Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Have the effect of safety protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

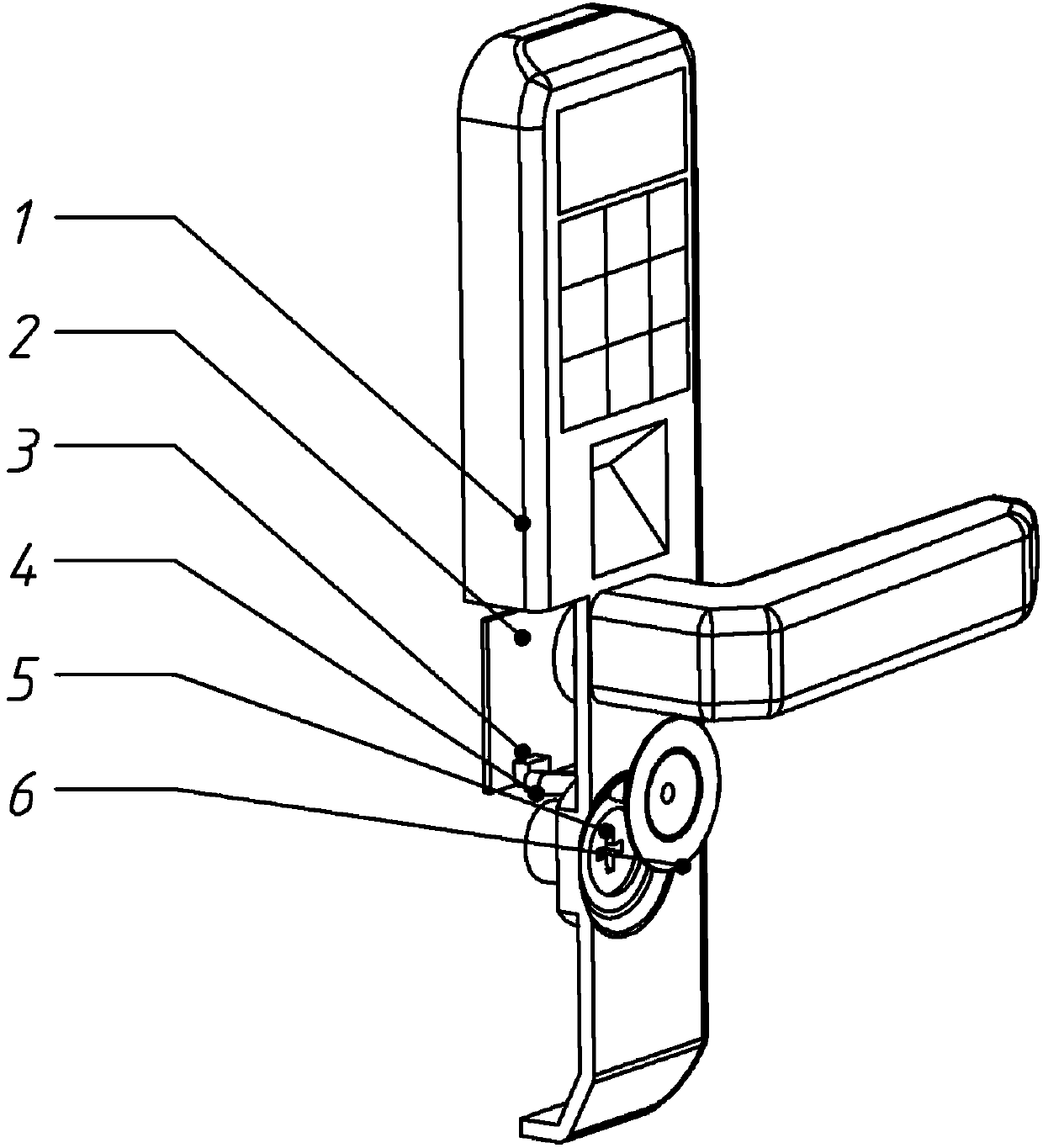

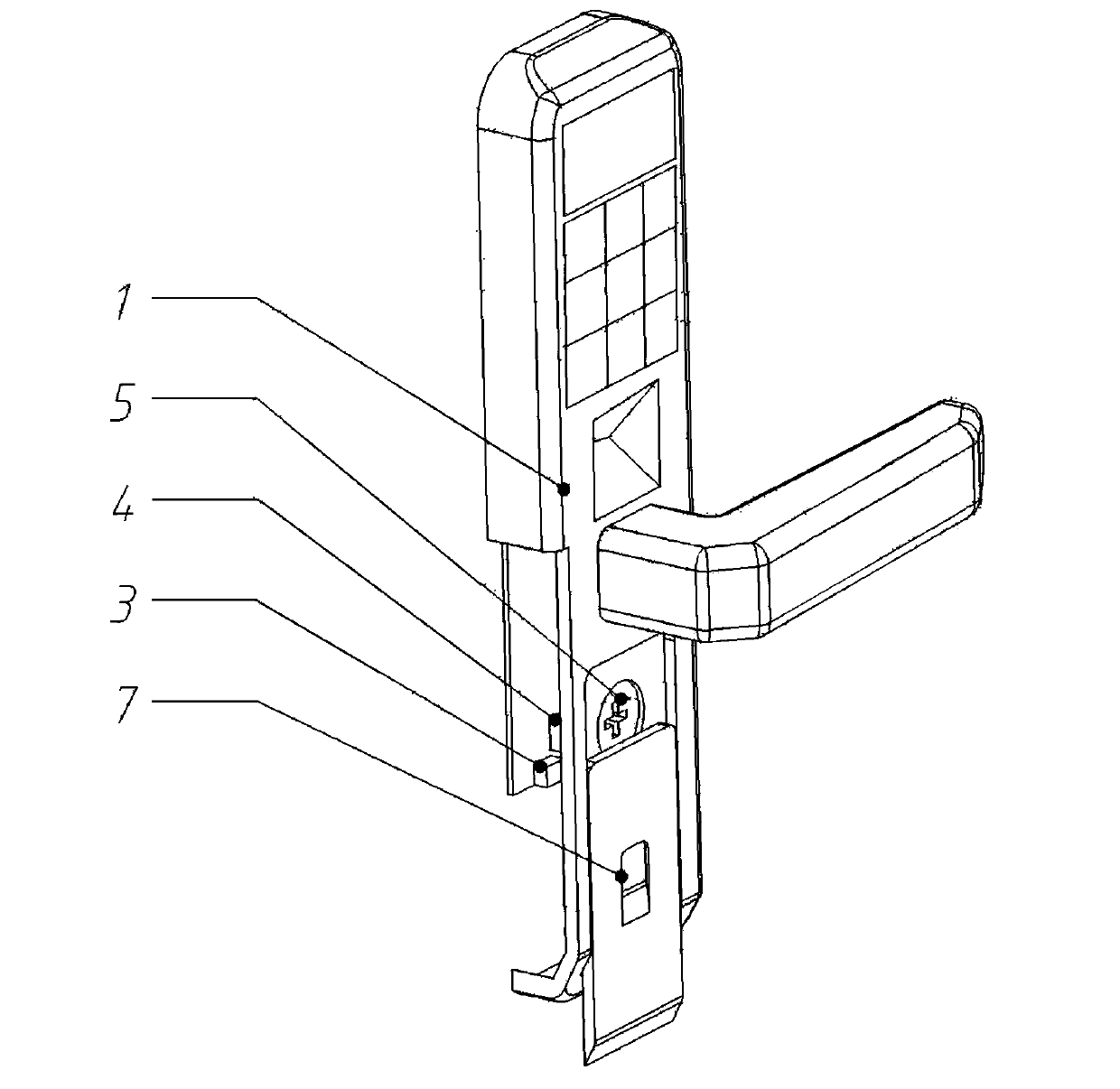

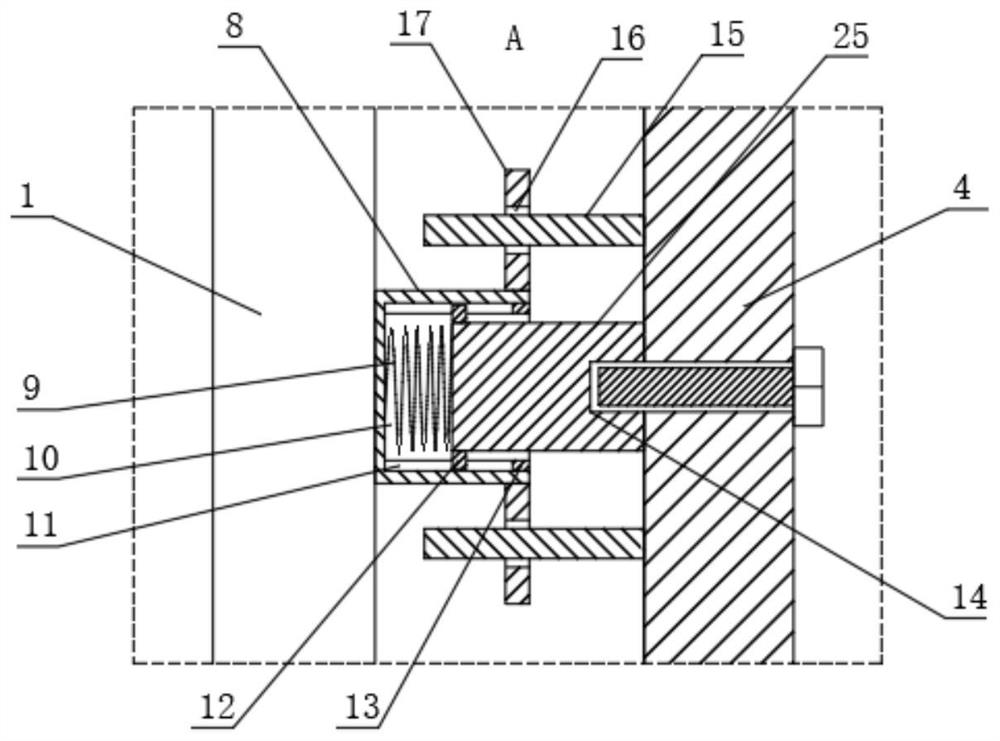

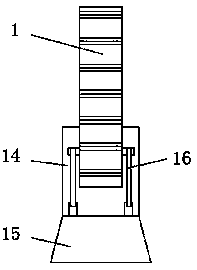

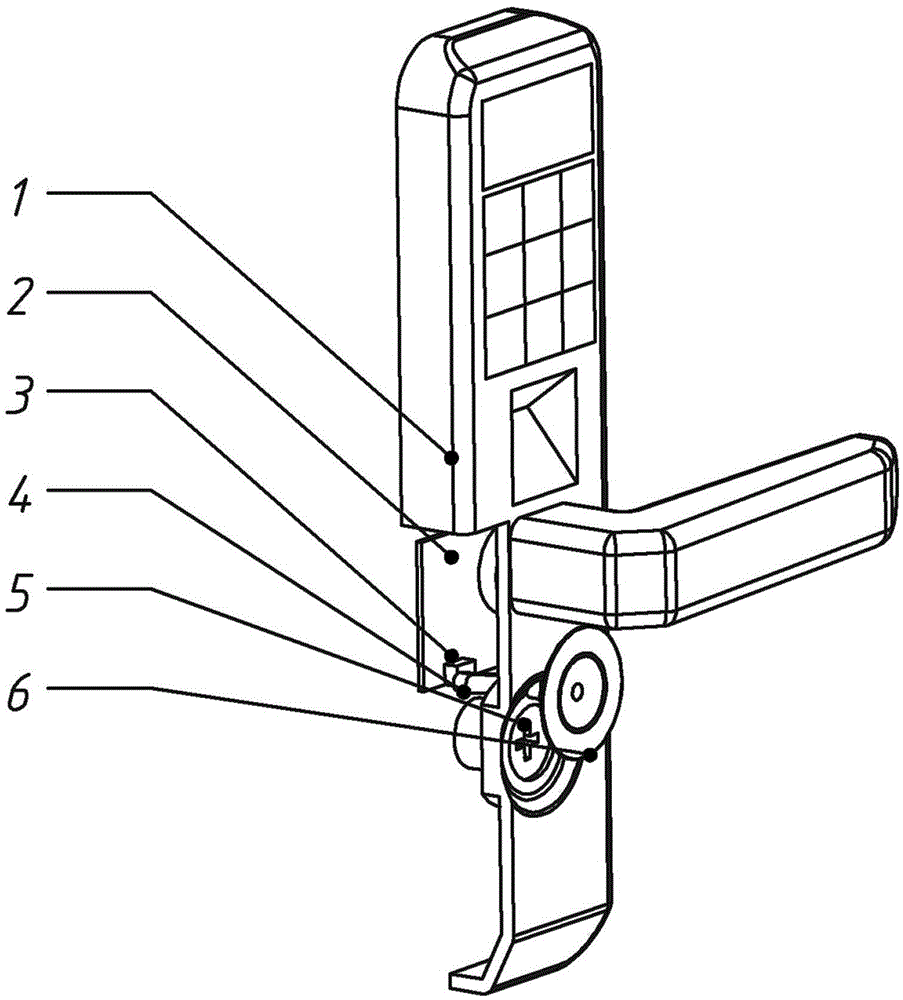

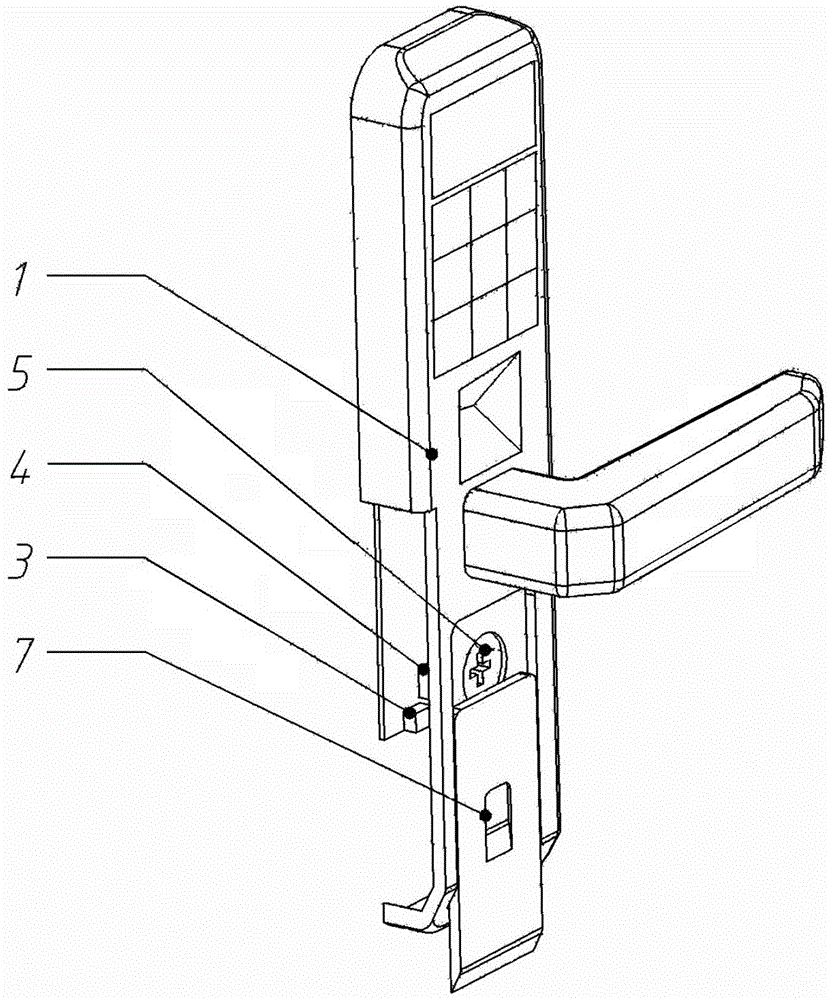

Emergency lock protection device for fingerprint lock

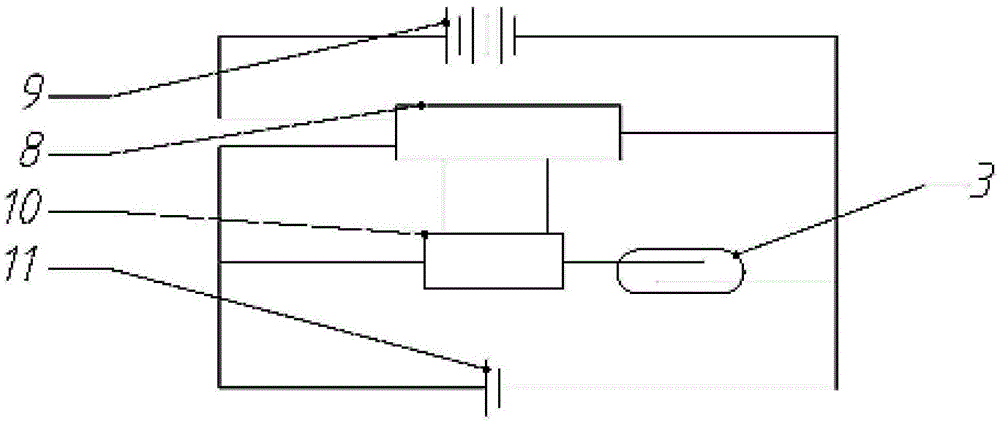

The invention relates to an emergency lock protection device for a fingerprint lock. The emergency lock protection device for the fingerprint lock comprises a lock body and an emergency lock which is arranged at the lower portion of the lock body, an emergency lock port cover is arranged on the front end surface of the emergency lock, a position magnet which is in magnetic suction with an emergency lock hole cover in a linked mode is arranged on the rear end surface of an emergency lock port, a position sensing element which corresponds to the position magnet is arranged on the position magnet, and the position sensing element is a switch of a warning circuit. The emergency lock protection device for the fingerprint lock has the advantages of being simple in structure, convenient to use and reliable in performance. When the emergency lock port cover plate is opened in a mechanical mode, alert is definitely triggered, and the effect of safety and protection is achieved. The emergency lock port cover enables the appearance of the lock to be simpler and more beautiful, and safety of the fingerprint lock can be increased through a warning device.

Owner:ZHEJIANG DUMA SEWING MACHINE

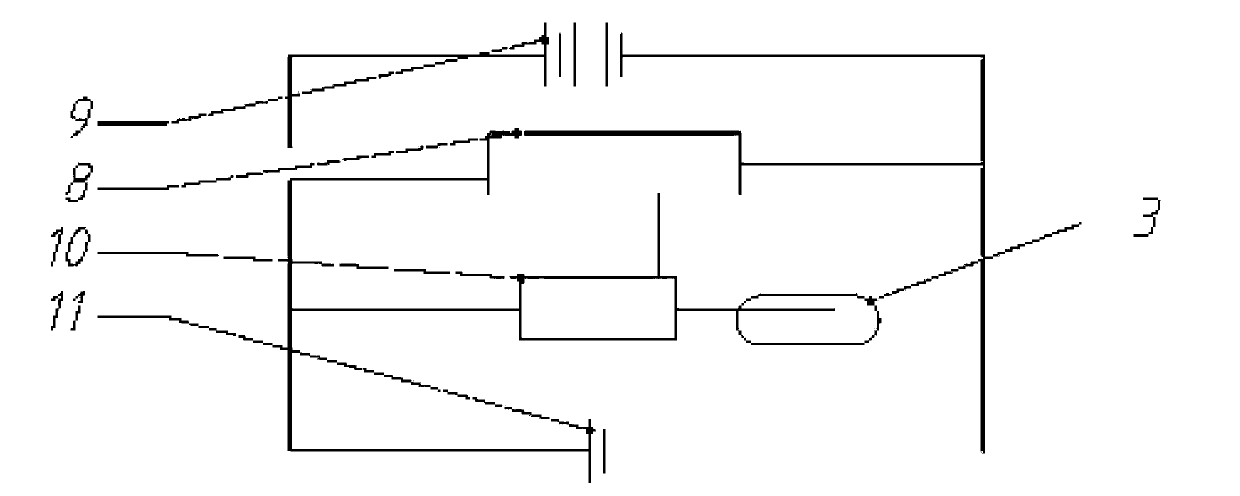

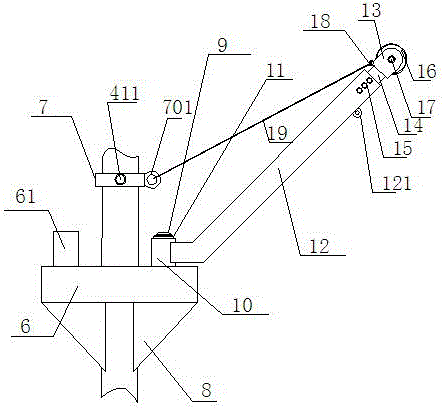

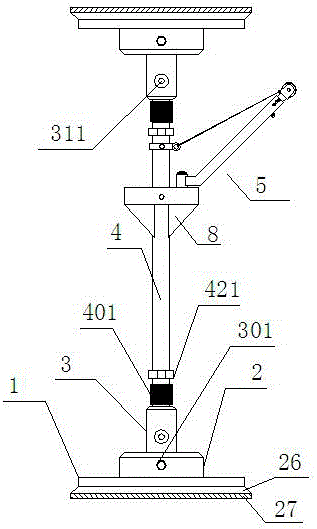

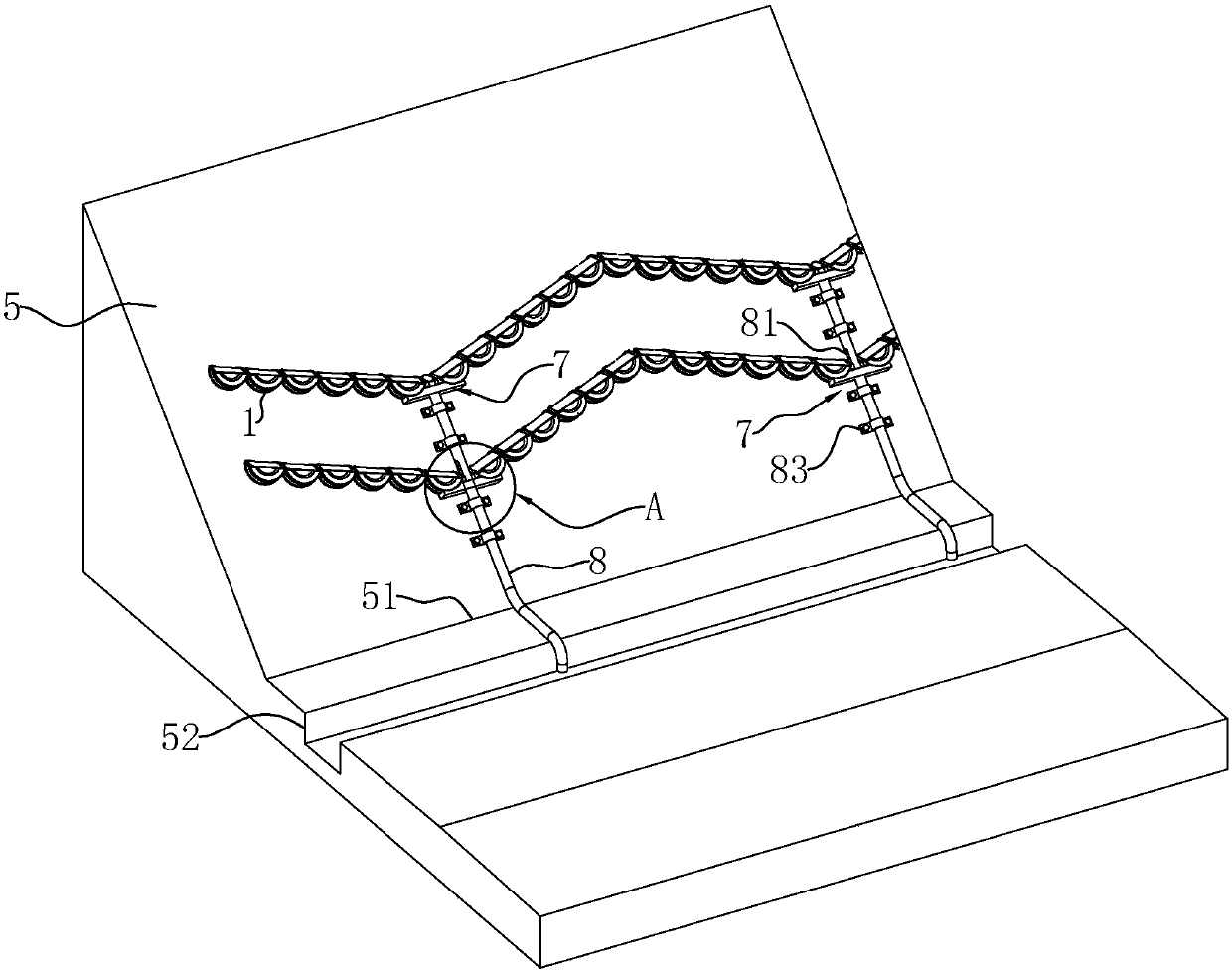

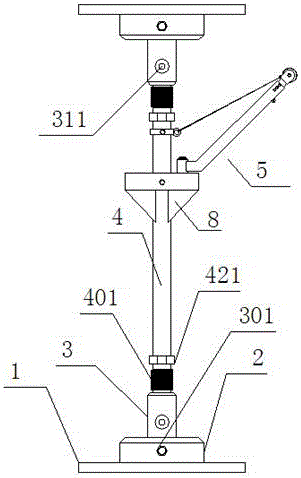

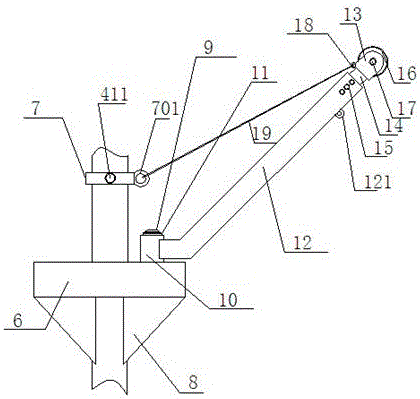

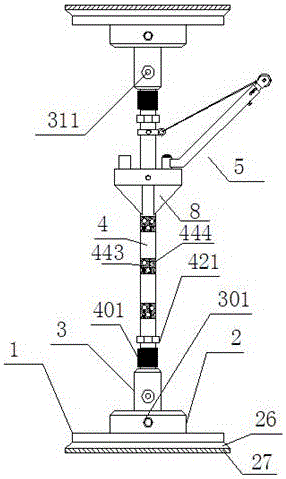

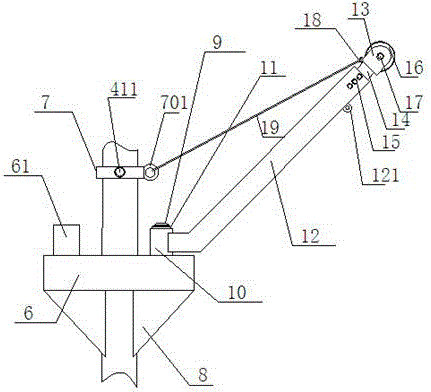

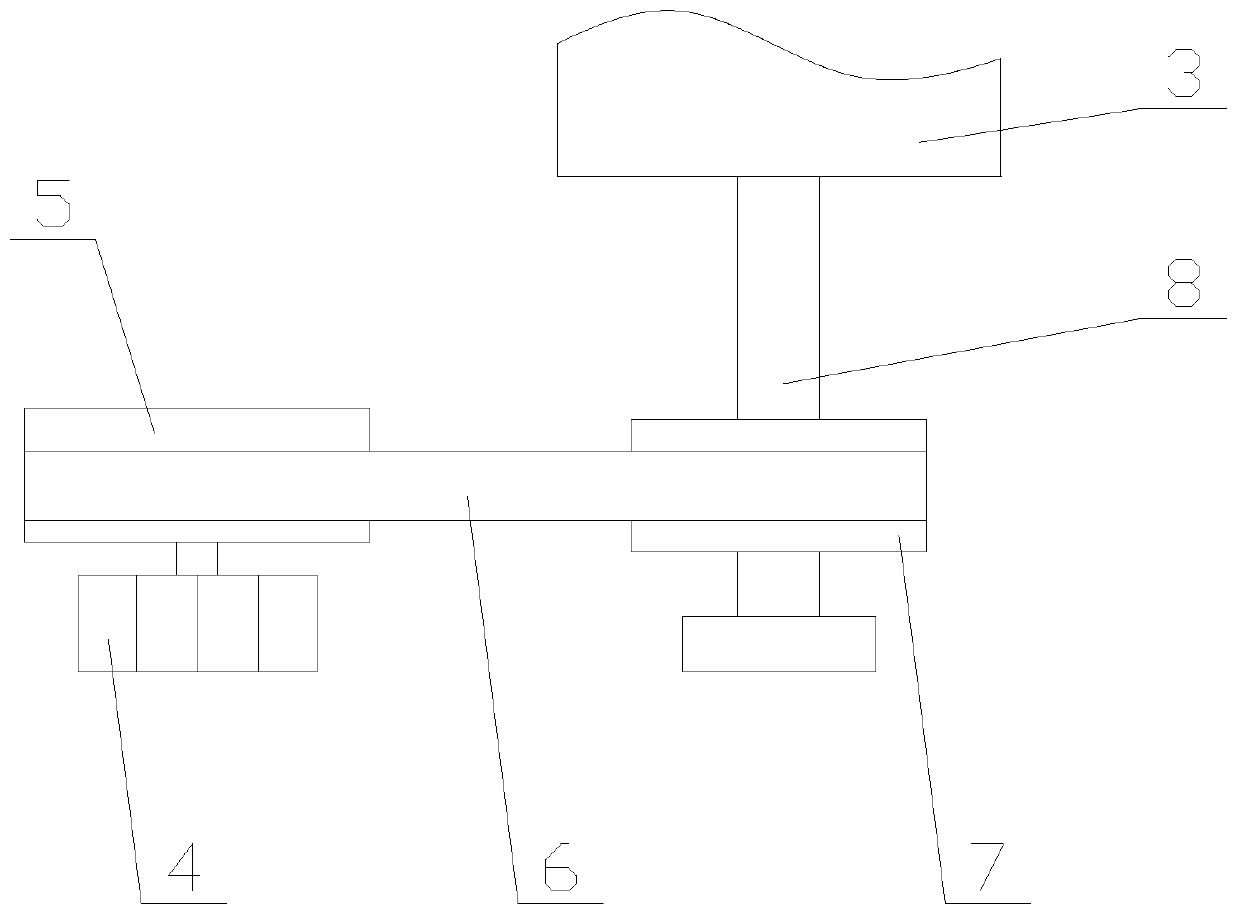

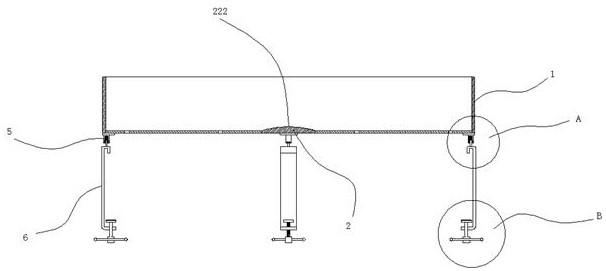

Energy-saving hoisting construction device

The invention discloses an energy-saving hoisting construction device. The energy-saving hoisting construction device comprises two bottom plates which are symmetrically arranged up and down; a cylindrical base is arranged on each bottom plate and internally provided with a threaded sleeve movably, and a first screw is arranged between each cylindrical base and the corresponding threaded sleeve in a matched mode; a support lever is arranged between the two threaded sleeves in a matched mode, the two ends of the support lever are provided with threaded portions matched with the threaded sleeves, and the spiral directions of the threaded portions at the two ends of the support lever are opposite; force applying ring parts are arranged in the positions, close to the threaded portions, of the two ends of the support lever; and the support lever is further provided with a hoisting assembly.

Owner:周锦泳

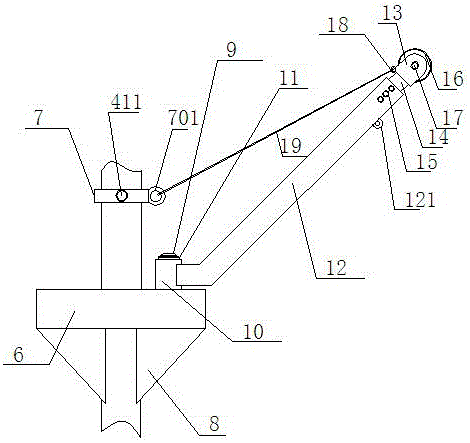

Construction device with suckers

The invention discloses a construction device with suckers. The construction device comprises two base plates arranged in up-and-down symmetry, and the two base plates are both provided with cylindrical bases. A threaded sleeve is arranged inside each cylindrical base in a movable manner, and a first screw is matched between each cylindrical base and the corresponding threaded sleeve. A support rod is matched between the two threaded sleeves. Threaded portions matched with the threaded sleeves are arranged at the two ends of the support rod, the turning directions of the threaded portions at the two ends of the support rod are opposite, force applying ring portions are arranged in the positions, close to the threaded portions, of the two ends of the support rod, and a hanging and conveying assembly is arranged on the support rod.

Owner:叶秀

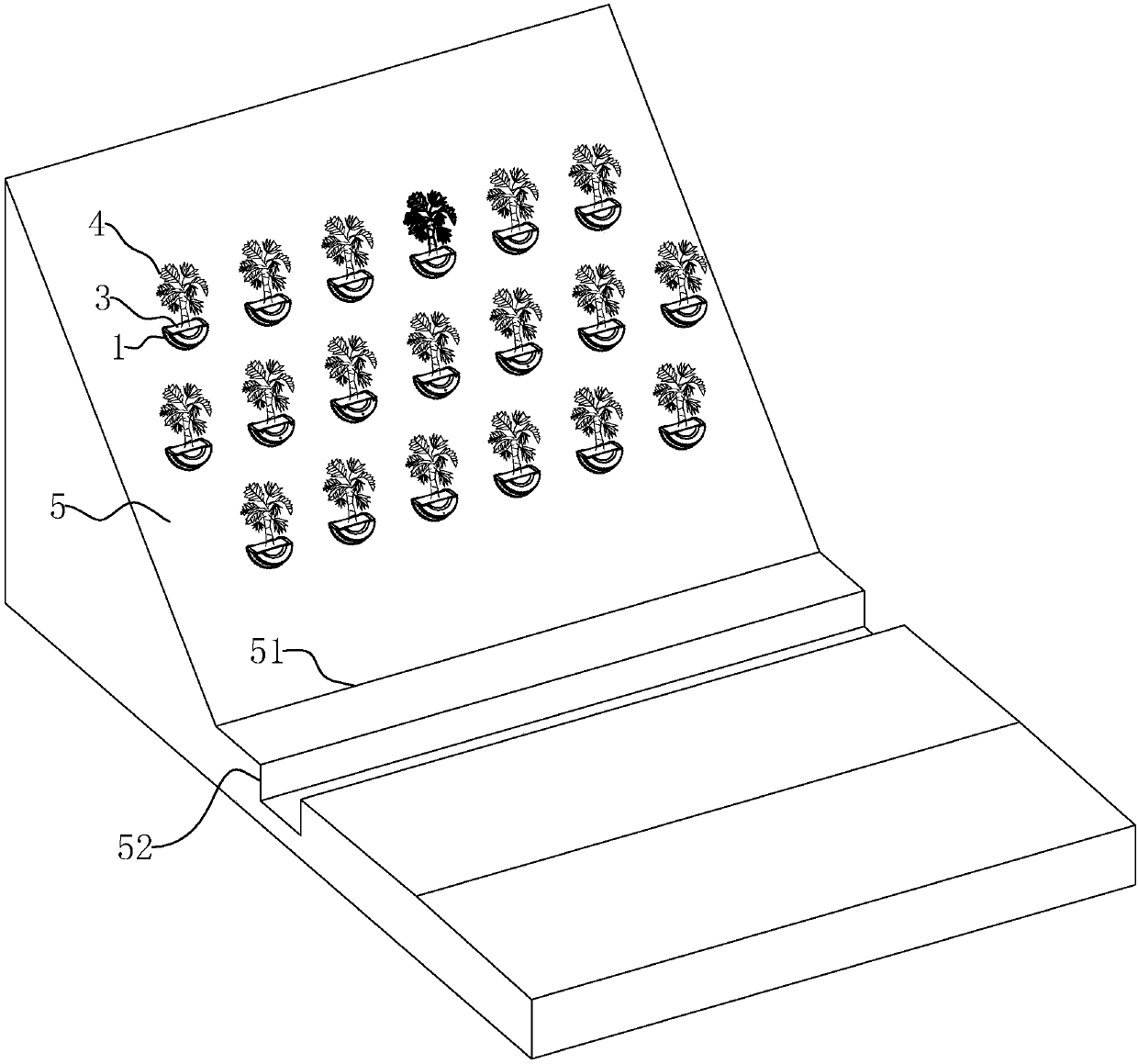

Ecological protection structure of rock slope and construction method of structure

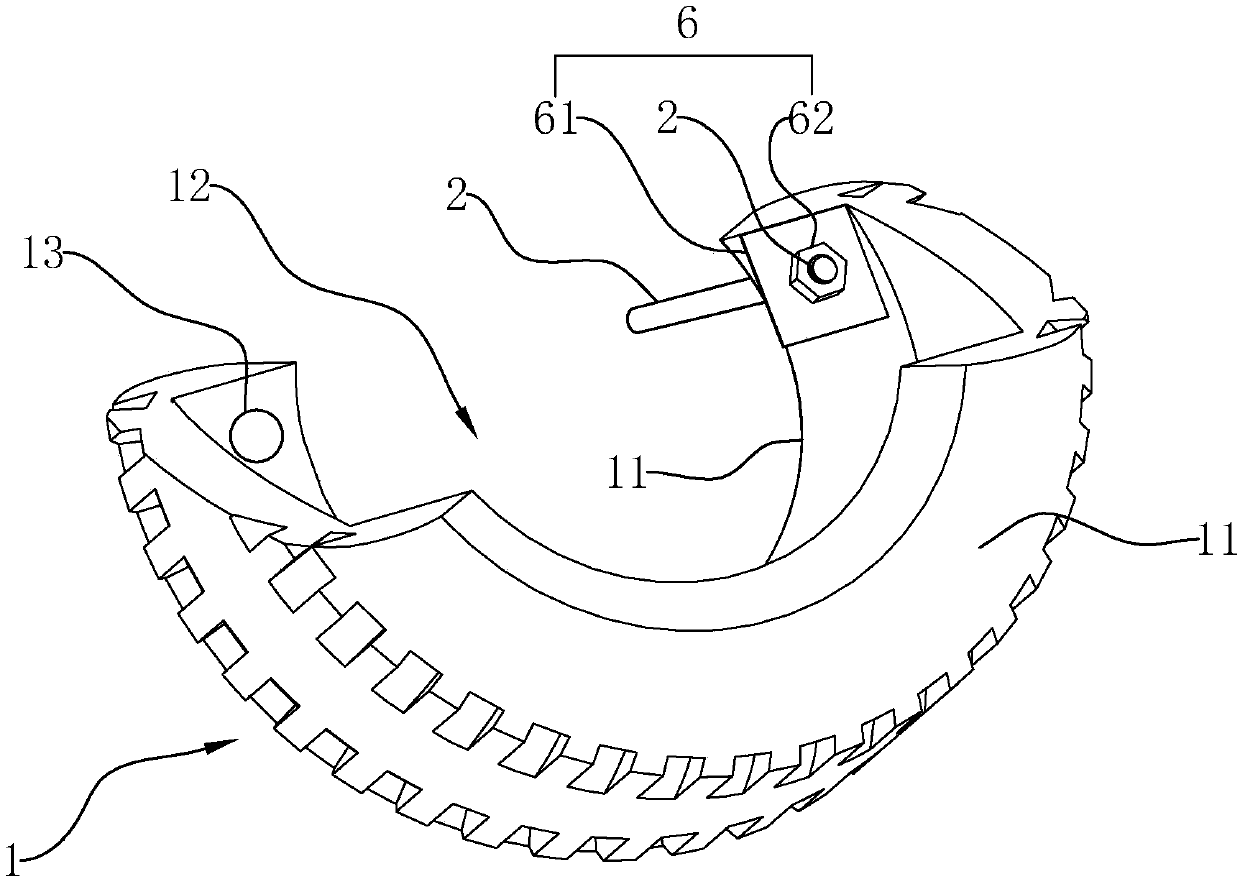

PendingCN107916673AHave the effect of safety protectionReduce direct sunlightExcavationsReceptacle cultivationEnvironmental resource managementStructural engineering

The invention discloses an ecological protection structure of a rock slope and a construction method of the structure. According to the technical scheme, the structure comprises multiple semi-circulartires, multiple fixing rods and planting soil and green plants located in the semi-circular tires; side walls of one faces of the semi-circular tires are attached to the slope face, openings of the semi-circular tires are upward to form a groove, the planting soil and the green plants are arranged in the groove, one parts of the fixing rods are inserted in the slope face, the other parts of the fixing rods are leaked out of the slope face, fixing holes are formed in the side walls attached to the slope face, the fixing rods penetrate the fixing holes to fix the semi-circular tires to the slope face, waste semi-circular tires are used for forming a platform, for stopping gravels, on the slope face, and the protection effect is achieved; meanwhile, the plants grown in the semi-circular tires and can shelter sunlight, the direct shooting of sunlight to the slope face can be reduced, the air slake speed of the rock on the slope face can be reduced, the main structure of the structure is made of waste tires, the structure is economical and environment-friendly, and in addition, the construction method is easy to operate and efficient in construction.

Owner:张家冀

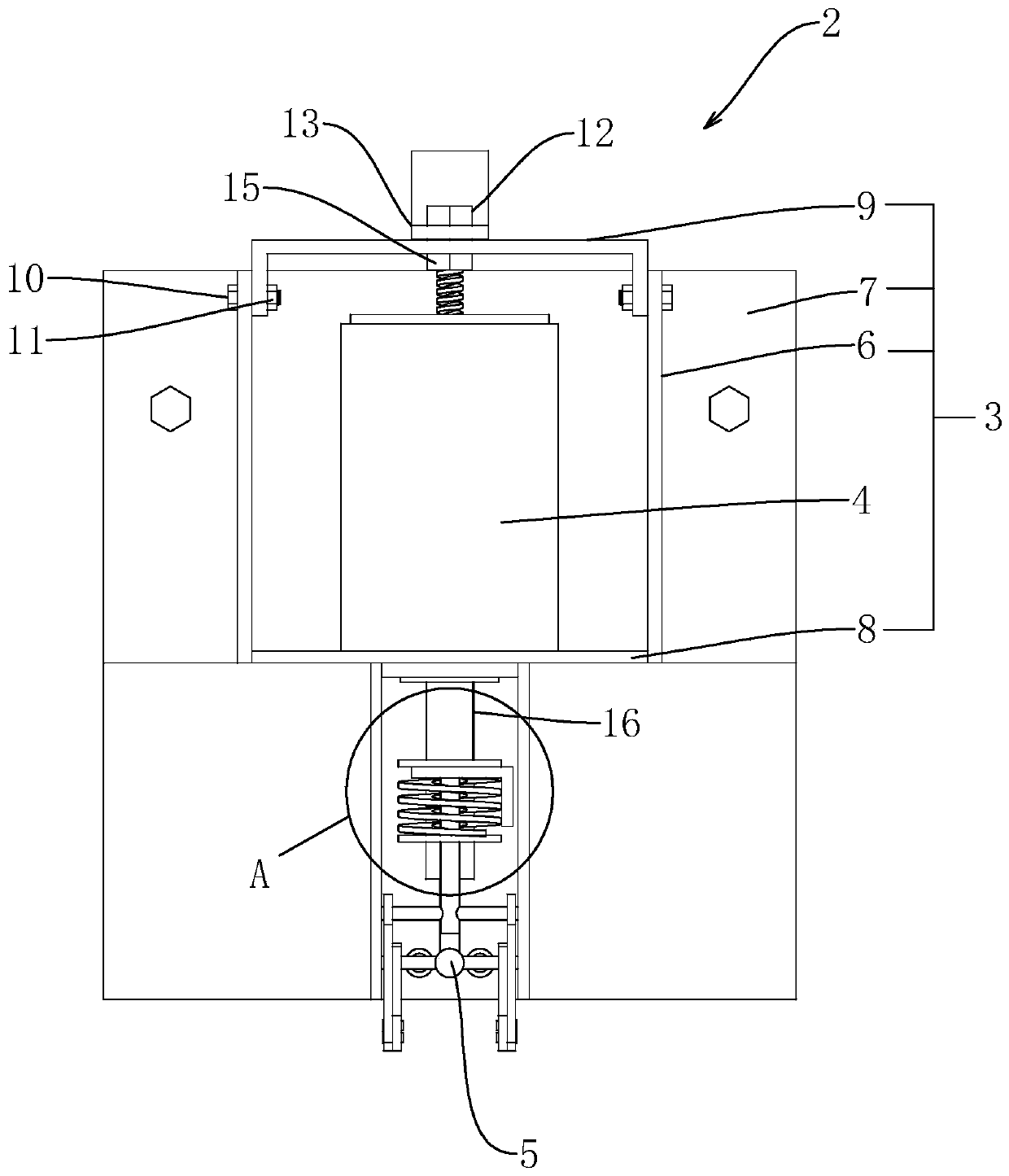

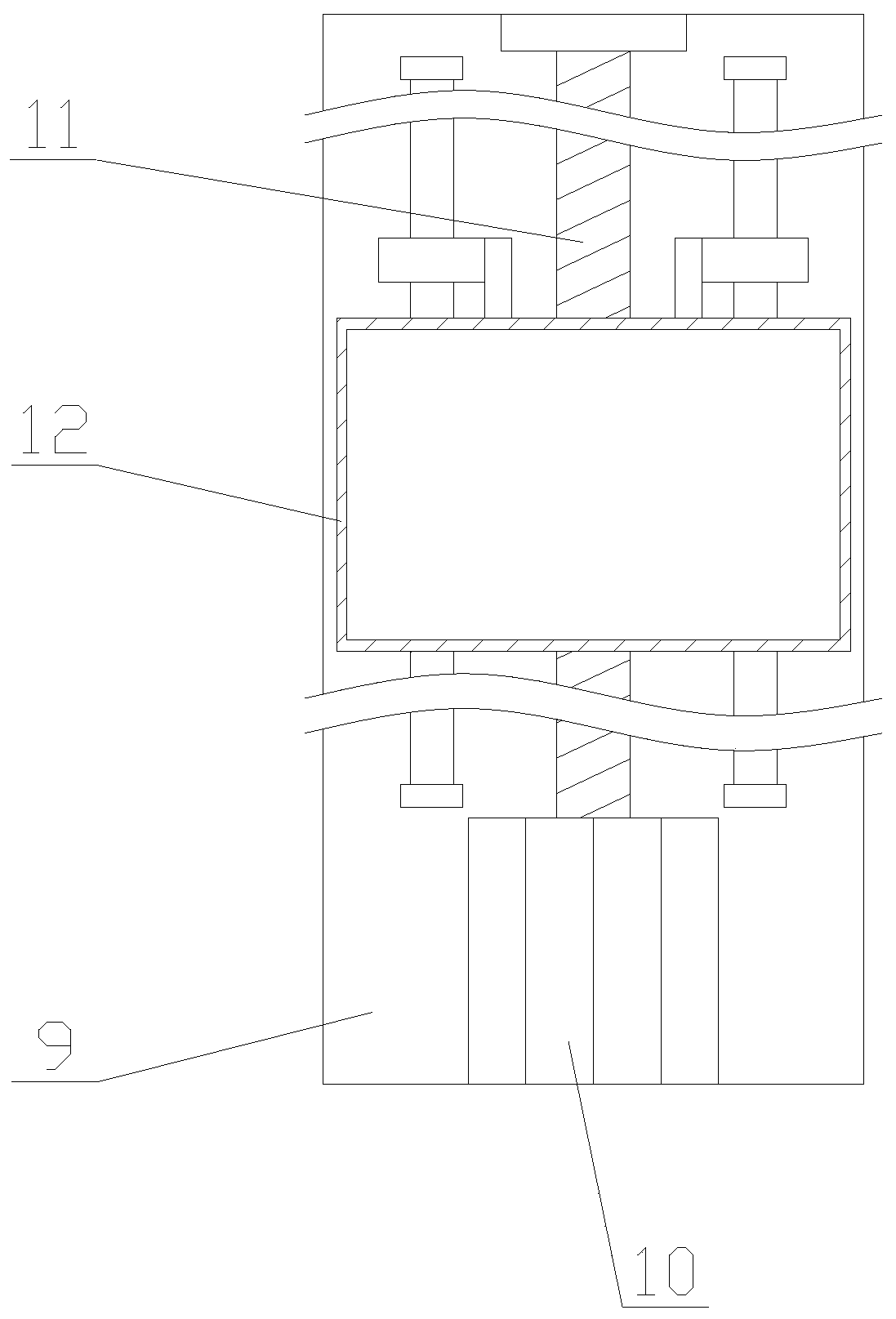

Ring main unit

ActiveCN110137026AButt tightReliable electrical connectionSubstation/switching arrangement casingsHigh-tension/heavy-dress switchesBiochemical engineeringElectrical connection

The invention relates to the technical field of power distribution cabinets, in particular to a ring main unit. The ring main unit comprises a unit body and a breaker located in the unit body, the breaker comprises a support frame, an arc extinguish chamber installed on the support frame and an operation mechanism controlling on-off of a circuit, a copper sleeve is fixed at the lower end of the arc extinguish chamber, a first butt ring having a diameter larger than the copper sleeve is integrally formed at the lower end of the copper sleeve, an insertion rod having an upper end connected witha moving contact is inserted into the copper sleeve, the diameter of the insertion rod is equal to the inner diameter of the copper sleeve, a first butt ring is formed at the position at the lower portion of the first butt ring on the insertion rod, a lower copper row penetrates the position at the upper portion of the second butt ring on the insertion rod, and a first strong spring sleeves the position between the lower copper row and the second butt ring on the insertion rod. The copper row is extruded upwards under the action of the first strong spring and is butted against the first butt ring to allow the copper row to be tightly butted against the first butt ring for stable electrical connection.

Owner:ZHEJIANG KANGGE ELECTRIC CO LTD

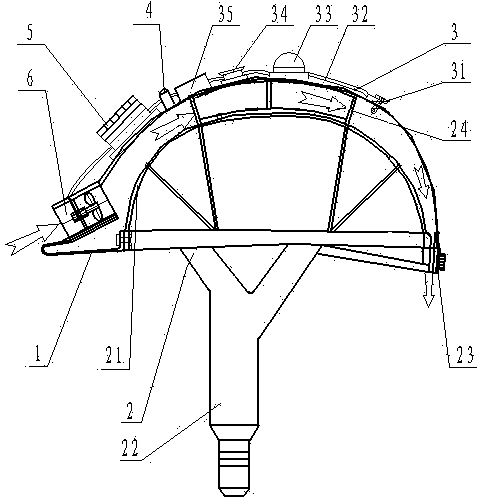

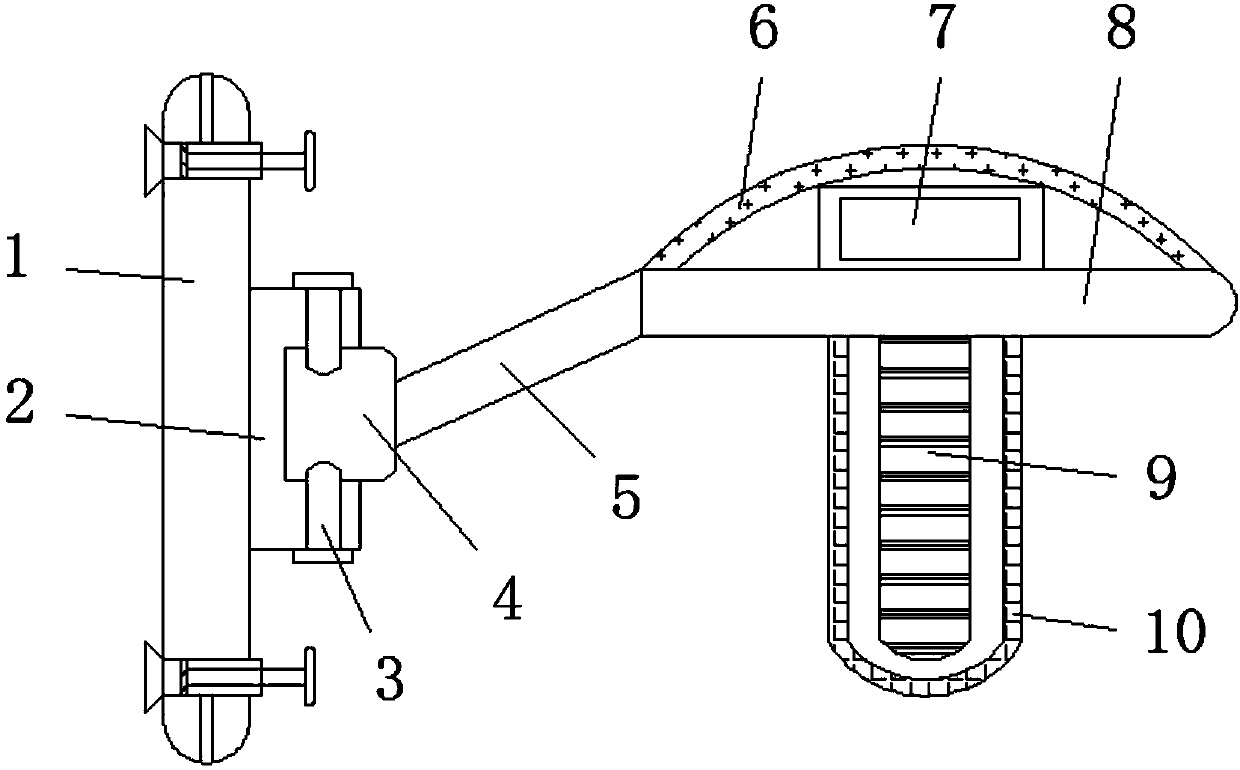

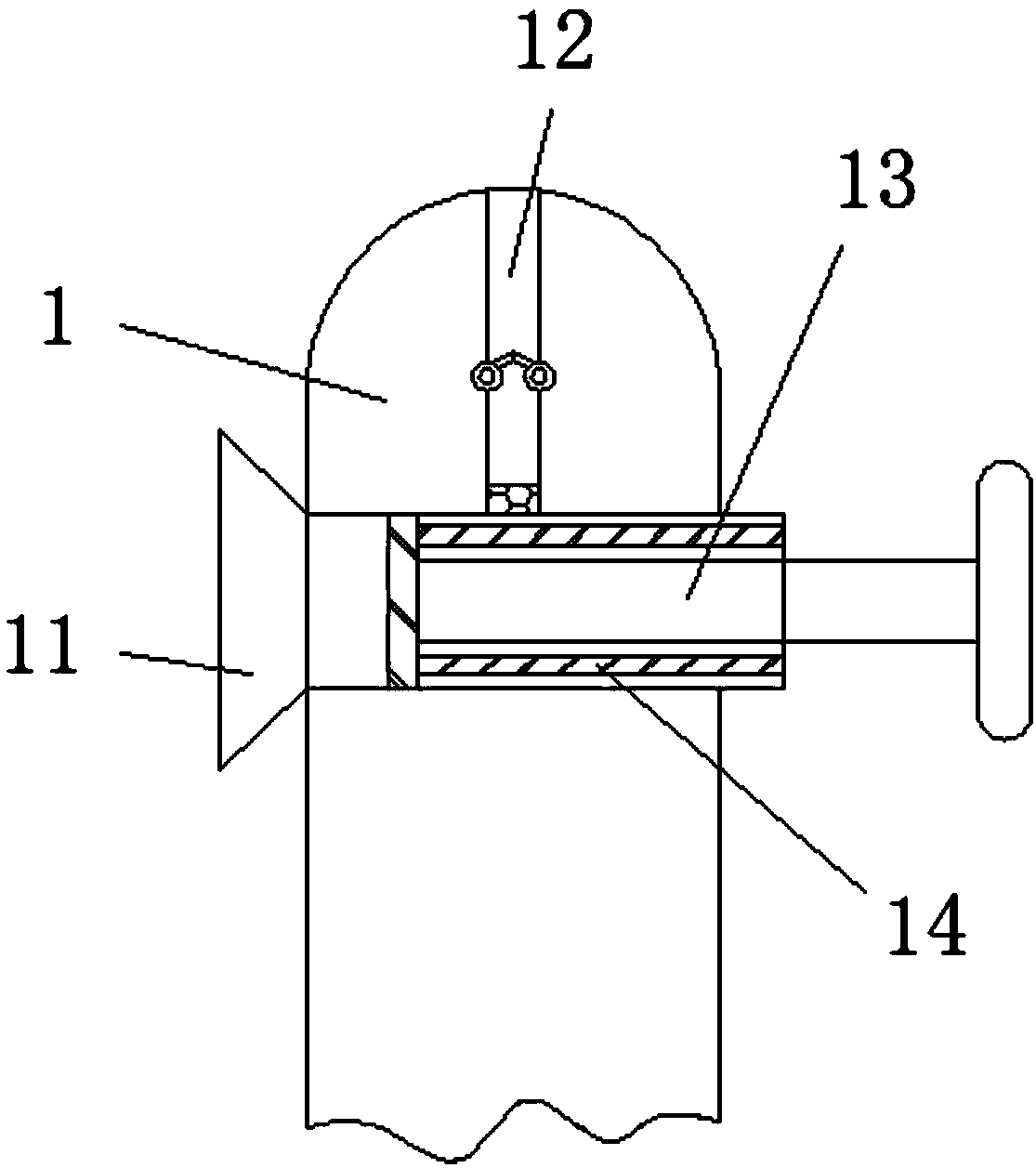

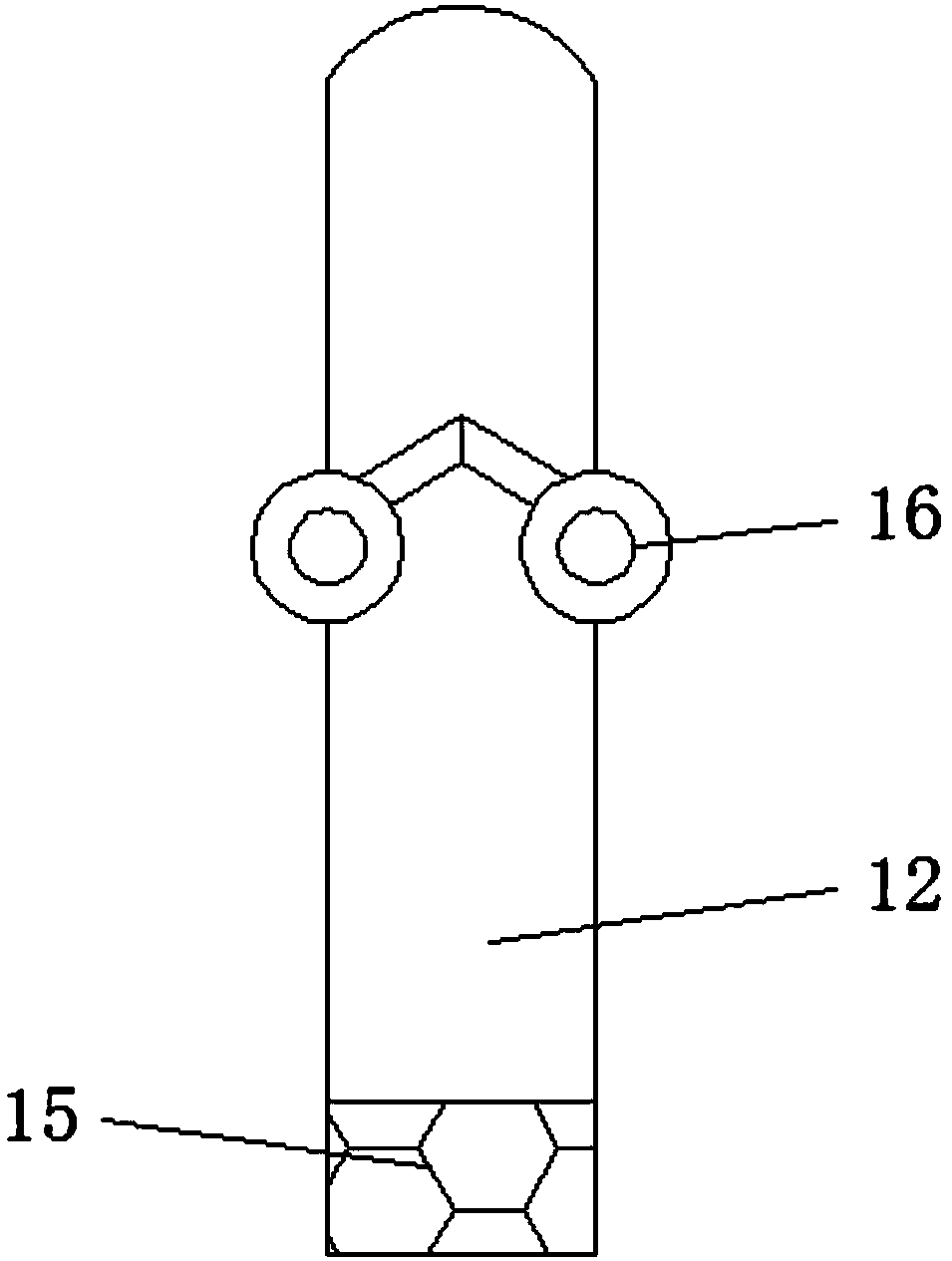

High-temperature alarm cooling solar helmet

The invention relates to a high-temperature alarm cooling solar helmet. The high-temperature alarm cooling solar helmet is composed of a helmet shell, an inner protecting and connecting device, an alarm control device, a switch, a solar cell and a miniature pipeline fan. The inner protecting and connecting device is arranged in the helmet shell, the alarm control device is arranged above the outer side of the helmet shell, the switch and the solar cell are respectively arranged on the helmet shell, and the miniature pipeline fan is fixedly mounted at an air port of the front end of the helmet shell and is started under control of a control circuit board in the alarm control device. Since a passage is formed between a protecting liner and the helmet shell, the passage behind the alarm control device is provided with an air outlet, and temperature inside the helmet around the head of an outdoor operator is effectively reduced. By the alarm control device, set temperature can be lowered. By arranging a flash alarm and a buzzer alarm, hot-line workers and monitors can be prompted of safety operation.

Owner:STATE GRID CORP OF CHINA +3

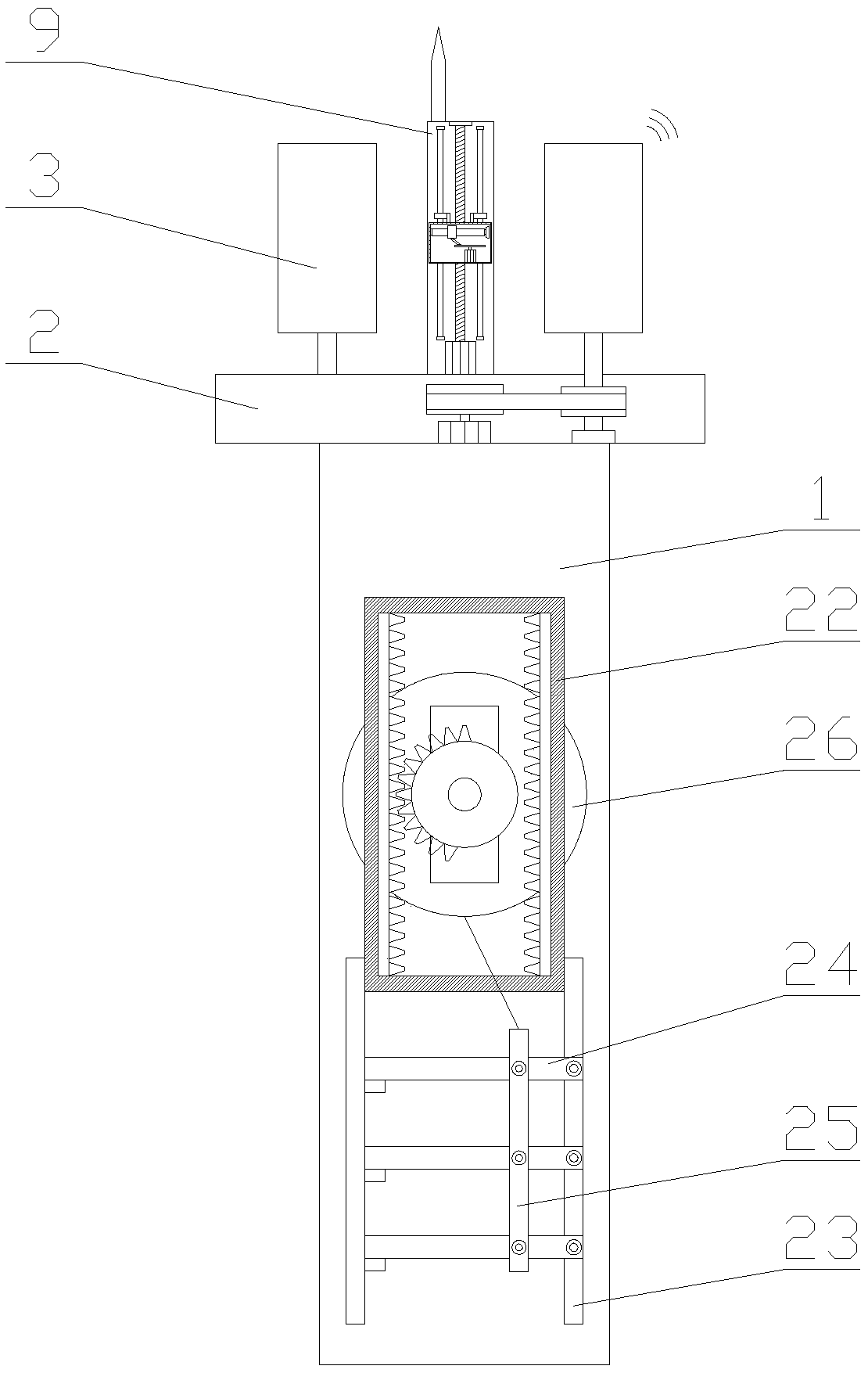

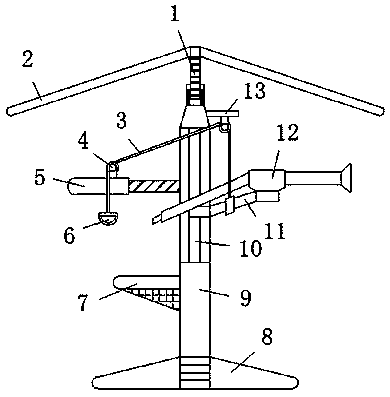

Safe communication tower with deicing and anti-climbing functions

The invention relates to a safe communication tower with deicing and anti-climbing functions. The tower comprises a supporting column, a platform, an antenna, a deicing mechanism and a prevention mechanism; the deicing mechanism comprises a rotating component, a lifting component and a deicing component, and the prevention mechanism comprises a reciprocation component and a rotating component. According to the safe communication tower with the deicing and anti-climbing functions, by means of the deicing mechanism, an ice layer around the antenna is cleaned away uniformly and comprehensively, the phenomenon that a load of the antenna is increased by the ice layer, so that the antenna collapses is prevented, use of the communication tower is affected, and the phenomenon that the ice layer falls from height, and then life and property safety of people around can be threatened is avoided; by means of the prevention mechanism, a cat ladder can stop after jittering and rising to certain height, a cross rod of the cat ladder is turned over by certain angle, the phenomenon that children make direct contact with the cat ladder is avoided, the children are prevented from climbing, the safetyprotection effect is achieved, and practicability and safety of the communication tower are improved.

Owner:国动网络通信集团山东有限公司

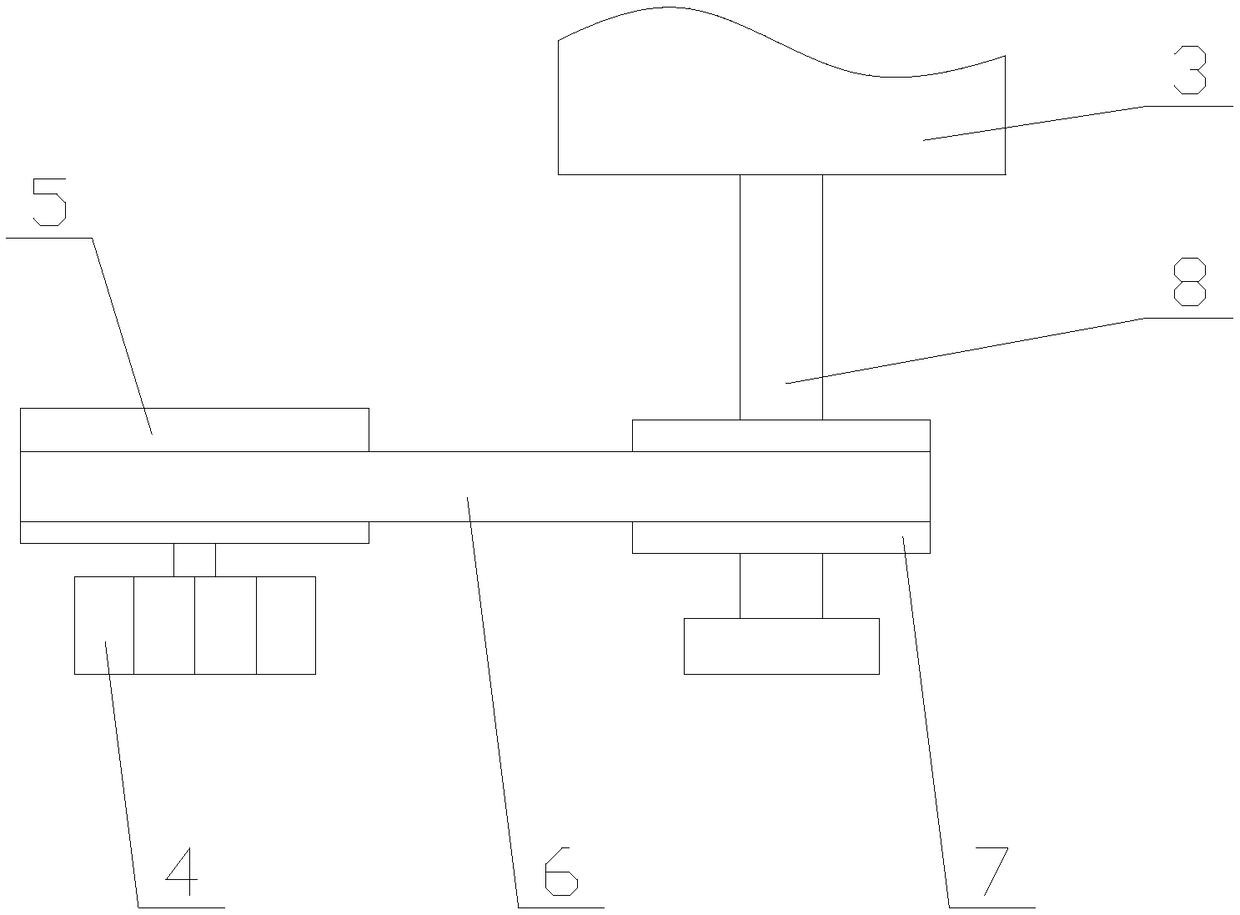

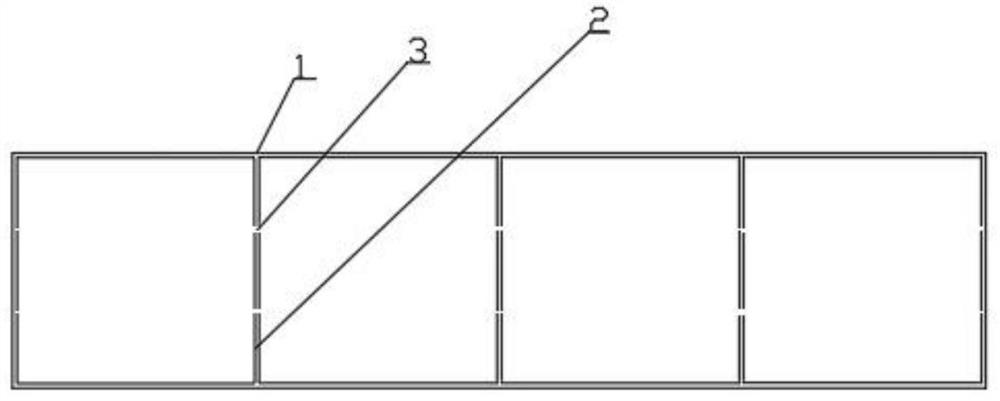

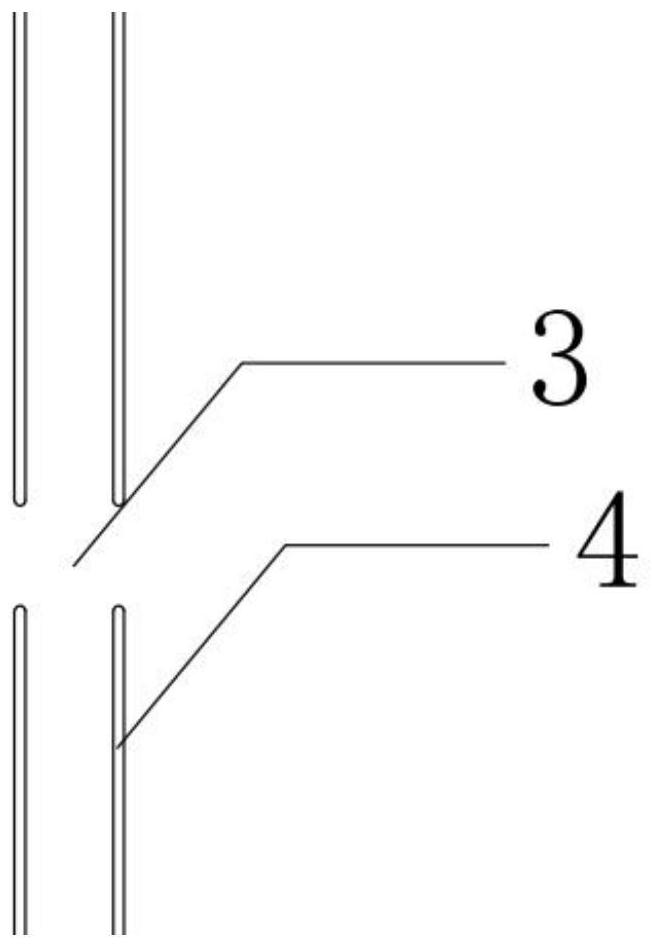

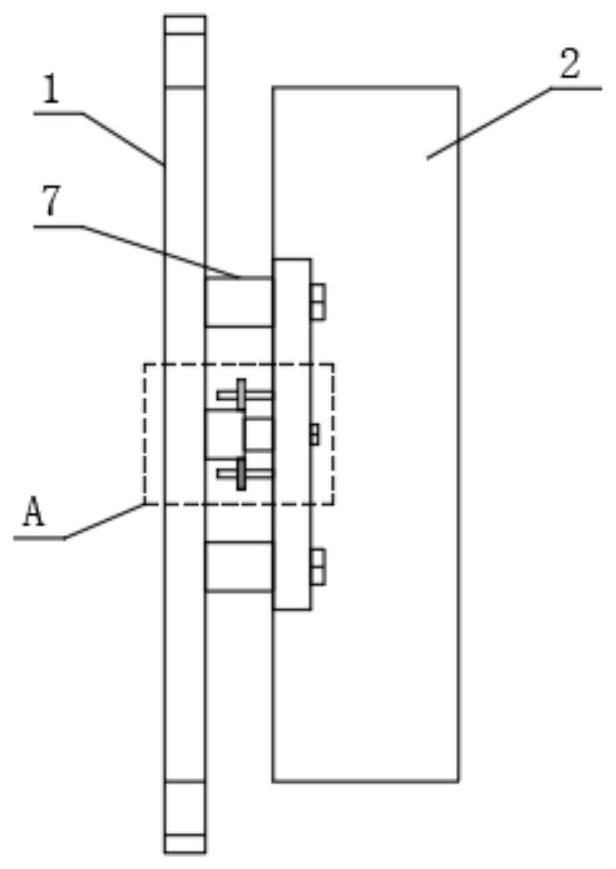

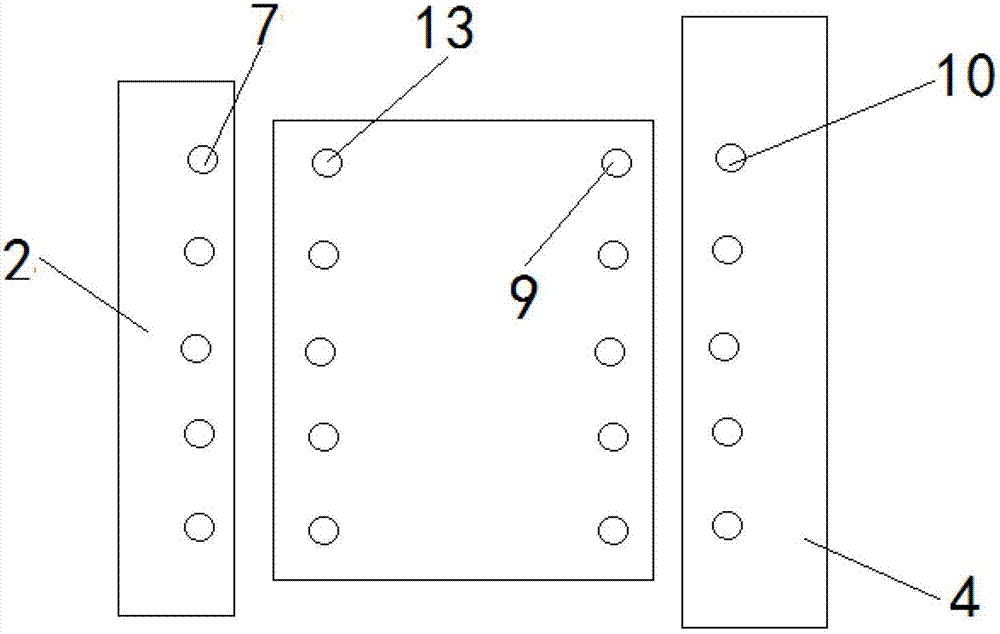

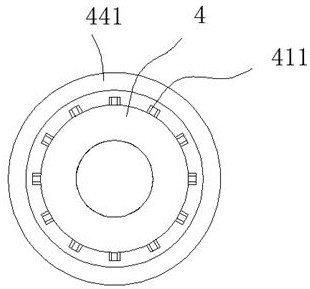

Mooring rope clamping device and safety hoisting device

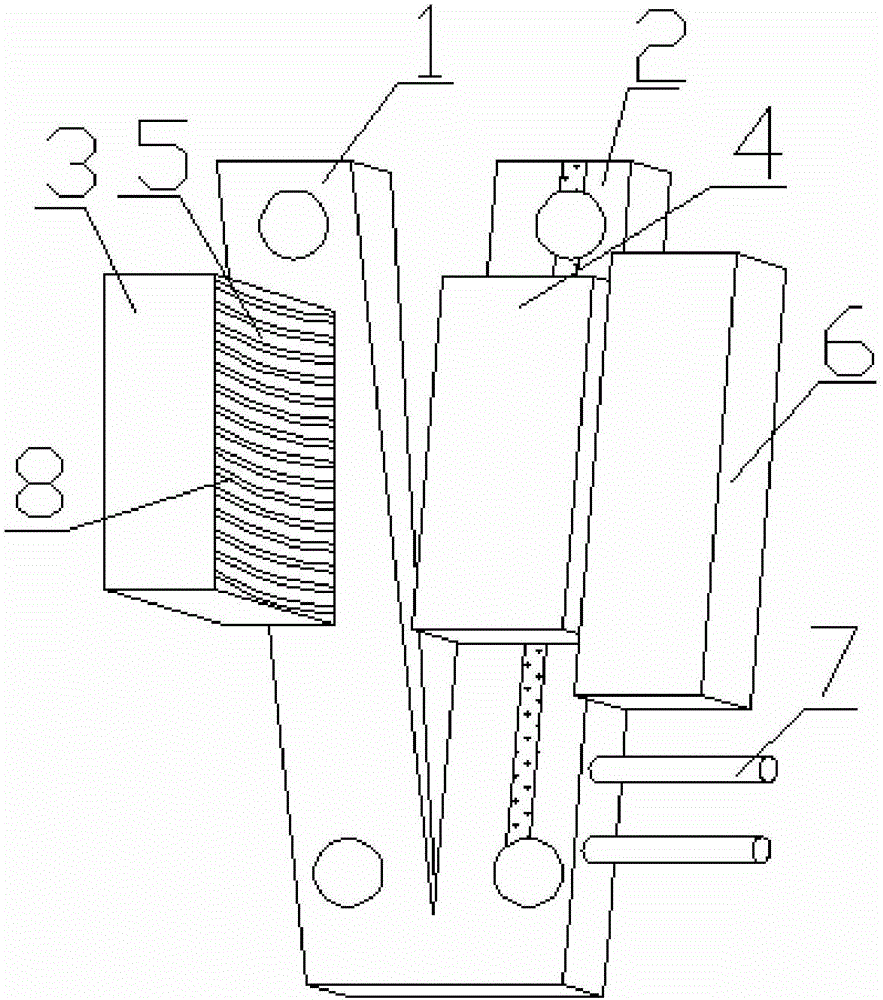

The invention discloses a mooring rope clamping device and a safety hoisting device. The mooring rope clamping device comprises a first bottom plate (1), a second bottom plate (2), a first clamping block (3) and a second clamping block (4); the first clamping block is arranged on the first bottom plate; the second clamping block is arranged on the second bottom plate; a first clamping face (5) is formed on the first clamping block; a second clamping face is formed on the second clamping block; the first clamping face and the second clamping face are oppositely arranged; an included angle is formed between the first clamping face and the second clamping face; the vertical face where the end face of the second clamping face is located gets close to the vertical face where the first clamping face is located from top to bottom; the face, provided with the second clamping block, in the second bottom plate is further provided with a slide rail; a sliding block is arranged on the second clamping block; and a stopping block (6) is further arranged on the side face, far away from the second clamping face, in the second clamping block. After a mooring rope is broken, falling of the hoisting device can be effectively prevented, a certain buffering function is achieved, and the effect of greatly reducing the sharp falling feel is achieved.

Owner:WUHU JINOU MACHINERY MFG CO LTD

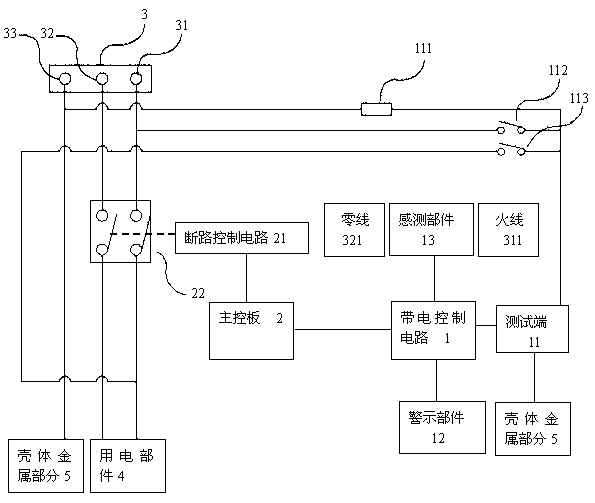

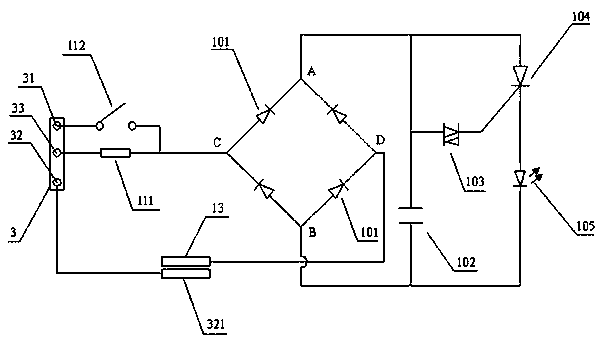

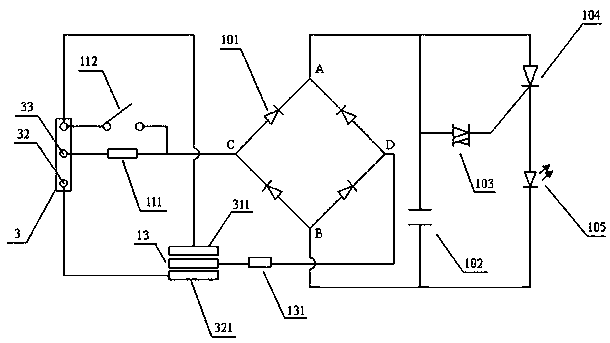

Household appliance

InactiveCN110827510AHave the effect of safety protectionImprove securityCoupling device detailsAlarmsPower gridElectrical connection

The invention discloses a household appliance. The household appliance comprises a housing, a main control board and a live control circuit, wherein a live wire port, a zero wire port, the main control board and the live control circuit are arranged in the housing; a test end of the live control circuit is electrically connected with a metal part of the housing or a conductive part which can be touched by a human body; a sensing part and a warning part are arranged on the live control circuit; the main control board is electrically connected with a power supply port; a circuit break control circuit is arranged on the main control board; the circuit break control circuit controls on and off of an electric control switch; and the live control circuit is electrically connected with the main control board. The technical effects of live warning of a metal housing of the household appliance without a ground wire and automatic power off are achieved; and potential safety hazards caused by disconnection of a ground wire bus of a household power grid of the household appliance with the ground wire are also achieved, so that the household appliance is safer and more reliable, and a user obtains better safety guarantee.

Owner:邝继伍

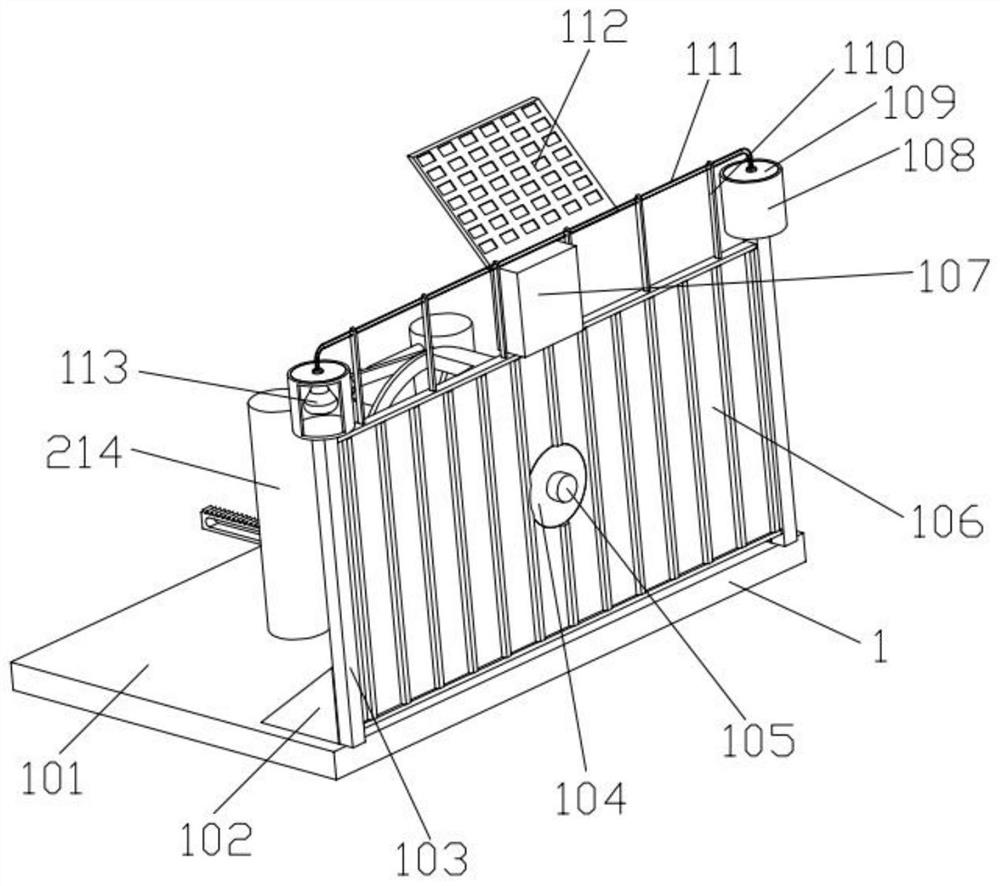

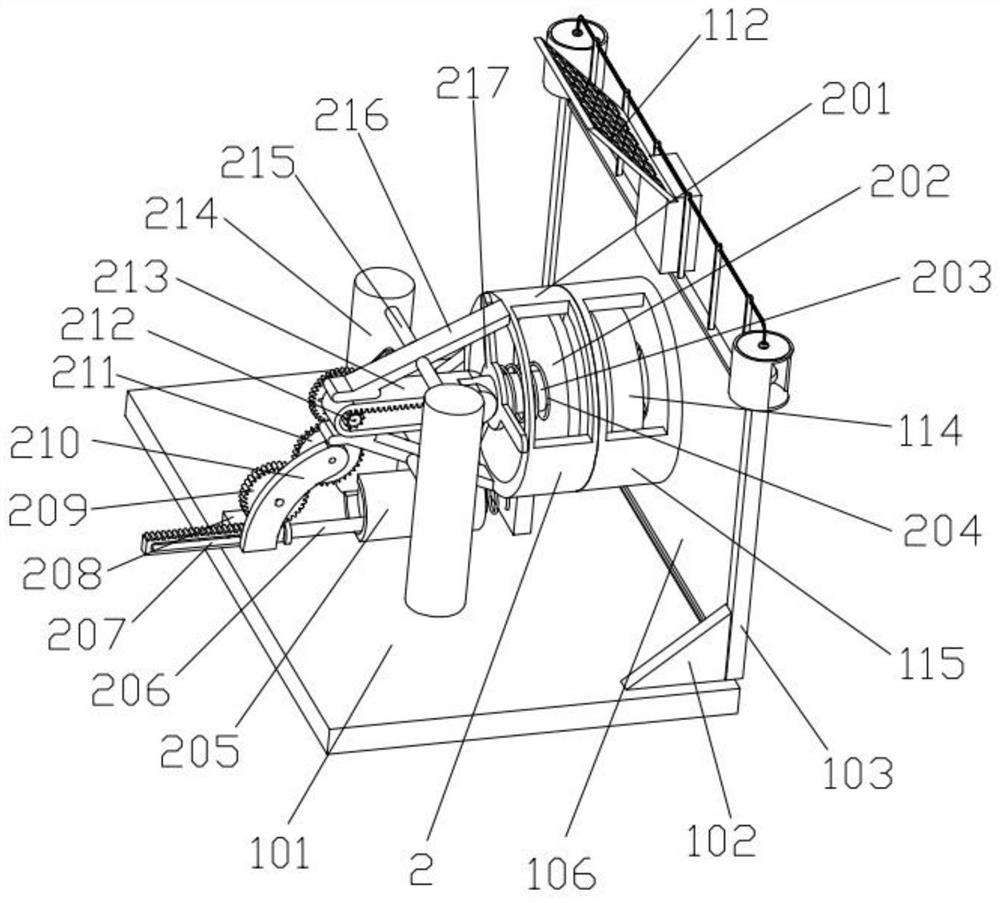

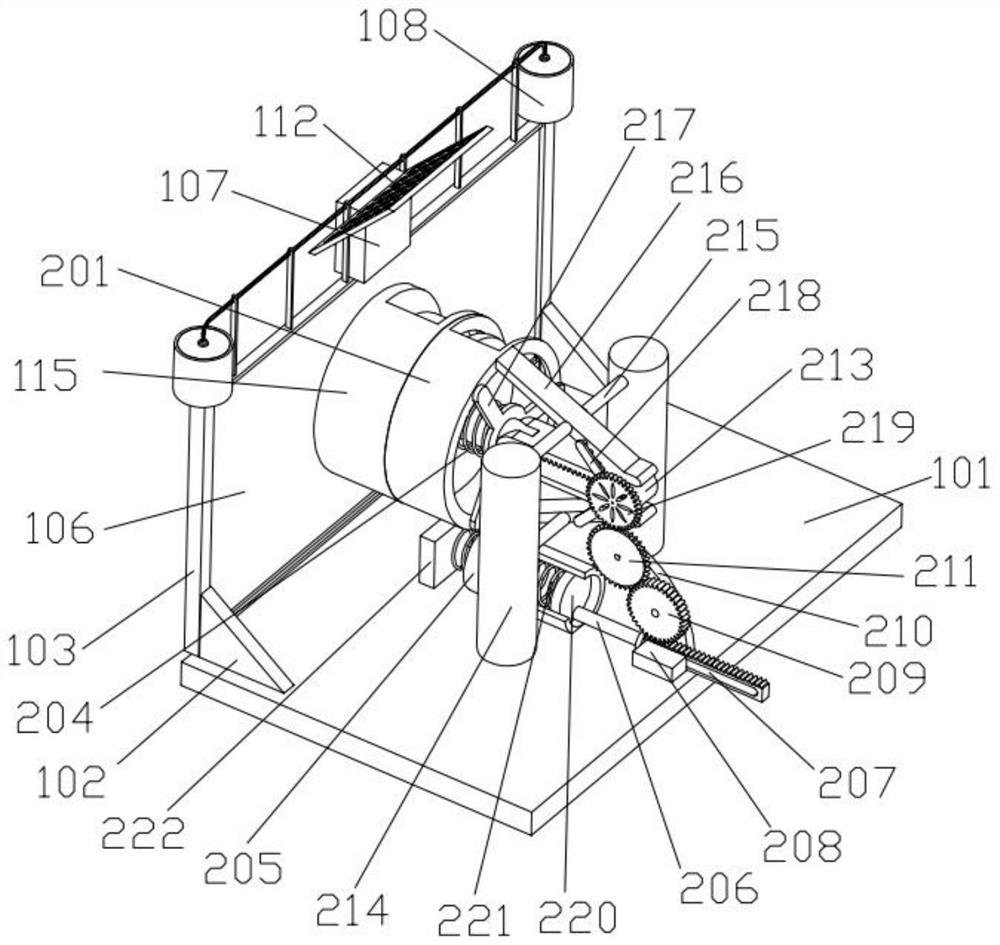

Early warning device for edge protection in building construction

InactiveCN111809542AShorten speedHave the effect of safety protectionElectric circuit arrangementsFencingLaser rangingFixed frame

The invention discloses an early warning device for edge protection in building construction. The device comprises an early warning module and a buffer module, and the early warning module comprises amounting plate, a reinforcing rib, a fixed frame, a paper sheet, a laser ranging sensor, a steel plate, a storage battery, a lampshade, a bulb bracket, a cable bracket, a cable, a photovoltaic panel,a bulb, a solid fuel and a pressure maintaining cavity. According to the invention, the early warning module is arranged, an illumination effect can be provided for approaching vehicles at night, anda warning effect is also provided; by arranging the solid fuel, the running speed of the vehicle can be reduced when the vehicle quickly gets close to the device, so that the safety protection effectis achieved; and by arranging the buffer module, recoil force generated by the solid fuel can be absorbed, and therefore the device becomes more stable during work.

Owner:邢飞

Safety helmet

PendingCN109662375AImprove impact resistancePrevent brittle cracks from losing safetyHelmetsHelmet coversReliability engineering

The invention discloses a safety helmet. The safety helmet comprises a safety helmet body, a head support is arranged inside the safety helmet body, a fixing band is arranged on the lower portion of the safety helmet, the safety helmet body comprises a shell (1) and a sandwiched layer, and the sandwiched layer is located in the shell (1) and detachably connected with the shell (1). The safety helmet is of a double-layer structure which forms double-layer guarantees, the anti-impact capacity of the safety helmet can be improved, it can be prevented that after being impacted, the helmet body isprone to brittle rupture and easily loses safety, and the safety helmet can adapt to field operation, special operation, down-hole operation and other environments, and safely protects the head of a human body.

Owner:郑州廉德建筑劳务分包有限公司

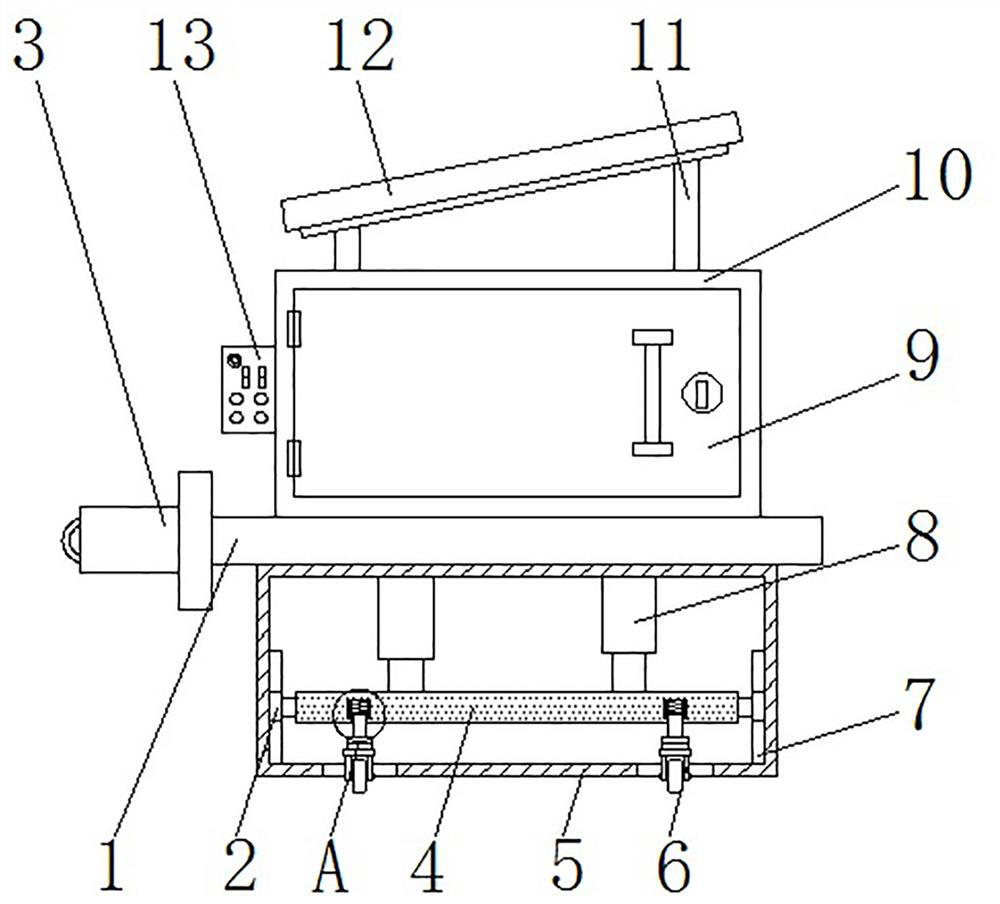

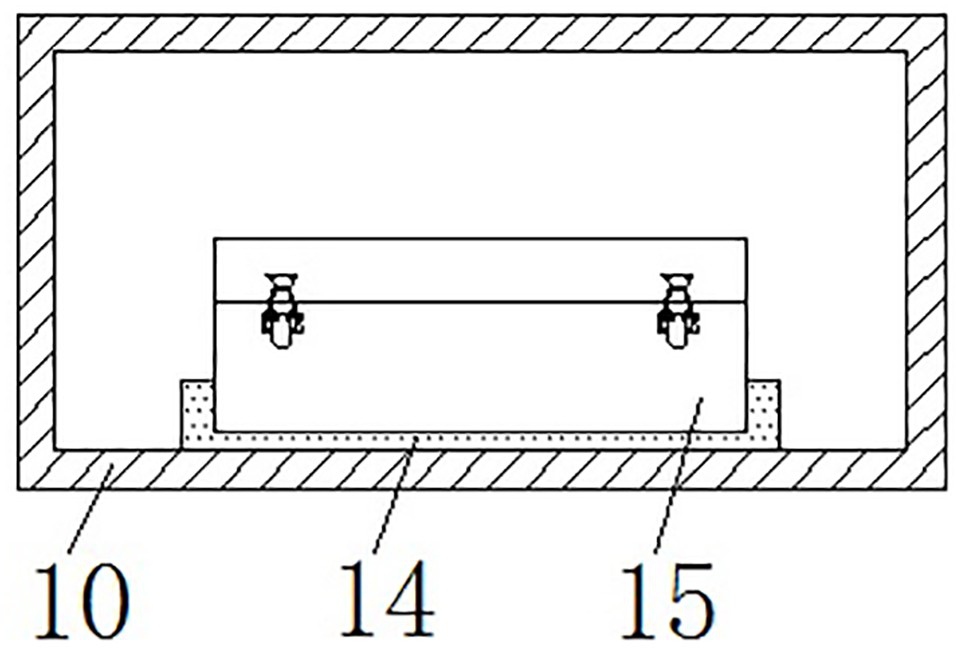

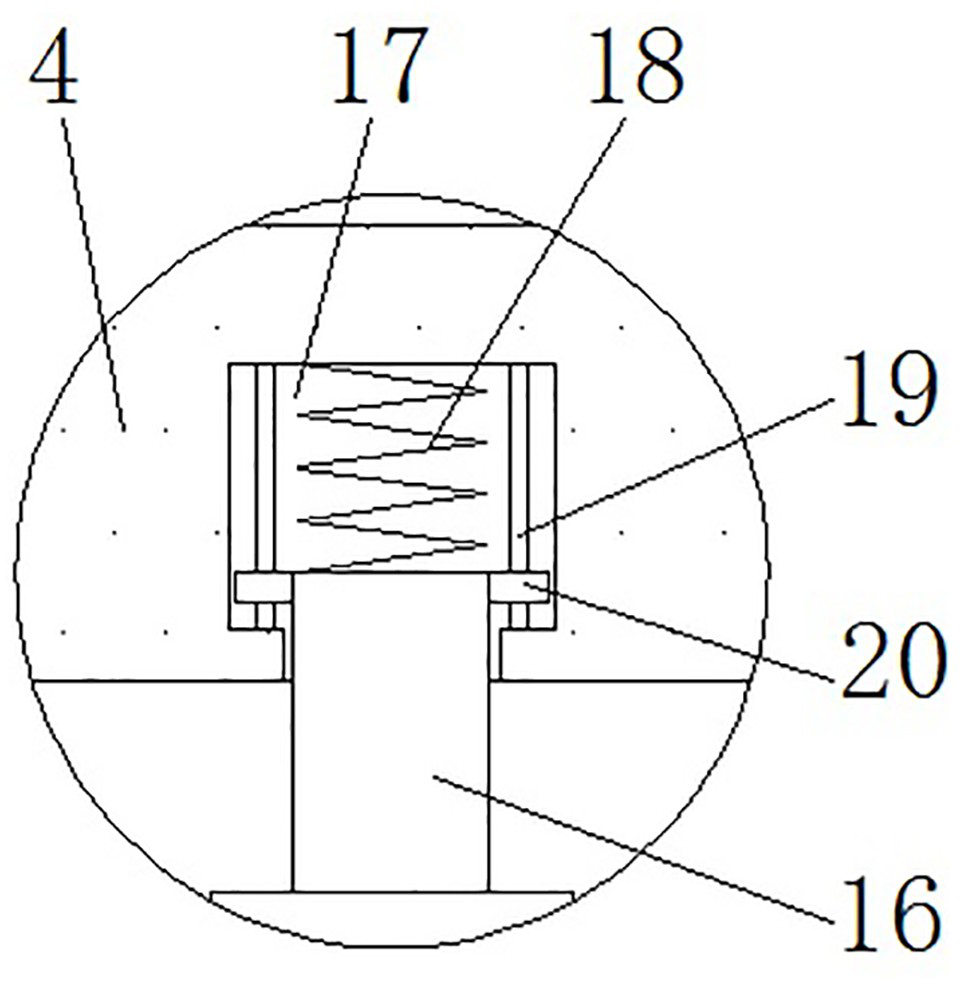

Remote sensing measurement device for geological survey

PendingCN113419293APlay a protective effectExtended service lifeGeological measurementsMeasurement deviceGeological survey

The invention discloses a remote sensing measurement device for geological survey, which comprises an operation table, wherein a protection box is fixedly connected to the top of the operation table, a box door is movably connected to the front face of the protection box, a supporting seat is fixedly connected to the bottom of an inner cavity of the protection box, remote sensing measurement equipment is arranged at the top of the supporting seat, and the bottom of the operation table is fixedly connected with a base box. According to the remote sensing measurement device, by arranging the protection box and the supporting seat, the remote sensing measurement device can be supported and protected, the sun-shading and rain-shielding effects are achieved, and the service life of the remote sensing measurement device is effectively prolonged; by arranging the movable plate, the base box, universal wheels and a telescopic air cylinder, the universal wheels can be driven to stretch out and draw back, and the maneuverability and the stability of the device are effectively improved; and by arranging a movable plate, a connecting rod, a telescopic groove and a spring, the buffering protection effect can be achieved, and when the road surface is not flat enough, jolt of the device can be relieved.

Owner:辽宁省冶金地质勘查研究院有限责任公司

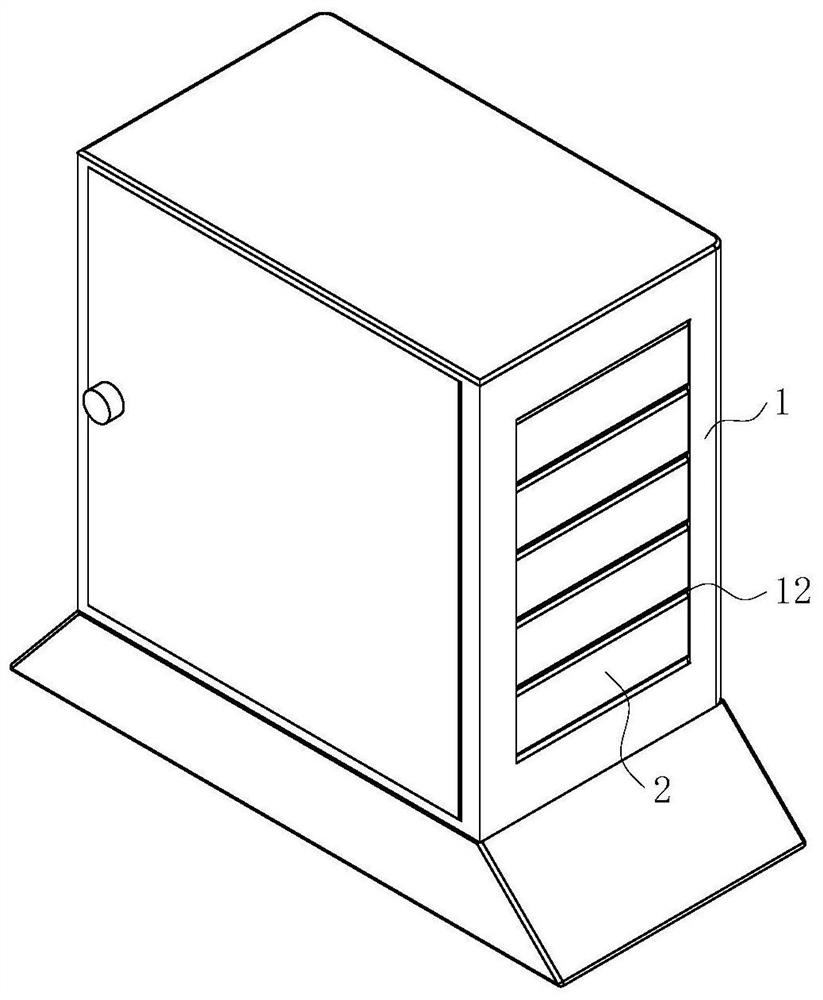

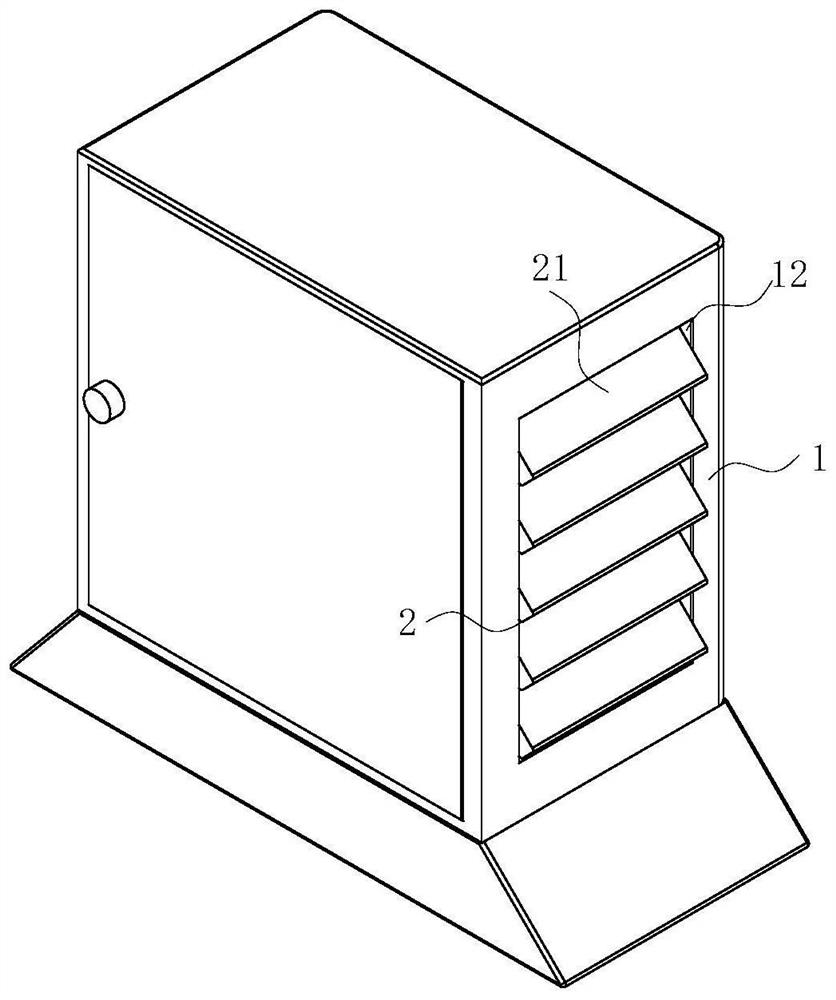

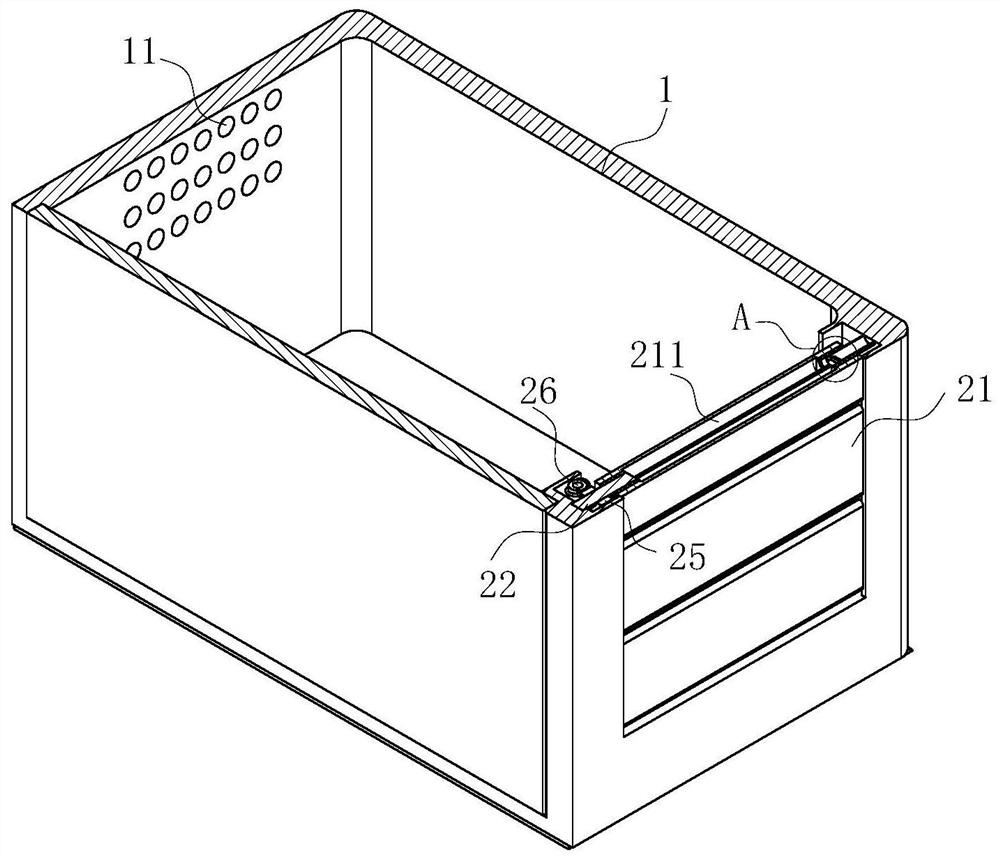

High-voltage power distribution cabinet safety protection method

PendingCN112421442AImprove cooling effectHave the effect of safety protectionSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsCold airAir pump

The invention belongs to the technical field of high-voltage power distribution cabinets, and particularly relates to a high-voltage power distribution cabinet safety protection method, which comprises the following steps that a high-voltage power distribution cabinet is installed in a to-be-used area according to an existing construction process; when a temperature sensor in the high-voltage power distribution cabinet detects that the temperature of external air flowing into the cabinet body is higher than the internal temperature of the cabinet body, a controller indirectly drives a plurality of fan blade plates to rotate and close, so that the cabinet body is sealed; cold air is intermittently supplied to multiple air guide pipes through an air supply pump, the cold air enters a coolingcavity to cool the fan blade plates, and then components in the sealed cabinet body are cooled; and an exhaust fan works to discharge the cold air in the cabinet body to the periphery of the outsideof the cabinet body, so that the cold air generated in the cabinet body circularly flows. According to the invention, the safe and stable heat dissipation effect in the cabinet body is effectively improved, and the safety protection effect on components in the power distribution cabinet can be achieved.

Owner:朱纪昀

Chemical-experiment protecting cover with safety protection function

InactiveCN108339577APrevents interference with in-house chemistry experimentsHave the effect of safety protectionEnclosures/chambersManipulatorEngineering

The invention provides a chemical-experiment protecting cover with a safety protection function. The chemical-experiment protecting cover comprises a supporting base and a transparent outer cover, wherein the transparent outer cover is located at the upper position of the supporting base; further, the transparent outer cover is closely abutted with the supporting base; a temperature measuring strip is embedded in the right lower position of the front end of the transparent outer cover; further, a rotating column is embedded in the upper part of the front end of the transparent outer cover; a movable magnetic plate is fixedly arranged at the lower part of the rotating column; further, two sides of the movable magnetic plate are magnetically connected with magnetic borders; a pull rod is embedded into the middle position of the bottom of the front end of the movable magnetic plate. In the device, through setting the components of the movable magnetic plate and the magnetic borders, the pull rod is grasped by hand to open the movable magnetic plate in a front-rear manner through the rotating column; the placement of a medicine and an agent is carried out; afterwards, due to the magnetic attraction principle of the movable magnetic plate and the magnetic borders, the movable magnetic plate is perfectly tallied with the magnetic borders; the influence on the implementation of an internal chemical experiment is prevented, and the chemical-experiment protecting cover is applicable to the production and use in the field of protecting covers, and has a favorable development prospect.

Owner:叶玉妹

Device for building

InactiveCN105858506AFixed firmlyImprove support strengthCranesArchitectural engineeringSalient point

Owner:周锦泳

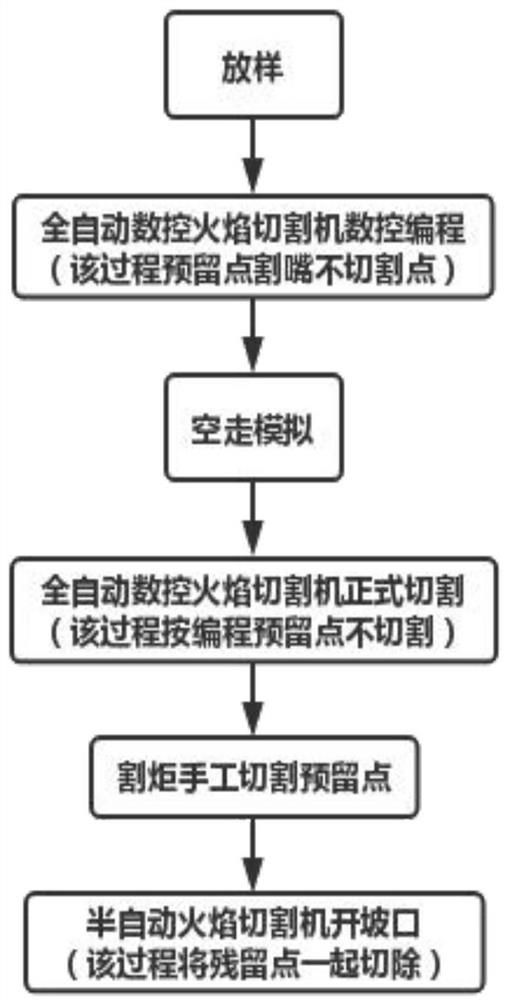

Method for improving flame cutting blanking precision of steel tube arch rib shell section base metal steel plate

PendingCN114523174AEnsure accuracy andQuality assuranceTotal factory controlGas flame welding apparatusNumerical controlFlame cutting

The invention discloses a method for improving flame cutting and blanking precision of a steel tube arch rib shell section base metal steel plate, which comprises the following specific blanking steps: step 1, selecting raw materials, determining the steps of the steel tube arch rib shell section base metal cutting and blanking method and corresponding raw material production equipment, and carrying out trial operation on the production equipment; step 2, lofting a steel plate, performing numerical control programming on a full-automatic numerical control flame cutting machine, compiling a running track of a cutting nozzle in a computer, and debugging related parameters; thirdly, before formal cutting, the cutting torch is made to run for one round in an idle mode according to numerical control programming, and the cutting running track is simulated; fourthly, the full-automatic numerical control flame cutting machine begins to conduct formal cutting, and after cutting is finished, four points of the shell section base metal steel plate are still not cut; the blanking and cutting precision of the steel pipe arch rib shell section base metal steel plate is improved, it is ensured that the blanking precision and quality of the steel plate are within the controllable range, and a foundation is laid for a series of subsequent machining and manufacturing of the steel pipe arch rib with the high precision requirement.

Owner:广西桂通工程管理集团有限公司

Household bedside ultraviolet anti-acarid lamp

InactiveCN107646813AImprove the safety of useGuaranteed installation stabilityInsect catchers and killersEngineeringExhaust pipe

The invention discloses a household bedside ultraviolet mites removing lamp, comprising a mounting plate, an air suction pipe is arranged inside the installation plate, a suction cup is arranged inside the air suction pipe, a piston rod is arranged inside the air suction pipe, and the suction pipe is An exhaust pipe is arranged at the edge of the surface of the air pipe, a filter screen is arranged at the connection between the exhaust pipe and the air extraction pipe, a one-way valve rod is rotatably connected inside the exhaust pipe, and a clamping plate is welded on the outside of the mounting plate. And the clamping plate is connected with the clamping post through the positioning pin, the clamping post is connected with the base through the connecting rod, the top of the base is provided with an ultraviolet generator, and the outer surface of the ultraviolet generator is provided with a protective cover, A UV lamp tube is arranged at the bottom of the base, and a protective grille is arranged on the outer surface of the UV lamp tube. In the present invention, the overall structure design of the ultraviolet mite removal lamp is simple and reasonable, the installation and disassembly process is convenient and flexible, the mite removal efficiency is high, and it has strong practicability.

Owner:CHENGDU XINXIN HIGH STRENGTH FASTENER MFRCO

A safe communication iron tower with deicing and anti-climbing functions

The invention relates to a safe communication tower with deicing and anti-climbing functions. The tower comprises a supporting column, a platform, an antenna, a deicing mechanism and a prevention mechanism; the deicing mechanism comprises a rotating component, a lifting component and a deicing component, and the prevention mechanism comprises a reciprocation component and a rotating component. According to the safe communication tower with the deicing and anti-climbing functions, by means of the deicing mechanism, an ice layer around the antenna is cleaned away uniformly and comprehensively, the phenomenon that a load of the antenna is increased by the ice layer, so that the antenna collapses is prevented, use of the communication tower is affected, and the phenomenon that the ice layer falls from height, and then life and property safety of people around can be threatened is avoided; by means of the prevention mechanism, a cat ladder can stop after jittering and rising to certain height, a cross rod of the cat ladder is turned over by certain angle, the phenomenon that children make direct contact with the cat ladder is avoided, the children are prevented from climbing, the safetyprotection effect is achieved, and practicability and safety of the communication tower are improved.

Owner:国动网络通信集团山东有限公司

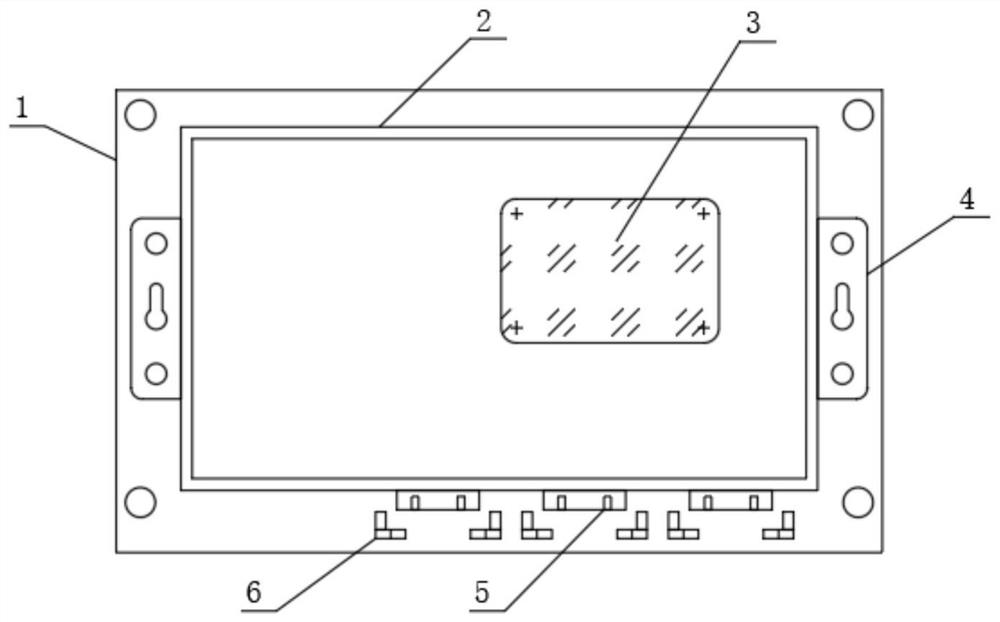

A high-efficiency environmental protection data acquisition and transmission instrument and its use method

ActiveCN109495589BHave the effect of safety protectionAvoid damageStands/trestlesTransmissionThe InternetData acquisition

The invention discloses a high-efficiency and environment-friendly data collection and transmission instrument, which includes a mounting plate and a transmission instrument main body. A plurality of Internet interfaces are embedded in the lower part of the transmission instrument main body, and a display screen is embedded in the front surface of the transmission instrument main body. The outer surface of the main body of the transmission instrument is fixed with two relatively distributed mounting pieces, and the bottom of the front surface of the mounting plate is also fixed with a plurality of stable components corresponding to the Internet interface, and each of the Internet interfaces There are two stabilizing components opposite to each other; a telescopic component is installed between the mounting plate and the mounting piece; the present invention facilitates the safety protection effect on the main body of the transmission instrument through the setting of the telescopic component, avoiding the The main body of the transmission instrument is damaged during the operation; the invention can make the connection between the cross network cable and the Internet interface more stable through the setting of the stabilizing component, and avoid the trouble of reconnecting and setting the cross network cable accidentally dropped.

Owner:山东润通科技有限公司

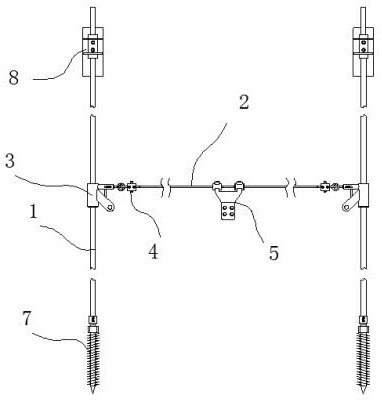

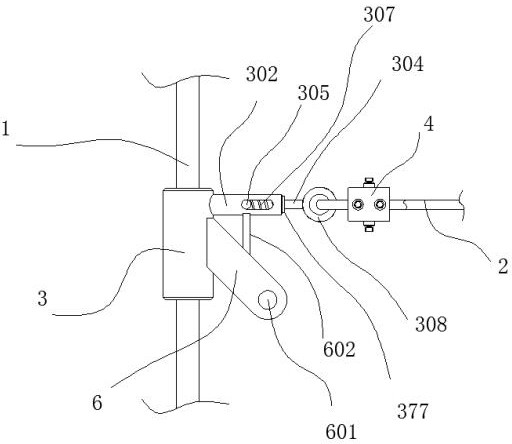

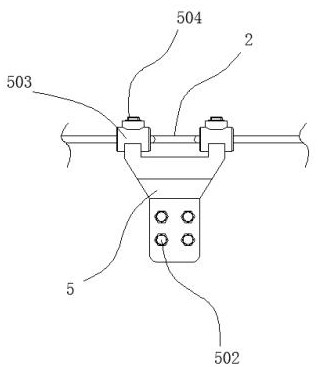

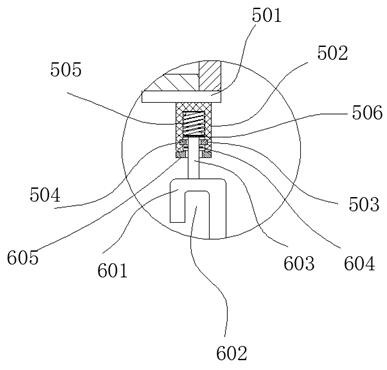

Safety device for movable window frame of building

ActiveCN110469253ALow retrofit costDoes not affect normal opening and closingWing accessoriesSpecial door/window arrangementsEngineeringMechanical engineering

The invention discloses a safety device for a movable window frame of a building. The safety device comprises an upper fixing piece, a lower fixing piece, a rope assembled between the two fixing pieces, and a safety mechanism movably assembled on the rope. Each fixing piece comprises a screw provided with a self-tapped thread, wherein one end of the screw is machined into a sharp end, the self-tapped thread extends to the sharp end, the outer wall of the screw is machined to form a baffle used for limiting, a connecting part is machined at the other end of the screw, and a connecting thread ismachined outside the connecting part. The safety device is of an external structure and thus can be used for transforming a mounted window, and the transformation cost is low.

Owner:浙江皓睿建设有限公司

Ship deck observation device

PendingCN107813903APlay the role of safety anti-looseningInhibit sheddingVessel partsMarine engineeringTelescope

The invention discloses a ship deck observation device which comprises a support rack, wherein a bearing plate is arranged at the top of the support rack; a hollow tube is arranged at the top of the bearing plate; the top of the hollow tube is connected with a spring tube through an anti-drop chain; a ceiling is arranged at the top of the spring tube; an anti-collision rod is arranged on one sideof the support rack; a fixed pulley is arranged at the top of the anti-collision rod; a chair is arranged below the anti-collision rod; a guide track is arranged on the surface of the support rack; the guide track is connected with a telescope through a clamping plate; the clamping plate penetrates through a hanging rod on the support rack and the fixed pulley on the anti-collision rod to be connected with a hand ring by a cable wire; and a base is welded at the bottom of the support rack. The ship deck observation device is simple and reasonable in structural design, the use security of devices and the operator security are effectively protected, and meanwhile, the ship deck observation device is flexible and convenient to operate and relatively good in practicability.

Owner:泰兴市汇辰过滤器制造有限公司

A control method of a fingerprint lock emergency lock protection device

The invention relates to an emergency lock protection device for a fingerprint lock. The emergency lock protection device for the fingerprint lock comprises a lock body and an emergency lock which is arranged at the lower portion of the lock body, an emergency lock port cover is arranged on the front end surface of the emergency lock, a position magnet which is in magnetic suction with an emergency lock hole cover in a linked mode is arranged on the rear end surface of an emergency lock port, a position sensing element which corresponds to the position magnet is arranged on the position magnet, and the position sensing element is a switch of a warning circuit. The emergency lock protection device for the fingerprint lock has the advantages of being simple in structure, convenient to use and reliable in performance. When the emergency lock port cover plate is opened in a mechanical mode, alert is definitely triggered, and the effect of safety and protection is achieved. The emergency lock port cover enables the appearance of the lock to be simpler and more beautiful, and safety of the fingerprint lock can be increased through a warning device.

Owner:ZHEJIANG DUMA SEWING MACHINE

A high-altitude stabilizing device for building exterior wall construction

ActiveCN112096046BStable supportWorking at heights safetyScaffold accessoriesBuilding support scaffoldsSafety wireArchitectural engineering

Owner:湖南中巨建设工程有限公司

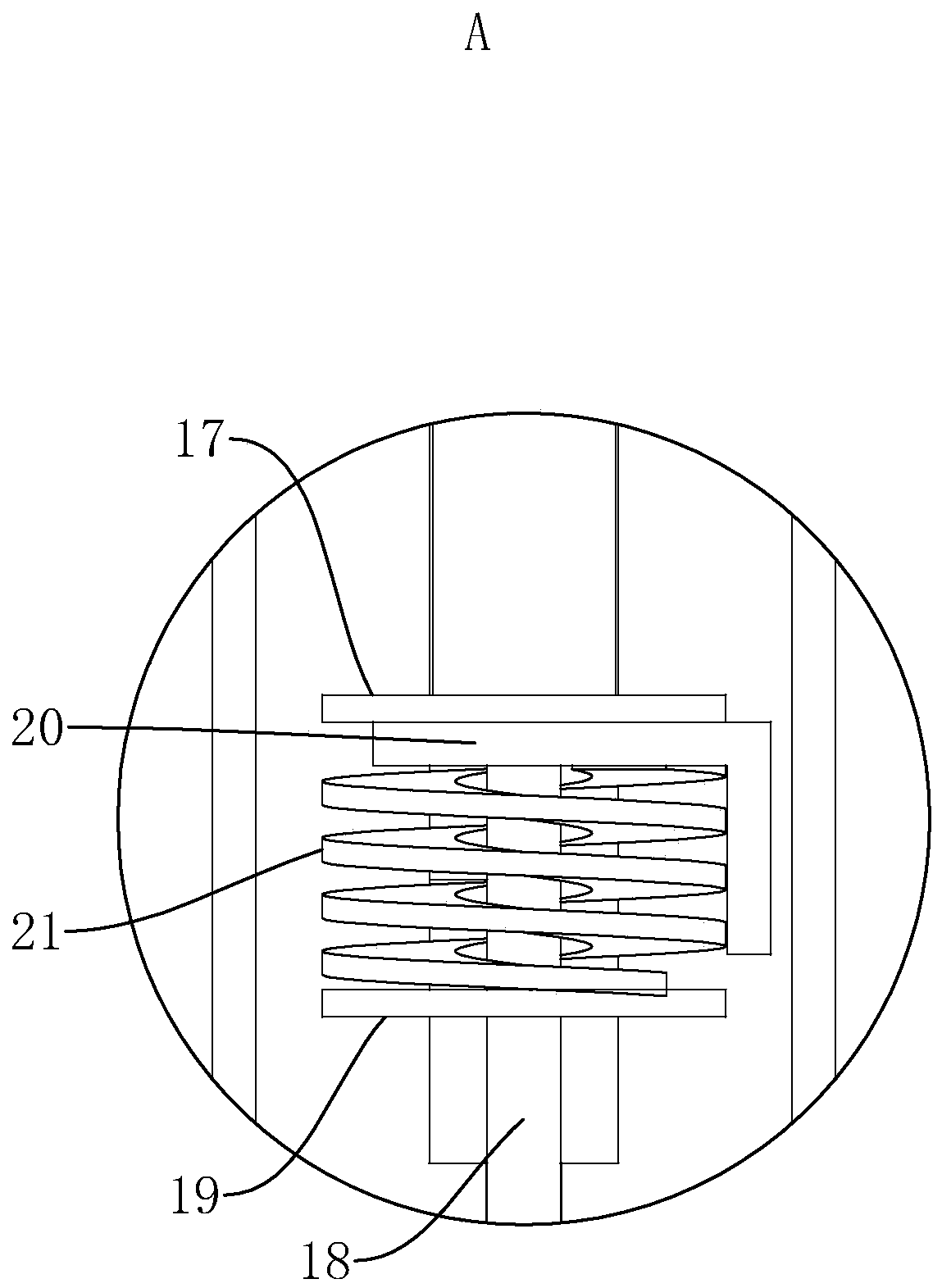

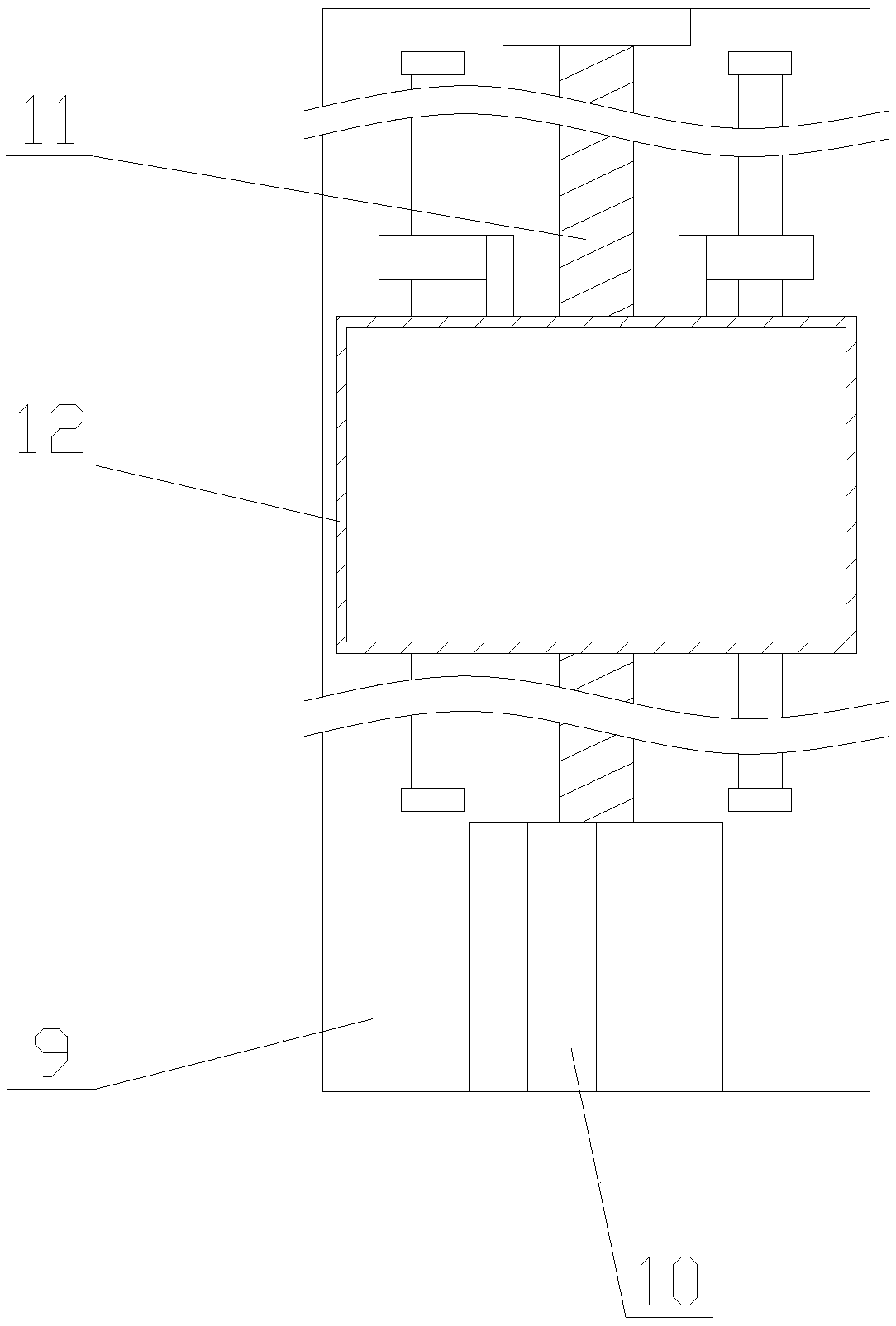

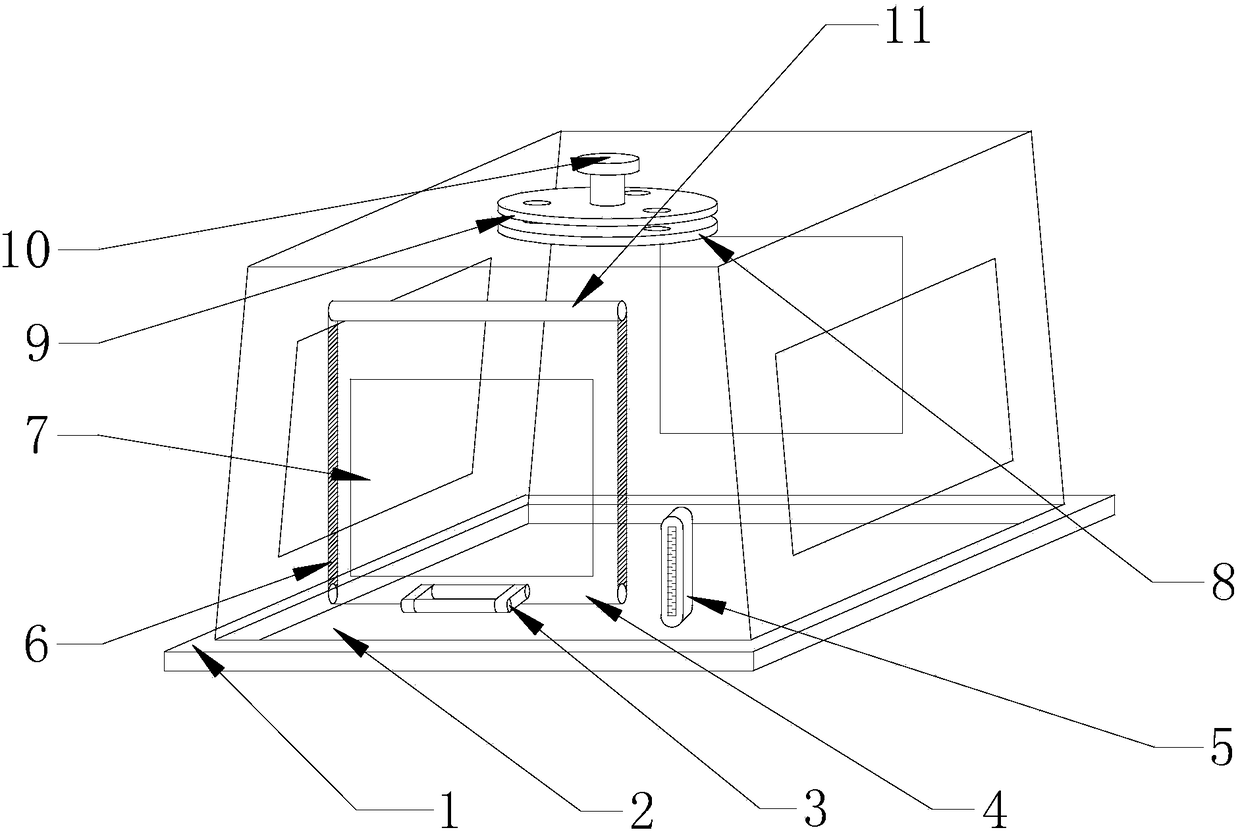

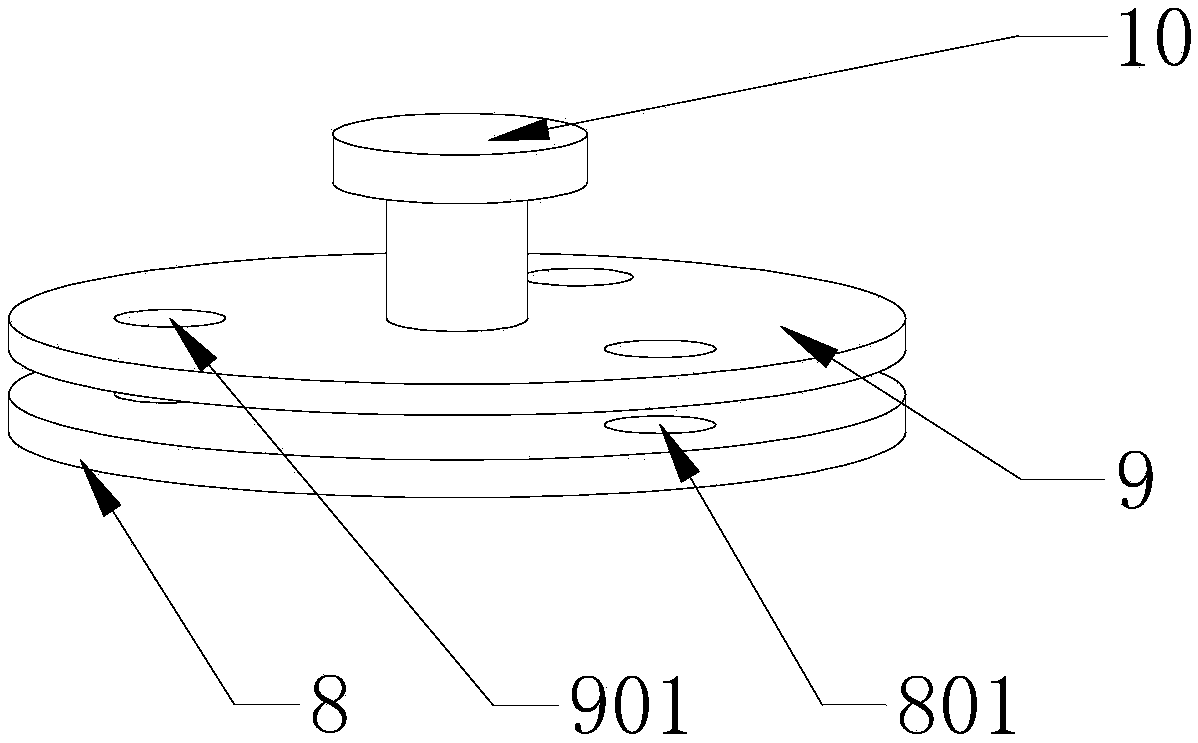

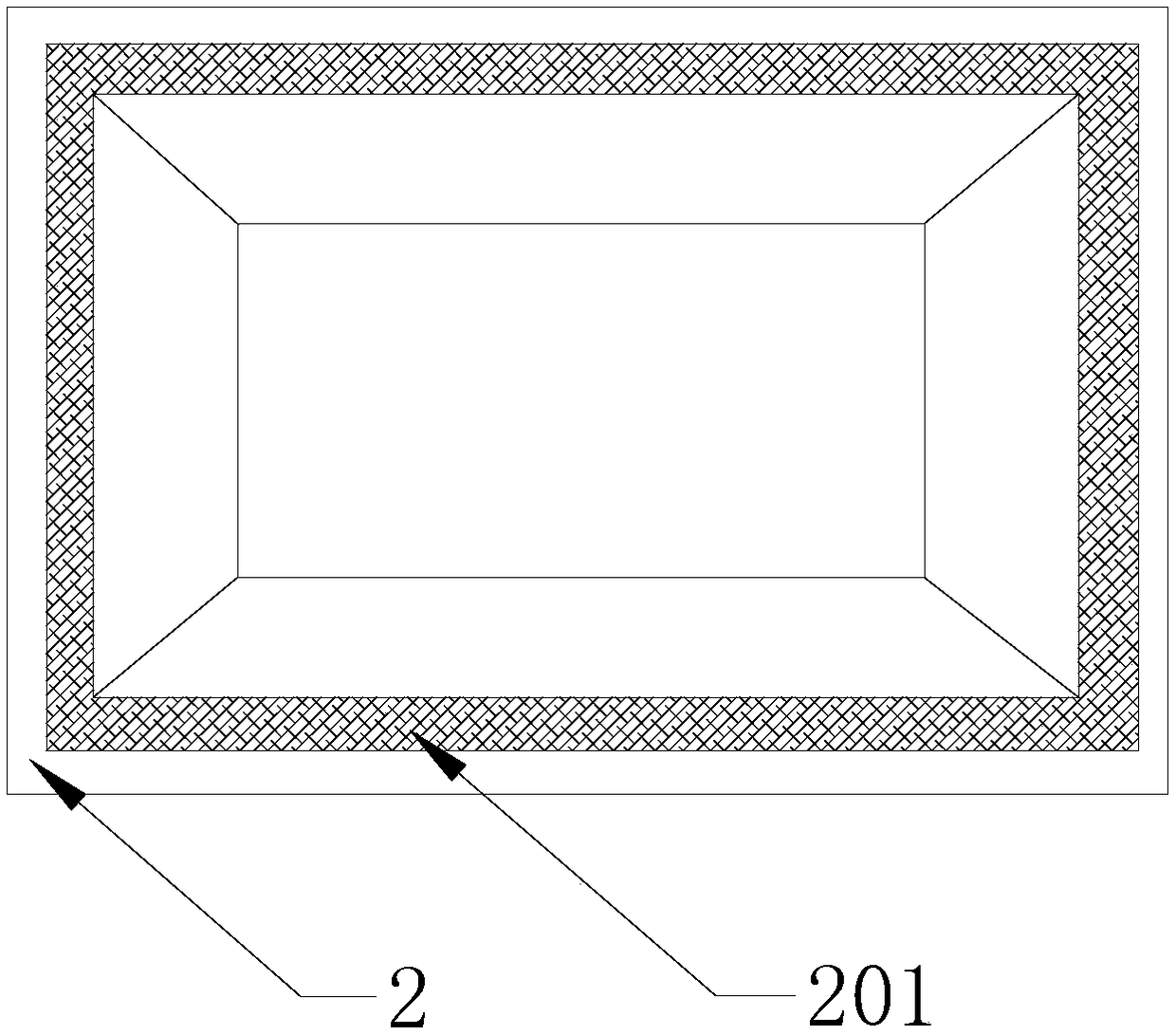

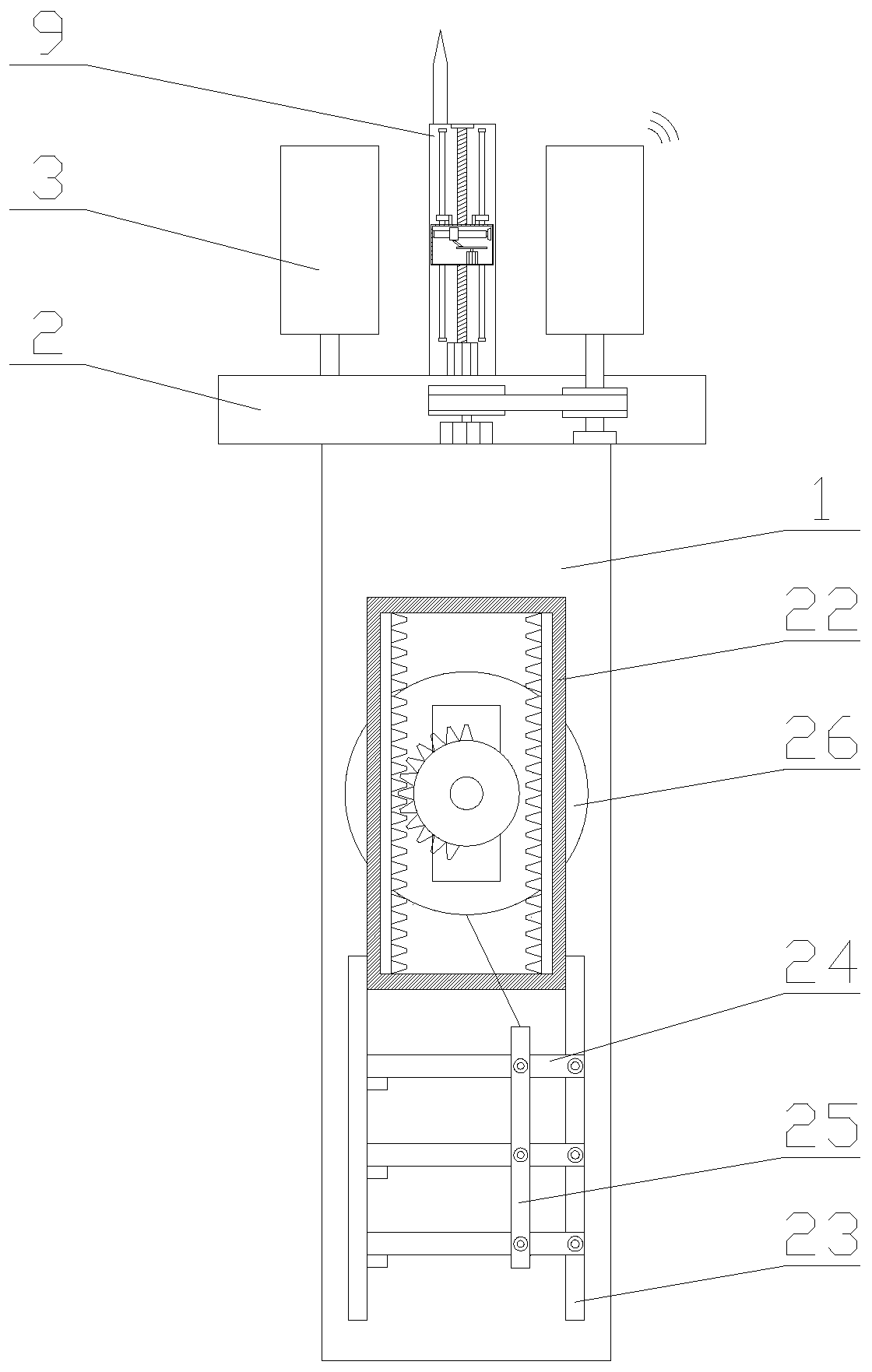

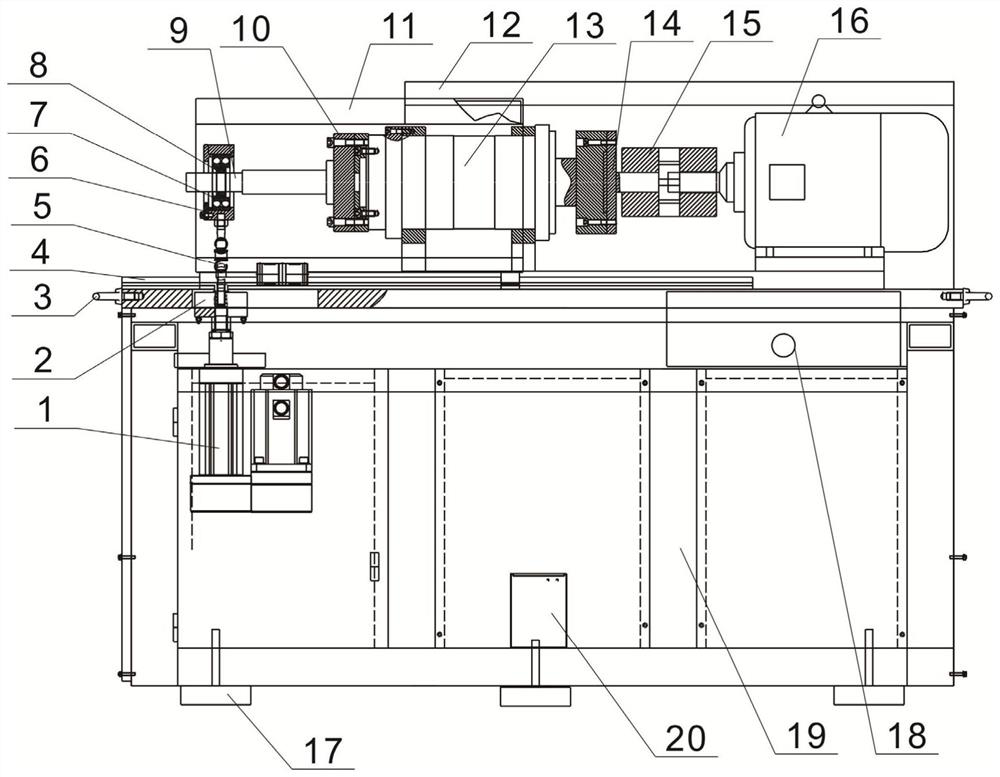

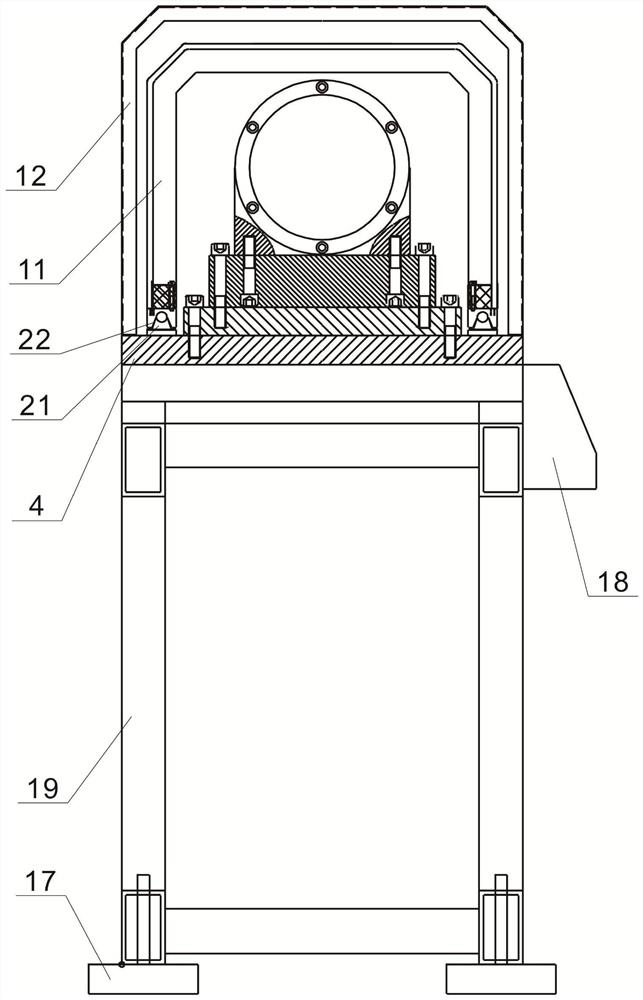

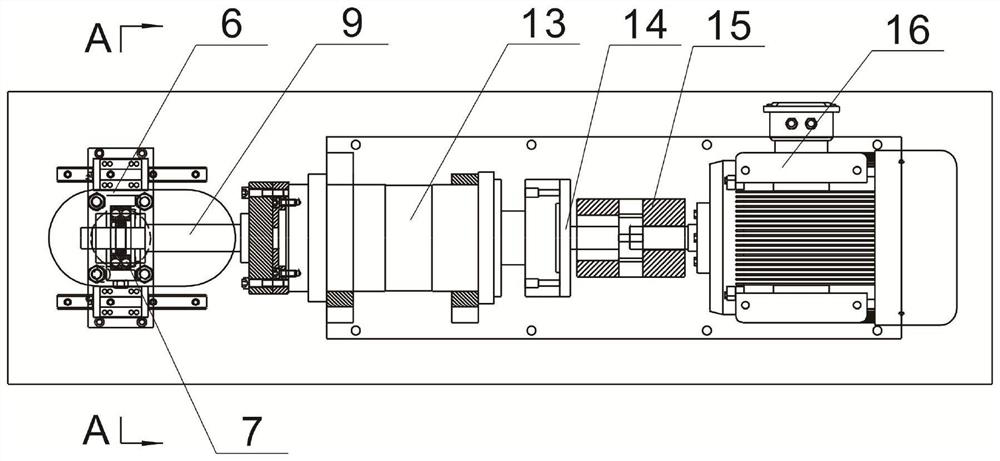

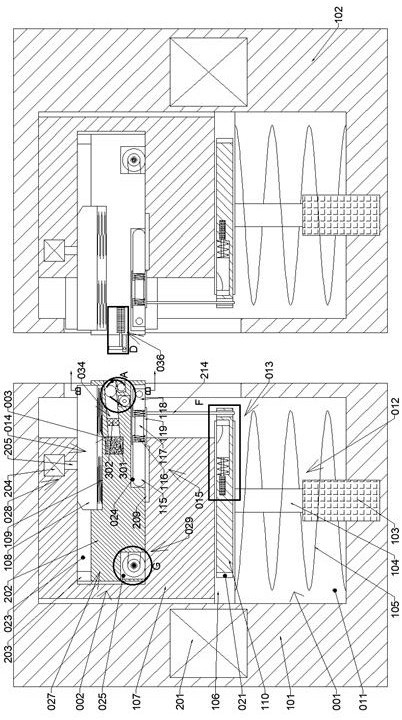

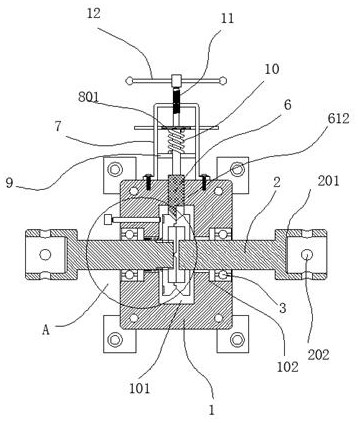

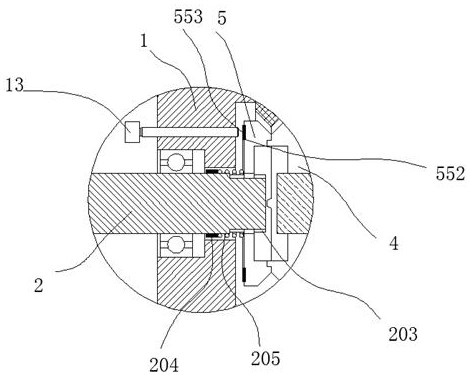

Rotary bending fretting fatigue test device for interference fit structure

PendingCN114252346AEasy to installHave the effect of safety protectionMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesInterference fitConstant force

The invention discloses an interference fit structure rotation bending fretting fatigue test device, which comprises a sample wheel and a sample shaft, a mounting hole of the sample wheel is in interference fit connection with the sample shaft, the sample wheel is fixedly connected with a rotation driving device, the sample shaft is rotatably arranged in a clamping device, and the clamping device is provided with a linear driving device. The driving direction of the linear driving device is perpendicular to the axis direction of the sample shaft, a circulating water cooling device is arranged at the clamping device, and the rotary driving device and the linear driving device are both arranged on the workbench. According to the invention, the rotary driving device applies a rotary load to the sample wheel and the sample shaft which are in interference fit, the linear driving device applies a bending load to the sample shaft and the sample wheel which are in interference fit, and the circulating water cooling device performs circulating water cooling; and the sample shaft and the sample wheel which are in interference fit rotate under a normal-temperature environment condition and bear a constant force for generating a bending moment, so that the sample shaft and the sample wheel which are in interference fit are subjected to a fatigue performance test of bearing a bending moment under a rotating condition.

Owner:SOUTHWEST JIAOTONG UNIV

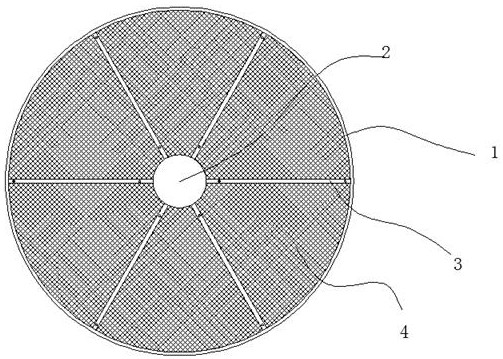

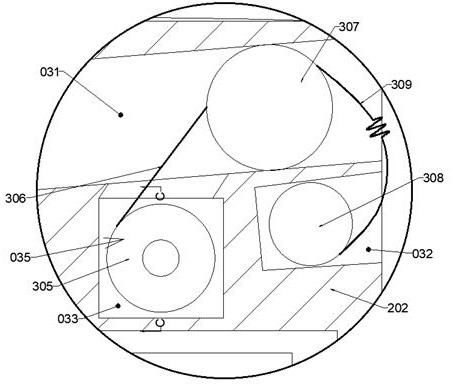

A mixer feeding device for building construction

ActiveCN111730756BAchieve tremorIncrease the feeding speedSievingScreeningArchitectural engineeringMechanical engineering

The invention discloses a mixer blanking device for building construction, which comprises a container arranged above the mixer, the diameter of the container is not smaller than the diameter of the mixer, and an axis block is arranged at the bottom axis of the container, so that A plurality of connecting rods are welded between the axis block and the container, a fan-shaped area is formed between two adjacent connecting rods, and a metal screen is welded in the formed fan-shaped area; There is a support structure, and there is a quick-release structure between the support structure and the container; this product can be assembled on the top of the mixer, and the raw materials are screened while discharging.

Owner:新昌县品创建筑设计有限公司

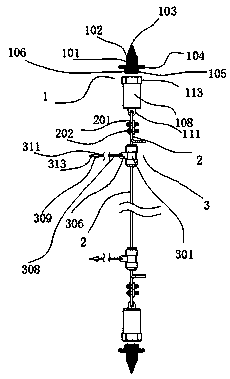

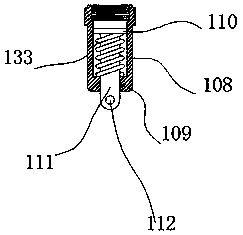

Equipment for braking falling elevator and protecting people against falling in elevator shaft

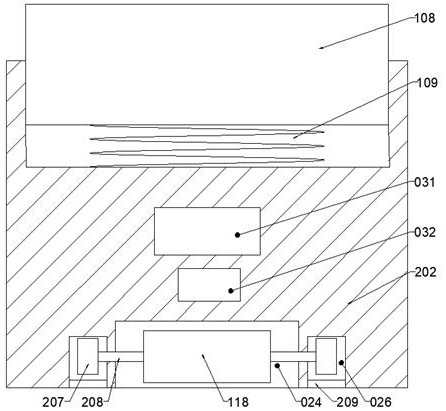

The invention relates to the technical field of elevator safety equipment, in particular to equipment for braking a falling elevator and protecting people from falling in an elevator shaft. The equipment for braking the falling elevator and protecting the people against falling in the elevator shaft comprises a first fixing body and a second fixing body which are arranged in the two side walls of the elevator shaft correspondingly, pushing air pumps are fixedly arranged in the first fixing body and the second fixing body correspondingly, buffering cavities are formed in the first fixing body and the second fixing body correspondingly, a damping main plate and a lifting block slide in each buffer cavity, the lifting blocks are placed on the damping main plates, and a pushing cavity is formed in each lifting block. The whole equipment is provided with a damping device for braking the falling elevator, so that the falling elevator and the people in danger can be subjected to safety protection, the elevator is braked, personal injury caused by falling of the people is prevented, and the safety protection effect is achieved.

Owner:深圳迪乐尔实业有限公司

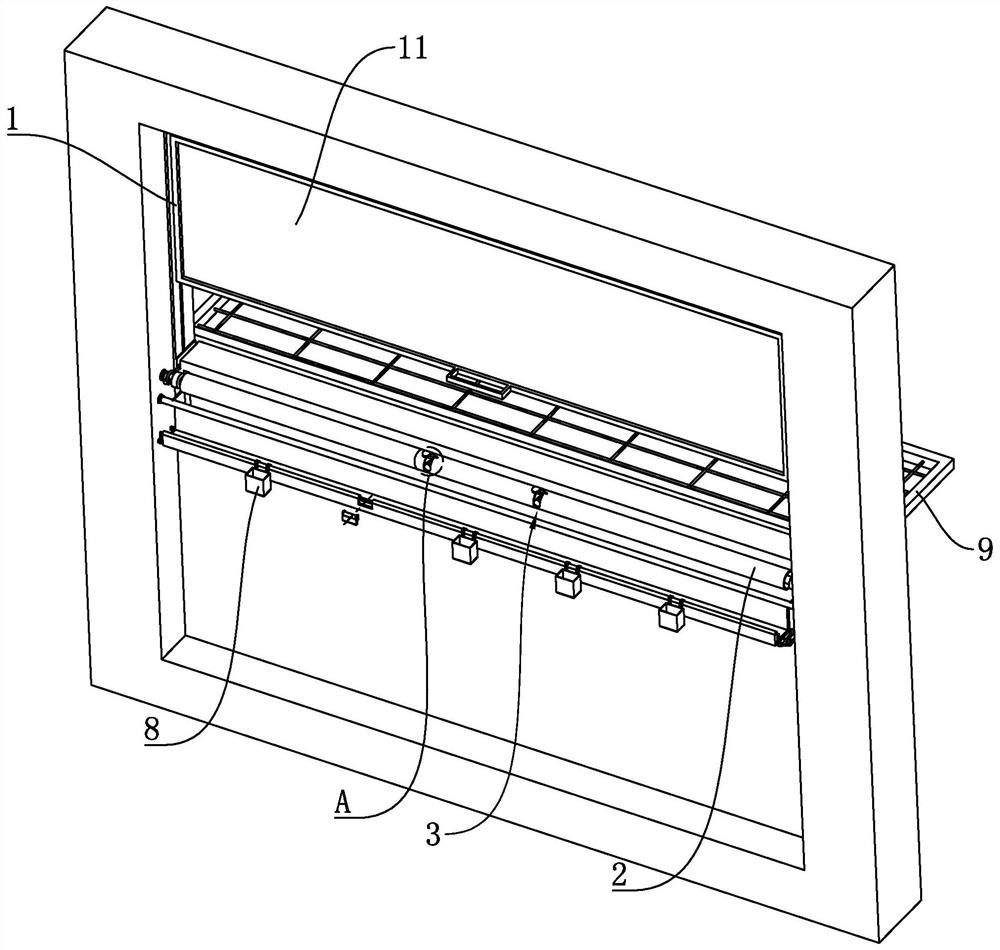

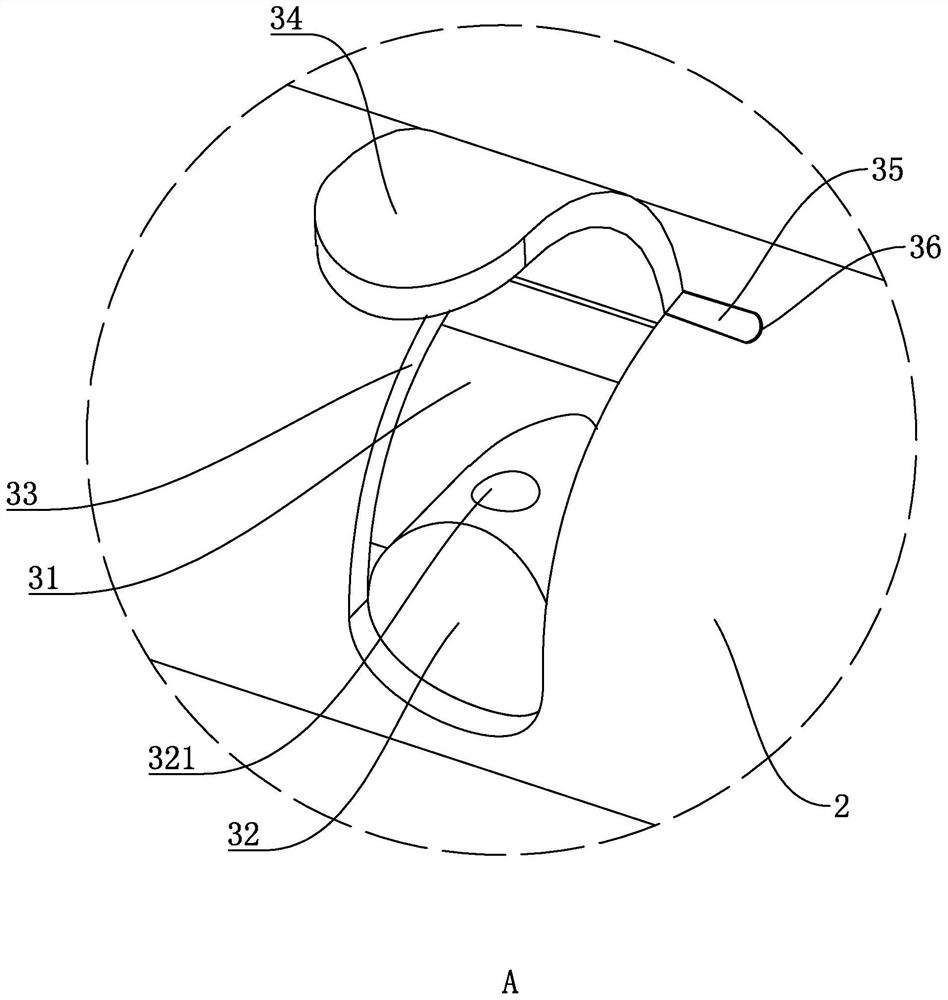

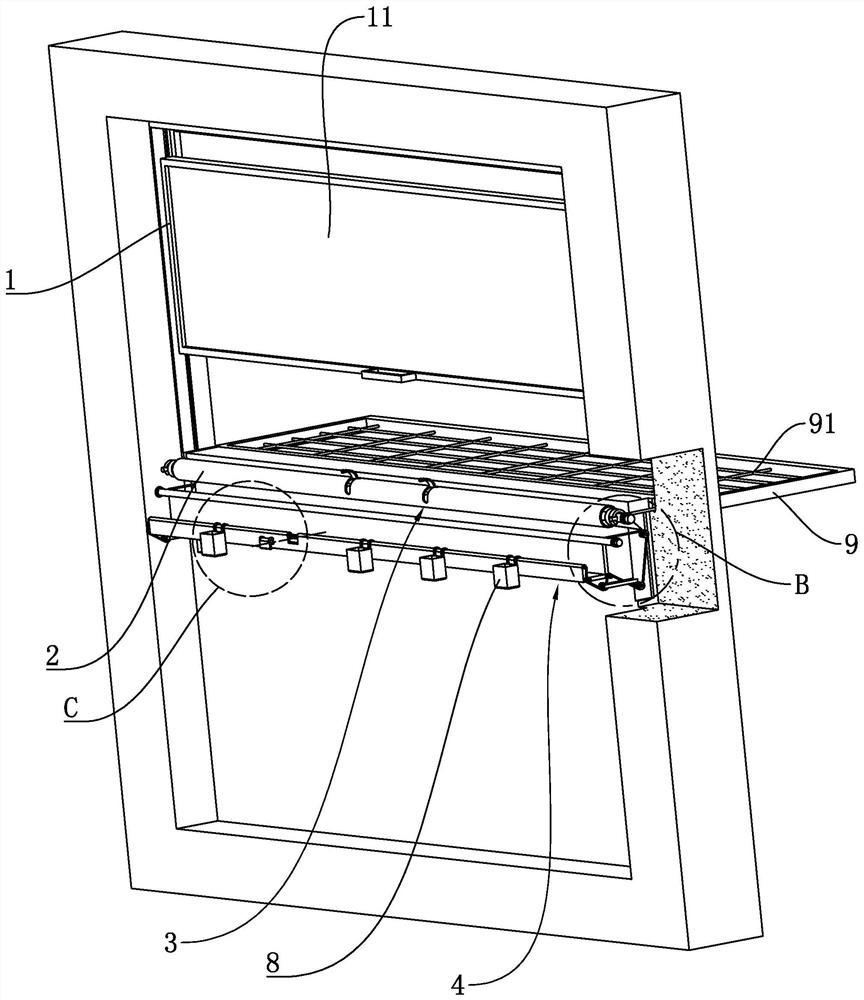

Window frame with escape handle rod

The invention relates to a window frame with an escape handle rod, and belongs to the technical field of window frames. The window frame comprises a window frame body and a window sash arranged in the window frame body; the window frame body is fixedly arranged on a wall body; and a fixing rod and a safe escape mechanism arranged on the fixing rod are arranged on the indoor wall body. When a fire disaster happens to a high-rise building, people need to be separated from a site in time, and at the moment, people fix a escape rope to the safe escape mechanism and can safely descend to the ground through the escape rope. The fixing rod and the safe escape mechanism are both arranged indoors, so that during installation and maintenance, people can stand indoors to install and maintain the fixing rod and the safe escape mechanism, and more convenience and quickness are achieved. The fixing rod is arranged indoors, so that the window frame with the escape handle rod is convenient to install and maintain, clothes can be conveniently aired by people, and people can do physical exercises, such as leg pressing and the like.

Owner:上海豪钰不锈钢有限公司

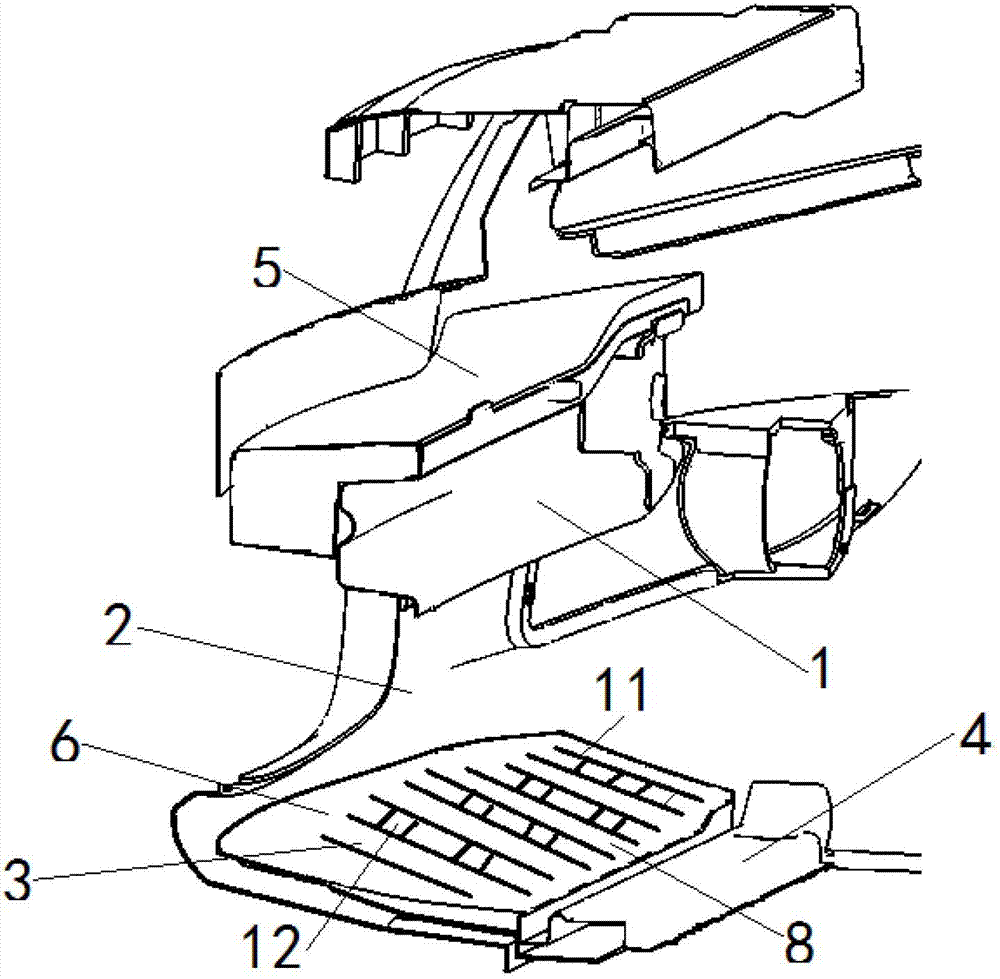

Automobile front bumper structure for enhancing pedestrian safety protection

InactiveCN102963332AImprove pedestrian safety protectionAvoid excessive bend anglesPedestrian/occupant safety arrangementBumpersEngineeringPedestrian

The invention provides an automobile front bumper structure for enhancing pedestrian safety protection, which is applied to the technical field of motor vehicle bodies. The automobile front bumper structure for enhancing the pedestrian safety protection comprises a front bumper cross beam (1), wherein the upper end part of the front bumper cross beam (1) is connected with a water tank upper cross beam (2); the front bumper cross beam (1) is also connected with a front bumper skin (2); the front bumper skin (2) is connected with a front bumper lower end plate (3); the front bumper lower end plate (3) is connected with a water tank lower cross beam (4); and a buffering foam (5) is arranged in the front bumper skin (2). Through the adoption of the automobile front bumper structure provided by the invention, the front bumper lower end plate and the buffering foam in the front bumper can simultaneously have an effect of protecting shanks of pedestrians when the pedestrians comes into collision with the automobile front bumper, so as to ensure that the shanks of the pedestrians cannot invade into the lower part of the front bumper, avoid overlarge bending angles of the shanks of the pedestrians and protect the shanks of the pedestrians against being damaged.

Owner:WUHU SHUNCHANG AUTO PARTS

An emergency braking device for a hoist

ActiveCN111717823BPrevent overloadAvoid damageWinding mechanismsStructural engineeringMechanical engineering

The invention discloses an emergency brake device for a hoist, which comprises a box body, an inner cavity is arranged inside the box body, and stepped holes communicating with the inner cavity are arranged on both sides of the box body, through the step The hole is equipped with a rotating shaft, and a bearing is matched between the rotating shaft and the stepped hole. One end of the rotating shaft is inserted into the inner cavity, and the other end is located outside the box body. The end of the rotating shaft located outside the box body A connecting sleeve is provided, and the outside of the connecting sleeve is processed with a threaded hole, a fixed engaging disc is processed on the right rotating shaft, and a movable engaging disc is matched on the left rotating shaft; the structure of this product is relatively simple, and the cost is low. Relatively cheap, suitable for promotional use.

Owner:SHENGZHOU YIYUAN INVESTMENT MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com