Water-based foamed coating shading cloth and preparation process thereof

A technology of foam coating and shading cloth, which is used in textiles and paper making, etc., can solve the problems of inability to maintain the dimensional stability of the picture, the woven fabric of the shading cloth is not strong, and the shading property is not enough, and it is difficult to achieve industrial transformation. Small size, good shading performance, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

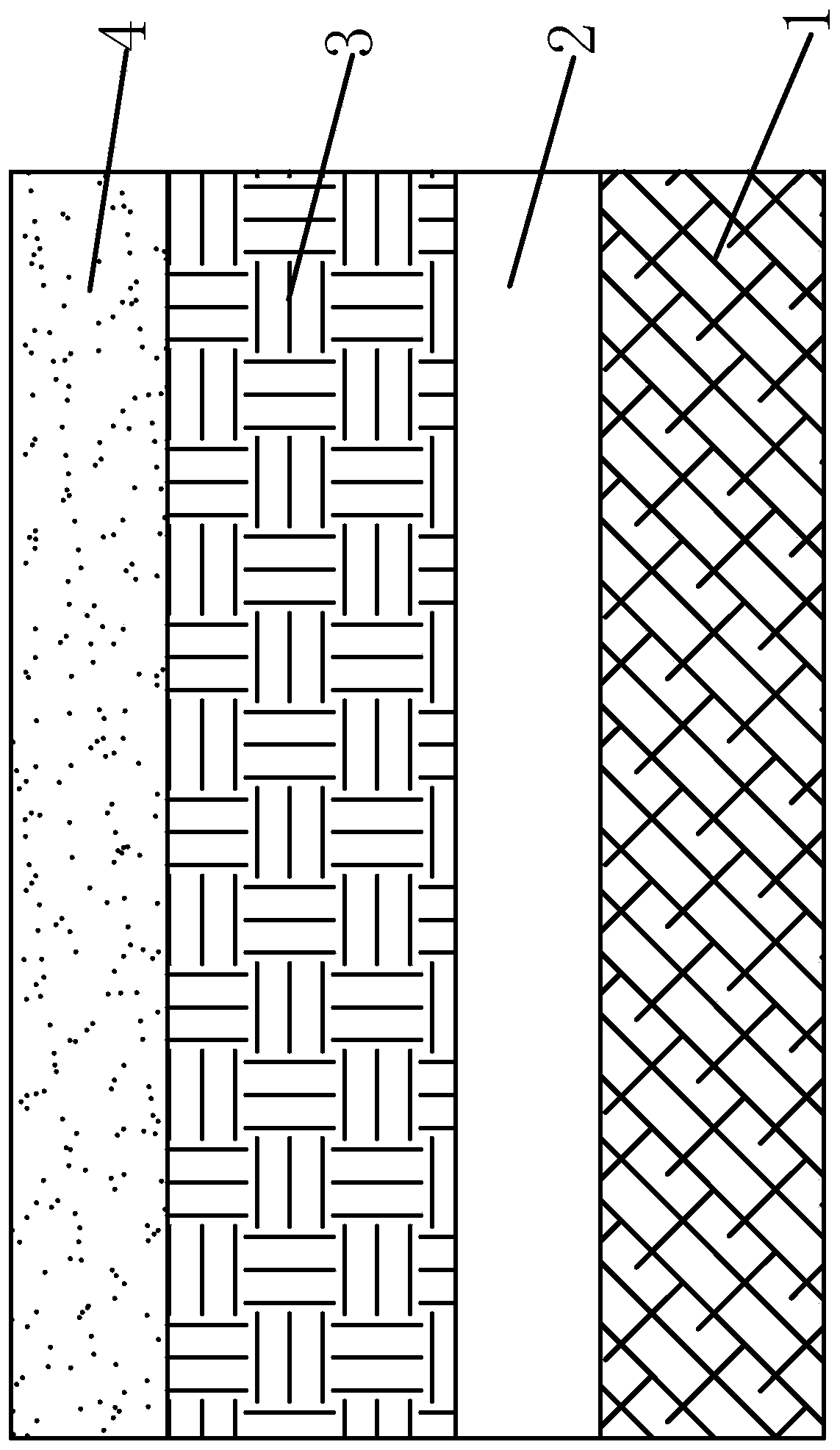

[0028] Such as figure 1 As shown, the water-based foam coating light-shielding cloth includes a base cloth layer 1, a white primer layer 2, a black light-shielding layer 3, and a scratch-resistant layer 4 from the front to the back. The fabric of the base cloth layer 1 adopts warp knitting Caused by the structure of the coil formation; the raw materials for the white primer layer 2 include 100 parts of water-based acrylic emulsion, 1-100 parts of environmentally friendly flame retardant, 1-30 parts of sunscreen, 1-20 parts of foam stabilizer, and 1 antioxidant ~10 parts, 1~10 parts of crosslinking agent, 1~10 parts of thickening agent; The raw materials for the production of black light-shielding layer 3 include 100 parts of water-based a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com