Solar cell module and method of fabricating the same

A technology of solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of optical materials limiting the shape of solar cell modules, increasing process steps and manufacturing costs, and reducing power generation efficiency, etc., to increase the light receiving area and light-gathering efficiency, improve installation efficiency, and reduce the effect of area or quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

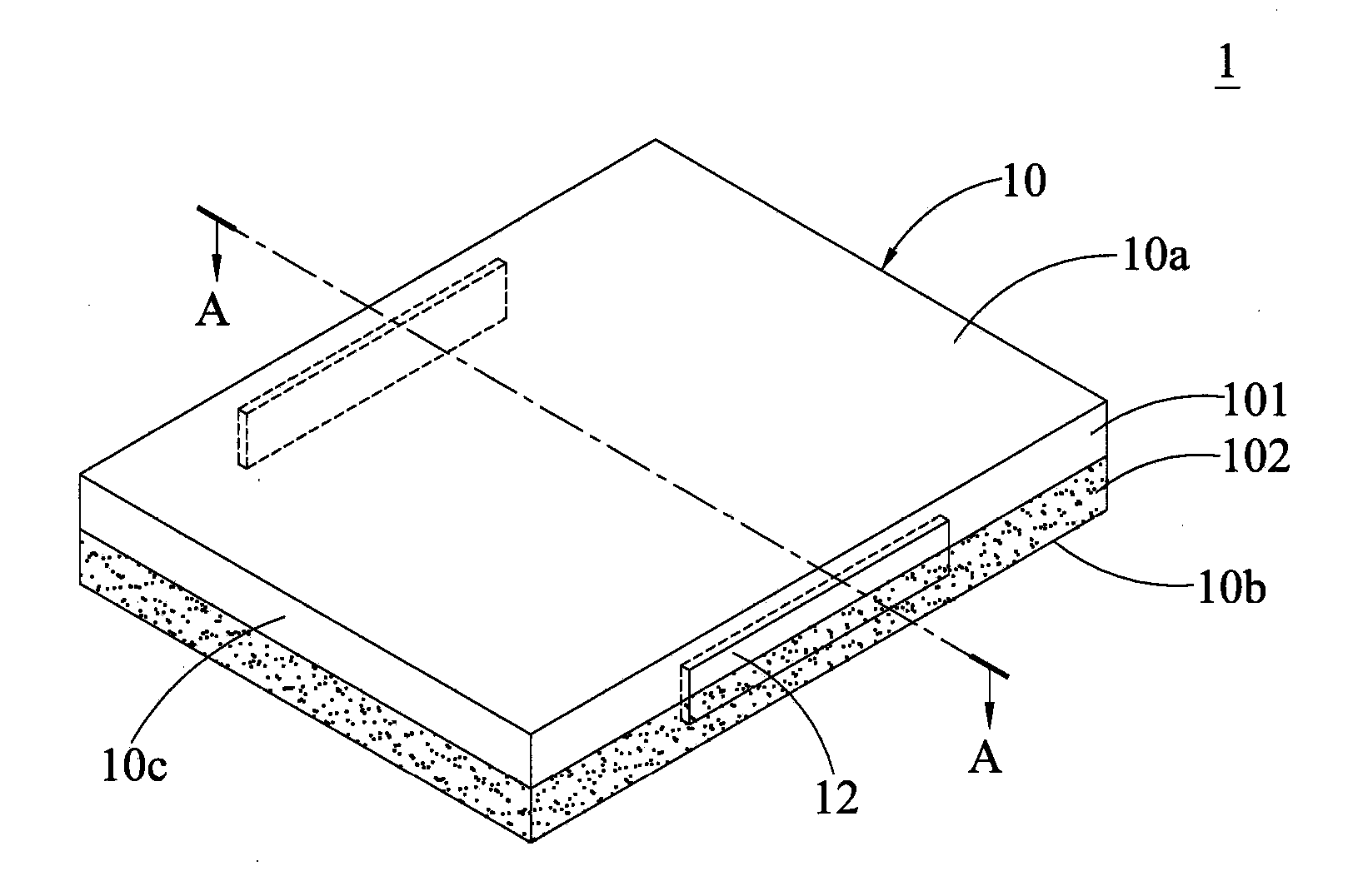

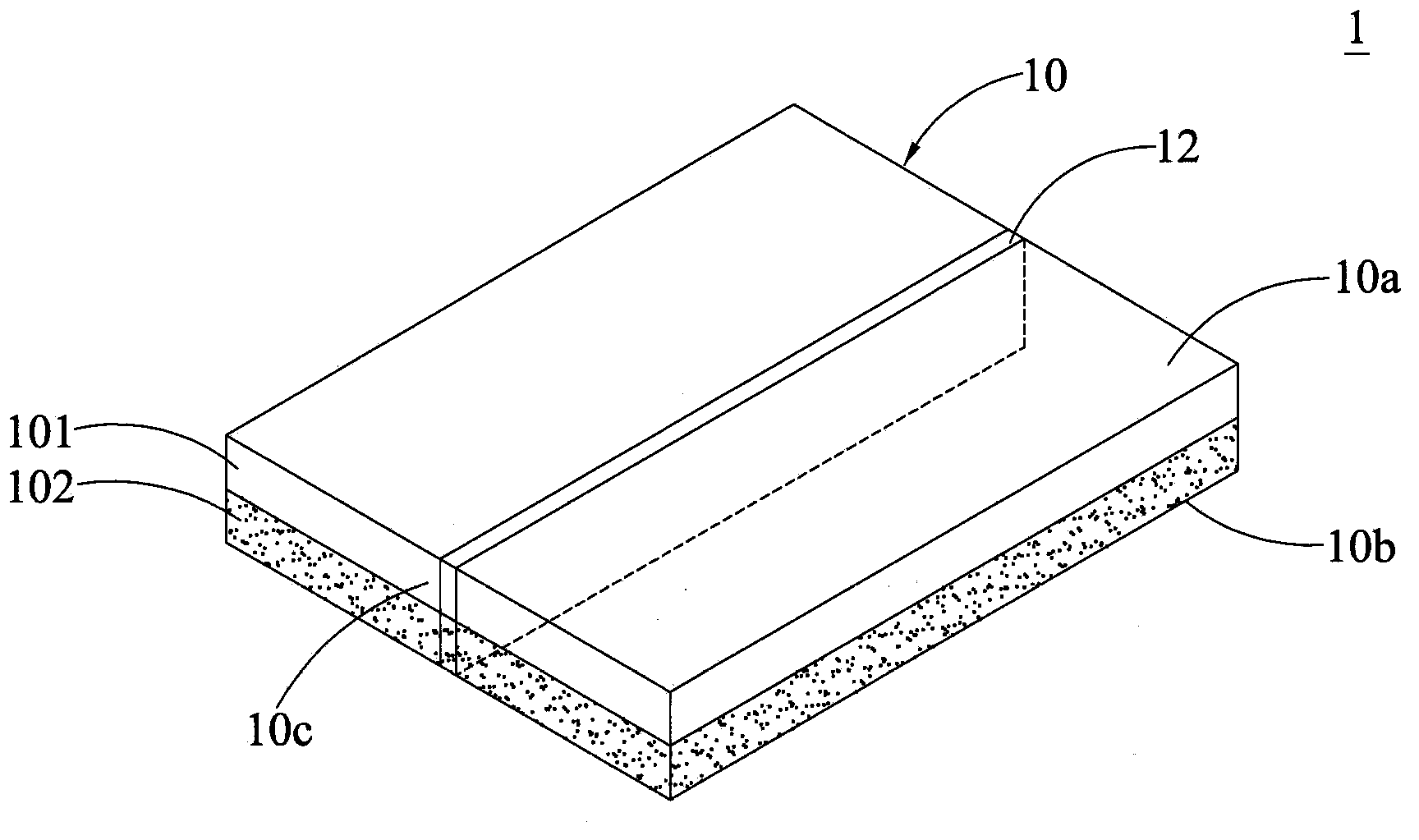

[0052] Example 1 Preparation of a solar cell module with a stack of the first layer and the second layer

[0053] According to the ratio shown in Table 1, the organic luminescent dye was dissolved in ethanol.

[0054] Table 1 Organic luminescent dye solution preparation ratio

[0055] Organic Luminescent Dye Solution

Organic luminescent dye / weight

Solvent / capacity

Solution 1

C545T / 0.08g

Ethanol / 16ml

Solution 2

Rhodamine640 / 0.001g

Ethanol / 5ml

[0056] C545T and Rhodamine (Rhodamine) 640 (purchased from Exciton)

[0057] Then, according to the solar cell module size (3×3×0.5cm 3 ) to draw 4.5ml of polydimethylsiloxane (Polydimethylsiloxane, PDMS, purchased from Qiaoyue Industry) and place it in a container, draw 0.3 ml of solution 1 and 0.2 ml of solution 2 and add them to the container and stir evenly. 1. After the solution 2 is evenly mixed with PDMS, heat the container on a heating plate at 90 to 120°C to accelerate the...

Embodiment 2

[0066] Example 2 Preparation of a solar cell module having a first layer body and a second layer body of three light-emitting layers

[0067] According to the ratio shown in Table 4, the organic luminescent dye was dissolved in ethanol.

[0068] Table 4 Organic luminescent dye solution preparation ratio

[0069]

Organic luminescent dye / weight

Solvent / capacity

Solution 3

C545T / 0.08g

Ethanol / 16ml

Solution 4

Rhodamine640 / 0.001g

Ethanol / 5ml

Solution 5

Nile Blue / 0.001g

Ethanol / 5ml

[0070] C545T, sulforhodamine (Sulforhodamine640 solution) and Nile Blue (Nile Blue) (purchased from Exciton)

[0071] Next, according to the ratio of each light-emitting layer shown in Table 5 below, the set volume of each light-emitting layer absorbs PDMS and puts them in three containers respectively, stirs them evenly with the solution, and heats them on a heating plate at 90 to 120°C to accelerate the volatilization of ethanol . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com