Process for preparing isobutyryl chloride by adopting phosphorus trichloride

A technology of phosphorus trichloride and isobutyryl chloride, which is applied in the field of medicine, can solve the problems of incomplete catalyst catalysis, low product yield, and discharge of three wastes, and achieve the effects of convenient production and operation, reduction of pollution, and reduction of discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

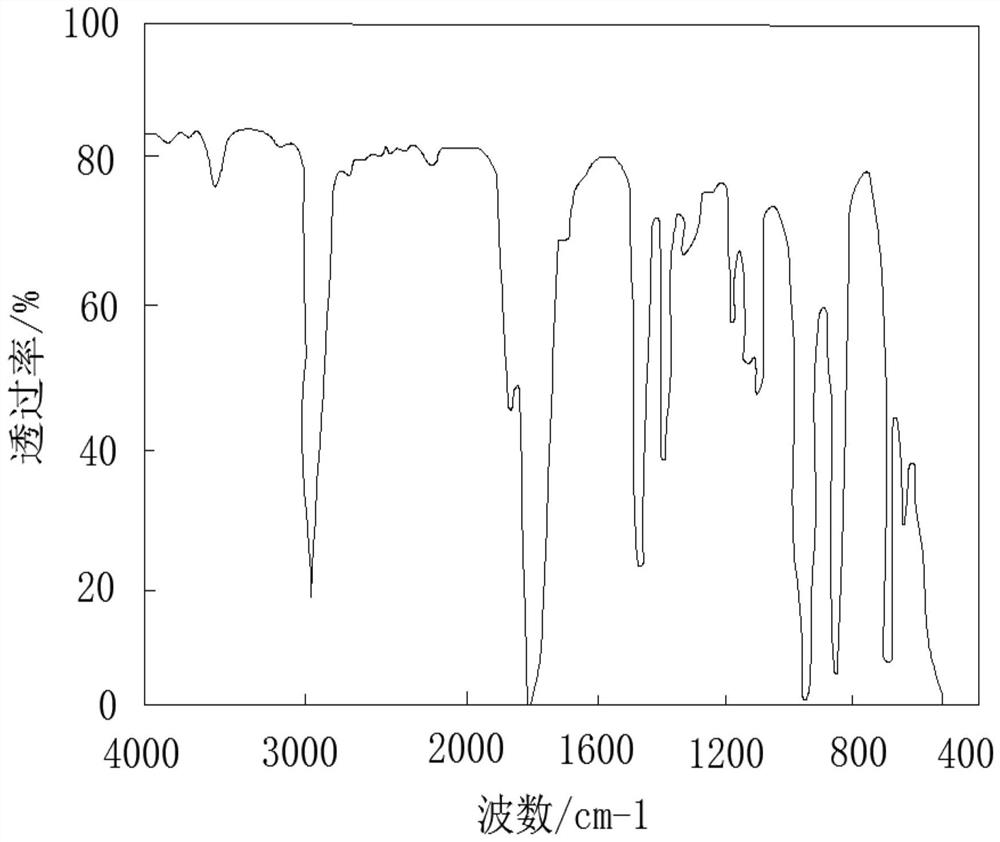

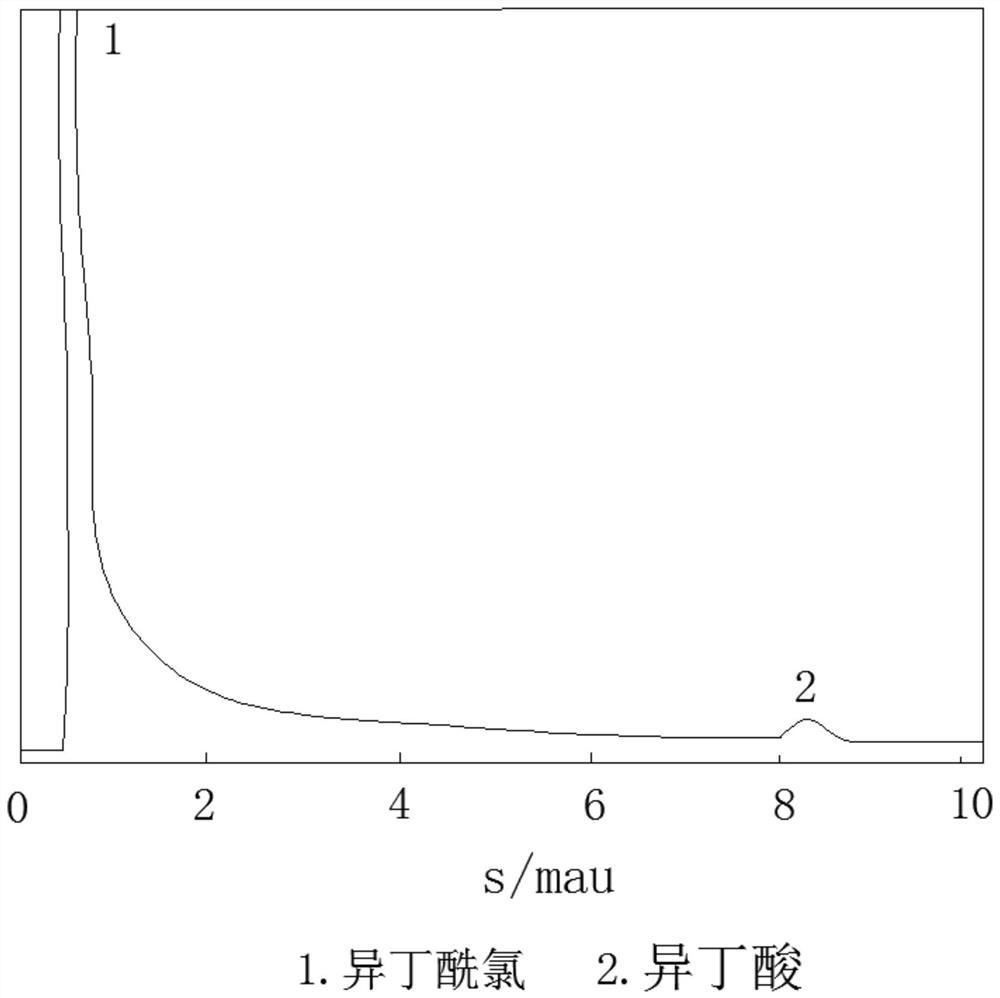

Image

Examples

Embodiment

[0024] A kind of isobutyryl chloride preparation technology that adopts phosphorus trichloride, concrete steps are as follows:

[0025] (1) Connect a 100ml constant pressure dropping funnel, a set of stirring device and a spherical condenser to a dry 250ml three-neck flask, and connect a tail gas absorption device to the top of the condenser:

[0026] (2) First add 542g (4.55mol) of thionyl chloride, and dropwise add 352g (4mol) of isobutyric acid to it, and emit HCL, SO2, pay attention to stirring:

[0027] (3) After the dropwise addition, continue to stir and raise the temperature to 80°C, keep it for 0.5h, collect a wide fraction at 83-100°C by distillation, and then collect a fraction at 90-92°C by distillation, which is isobutyryl chloride.

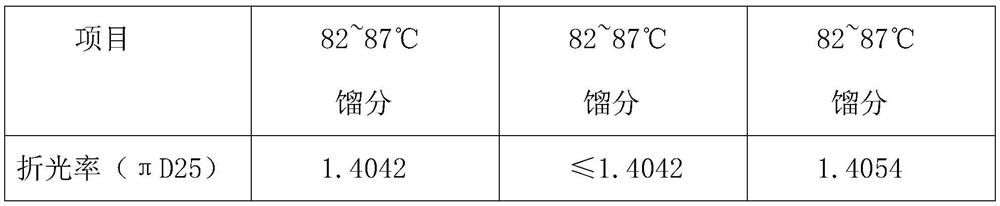

[0028] Following is the experimental data in the product process that the present application obtains by embodiment:

[0029] 1. Selection of Experimental Conditions

[0030] (1), physical mass ratio

[0031] Theoretically speakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com