Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve anti-pilling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of worsted shell fabric containing polyolefin elastic fibers

InactiveCN103898645ALittle change in elasticityReduce disadvantagesBiochemical fibre treatmentYarnPolyesterPolymer science

The invention discloses a production method of worsted shell fabric containing polyolefin elastic fibers. The shell fabric is formed by spinning wool fibers, cashmere fibers, bamboo charcoal polyester fibers, superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers, and anti-pilling treatment, enzyme treatment and softening treatment are respectively conducted on the wool fibers and the cashmere fibers; the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers are spun into the shell fabric according to the weight ratio of 55-75 : 12-18 : 18-28 : 12-15 : 5-8, and eventually aftertreatment is conducted on the shell fabric through a water-soluble polyurethane wool anti-shrinking agent. The production method has the advantages that damage to wool fiber products can be greatly reduced, the pilling phenomenon is reduced, the shell fabric made of the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers as major raw materials is softer, the felting shrinking percentage is greatly reduced, and the quality of the shell fabric is better.

Owner:汤丽娟

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

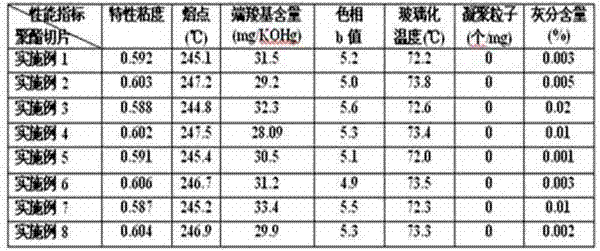

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

Processing method of multifunctional cotton like shirt fabric

ActiveCN103015019AGood moisture absorptionGood hygroscopicityWeft knittingBleaching apparatusPolymer scienceCarbon fibers

The invention discloses a processing method of multifunctional cotton like shirt fabric, which comprises the following steps: blending functional bamboo carbon fiber, chitosan fiber, bamboo carbon cotton and mimic silk floss by proportion of 1:1:1:1; adding blended materials into a vat with bath ratio of 5:1; adding a refining agent, a dispersant and a stabilizer into the vat; adding sodium hydroxide after operation for 3 min, adding hydrogen peroxide after operation for 2 min, and emptying liquid in the vat after operation for 20 min; filling the vat with cold water, adjusting pH value to 6-7, and adding a leveling agent and anhydrous sodium sulphate into the vat; heating to 60 DEG C; adding dye and an uvioresistant assistant; operating for 30 min; adding soda ash; padding a wet absorbing softener and an antibacterial assistant in the emptied solution; then setting and drying; and finally tentering and preshrinking. The cotton like shirt fabric prepared has the functions of wet absorption and sweat release, deodorization, insulation, uvioresistance, flexibility, washability, crease proofness, and difficulty in deformation and silk escapement.

Owner:YANGZHOU JIYUAN TEXTILE

High-count multi-ply colorful apparel yarn and manufacturing process thereof

The invention relates to a high count multi-strands and multicolour knitting wool and the manufacturing technology thereof. The knitting wool is composed of the second twist and mergence of three to ten single twisting doubled yarns which is formed by two to three double twisting doubled yarns by twisting. The double twisting doubled yarns is formed by two to three single yarns by twisting. The main technology of the invention is that the spinning technology spins 20Nm to 60Nm single yarns; the number of the strands of double twisting technology is two to three; the single twisting technology carries out the single twisting and doubling of two to three dyed and dried double twisting color yarns according to the color number requirement. The second twisting technology has the single twisting doubled yarns second twisted and doubled with three to ten strands according to the color number requirement. The invention has the advantages that the product is high count multi-strands and multicolour yarn; the color match, different combinations of strands and the change of twisting direction take place in the merging process; compared with the traditional product, the spinned yarns with compatible color and unique style enrich the product color for which can be matched differently. The invention has unique and novel style, better strength and stretch than that of the traditional product, good anti-pilling effect and extremely soft feeling and the multi --strands are flat-lying.

Owner:天津天纺投资控股有限公司抵羊纺织分公司

Production method of polylactic-acid-fiber-containing spun wool fabric

InactiveCN103898765AEasy to blendGood water absorption and heat preservation performanceCarbon fibresBiochemical fibre treatmentYarnPolymer science

The invention discloses a production method of a polylactic-acid-fiber-containing spun wool fabric. The fabric is spun from wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and polylactic acid fibers. The production method comprises the following steps: respectively carrying out anti-pilling treatment, enzyme treatment and softening treatment on the wool fibers and cashmere fibers; spinning the wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and polylactic acid fibers in a weight ratio of (55-75):(12-18):(18-28):(12-15):(5-8) into a fabric; and finally, carrying out after-treatment on the fabric by using a water-soluble polyurethane wool anti-shrinking agent. The method can greatly reduce the damage of the wool fiber product and reduce pilling; and the fabric has the advantages of softer feeling, greatly lower felting shrinkage and better quality.

Owner:汤丽娟

Production method of worsted wool fabric containing algae carbon fiber

InactiveCN103898644AReduce disadvantagesHigh strengthBiochemical fibre treatmentYarnPolyesterWorsted

The invention discloses a production method of a worsted wool fabric containing algae carbon fiber. The wool fabric is worsted through wool fiber, cashmere fiber, bamboo carbon modified polyester fiber, ultrafine poly butylene succinate silk and algae carbon fiber. Anti-pilling treatment, enzyme treatment and softening treatment are performed on the wool fiber and cashmere fiber are respectively; the wool fiber, cashmere fiber, bamboo carbon modified polyester fiber, ultrafine poly butylene succinate silk and algae carbon fiber with the weighting ratio of 55 to 75 : 12 to 18 : 18 to 28 : 12 to 15 : 5 to 8 are worsted to form the fabric, and finally the fabric is processed through the water-soluble polyurethane wool shrink proofing agent. The method has the advantages that damages of wool fiber products can be reduced greatly, pilling is reduced, meanwhile, the fabric produced through the raw materials are softer in touch feelings, felting shrinkage rate is decreased greatly, and fabric quality is better.

Owner:汤丽娟

Production method of worsted shell fabric containing stainless steel fibers

The invention discloses a production method of worsted shell fabric containing stainless steel fibers. The shell fabric is formed by spinning wool fibers, cashmere fibers, bamboo charcoal polyester fibers, superfine poly(butylene succinate) silk yarns and the stainless steel fibers, and anti-pilling treatment, enzyme treatment and softening treatment are respectively conducted on the wool fibers and the cashmere fibers; the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the stainless steel fibers are spun into the shell fabric according to the weight ratio of 55-75 : 12-18 : 18-28 : 12-15 : 5-8, and eventually aftertreatment is conducted on the shell fabric through a water-soluble polyurethane wool anti-shrinking agent. The production method has the advantages that damage to wool fiber products can be greatly reduced, the pilling phenomenon is reduced, the shell fabric made of the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the stainless steel fibers as major raw materials is softer, the felting shrinking percentage is greatly reduced, and the quality of the shell fabric is better.

Owner:汤丽娟

Production method of Newdal-fiber-containing spun wool fabric

InactiveCN103898745AWrinkle resistantReduce disadvantagesBiochemical fibre treatmentAnimal fibresAfter treatmentWorsted

The invention discloses a production method of a Newdal-fiber-containing spun wool fabric. The fabric is spun from wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and Newdal fibers. The production method comprises the following steps: respectively carrying out anti-pilling treatment, enzyme treatment and softening treatment on the wool fibers and cashmere fibers; spinning the wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and Newdal fibers in a weight ratio of (55-75):(12-18):(18-28):(12-15):(5-8) into a fabric; and finally, carrying out after-treatment on the fabric by using a water-soluble polyurethane wool anti-shrinking agent. The method can greatly reduce the damage of the wool fiber product and reduce pilling; and the fabric has the advantages of softer feeling, greatly lower felting shrinkage and better quality.

Owner:汤丽娟

Process for felting treatment of cashmere sweater by virtue of environment-friendly biological enzyme method

ActiveCN104727153ANo damageGood drapabilityBiochemical fibre treatmentAnimal fibresPectinaseMoisture absorption

The invention discloses a process for felting treatment of a cashmere sweater by virtue of an environment-friendly biological enzyme method. According to the process, the process condition is optimized, biological enzymes are fully utilized in the process, and specifically, papain, laccase and alkaline pectinase are used together. The treatment process provided by the invention is simple to operate, short in consumed time and very good in effect, and causes small damages to cashmere, and the treated cashmere sweater almost does not shrink, is obviously softer and plumper in hand feeling, shows luster as real silks, and is good in dropping feeling, strong in moisture absorption capability and more gorgeous in color.

Owner:ZHEJIANG MIHUANG CASHMERE

Anti-pilling flannel fabric

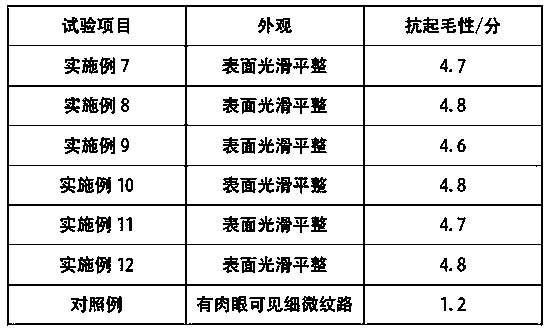

InactiveCN105525416AStrong warmth retentionImprove anti-pilling effectWoven fabricsFullingPolyesterYarn

The invention discloses anti-pilling flannel fabric. The anti-pilling flannel fabric is formed by interweaving upper yarn and ground yarn, wherein the upper yarn is blended yarn composed of cotton fiber and polyester fiber; the ground yarn is viscose; the cotton fiber is 35 percent to 40 percent of the mass of the upper yarn; the polyester fiber is 60 percent to 65 percent of the mass of the upper yarn; an after-finishing technology of the anti-pilling flannel fabric comprises the following steps of primary anti-pilling finishing, napping, preshrinking, drying, secondary anti-pilling finishing and forming. Through the manner, the anti-pilling flannel fabric disclosed by the invention has the advantages that the effects of softness, comfortableness and strong heat retention property are achieved, and the anti-pilling property of the flannel fabric is improved at the same time.

Owner:常熟市梅李镇赵市盛欣纺织制品厂

Technology for anti-pilling worsted fabric

InactiveCN106480576AImprove qualityStrong water absorption and heat preservation performanceWeft knittingBiochemical fibre treatmentPhosphateWater soluble

The invention relates to a technology for anti-pilling worsted fabric. The technology for the anti-pilling worsted fabric is selected from the mixture of organic phosphate antimonous oxide to serve as an anti-pilling agent for anti-pilling treatment, the anti-pilling effects of fibers and the fabric are further improved, and the anti-pilling effect can be 4 grade to 5 grade. A water-soluble silicone softening agent is used for softening treatment, and wool-cashmere fiber fabric has smoother and richer hand feelings. Stainless steel fibers have the good characteristics of being resistant to radiation, high temperature and corrosion and high in strength, and therefore advantage complementary and disadvantage reduction of all the fibers are well achieved; the fabric made from the fibers is better in strength and higher in water-absorption heat preservation performance and is stiffer and smoother, and the technology has good benefits on human-body health and environmental protection.

Owner:JIANGSU SUNSHINE

Method for reducing balling-up property of acrylic fibre

InactiveCN1737246AGood anti-pilling effectImprove anti-pilling effectFibre typesChemistryAcrylic fibre

This invention relates to a method for decreasing acrylic fiber balling up property, which comprises the following steps: a) soaking the acrylic fiber or textile contenting acrylic fiber into the finishing agent 5-60 minutes in 50-80 Deg.C; b) drying the fiber or textile with the liquid content 60-120% in 60-120 Deg.C. The finishing agent is the water solution of compound A and compound B, wherein the content of A is 0.05-3.50wt%, B: 0.1- 6.0wt%, A is the alkyl sulfonate of C8-C18, B is baking soda; it needs A 0.04-2.8g per 100g acrylic fiber or textile.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Process for producing anti-radiation worsted wool fabric containing stainless steel fibers

InactiveCN106498601AAccelerated corrosionHigh strengthSucessive textile treatmentsBiochemical fibre treatmentPhosphateThermal insulation

The invention relates to a process for producing an anti-radiation worsted wool fabric containing stainless steel fibers. The process for producing the anti-radiation worsted wool fabric containing stainless steel fibers includes: selecting a phosphate ester-antimony trioxide mixture as an anti-pilling agent to perform anti-pilling treatment so as to improve the anti-pilling effect of fibers and the fabric, wherein the anti-pilling effect can reach 4-5 grade; and selecting a water-soluble organic silicon softener to perform softening treatment so as to allow a wool cashmere fiber fabric to possess a smooth and plump hand feeling. The stainless steel fibers have excellent characteristics including anti-radiation, high temperature resistance, corrosion resistance, and high strength, and then advantage complementation and weakness subduction of all the fibers can be achieved, and the fabric made of the fibers is high in strength, is high in water absorbing and thermal insulation performance, is stiff and smooth, and is beneficial to human health and environment protection.

Owner:JIANGSU SUNSHINE

Technology for worsted spinning of high-elasticity thermal wool fabric

The invention relates to a technology for worsted spinning of a high-elasticity thermal wool fabric. According to the technology for worsted spinning of the high-elasticity thermal wool fabric, a phosphate ester and antimonous oxide mixture serves as an anti-pilling agent for anti-pilling treatment, the anti-pilling effect of fibers and textiles is further improved, and the anti-pilling effect can reach the 4th-5th grade. A water-soluble organic silicon softening agent is used for softening treatment, so a wool and cashmere fiber textile has smoother and fuller hand feeling. Polyolefin elastic fibers have good characteristics of small elastic change and high tensile resilience, so advantage complementation and disadvantage reduction of various fibers are well achieved, and the fabric made from the fibers is better in strength, higher in water-absorbing and thermal performance, stiffer and beneficial to human body health and environment protection.

Owner:JIANGSU SUNSHINE

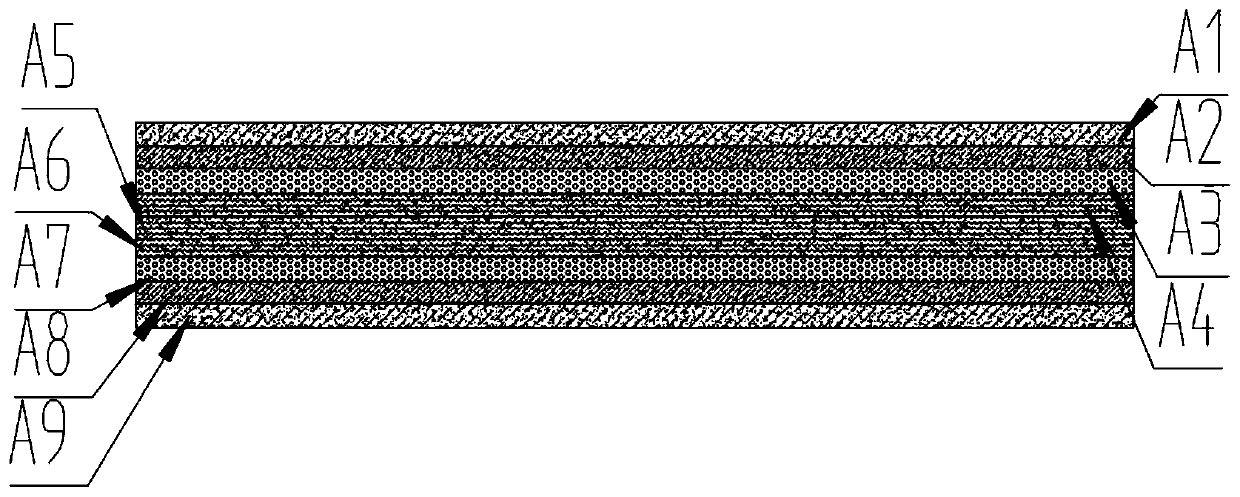

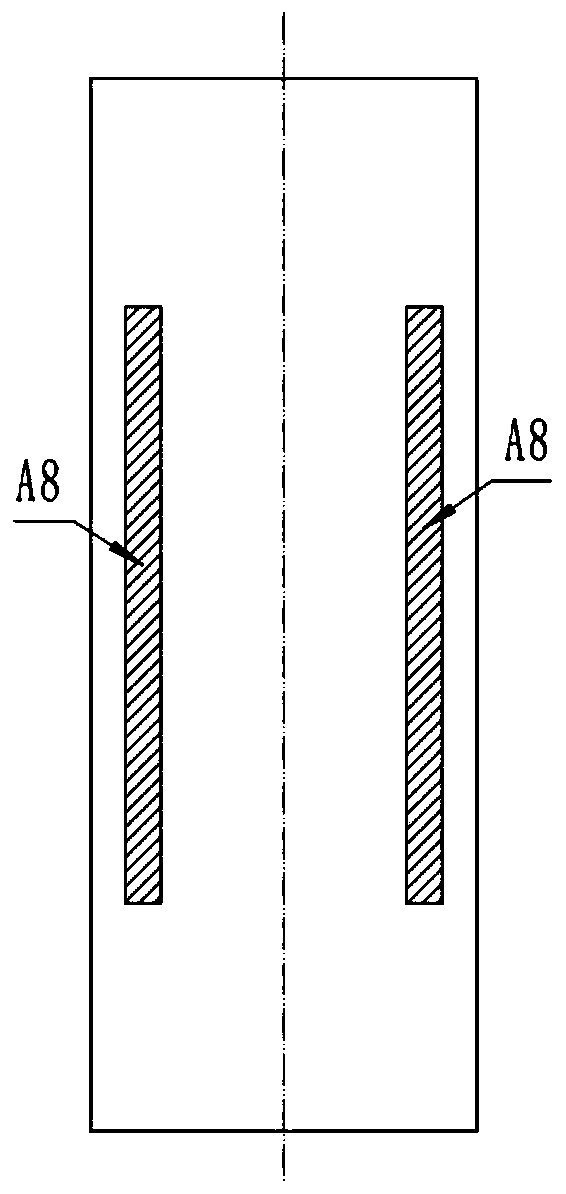

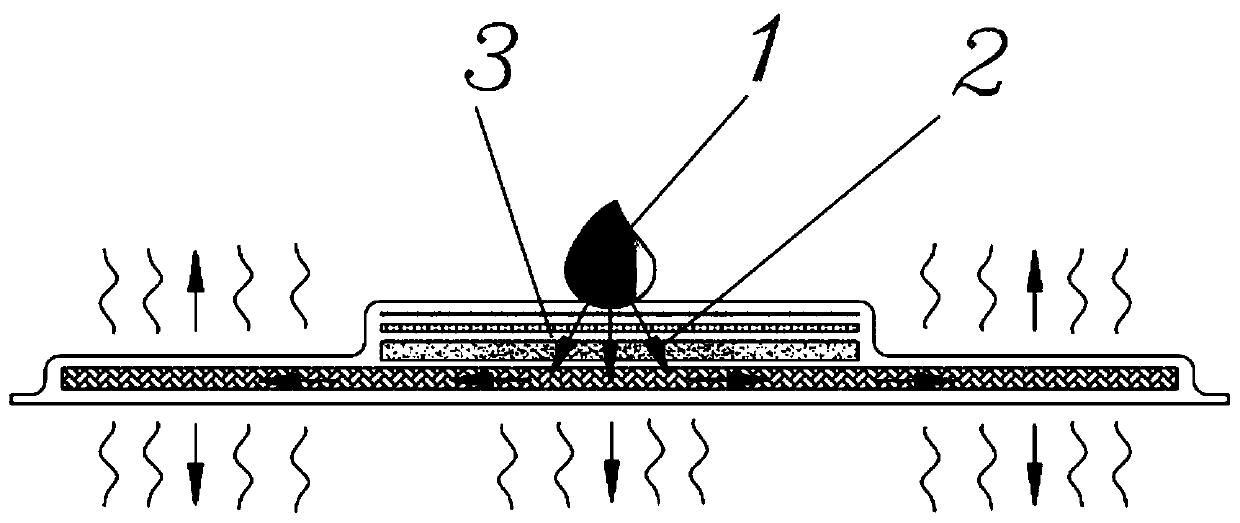

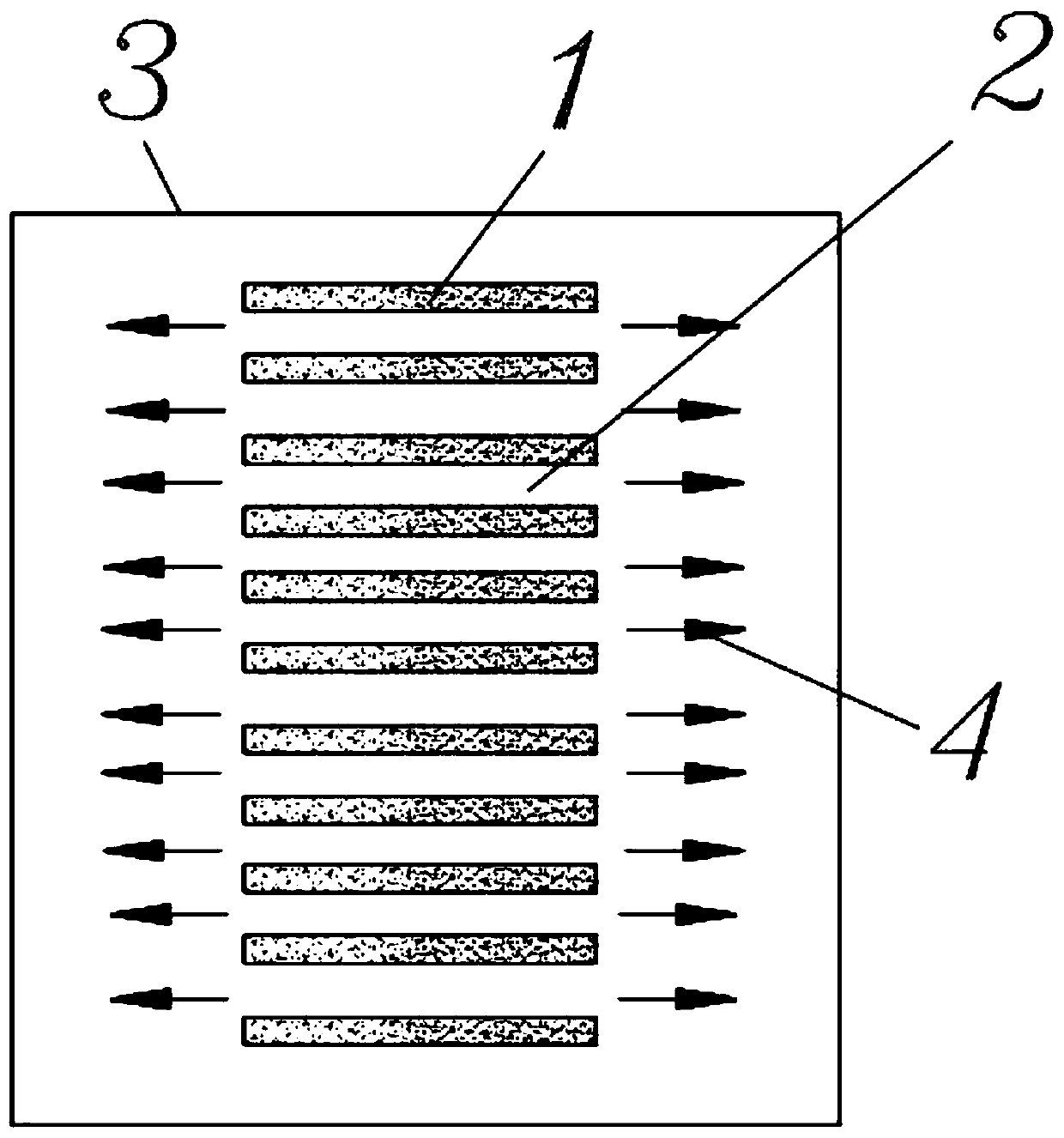

Integrated self-adhesion composite core and preparation process thereof

InactiveCN110393638AImprove anti-pilling effectExcellent diversion and diffusionAbsorbent padsBaby linensSurface layerFluff pulp

The invention relates to an integrated self-adhesion composite core. The core comprises a composite surface layer, a high water absorption resin layer, an expansion supporting layer, a high water absorption resin layer and a composite bottom layer from top to bottom, wherein the composite surface layer consists of an upper surface layer and a lower surface layer; the composite bottom layer consists of an upper bottom layer and a lower bottom layer; each surface layer and each bottom layer are formed by hot-melt superfine short fibers and fluff pulp fibers; the expansion supporting layer consists of an upper supporting layer, a middle supporting layer and a lower supporting layer; and each supporting layer is formed by hot-melt long fibers and fluff pulp fibers. Through the thermal pressurewelding joint effect which is generated by respectively subjecting the hot-melt superfine short fibers and the hot-melt long fibers to hot melting, the layers are bonded and connected into a whole. Meanwhile, the high water absorption resin and the fluff pulp fibers are connected and fixed, so that the fixing effect on the high water absorption resin is realized, the effect that the composite core absorbs the core material without lumping and cotton breaking is realized, and the cost is greatly reduced.

Owner:佛山市合正新型材料有限公司

Novel anti-pilling fabric and manufacturing method thereof

InactiveCN107244106AStrong flame retardancyGood anti-pilling performanceLaminationLamination apparatusYarnAntistatic agent

The invention discloses a novel anti-pilling fabric. The novel anti-pilling fabric comprises a fabric layer, wherein a flame-retardant layer is bonded to the upper surface of the fabric layer by an adhesive; an antistatic layer is arranged on the aluminum alloy film; the antistatic layer is composed of strips with electroconductive fibers; the base layer is prepared from a fabric; the fabric comprises a surface layer, a core layer and an inner layer; the surface layer is a true silk layer, the core layer is a terylene layer, and the inner layer is a true silk layer; and the core layer is prepared from stretch yarns subjected to interlacing treatment. By arranging the flame-retardant layer, the whole anti-pilling fabric has higher flame retardancy; by arranging the antistatic layer, the whole anti-pilling fabric has the antistatic property and favorable anti-pilling property; and the manufacturing method is simple and scientific.

Owner:SHOWMETEX KNITTING & DYEING

Finishing agent for reducing balling-up property of acrylic fibre

InactiveCN1737245AGood anti-pilling effectImprove anti-pilling effectFibre typesSodium bicarbonateCompound a

This invention relates to a finishing agent used for declining acrylic fibre balling up property, which comprises a water solution including compound A and compound B, wherein the A content is 0.05-3.50wt%, B content is 0.1-6.0wt%, the A is alkyl sulfonate of the C8-C18, B is baking soda. When using, soaking the acrylic fibre or the textile including acrylic fibre into the agent, then drying the textile with a certain agent water in 60-120 Deg. C. The valid component of the agent is innocuous to the human, and has no objectionable odor; besides, it is effective to against balling up of the acrylic fibre.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

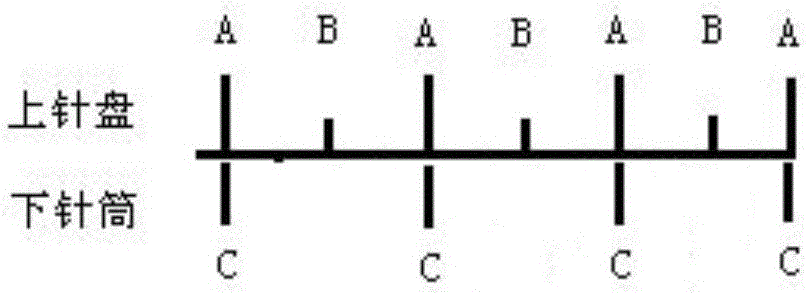

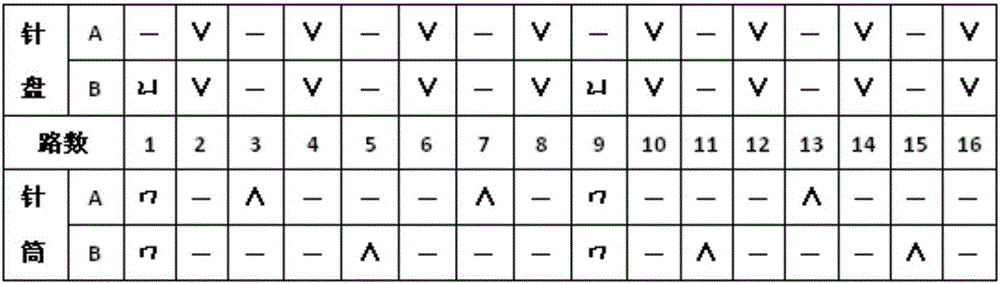

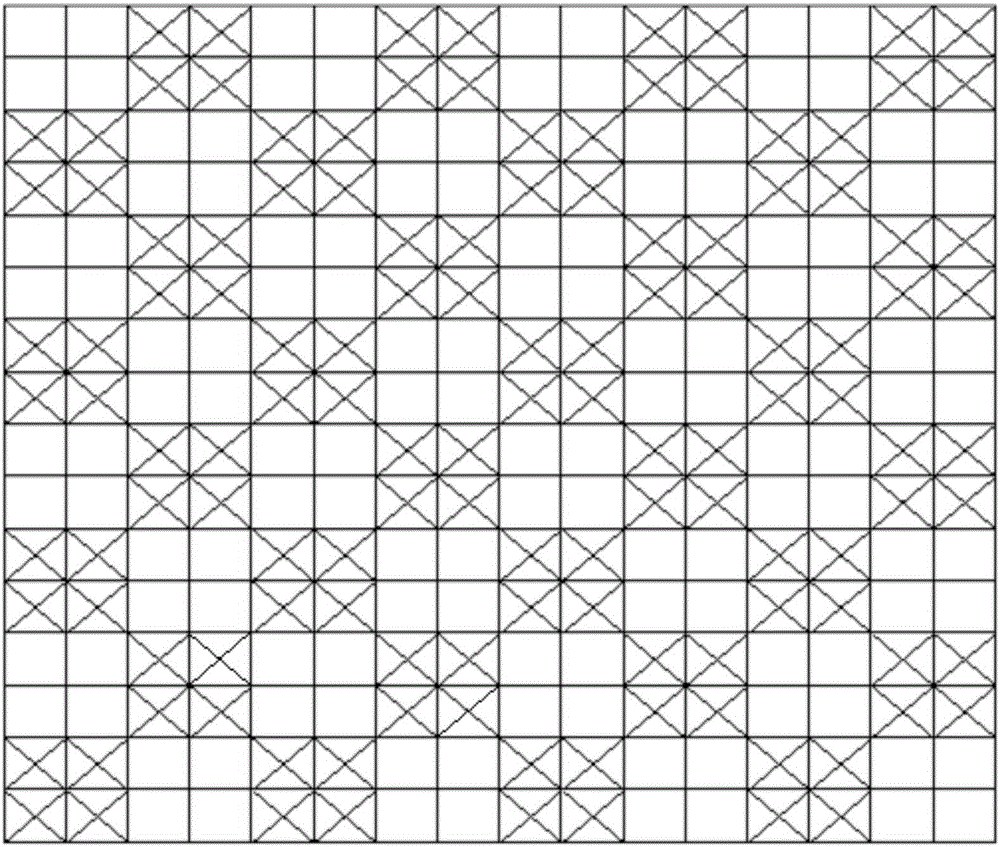

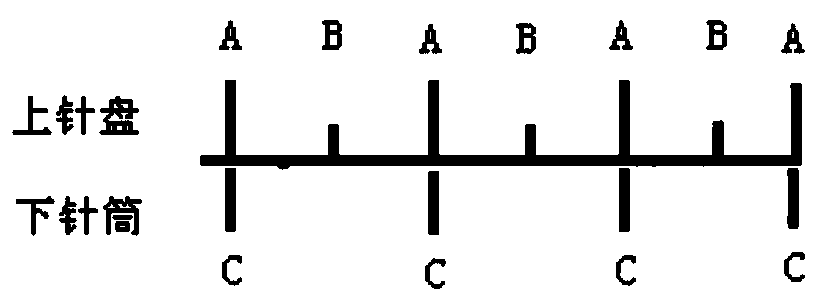

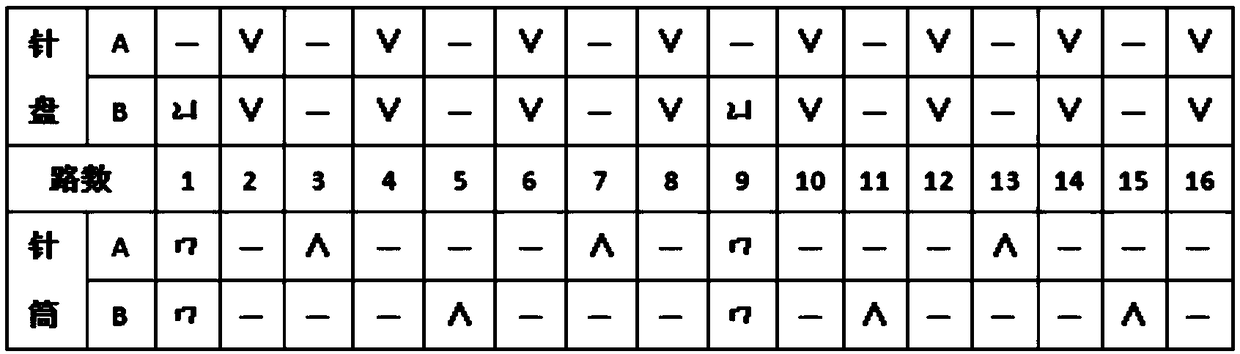

Acrylic-cellulose acetate fiber functional knitted fabric and knitting method

The invention discloses an acrylic-cellulose acetate fiber functional knitted fabric and a knitting method and relates to the field of textiles. Jacquards are knitted in the front surface of the fabric; polyester fibers in the middle layer are tightly connected; acrylic-cellulose acetate fiber blended yarns are knitted on the back surface of the fabric; the fabric is knitted by combination of jacquard threading yarns and variation whorl textiles and variation plain stitch textiles; the variation whorl textiles are alternately knitted by acrylic fibers-viscose blended yarn strands, cotton-chinlon 6 blended yarn strands and polyester fibers; the variation plain stitch textiles are knitted by acrylic fiber blended yarns in a needle dial; the acrylic-cellulose acetate fiber blended yarns are acrylic fibers-modal Viloft blended yarns. Static resistance, pilling resistance, warmth retention, moisture conductivity, smoothness and comfort level of the fabric are all obviously improved.

Owner:QINGDAO XUEDA GRP

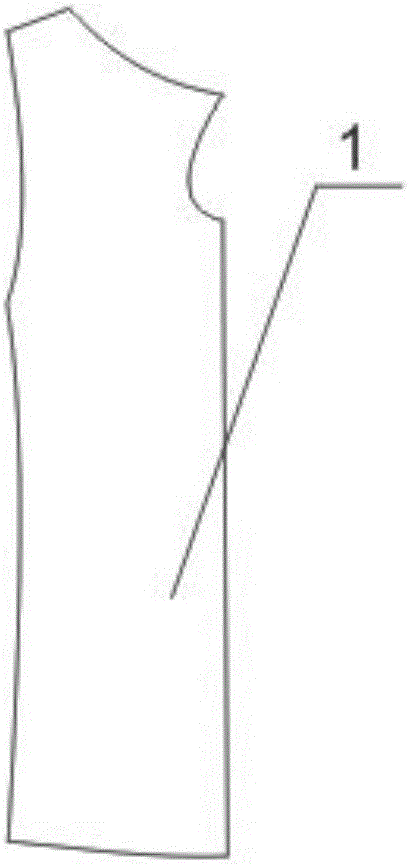

Health-care neck knitted underwear with compounding function and production method thereof

ActiveCN106263101AExcellent functional indicatorsGood anti-pilling effectWeft knittingTrousersFiberFunctional indices

The invention relates to health-care neck knitted underwear with a compounding function and a production method thereof. The underwear is characterized in that on the aspects of ready-made underwear production design and tailoring method, upper underwear is made of a vinegar green fiber knitted fabric, the front chest part is of a water drop model, an opening is formed in the front middle part of the collar part, a magnetic therapy health-care necklace is put into the collar part, the front part of the trousers is made of a cherokee rose fruit antibacterial viscose fiber knitted fabric, and the waist and legs of the trousers are made of a vinegar green fiber knitted fabric. The underwear provided by the invention has excellent functional indexes, and particularly has obvious anti-static, anti-pilling and anti-bacterial effects. Meanwhile, after coming into contact with a human body, the magnetic therapy necklace can release a large quantity of negative ions, so as to promote blood circulation, resist fatigue, relieve the pain of cervical vertebra, balance the function of the human body, and also effectively prevent radiation, so that the underwear is very suitable for wearing demands of office workers and businessmen.

Owner:QINGDAO XUEDA GRP

Method for producing worsted wool fabrics with polyolefin elastic fibers

InactiveCN106480564ALittle change in elasticityStrong stretch recoveryBiochemical fibre treatmentWoven fabricsFiberPolyolefin

The invention relates to a method for producing worsted wool fabrics with polyolefin elastic fibers. The method for producing the worsted wool fabrics with the polyolefin elastic fibers has the advantages that anti-pilling treatment is carried out by the aid of organophosphate and antimony trioxide mixtures which are used as anti-pilling agents, and accordingly anti-pilling effects of the fibers and textile fabrics further can be improved and can reach 4-5 levels; softening treatment is carried out by the aid of water-soluble organosilicone softening agents, and accordingly the wool and cashmere fiber textile fabrics can have smooth and plump hand feel; the polyolefin elastic fibers have excellent characteristics of extremely low elasticity change and high elastic recovery of elongation, accordingly, merits of the various fibers can complement one another, weakness of the various fibers can be reduced, and the fabrics made of the fibers are good in strength and high in water absorption and thermal property, are stiff and smooth and are beneficial to human health and environmental protection.

Owner:JIANGSU SUNSHINE

Production technology of wash-fast worsted wool fabric

InactiveCN106480575AImprove qualityHigh strengthBiochemical fibre treatmentWoven fabricsFiberPhosphate

The invention relates to a production technology of wash-fast worsted wool fabric. The production technology of the wash-fast worsted wool fabric has the advantages that a mixture of phosphate ester and antimony trioxide serves as an anti-pilling agent for anti-pilling treatment, so that anti-pilling effects of fibers and fabrics are further improved and can reach grade 4-5; since water-soluble organosilicone softening agents are selected for softening treatment, wool and cashmere fiber fabrics are smooth and full in hand feel; Newdal fibers are good in hand feel and drapability, wash-fast and resistant to creases, so that complementary advantages and disadvantage reduction of all the fibers can be well achieved, and the wash-fast worsted wool fabric prepared from the fibers is stiffer, higher in strength, more excellent in water absorption and heat insulation performance and beneficial to human health and environmental protection.

Owner:JIANGSU SUNSHINE GRP CO LTD

Anti-pilling manufacturing method of cotton-polyester blended fabric

The invention discloses an anti-pilling manufacturing method of a cotton-polyester blended fabric. The anti-pilling manufacturing method comprises the following steps: S1, selecting materials; s2, weaving; s3, scutching is carried out; s4, fixing the blank; s5, dyeing and washing; s6, fixed polyester; s7, singeing; s8, cylinder returning and wool etching are carried out; s9, cylinder returning and cotton dyeing; s10, washing water in the vat; s11, wool etching is carried out; and S12, finished product shaping. The process is suitable, singeing is carried out after high-temperature polyester dyeing and high-temperature polyester fixing, polyester fibers are fully foamed in the polyester dyeing process, hairiness fully drills out of a cloth cover, then the hairiness is effectively removed through high-temperature singeing, and the anti-pilling effect can be better achieved. In the process, the sublimation fastness of the polyester can be better solved through two times of high-temperature treatment. The silk length, the strength and the weaving method of the raw materials are proper, so that the fabric has a very good anti-pilling effect on the basis of ensuring the rebound resilience.

Owner:渡帮针织科技(中山)贸易有限公司

Method for producing high-strength worsted woolen fabrics

InactiveCN106521755AStrong water absorption and heat preservation performanceHigh strengthSucessive textile treatmentsFabric breaking/softeningFiberPhosphate

Owner:JIANGSU SUNSHINE

Paper plastic package anti-fluffing sealing and coating process and paper plastic package

PendingCN110420815ASolve the problem of dandruffAvoid it happening againPretreated surfacesHyaluronic acid coatingsMolded pulpCellulose

The invention discloses a paper plastic package anti-fluffing sealing and coating process, and relates to the technical field of paper-plastic package processing. According to the technical scheme, the paper plastic package anti-fluffing sealing and coating process comprises the following steps of preparing sealing and coating liquid, wherein a sealing and coating agent is prepared into an aqueoussolution to obtain the sealing and coating liquid, and the sealing and coating agent is selected from one or more of chitin, derivatives of the chitin, water-soluble cellulose ether, derivatives of the water-soluble cellulose ether, water-soluble bioglue or water-soluble synthetic high molecular polymer; conducting spraying, wherein a spraying manner is adopted for evenly applying the sealing andcoating liquid to the paper-plastic package surface; and conducting heat treatment, wherein a paper-plastic package treated by spraying is heated at 200 DEG C to 230 DEG C for 5 s to 90 s. A paper-plastic product treated by the process has a smooth surface, and fine debris is not prone to being generated in the storage and transportation processes. Another object of the invention is to provide the paper-plastic package. After sealing and coating treatment with the paper plastic package anti-fluffing sealing and coating process, the advantage that the fine debris is not prone to being caused by friction is achieved.

Owner:SUZHOU SHENGLIN PAPER PROD CO LTD

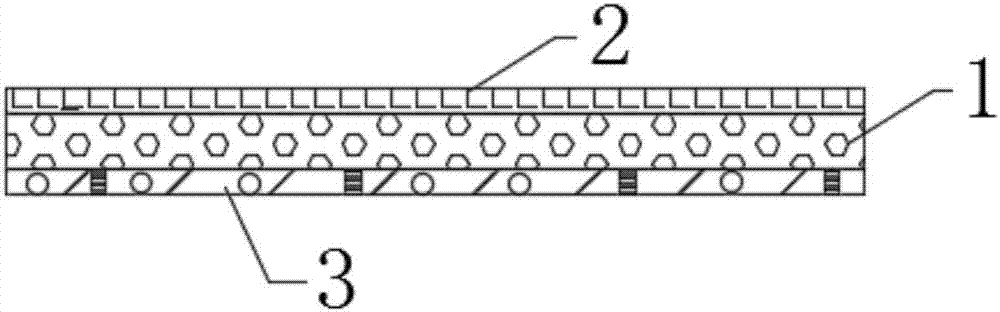

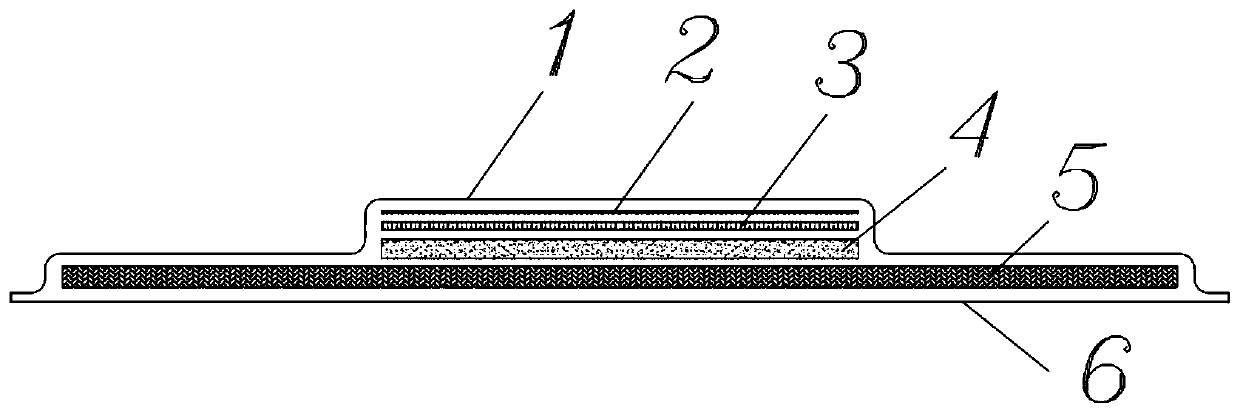

A medical nursing pad for preventing puerperal infection of puerpera

ActiveCN106821650BAvoid humid environmentsAvoid breedingNursing bedsAbsorbent padsFiberSurface layer

The invention provides a medical caring pad for preventing infection of lying-in women in puerperium. For the medical caring pad, a core layer is divided into a lochia absorption area and eczema flowing guiding areas, namely the core layer is formed by overlaying the lochia absorption area which is of a trapezoidal structure and the relatively wide eczema flowing guiding areas on two sides. The core layer is divided into the following layers from top to bottom in sequence: 1, a surface layer, 2, a sterilization layer, 3, a liquid flowing guiding layer, 4, an absorption layer, 5, an eczema flowing guiding layer and 6, a bottom layer; the sterilization layer, the liquid flowing guiding layer and the absorption layer form the lochia absorption area; the eczema flowing guiding layer forms the eczema flowing guiding area. In the medical caring pad, flowing guiding grooves formed at intervals are formed in the absorption layer of the lochia absorption area; at the same time, the sterilization layer is formed by nano-silver or zein fibers or chitosan fibers; by using the lochia absorption area which is of the trapezoidal structure, static blood and grume discharged by a lying-in woman can be guided fast, the widened eczema flowing guiding areas can enlarge the eczema discharging area, so that the aim of effectively preventing the infection of the lying-in women in the puerperium is realized by the combination of the two. In the medical caring pad, improved strip-shaped grooves form the absorption layer in an interval structure, a ladder-type compaction method is used for compacting the lochia absorption area and the eczema flowing guiding areas in the pad to form a whole body.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

A cashmere sweater milling treatment process with environmental protection biological enzymatic method

ActiveCN104727153BNo damageGood drapabilityBiochemical fibre treatmentAnimal fibresPectinaseMoisture absorption

The invention discloses a process for felting treatment of a cashmere sweater by virtue of an environment-friendly biological enzyme method. According to the process, the process condition is optimized, biological enzymes are fully utilized in the process, and specifically, papain, laccase and alkaline pectinase are used together. The treatment process provided by the invention is simple to operate, short in consumed time and very good in effect, and causes small damages to cashmere, and the treated cashmere sweater almost does not shrink, is obviously softer and plumper in hand feeling, shows luster as real silks, and is good in dropping feeling, strong in moisture absorption capability and more gorgeous in color.

Owner:ZHEJIANG MIHUANG CASHMERE

Processing method of multifunctional cotton like shirt fabric

InactiveCN103015019BGood moisture absorptionGood hygroscopicityWeft knittingBleaching apparatusPolymer scienceCarbon fibers

Owner:YANGZHOU JIYUAN TEXTILE

Production process of warm-keeping worsted wool fabric

InactiveCN106498600AImprove qualityImprove anti-pilling effectBiochemical fibre treatmentSingeingFiberWorsted

The invention relates to a production process of a warm-keeping worsted wool fabric. The production process of the warm-keeping worsted wool fabric comprises the steps that a phosphate antimony trioxide mixture is selected as an anti-pilling agent to perform anti-pilling processing, and the anti-pilling effect of fiber and the fabric is further improved and can be up to the level 4-5. A water-soluble organic silicon softener is selected for softening processing, so that wool and cashmere fiber fabrics can have smooth and full hand feeling. Finally, the fabric is post-processed by using a water-soluble polyurethane wool shrink-proof agent, the area felting shrinkage rate of the processed wool fabric is 3% or below and is far lower than 8% specified by international bureau of international wool, and the comprehensive quality of the fabric is greatly improved. The seaweed carbon fiber fabric has a heat preservation and health care effects, is suitable for T-shirts, underwear and other clothes, makes human body molecules produce thermal reaction through friction after long-term wearing, promotes body blood circulation and can play heat accumulation and heat preservation effects.

Owner:JIANGSU SUNSHINE

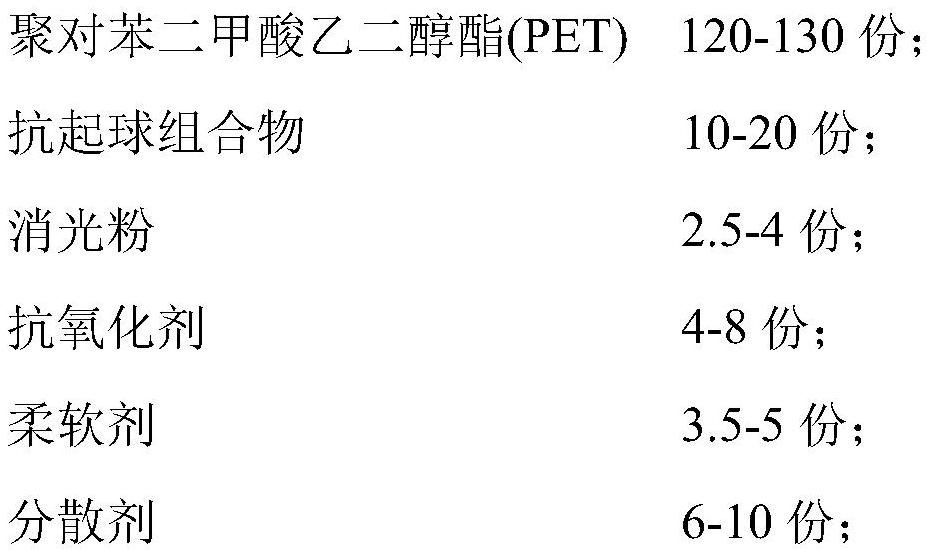

Full-dull polyester filament yarn and processing technology thereof

PendingCN114790588ALess hairyNot easy to pillGrip property fibresMonocomponent polyesters artificial filamentPolyethylene glycolPolyethylene terephthalate glycol

The invention relates to the field of polyester yarns, and discloses a full-dull polyester filament yarn and a processing technology thereof. The raw materials comprise, by mass, 120-130 parts of polyethylene glycol terephthalate (PET), 10-20 parts of an anti-pilling composition, 2.5-4 parts of matting powder, 4-8 parts of an antioxidant, 3.5-5 parts of a softening agent and 6-10 parts of a dispersant. The anti-pilling composition is a mixture of apple fibers, propolis and high-hydrogen-content silicone oil, and the mass ratio of the apple fibers to the propolis to the high-hydrogen-content silicone oil is (3-5): (0.8-1.5): 1. The full-dull polyester filament yarn is obtained by mixing, melting and extruding an anti-pilling composition, polyethylene glycol terephthalate, matting powder, an antioxidant, a softening agent and a dispersing agent to obtain master batches, melting and spinning the master batches, finally cooling and forming, and finishing the cooled polyester filament yarn with malic acid. According to the full-dull polyester filament yarn, the defect that the full-dull polyester filament yarn is prone to pilling is overcome.

Owner:杭州灵杰花边线带有限公司

A kind of acetate green fiber functional knitted fabric and weaving method

The invention discloses an acrylic-cellulose acetate fiber functional knitted fabric and a knitting method and relates to the field of textiles. Jacquards are knitted in the front surface of the fabric; polyester fibers in the middle layer are tightly connected; acrylic-cellulose acetate fiber blended yarns are knitted on the back surface of the fabric; the fabric is knitted by combination of jacquard threading yarns and variation whorl textiles and variation plain stitch textiles; the variation whorl textiles are alternately knitted by acrylic fibers-viscose blended yarn strands, cotton-chinlon 6 blended yarn strands and polyester fibers; the variation plain stitch textiles are knitted by acrylic fiber blended yarns in a needle dial; the acrylic-cellulose acetate fiber blended yarns are acrylic fibers-modal Viloft blended yarns. Static resistance, pilling resistance, warmth retention, moisture conductivity, smoothness and comfort level of the fabric are all obviously improved.

Owner:QINGDAO XUEDA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com