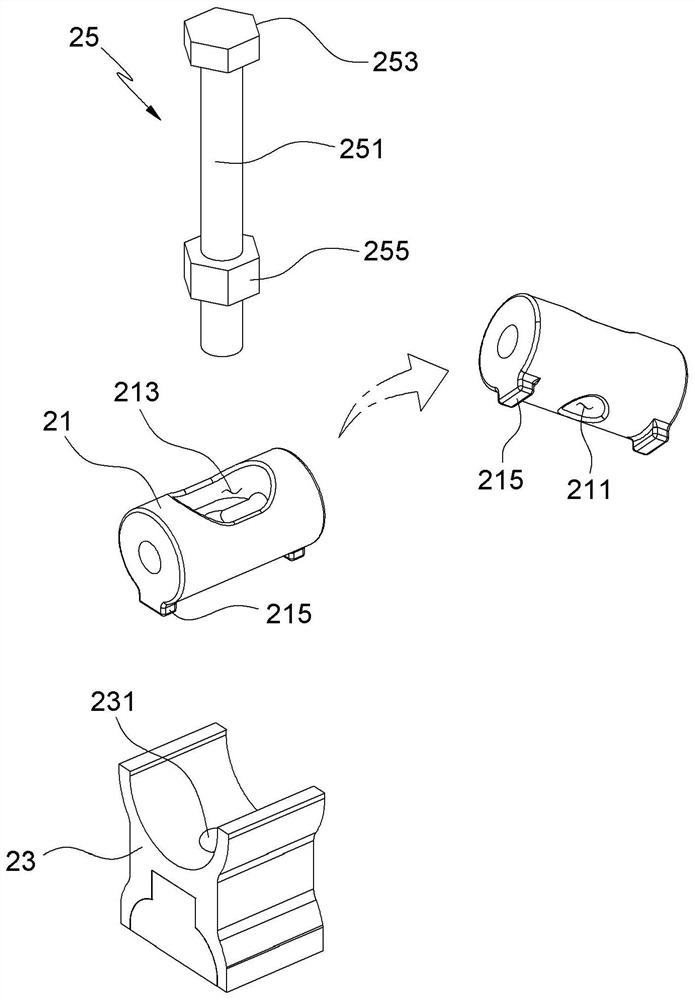

Metal semi-autogenous-grinding ball mill lining plate

PendingCN110339913AReduce unit consumption costReduce labor intensitySound producing devicesGrain treatmentsWear resistantEngineering

The invention discloses a metal semi-autogenous-grinding ball mill lining plate. The lining plate is composed of a plurality of composite cylinder plates uniformly distributed according to the circumference of the semi-autogenous-grinding cylinder body and installed in the semi-autogenous-grinding cylinder body and composite lifting strips installed between every two composite cylinder plates; thecomposite cylinder platse comprise a rubber cylinder plate body with a plurality of embedding grooves, and the cylinder plate body is arc-shaped conforming to the circumference of the semi-autogenous-grinding cylinder body, and two installing lugs are arranged on the two sides of the cylinder plate body; and two rows of embedded groove bodies which are higher than the installing lugs are formed in the middle of the cylinder plate body, one of the rows of embedding groove bodies is higher than the other row of embedding groove body to form steps, the plurality of embedding grooves are formed in each row of embedding groove bodies, and wear-resistant alloy blocks are installed in the embedding grooves; and the composite lifting strips comprise rubber lifting strip bodies, a connecting framework is installed in the middle of the bottoms of the lifting strip bodies, the connecting framework is connected with the installing lugs, a plurality of embedding grooves are formed in the lifting strip bodies, and the wear-resistant alloy blocks are installed in the embedding grooves. According to the metal semi-autogenous-grinding ball mill lining plate, a mill body is high in efficiency, lowin power consumption, long in service life, low in noise, light in weight, convenient to install, safe and reliable.

Owner:ANHUI KELLEBURG RUBBER ROLLER

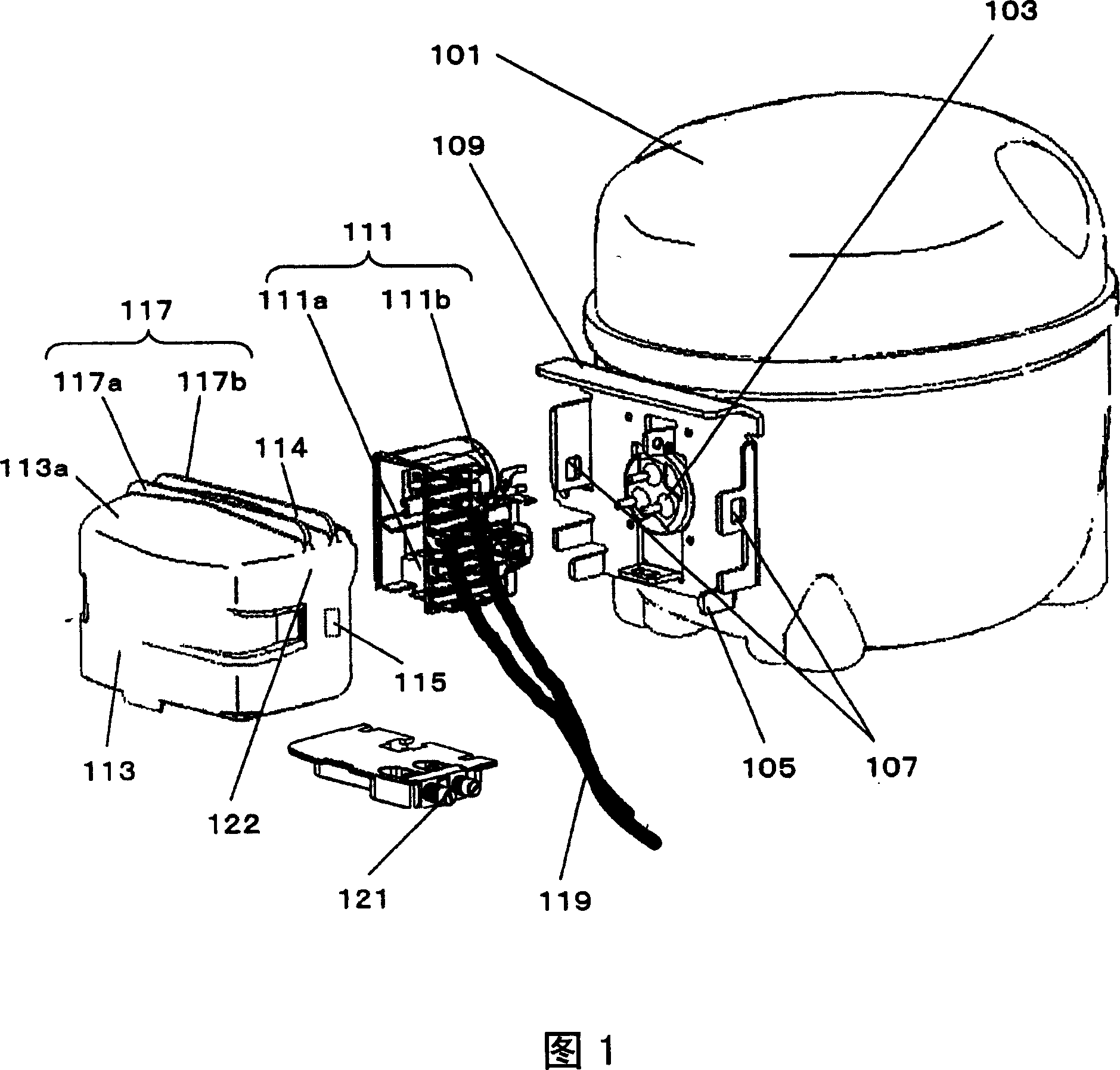

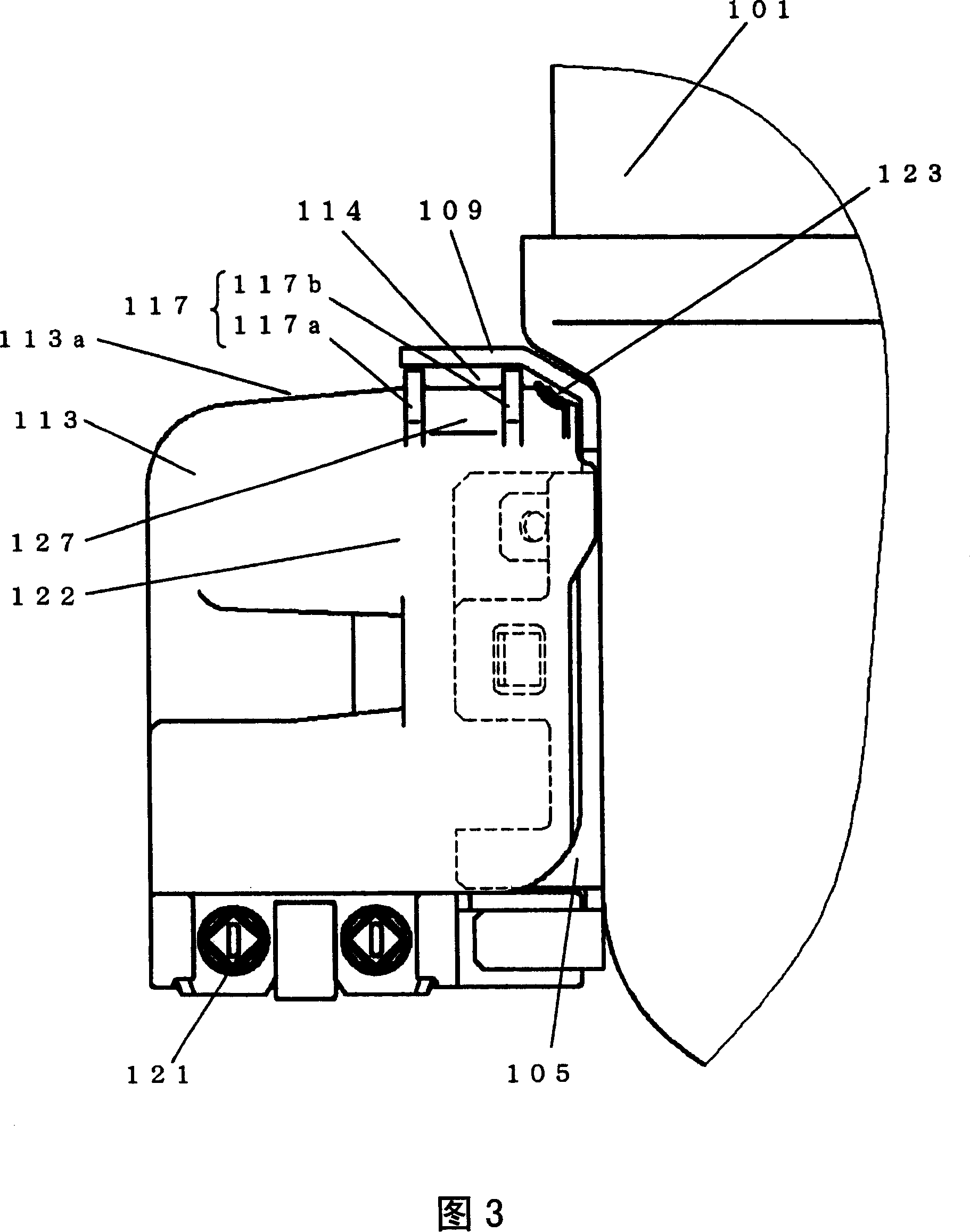

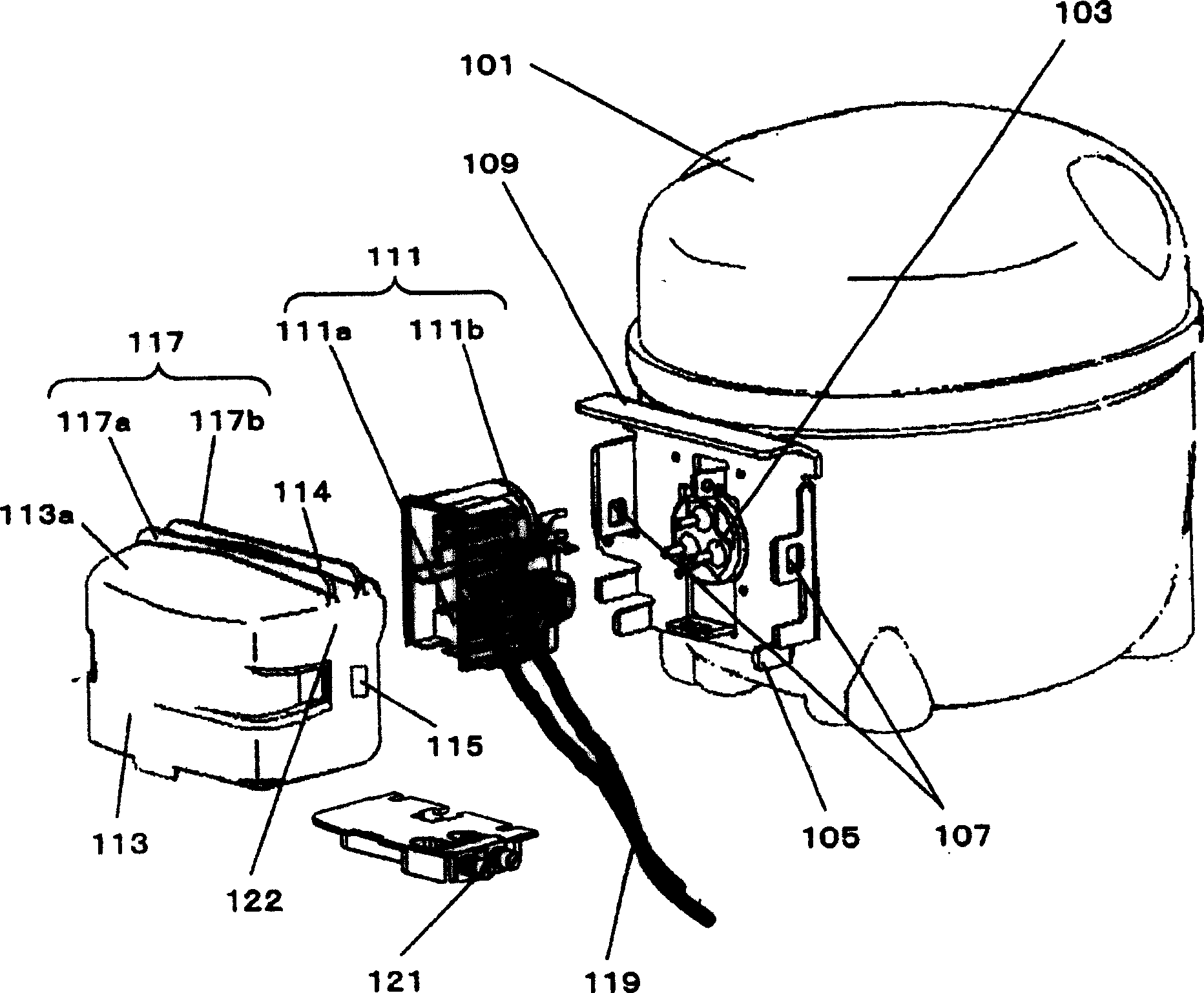

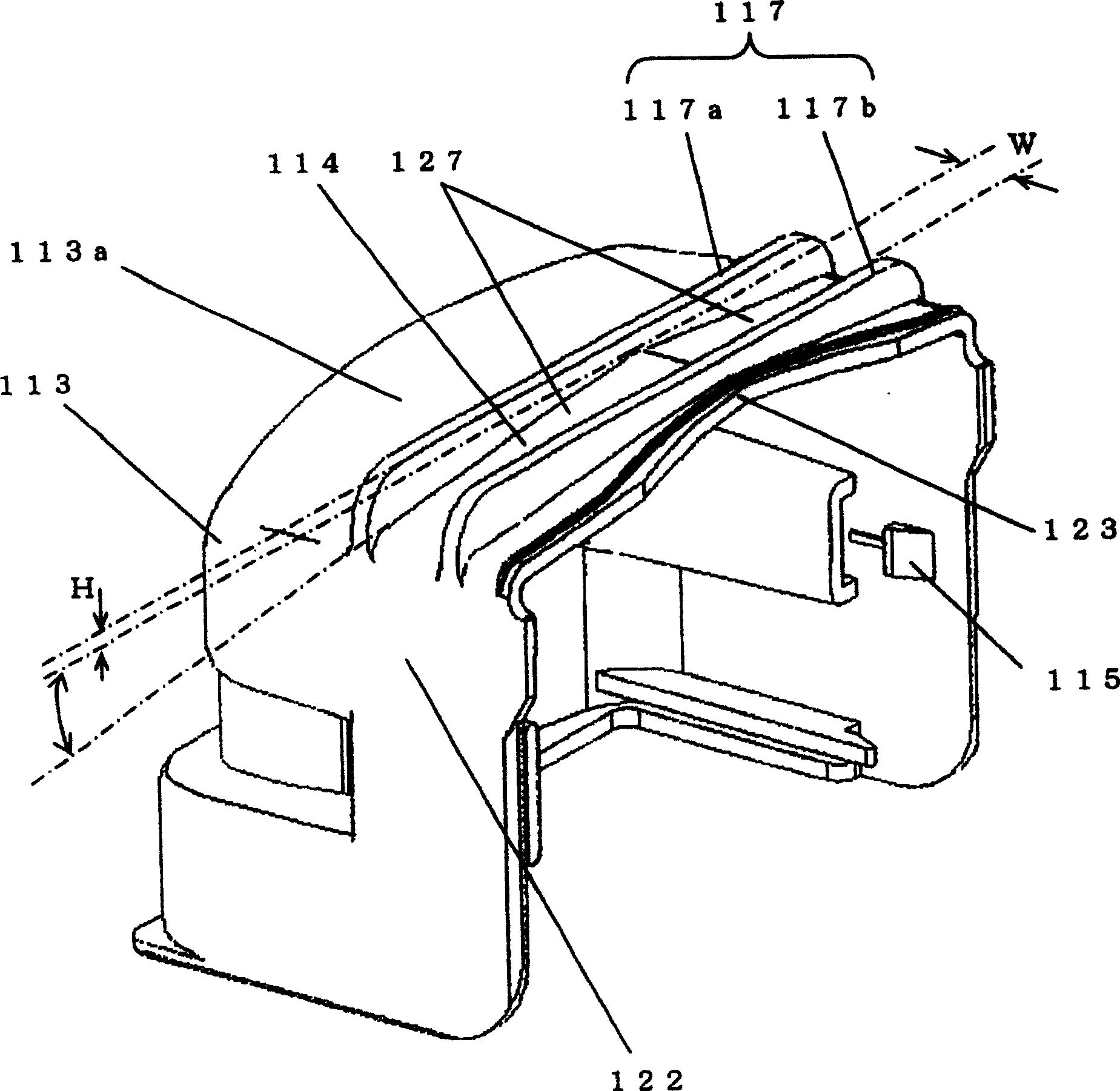

Electric equipment protective device

InactiveCN1991169APrevent infiltrationWill not reduce work efficiencyPositive displacement pump componentsPositive-displacement liquid enginesEngineeringElectrical and Electronics engineering

A penetration of water into the electric equipment cover can be positively prevented without deteriorating the working property of one-touch inserting motion of the electric equipment cover and a highly reliable electric equipment protective device of compressor is provided. The electric equipment protective device of a compressor includes: an electric equipment cover 113 for accommodating the electric equipment 111; a hood portion 109 which is arranged in an upper portion of the electric equipment cover and closely fixed onto an outer surface of the compressor body 101; and a drain ditch 114 arranged at a position in an upper face portion 113a of the electric equipment cover opposed to the hood portion. Due to the above constitution, the penetration of water into the electric equipment cover can be positively prevented without deteriorating the working property of one-touch inserting motion of the electric equipment cover and a highly reliable electric equipment protective device of compressor is provided.

Owner:PANASONIC CORP

Solar cell module and method of fabricating the same

ActiveCN103855248ASimple processReduce areaPhotovoltaic energy generationSemiconductor devicesSolar cellMaterials science

A solar cell module and a method of fabricating the same are provided. The method includes providing a solution having a luminescent dye, mixing the solution with a first waveguide material to obtain a first mixture, and placing the first mixture and a second mixture comprising nano-powder and a second waveguide material into a mold to form a waveguide body having a first layer body and a second layer body stacked on the first layer body. The waveguide body has a top surface, a bottom surface opposing to the top surface, and a lateral surface connecting the top surface with the bottom surface. At least one solar cell is disposed in the mold and embedded in the waveguide body, to enlarge a light reception area and light collection.

Owner:FLEXWAVE

Hydraulic control clamping and overturning system for large-power diesel engine cylinder cover air valve assembling

InactiveCN108194436AHigh degree of flexibilityGuaranteed assembly qualityServomotor componentsServomotorsHydraulic pumpCheck valve

A hydraulic control clamping and overturning system for large-power diesel engine cylinder cover air valve assembling comprises a hydraulic supply loop, a hydraulic motor control mechanism, a hydraulic arm clamping mechanism and a hydraulic cylinder stroke control mechanism. The hydraulic supply loop comprises an oil tank, a flow meter, an oil injection filter, a filter with a pressure meter and aspring check valve, a motor, a hydraulic pump, the pressure meter, a pressure reduction safety valve and a two-position two-way electromagnetic valve. The hydraulic motor control mechanism comprisesa three-position four-way electromagnetic valve, a mutual control type double hydraulic control one-way valve, a pressure reduction safety valve and a hydraulic motor. The hydraulic arm clamping mechanism comprises a three-position four-way electromagnetic valve, a mutual control type double hydraulic control one-way valve, a duplex one-way speed adjusting valve, a pressure accumulator, a stop valve capable of being opened and closed, a pressure reduction safety valve, a plunger hydraulic cylinder and a pressure relay, and the plunger hydraulic cylinder is provided with a hydraulic arm. The hydraulic cylinder stroke control mechanism comprises a three-position four-way electromagnetic valve, a mutual control type double hydraulic control one-way valve, a one-way speed adjusting valve withelectromagnetic releasing, a pressure relay and a plunger hydraulic cylinder. The hydraulic control clamping and overturning system is high in automation degree and functionality, the operation efficiency is improved, the installing precision is improved, and safety and stability are achieved.

Owner:HUDONG HEAVY MACHINERY

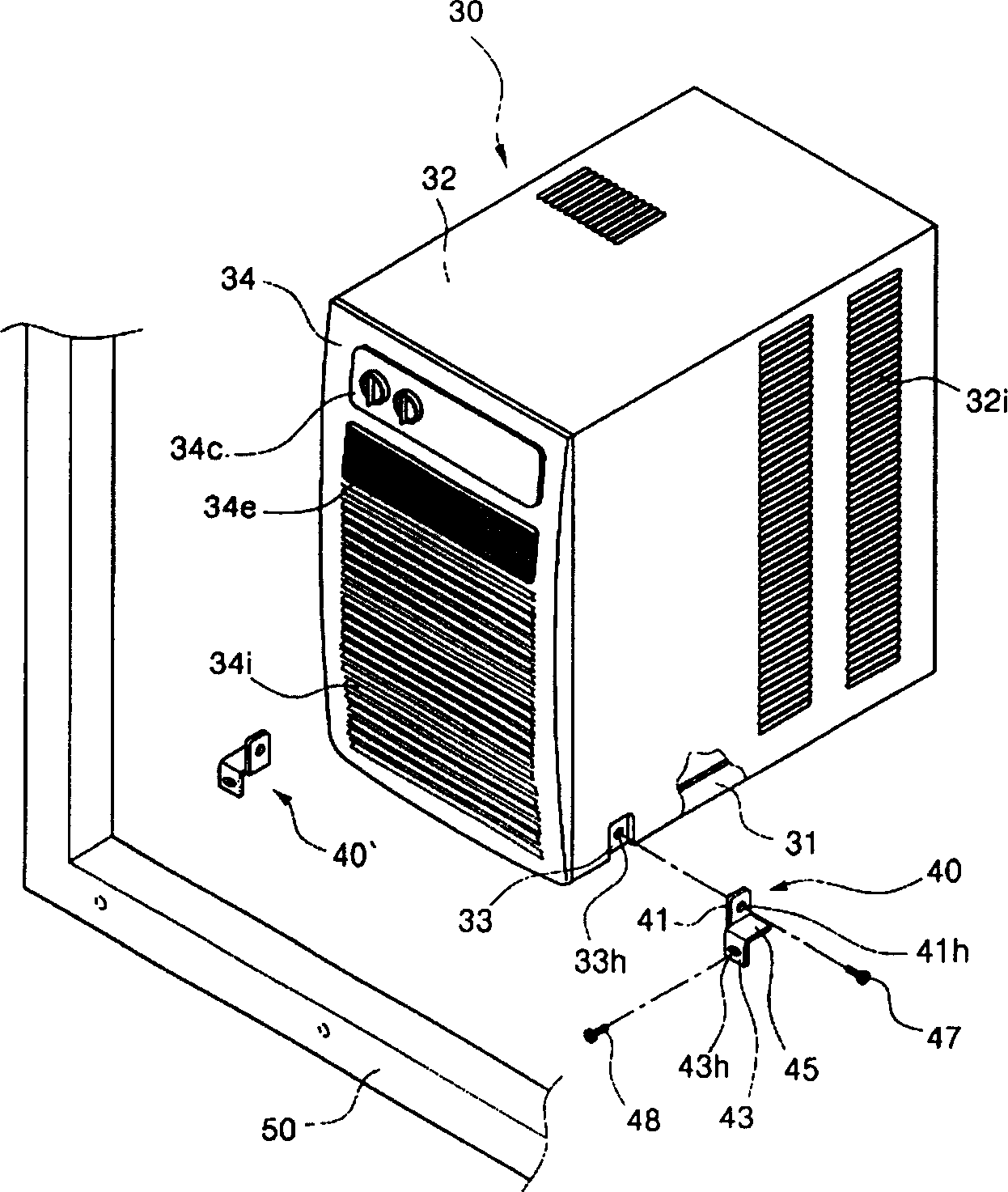

Configuration arrangement for integrated conditioner

InactiveCN1542334AEasy to fixReduce manufacturing costLighting and heating apparatusSpace heating and ventilation detailsArchitectural engineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

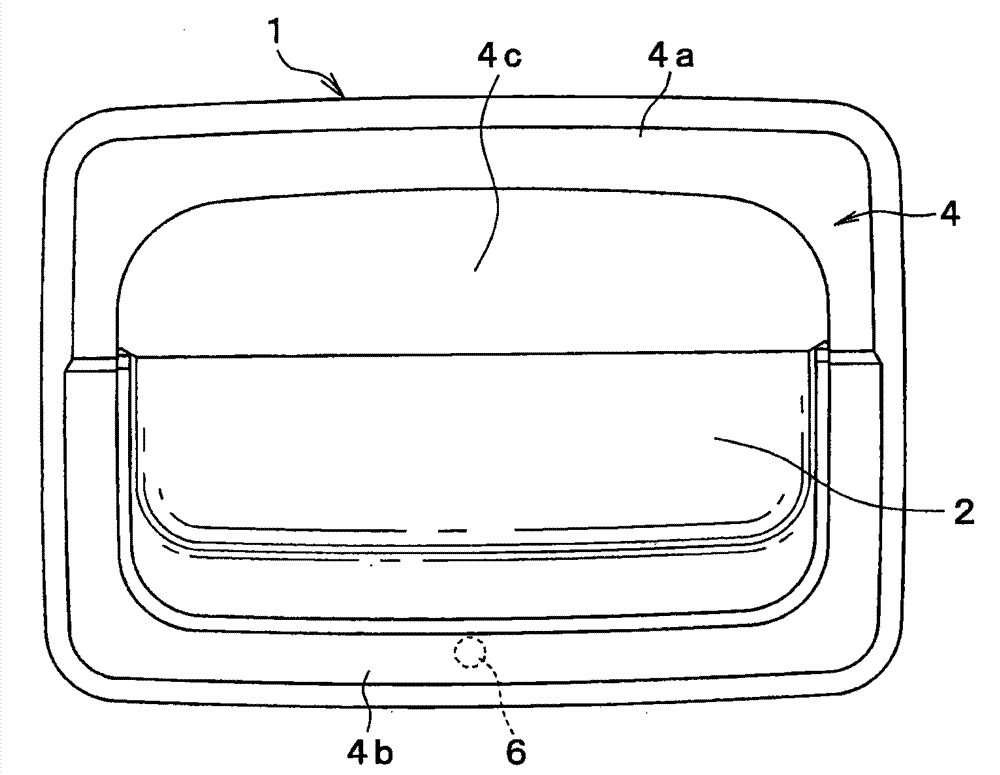

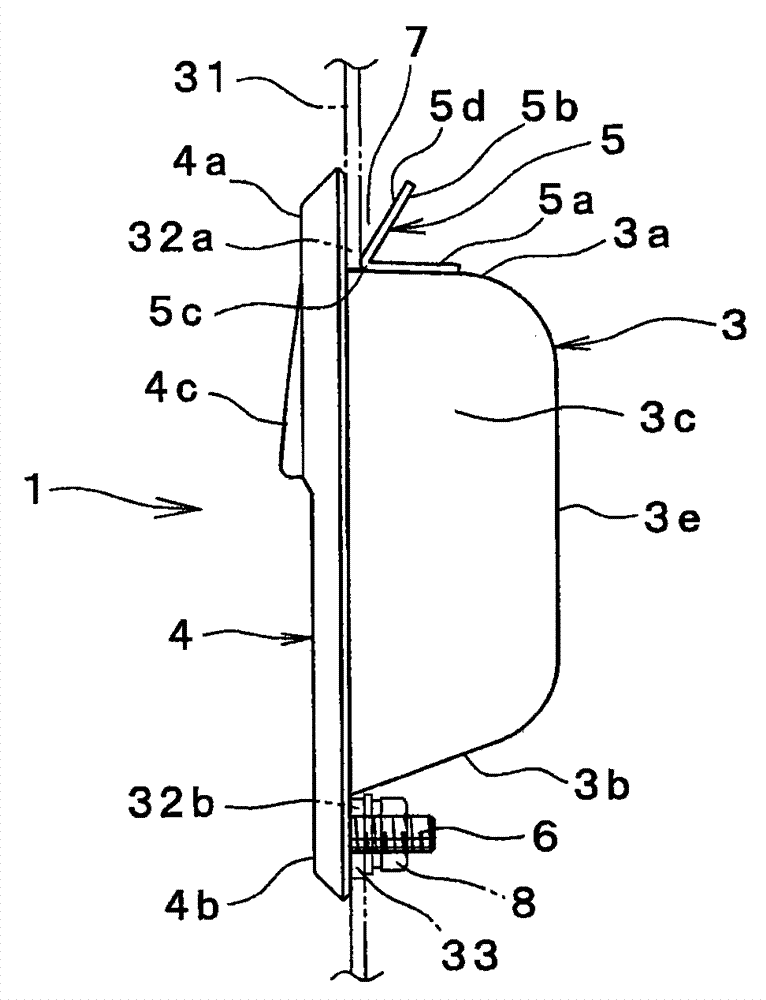

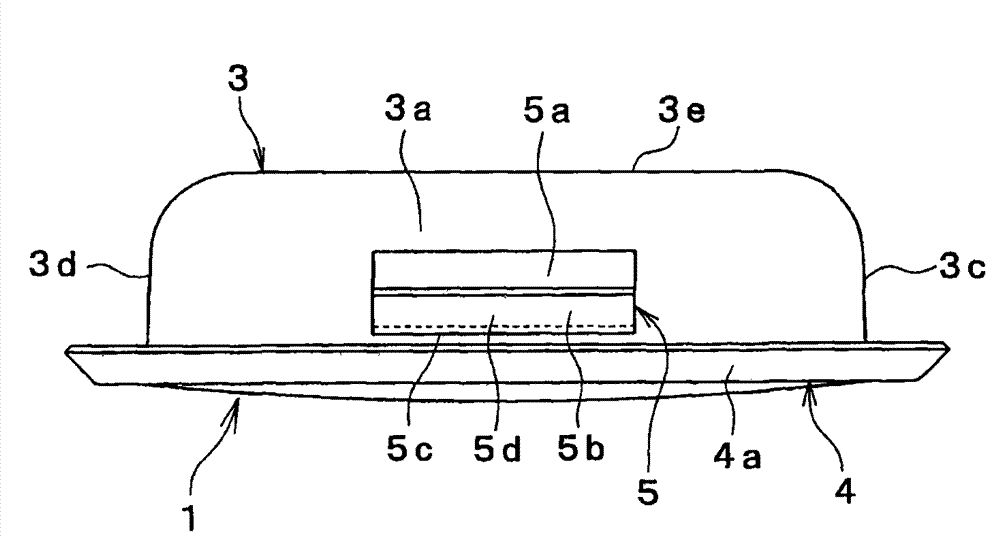

Embedded handle of doors

InactiveCN101994418AReduced tightening workReduce manufacturing costWing handlesWing accessoriesFlangeFront panel

An embedded handle can be easily mounted to a door in a short time. The embedded handle (1) includes: a protrusion (3) protruding toward a back face side in a form of forming an insertion dent (2), and a flange part (4) around the protrusion (3). The protrusion (3) is jogged with a front surface of a front panel (31), and the flange part (4) clings to a front surface of the front panel (31). A clamping member (5) is fixed to an external side face of the protrusion (3). A back face of the flange part (4b) is provided with a double-end bolt (6) in a projection form. The clamping member (5) is fixed to the external side face of the protrusion (3) through a mounting piece (5a). a clamping piece (5b) stands from a side edge (5c) of the mounting piece (5a) and slopes in a direction of departingfrom the back face of a flange part (4a) slowly. A clamping space (7) for accepting a side edge (32a) of an opening (32) is formed between a clamping piece (5b) and the back face of the flange part (4a). The double-end bolt (6) corresponds to a bolt hole (33) arranged on an external side of the side edge (32a), and is fastened by a nut (8) from a back face side of the door.

Owner:TAKIGEN MFG CO LTD

Plug connector

ActiveCN105375141AImprove installation work efficiencyImprove yieldCoupling contact membersContactorEngineering

Owner:ITT MFG ENTERPRISES LLC

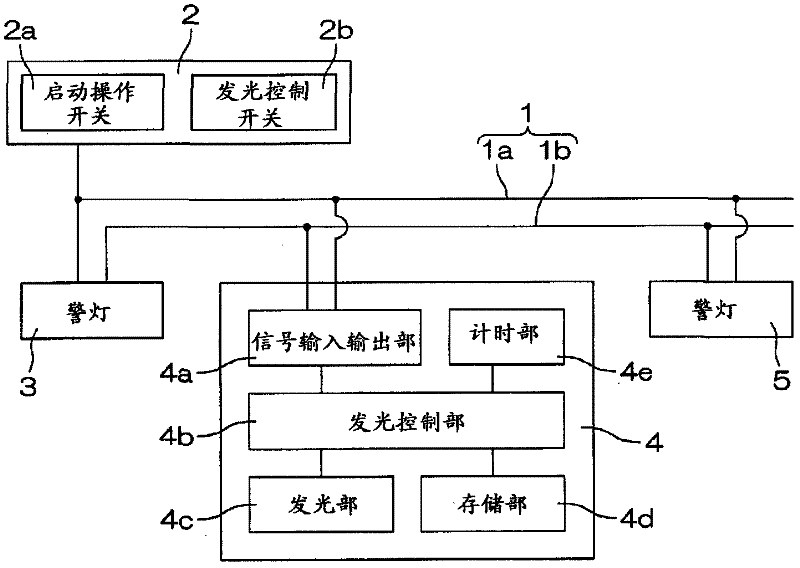

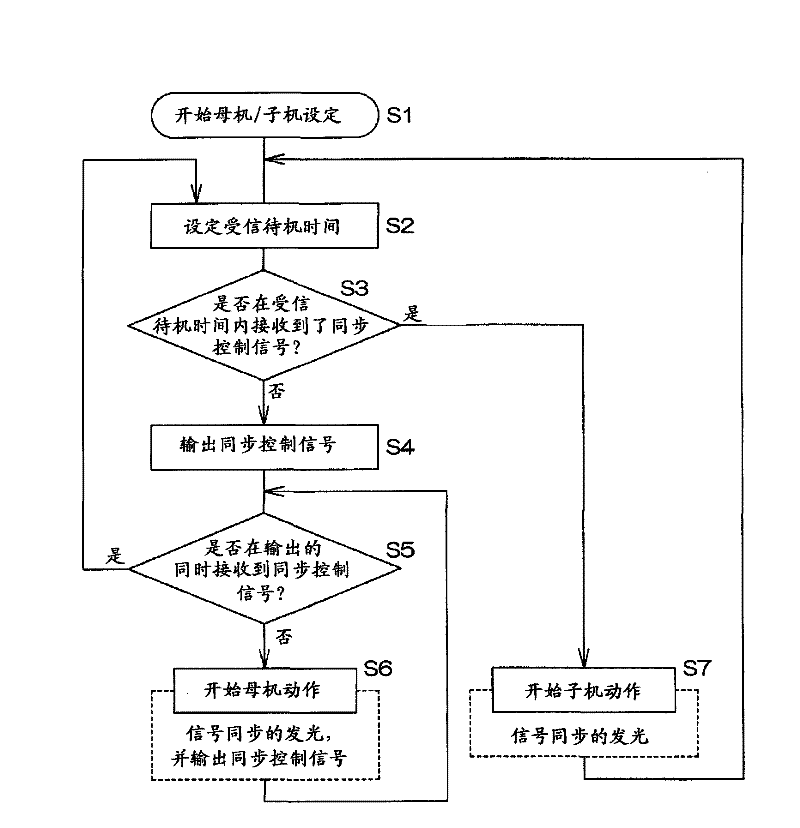

Mars light, mars light system and method for controlling light emitting of mars light

InactiveCN102365903APrevent not brightEasy to manageElectrical apparatusElectric lightingControl signalLighting system

Provided is a mars light system wherein the light emitted from mars lights which are connected to each other can be synchronized even when problems occur in a part of mars lights or the disconnection of a signal line occurs. A mars light (4) is comprised of a light emitting portion (4c); a storage portion (4d) which stores light emitting information; a light emitting control portion (4b) which causes the light emitting portion (4c) to emit light on the basis of the light emitting information; and a signal input / output portion (4a) to which a synchronization control signal is input from other mars lights (3, 5), and from which the synchronization control signal is output to the other mars lights (3, 5). The mars light (4) judges whether or not another mars light which outputs a synchronization control signal is connected to the signal input / output portion (4a), and outputs a synchronization control signal when it is judged that a synchronization control signal is not input for a predetermined period of time.

Owner:PATO RAITO KK

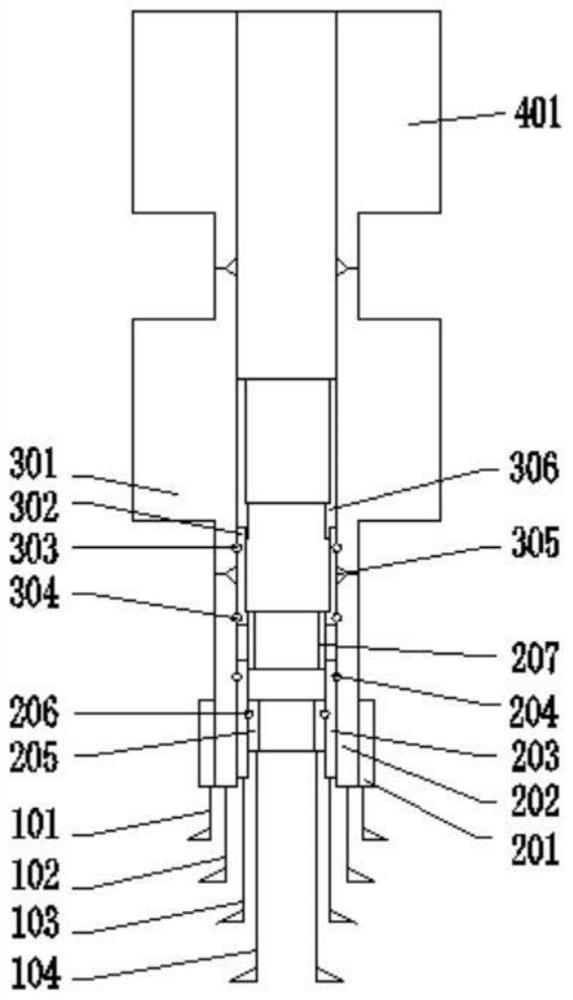

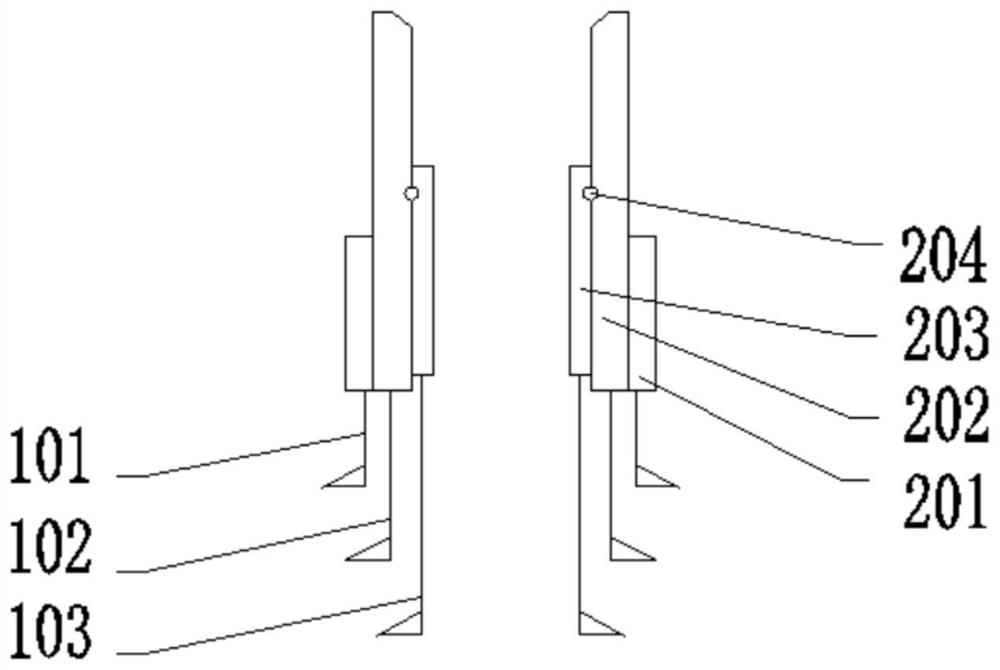

Drilling type underwater horizontal Christmas tree and wellhead system

ActiveCN113187427AImprove installation work efficiencyImprove economyWell/borehole valve arrangementsSealing/packingMarine engineeringBlowout preventer

The invention relates to a drilling type underwater horizontal Christmas tree and wellhead system. The drilling type underwater horizontal Christmas tree and wellhead system comprises a drilling type underwater Christmas tree, an underwater wellhead system and an underwater blowout preventer unit, wherein the underwater wellhead system comprises a guide pipe head, a high-pressure wellhead head, a drilling type conversion connector and a casing hanger which are arranged in sequence from outside to inside in a sleeving mode, the lower end of the guide pipe head is connected with a guide pipe, the lower end of the high-pressure wellhead head is connected with a surface casing, the lower end of the drilling type conversion connector is connected with an intermediate casing, the lower end of the casing hanger is connected with a production casing, and the guide pipe, the surface casing, the intermediate casing and the production casing are arranged in sequence from outside to inside in the sleeving mode; and the lower end of the drilling type underwater Christmas tree is connected with the upper end of the high-pressure wellhead head of the underwater wellhead system, and the upper end of the drilling type underwater Christmas tree is connected with the lower end of the underwater blowout preventer unit. The drilling type underwater horizontal Christmas tree and wellhead system has the passing capacity of a 12-1 / 4" drill bit, and the underwater blowout preventer unit only needs to be installed once in the installation process, so that the installation operation efficiency and the project economy are obviously improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

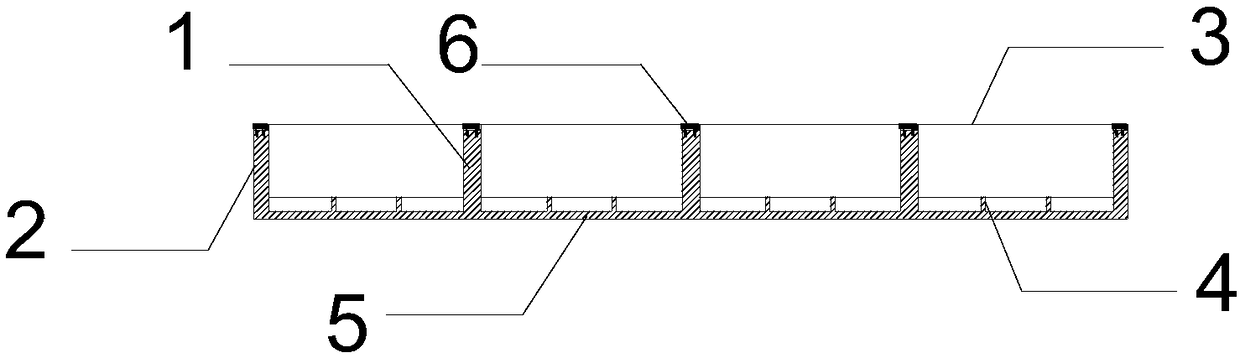

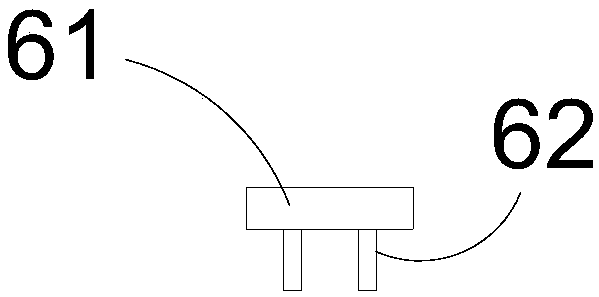

Composite building formwork

PendingCN109252654AReduce procurement costsReduce use costForming/stuttering elementsSelf weightSurface plate

The invention provides a composite building formwork, comprising a panel at the bottom. Transverse ribs and longitudinal ribs are arrayed no the panel in crisscross form and form a plurality of filling cells recessed down; stiffeners are arranged in the filling cells; a stiffening structure is fixed to the upper portion of each of the transverse ribs and / or the longitudinal ribs. The composite building formwork can be used with an aluminum alloy formwork quick-detach system without changing existing construction methods and processes; most aluminum alloy formworks are replaced; panel purchasecost and application cost of the aluminum alloy formwork system are decreased; as the weight of the composite building formwork is low, mounting efficiency can be greatly improved for workers, and different types of products can be more universal and interactive.

Owner:佛山市易拓迅建筑科技有限公司

Electronic element mounting device and electronic element mounting method

InactiveCN103813704AEliminate wasting timeImprove installation work efficiencyElectrical componentsEngineeringElectronic component

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

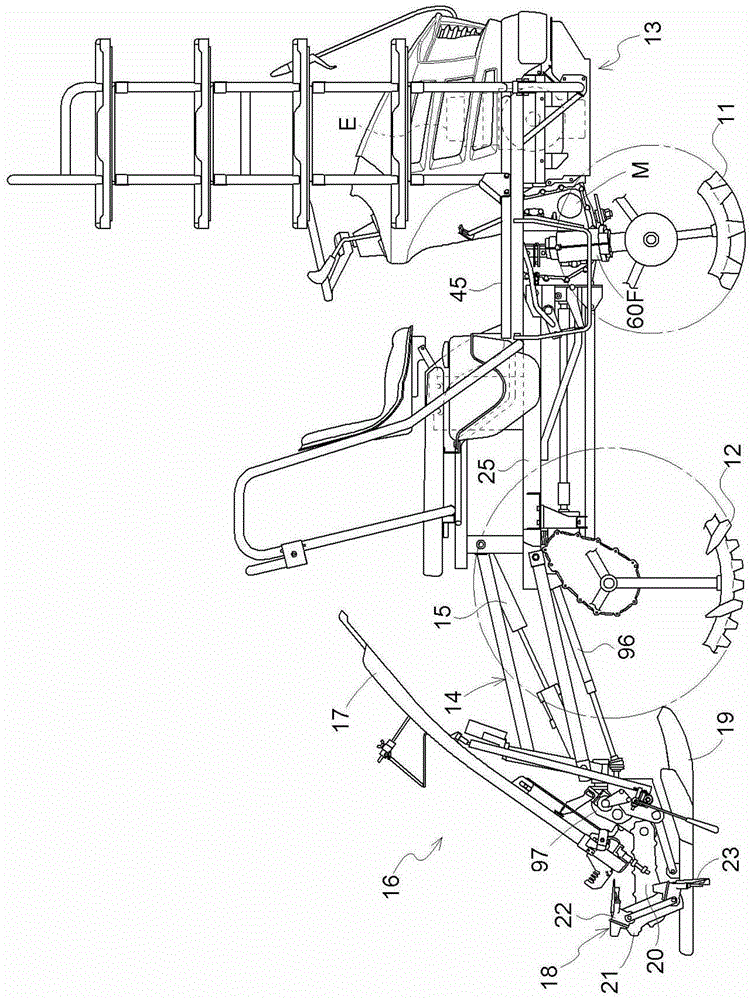

Transplanting machine or direct seeding machine

InactiveCN104412763AIncrease laborExtension of timeSowingTransplantingOperations managementLinkage concept

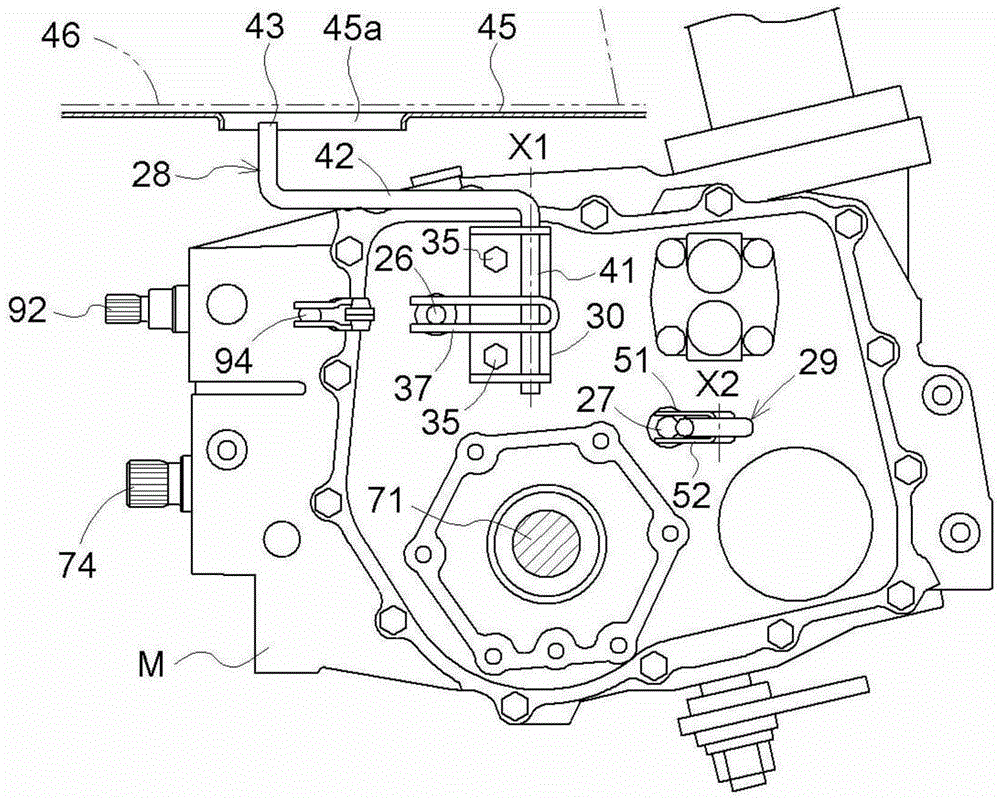

The present invention provides a transplanting machine or a direct seeding machine, wherein a gearlever can be reasonably installed as a shifting operation rod. The shifting operation rod is used for conducting the shifting operation on a gear shifting mechanism for driving the interval change of the ground work by an operation device. The transplanting machine or the direct seeding machine comprises an engine, a body frame, a gearbox (M) fixed on the body frame, a seedling planting device, a first gear shifting mechanism arranged in the gearbox and used for drivin the multi-level transmission process of the engine, a first gear shifting operation rod (26) used for conducting the gear shifting operation on the first gear shifting mechanism, and a first gear shifting lever (28) in linkage connection with the first gear shifting operation rod (26). The first gear shifting lever (28) is supported on the gearbox (M).

Owner:KUBOTA LTD

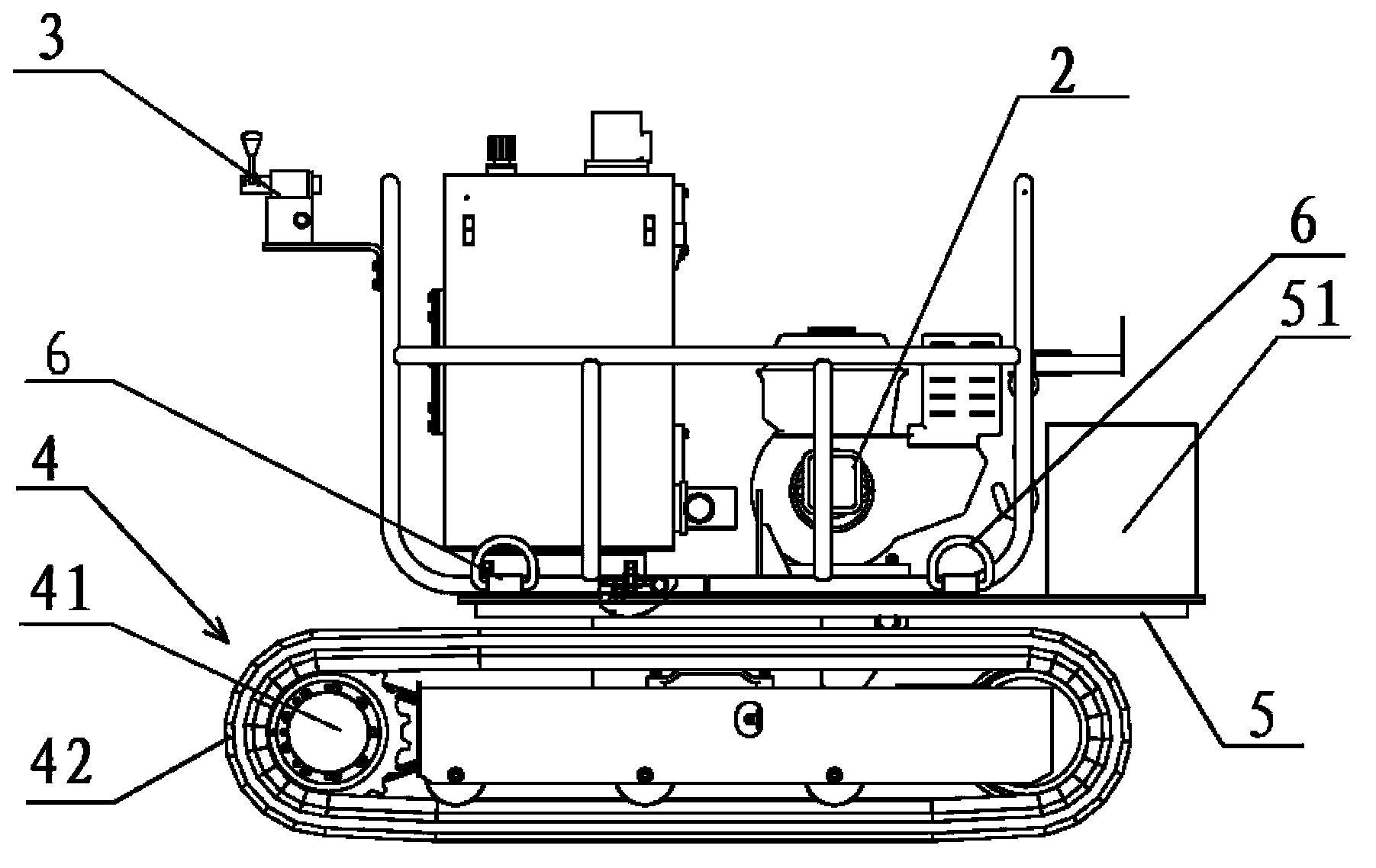

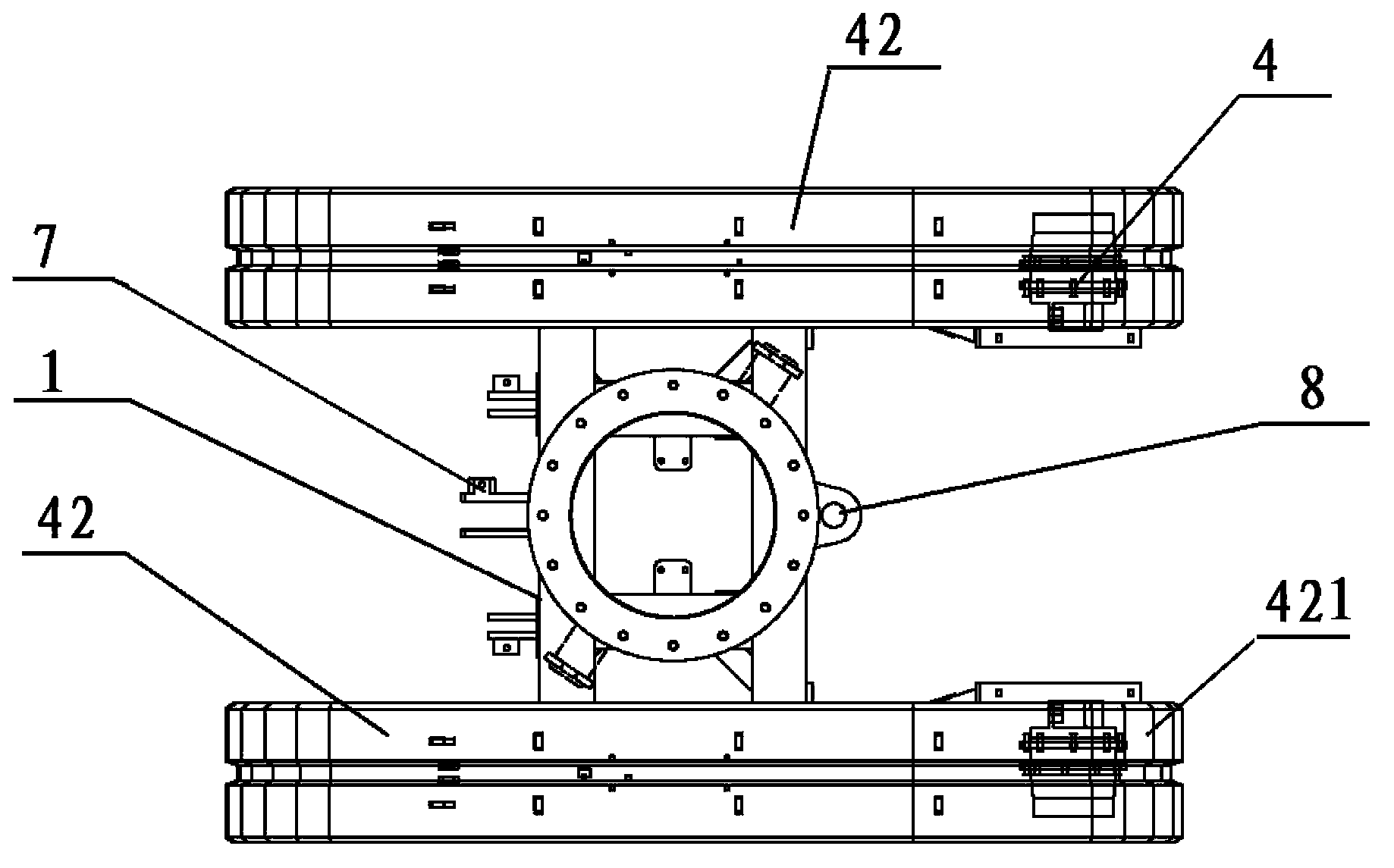

Self-propelled power device and auxiliary mounting system for crane

ActiveCN103574232AImplement assisted installation operationsReduce labor intensityPortable framesServomotorsHydraulic motorDrive wheel

The invention discloses a self-propelled power device and an auxiliary mounting system for a crane, relates to the technical field of engineering machinery, and solves the technical problems of inconvenience in movement and high operation intensity in the prior art. The self-propelled power device comprises a chassis frame, a hydraulic oil power source, a control valve and a travelling mechanism, the control valve comprises an oil inlet, a first oil outlet and a second oil outlet, the travelling mechanism comprises a hydraulic motor and at least one driving wheel, the first oil outlet of the control valve is communicated with a hydraulic oil inlet of the hydraulic motor, a power output shaft of the hydraulic motor is connected with the driving wheel and can drive the driving wheel to rotate relative to the chassis frame, and the driving wheel can drive a crawler belt to travel in the rotating process. The auxiliary mounting system for the crane comprises the self-propelled power device. Moving difficulty of the self-propelled power device is reduced, and auxiliary mounting operation intensity of the crane is relieved.

Owner:XCMG CONSTR MACHINERY

Fastening structure of lamp body and bracket

PendingCN112944244AImprove installation work efficiencyLow priceLighting support devicesRoad vehiclesEngineeringStructural engineering

Owner:BROWN & WATSON INT LTD

Handle device

ActiveCN101619631BEasy to installImprove installation work efficiencyWing handlesCasings/cabinets/drawers detailsEngineering plasticEngineering

A handle device is capable of being mounted on a door board by one step, which improves the mounting operation efficiency greatly. A casing (2) is formed by forming engineering plastics having prescribed rigidity and spring, the circumference surface of the casing (2) is provided with a casing locking member (27) which extends to a prescribed position in an opening (60) for mounting from a back face side of the casing (2), and then extends toward a flange (211) side that is a prescribed position outside the opening (60) from said position in the opening (60), the casing locking member (27) isprovided with a fixation part (28) on its front end, the marginal part of the opening (60) is clipped between the fixation part (28) and the flange (211) by inserting the casing (2) in the opening (60), and the casing (2) is fixed by a reaction of the casing locking member (27).

Owner:TAKIGEN MFG CO LTD

Multi-cycle cooling phase change material cold storage system

InactiveCN102607308BChanging the way the natural air-conditioning is releasedAvoid frostHeat storage plantsVehicle heating/cooling devicesThermal energyEngineering

A multi-cooling type PCM(Phase-Change Material) thermal storage system is provided to reduce heat loss through unnecessary heat exchange by employing insulating panels and maintain desired temperature of a storage container. A multi-cooling type PCM thermal storage system comprises a brine circulation heat exchange coil(10), an air circulation heat exchange tube(5), a circulating pump(9), and a blower(12). The brine circulation heat exchange coil is connected to the circulating pump and heat-exchanges with a low temperature latent heat PCM(11) stored in a thermal storage tank. The air circulation heat exchange tube heat-exchanges the low temperature latent heat PCM secondly. The circulating pump is installed in the upper part of the storage tank and circulates the brine, which is cooled by heat-exchange with the low temperature latent heat PCM, into the brine circulation heat exchange coil. The blower draws the internal air of the storage container, implements first and second heat-exchange with the brine circulation heat exchange coil and the air circulation heat exchange tube, and discharges the multi-cooled air into the storage container in order to maintain the required temperature.

Owner:KDPCM +1

Electric equipment protective device

InactiveCN100487242CPrevent infiltrationWill not reduce work efficiencyPositive displacement pump componentsPositive-displacement liquid enginesElectrical and Electronics engineering

Owner:PANASONIC CORP

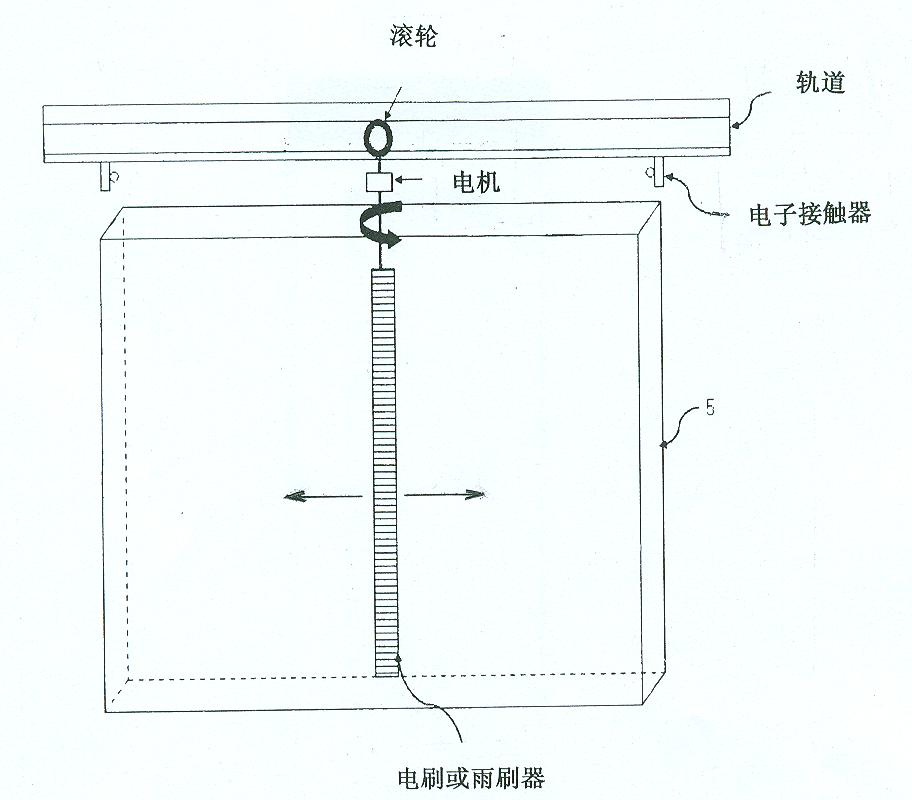

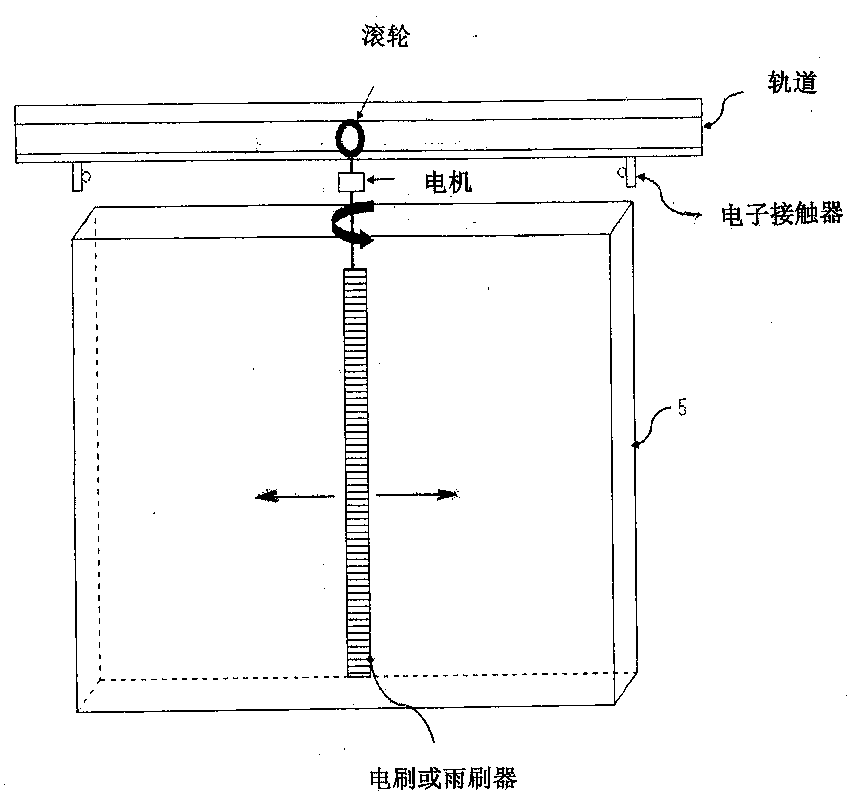

Convenient and fast installation method for bridge crane slide wire supports

InactiveCN105776016ASave human effortImprove installation work efficiencyLoad-engaging elementsOverhead craneSteel tube

The invention relates to a convenient and fast installation method for bridge crane slide wire supports. The convenient and fast installation method comprises the steps of 1, adjusting a bridge crane track; 2, installing a base trolley, wherein wheels are arranged on the bottom of a trolley frame through wheel connection plates, the base trolley is arranged at the upper part of the track at the top of a crane beam, the trolley frame is connected to the track through fixed limiting plates and movable limiting plates, and the base trolley walks at the upper part of the crane beam through the track; 3, installing a basket, wherein the basket is connected to the base trolley through a connection steel pipe; 4, making a worker enter the basket, selecting an appropriate insertion groove according to the size of the crane beam and enabling the basket to be stably supported on a web of the crane beam; 5, after welding of one slide wire support is completed, taking down plug type basket supporting rods, pushing the trolley to the installation point of a next slide wire support on the crane beam and continuing the welding work after the plug type basket supporting rods are reinstalled; and 6, after the work is completed, disassembling and recycling a base and the basket in order for being used next time. According to the method, the construction cost is saved, and the personnel security is guaranteed.

Owner:CHINA MCC20 GRP CORP

Embedded handle of doors

InactiveCN101994418BReduced tightening workReduce manufacturing costWing handlesWing accessoriesEngineeringFlange

Owner:TAKIGEN MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com