Method for measuring parameter of omega welding seam defect

A technology of parameter measurement and defect, which is applied in the direction of measuring device, material magnetic variable, and material analysis using sound wave/ultrasonic wave/infrasonic wave, etc. It can solve the problem of inability to accurately quantify defects, inability to detect Ω weld defects, and inability to meet preventive maintenance and other issues to achieve the effect of ensuring accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

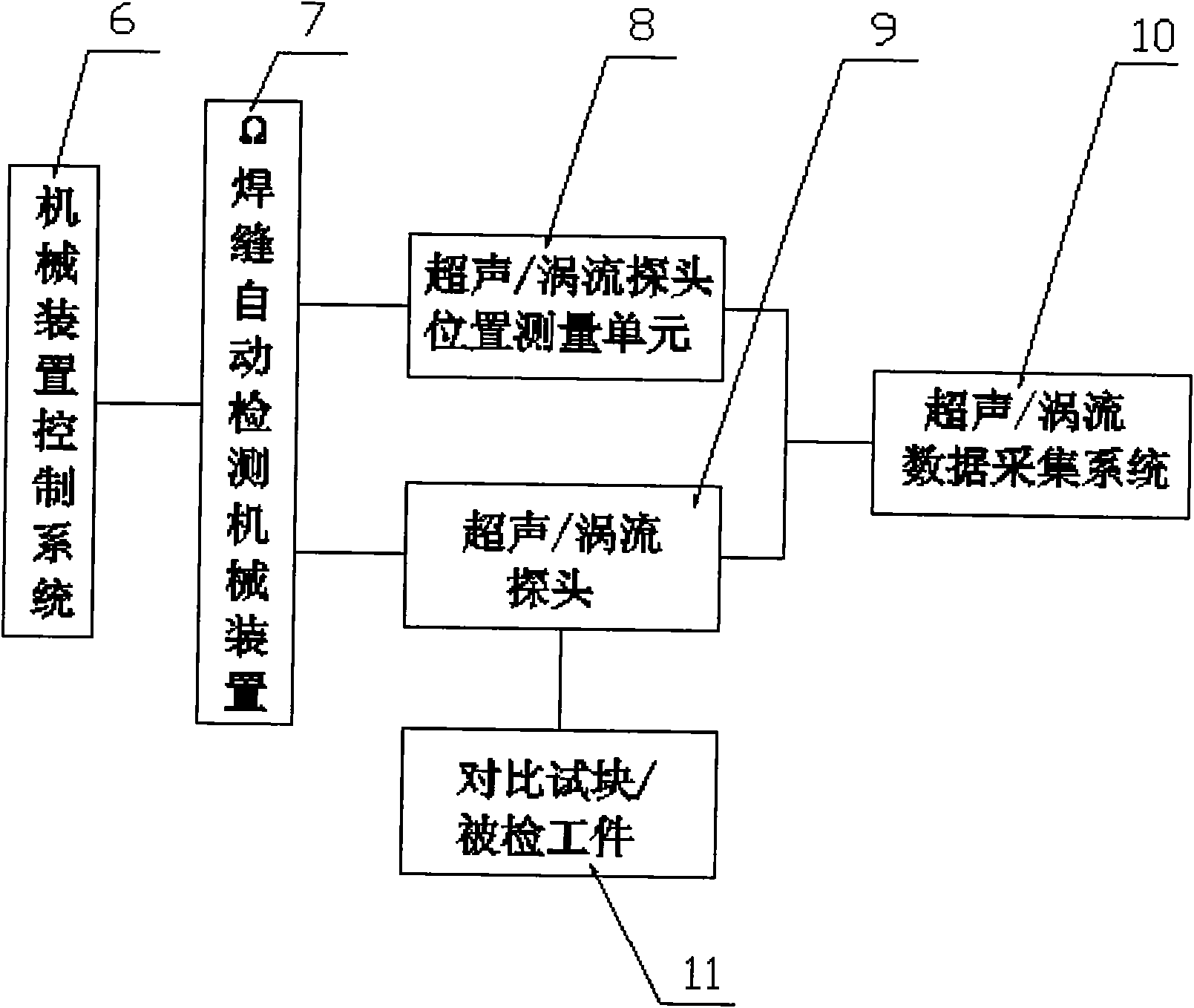

[0019] The specific implementation method of the Ω weld defect quantification of the control rod drive mechanism of the nuclear power plant is as follows:

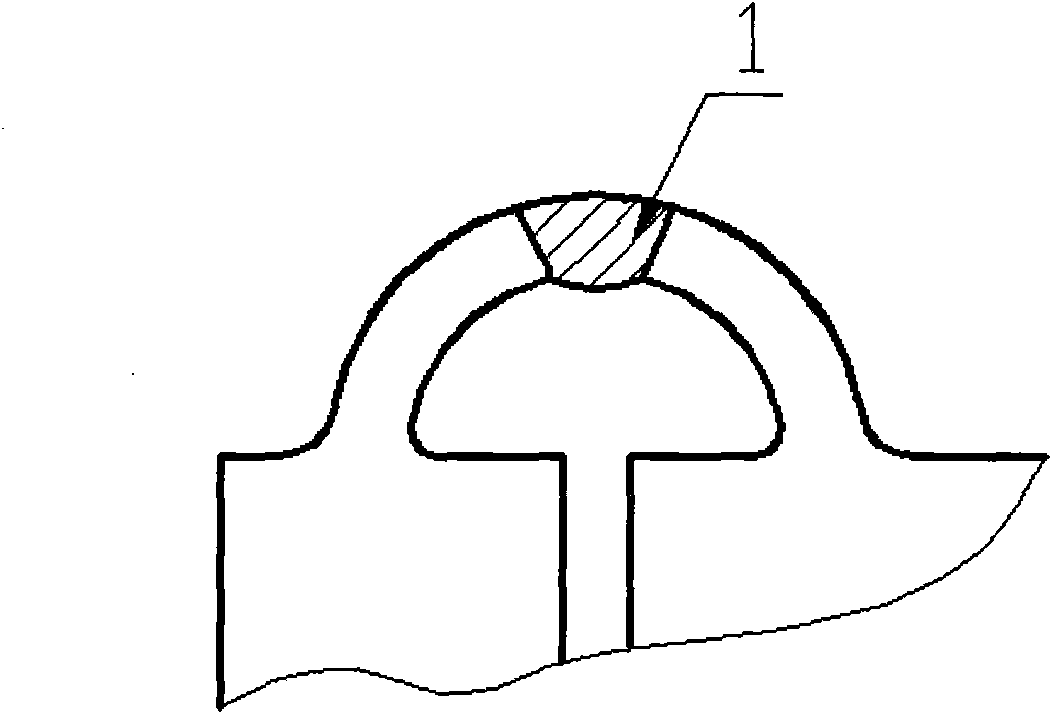

[0020] like figure 1 As shown, 1 is the Ω weld existing in the upper, middle and lower parts of the control rod drive mechanism.

[0021] Preparation of Ω weld comparison test block

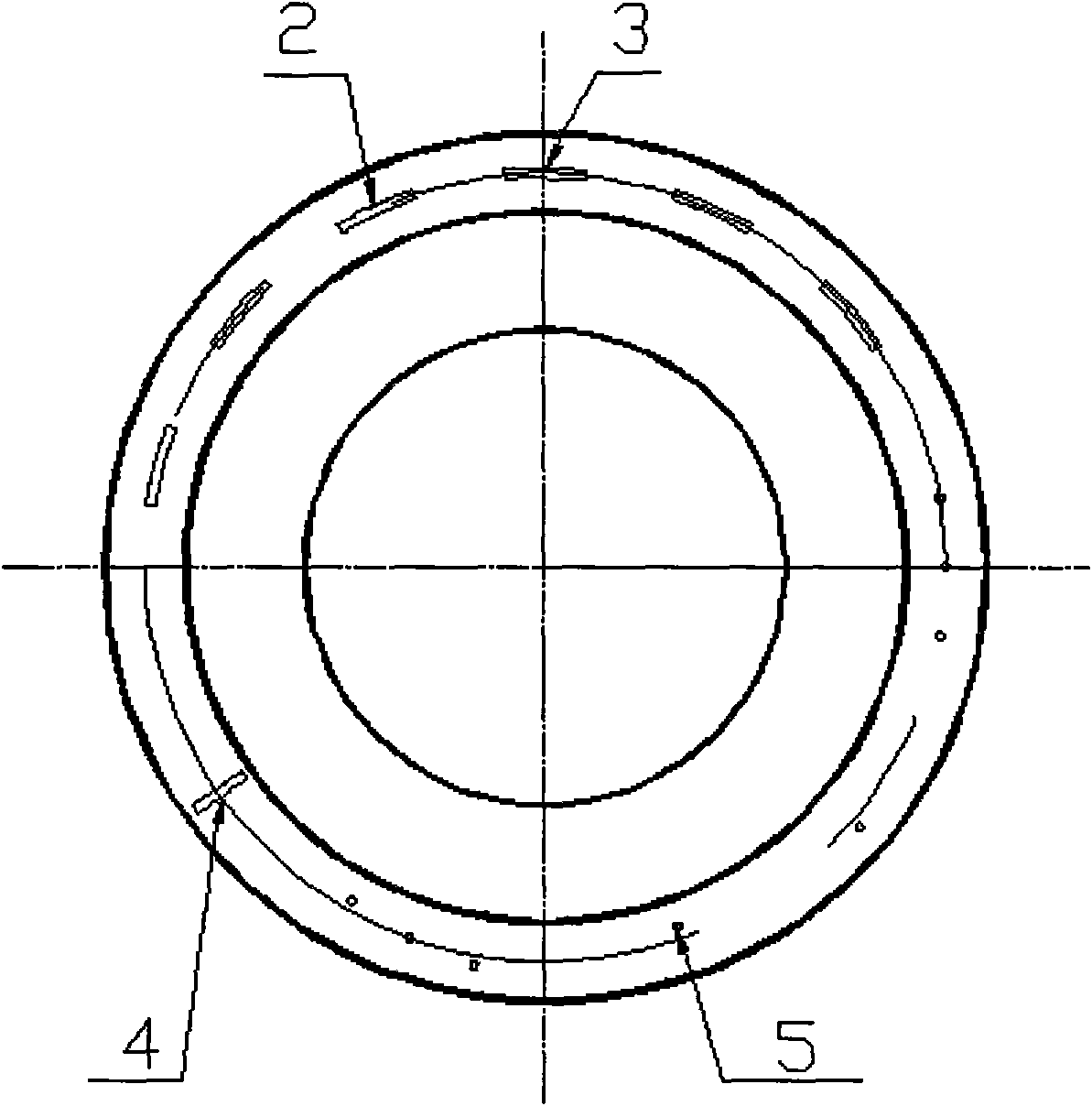

[0022] Use the Ω weld 1 welding process qualification test piece to make a comparison test block, which is used to calibrate the ultrasonic and eddy current testing system during the testing process, see figure 2 As shown, the steps are as follows:

[0023] ① On the center line of the inner and outer surfaces of the Ω weld 1, six circumferential electric spark grooves with a height of 1mm, 1.5mm and 2mm, a width of 0.7mm and a length of 25mm were processed respectively, that is, the circumferential inner groove 2 and the The circumferential outer groove 3 of the comparison test block is used to simulate linear defects along the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com