Discharging electrode and light catalyst reactor

一种光催化剂、放电电极的技术,应用在光催化剂反应装置领域,能够解决不能稳定照射放电光、破损、电极变形等问题,达到高物质分解性能、耐腐蚀性提高、提高处理效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

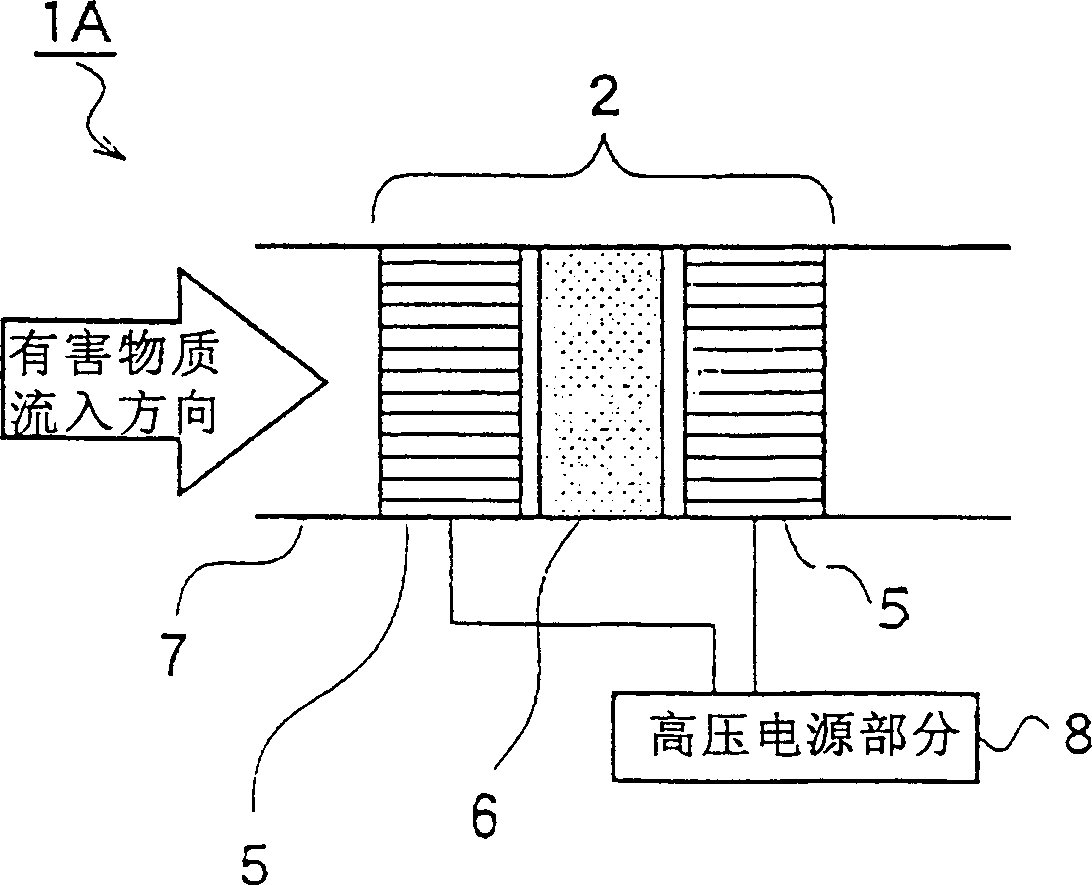

[0046] first according to figure 1 and figure 2 The minimum constituent unit of the photocatalyst reaction device of the present invention will be described. figure 2 yes figure 1 Schematic diagram of the photocatalyst reaction device.

[0047] figure 1 The photocatalyst reaction device 1 in figure 2 Among them, the photocatalyst reaction device 1A) is composed of a unit structure and its housing case 7 . The casing 7 has a cylindrical structure, has an inlet and an outlet, and allows the gas containing harmful substances to pass through. The unit structure 2 is composed of a pair of honeycomb electrodes 5 and a photocatalyst assembly 6 sandwiched therebetween. A pair of honeycomb electrodes 5 and the unshown high-voltage power supply part ( figure 2 In, the high-voltage power supply part 8) is connected.

[0048] The honeycomb electrode 5 is a three-dimensional electrode, which is formed into a honeycomb shape with a conductive film. It is composed of a honeyco...

no. 2 Embodiment approach

[0077] image 3 for will be in figure 1 ( figure 2 ) shows a case where the unit structure 2 is made into a plurality of stacked layers.

[0078] image 3 The photocatalyst reaction device 1B is composed of four unit structures 2 and their storage cases 7 and a high-voltage power supply part 8 . The unit structure body 2 is composed of a pair of honeycomb electrodes 5 and a photocatalyst assembly 6 sandwiched therebetween. The honeycomb electrodes 5 are respectively connected to high voltage power supply parts 8 .

[0079] In the present embodiment, by arranging four unit structures 2, adjacent electrodes are shared among the unit structures 2. FIG. By arranging the electrodes alternately so that both sides of the electrodes emit light, discharge light can be efficiently obtained.

[0080] Because the composition and structure of the honeycomb electrode 5 and the material used for the electrode, the structure of the photocatalyst module 6 and the material of the semico...

no. 3 Embodiment approach

[0085] Figure 4 is in figure 1 ( figure 2 ) on the photocatalyst reaction device 1 (1A) has increased the situation of the ozonolysis catalyst 9.

[0086] Figure 4 The photocatalyst reaction device 1C is composed of a housing unit structure 2 , a housing 7 for an ozonolysis catalyst 9 , and a high-voltage power supply 8 .

[0087]The unit structure 2 is composed of a pair of honeycomb electrodes 5 connected to a high-voltage power supply section 8 and a photocatalyst assembly 6 sandwiched therebetween. In addition, the ozonolysis catalyst 9 is located on the downstream side of the unit structure 2 with respect to the gas inflow direction.

[0088] Because the composition and structure of the honeycomb electrode 5 and the material used for the electrode, the structure of the photocatalyst module 6 and the material of the semiconductor particles used in the module, and the high-voltage power supply part 8 are the same as those of the first embodiment, so the description ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com