Full-dull polyester filament yarn and processing technology thereof

A technology of full-dull polyester and filament, which is applied in the field of polyester yarn, can solve the problems of low cohesion of polyester fibers, etc., and achieve good anti-pilling performance and anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

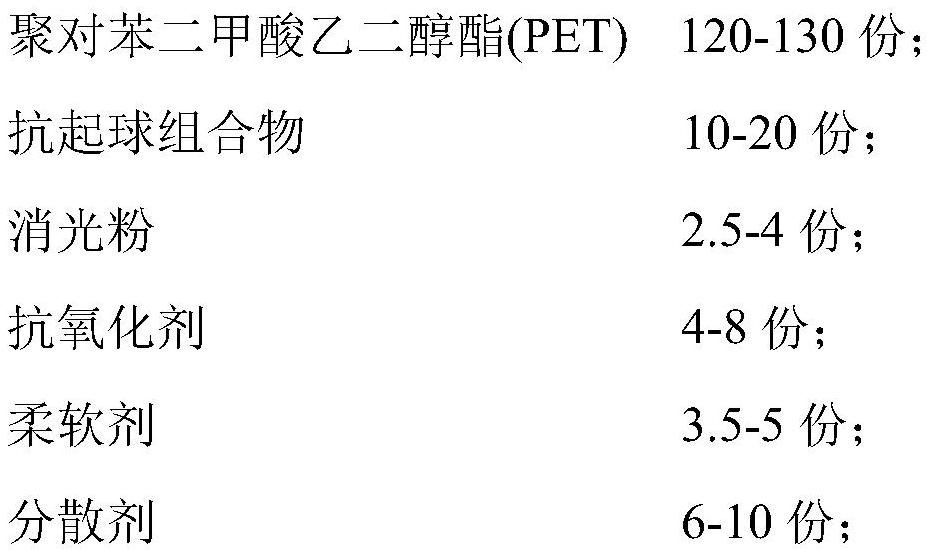

Method used

Image

Examples

preparation example 1

[0042] The preparation method of apple fiber is as follows:

[0043] T1. Squeeze the apples to obtain apple pomace and apple juice, the apple juice is reserved;

[0044] T2. Soak the apple pomace in 0.1% sodium chloride solution for 2 hours, then soak in water for 2 hours, squeeze out the water and dry at 65°C, then grind the dried apple pomace, pass through 70 mesh, Apple powder is obtained after 50-mesh and 30-mesh sieves;

[0045]T3. Weigh 10kg of apple powder, add 10kg of water and 0.4kg of cellulase, stir at room temperature for 2 hours, then place in microwave for 20s, and set the microwave power to 700W; then heat to 35°C, stir for 0.5h under microwave Place for 15s; reheat to 45°C, stir for 0.2h, place under microwave for 10s, and place at room temperature;

[0046] T4. Centrifuge the mixture obtained in step T3 and take the supernatant, then soak the supernatant with 3 times the mass of ethanol for 8 hours, then centrifuge again, collect the precipitate and dry to o...

preparation example 2

[0048] The difference between Preparation Example 2 and Preparation Example 1 is that in step T2, the apple pomace is soaked in 0.1% sodium chloride solution for 3 hours, then soaked in water for 1 hour, and dried at 55° C. after being squeezed out of water. In step T3, 0.2 kg of cellulase was added, stirred at room temperature for 1 hour, and then placed in the microwave for 30 s; then heated to 30 °C, stirred for 1 h, and placed in the microwave for 25 s; then heated to 40 °C, stirred for 0.5 h, and then placed in the microwave for 25 seconds. After being placed under the microwave for 20 s, it was placed at room temperature; in step T4, the supernatant was soaked with 3 times the mass of ethanol for 6 h.

preparation example 3

[0050] The difference between Preparation Example 3 and Preparation Example 1 is that in step T3, after adding cellulase to the apple powder, it is stirred and heated at 45° C. for 2 hours and then placed at room temperature without microwave treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com