Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High underflow concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

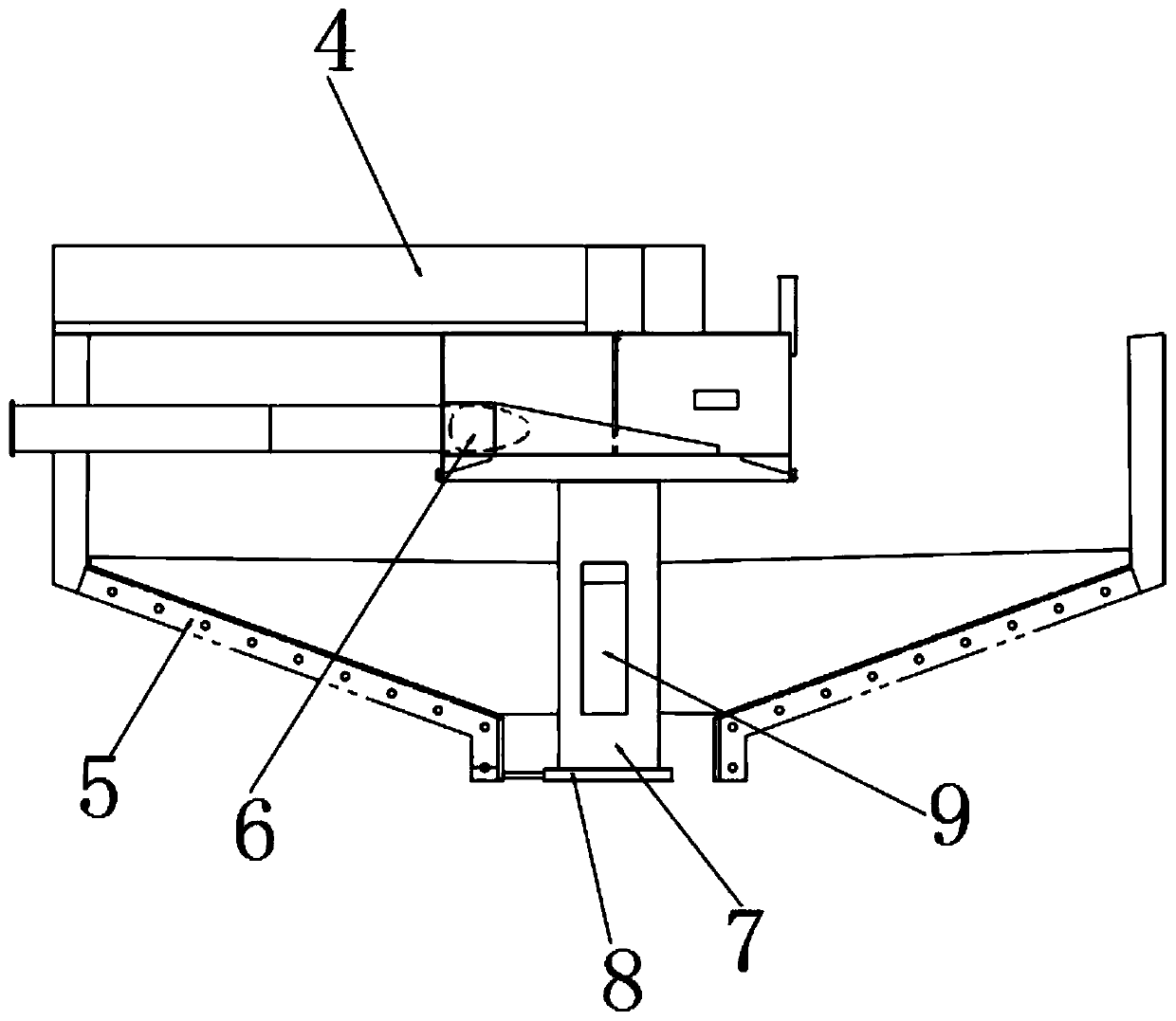

Continuous preparation system and preparation technology of whole grain grade tailing cemented filling slurry

ActiveCN105834012AAdvantages of preparation processImprove concentration efficiencyDifferential sedimentationMaterial fill-upAir compressionHigh concentration

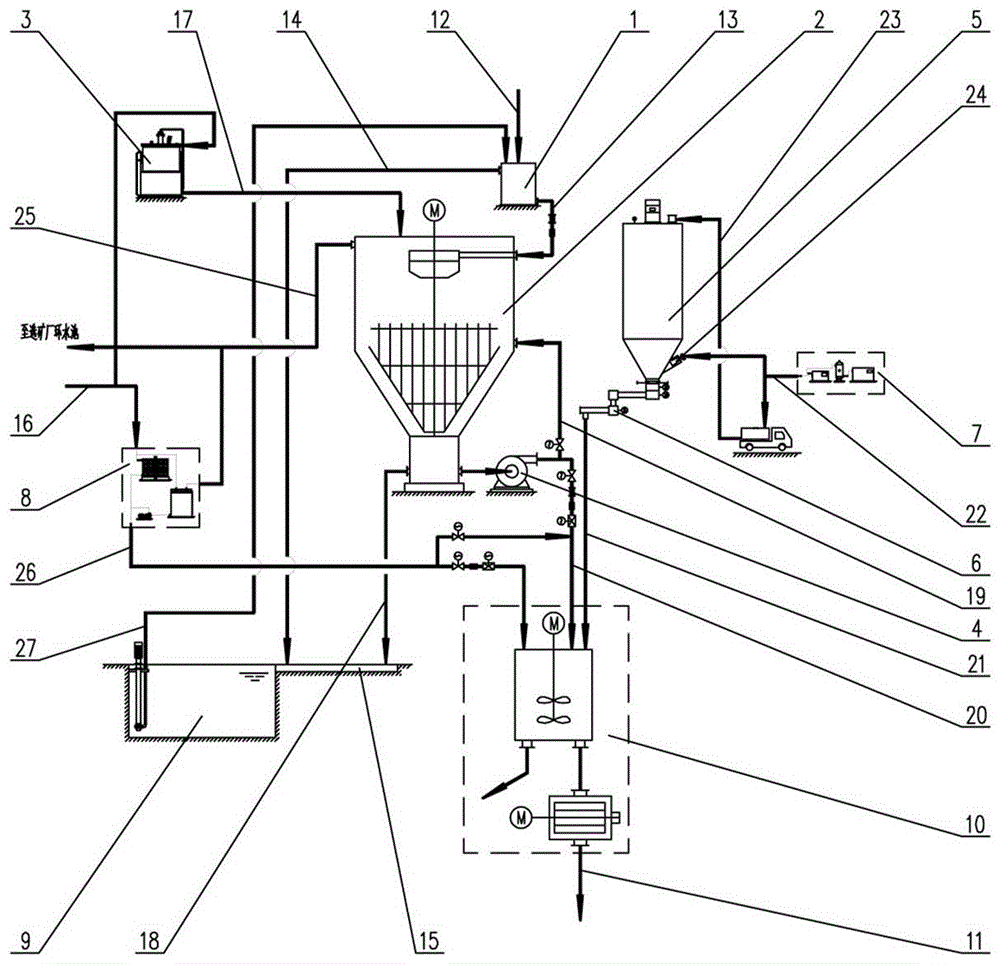

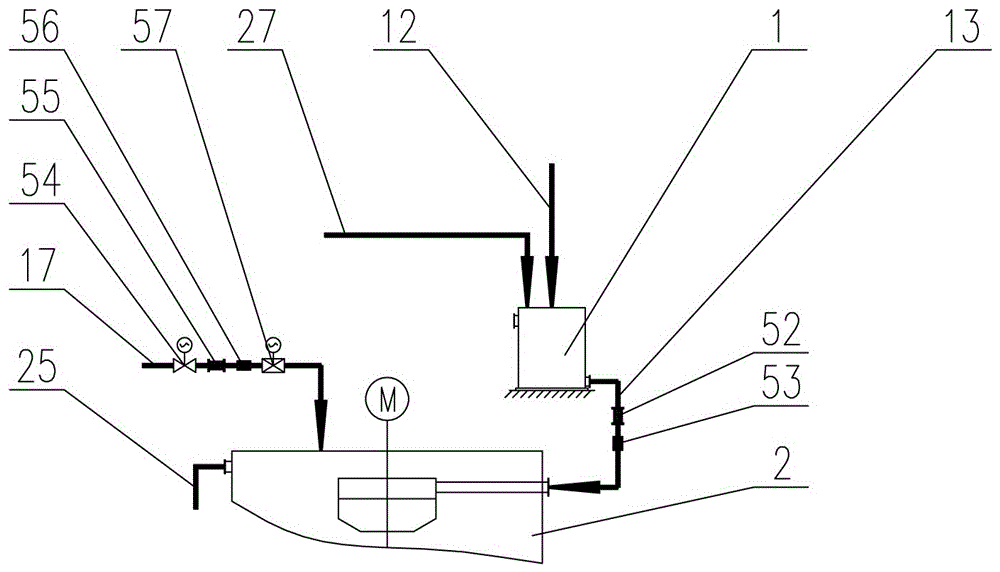

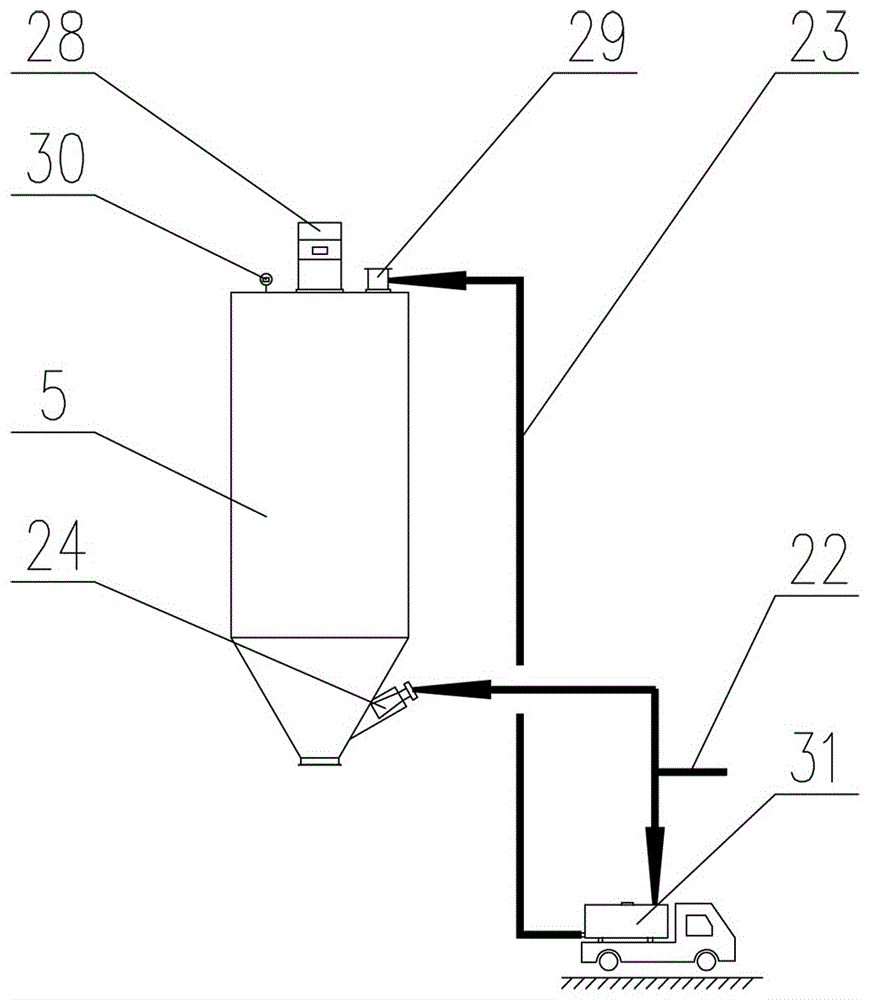

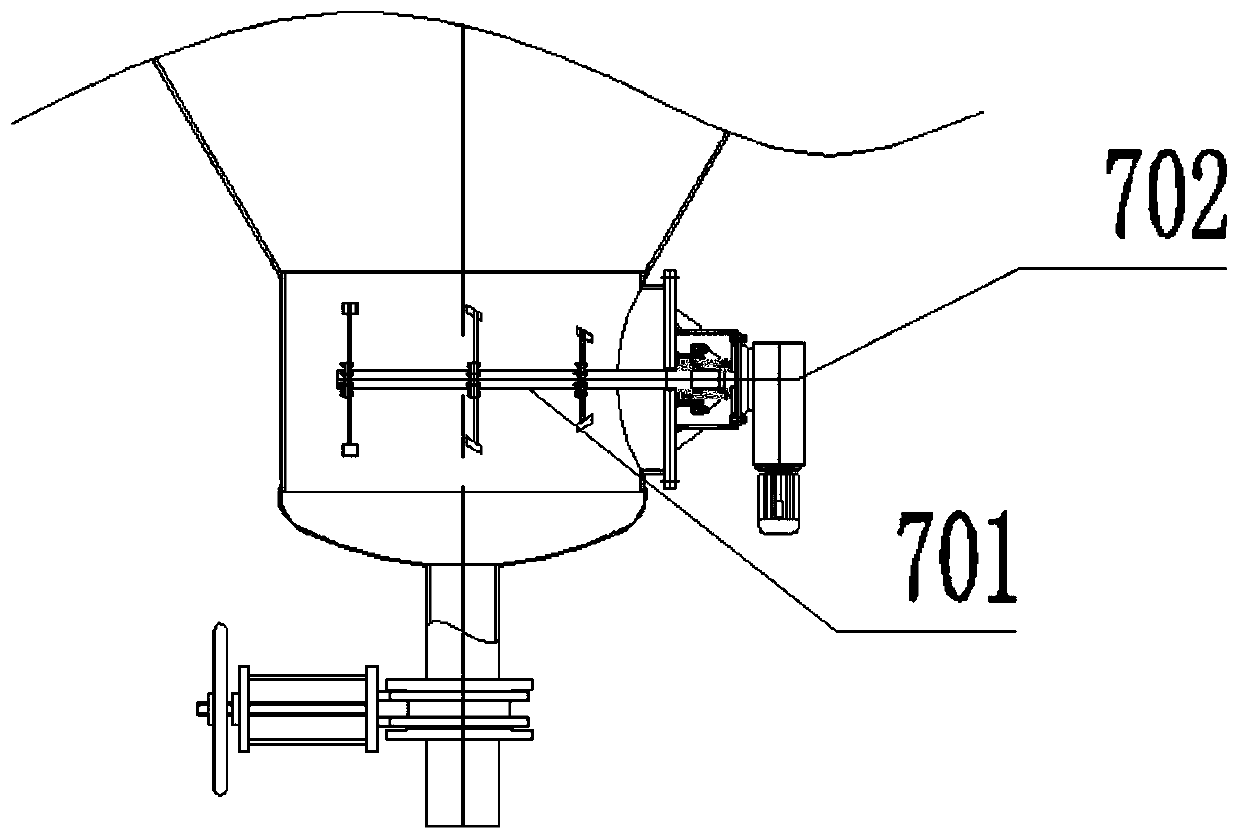

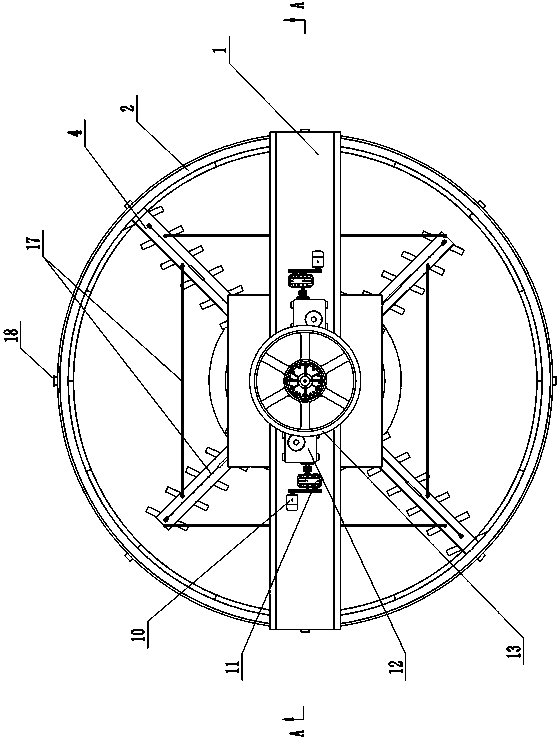

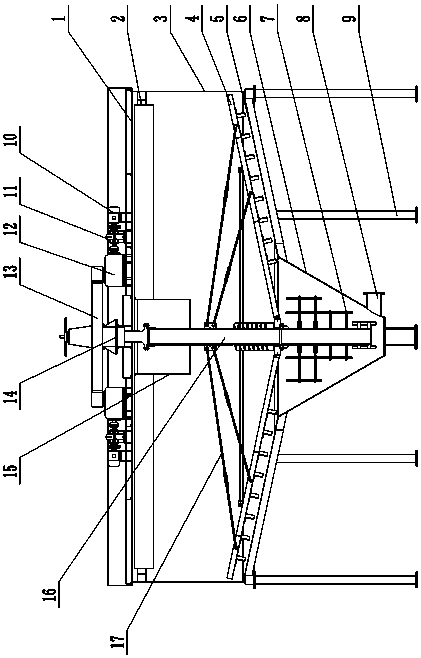

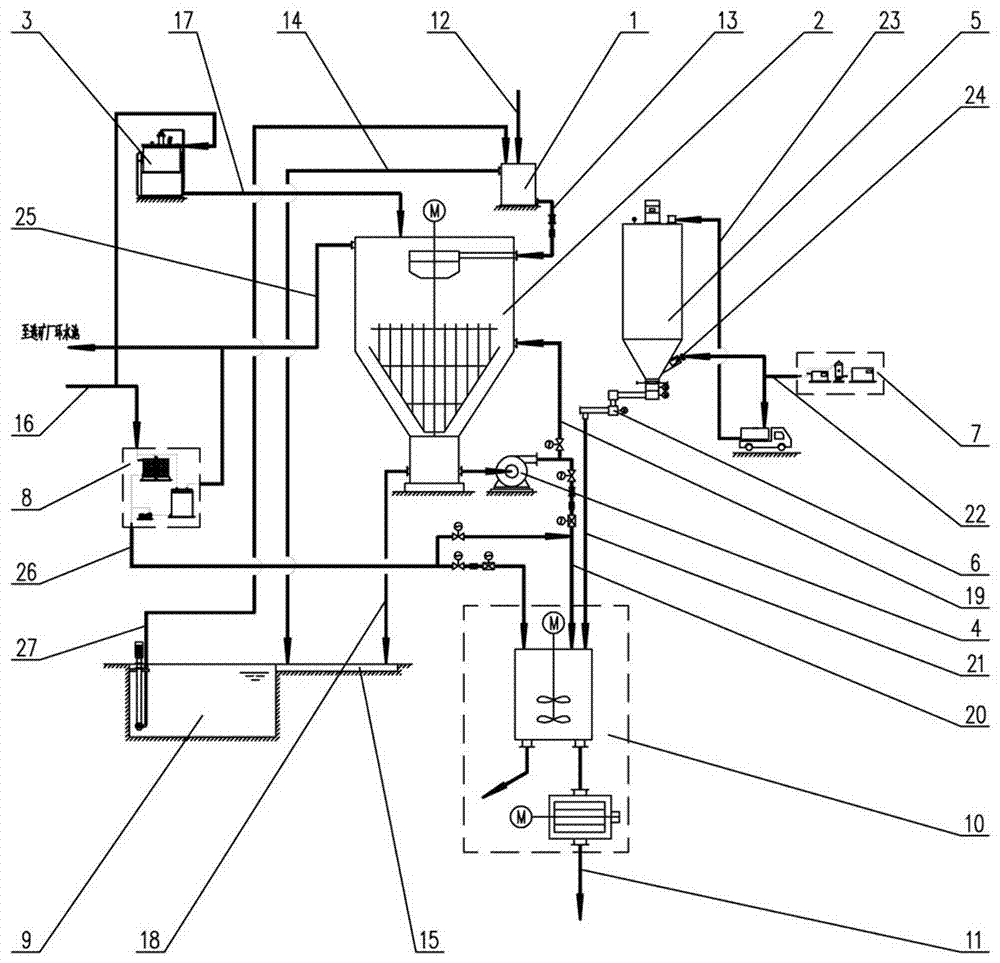

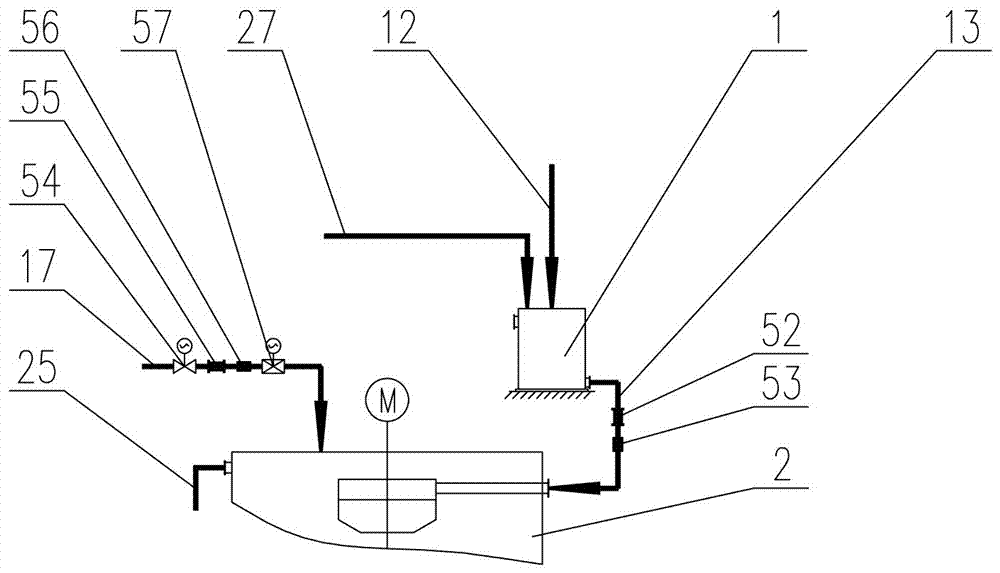

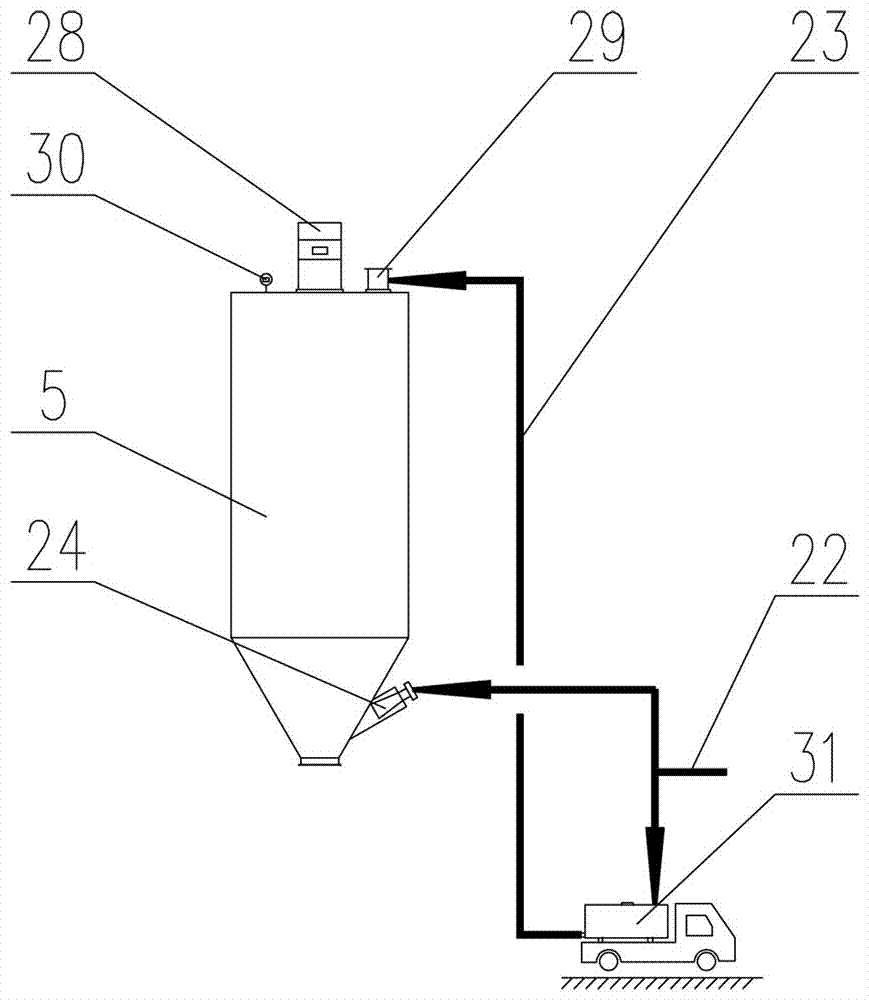

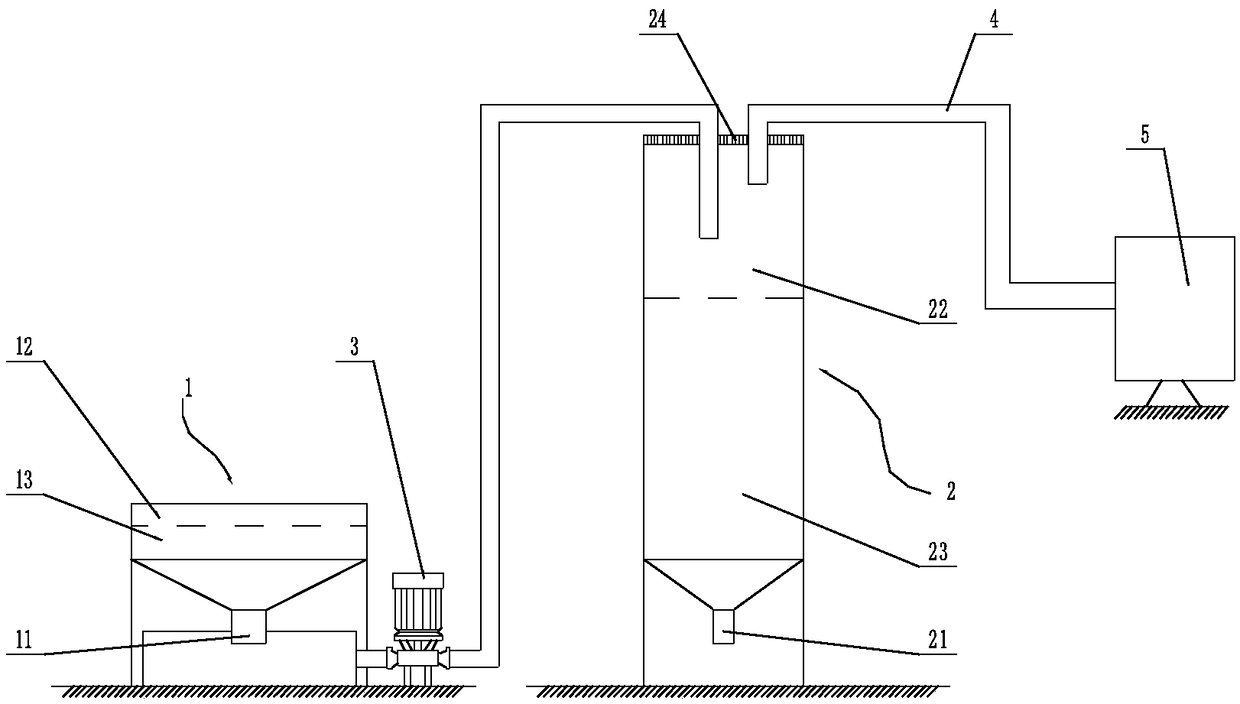

The invention relates to a continuous preparation system and a preparation technology of whole grain grade tailing cemented filling slurry. The continuous preparation system mainly comprises a tailing slurry collecting buffer feeding device, a deep-cone thickener, a flocculating agent preparing and adding device, an underflow slag slurry pump, a cementing material storage bin, a cementing material measuring and conveying device, an air compression system, a water supply system, a filling accident pool, a stirring system and a filling slurry output pipeline. The preparation technology comprises the steps of conveying tailing slurry to the tailing slurry collecting buffer feeding device through the slag slurry pump, after reducing the pressure to 0.03 MPa through the collecting buffer feeding device and carrying out energy dissipation, feeding the tailing slurry into the deep-cone thickener, and adding a flocculating agent into the deep-cone thickener according to the principle that for per ton of tailing slurry, every 5 to 20 g of the flocculating agent is added, so as to obtain high-concentration tailing slurry with the concentration of 65 to 75%; and conveying the high-concentration tailing slurry and a cementing material into the stirring system according to the fact that the mass ratio of the high-concentration tailing slurry to the cementing material is 1 to (5 to 40), adding water, stirring, and preparing the mixture into the high-concentration whole grain grade tailing cemented filling slurry with the concentration of 65 to 75%. According to the continuous preparation system and the preparation technology, the system is simple, the automation degree during the preparation process is high, the operation is convenient, and the filling slurry can be continuously prepared.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Flotation gangue subsidence method of alumyte

The present invention relates to the deposition dewatering process of floated tail ore, and is especially the deposition dewatering process of floated tail ore of diaspore type alumyte. The present invention features that into the floated tail ore slurry, sulfuric acid or sulfate, aluminum sulfate, ferrous sulfate, zinc sulfate, copper sulfate, barium sulfate or alum in acidity after hydrolysis is first added to regulate pH value to 6.5-7.5; and polyacrylamide as organic flocculant in the amount of 0.001-0.01 % of the dry tail ore slurry weight is then added for flocculation and deposition. The present invention can raise the concentration of tail ore slurry from 6-11 % to over 25 %, reduce the overflow floated matter to below 1 g / L and make the overflow water capable of being reused.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

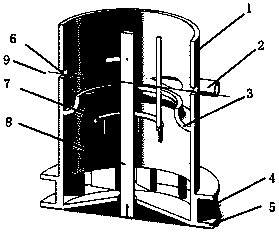

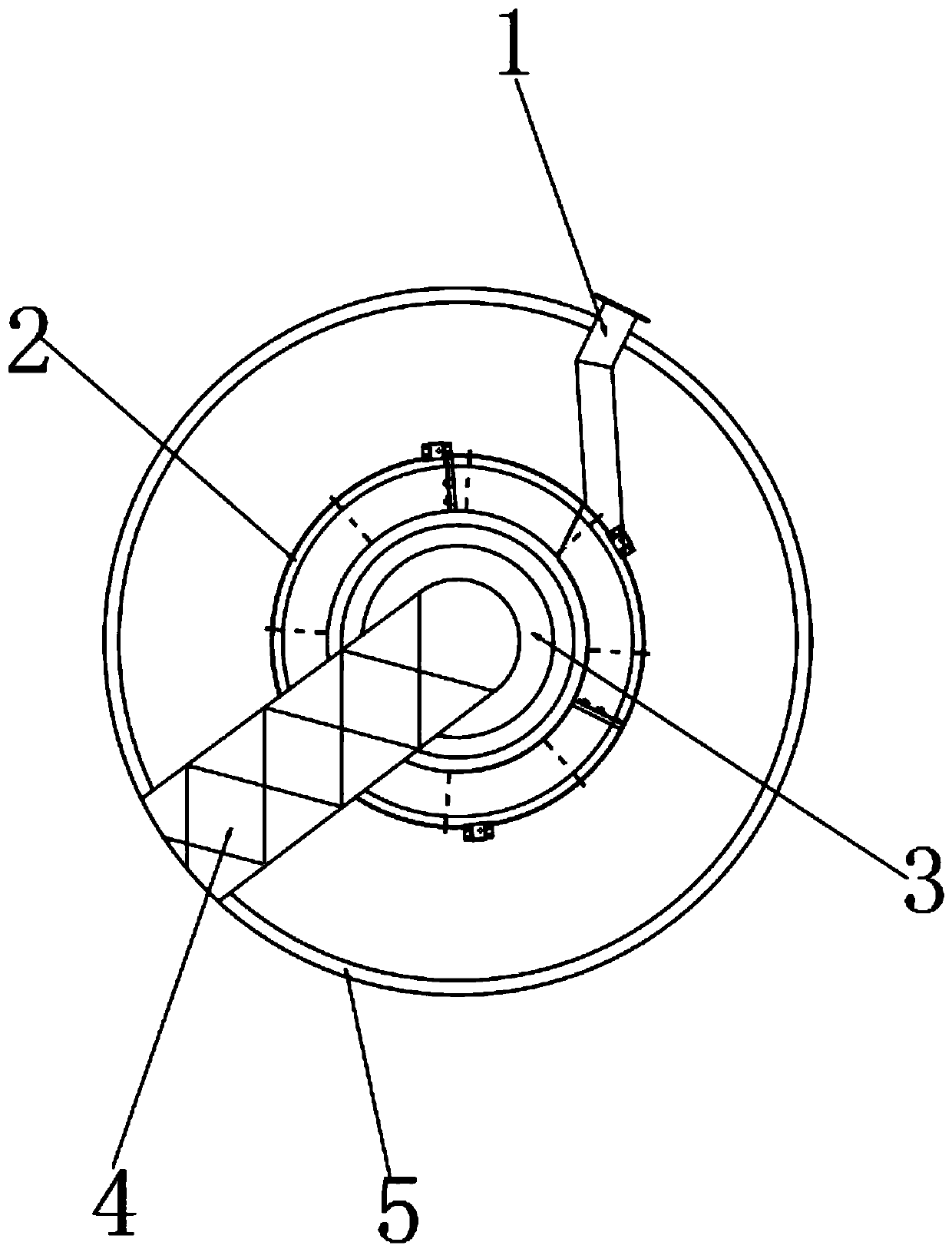

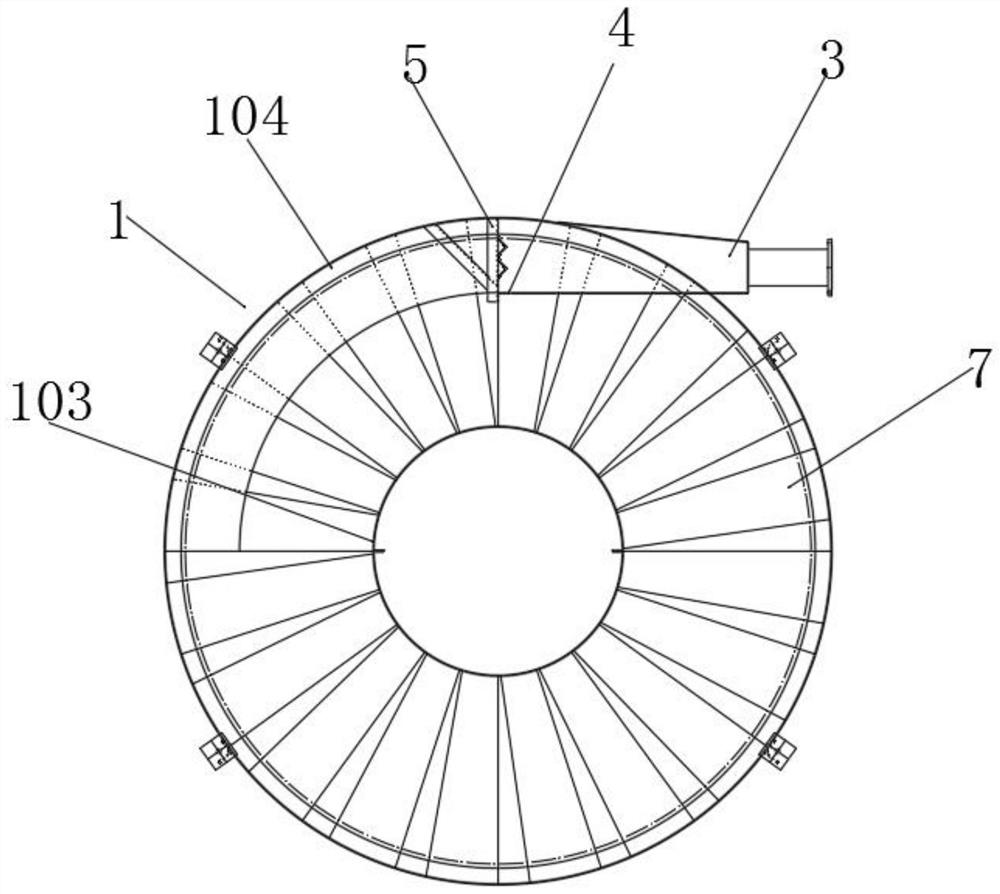

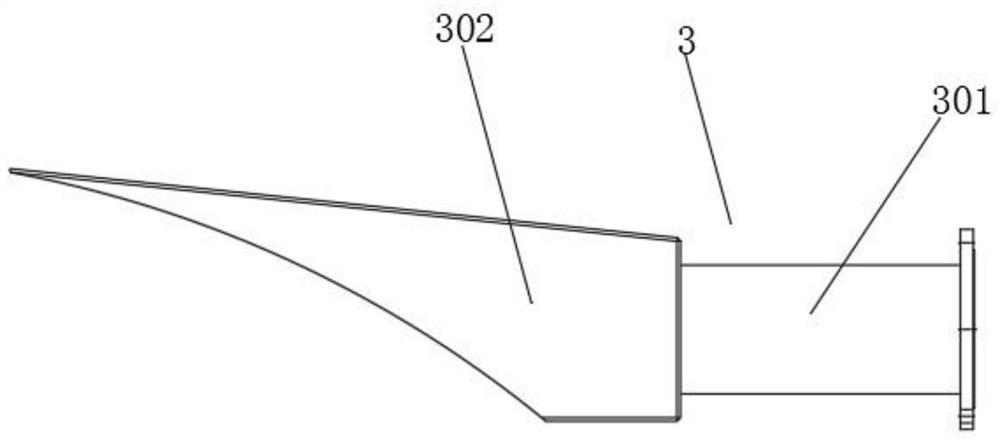

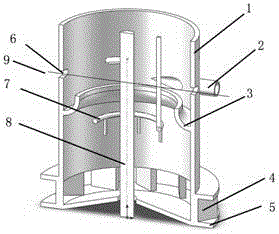

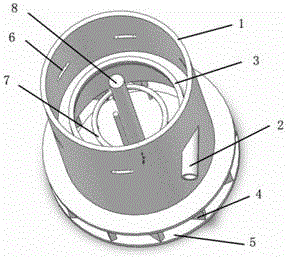

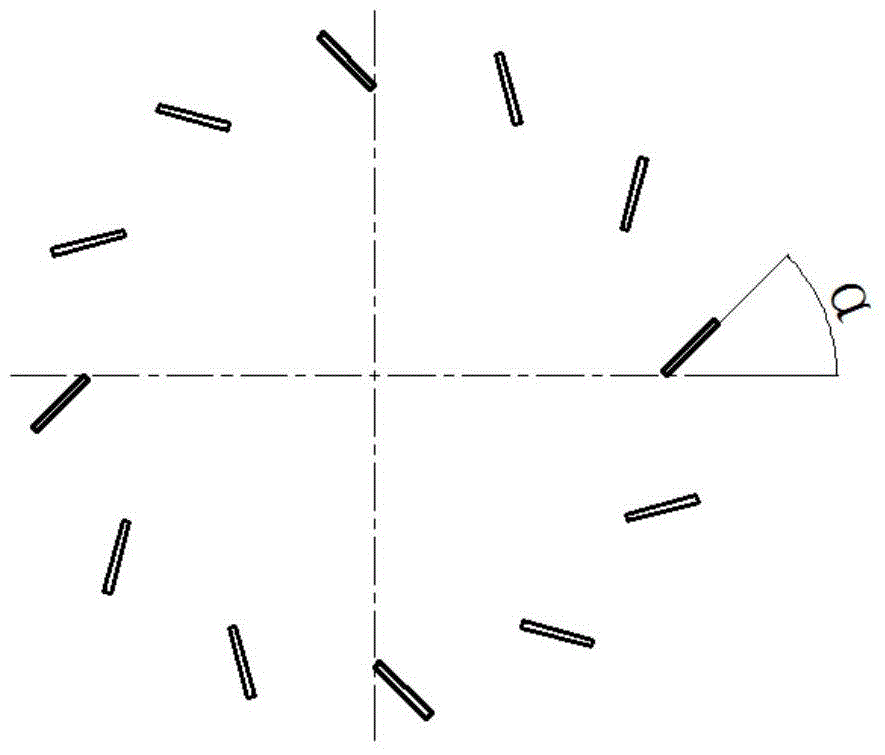

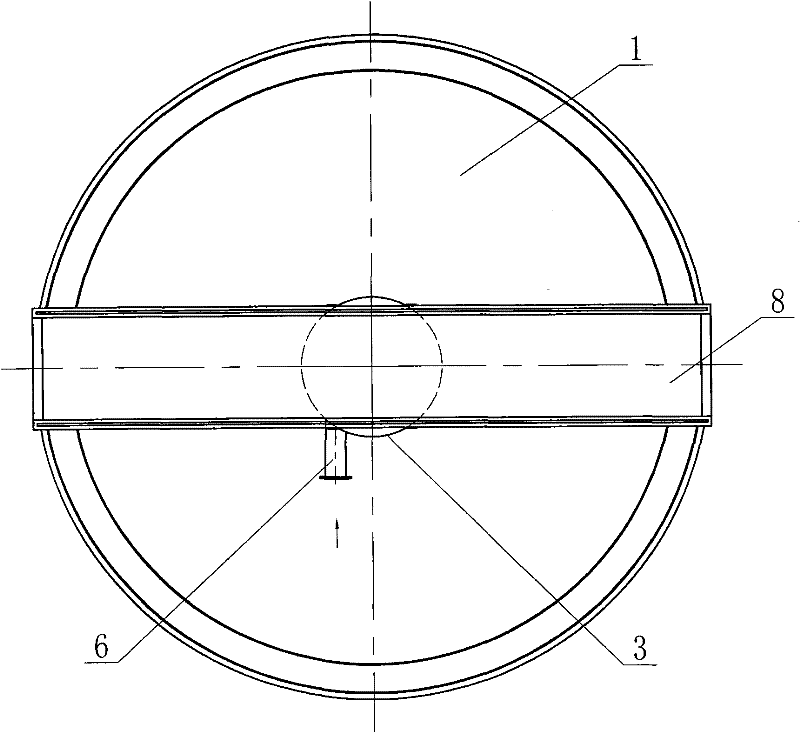

Feeding well device for thickener

ActiveCN104208923AExtension of timeRealize automatic dilutionSettling tanks feed/dischargeEngineeringEnergy consumption

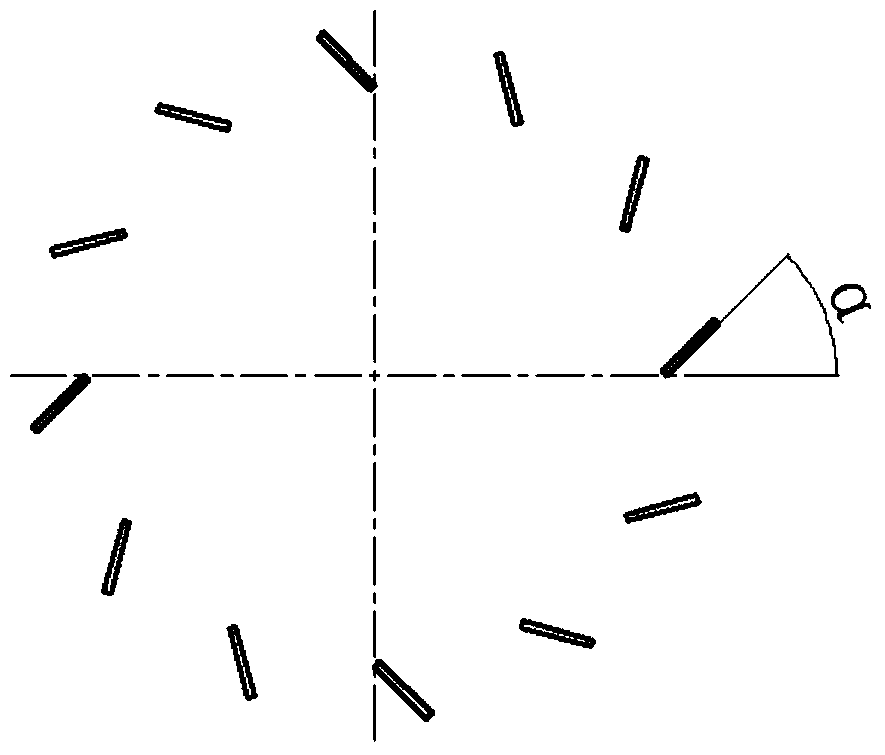

The invention discloses a feeding well device for a centre drive thickener. A feeding well wall is cylindrical; an annular horizontal outer edge is formed in the lower edge of the feeding well wall; a feeding pipe is connected with the outer side of the feeding well wall; a feeding pipe orifice is positioned below the overflow liquid level of the thickener; an overflow tank is arranged below the feeding pipe orifice; the overflow tank is horizontally distributed in a circle along the inner side of the feeding well wall, and the edges of the overflow tank are equal in heights; a conical guide plate is arranged at a lower outlet of the feeding well wall, the edge of the conical guide plate is connected with the outer edge of the lower edge of the feeding well wall through guide vanes, and the guide vanes are uniformly distributed; a flocculating agent addition tube is arranged on the inner side of the overflow tank; and dilution openings are uniformly formed in the feeding well wall. According to the feeding well, any extra power is not needed, and the energy consumption is reduced; ore pulp is uniformly distributed in the feeding well and flows out of the feeding well from all directions, and the utilization rate of settling area is improved; and moreover, the ore pulp flows out of channels between the guide vanes which form an included angle of 40-50 degrees with the radial direction, so that a settled layer in the thickener is prevented from being impacted, the underflow concentration is high, and the feeding well device is convenient to popularize.

Owner:TIANJIN UNIV

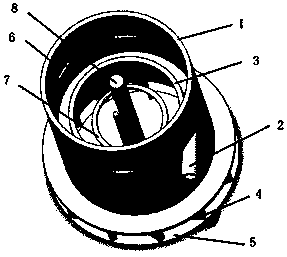

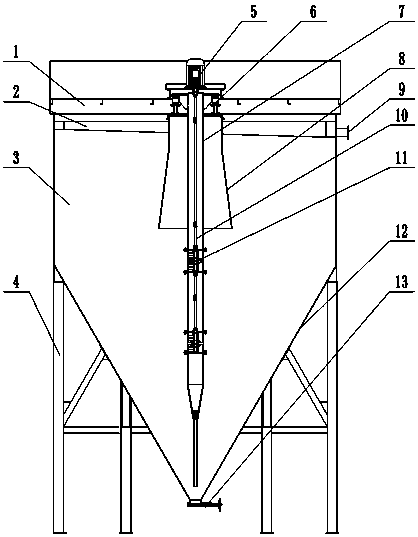

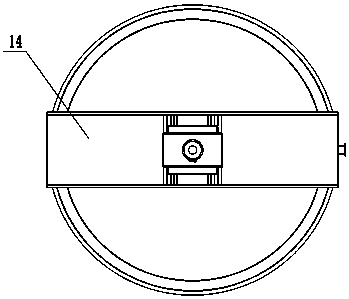

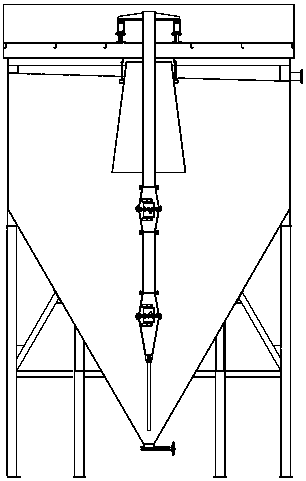

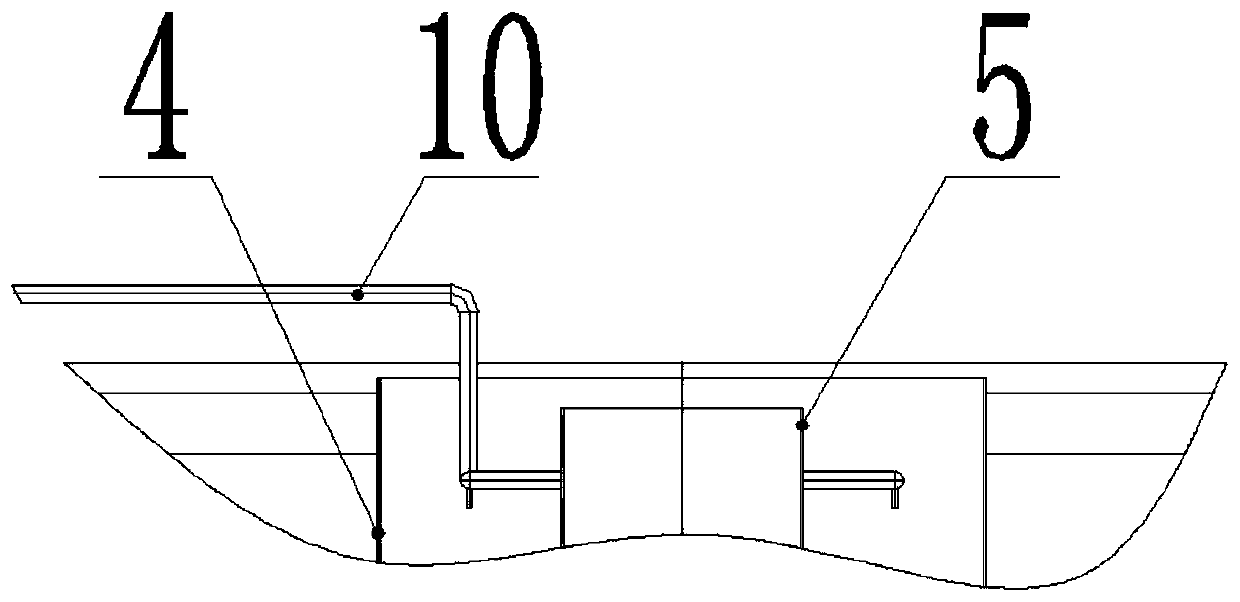

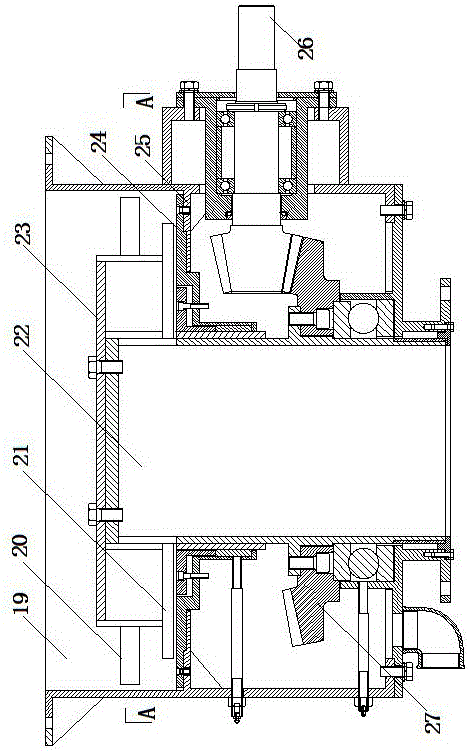

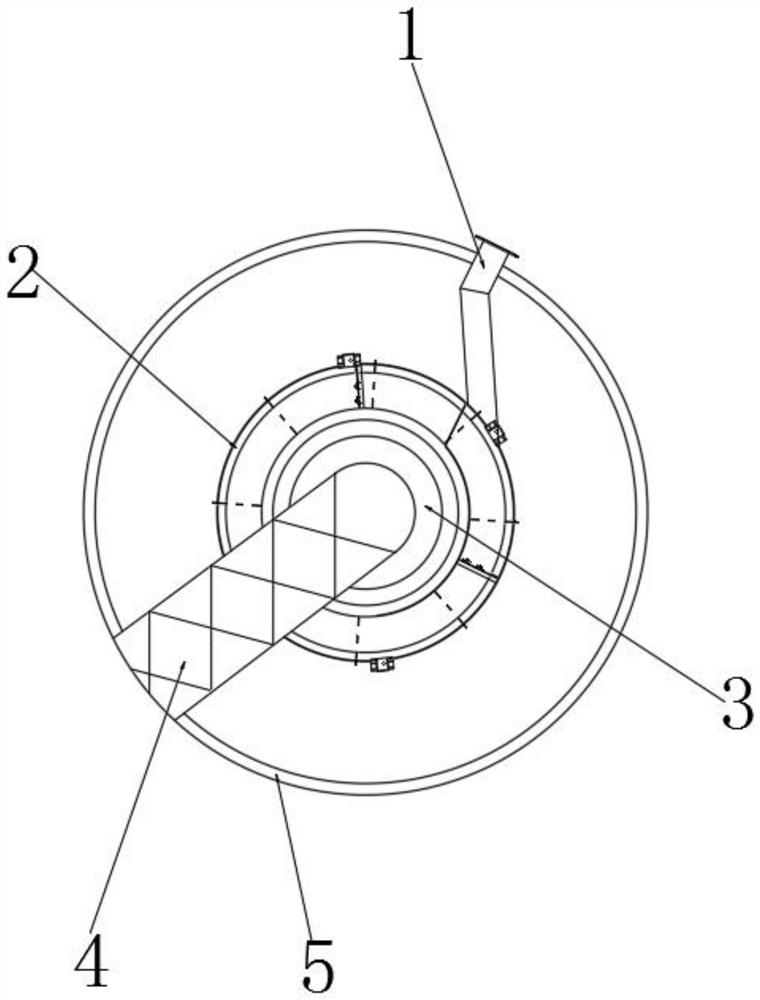

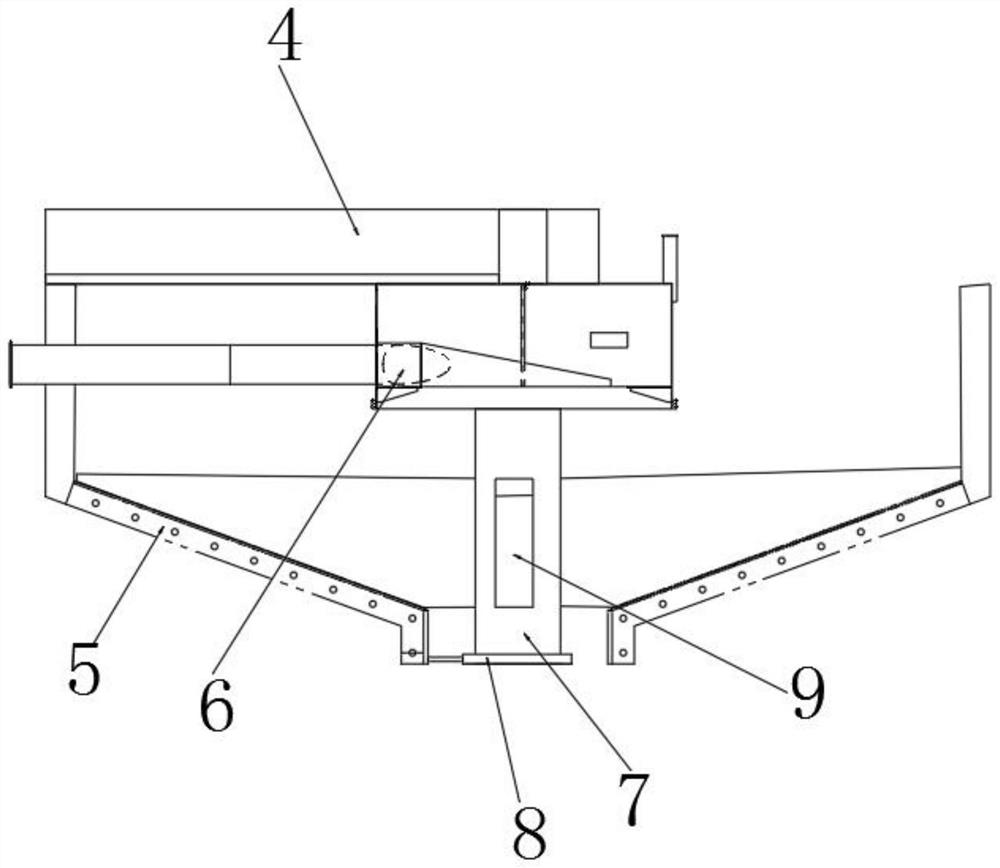

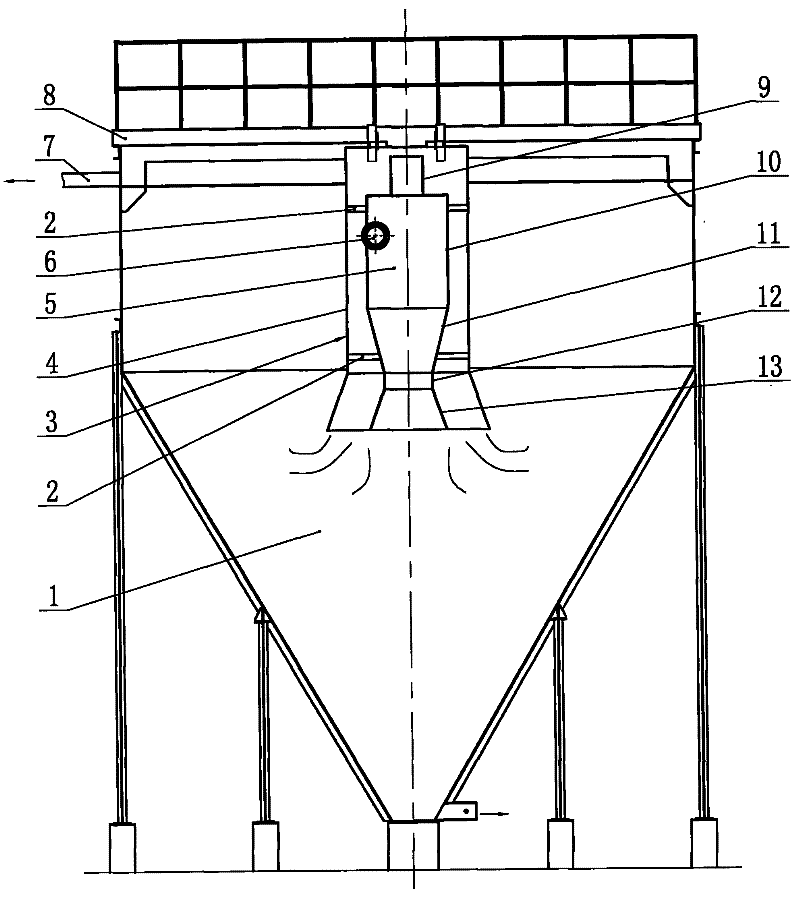

Deep-cone thickener

ActiveCN104524820AHigh underflow concentrationSimple structureSettling tanks feed/dischargeSedimentation settling tanksEngineeringCylindrical tube

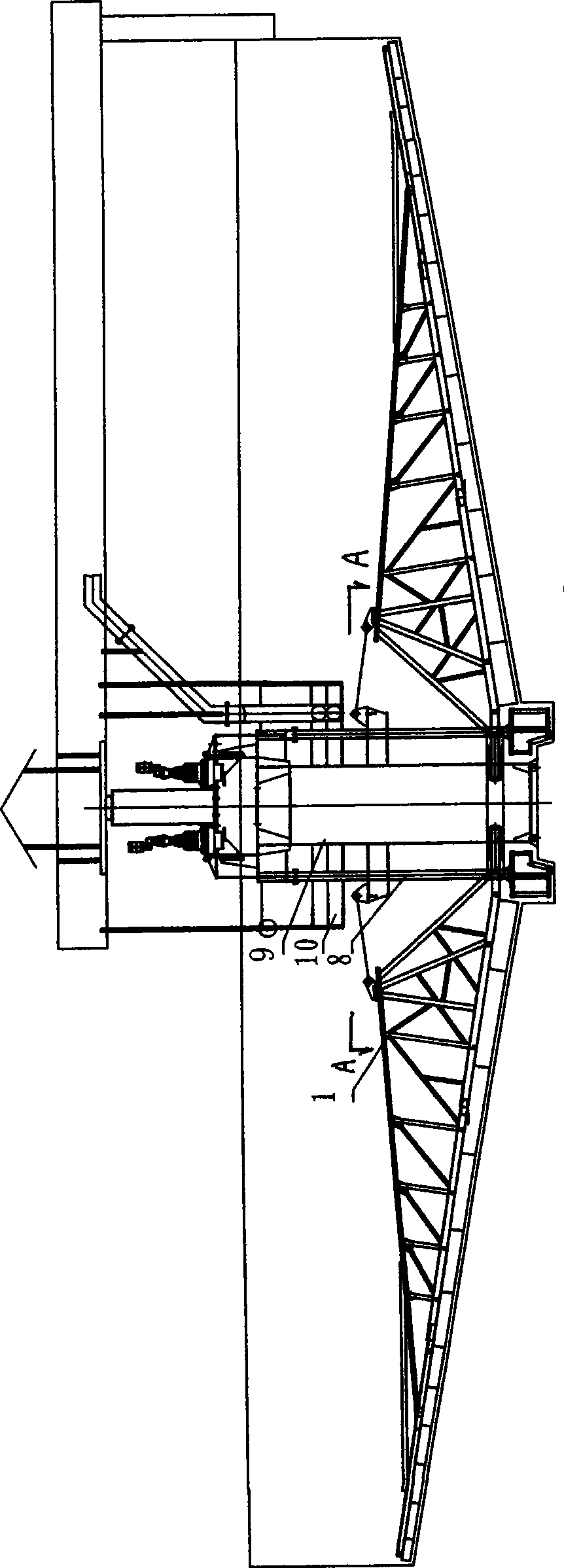

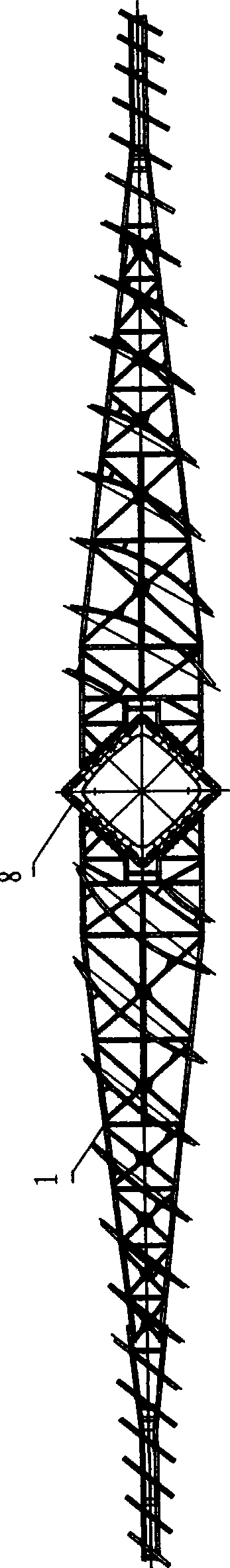

The invention discloses a deep-cone thickener, which comprises a tank, a large frustum, a small frustum, a harrow frame, a feeder and a harrow frame lifting driving device, wherein the tank is of a cylindrical tube structure, and the upper and lower ends of the tank are respectively provided with flanges; the major-diameter end of the large frustum is upwardly connected with the flange at the lower end of the tank through the flange, and the small-diameter end of the large frustum is downwardly connected with the major-diameter end of the small frustum; the small-diameter end of the small frustum is provided with a throat and a valve device, and the flange at the upper end of the tank is connected with the harrow frame lifting driving device; a spindle of a speed reducer of the harrow frame lifting driving device is connected with a central transmission shaft of the harrow frame, and the upper end of the feeder is connected with a take-off and landing plate through a screw rod. The deep-cone thickener provided by the invention has the advantages of simple structure, low power consumption, high thickening efficiency, high underflow density, and strong adjustability, and is especially suitable for the dry heaping and dry discharge of different minerals and the tailing filling operation. The efficient concentration can be realized, and the discharge concentration of underflow of the thickener is enhanced, so that a mine mouth cannot be clogged.

Owner:BEIJING GENERAL RES INSITUTE OF MINING & METALLURGY GUAN MACHINERY +1

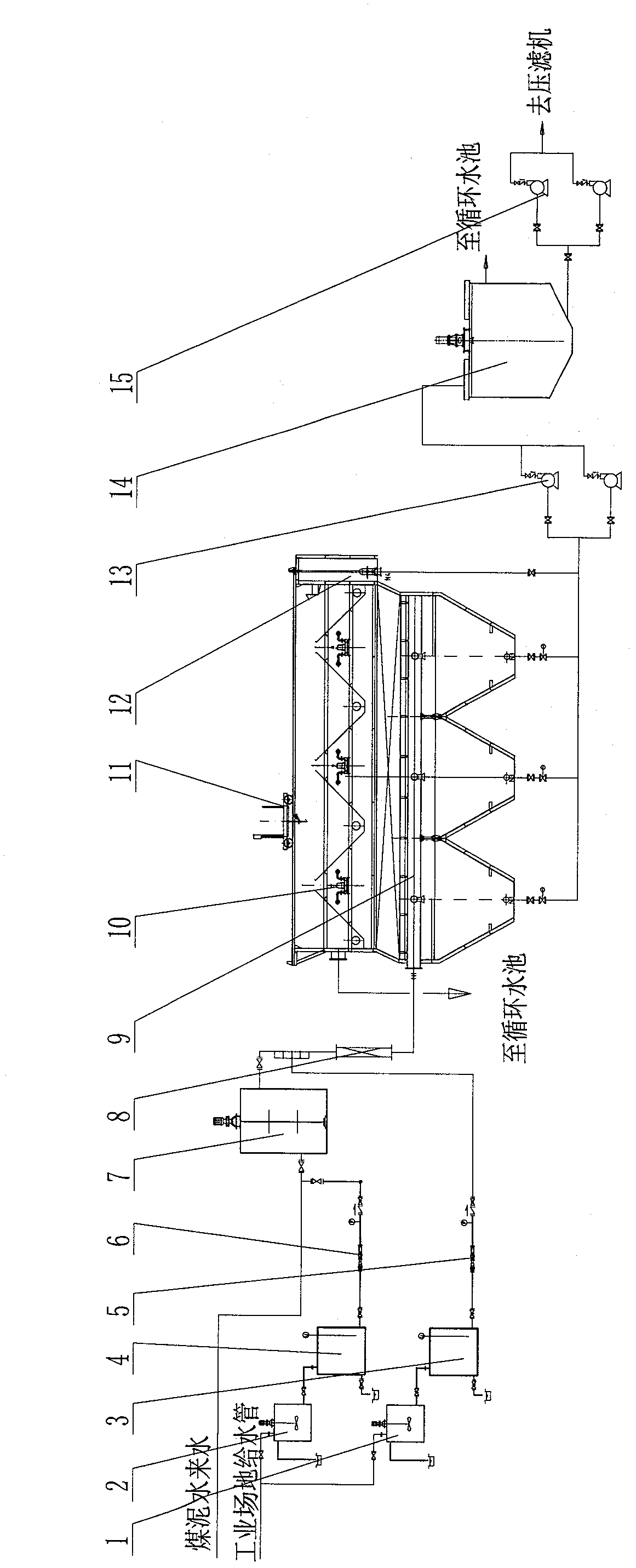

High-efficient process system for slime water through drifting separation

InactiveCN103043811AImprove water quality indicatorsHigh underflow concentrationSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentFiltrationSlag

The invention discloses a high-efficient process system for slime water through drifting separation. The system comprises a slime water mixing unit, a medicament adding system, a high-efficient drifting separator and a density modifying machine. The slime water passes through a slime water mixing barrel. The slime water is added with cation medicaments before entering into the mixing barrel, wherein the medicament adding system adds the medicaments for the first time, and the slime water flows out of the mixing barrel, passes through a pipe mixing device, and then is added with anion medicaments as a second medicament adding, wherein the slime water is fully mixed with the medicaments under the action of the pipe mixing device. The slime water passes through the slime water mixing barrel and flows to the high-efficient drifting separator for further separation and deposition of the slime water, wherein by using effects of an inclined tube in the high-efficient drifting separator, large particulate matters sink to the bottom, thereby forming underflow condensation precipitation, and fine particulate matters suspended in water (mainly ash) combine with micro-bubbles generated by an air flotation device and float to the liquid surface, thereby forming floating slag which is then collected by a slag scraper and a slag collector and discharged out of a groove. The treated discharge water is discharged to a cyclic pool through a water collection device. The underflow condensation precipitation is pumped to the density modifying machine for further compression and buffering through a slag and slurry pump, the compressed slime is sent into a press filtration workshop through the slag and slurry pump, and a supernatant is discharged to the cyclic pool.

Owner:北京中宇科博环保工程有限公司

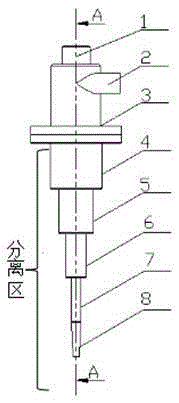

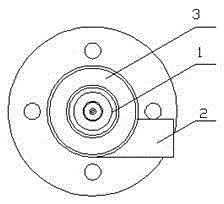

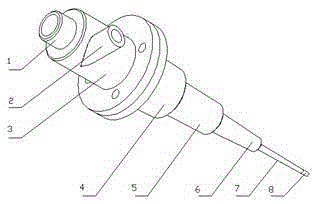

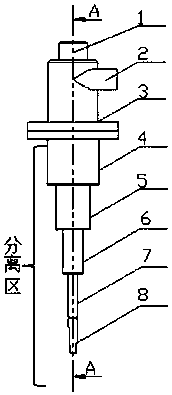

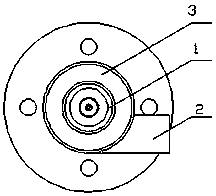

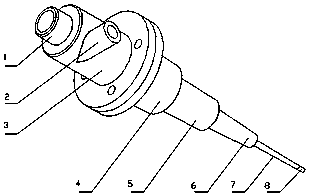

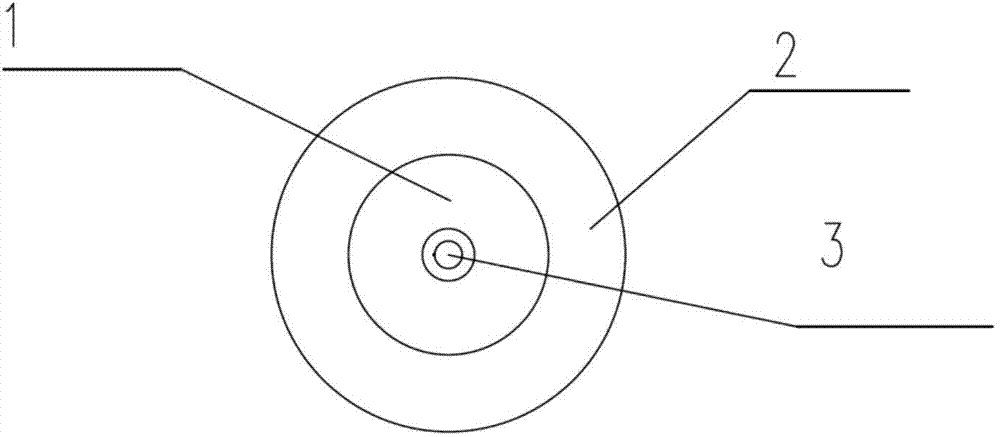

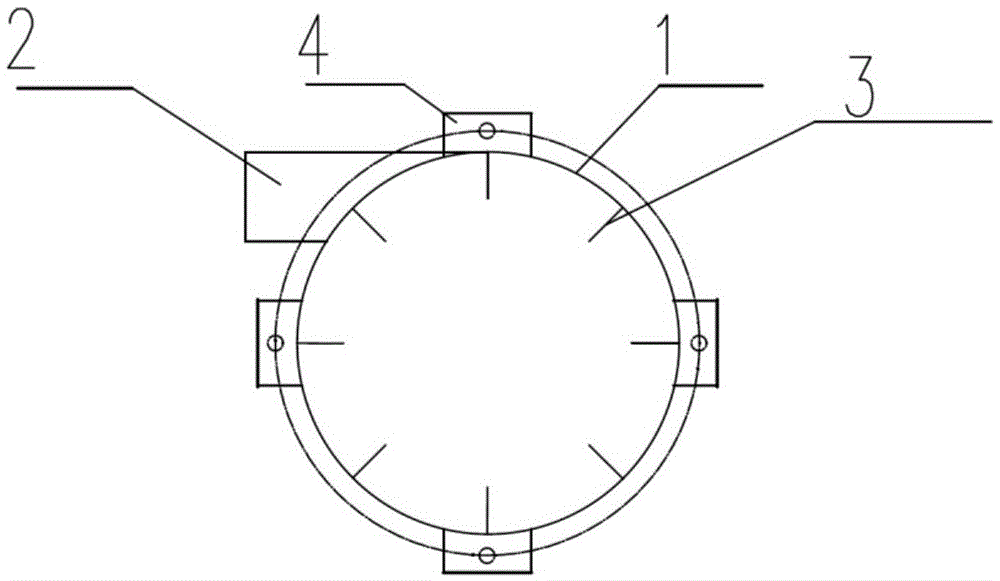

Retractable hydrocyclone

InactiveCN105797877AEasy to handleImprove separation efficiencyReversed direction vortexSewage treatmentPetroleum

The invention discloses a retractable hydrocyclone and belongs to multi-phase flow separation equipment. The retractable hydrocyclone comprises a feeding hole, an overflow pipe, a swirling chamber, a separation zone and an underflow pipe, wherein the separation zone is a main separation working part and is characterized by being formed by nested connection of a plurality of column segments with different internal diameters. The length of the separation zone of the hydrocyclone has certain influence on the separation precision. The device can adjust the length of the separation zone of the hydrocyclone according to the separation precision of materials, namely when the concentration requirement of a to-be-separated substance changes, the length of the column segments of the separation zone of the hydrocyclone can be extended or shrunk directly according to requirements to achieve use requirements, without re-designing a new hydrocyclone. The hydrocyclone is increased in handling capacity, improved in separation efficiency, increased in underflow concentration, convenient to adjust and low in cost, and is applicable to separation operations of industries including petroleum, chemical engineering, coal dressing, food, sewage treatment and the like, especially applicable to occasions with requirements for obtaining multi-phase flow substances with different concentrations.

Owner:SHIHEZI UNIVERSITY

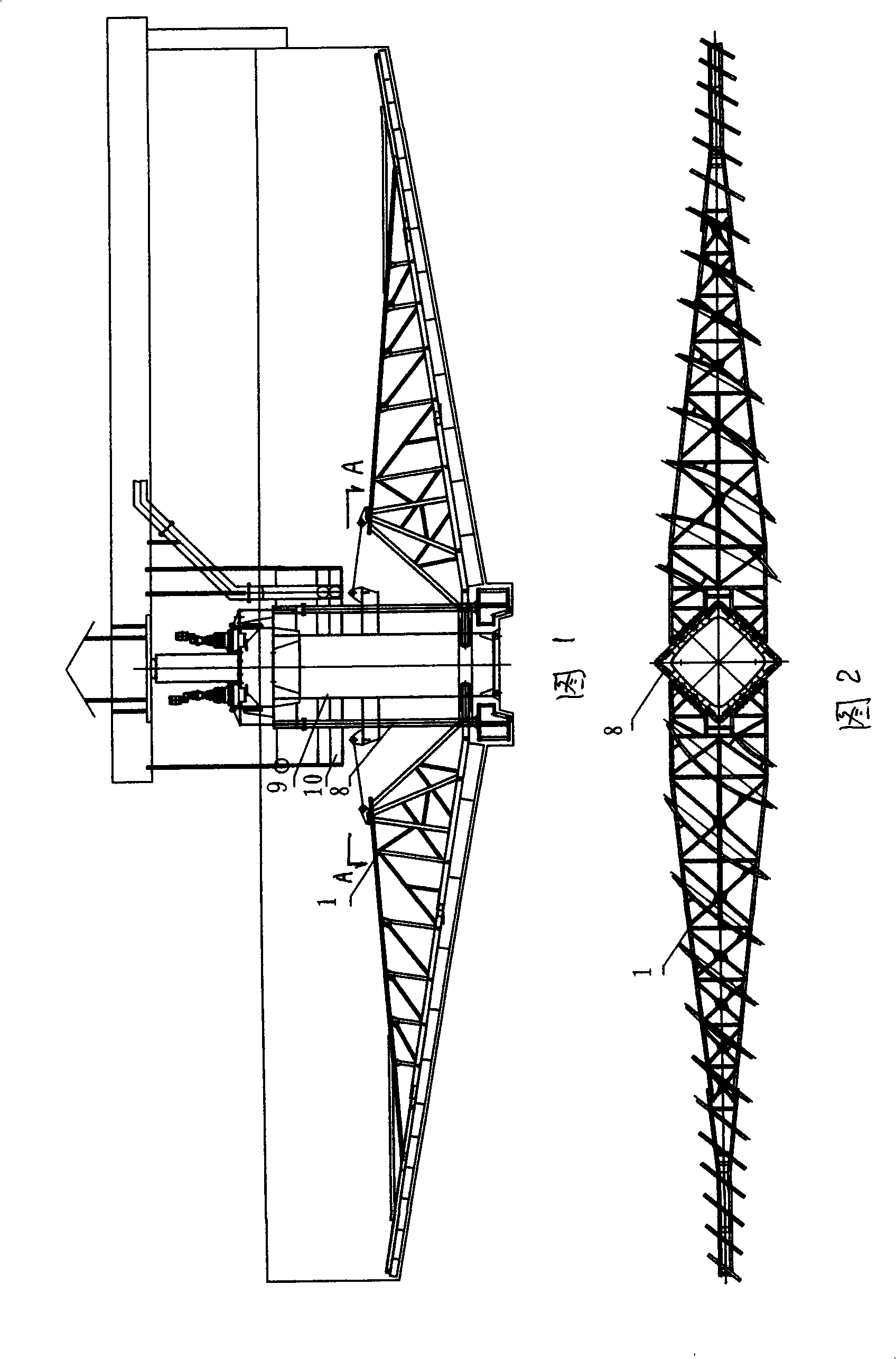

Fine-fraction high-concentration tailing filling and thickening device

ActiveCN113513363AImprove concentrationImprove the cycle efficiency of mining and chargingWaste water treatment from quariesWater/sewage treatment by centrifugal separationEngineeringSlurry

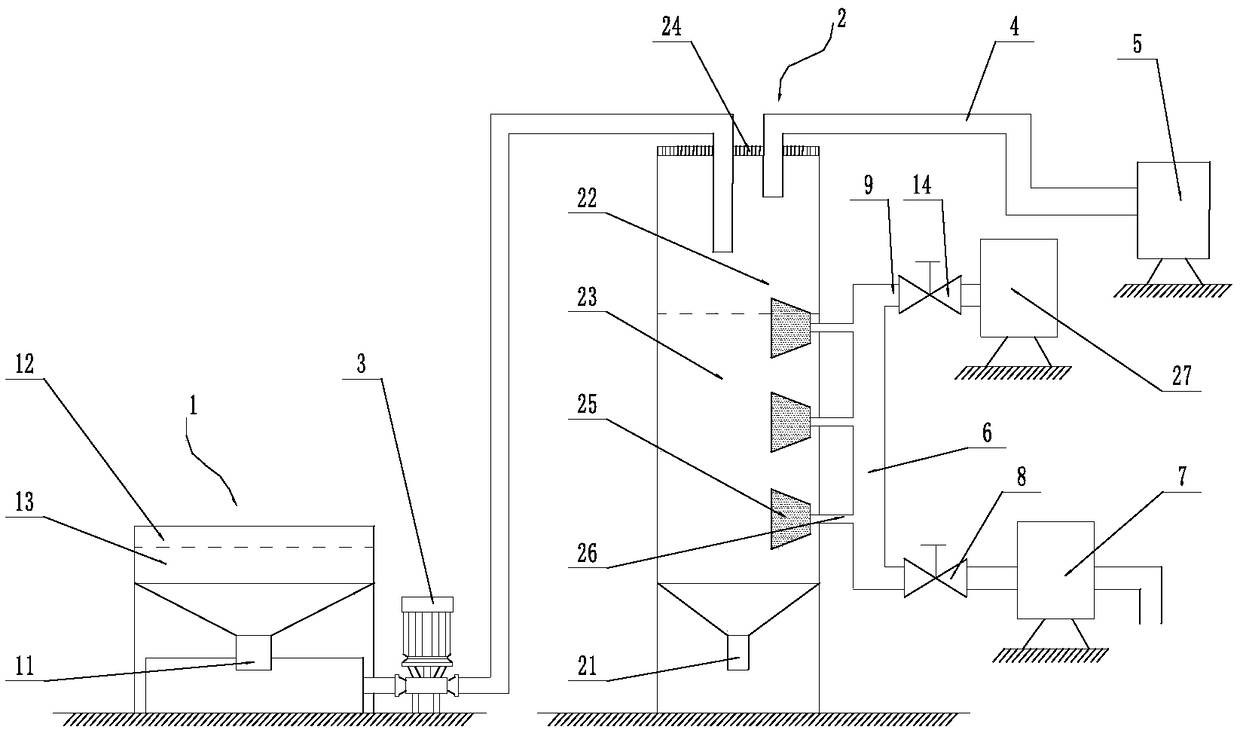

The invention discloses a fine-fraction high-concentration tailing filling and thickening device which comprises a tank body part, a wind-water slurry making system, an underflow conveying system, an electric control system, a flocculating agent preparing and adding system and the like. The wind-water slurry making system comprises an annular water pipe group and an annular gas pipe group; annular water pipes of all layers of the annular water pipe group and annular air pipes of all layers of the annular air pipe group are located at different height positions and distributed in an inverted cone shape, the annular water pipes and the annular air pipes of each layer are respectively connected with a plurality of high-pressure rubber water (air) spraying pipes, valves and external water (wind) slurry making nozzles; and the annular water pipes are connected with a water supply and drainage header pipe, and the annular air pipes are connected with an air supply and exhaust header pipe. By means of the fine-fraction high-concentration tailing filling and thickening device, the material storage capacity is large, the mining and filling circulation efficiency of a mine is improved, no power part exists, fault points are few, power consumption is low, and the operation cost is low; and long-time continuous steady-state slurry discharging is achieved, the stability of technological parameters and the working efficiency of filling operation are improved, the concentration capacity of the thickening device is improved, and the continuity of filling operation of the thickening device is guaranteed.

Owner:山金重工有限公司

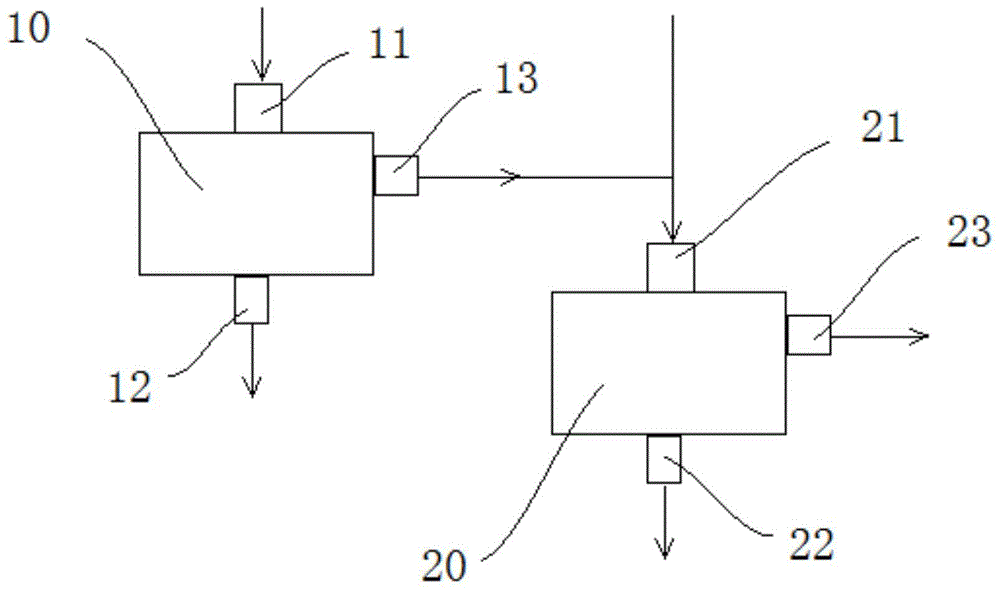

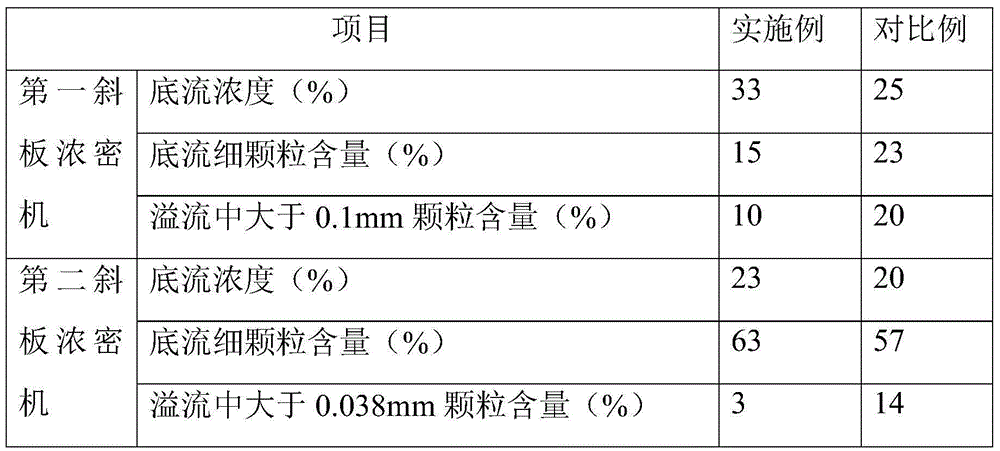

Method and system for concentrating and separating two segments of low-intensity magnetic separation iron tailings to obtain ilmenite

InactiveCN104923389AReduce workloadHigh underflow concentrationSolid separationSedimentation settling tanksTitaniumSlurry

The invention discloses a method for concentrating and separating two segments of low-intensity magnetic separation iron tailings to obtain ilmenite and a corresponding separation system. The method comprises the following steps: concentrating a first segment of low-intensity magnetic separation iron tailings by using a first sloping-plate thickener (10), and thus obtaining first overflow and first underflow as a coarse ilmenite raw material; mixing the first overflow with a second segment of low-intensity magnetic separation iron tailings, then feeding the mixture into a second sloping-plate thickener (20) for concentration, and thus obtaining second underflow as a fine ilmenite raw material and second overflow as slurry. The concentrations of the first underflow and the second underflow are increased, the particle size separation effect of the first underflow and the second underflow is better, and the phenomenon of coarse particle overflowing of the first overflow and the second overflow is decreased.

Owner:PANGANG GRP MINING

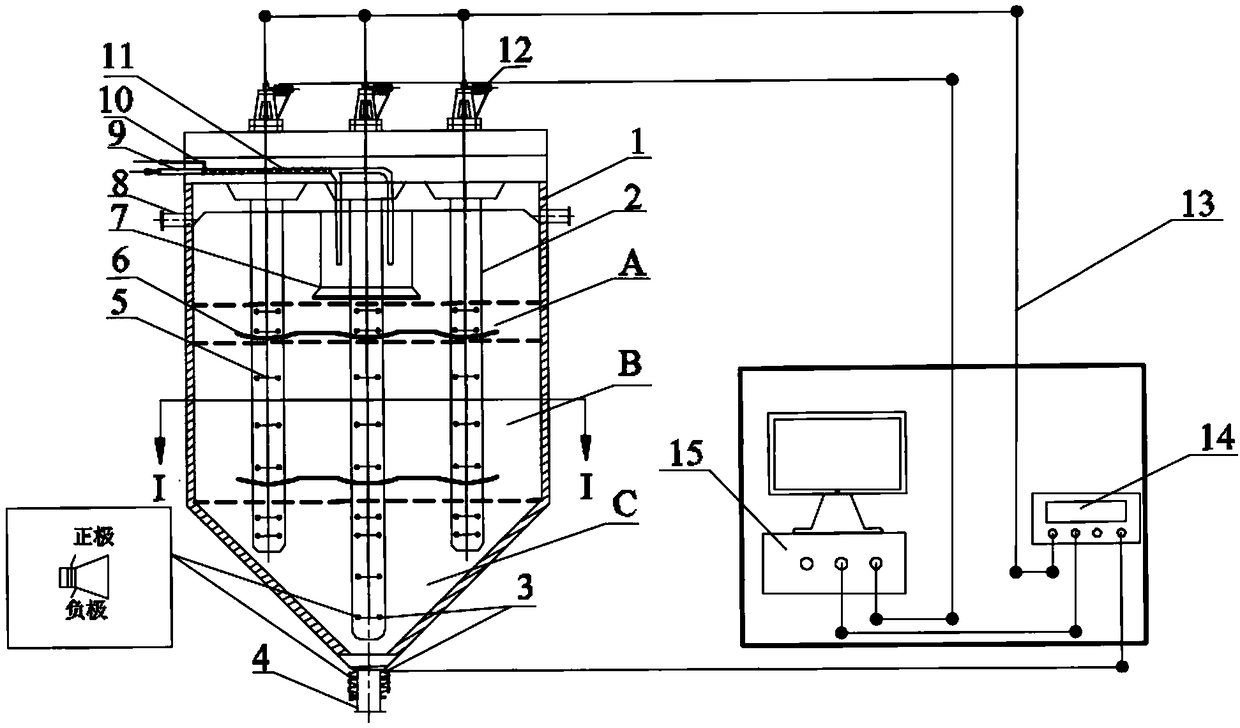

Effective slurry thick and stable discharging device and method

PendingCN109260774ASettling thickening time shortenedSingle consumption saturation point dropSettling tanks feed/dischargeSedimentation settling tanksUltrasonic generatorEngineering

The invention provides an effective slurry thick and stable discharging device and method and belongs to the technical field of flocculation settling. The device comprises a cabin body, transducer carrier tubes, sound / ultrasonic transducers, a digital controller, a rotation driving device, a mixing helix tube, a flocculant tube, an overflow pipe, a barretter, a carrier tube stabilizer and a sand outlet, wherein the transducer carrier tubes are arranged inside the cabin body, the rotation drive device is arranged at the upper end of the cabin body, and thus a rotation blind-less scanning systemis formed; the sound / ultrasonic transducers are respectively arranged at a settling section, a thickening section and a discharging section in each transducer carrier tube to form a sound field destabilization granulating active region, a sound field resonant draining thickening active region and a sound field excitation liquefying discharge active region respectively, and are connected with thesound / ultrasonic transducers through transducer connecting wires; the mixing helix tube is connected with the flocculant tube and is communicated with the barretter. The device has simple structure and process, and can realize quickly thick and stable discharging of slurry.

Owner:UNIV OF SCI & TECH BEIJING

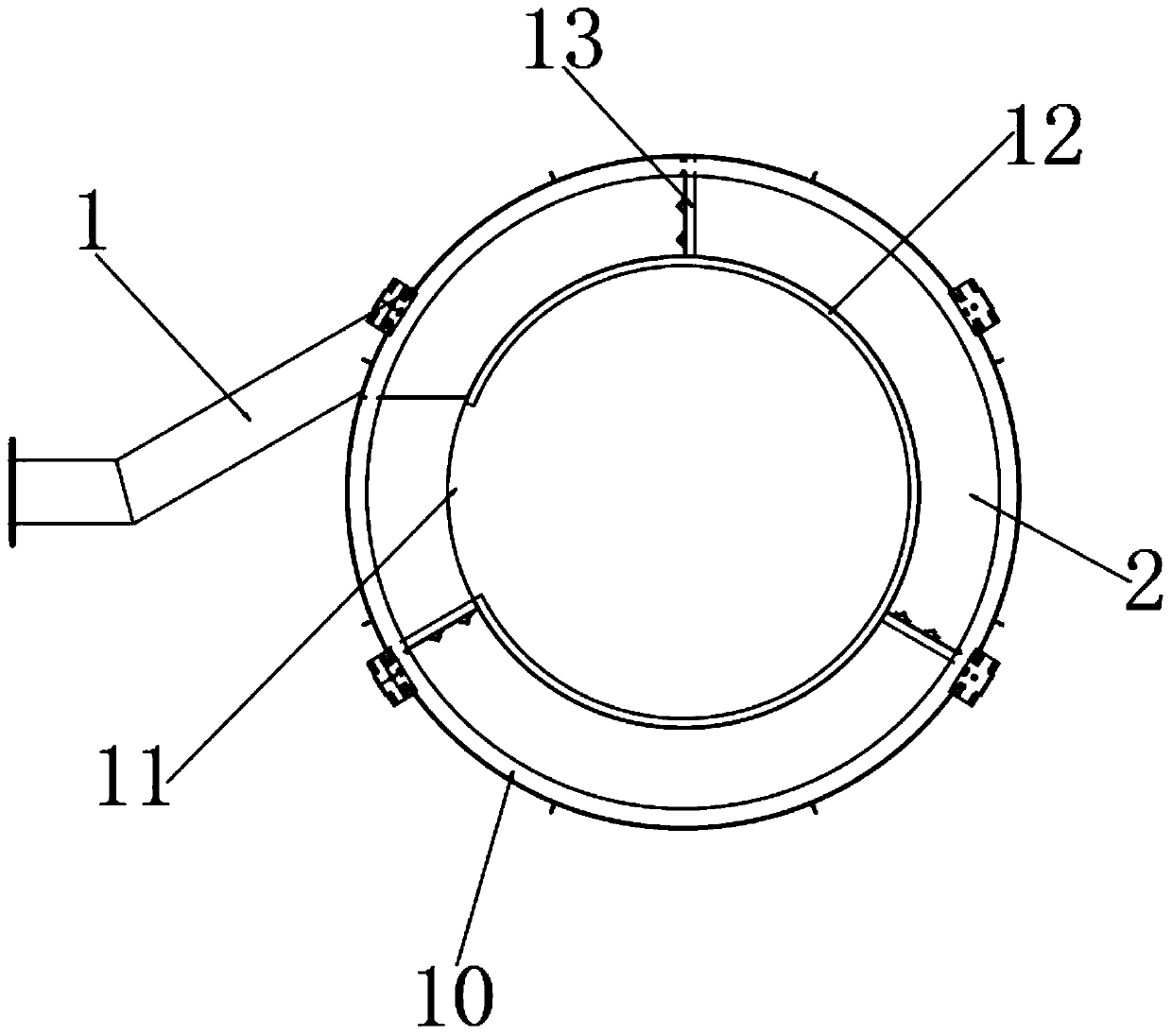

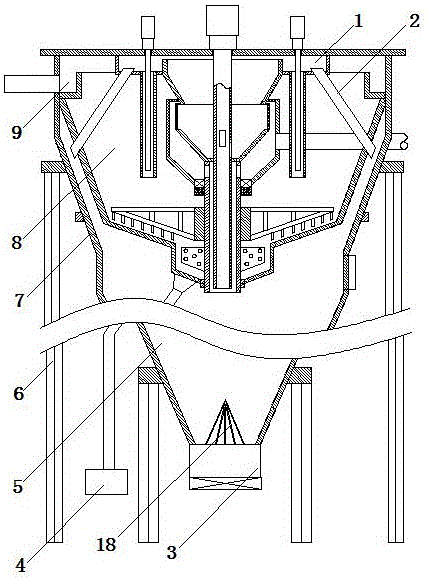

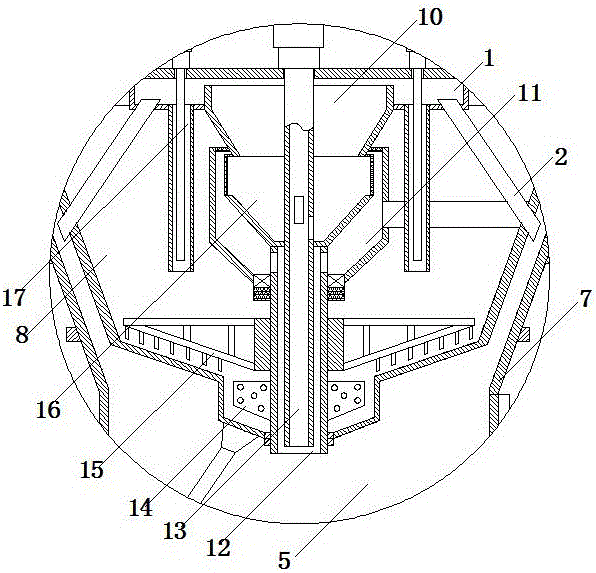

Deep-cone concentration machine used for acid waste water treatment in non-ferrous metal industry

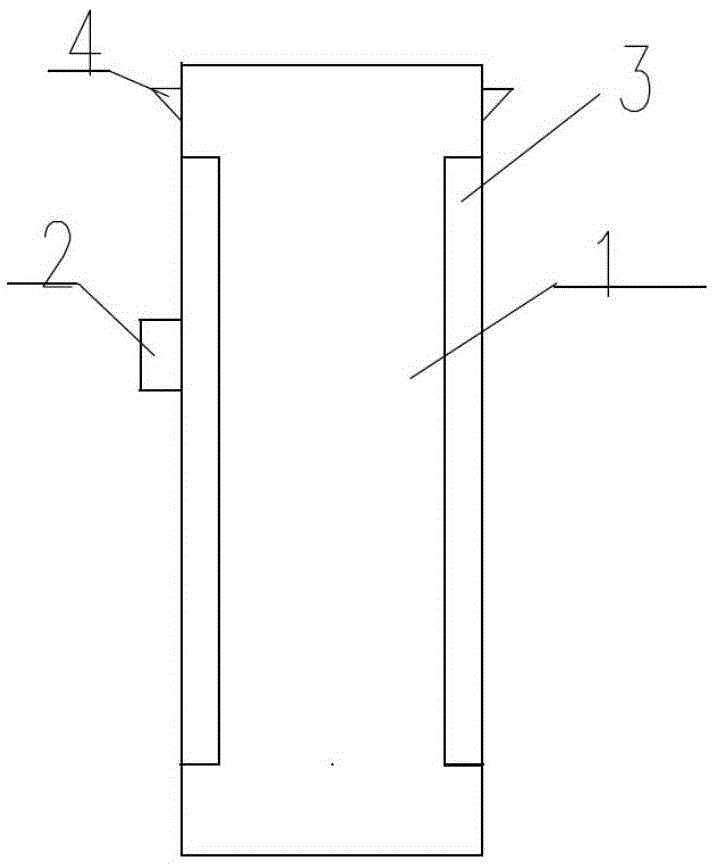

The invention provides a deep-cone concentration machine used for acid waste water treatment in non-ferrous metal industry, which comprises a tank body, a bridge frame, a material distributor and a material feeding pipe, wherein the bridge frame (8) spans across the top of the tank body (1), the upper part of the material distributor (3) is fixed on the bridge frame (8), the lower end of the material distributor (3) extends into the cone body part of the tank body (1), the material distributor (3) is in a double-layer structure provided with an outer tube and an inner rube, the upper part of the outer tube (4) of the material distributor is a column body, the lower part of the outer tube (4) is a cone body with a smaller upper part and a larger lower part, the inner tube (5) of the material distributor is divided into several parts: an upper column section (10), an upper cone section (11) with the larger upper part and the smaller lower part, a column-shaped transition section (12) and a lower cone section (13) with the smaller upper part and the larger lower part, the top of the upper column section (10) is provided with an exhaust pipe (9), and the material feeding pipe (6) enters the upper column section (10) of the inner tube of the material distributor along the tangent line. The deep-cone concentration machine has good effect and high efficiency when being used for treating the acid waste water in the non-ferrous metal industry, and in addition, the deep-cone concentration machine has no motive power consumption.

Owner:淮北重科矿山机器有限公司

Vibrating type thickener

InactiveCN108499169ASimple structureReduce energy consumptionSedimentation separationEngineeringMiddle line

The invention relate to a vibrating type thickener. The thickener comprises a thickener support, wherein a tank is mounted on the thickener support and formed by connecting an upper cylinder and a lower cone, an unloading port is formed in the lower end of the lower cone, a supernatant overflow groove and an overflow groove outlet are mounted in the upper periphery of the tank, a cross beam and acorridor are arranged at the center line part above the tank, a feeding channel is lifted below the middle of the cross beam, and the inclined included angle formed between the conical surface of thelower cone and the horizontal plane is 50-70 degrees; a motor and a long-column-shaped vibrating rod are mounted in the middle of the cross beam, the motor is fixed on the cross beam through a motor base, the long-column-shaped vibrating rod is hung on the cross beam through a damper spring and consists of a hollow column and 1-3 vibration exciters, all the vibration exciters are arranged along the axis of the hollow column, the vibration exciter at the top is in drive connection with the motor through a universal shaft, and every two adjacent vibration exciters are in drive connection througha universal shaft. The thickener has novel structural design and outstanding use effects.

Owner:周万龙

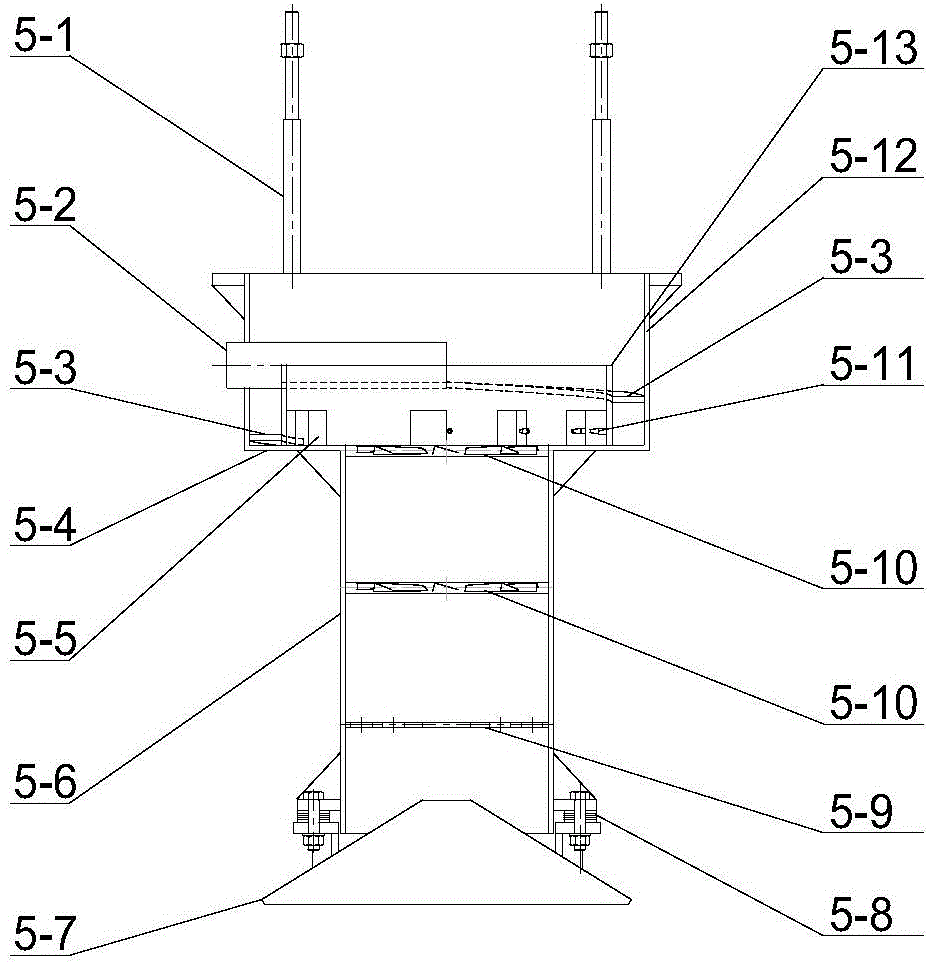

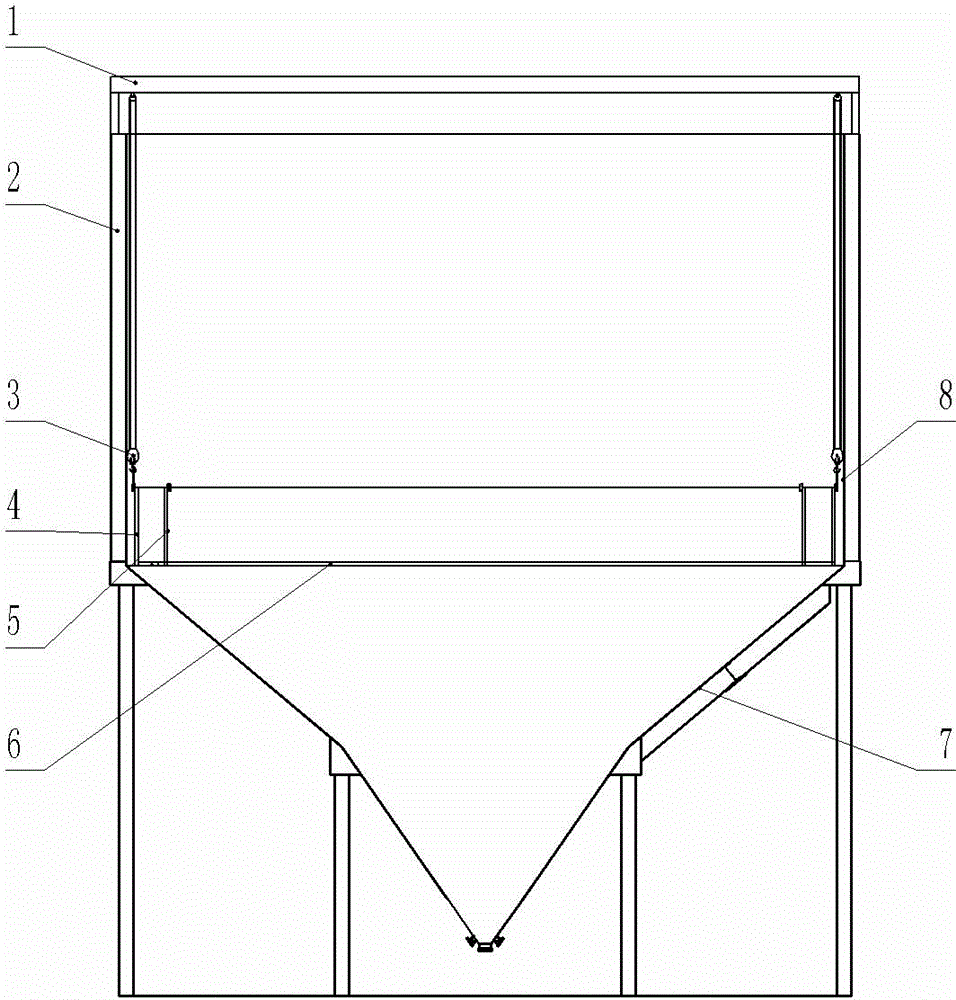

Deep-cone thickening sand bin with fluidized sand discharging device

PendingCN110152358AAccelerate the speed of flocculation and agglomerationReduce concentrationSettling tanks feed/dischargeCentrifugal force sediment separationEngineeringTailings

The invention relates to a deep-cone thickening sand bin with a fluidized sand discharging device. The deep-cone thickening sand bin with a fluidized sand discharging device comprises a sand bin body,a material feeding pipe, a flocculant inlet pipe, an overflow tank, a material feeding well, a circulation well, an annular guide cone and a stirring fluidization device, wherein the overflow tank isfixedly connected to the top of the inner wall of the sand bin body, and communicates with a supernatant return pipe, the material feeding well is disposed at the center of the top of the sand bin body, and is fixedly connected with the sand bin body, and the circulation well is disposed in the material feeding well, and is fixedly connected with the material feeding well; a material feeding zoneis formed between the material feeding well and the circulation well, the material feeding pipe communicates with the material feeding zone, and the annular guide cone is disposed directly below thecirculation well, and is fixedly connected with the inner wall of the sand bin body; and the diameter of the top of the annular guide cone is the same as the diameter of the circulation well, a material outlet is formed in the bottom of the sand bin body, and the stirring fluidization device is fixedly connected with the mouth outlet. A special flow field is formed after tailings is introduced into the sand bin, no consumption of waterpower and gas power is generated, the fluidization effect is good, and it is ensured that the mortar concentration and the thickening effect are not reduced.

Owner:金诚信矿山工程设计院有限公司

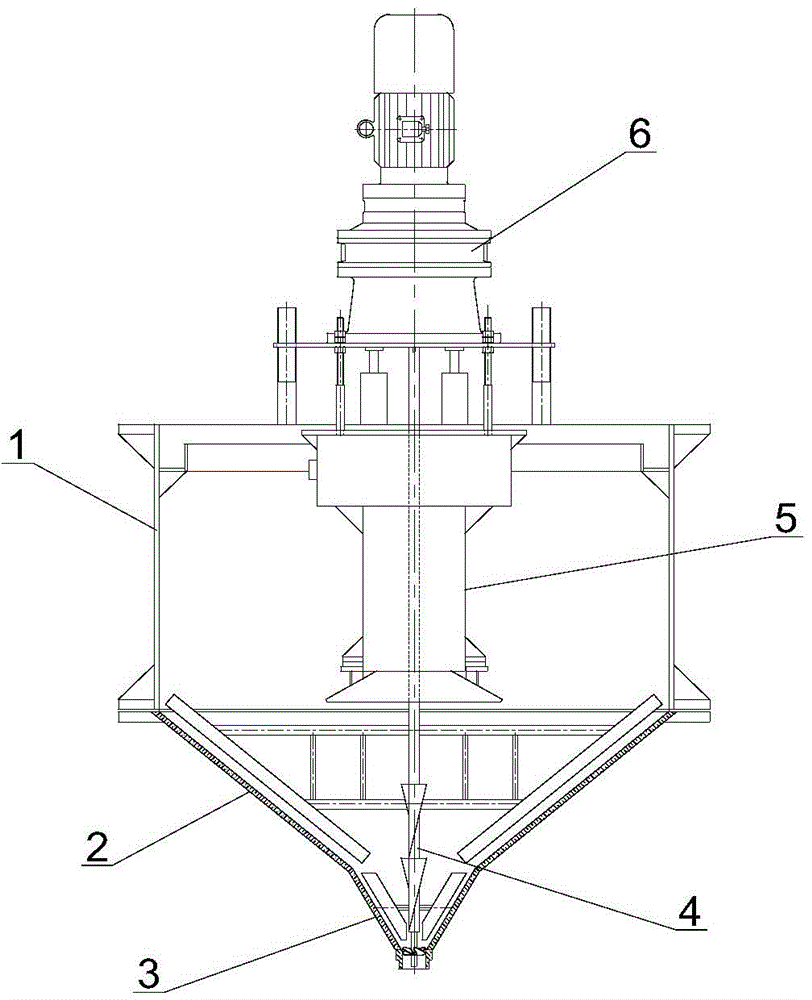

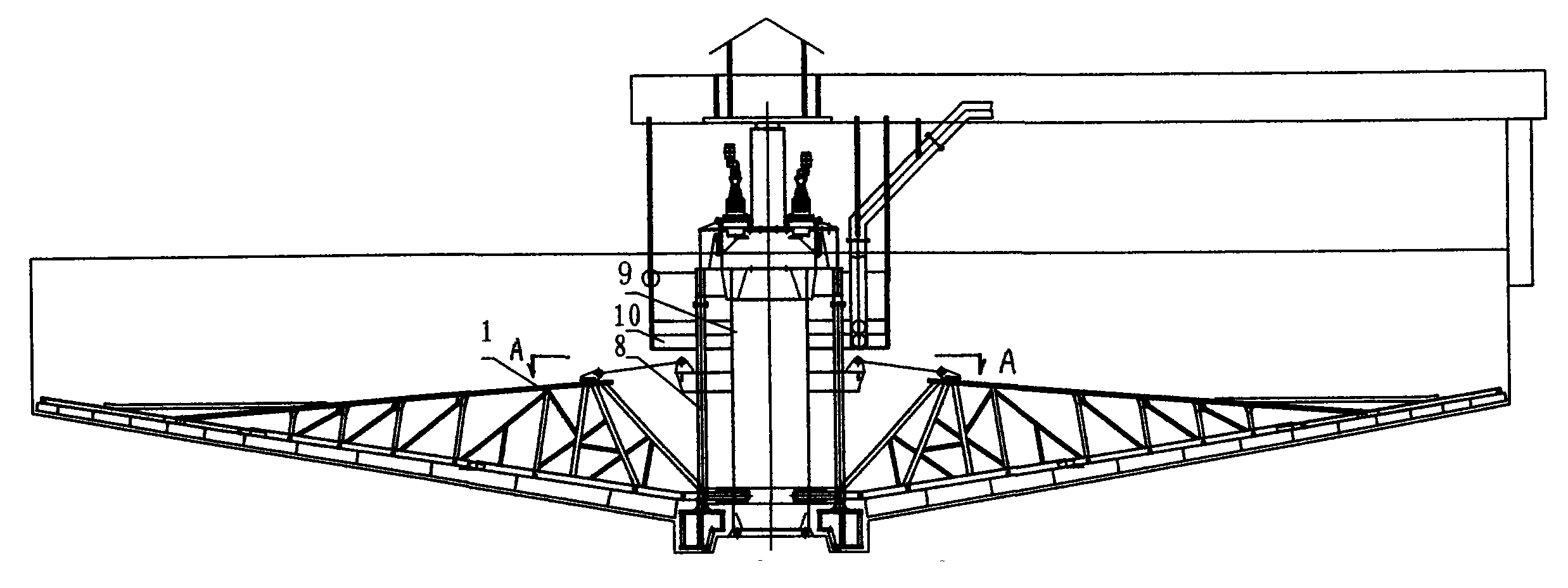

Half-deep-cone thickener

InactiveCN108479127AHigh underflow concentrationMeet the requirements for outputting high-concentration productsSettling tanks feed/dischargeSedimentation settling tanksEngineeringActual use

The invention relates to a half-deep-cone thickener. The half-deep-cone thickener is provided with a thickener support, a pool is formed in the thickener support, a beam is arranged on the upper partof the pool in the diameter direction, a feeding barrel is arranged at the center of the pool, and the pool is composed of an upper part cylinder and a lower part double cone structure, wherein the lower part double cone structure is formed by connecting an inverted large cone and an inverted small cone; a driving device is arranged on the part, located at the center of the pool, on the beam, a transmission vertical shaft which is arranged downwards is in transmission connection with the driving device, a rake device and a stirring device are arranged on the transmission vertical shaft, the rake device and the stirring device are integrated together through a flange and are driven to run by the driving device respectively and simultaneously, and the rake device is arranged in the inner space of the large cone, while the stirring device is arranged in the inner space of the small cone. The thickener is novel in structural design and obvious in use effect and has high actual use and popularization values.

Owner:周万龙

Continuous preparation system and preparation process of full-size tailings cemented filling slurry

ActiveCN105834012BImprove concentration efficiencyHigh underflow concentrationDifferential sedimentationMaterial fill-upHigh concentrationAir compression

The invention relates to a continuous preparation system and a preparation technology of whole grain grade tailing cemented filling slurry. The continuous preparation system mainly comprises a tailing slurry collecting buffer feeding device, a deep-cone thickener, a flocculating agent preparing and adding device, an underflow slag slurry pump, a cementing material storage bin, a cementing material measuring and conveying device, an air compression system, a water supply system, a filling accident pool, a stirring system and a filling slurry output pipeline. The preparation technology comprises the steps of conveying tailing slurry to the tailing slurry collecting buffer feeding device through the slag slurry pump, after reducing the pressure to 0.03 MPa through the collecting buffer feeding device and carrying out energy dissipation, feeding the tailing slurry into the deep-cone thickener, and adding a flocculating agent into the deep-cone thickener according to the principle that for per ton of tailing slurry, every 5 to 20 g of the flocculating agent is added, so as to obtain high-concentration tailing slurry with the concentration of 65 to 75%; and conveying the high-concentration tailing slurry and a cementing material into the stirring system according to the fact that the mass ratio of the high-concentration tailing slurry to the cementing material is 1 to (5 to 40), adding water, stirring, and preparing the mixture into the high-concentration whole grain grade tailing cemented filling slurry with the concentration of 65 to 75%. According to the continuous preparation system and the preparation technology, the system is simple, the automation degree during the preparation process is high, the operation is convenient, and the filling slurry can be continuously prepared.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

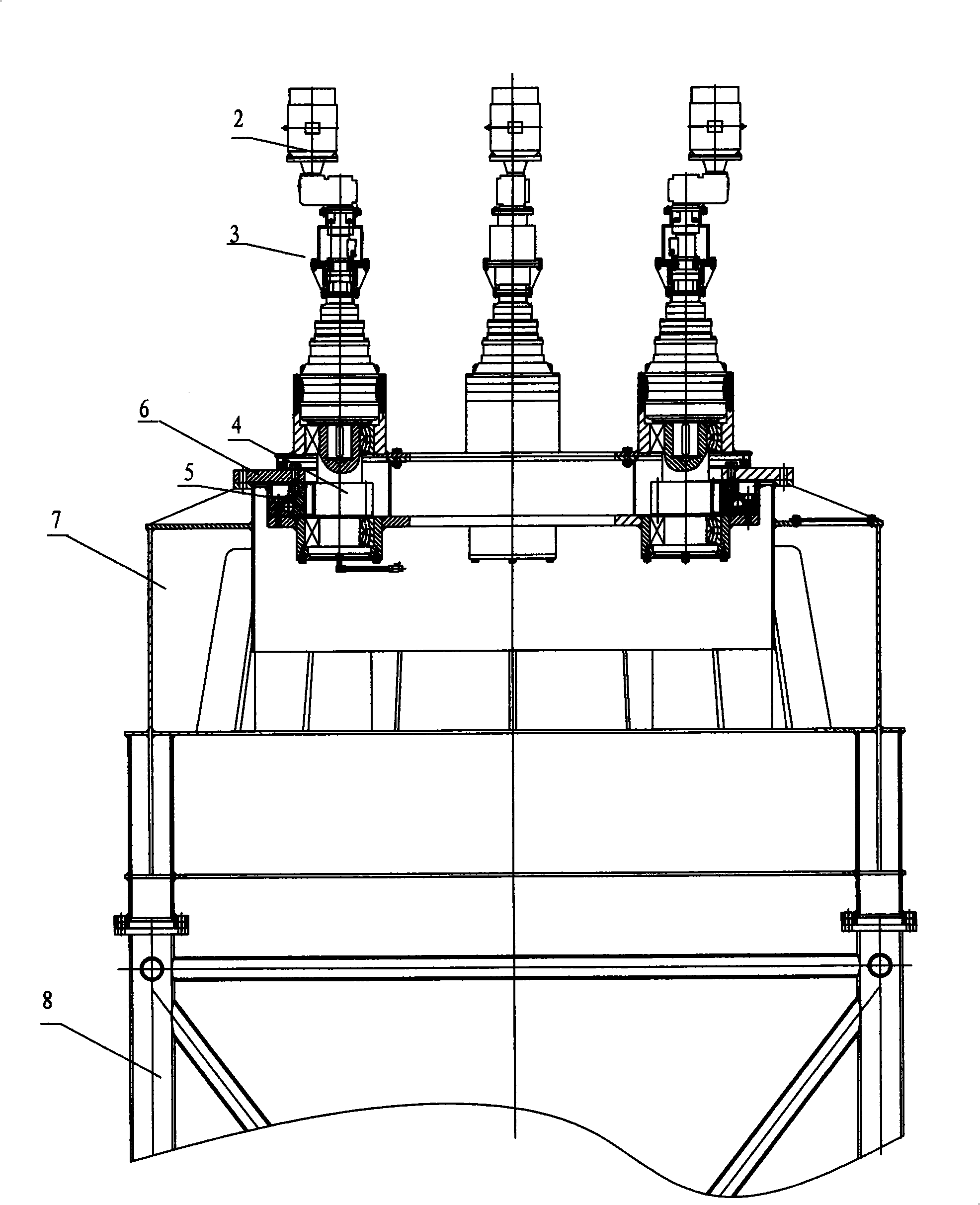

Hhigh-efficient thickener

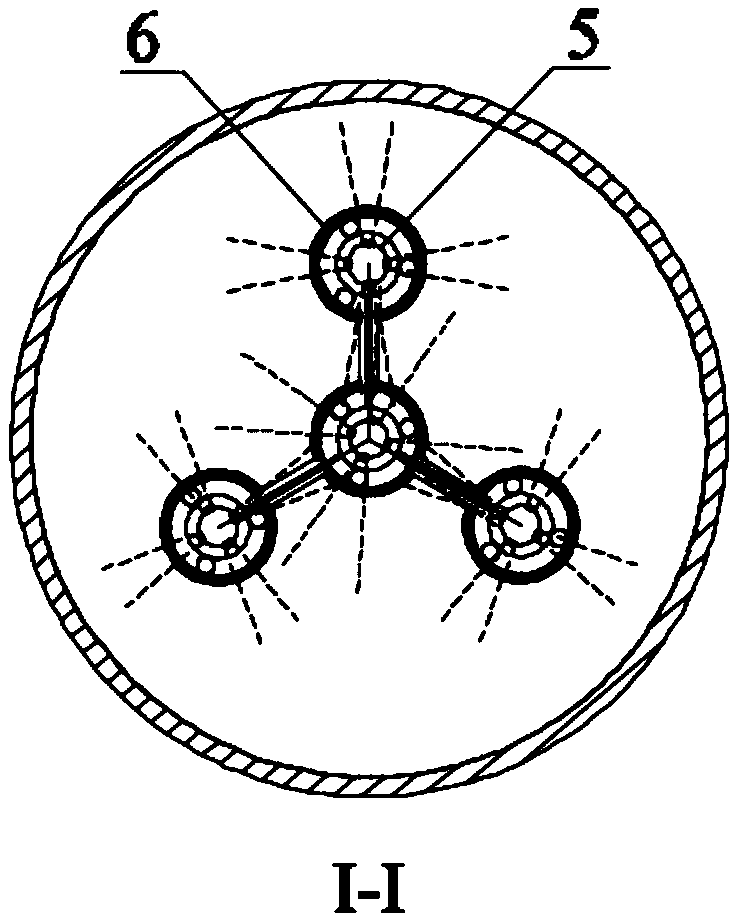

ActiveCN101530683AImprove efficiencyImprove stabilitySedimentation settling tanksGear wheelDrive motor

The invention relates to a high-efficient thickener, comprising rakes and a power source consisting of driving motors and reducing mechanisms, wherein the power source has three sets distributed in a triangle shape, the output shaft of the reducing mechanism of each power source is provided with a small gear wheel, the small gear wheel is internally joggled with a rotary supporting disk, the rotary supporting disk is connected with a driving cage top via an external rotary table, the lower end of the driving cage top is fixedly connected with a rotary main shaft, the rakes are fixed at both sides of the rotary main shaft, the section of the rotary main shaft is a square frame, and the middle part of the rotary main shaft is provided with a steel pipe support. The invention overcomes the defects that the ordinary thickener has difficultly guaranteed transmission stationarity and small application range in the existing technology, and the supporting role for the groove wall is eliminated by the central transmission mechanism by means of the above design, thereby improving the use stability of equipment, and also being capable of being applied to deep cone groove bodies, and having the advantages of simple and compact structure, high work stability, broad application range and strong reliability.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

Efficient tangential drainage feeding flow stabilizing device of central transmission thickener

ActiveCN111494996AHigh underflow concentrationEfficient mixingSedimentation regulating devicesSettling tanks feed/dischargeControl engineeringSlurry

The invention discloses an efficient tangential drainage feeding flow stabilizing device of a central transmission thickener, which comprises a tangential feeder, a bucket body, a conical distributor,a drainage plate, a distribution frame, a baffle, a servo motor and a generator; the bucket body is communicated with one end of the tangential feeder, and the inner side of one end of the tangentialfeeder is provided with the drainage plate; according to the invention, slurry passes through the tangential feeder and enters the bucket body, so that by means of the guide effect of the drainage plate, the slurry moves in the tangential direction and tangentially moves along the inner wall of the outer stop seat of the bucket body, so that the speed is gradually reduced through a plurality of baffles in sequence; after speed reduction, the materials flow to the conical distributor through the discharge port and the arc-shaped notch; slurry is uniformly distributed and enters the concentration tank and the central transmission thickener to be efficiently and tangentially guided into the feeding and flow stabilizing device; therefore, the materials can be effectively mixed and are dispersed and fed through the conical distributor to achieve the optimal effect, so that the purpose of improving the underflow concentration of the central transmission thickener is achieved on the premisethat the deposition effect is not affected.

Owner:HUAIBEI ZHONGFEN MINING MACHINERY

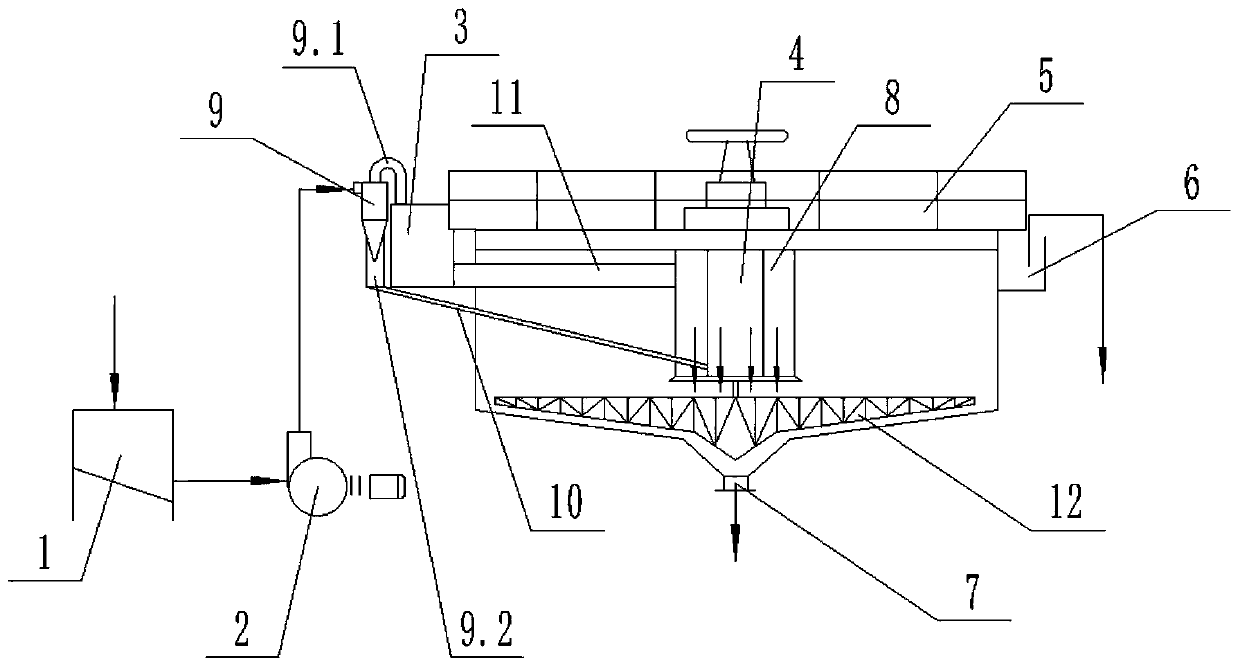

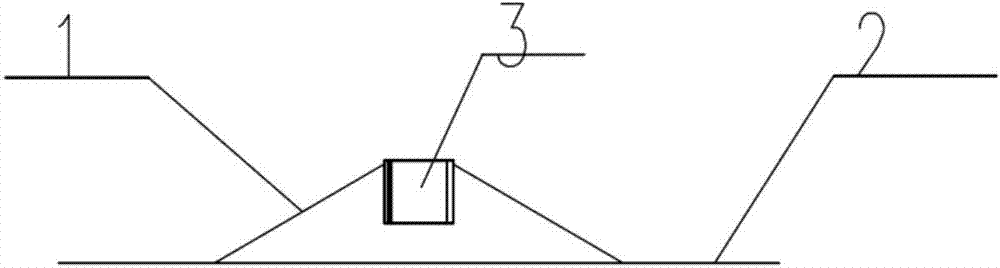

System and method for improving thickener handling capacity

ActiveCN110732165AIncrease the settlement areaIncrease throughputCentrifugal force sediment separationProcess efficiency improvementThermodynamicsProcess engineering

The invention relates to a system for improving thickener handling capacity. The system is characterized by comprising a slurry pump, a cyclone, and a thickener; a central feeding cylinder is arrangedat the upper part in the thickener; an outer feeding cylinder is arranged outside the central feeding cylinder; a feeding pipe of the cyclone is connected with the slurry pump; an overflow pipe of the cyclone is connected with a feeding port of a degassing tank, and a feeding port of the degassing tank is connected with the upper portion of the outer wall of the outer feeding cylinder through a low-concentration feeding pipe; an underflow pipe of the cyclone is connected with the bottom of the outer wall of the central feeding cylinder through a high-concentration feeding pipe. The inventionfurther relates to a method for improving thickener handling capacity. by utilizing the system. The system is simple in design and economical in cost; ore pulp is divided into low-concentration fine particles and high-concentration coarse particles for settling and reasonable flow separation; the handling capacity of the thickener is increased without changing the appearance of the thickener, theuse amount of a flocculating agent is reduced, meanwhile, the underflow concentration of the thickener is increased, and a promising application prospect is achieved.

Owner:烟台鑫矿服工程管理集团有限公司

retractable hydrocyclone

InactiveCN105797877BEasy to handleImprove separation efficiencyReversed direction vortexSewage treatmentPetroleum

The invention discloses a retractable hydrocyclone and belongs to multi-phase flow separation equipment. The retractable hydrocyclone comprises a feeding hole, an overflow pipe, a swirling chamber, a separation zone and an underflow pipe, wherein the separation zone is a main separation working part and is characterized by being formed by nested connection of a plurality of column segments with different internal diameters. The length of the separation zone of the hydrocyclone has certain influence on the separation precision. The device can adjust the length of the separation zone of the hydrocyclone according to the separation precision of materials, namely when the concentration requirement of a to-be-separated substance changes, the length of the column segments of the separation zone of the hydrocyclone can be extended or shrunk directly according to requirements to achieve use requirements, without re-designing a new hydrocyclone. The hydrocyclone is increased in handling capacity, improved in separation efficiency, increased in underflow concentration, convenient to adjust and low in cost, and is applicable to separation operations of industries including petroleum, chemical engineering, coal dressing, food, sewage treatment and the like, especially applicable to occasions with requirements for obtaining multi-phase flow substances with different concentrations.

Owner:SHIHEZI UNIVERSITY

High-efficiency, steady-flow and uniform distribution device for central drive thickener

ActiveCN111494995BShorten speedReduce kinetic energySedimentation regulating devicesSettling tanks feed/dischargeProcess engineeringSlurry

Owner:HUAIBEI ZHONGFEN MINING MACHINERY

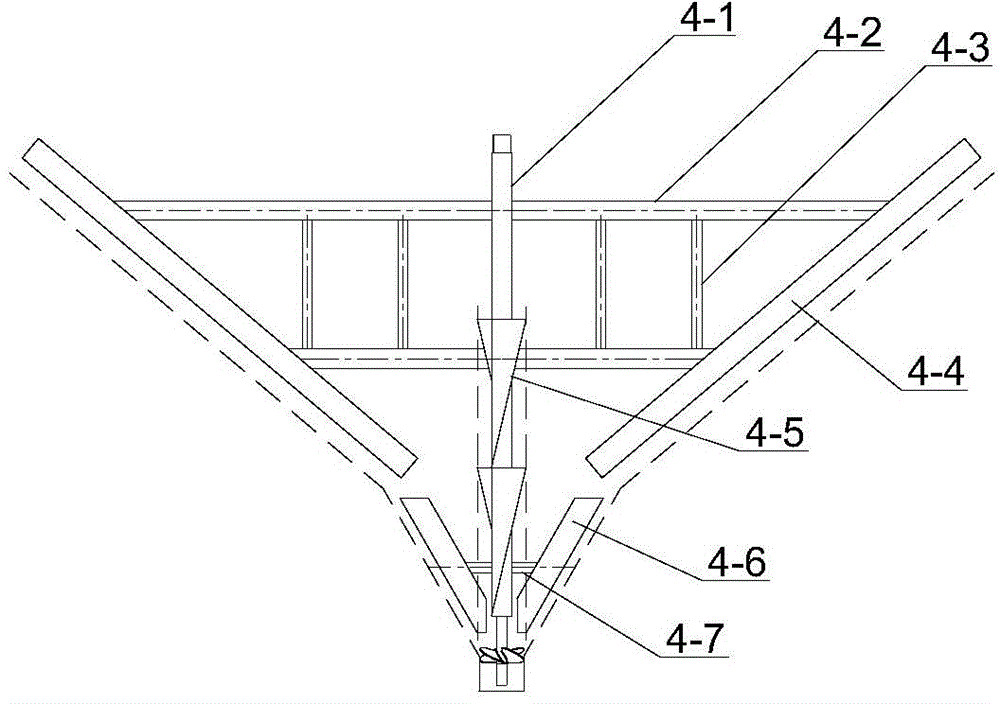

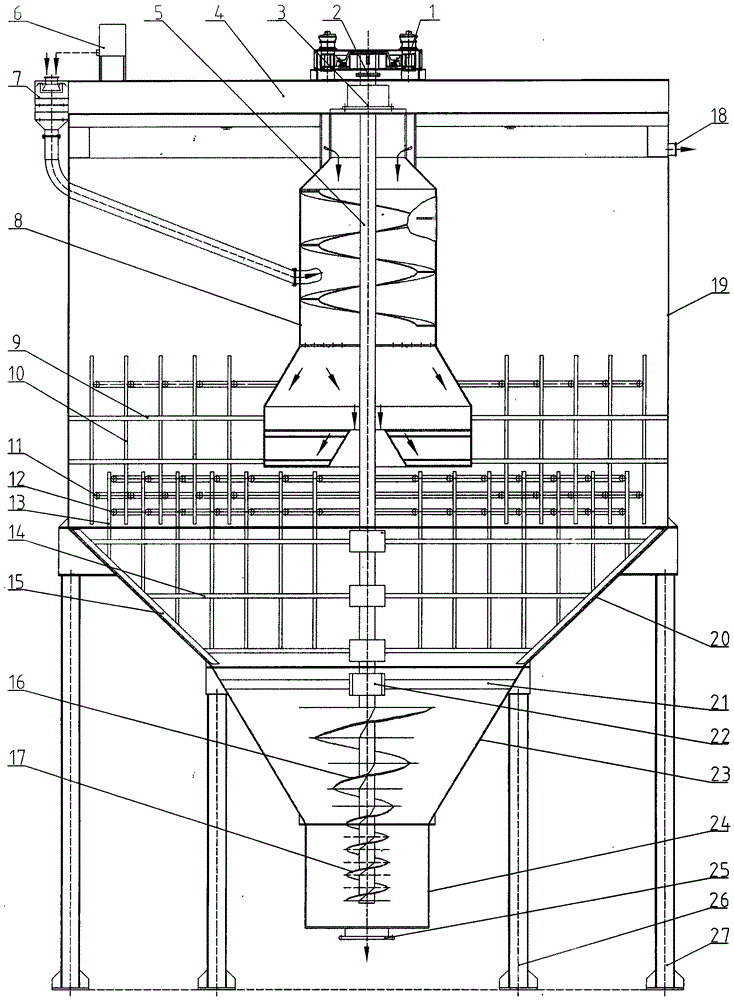

High-efficiency classification thickener for tailings slurry

InactiveCN104998441BReduce exposureEasy to separateSettling tanks feed/dischargeSedimentation settling tanksDrive shaftTailings

The invention discloses an efficient classification and thickening machine for tailing slurry. The efficient classification and thickening machine comprises a supporting frame, a hopper, a material classifying device, a stirring device, a backflow pipe, an overflow tank and an unloading device. The hopper, the material classifying device, the stirring device, the backflow pipe, the overflow tank and the unloading device are arranged on the supporting frame. The hopper is internally divided into a classifying cavity and a material storing cavity through a partition plate. The material classifying device is arranged in the classifying cavity. The material classifying device comprises a primary material chamber, a secondary material chamber, a fall pressure chamber and a circulation plate. The stirring device comprises a first rotating shaft, a second rotating shaft and a slurry pump. The first rotating shaft and the second rotating shaft are hollow and are each in a cylindrical shape. One end of the first rotating shaft is connected with a motor in a transmission mode, and the other end of the first rotating shaft extends into the material storing cavity sequentially through the fall pressure chamber, the secondary material chamber and the primary material chamber. The first rotating shaft is sleeved with the second rotating shaft. The top end of the backflow pipe is arranged above the circulation plate and is lower than the top of the fall pressure chamber. The unloading device is arranged at the bottom of the material storing cavity and comprises a feed cylinder, a material guide cylinder, a spiral bevel gear and a transmission shaft.

Owner:郴州德瑞福机械设备有限公司

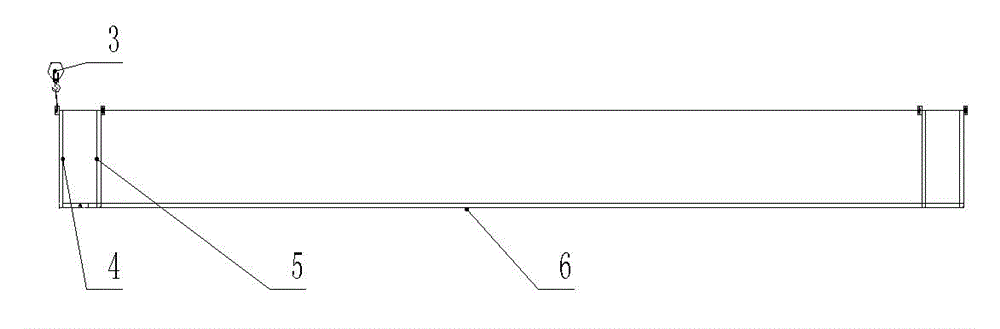

Feeding guide plate of novel thickener

InactiveCN104324532AReduce usageReduce manufacturing costSettling tanks feed/dischargeEngineeringDehydration

The invention relates to a feeding guide plate of a novel thickener. The feeding guide plate comprises an umbrella-shaped cylinder, a circular ring and a fixed shaft sleeve; the feeding umbrella-shaped cylinder of the novel thickener is circular truncated cone-shaped and is located at the position which is under a central feeding cylinder of the thickener and is away from the bottom end of the central feeding cylinder by 300-400mm; the umbrella-shaped cylinder is fixed together with a main shaft rake of the thickener by the fixed shaft sleeve, so that ore pulp goes into the thickener in the horizontal direction and flows to the four directions dispersively, and therefore, a stable sedimentation layer can be formed, the efficiency of the thickener is improved, and meanwhile, the cutting-out of the fed ores and the bottom flow is also prevented, the concentration of the bottom flow is increased and the dehydration effect is improved.

Owner:YANTAI XINHAI MINING MACHINERY

High-efficient thickener

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

Spraying method of deep cone thickener

InactiveCN104646259AImprove liquidityEffective antisepticPretreated surfacesLifting framesEngineeringMechanical engineering

The invention discloses a spraying method of a deep cone thickener. A barrel spraying special tool is used to spray the inner wall of a cylinder part. The spraying method of the deep cone thickener comprises the following operating steps of falling an elevating scaffold to the bottom part of the cylinder part, and spraying high wear-resisting anticorrosion polyurea on the inner wall of the cylinder part through an operator standing on an annular aisle; lifting the elevating scaffold to a spraying height, and spraying the high wear-resisting anticorrosion polyurea on the inner wall of the cylinder part through the spraying tool used by an operator standing on an annular aisle until the inner wall of the cylinder part is fully sprayed with a wear-resisting anticorrosion polyurea coating; repeating the steps until the thickness of the wear-resisting anticorrosion polyurea coating of the inner wall of the cylinder part is 2.5mm-3.5mm. Compared with the prior art, the spraying method of the deep cone thickener can solve the problems that the existing deep cone thickener is short in service life and high in cost.

Owner:广西华锡集团股份有限公司

A feed well device of a concentrator

ActiveCN104208923BExtension of timeRealize automatic dilutionSettling tanks feed/dischargeHorizontal distributionEngineering

The invention discloses a feeding well device for a centre drive thickener. A feeding well wall is cylindrical; an annular horizontal outer edge is formed in the lower edge of the feeding well wall; a feeding pipe is connected with the outer side of the feeding well wall; a feeding pipe orifice is positioned below the overflow liquid level of the thickener; an overflow tank is arranged below the feeding pipe orifice; the overflow tank is horizontally distributed in a circle along the inner side of the feeding well wall, and the edges of the overflow tank are equal in heights; a conical guide plate is arranged at a lower outlet of the feeding well wall, the edge of the conical guide plate is connected with the outer edge of the lower edge of the feeding well wall through guide vanes, and the guide vanes are uniformly distributed; a flocculating agent addition tube is arranged on the inner side of the overflow tank; and dilution openings are uniformly formed in the feeding well wall. According to the feeding well, any extra power is not needed, and the energy consumption is reduced; ore pulp is uniformly distributed in the feeding well and flows out of the feeding well from all directions, and the utilization rate of settling area is improved; and moreover, the ore pulp flows out of channels between the guide vanes which form an included angle of 40-50 degrees with the radial direction, so that a settled layer in the thickener is prevented from being impacted, the underflow concentration is high, and the feeding well device is convenient to popularize.

Owner:TIANJIN UNIV

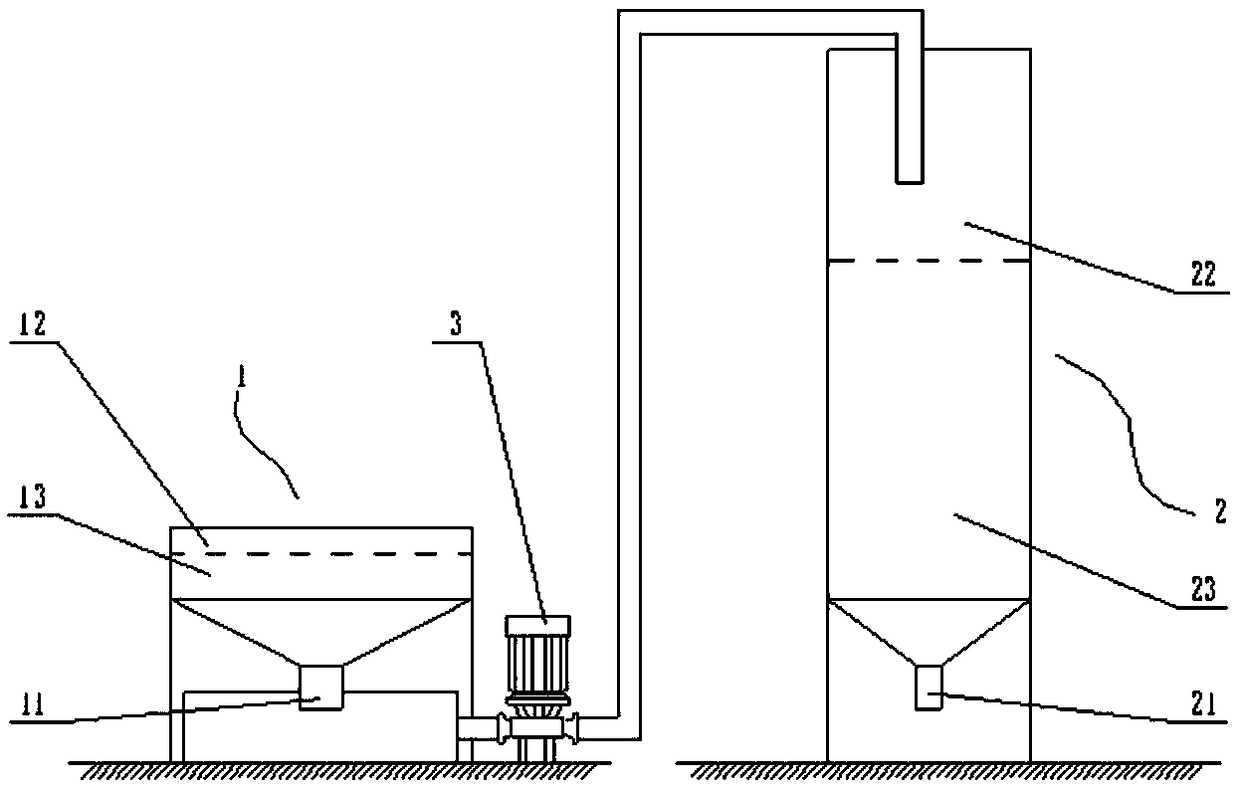

A high-efficiency settling device

ActiveCN106139651BHigh underflow concentrationReduce construction costsFiltration circuitsSedimentation settling tanksEngineeringSlurry flow

The invention belongs to the field of solid-liquid separation, and concretely discloses an efficient settling device. The efficient settling device comprises a primary settling groove and a secondary settling groove; the height H1 of the primary settling groove is smaller than or equal to 5.0m; the ratio (H2 / D2) of the height H1 to the diameter D1 is smaller than or equal to 0.3; the height H2 of the second settling groove is greater than or equal to 5.0m; the ratio (H2 / D2) of the height H2 to the diameter D2 is greater than or equal to 5; the ratio(D1 / D2) of the diameter D1 of the primary settling groove to the diameter D2 of the secondary settling groove is greater than or equal to 5; a feeding pump is arranged between the primary settling groove and the secondary setting groove; the feeding pump is used for pumping slurry flowing out from a primary bottom flow slurry outlet into the secondary setting groove. The efficient settling device provided by the invention has the advantages that the manufacturing cost is low; the construction difficulty is small; the stability after installation is high; the underflow concentration is high; the setting effect is good.

Owner:国家电投集团山西铝业有限公司

A thickener center feeding barrel

ActiveCN104353268BReduce usageReduce manufacturing costSettling tanks feed/dischargeSlurryEngineering

Owner:YANTAI XINHAI MINING MACHINERY

A high-efficiency tangentially diverted inflow stabilization device for a center-driven thickener

ActiveCN111494996BHigh underflow concentrationEfficient mixingSedimentation regulating devicesSettling tanks feed/dischargeEngineeringSlurry

The invention discloses a high-efficiency tangentially diverted and stabilized flow device for a central drive concentrator, comprising a tangential feeder, a barrel body, a conical distributor, a diversion plate, a cloth rack, a baffle, a servo motor and a generator , the barrel is electrically connected to one end of the tangential feeder, and a drain plate is installed inside one end of the tangential feeder; in the present invention, the slurry enters the barrel through the tangential feeder, and passes through the drain plate The guiding function makes the slurry move tangentially along the inner wall of the outer block seat of the barrel, and gradually slow down through several baffles in turn, and then flow to the conical distributor through the discharge port and the arc-shaped gap after the speed is reduced , the slurry is evenly distributed, and enters the thickening tank. The central drive thickener efficiently tangentially diverts the incoming material and stabilizes the flow device, which can effectively mix the material, and through the cone distributor, it can disperse the material to achieve the best effect, so that in Under the premise of not affecting the deposition effect, the purpose of increasing the underflow concentration of the central drive thickener is achieved.

Owner:HUAIBEI ZHONGFEN MINING MACHINERY

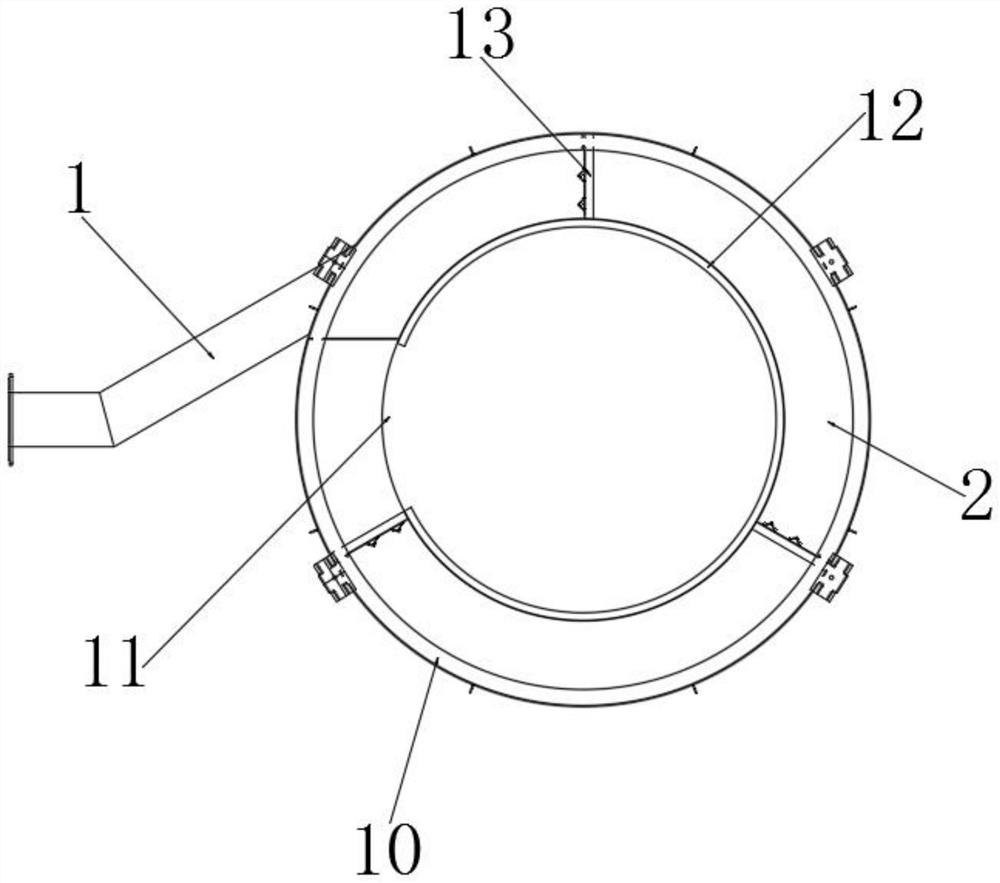

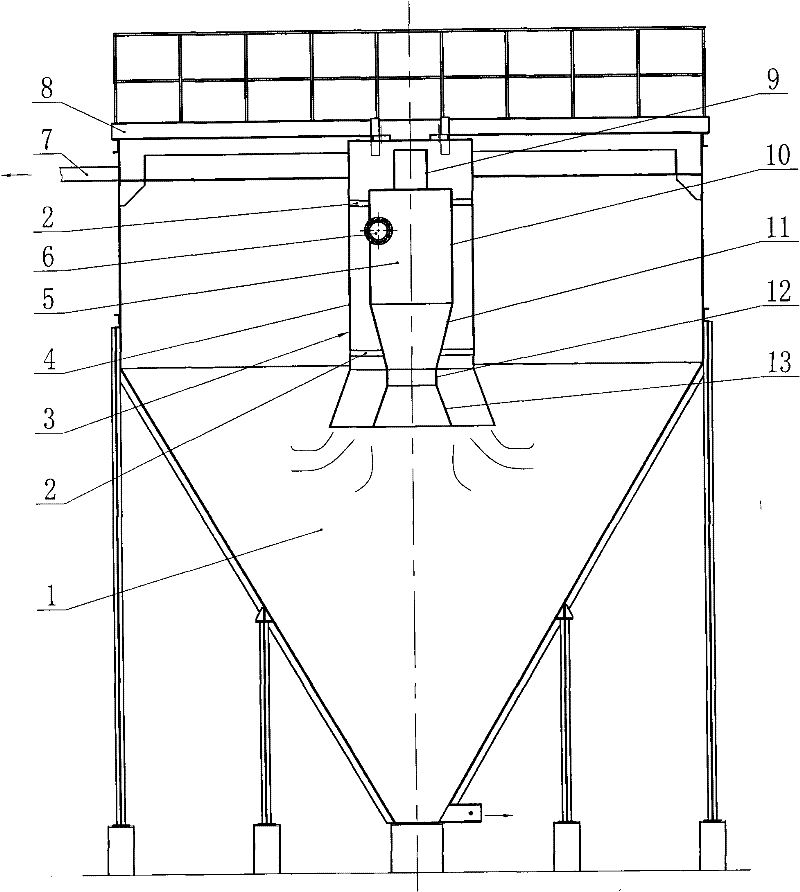

Deep-cone concentration machine used for acid waste water treatment in non-ferrous metal industry

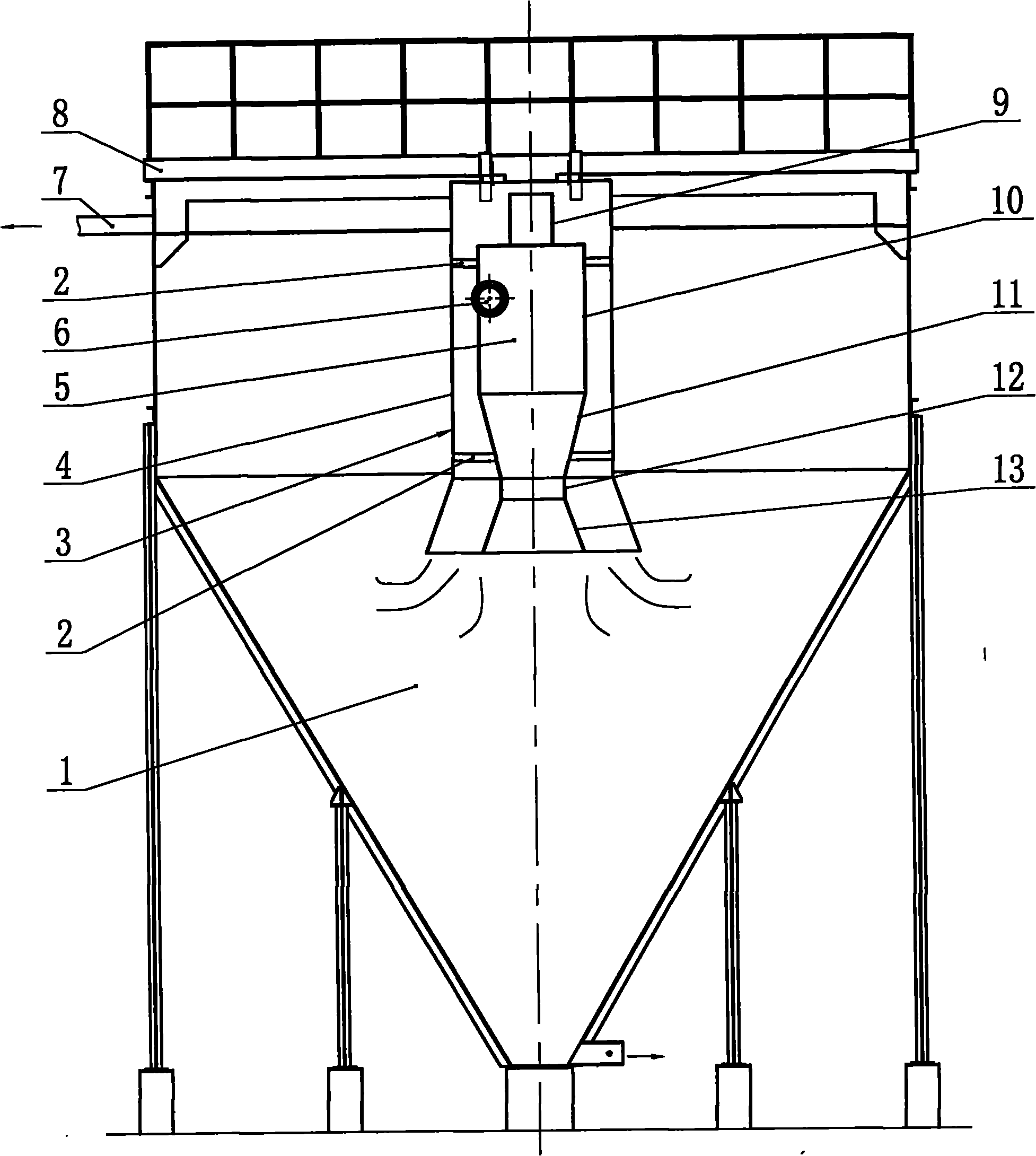

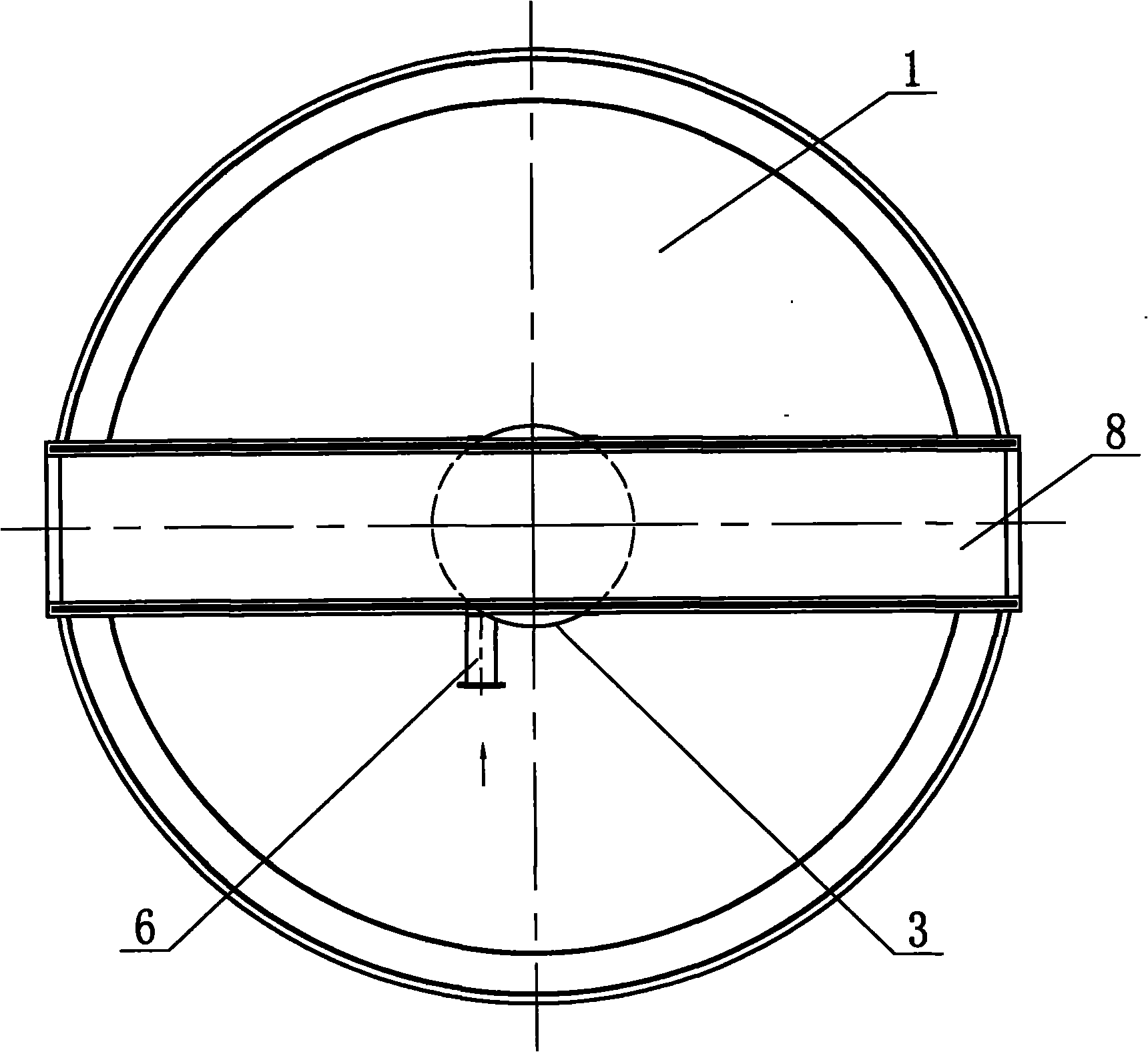

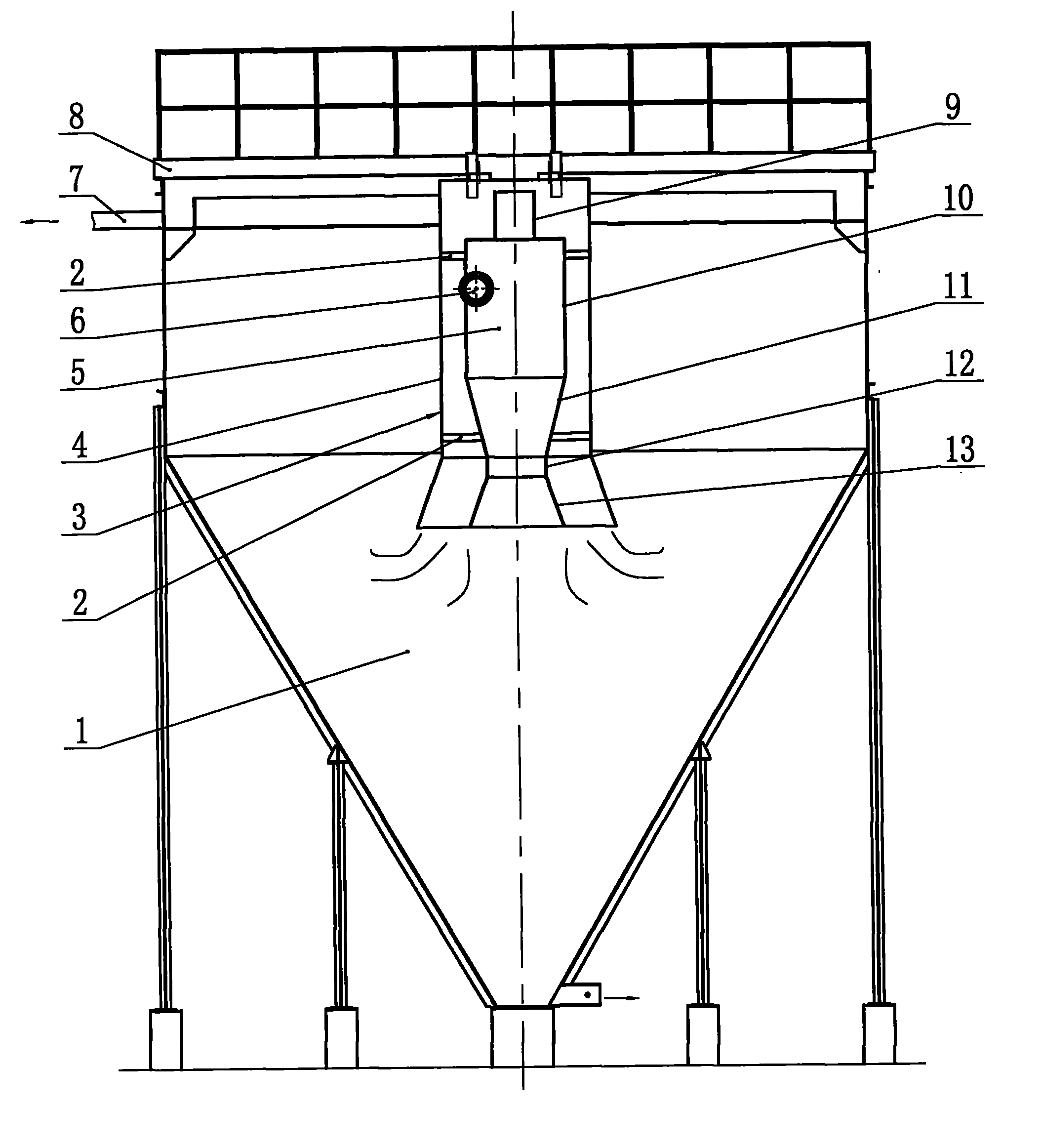

InactiveCN101791496BReduce consumptionLow solidsSedimentation settling tanksNonferrous metalEngineering

The invention provides a deep-cone concentration machine used for acid waste water treatment in non-ferrous metal industry, which comprises a tank body, a bridge frame, a material distributor and a material feeding pipe, wherein the top of the tank body (1) is a cylinder, and the bottom thereof is a cone, the bridge frame (8) spans across the top of the tank body (1), the upper part of the material distributor (3) is fixed on the bridge frame (8), the lower end of the material distributor (3) extends into the cone body part of the tank body (1), the material distributor (3) is in a double-layer structure provided with an outer tube and an inner rube, the upper part of the outer tube (4) of the material distributor is a column body, the lower part of the outer tube (4) is a cone body with a smaller upper part and a larger lower part, the inner tube (5) of the material distributor is divided into several parts: an upper column section (10), an upper cone section (11) with the larger upper part and the smaller lower part, a column-shaped transition section (12) and a lower cone section (13) with the smaller upper part and the larger lower part, the top of the upper column section (10) is provided with an exhaust pipe (9), and the material feeding pipe (6) enters the upper column section (10) of the inner tube of the material distributor along the tangent line. The deep-cone concentration machine has good effect and high efficiency when being used for treating the acid waste water in the non-ferrous metal industry, and in addition, the deep-cone concentration machine has no motive power consumption.

Owner:淮北重科矿山机器有限公司

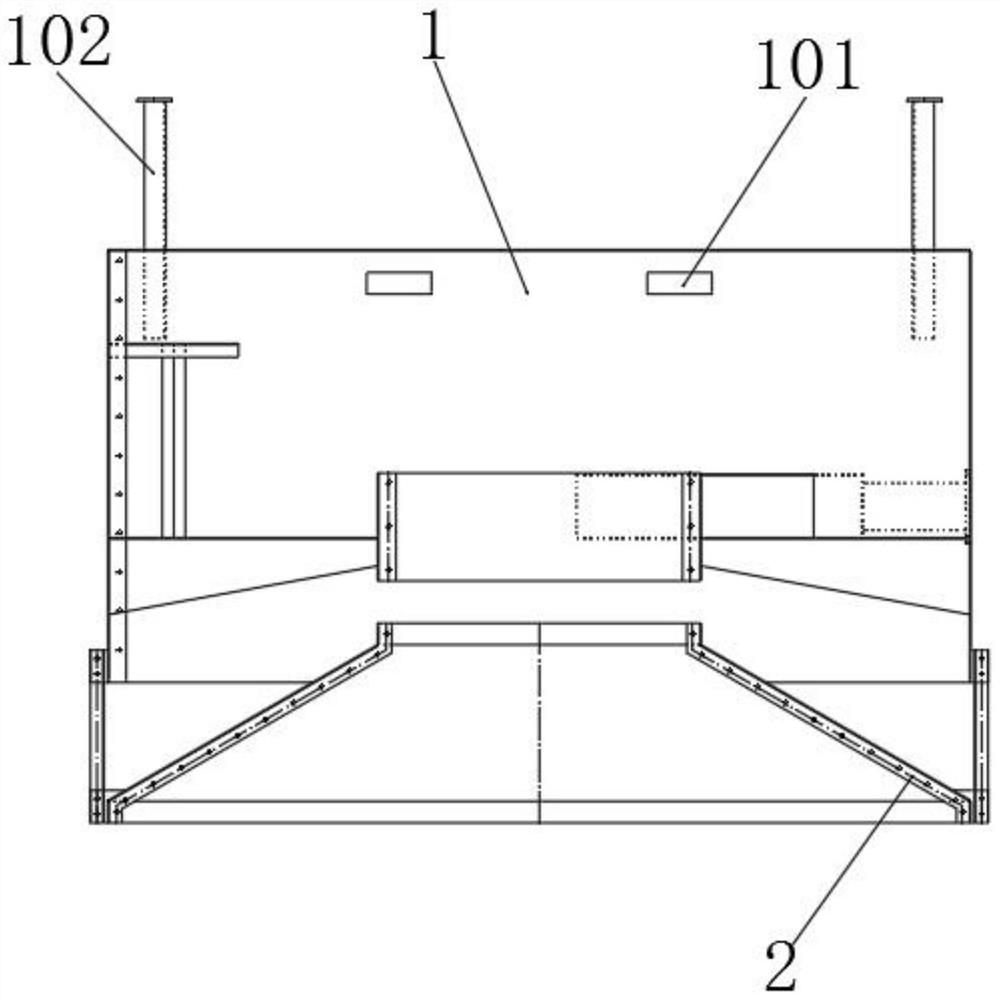

A paste concentrator for a steel structure pool

ActiveCN104784981BShorten the construction periodLess investmentSedimentation settling tanksHydraulic motorHigh concentration

The invention relates to a paste thickener of a steel-structure tank body, which is suitable for concentration equipment for concentrating high-concentration high-density ore pulp of metal ore and obtaining higher underflow concentration, and belongs to the field of solid-liquid separation equipment. The paste thickener of the steel-structure tank body, which is provided by the invention, is provided with a hydraulic-motor driving device, a coupler, an upper bearing pedestal, a bridge rack, a transmission shaft, a flocculant dosing device, a static mixer, a central mixing well, fixed horizontal rods, fixed vertical rods, fixed reinforcing rings, rotary reinforcing rings, rotary vertical rods, rotary horizontal rods, sludge scrapers, a tapered helical blade, a lower helical blade, an overflow pipe, an upper cylinder, an upper taper cylinder, a lower bracket, a lower bearing pedestal, a lower taper cylinder, a lower cylinder, a discharging pipe, inner support legs and outer support legs. The paste thickener disclosed by the invention has the benefits that the steel-structure tank body is adopted, the period of civil construction is shortened, the investment is reduced, and the effects can be quickly generated; the stirring effect is good, and the underflow concentration is high.

Owner:SHANDONG LAIWU COAL MINING MACHINERY

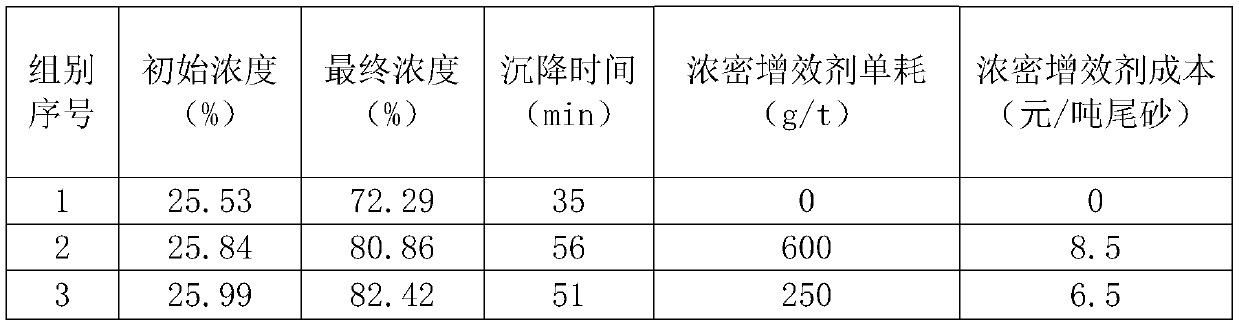

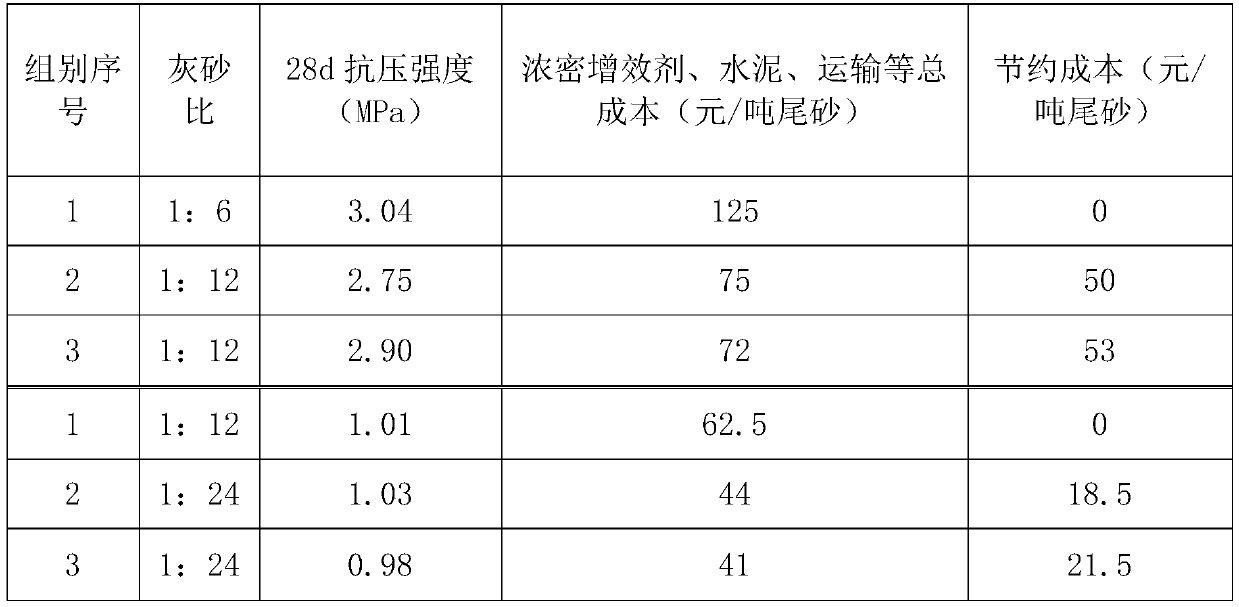

Composition for improving settling effect of solid particles, dense synergist comprising the same, preparation method and application

ActiveCN109821278BImprove liquidityHigh underflow concentrationSedimentation separationPolyaspartic acidPolyethylene glycol

The invention relates to the technical field of mine filling, and specifically discloses a composition for improving the setting effect of solid particles, a thickening synergist containing the same,and a preparation method and applications thereof. The composition comprises following components in parts by weight: 16 to 38 parts of complexing component, 14 to 27 parts of air entraining component, 24 to 51 parts of dispersing component, and 9 to 22 parts of linear ionic polymer component; the dispersing component is composed of maleic acid-acrylic acid copolymer sodium salt, polyethylene glycol monomethyl ether, and sodium of polyaspartic acid according to a mass ratio of (2-4): (1-2): 1; and the mass ratio of the dispersing component to the linear ionic polymer component is 2-3:1. The provided composition can destroy the floccules structure to release free water and increase the solid concentration after settlement; and can be used to increase the concentration of underflow of a thickening machine. All components are mixed and dissolved to prepare a solution with a concentration of 10 to 20%; the preparation method is simple, and the composition is convenient to use.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com