Composite building formwork

A technology of building formwork and composite materials, which is applied in the direction of architecture, building structure, formwork/formwork components, etc. It can solve the problems of high labor consumption, low bending rigidity, and difficulty in reflecting economical, applicable, and safe system attributes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

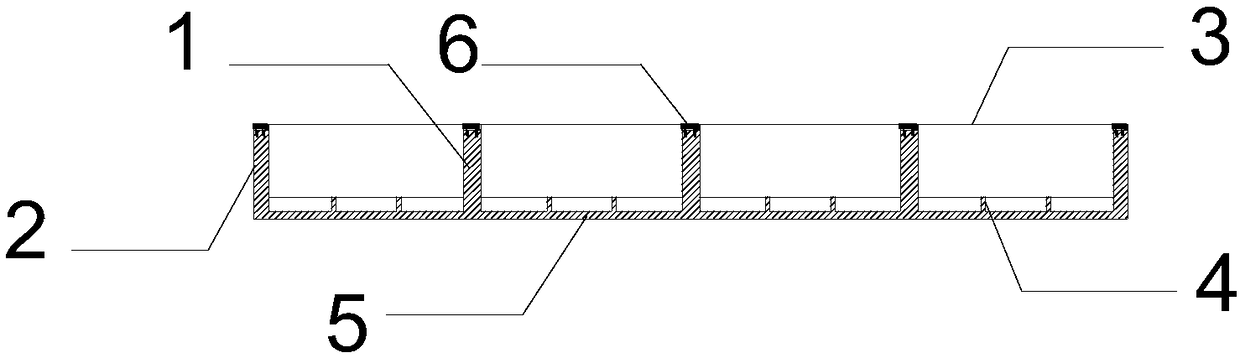

[0022] like Figures 1 to 3 The composite building formwork includes a panel 5 at the bottom, and the panel 5 is arrayed with transverse ribs 3 and longitudinal ribs 1 that criss-cross. The transverse ribs 3 and the longitudinal ribs 1 form a plurality of concave filling grooves. There are stiffening ribs, and the upper part of the transverse rib 3 and / or the longitudinal rib 1 is fixed with a stiffening structure 6 .

[0023] An upright side rib 2 is provided on the outer edge of the panel 5 , and the height of the side rib 2 is flush with the transverse rib 3 and the longitudinal rib 1 .

[0024] The height of the stiffener is B, and the height of the longitudinal rib 1 is A, where 3≤A / B≤5.

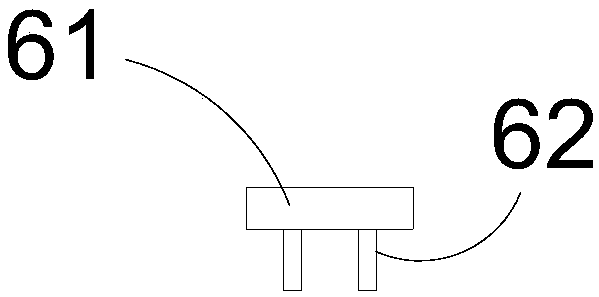

[0025] The reinforcement structure 6 includes a horizontal reinforcement piece 61 and a dowel bar 62 under the reinforcement piece 61 , and the dowel bar 62 is inserted into the upper end surface of the transverse rib 3 and / or the longitudinal rib 1 .

Embodiment 2

[0027] like Figures 1 to 3 The composite building formwork includes a panel 5 at the bottom, and the panel 5 is arrayed with transverse ribs 3 and longitudinal ribs 1 that criss-cross. The transverse ribs 3 and the longitudinal ribs 1 form a plurality of concave filling grooves. There are stiffening ribs, and the upper part of the transverse rib 3 and / or the longitudinal rib 1 is fixed with a stiffening structure 6 .

[0028] An upright side rib 2 is provided on the outer edge of the panel 5 , and the height of the side rib 2 is flush with the transverse rib 3 and the longitudinal rib 1 .

[0029] The height of the stiffener is B, and the height of the longitudinal rib 1 is A, where 3≤A / B≤5.

[0030] The reinforcement structure 6 is a reinforcement bundle composed of several parallel rib units.

[0031] Side rib: the outer frame of the ribbed composite building formwork, which mainly serves as the connection between the formwork and bears part of the external force.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com