Deep-cone thickening sand bin with fluidized sand discharging device

A deep cone thickening and chemical device technology, which is applied to the feeding/discharging device of the settling tank, chemical instruments and methods, settling tank, etc. , interfere with tailings thickening rate and other issues, to achieve the effect of maintenance-free power consumption, wide applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

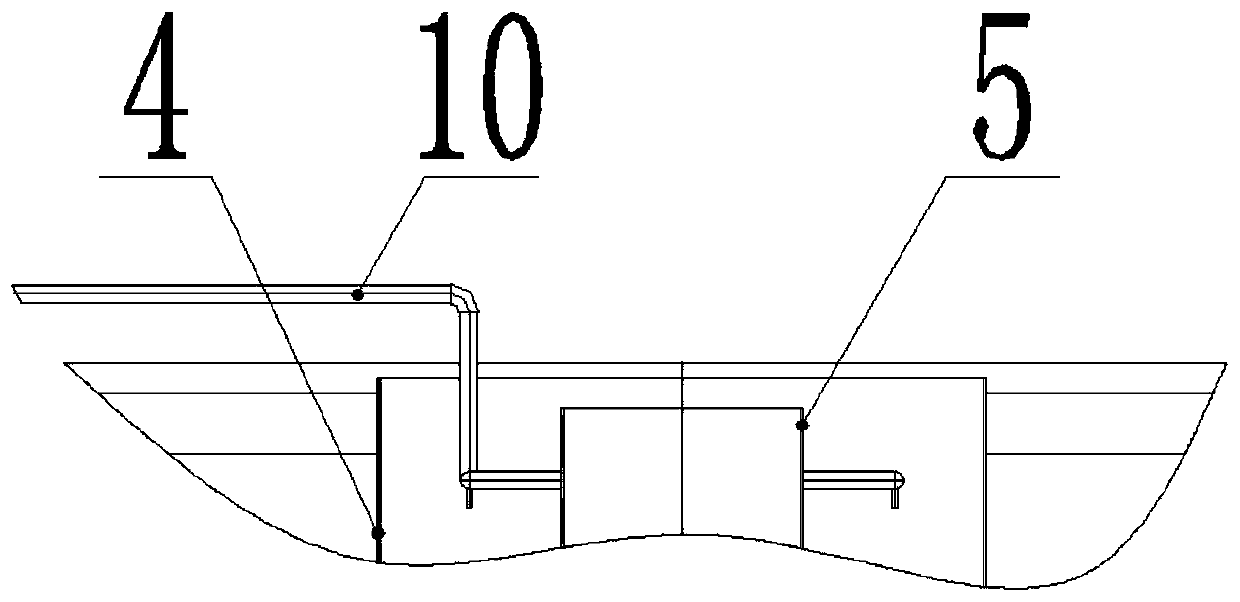

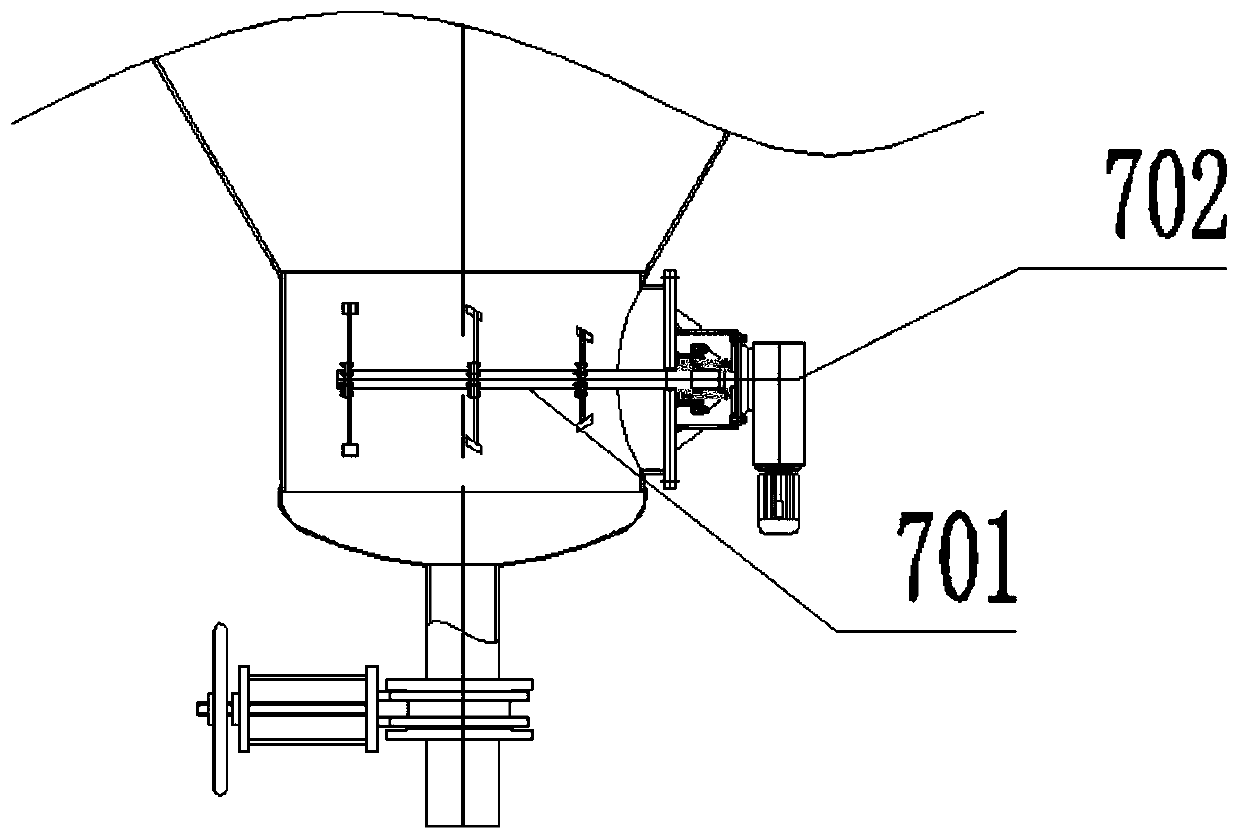

[0042] Such as Figure 1-Figure 5As shown, a deep cone dense sand bin with a fluidized sand release device includes a sand bin body 1, a feed pipe 2, an overflow tank 3, a feed well 4, a circulation well 5, an annular diversion cone 6, a stirring The fluidization device 7 and the flocculant inlet pipe 10; the overflow tank 3 is fixedly connected to the top of the inner wall of the sand bin body 1, and the overflow tank 3 communicates with the supernatant return pipe 9; The feed well 4 is set in the top center of the cavity of the sand bin body 1 and is fixedly connected with the sand bin body 1; the circulation well 5 is set in the feed well 4 and connected with the feed well 4. The top of the feed well 4 is fixedly connected by a steel structure support, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com