Continuous preparation system and preparation technology of whole grain grade tailing cemented filling slurry

A cemented filling and preparation system technology, which is applied to fillings, safety devices, mining equipment, etc., can solve problems such as uneven mixing of filling slurry, loss of water supply system, and affecting the working environment, and achieve tailings settlement and concentration effects Better, shorter infrastructure construction cycle, simple system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

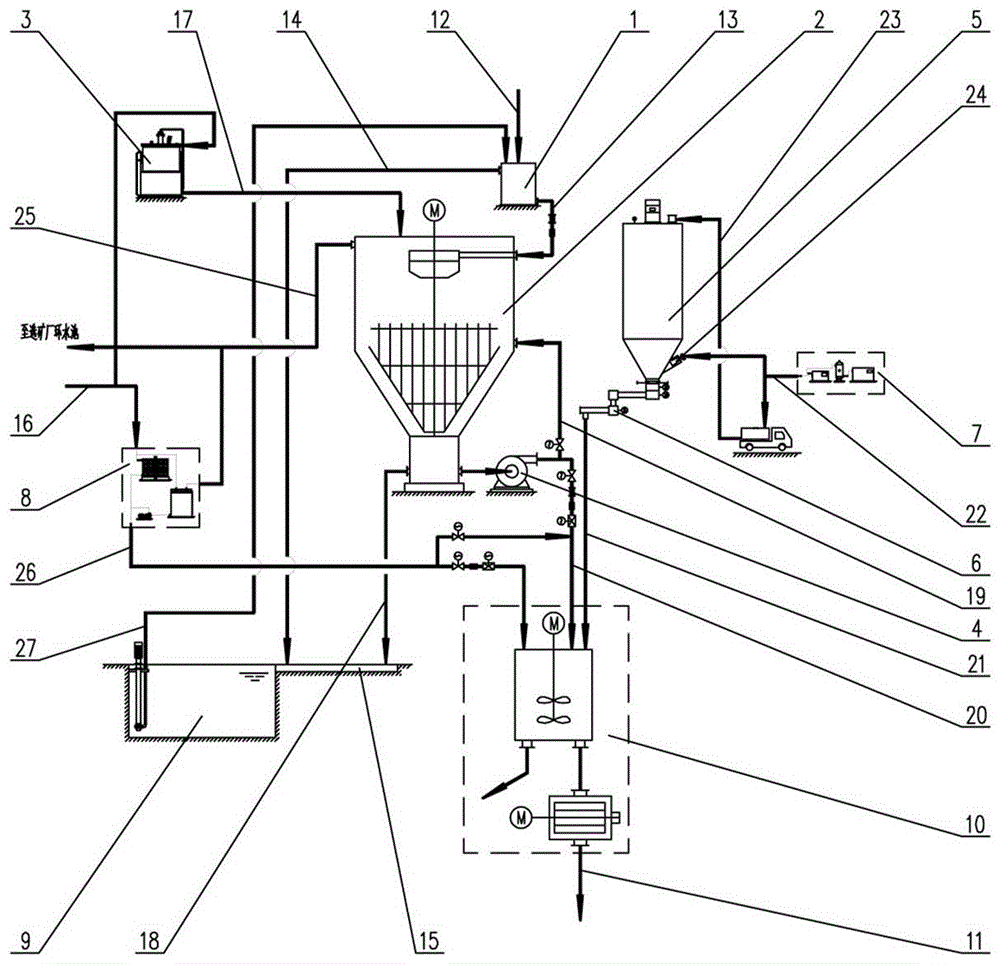

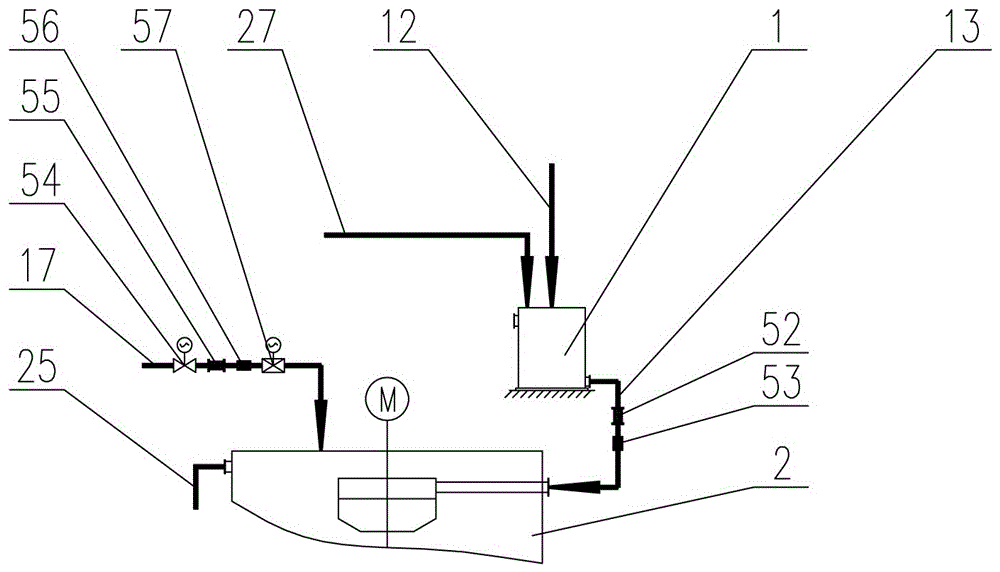

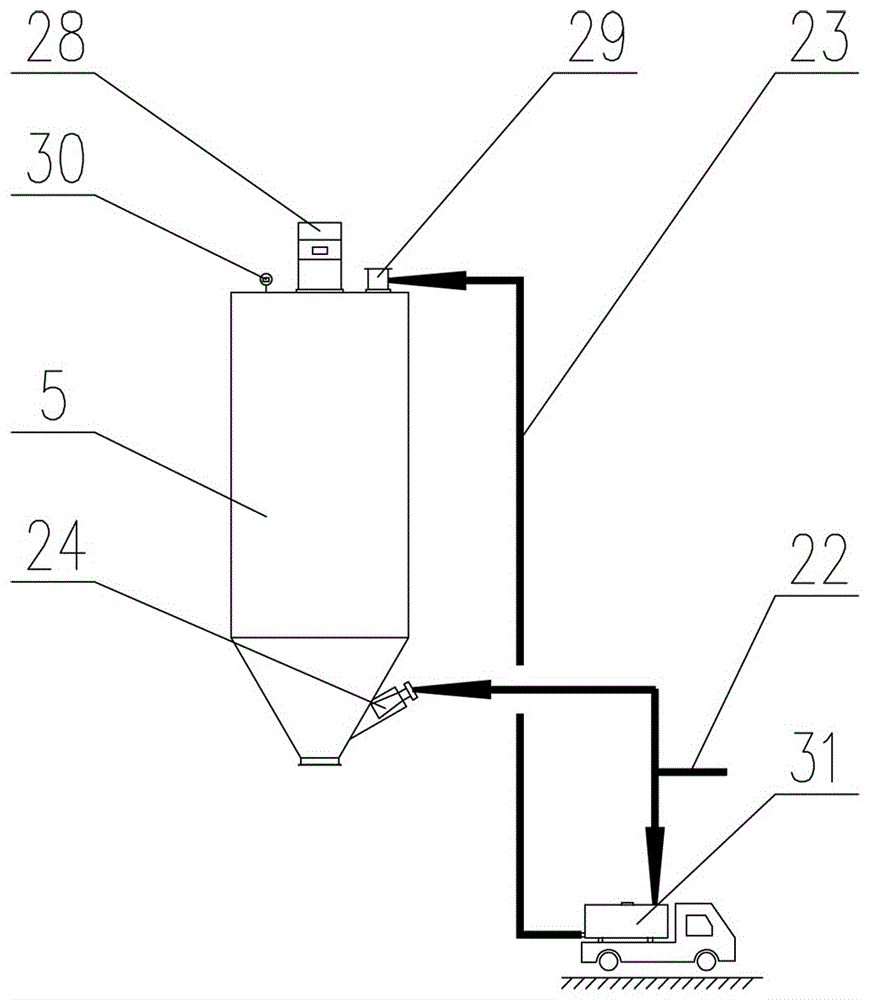

[0047] Labeled in the figure:

[0048] 1. Tailing mortar collection buffer feeding device, 2. Deep cone thickener, 3. Flocculant preparation and dosing device, 4. Underflow slurry pump, 5. Cement storage bin, 6. Cement metering and delivery device, 7. Compressed air system, 8. Water supply system, 9. Filling accident pool, 10. Stirring system, 11. Filling slurry output pipeline, 12. Tailing mortar conveying pipeline of mineral processing plant, 13. Tailing mortar concentration and flow monitoring pipeline, 14 . Tailing mortar overflow pipeline, 15. Accident ditch, 16. Fresh water pipeline in the plant area, 17. Flocculant conveying pipeline, 18. Accident emptying pipeline, 19. Tailing mortar underflow circulation pipeline, 20. Tailing mortar underflow conveying pipeline, 21 . Cement material feeding pipe, 22. Compressed air pipeline, 23. Pneumatic conveying pipeline, 24. Flow aid and anti-blocking device, 25. Deep cone thickener overflow water pipeline, 26. Water supply pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com