A mixer feeding device for building construction

A technology for building construction and mixer, which is applied to clay preparation devices, mixing operation control devices, mixing operation control and other directions, can solve problems such as difficulty, troublesome operation, low efficiency, etc., and achieves improved cutting speed, simple structure, and difficulty in operation. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

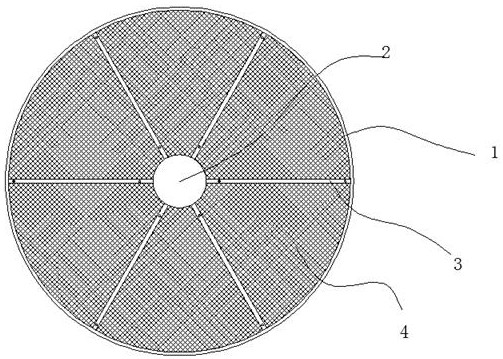

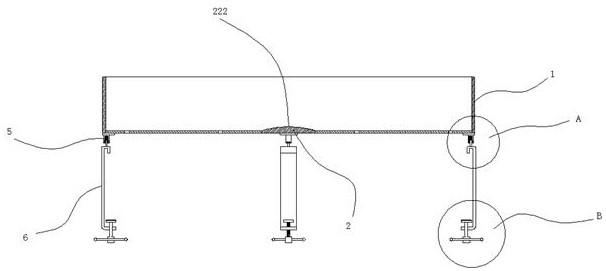

[0035]A mixer blanking device for building construction, comprising a container 1 arranged above the mixer, the diameter of the container 1 is not smaller than the diameter of the mixer, and an axis block 2 is arranged at the bottom axis of the container, the A plurality of connecting rods 3 are welded between the axis block 2 and the container 1, a fan-shaped area is formed between two adjacent connecting rods 3, and a metal screen 4 is welded in the formed fan-shaped area; A support structure 6 is installed at the side wall, and a quick-release structure 5 is fitted between the support structure 6 and the container 1; a scraper device 7 is installed at the position of the stirring shaft of the mixer, and the scraper device 7 follows the The rotation of the stirring shaft rotates, and the scraping device 7 acts on the metal screen 4 .

[0036] The depth of the container 1 is 20cm~30cm.

Embodiment 2

[0038] The top of the connecting rod 3 is processed into a ∧ shape, the top of the connecting rod 3 is vertically penetrated with a through hole 301, and a partition 302 is installed above the connecting rod 3, and the bottom of the partition 302 is arranged There is a ∧-shaped groove 303 corresponding to the connecting rod 3, and an insertion shaft 304 inserted into the through hole 301 is welded at the bottom of the partition 302, and the mesh sizes of the adjacent two metal screens 4 are different. . A blanking gap is formed between two adjacent partitions. When we are blanking, we start blanking through the edge of the container 1. The end of the partition away from the inner wall of the container 1 is disconnected, so when the blanking is insufficient, or the metal sieve When the screen is blocked and the material cannot be discharged in time, the excess raw material can leak from the gap between the ends of the adjacent partitions, and the material can be discharged from...

Embodiment 3

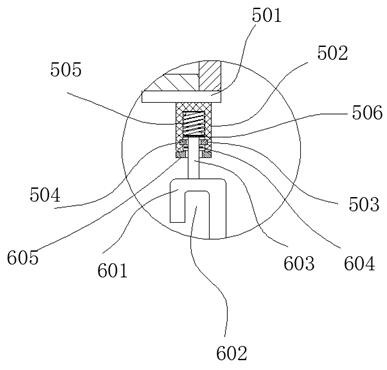

[0040] The quick-release structure 5 includes a steel plate 501 welded at the bottom of the container 1, and a sleeve 502 arranged at the bottom of the steel plate 501, and an annular groove 503 is provided on the inner wall of the sleeve 502. A rubber limit ring 504 is installed in the annular slot 503, a spring 505 is arranged inside the sleeve 502, and a slider 506 is arranged below the spring 505 inside the sleeve 502, the slider 506 The block 506 moves down and is limited by the rubber stop ring 504; the support structure 6 includes a rod 601, and the upper end of the rod 601 is bent to form a buckle groove 602. When installed, the mixer shell snapped into the buckle groove 602, an insertion shaft 603 is arranged on the top of the rod 601, the insertion shaft 603 is inserted into the sleeve 502, and the upper end of the insertion shaft 603 is against the slider 506, the insertion shaft 603 is provided with a retaining ring 604, the retaining ring 604 is located below the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com