Method for improving flame cutting blanking precision of steel tube arch rib shell section base metal steel plate

A technology for flame cutting and steel pipe arch ribs, applied in gas flame welding equipment, metal processing equipment, comprehensive factory control, etc., can solve the problem of not being able to improve the geometric dimension accuracy of the base metal steel plate used for steel pipe arch rib tube joints, and is not suitable for widespread use , complex operation and other issues, to achieve good economic and social benefits, low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

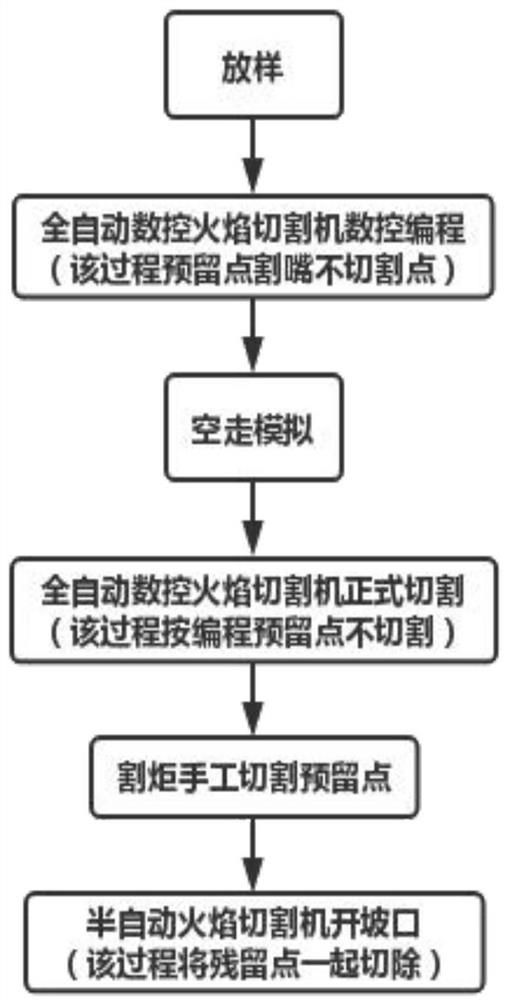

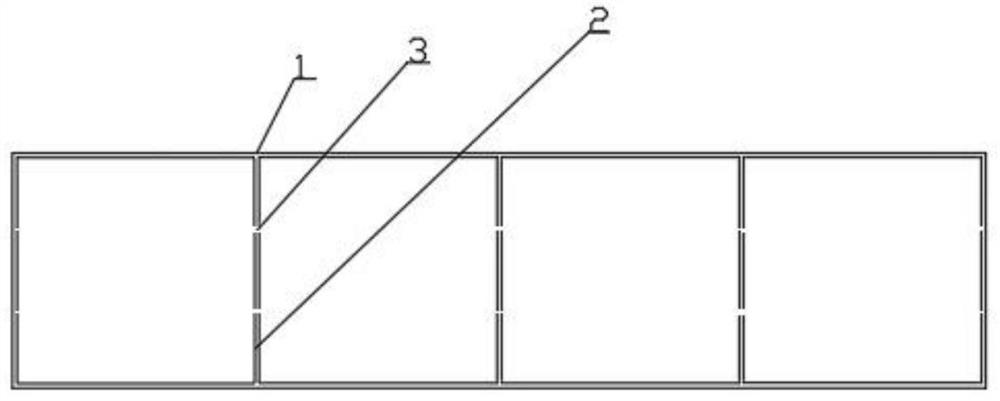

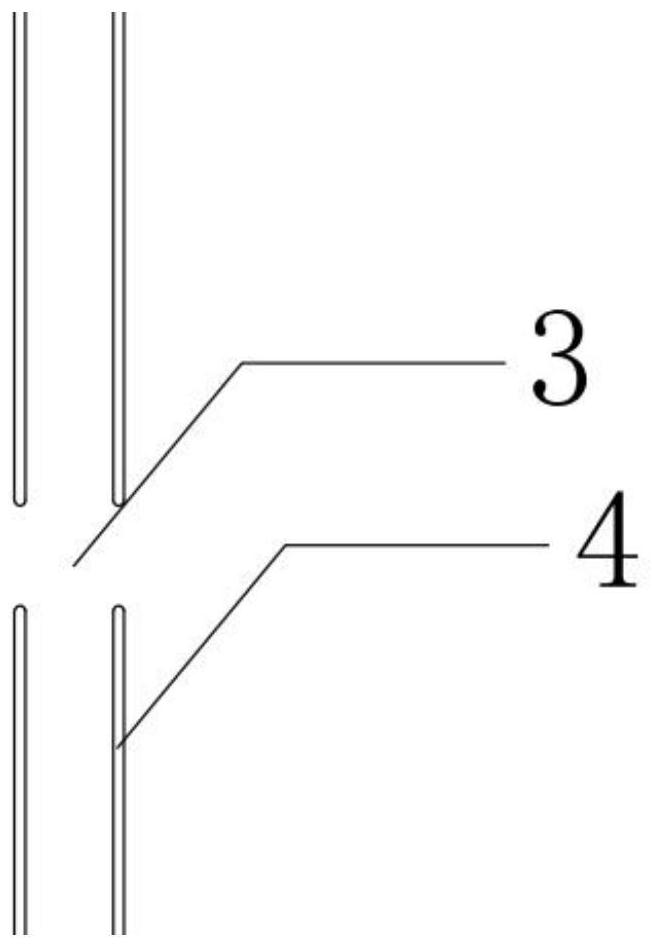

[0035] as Figure 1-8 As shown, a method to improve the precision of steel pipe arch rib section base metal steel plate flame cutting, the specific unloading method steps are as follows:

[0036]Step 1: Select raw materials, determine the steel pipe arch rib tube section base metal cutting and unloading method steps and corresponding raw material production equipment, and carry out trial operation of production equipment;

[0037] Step 2: Sheet lofting, numerical control programming of the automatic CNC flame cutting machine, compiling the running trajectory of the nozzle in the computer, and debugging the relevant parameters;

[0038] Step 3: Before the formal cutting, let the nozzle go empty according to the NUMERICAL control programming to simulate the cutting trajectory;

[0039] Step 4: The automatic CNC flame cutting machine begins to cut formally, and after the cutting is completed, a piece of barrel base metal steel plate is still four points uncut;

[0040] Step 5: Manuall...

Embodiment 2

[0051] as Figure 1-8 As shown, a method to improve the precision of steel pipe arch rib section base metal steel plate flame cutting, the specific unloading method steps are as follows:

[0052] Step 1: Select raw materials, determine the steel pipe arch rib tube section base metal cutting and unloading method steps and corresponding raw material production equipment, and carry out trial operation of production equipment;

[0053] Step 2: Sheet lofting, CNC programming of the automatic CNC flame cutting machine, compiling the running trajectory of the nozzle in the PLC controller, and debugging the relevant parameters;

[0054] Step 3: Before the formal cutting, let the nozzle go empty according to the NUMERICAL control programming to simulate the cutting trajectory;

[0055] Step 4: The automatic CNC flame cutting machine begins to cut formally, and after the cutting is completed, a piece of barrel base metal steel plate is still four points uncut;

[0056] Step 5: Manually use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com