Method for installing thruster at bottom of drilling platform

A technology for drilling platforms and thrusters, which is applied to propulsion components, ship propulsion, ship components, etc., can solve the problems of poor positioning accuracy, long time, poor operability, etc., and achieve easy and precise adjustment and alignment, less time, The effect of fewer people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In the following, the present invention will be specifically described through exemplary embodiments. It is to be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

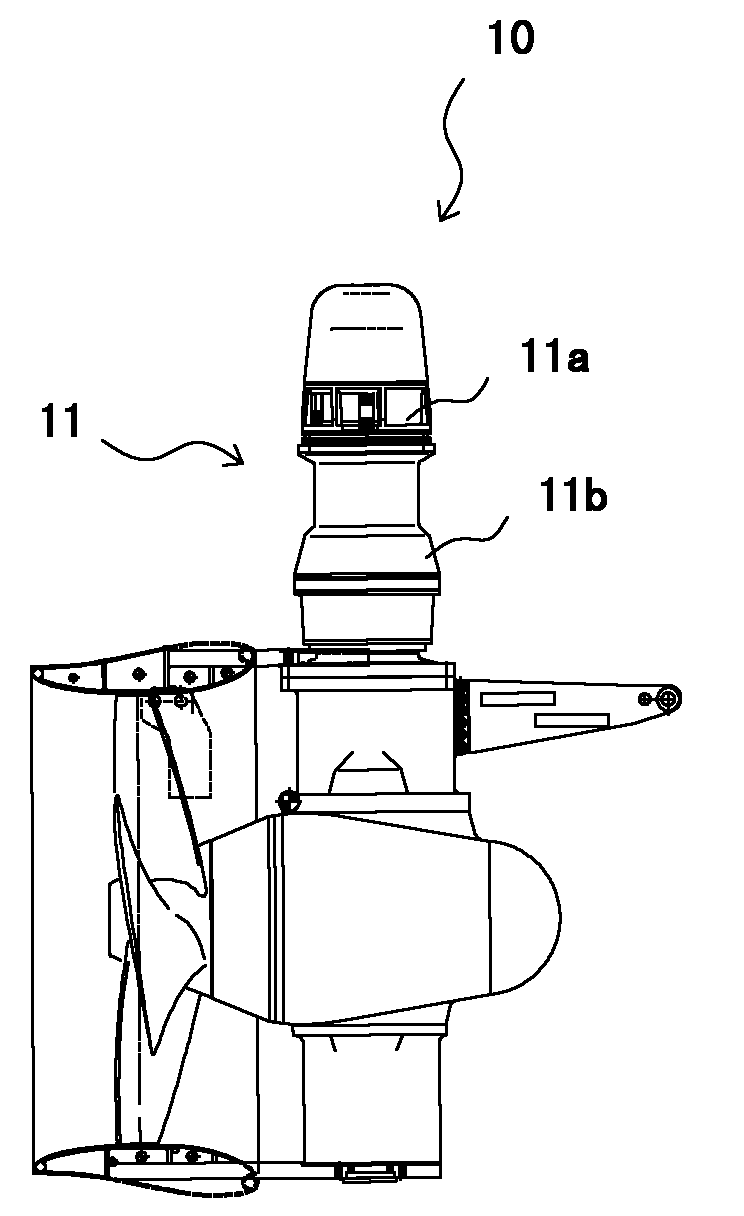

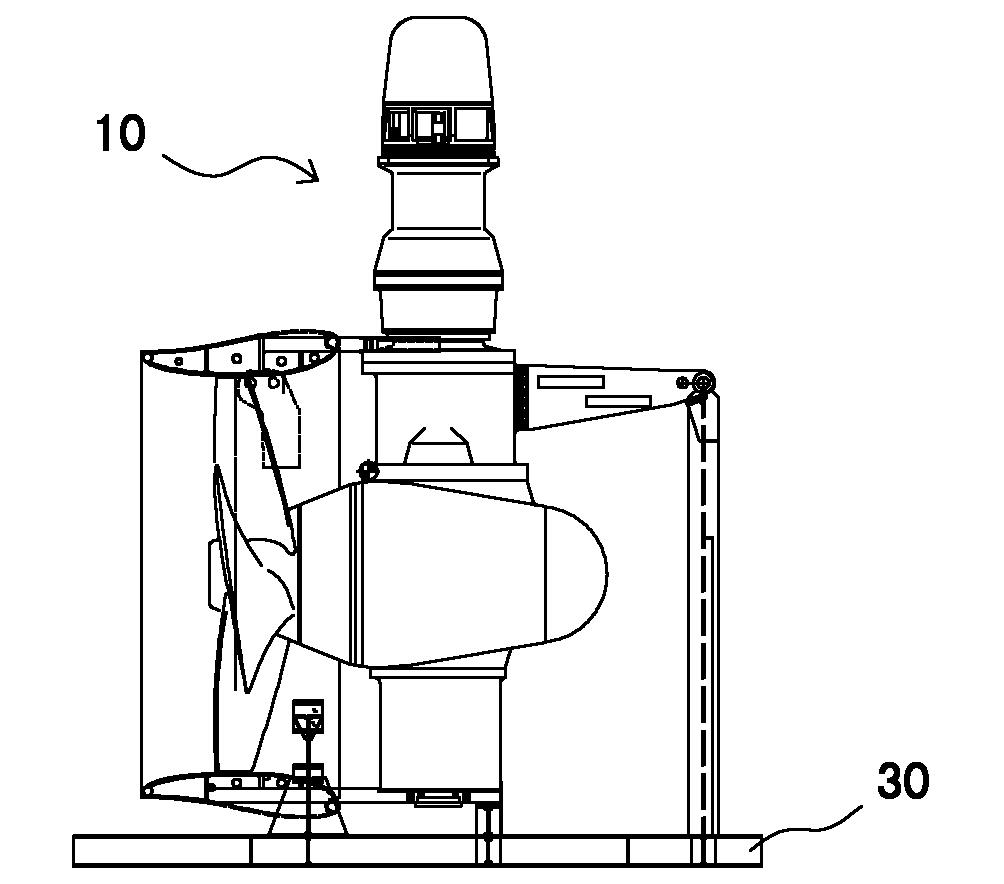

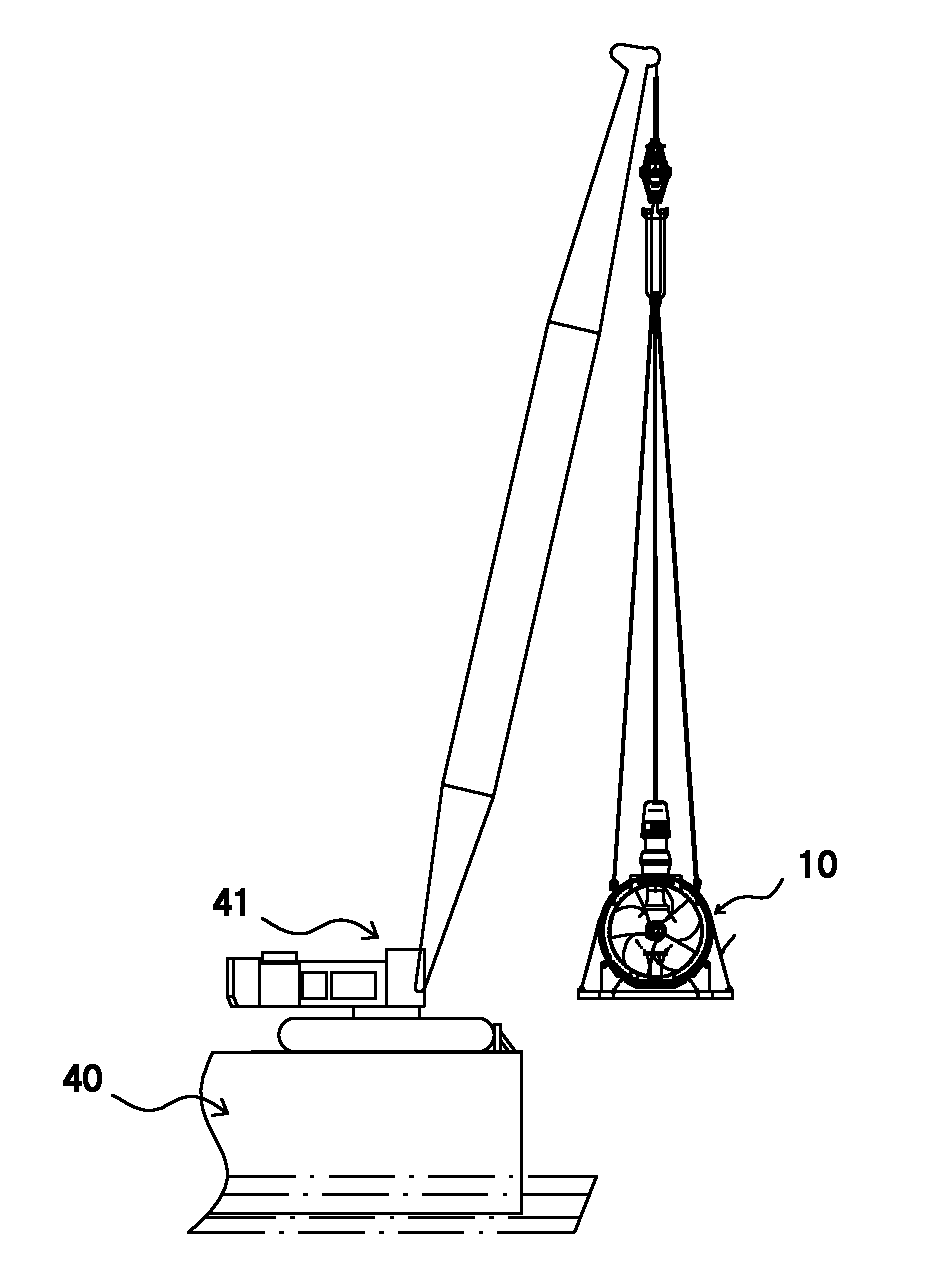

[0051] The present invention provides a method for mounting a thruster, in particular a large thruster, to the bottom of a drilling platform. figure 1 A schematic diagram of a propeller 10 according to an embodiment of the present invention is shown, wherein the head of the propeller 10 is provided with multiple sealing rings 11 . combine Figure 5 and Figure 6 As shown, the drilling platform includes a lower hull 20 at its bottom, a socket 21 is provided at the bottom of the lower hull 20, and the socket 21 has an outwardly opening accommodating space 211 for accommodating at least a part of the propeller 10, and A sealing cover 212 that closes the accommodation space.

[0052] The meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com