Anti-pilling manufacturing method of cotton-polyester blended fabric

A manufacturing method and anti-pilling technology, applied in the field of knitted fabrics, can solve the problems of environmental pollution and difficult disposal of waste liquid, and achieve the effects of suitable weaving method, solving sublimation fastness and good anti-pilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

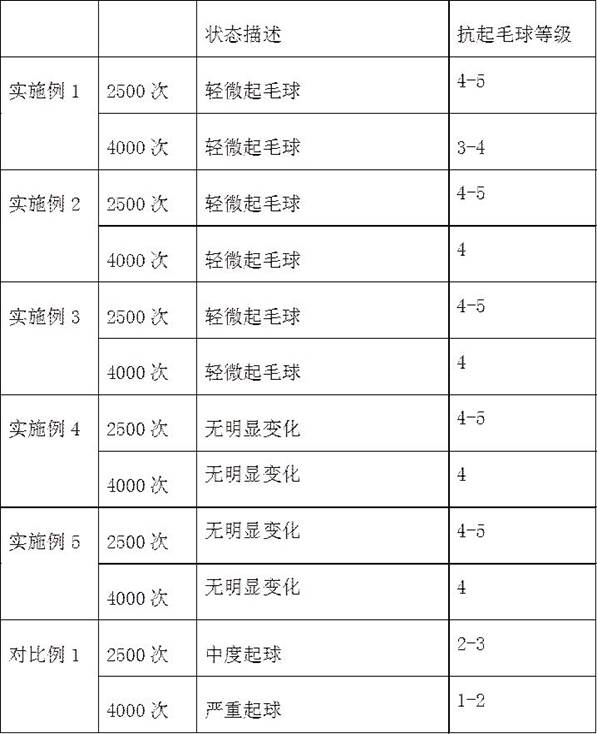

Embodiment 1

[0039] A method for producing anti-pilling of cotton-polyester blended fabric, comprising the following steps:

[0040] S1, material selection: select polyester fiber and cotton fiber raw materials; the intensity of the polyester fiber is 16F, the length of the cotton fiber is 28mm, and the length of the polyester fiber is 54mm;

[0041] S2. Weaving: according to the sandwich weaving method, weave gray cloth, wherein the surface layer and the bottom layer are cotton fiber layers, and the middle layer is a polyester fiber layer;

[0042] S3, opening width: the cotton-polyester gray cloth after weaving is subjected to opening width treatment;

[0043] S4. Determining embryos: put the gray cloth after opening into a shaping machine at 200°C for high-temperature embossing;

[0044] S5, dyeing and washing: put the gray cloth after the embryo determination into the dyeing tank, and carry out high-temperature dyeing and washing at 110°C;

[0045] S6, fixing polyester: heat the dyed...

Embodiment 2

[0053] A method for producing anti-pilling of cotton-polyester blended fabric, comprising the following steps:

[0054] S1, material selection: select polyester fiber and cotton fiber raw materials; the strength of the polyester fiber is 17F, the length of the cotton fiber is 30mm, and the length of the polyester fiber is 56mm;

[0055] S2. Weaving: according to the sandwich weaving method, weave gray cloth, wherein the surface layer and the bottom layer are cotton fiber layers, and the middle layer is a polyester fiber layer;

[0056] S3, opening width: the cotton-polyester gray cloth after weaving is subjected to opening width treatment;

[0057] S4. Determining embryos: put the gray cloth after opening into a setting machine at 210°C, and perform high-temperature embryo determination;

[0058] S5. Dyeing and washing: put the gray cloth after the embryo determination into the dyeing tank, and carry out high-temperature dyeing and washing at 130°C;

[0059] S6, fixing polye...

Embodiment 3

[0067] A method for producing anti-pilling of cotton-polyester blended fabric, comprising the following steps:

[0068] S1, material selection: select polyester fiber and cotton fiber raw materials; the intensity of the polyester fiber is 18F, the length of the cotton fiber is 32mm, and the length of the polyester fiber is 58mm;

[0069] S2. Weaving: according to the sandwich weaving method, weave gray cloth, wherein the surface layer and the bottom layer are cotton fiber layers, and the middle layer is a polyester fiber layer;

[0070] S3, opening width: the cotton-polyester gray cloth after weaving is subjected to opening width treatment;

[0071] S4. Determining embryos: put the gray cloth after opening into a shaping machine at 220°C for high-temperature embryo determination;

[0072] S5. Dyeing and washing: put the gray cloth after the embryo determination into the dyeing tank, and carry out high-temperature dyeing and washing at 140°C;

[0073] S6, fixing polyester: he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com