Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Guaranteed backwash effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Urban sewage waterpower self-cleaning device with drum grid

The invention discloses an urban sewage waterpower self-cleaning device with drum grid which comprises, a sewage water pumping pipe, a sewage backwater pipe, a sewage elevating pump and a scrubbing apparatus arranged on the sewage water pumping pipe, wherein the water intake port of the sewage water pumping pipe and the water return port of the sewage backwater pipe are arranged in the sewage trunk canal, the other ends of the sewage water pumping pipe and the sewage backwater pipe are provided with a scrubbing installation.

Owner:HARBIN INST OF TECH

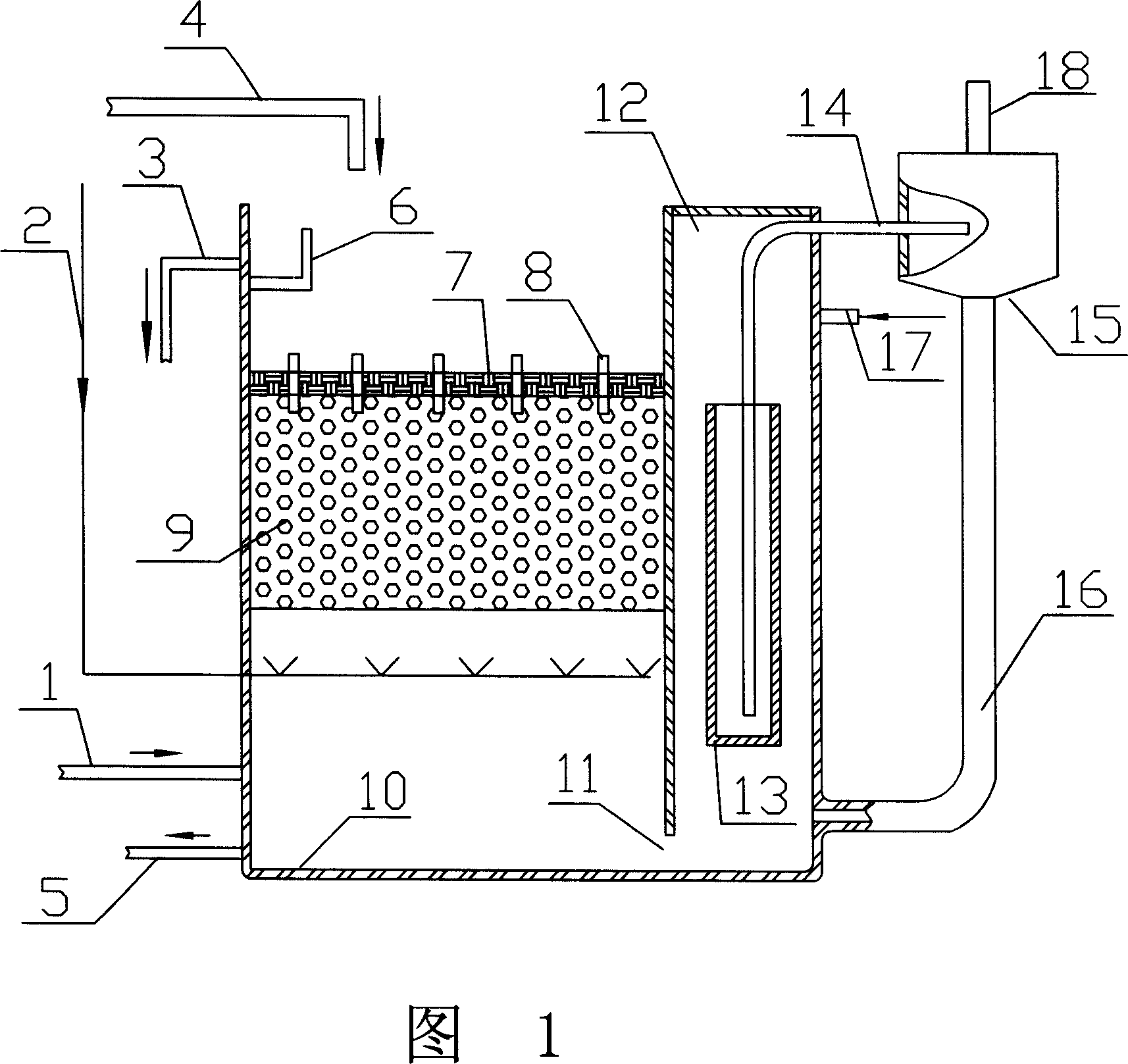

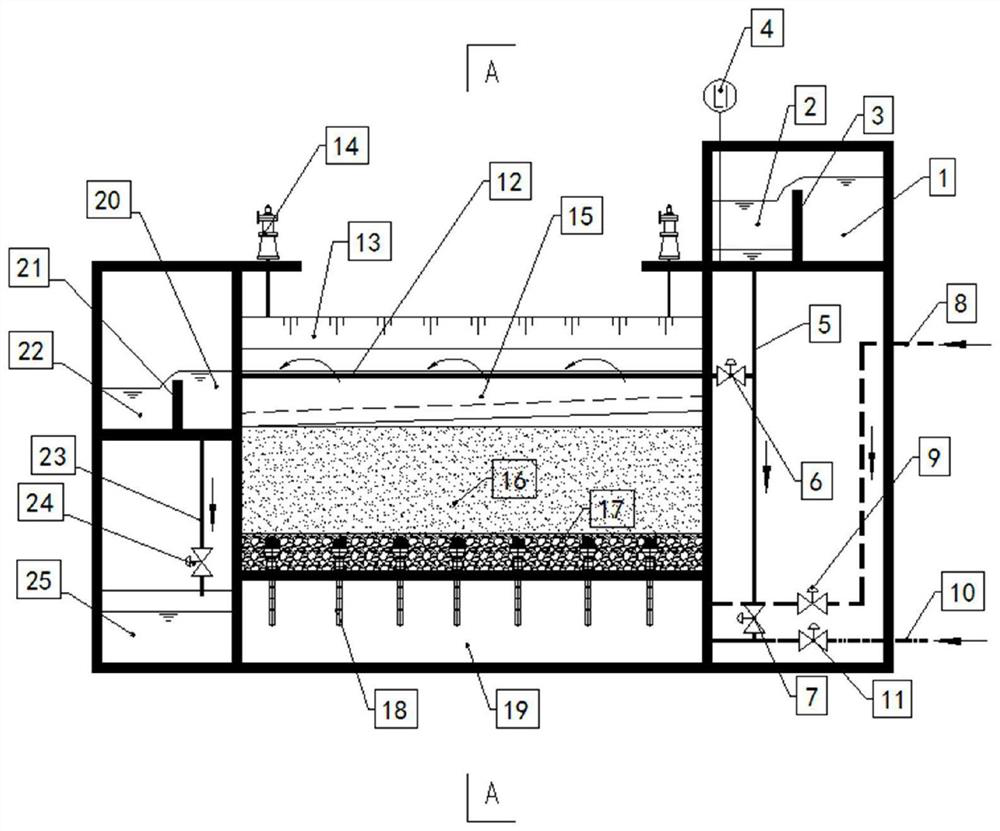

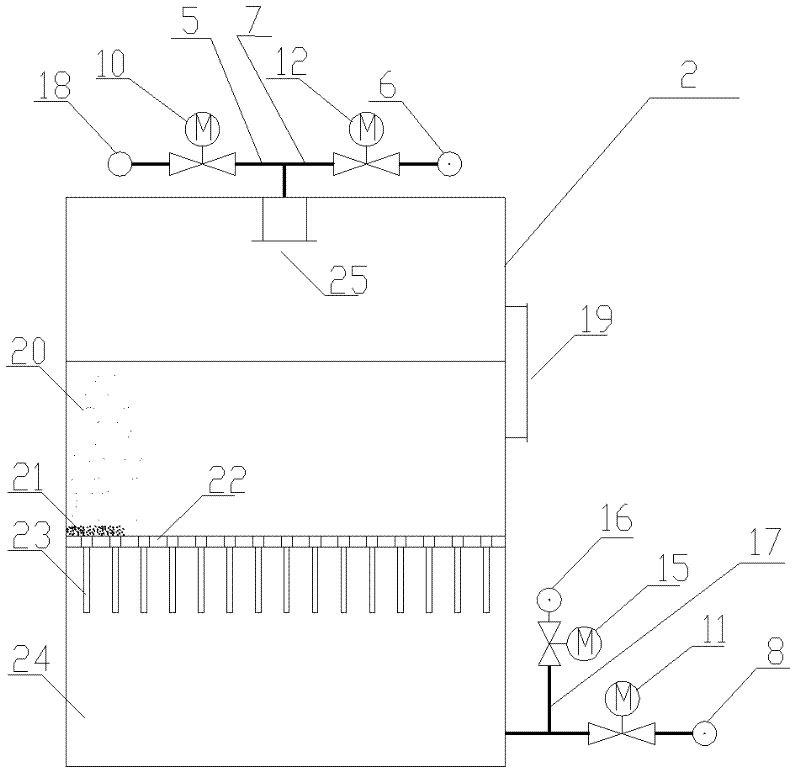

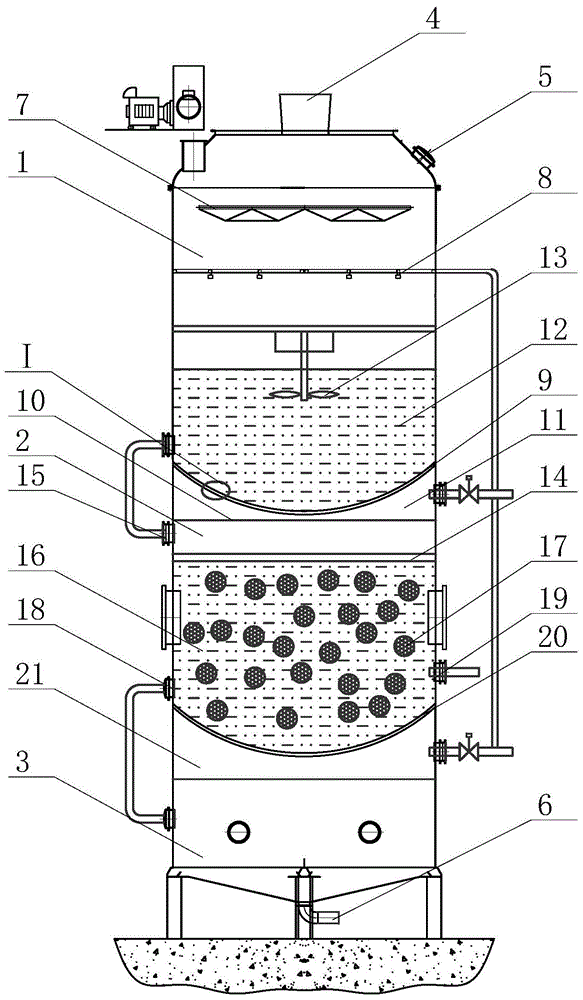

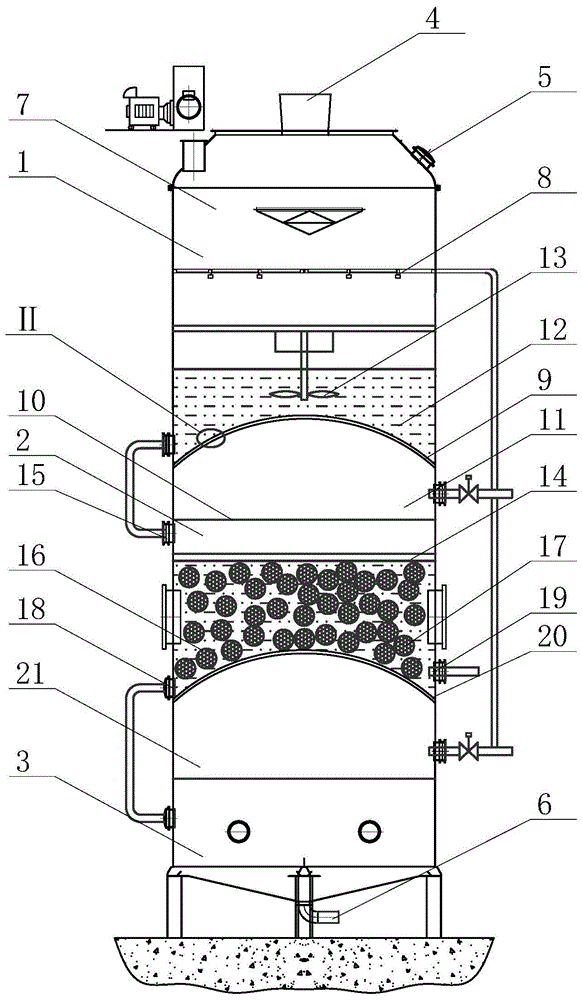

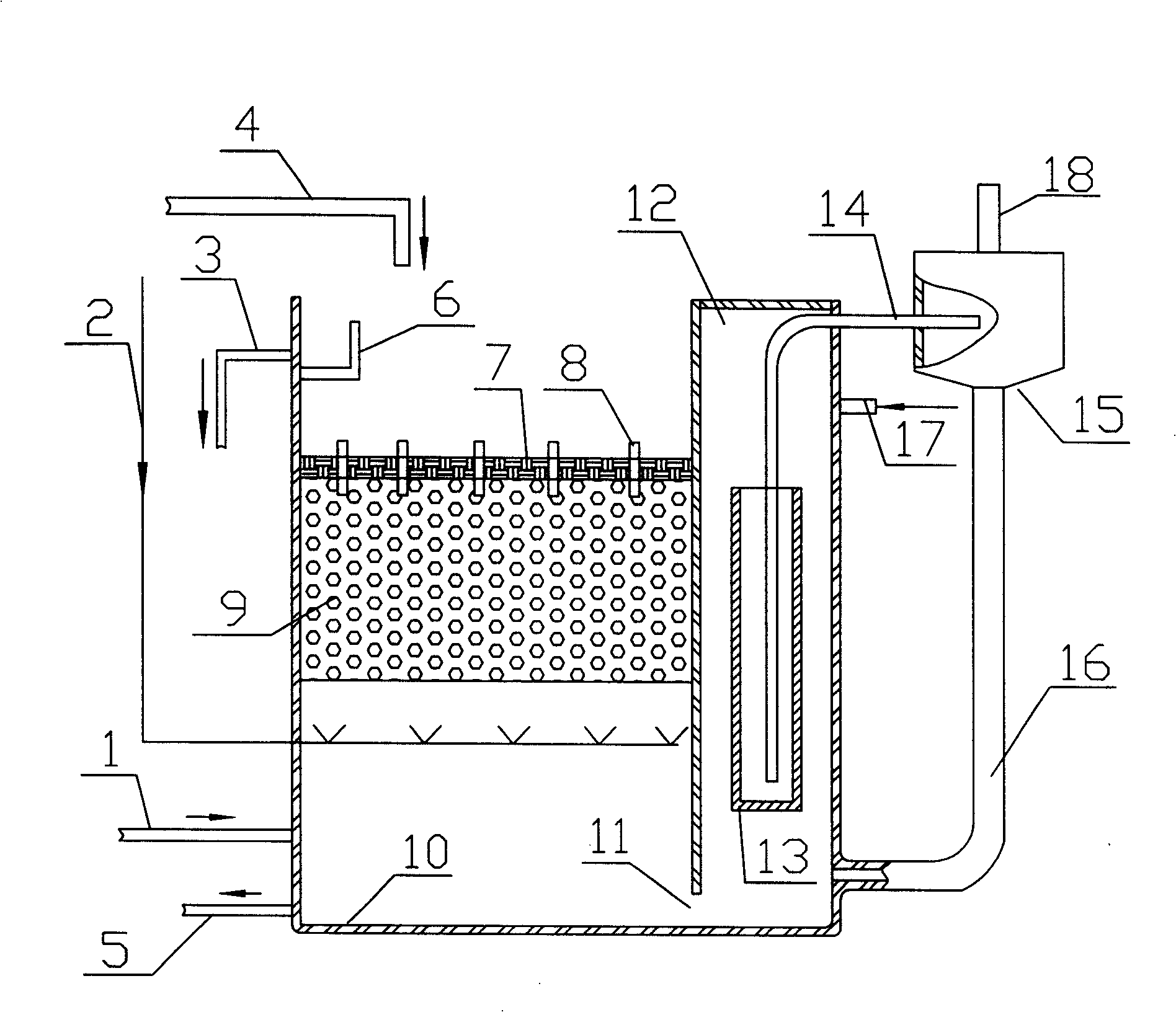

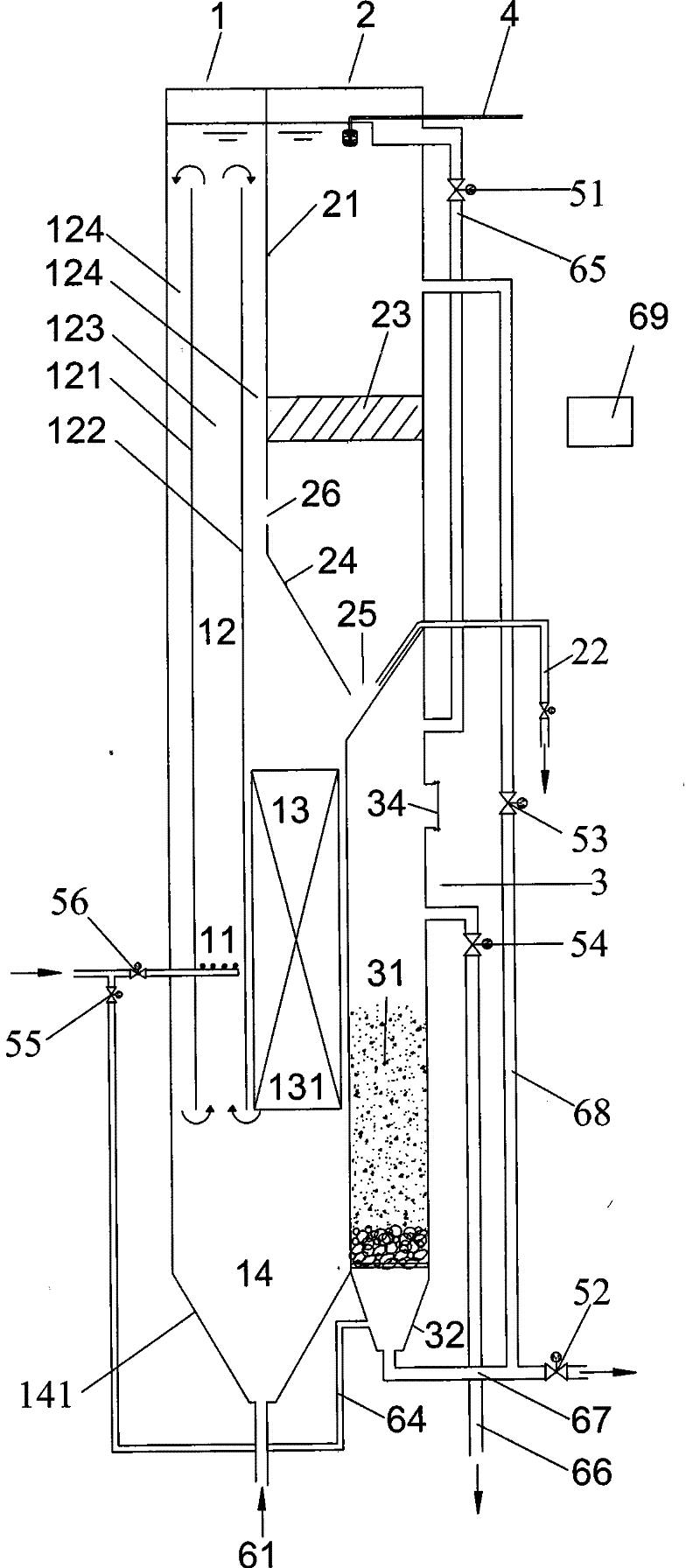

Aerating biological filter

InactiveCN1923724ASimple structureReduce manufacturing costTreatment using aerobic processesSustainable biological treatmentBiological filterWater treatment

The invention discloses an aerating biological filter pool in the water disposal device domain, which comprises the following parts: filter pool within aerating device and filtering device, water inlet pipe on the bottom of filter pool, backwash drainage pipe on the bottom of filter pool, pulse air-chamber to interconnect bottom of filter pool through backwash inlet pipe and vent pipe, wherein the vent pipe lies in one end of water sealing pipe in the pulse air-chamber; the other end of vent pipe connects gas-water separator, whose top possesses connection pipe with bottom interconnecting the bottom of pulse air-chamber through connection pipe.

Owner:SHANDONG JIANZHU UNIV

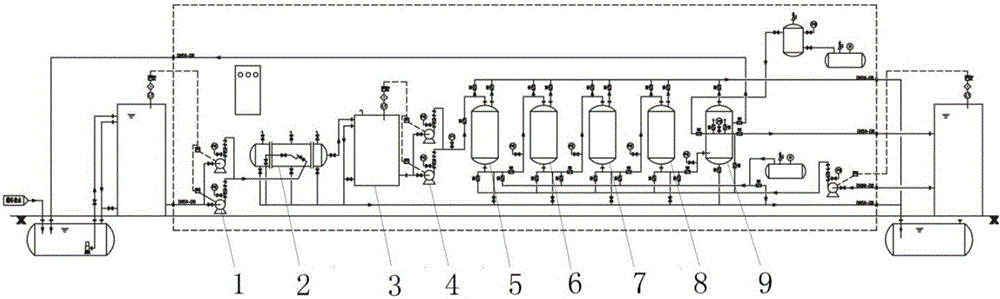

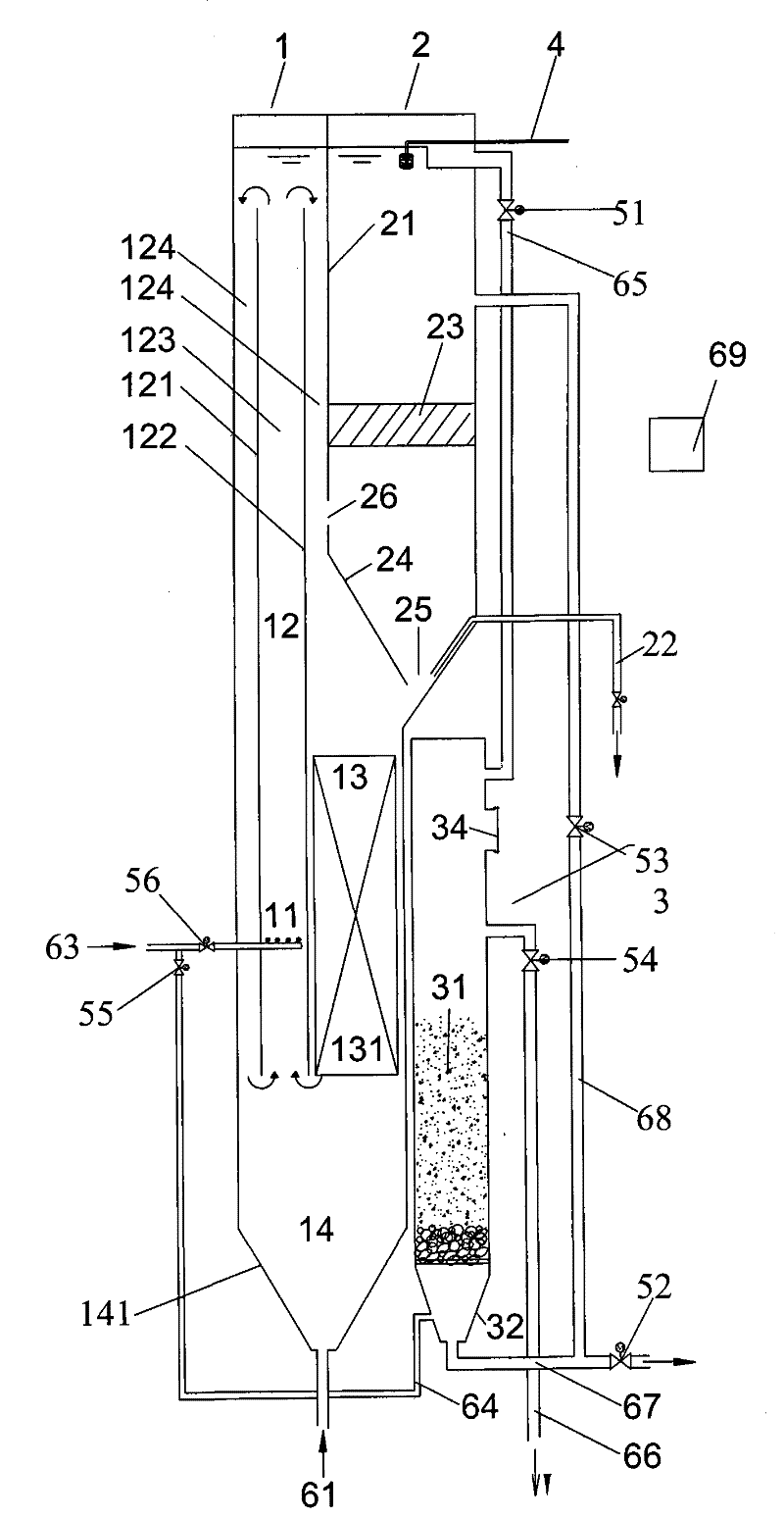

Microfiltration membrane oil filed sewage processing device and processing method

InactiveCN106219797AGood effectInnovative designWater/sewage treatment by centrifugal separationSpecific water treatment objectivesFiberWater quality

The invention discloses a microfiltration membrane oil filed sewage processing device. The device comprises a flocculation settlement facility, a cyclone oil-water separator, a multistage mechanical filtering device, and a metal membrane filtering device, which are connected in sequence. The multistage mechanical filtering device comprises a walnut shell filtering device, a fine walnut shell filtering device, a modified fiber ball filtering device, and a dual-layer filtering material filtering device, which are connected in sequence. The sewage processing method comprises the following steps: removing pollutants by the flocculation settlement facility, pumping sewage into the cyclone oil-water separator to carry out separation, and filtering the separated water phase by the walnut shell filtering device, the fine walnut shell filtering device, the modified fiber ball filtering device, the dual-layer filtering material filtering device, and the metal membrane filter device to obtain qualified water phase. The design is novel, the operation is safe, stable, and reliable, the effect is good; the produced water in oil field can be purified and the processed water can reach the standards of reinjection. The provided device can realize gas-water combined backwashing, the backwashing effect is guaranteed, and the device can be used for a long term.

Owner:YANCHANG OIL FIELD

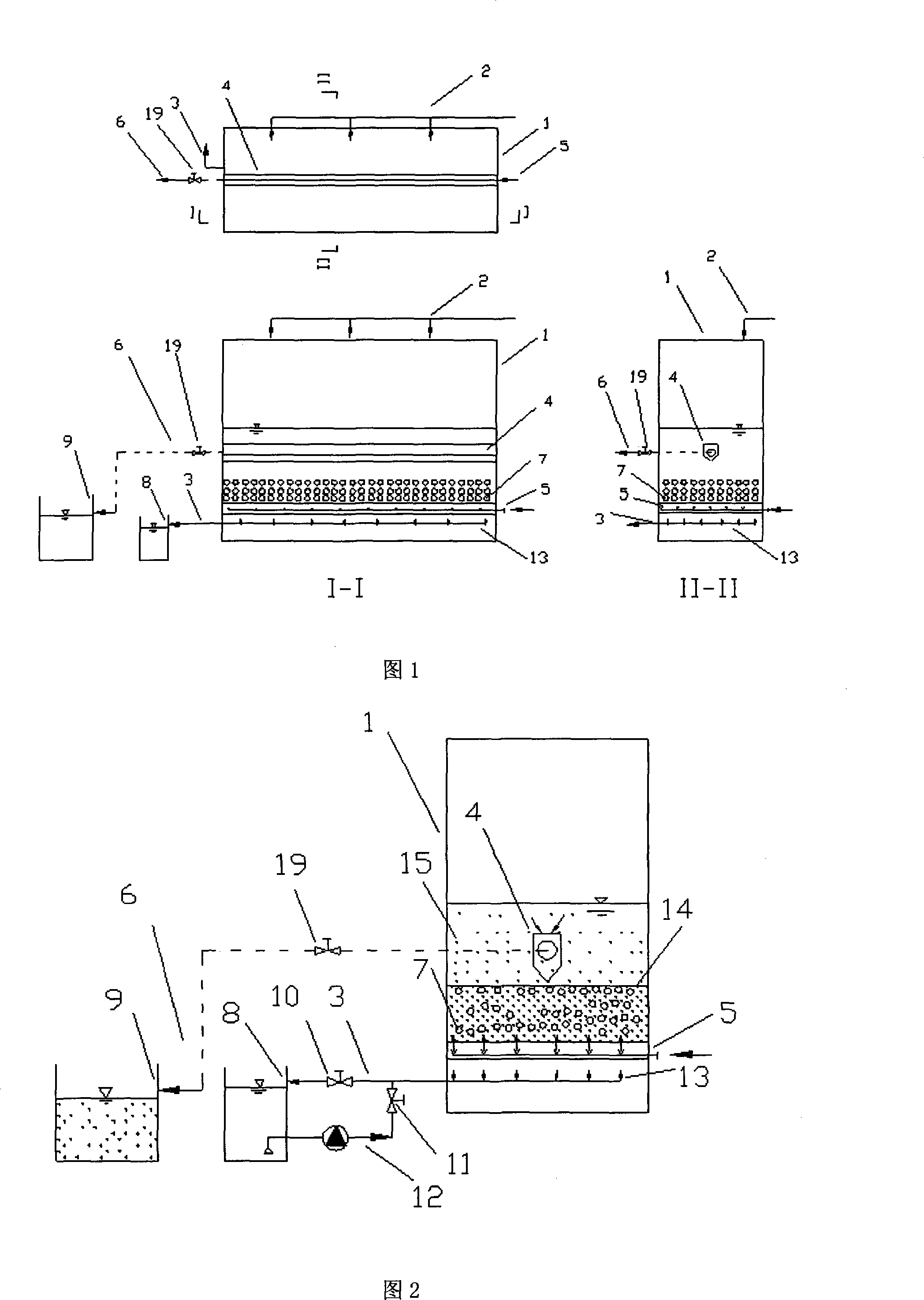

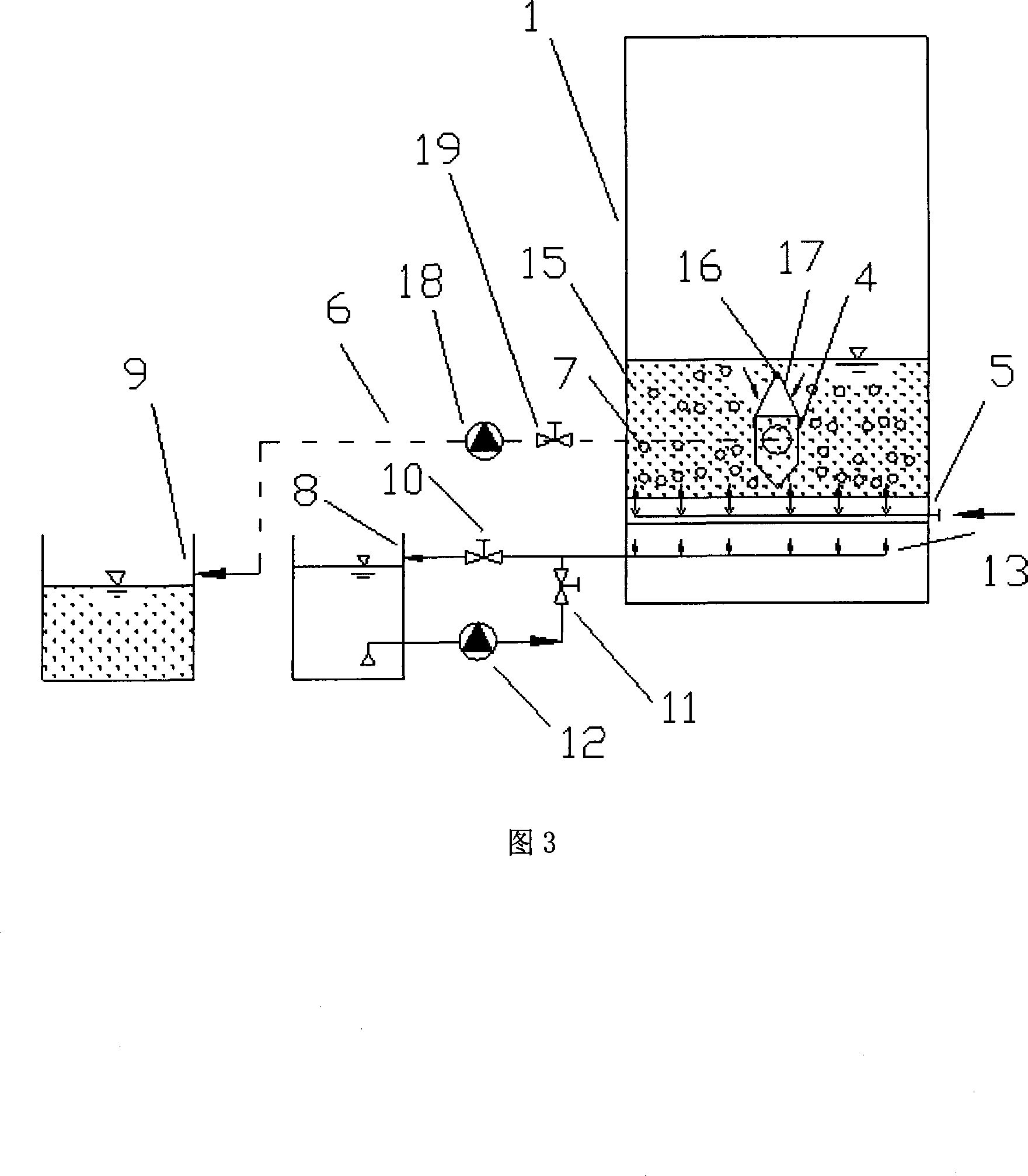

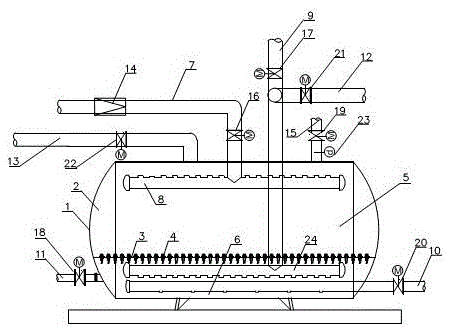

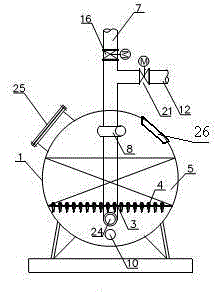

Improved structure for gas and water mix backwash of aerating biological filter

InactiveCN101172699AAchieve separationNo reduction in flow areaSustainable biological treatmentBiological water/sewage treatmentBiological filterMaterial consumption

The invention relates to an improved gas-water mixed backwash structure of an aeration biological filter chamber. The clear water in a clear water pool (8) is pumped out by a pressurizing water pump (12) and is led to the bottom of a chamber body (1) through a water distributing pipe net (13), then the clear water passes through a filter material (7) from bottom to top so as to take filter residue (15); then the water enters into a backwash water collecting groove (4) through a sieve (17); the sewage flows to a sewage pool (9) through a water drainage pipeline (6); the upward side of the backwash water collecting groove (4) is provided with a through length supporting lever (16); the sieve (17) encases the backwash water collecting groove (4) and the supporting lever (16) so as to ensure that the filter bed restores the function of filtering and purifying the sewage, prolongs the backwash period and reduces the backwash frequency, as well as ensure that the sewage purifying system canbe better and normally operated; the sieve has simple mounting and dismounting, less material consumption and convenient maintenance.

Owner:DONGHUA UNIV

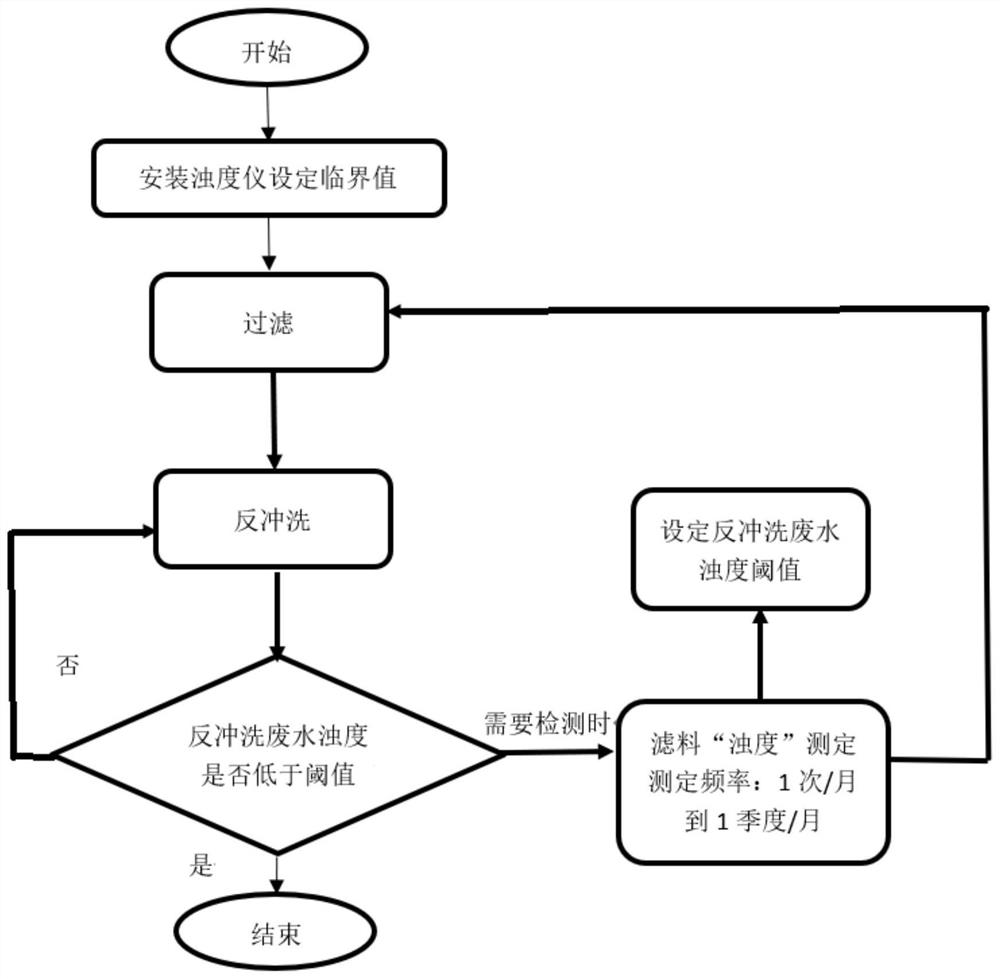

Filter tank backwashing duration control method and system

InactiveCN111672172AEasy to operateLow equipment requirementsLoose filtering material filtersGravity filtersFilter materialAir pump

The invention provides a filter tank backwashing duration control method and system. The method comprises the steps: sequentially carrying out air flushing and water flushing on a filter tank after afilter material in the filter tank is filtered, detecting the turbidity of backwashing wastewater through an online turbidity detection device arranged on a backwashing wastewater tank of the filter tank, stopping water flushing when a detection value is lower than a set value; repeating the steps for several times, and detecting the mud content (expressed by turbidity) of the filter material so as to control the next backwashing duration. The system comprises an online turbidity detection device, a filter material mud content (expressed by turbidity) detection unit, a backwashing water pump and an air pump, wherein the online turbidity detection device and the filter material mud content (expressed by turbidity) detection unit are respectively connected with two sensors, each sensor is connected with controllers of the backwashing water pump and the air pump, and switches of the backwashing water pump and the air pump are controlled through received turbidity information and filter material mud content (expressed by turbidity) information. The method has the advantages of saving water consumption and medicine consumption, and is simple to operate.

Owner:TSINGHUA UNIV

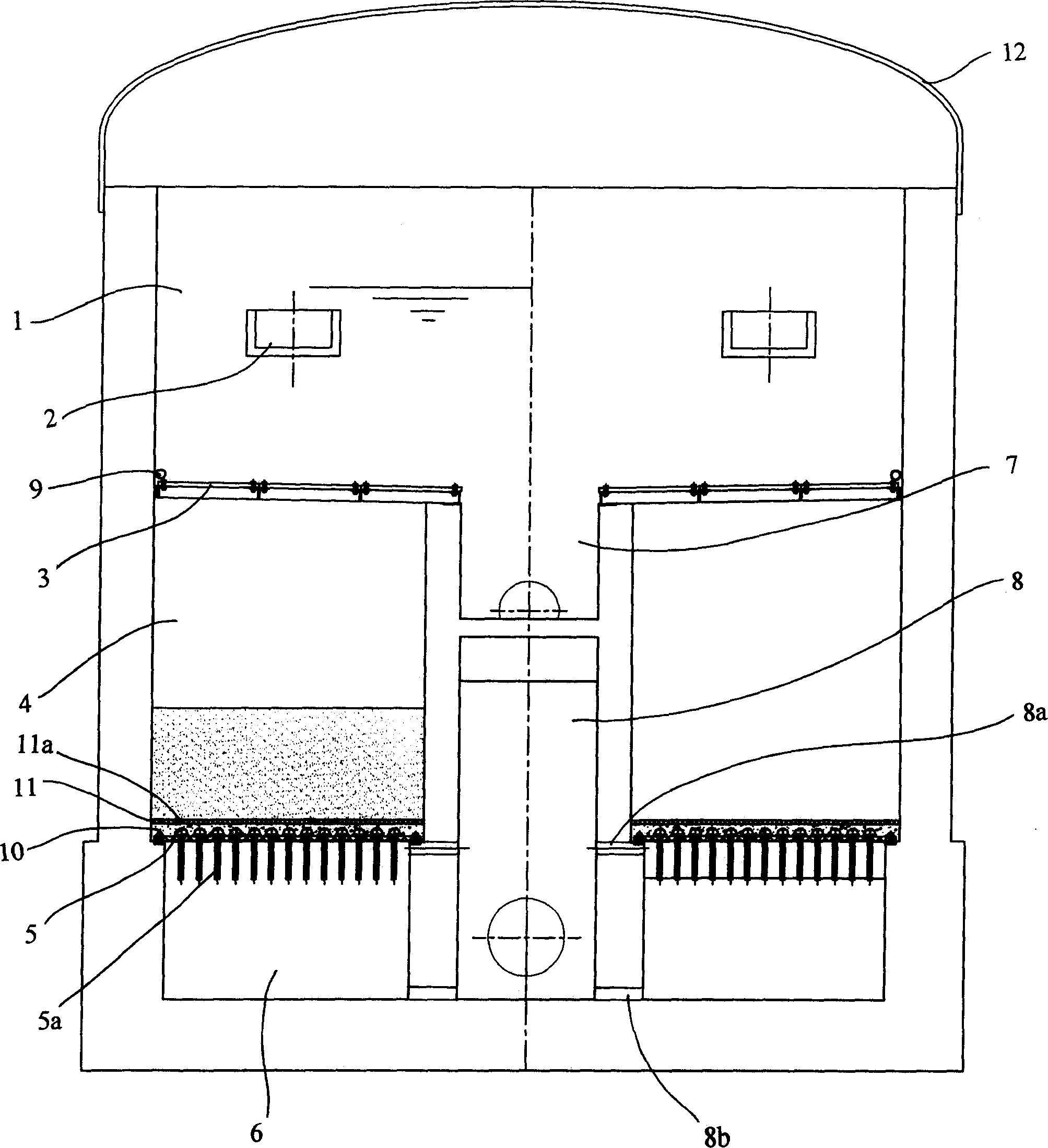

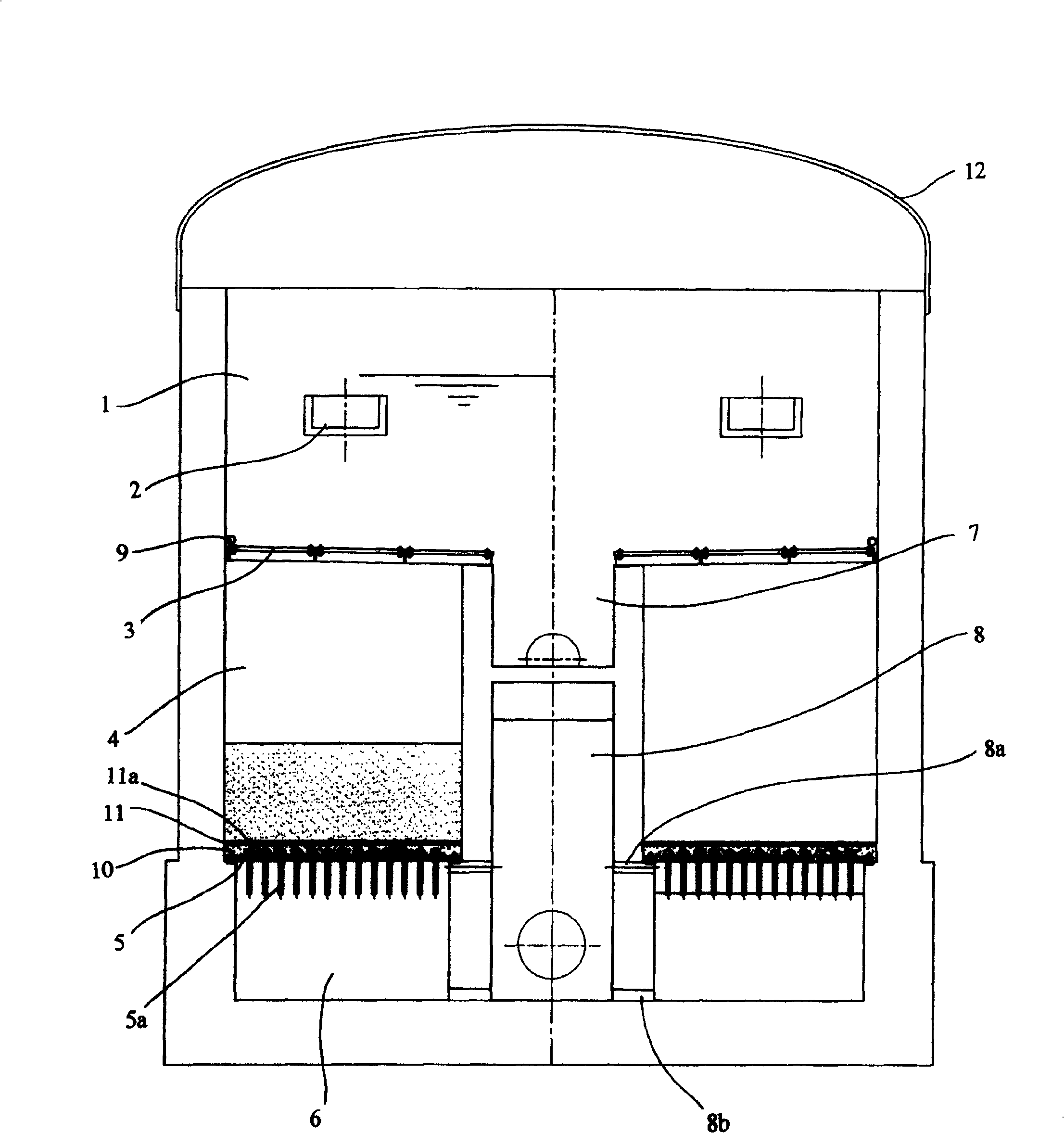

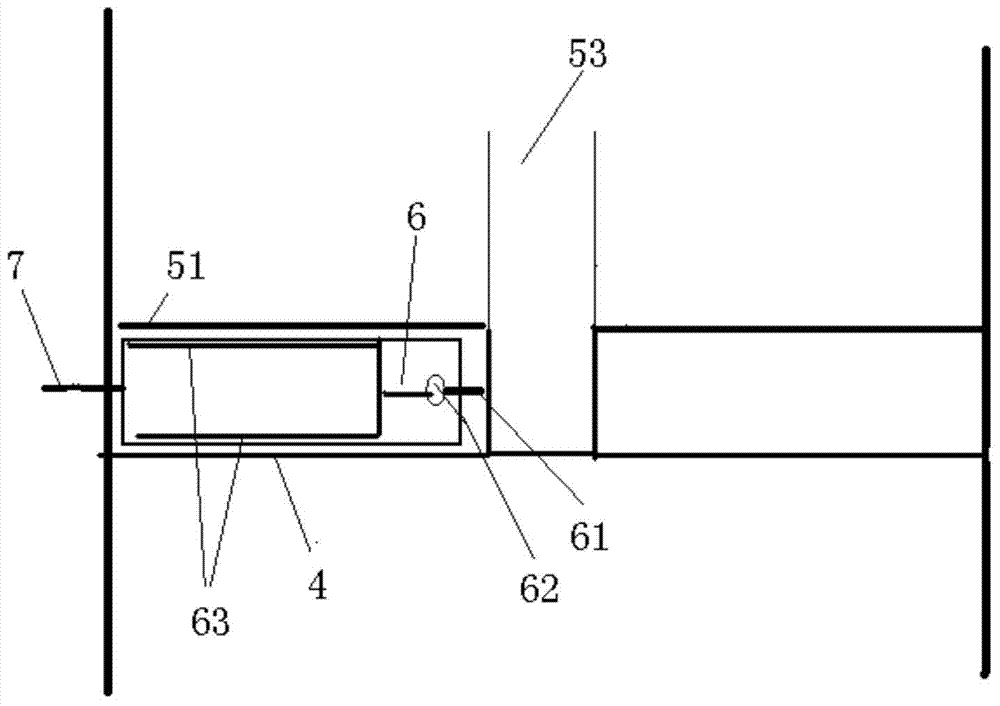

A filter tank

ActiveCN1864794AAvoid cloggingSuitable for useLoose filtering material filtersGravity filtersWater flowDitch

The invention discloses a filter tank, comprising filter chamber (1), water inlet tank (2) above said chamber and backwash water distributing device on side; said filter chamber includes up and down filtering material fending device (3), filtering layer (4), filtering material carrying device (5) and air-water chamber (6); the upper layer of said backwash water distributing device is backwash discharge tank (7) near to filtering material fending device, and lower layer is air-water water distributing ditch (8) connected to air-water chamber; said filtering material fending device is inclined installed above said filtering layer and extends to edge of backwash discharge tank. The backwash water flows into backwash discharge tank after overflowing from filtering materialfending device, and will not retent on filtering material fending device, which avoids impurity substance settling and clogging on filtering material fending device.

Owner:ZHEJIANG DEAN TECH

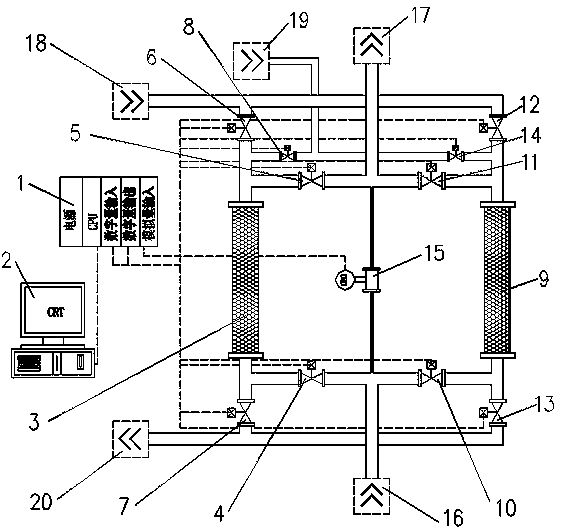

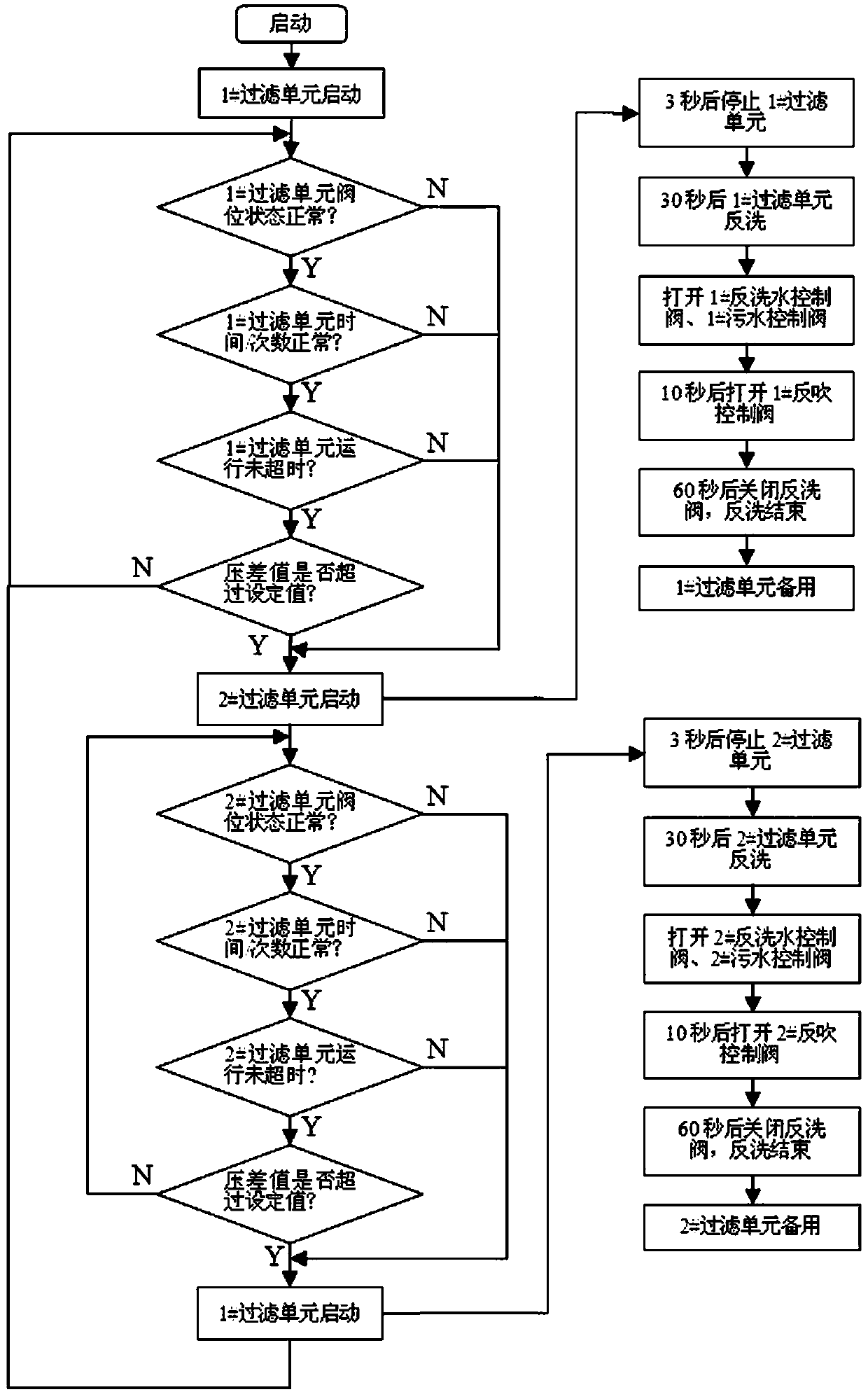

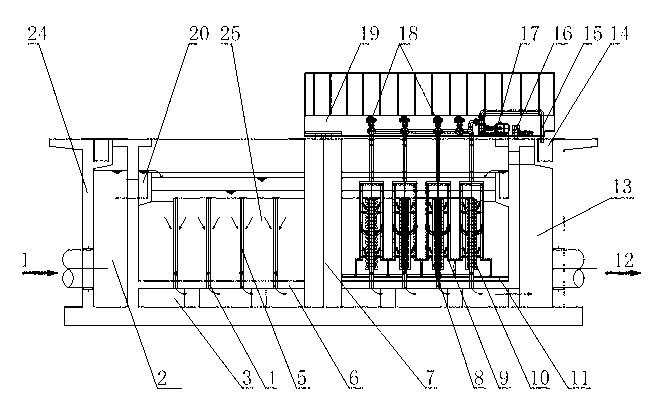

Filter device with capabilities of switching operation and automatic backwashing and control method

PendingCN107670373AGuaranteed backwash effectGuaranteed uptimeFiltration separationDifferential pressureMonitor equipment

The invention relates to a filter device with capabilities of switching operation and automatic backwashing and a control method. The filter device and the control method are used for keeping continuous operation of filters and realizing automatic deep backwashing. The filter device comprises filter units, a programmable controller and monitoring equipment, wherein the two filter units are identical in structure and connected in parallel; a differential pressure transmitter monitors pressure values of inlets and outlets of the filters; the programmable controller switches operation of the twofilter units according to the pressure values monitored by the differential pressure transmitter and filter time, filter operation can be performed continuously, the stopped filter unit is controlledby the programmable controller for backwashing, and the backwashing effect is guaranteed. The problems about continuous operation and automatic backwashing of the filter device are solved, filter operation can be still exerted during backwashing for pollution discharge, and normal operation of the filter device is not affected. The filter device has the advantages of compact structure, stable andreliable operation, high treating capacity, long service life and the like and has great popularization and application values.

Owner:TANGSHAN COLLEGE +1

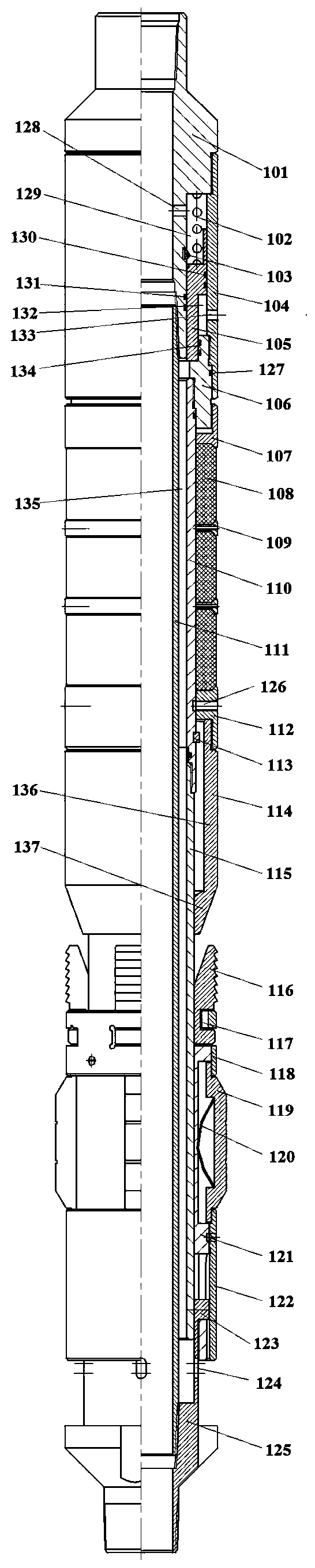

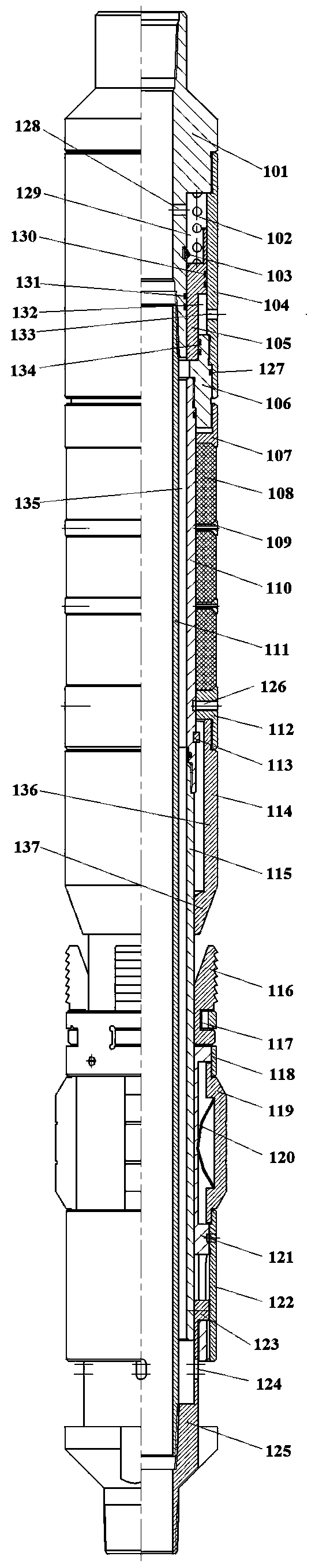

Packer

ActiveCN111395990AAvoid accidental openingMake sure to turn on stabilityDrilling rodsFluid removalUpper jointStructural engineering

The invention discloses a Y221 packer with an anchoring function. The Y221 packer comprises a central pipe, wherein the central pipe is sequentially provided with an upper joint, a backwashing mechanism, a rubber sleeve mechanism, an anchoring mechanism, a centralizing mechanism and a lower joint from top to bottom; the backwashing mechanism comprises an outer sleeve, a backwashing piston sleeve and a backwashing spring, wherein the outer sleeve fixedly sleeves the exterior of the upper joint, a backwashing space is formed between the outer sleeve and the upper joint, and the backwashing piston sleeve is arranged in the backwashing space and divides the backwashing space into a first space and a second space in a sealing manner; the upper joint is provided with a first through hole communicating with the first space, and the outer sleeve is provided with a second through hole communicating with the second space; a containing ring groove for containing a blocking ring is further formedin the position, below the first through hole, of the wall of the upper joint; and the backwashing piston sleeve is provided with a blocking position for blocking communication between an inner runnerand the second space as well as an opening position for communicating the inner runner with the second space.

Owner:东营市金旺石油机械制造有限公司

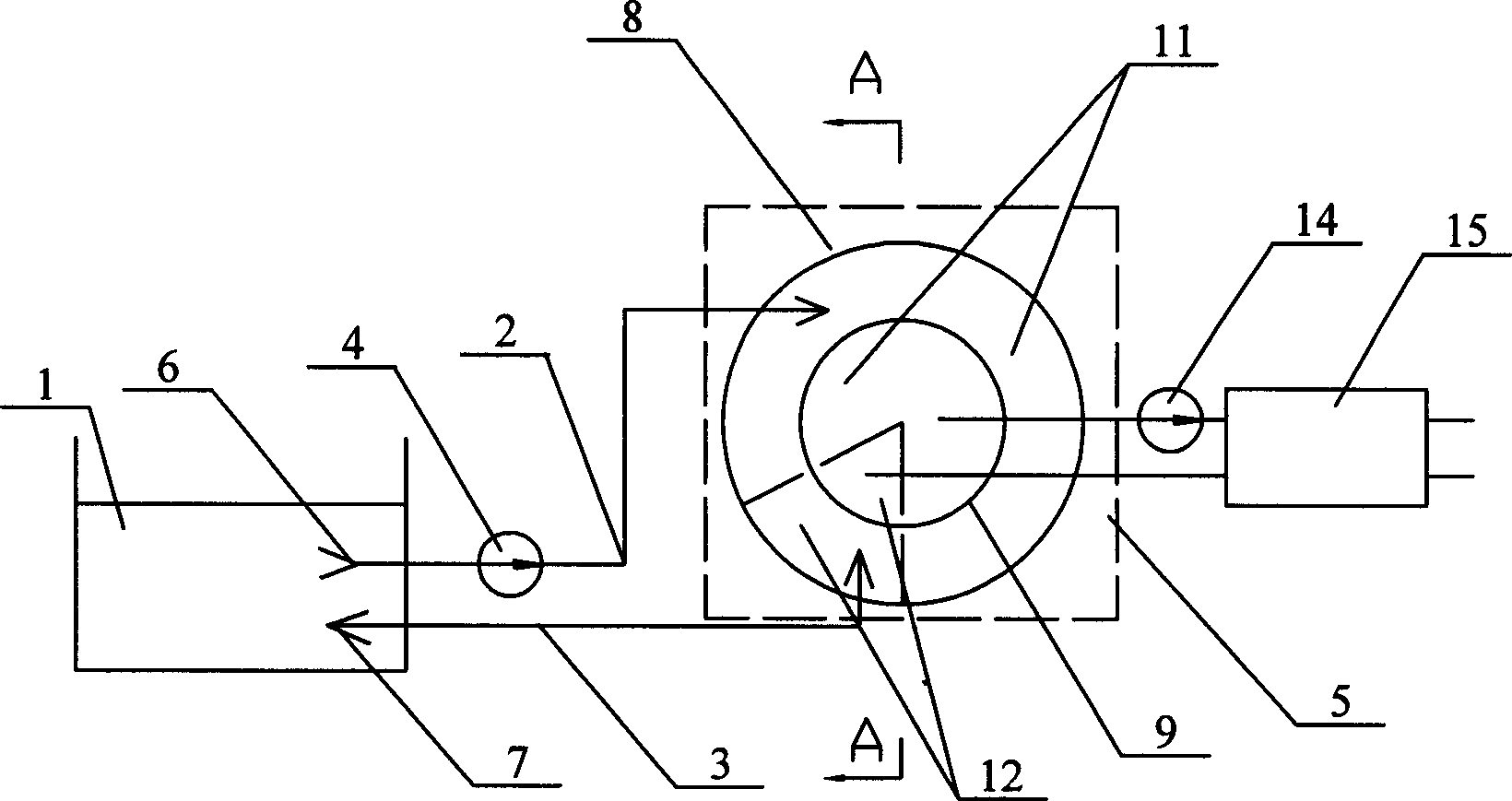

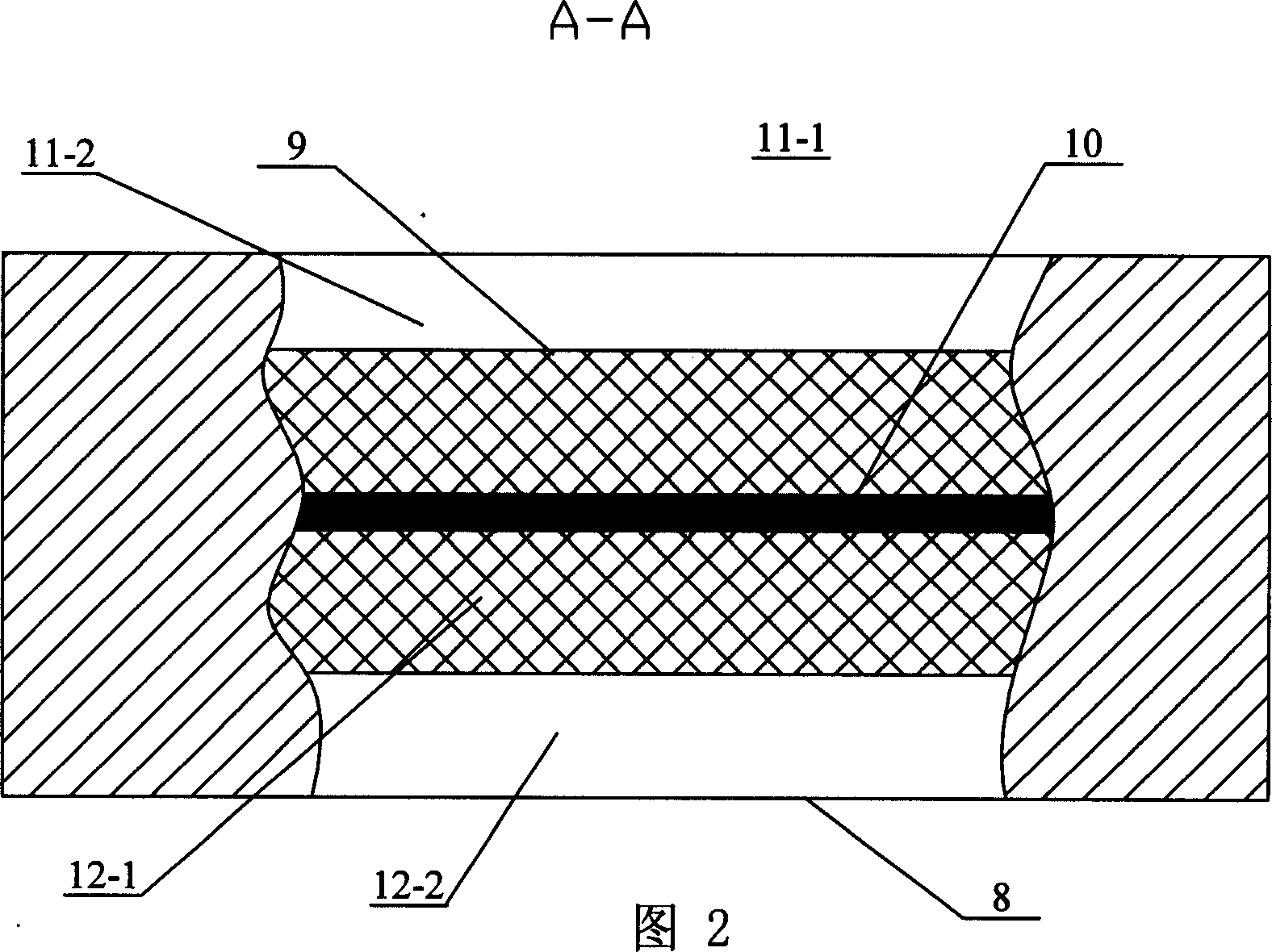

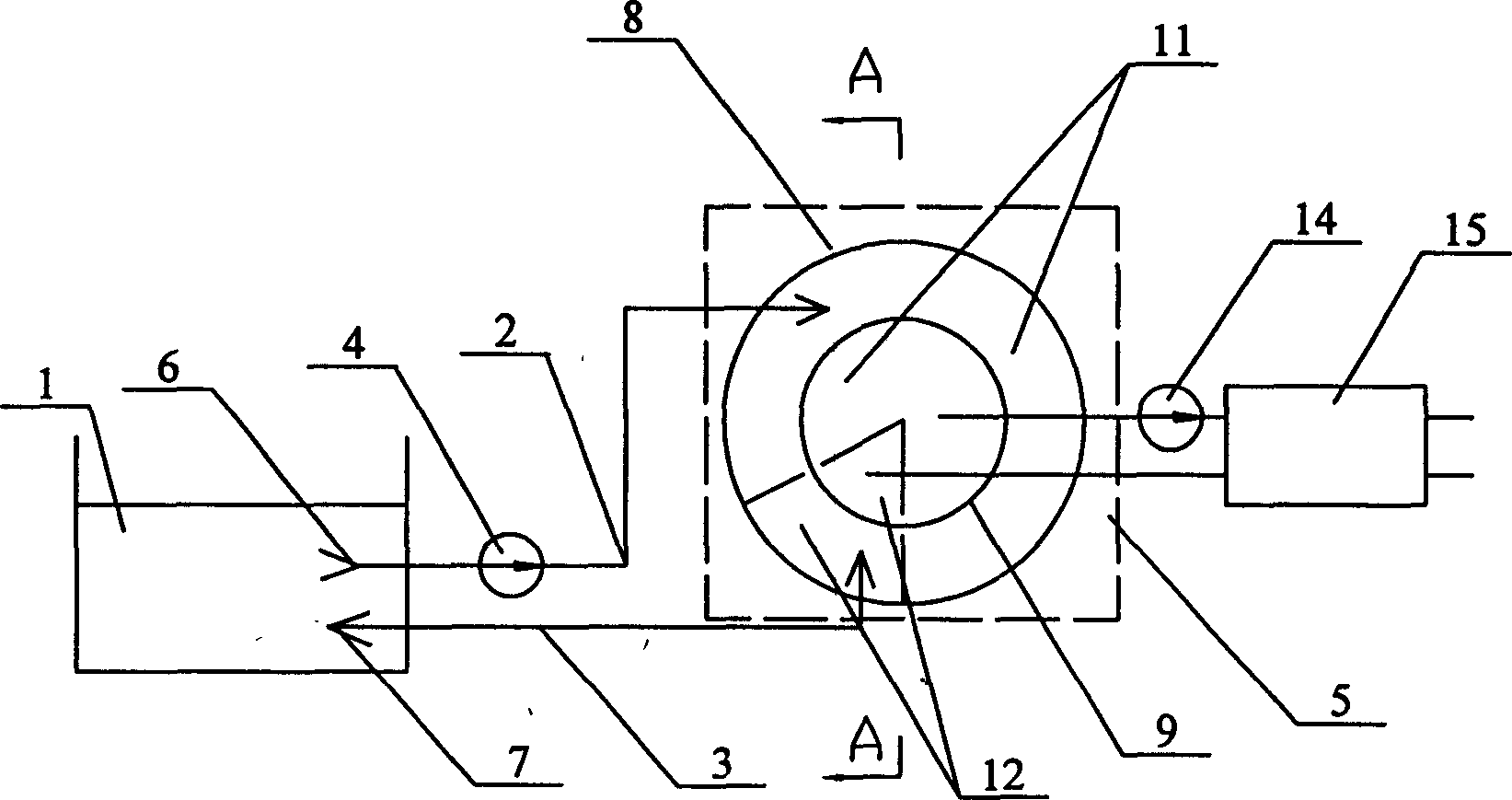

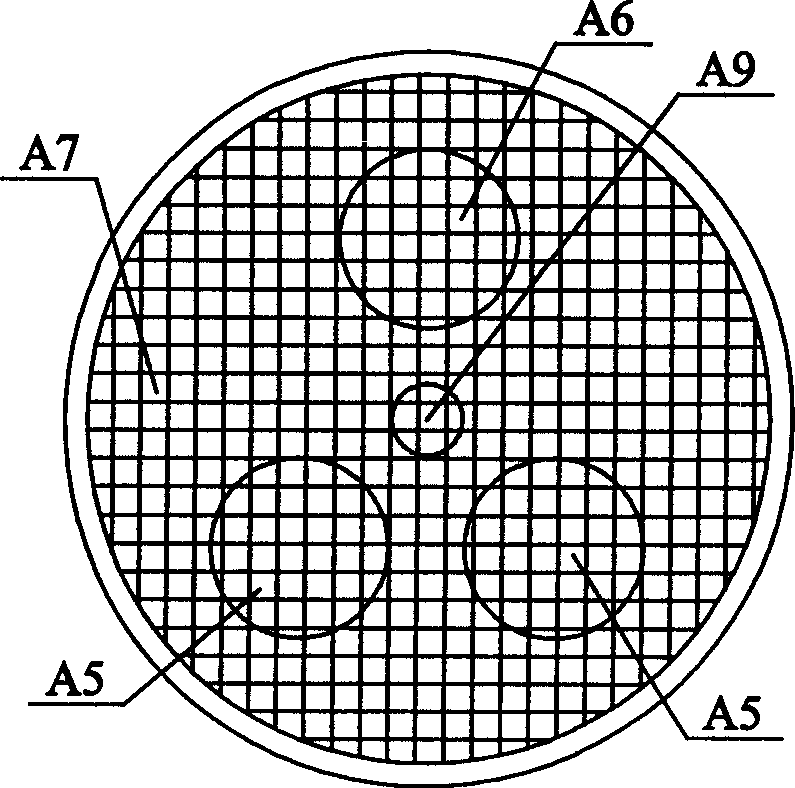

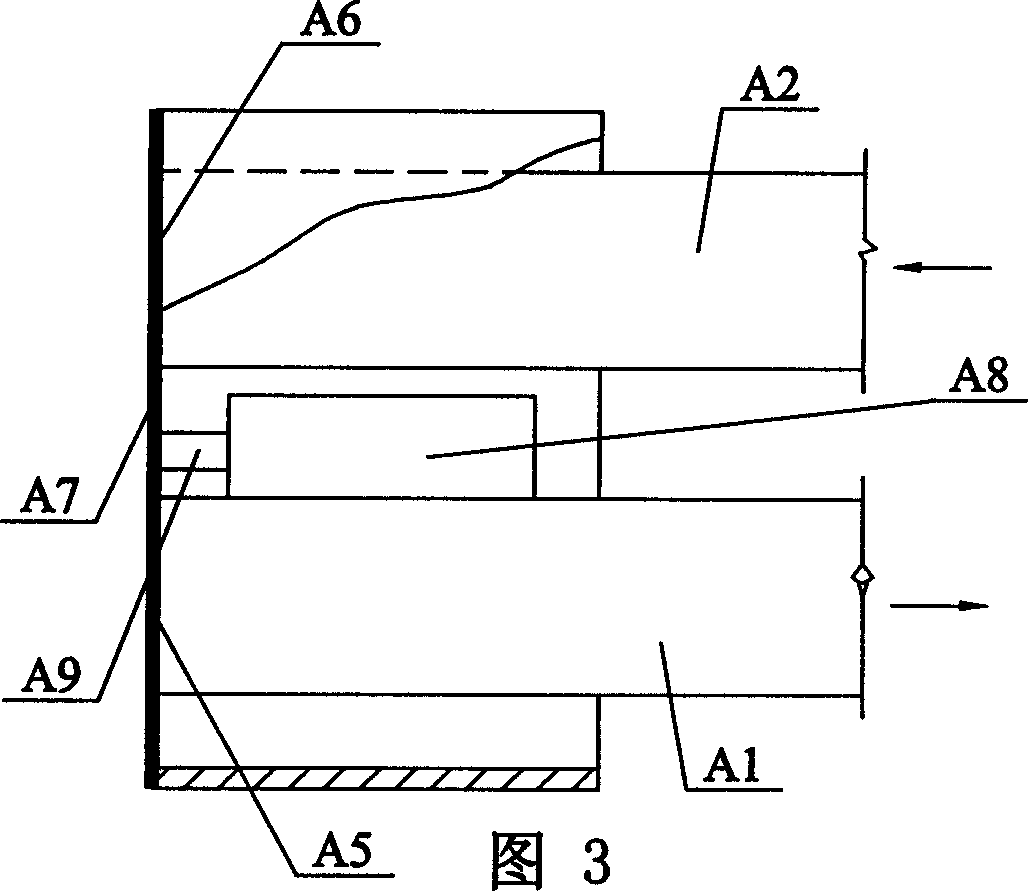

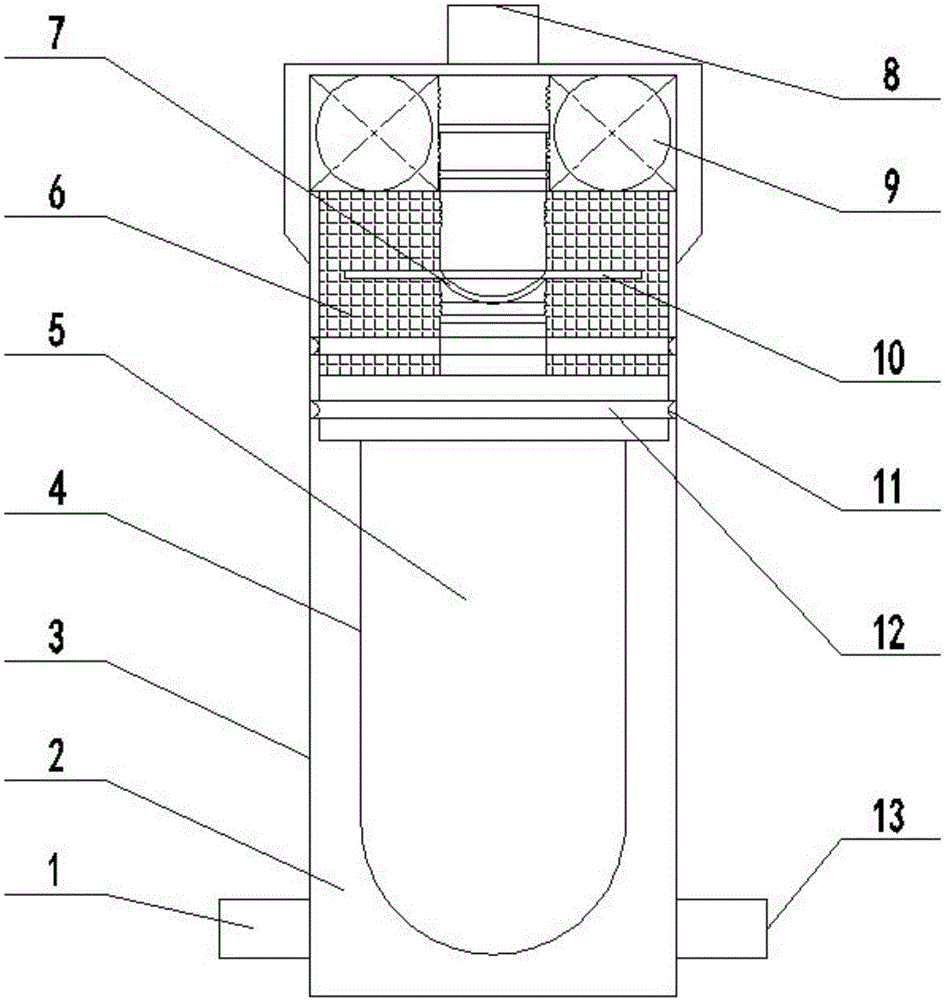

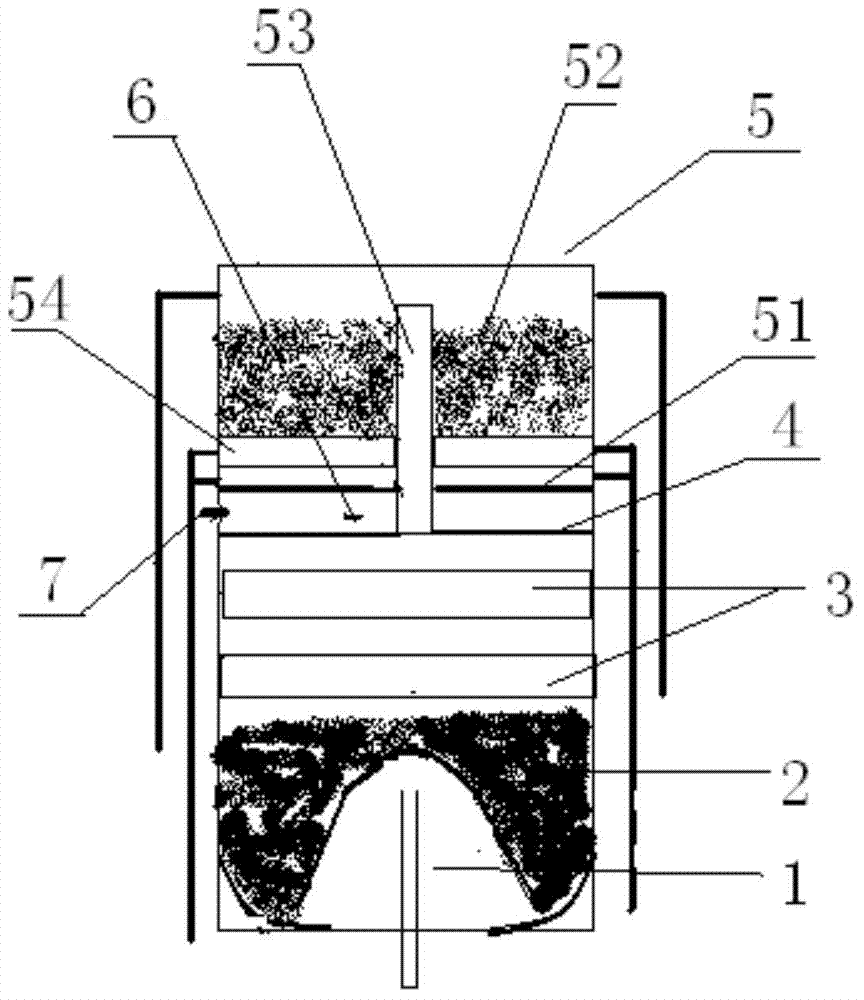

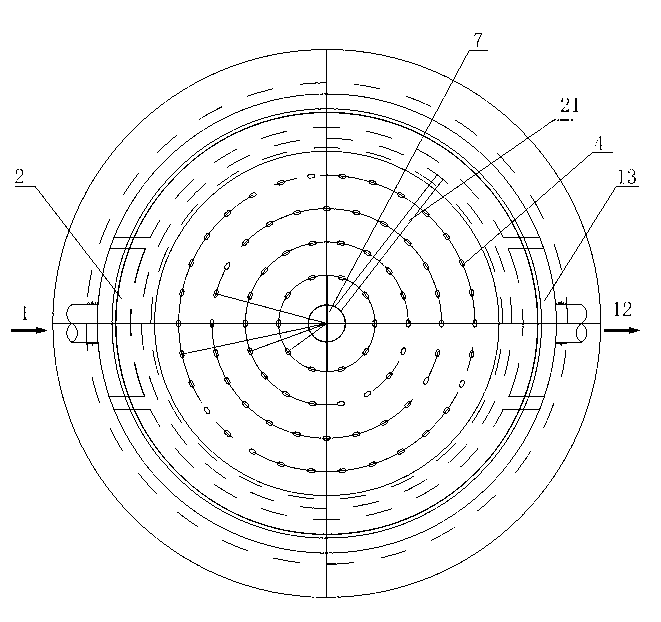

Urban sewage waterpower self-cleaning method with drum grid and device thereof

InactiveCN1281513CSolve siltGuaranteed backwash effectWater/sewage treatmentWastewaterSmall footprint

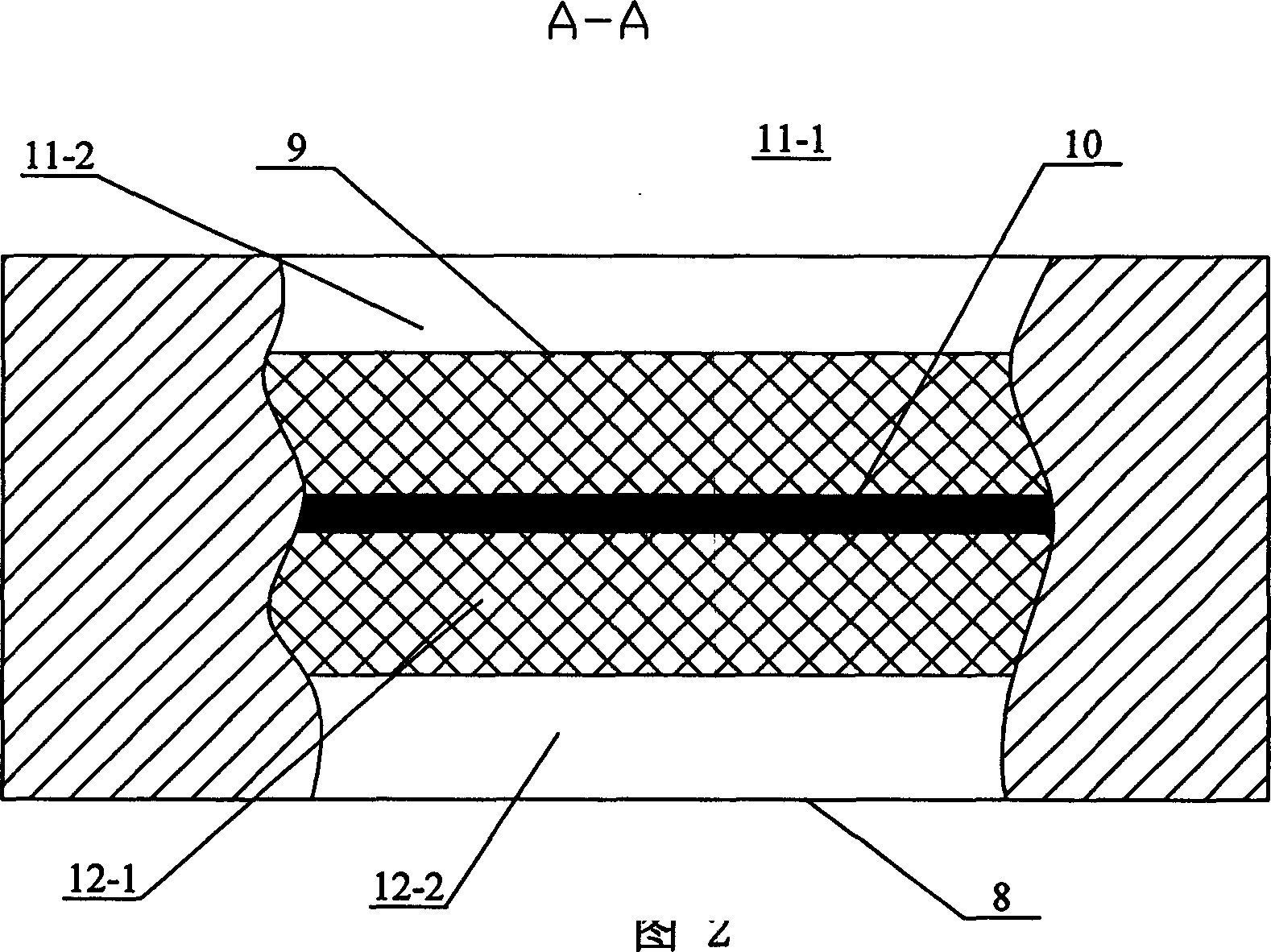

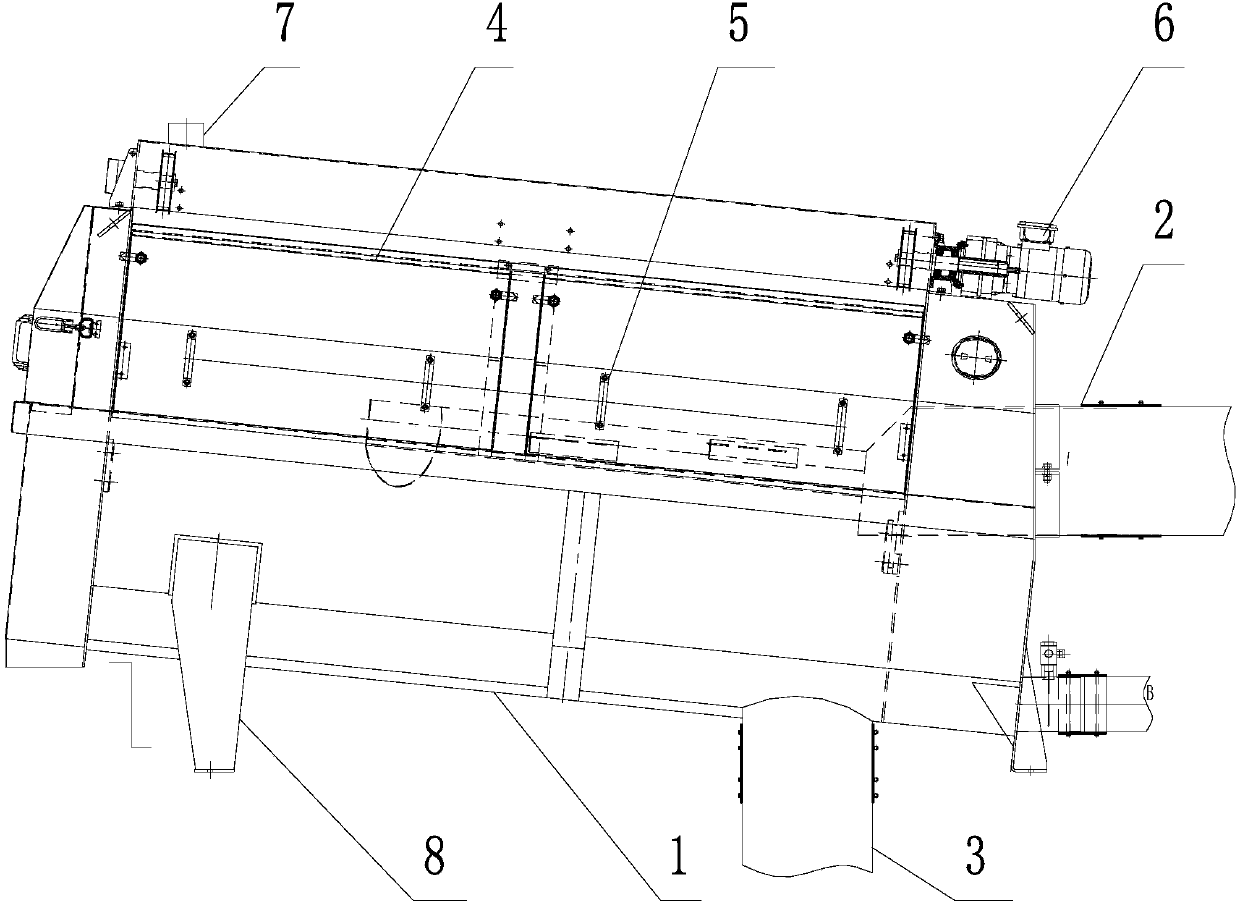

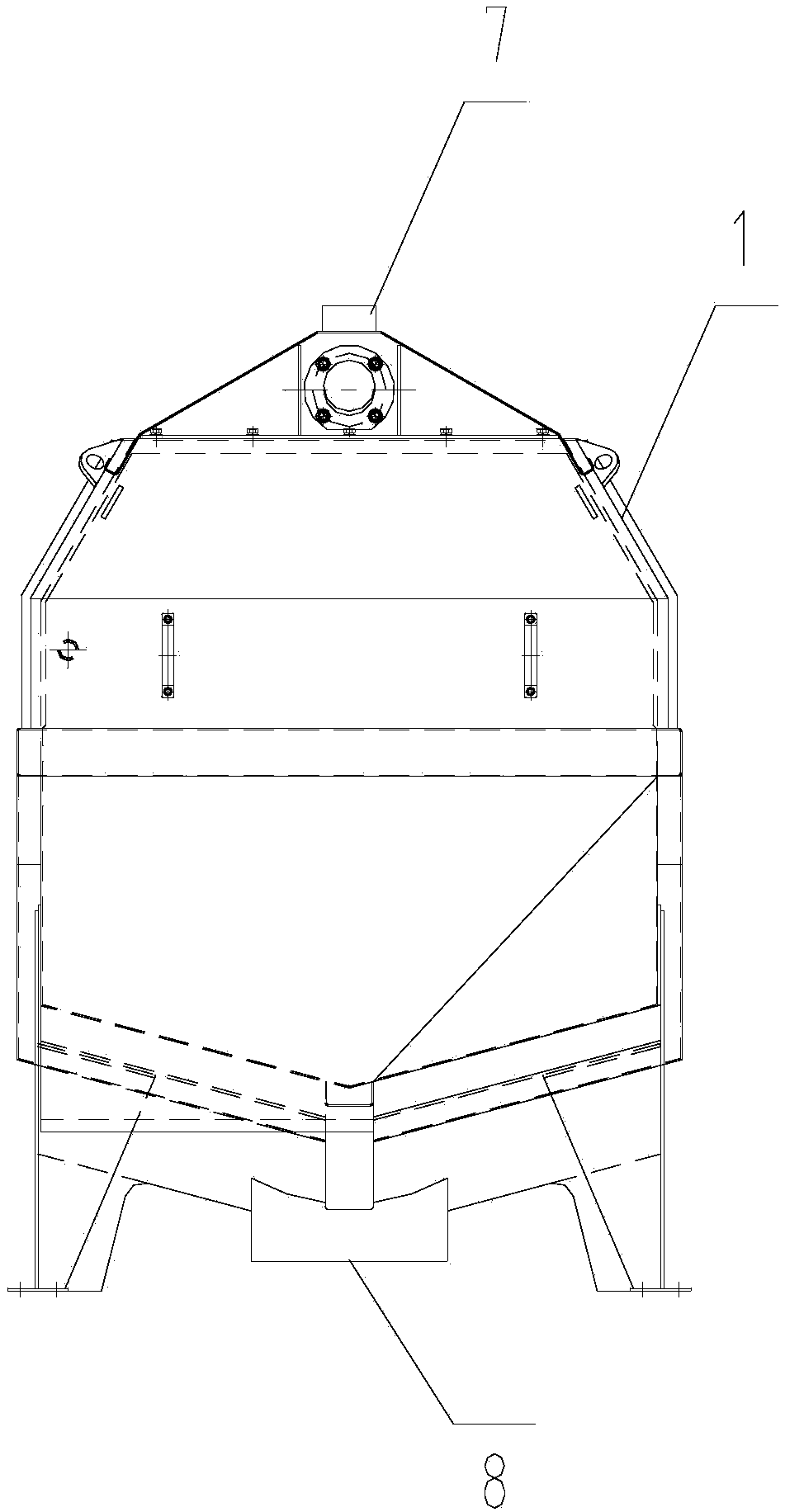

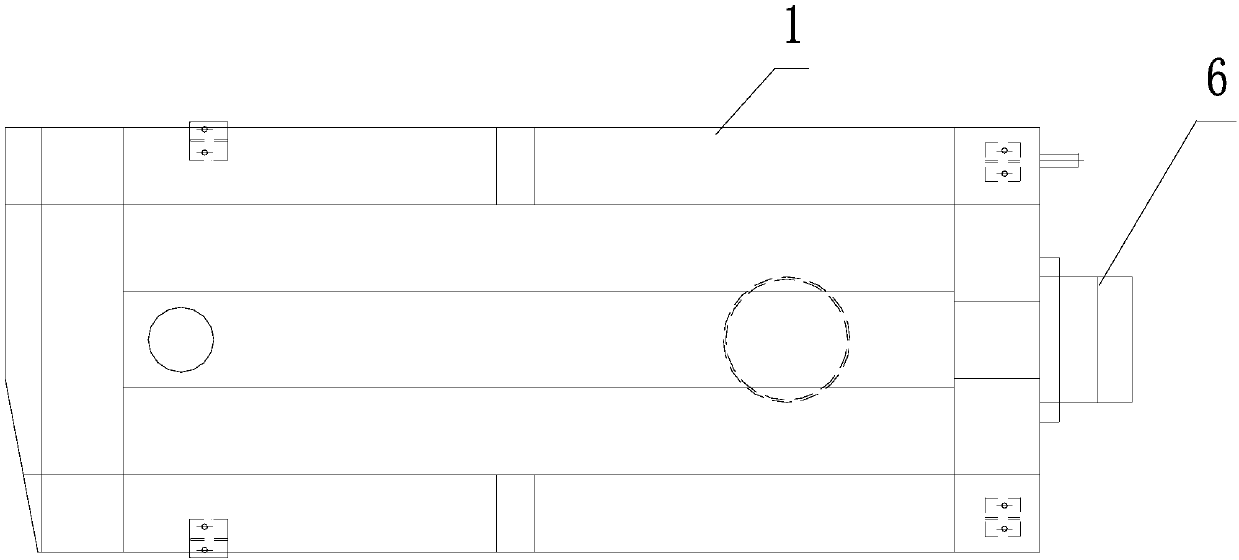

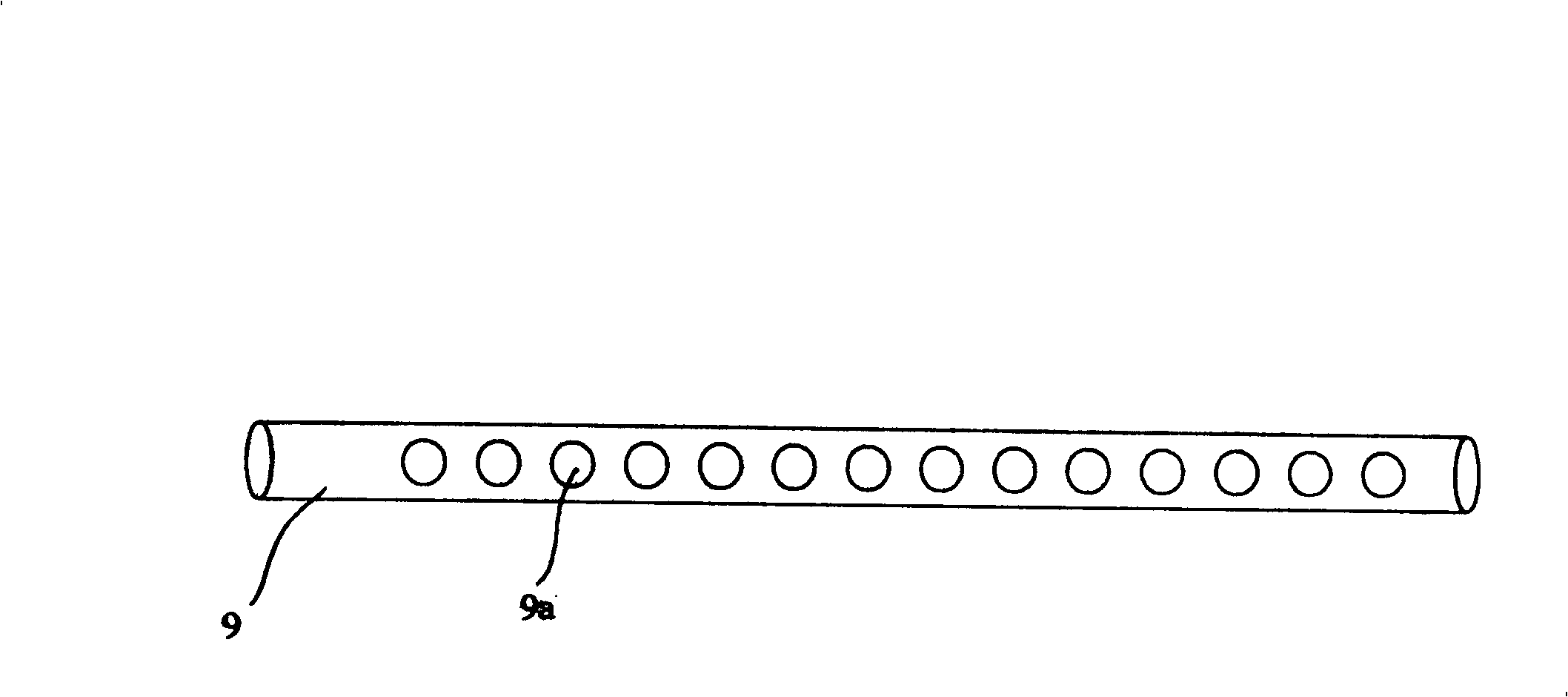

The utility model relates to an urban sewage hydraulic self-cleaning device provided with a roller grill, which relates to an improvement of a device which utilizes urban sewage to provide energy. It consists of a sewage suction pipe (2), a sewage return pipe (3), a sewage lifting pump (4) installed on the sewage suction pipe (2) and a decontamination device (5). The sewage suction pipe (2) The water suction port (6) and the return port (7) of the sewage return pipe (3) are arranged in the main sewage canal (1), and the other end of the sewage suction pipe (2) and the sewage return pipe (3) is provided with a decontamination device (5), the decontamination device (5) consists of a housing (8), a cylindrical grid filter (9) and a transmission device (10) that drives the rotation of the cylindrical grid filter (9) , the inside of the housing (8) is divided into a water supply area (11) and a return water area (12), and the cylindrical grille filter (9) divides the water supply area (11) into the inner water supply area (11-1) and The water supply area (11-2) outside the tube, the backwater area (12) is divided into the backwater area (12-1) inside the tube and the backwater area (12-2) outside the tube by the cylindrical grid filter (9) . The invention has the advantages of small occupied area, low cost, simple equipment and wide application range.

Owner:HARBIN INST OF TECH

Drum grille and using method thereof

PendingCN107823952AReasonable structural designLess requirements for civil engineering foundation conditionsMoving filtering element filtersStructural engineeringSewage

The invention relates to a drum grille and a using method thereof. The drum grille comprises a shell and a supporting frame arranged at the bottom of the shell, wherein a sewage inlet is formed in theend part of the left side of the shell; a water draining port is formed in the bottom of the shell; a drum assembly and brush assemblies are arranged inside the shell; the drum assembly is horizontally placed inside the shell; the drum assembly comprises a cylindrical drum screen plate and a drum rotating shaft; the brush assemblies are arranged on the inner wall of the drum screen plate and is used for cleaning the inner wall of the drum screen plate; each brush assembly comprises a brush and a brush rotating shaft; the sewage inlet is connected with an inlet water distributing pipe of the drum assembly through a water inlet pipe; the water draining port is connected with an outlet water distributing pipe of the drum assembly through a water draining pipe; the drum grille further comprises a driving assembly, a back flushing assembly and an electric control system. The drum grille has the advantages of a reasonable structural design, convenience in operation and use, low production cost and maintenance cost, safe, stable and reliable operation, high efficiency of intercepting impurities such as fiber and hair in the sewage treatment process, stable effluent quality, high degree of automation and the like.

Owner:BEIJING DRAINAGE EQUIP

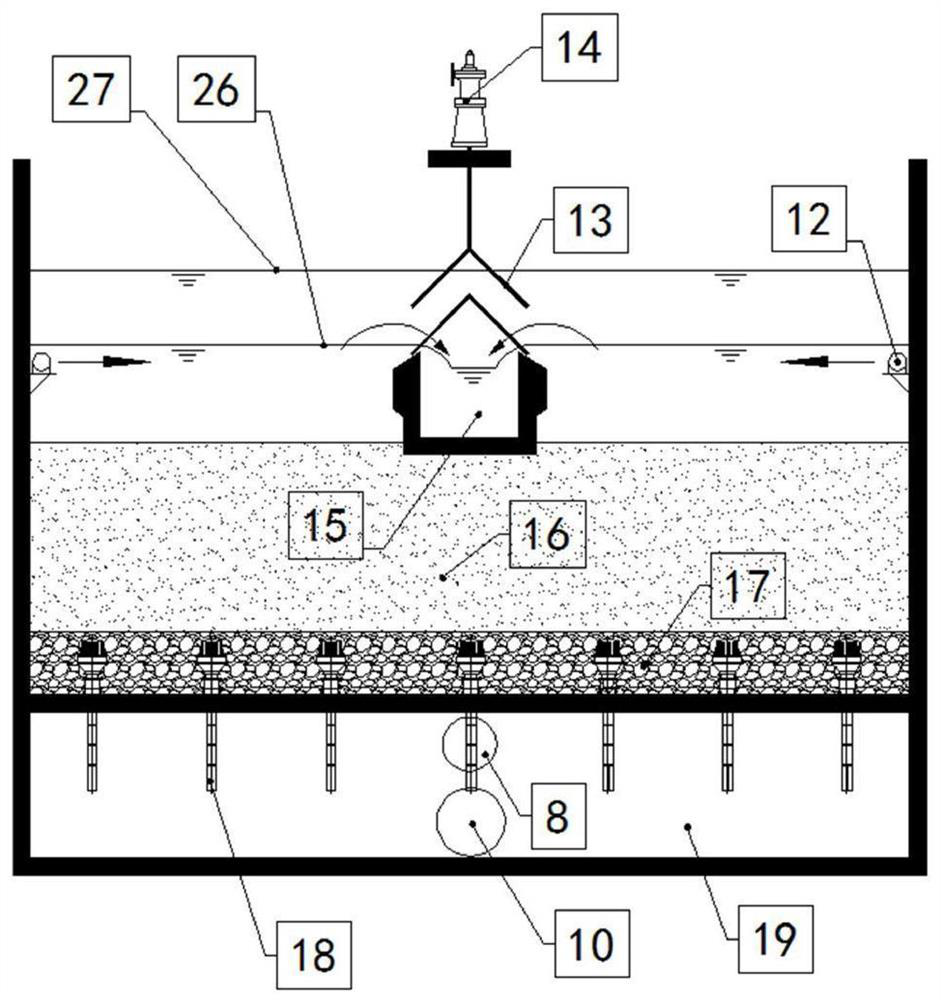

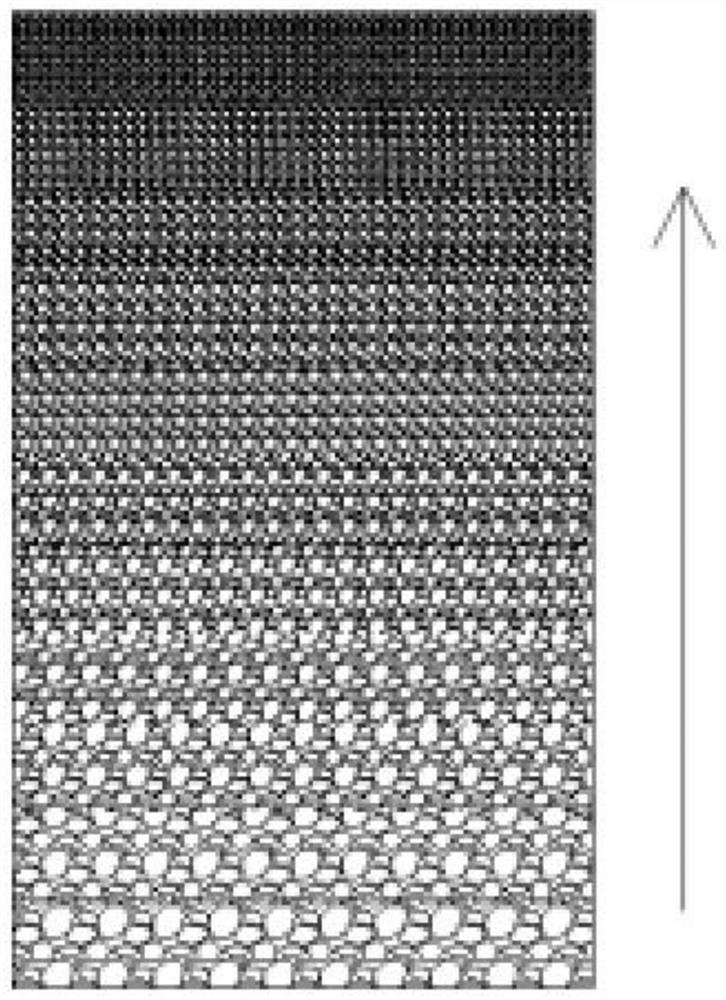

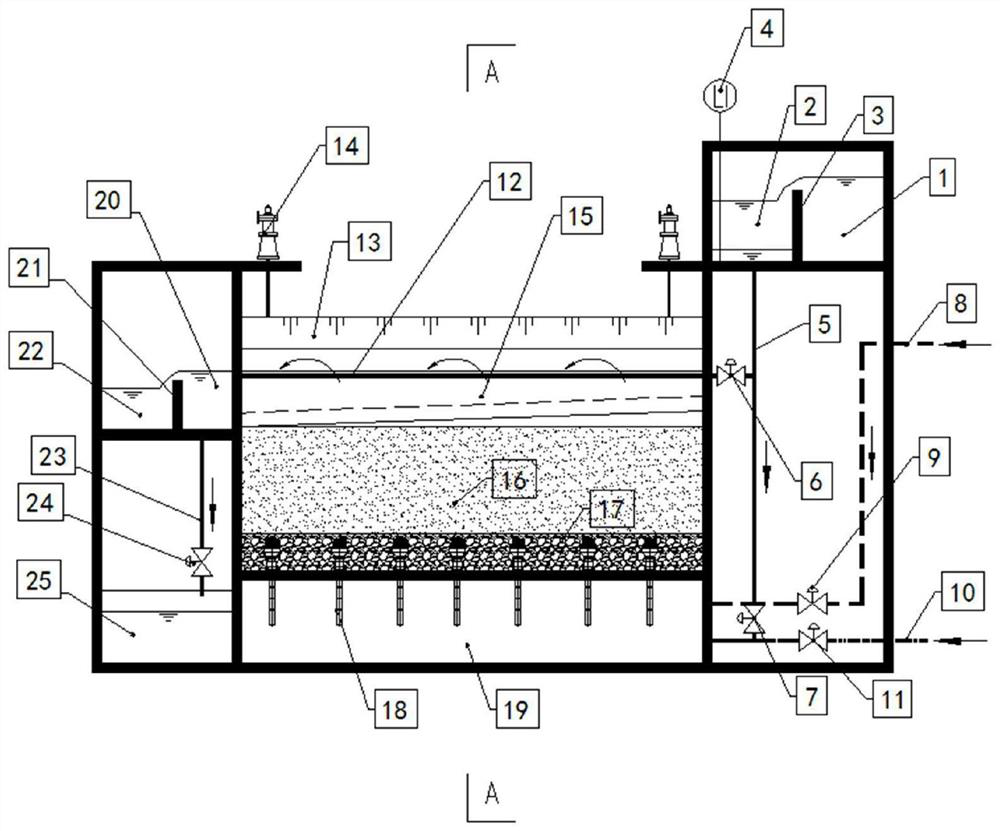

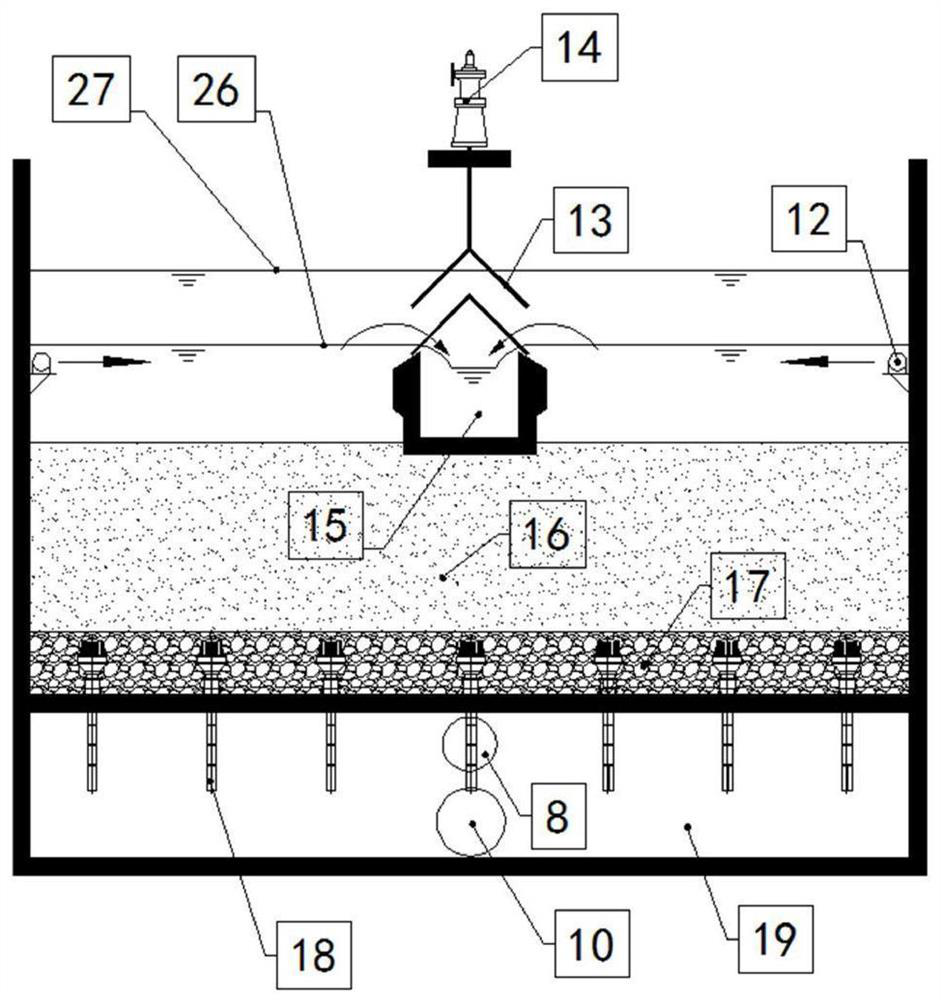

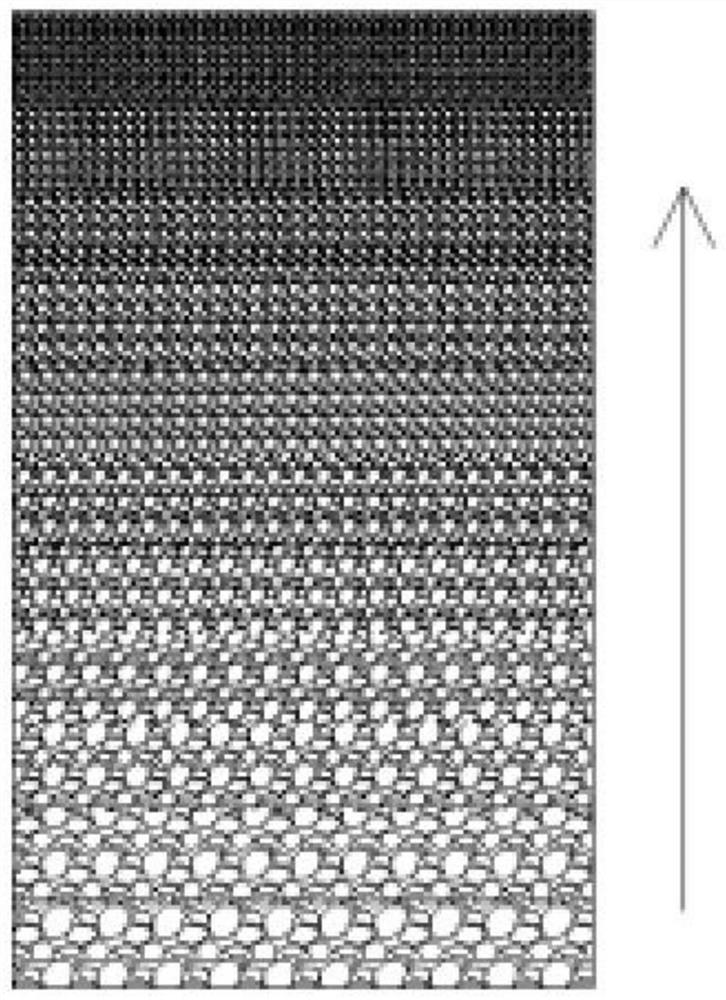

Upward-flow heterogeneous filter material filter tank

ActiveCN112657241AReduce backwash timesUse the filtering abilityLoose filtering material filtersSustainable biological treatmentEnvironmental engineeringFilter material

The invention discloses an upward-flow heterogeneous filter material filter tank which comprises a filter tank body, the bottom of the filter tank body is divided into a water and gas distribution space at the bottom and a filter tank at the upper part through a partition plate, a plurality of long-handle filter heads are arranged on the partition plate to communicate the water and gas distribution space with the filter tank, the bottom of the filter tank is a supporting layer, and the upper part of the supporting layer is a filter material layer. A water outlet groove is formed above the filter material layer in the length direction of the filter tank, the tail of the water outlet groove is communicated with a water outlet channel in one side of the filter tank, a water inlet branch channel is formed in the other side, symmetrical to the water outlet channel, of the filter tank, a water inlet pipe is arranged at the bottom of the water inlet branch channel, and the outlet end of the water inlet pipe is communicated with the water and gas distribution space; and the filter material layer and the supporting layer are filled with a filter material which is a heterogeneous filter material, and the particle sizes of the heterogeneous filter materials are sequentially increased from top to bottom. The heterogeneous filter material is adopted in the filter tank, the obtaining cost of the filter material is low, arrangement with the small upper particle size and the large lower particle size can be naturally formed after backwashing, and the filtering efficiency of the filter tank can be better improved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

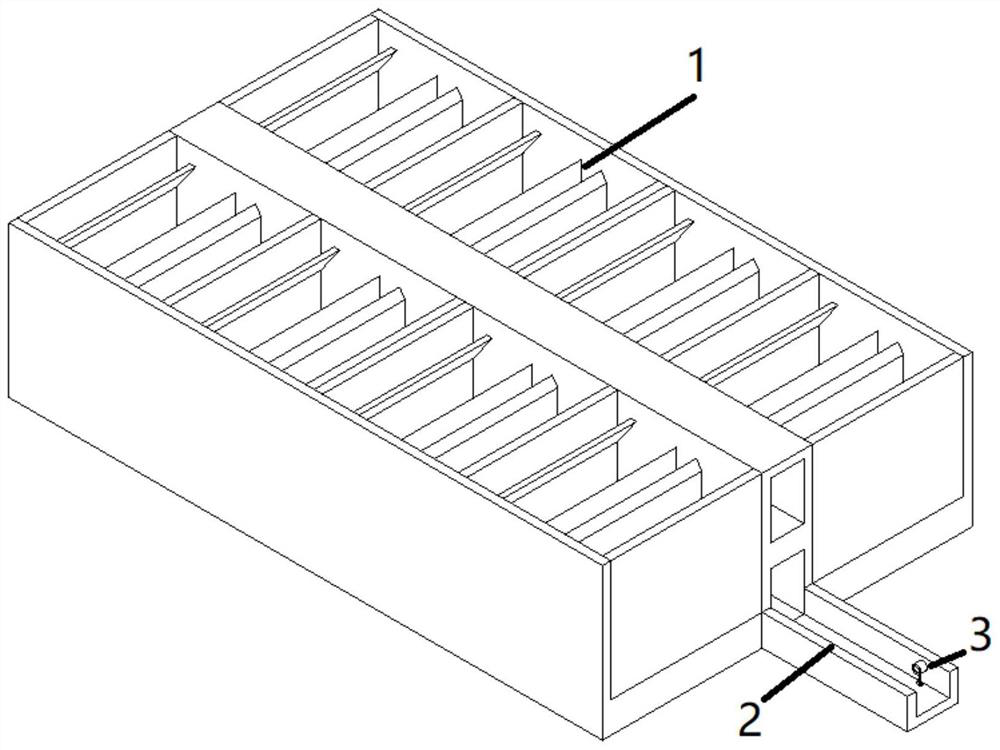

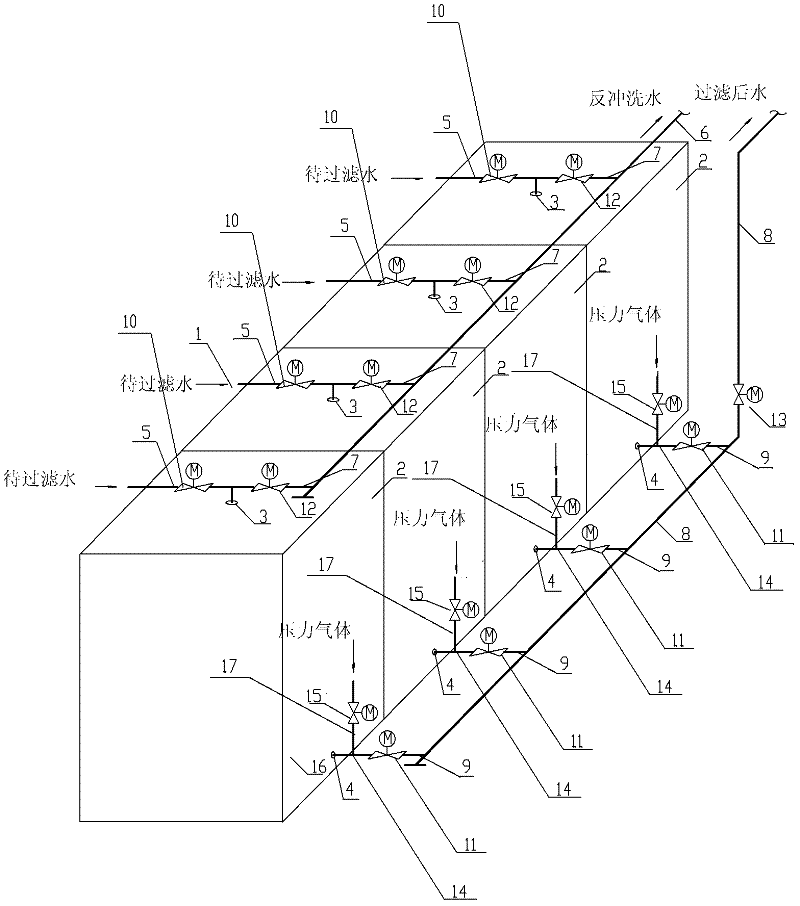

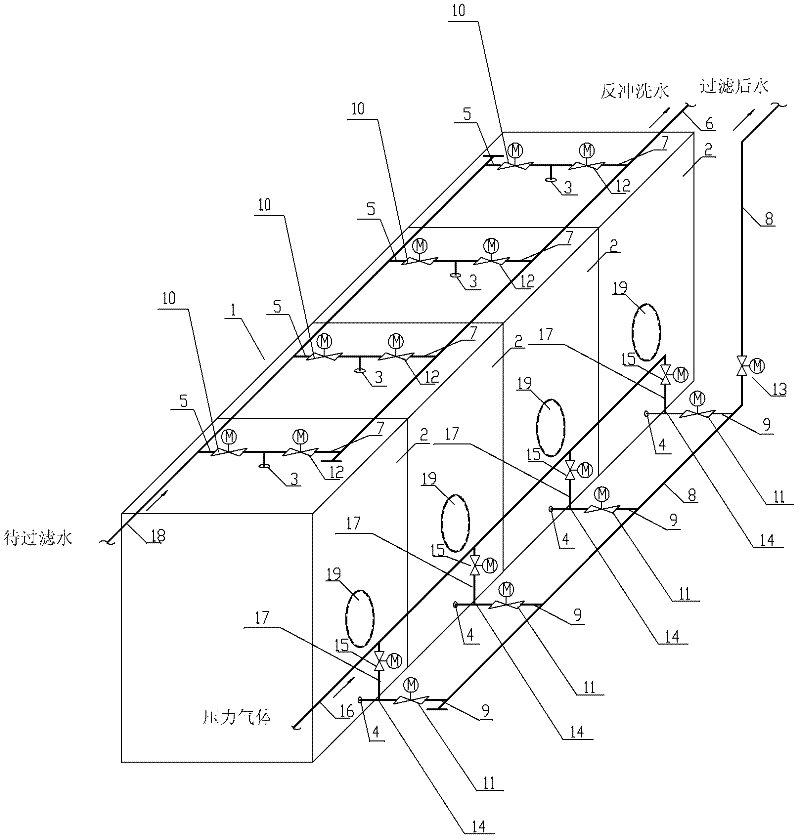

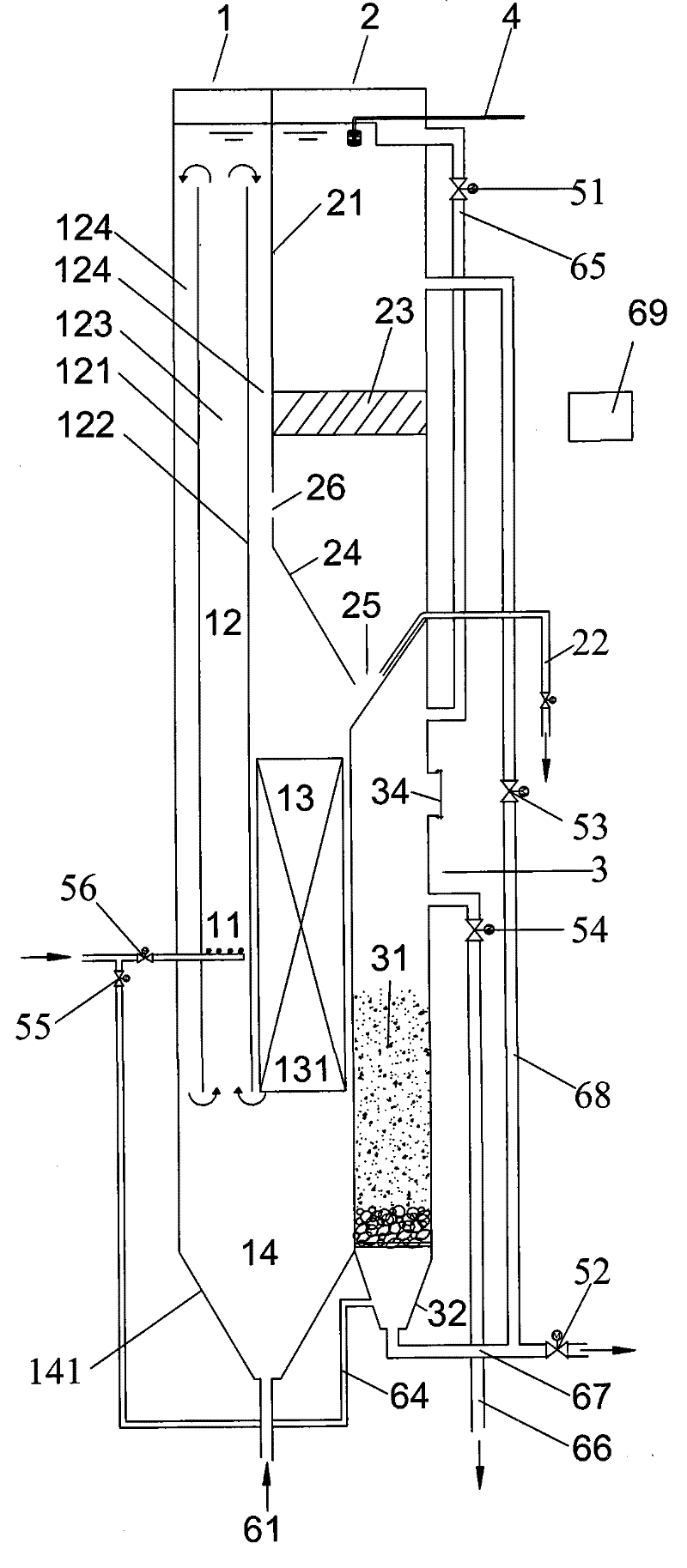

Pressure type gas-water mutual flushing filter tank and filtration method

InactiveCN102266685ALower the altitudeSmall footprintLoose filtering material filtersGravity filtersAir filterFiltration

The invention discloses a pressure-type air-water mutual flushing filter tank and a filtering method. The filter tank includes a tank body, a water inlet branch pipe, an air inlet branch pipe, a first water main pipe, a second water main pipe and an on-off control device. It includes at least two closed filter grids, each filter grid is provided with a filter material layer, and each filter grid is respectively arranged with a first water outlet and a second water outlet; the water inlet branch pipe is connected with each first water outlet for Import the water to be filtered; the first water outlet of each filter grid is connected with the first water main pipe through the first branch pipe; the second water outlet of each filter grid is connected with the second water main pipe through the second branch pipe; each second branch pipe is provided with inlet The air port is connected with each air inlet through the air intake branch pipe; the on-off control device is used to respectively control the on-off of each water inlet branch pipe, each first branch pipe, each second branch pipe and the second water main pipe. The filter tank reduces the overall height of the tank body and reduces the occupied space of the filter tank.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

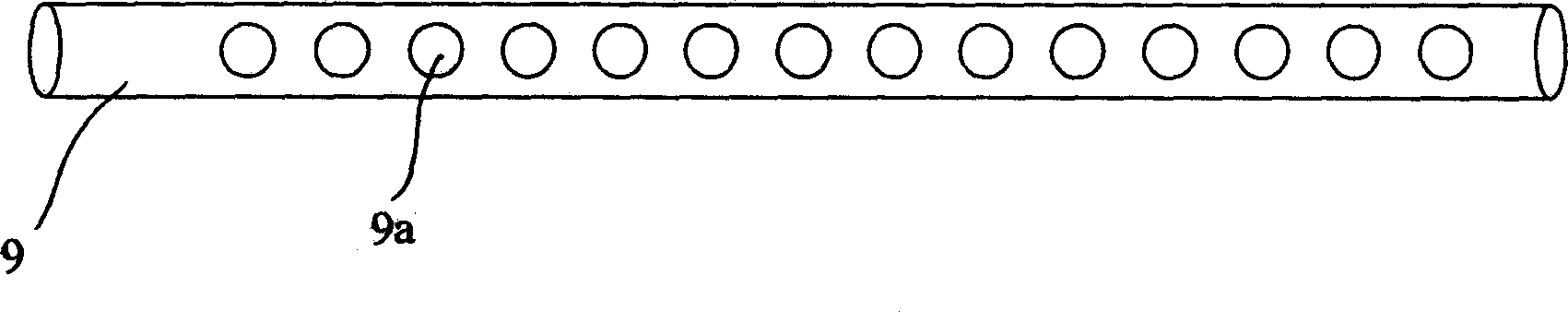

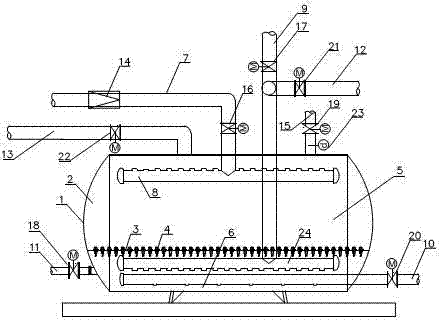

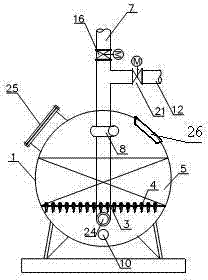

Novel filter tank

InactiveCN104511188AEasy to handleReduce volumeLoose filtering material filtersGravity filtersWash waterFilter material

The invention relates to a novel filter tank which comprises a tank body, a water collection pipe and a water distribution pipe. A water inlet pipe, a water outlet pipe, an air outlet pipe and a back wash water drainage pipe are arranged on the tank body. A manhole and an observation hole are arranged on the lateral side of the tank body. The water distribution pipe is arranged on the upper portion of the interior of the tank body and connected with the water inlet pipe. Orifices are arranged upwards. A back wash water inlet is arranged on the water drainage pipe. A blow-down pipe is arranged at the lower part of the tank body. An air inlet pipe is arranged on the bottom of the interior of the tank body. The water collection pipe is arranged above the air inlet pipe and connected with the water outlet pipe. A filter plate is arranged between the water distribution pipe and the water collection pipe. A material filtering layer is arranged above the filter plate. A flowmeter and an electrically operated valve of the water inlet pipe are arranged on the water inlet pipe. The novel filter tank adopts the arrangement of reversed graded filter materials. Filter materials of a large grain size and a large proportion are kept at the bottom of the tank body and can be automatically graded after back wash.

Owner:QINGDAO GUANDA TRADE

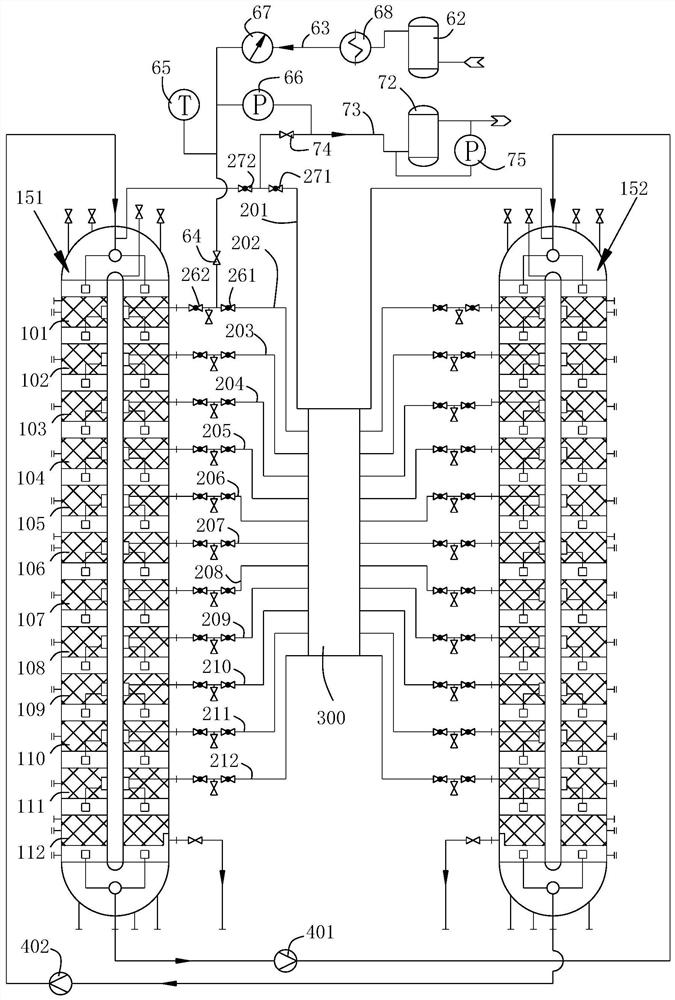

Backwashing method of simulated moving bed device for adsorbing and separating xylene

ActiveCN111603805AAvoid interferenceGuaranteed stabilitySolid sorbent liquid separationAdsorption purification/separationXylyleneLine tubing

The invention discloses a backwashing method of a simulated moving bed device for adsorbing and separating xylene. Two adjacent inlet and outlet pipelines of the simulated moving bed device are used as a group of cleaning pipes, the inlet and outlet pipeline positioned on the downstream side of a material path is used as a washing liquid inlet pipe, and the inlet and outlet pipeline positioned onthe upstream side of the material path is used as a washing liquid outlet pipe; a backwashing liquid enters connected grids from the washing liquid inlet pipe, flows upwards, is used for backwashing abed layer positioned on the upper side of the washing liquid inlet pipe and then is discharged from the washing liquid outlet pipe; and the backwashing liquid does not pass through a rotary valve. Only the single bed layer can be subjected to backwashing, adsorbents and internal components of other bed layers are not influenced, and the backwashing liquid does not pass through the rotary valve, so that the interference to the work of the rotary valve is avoided, and the overall stability of production is ensured.

Owner:CHINA PETROLEUM & CHEM CORP

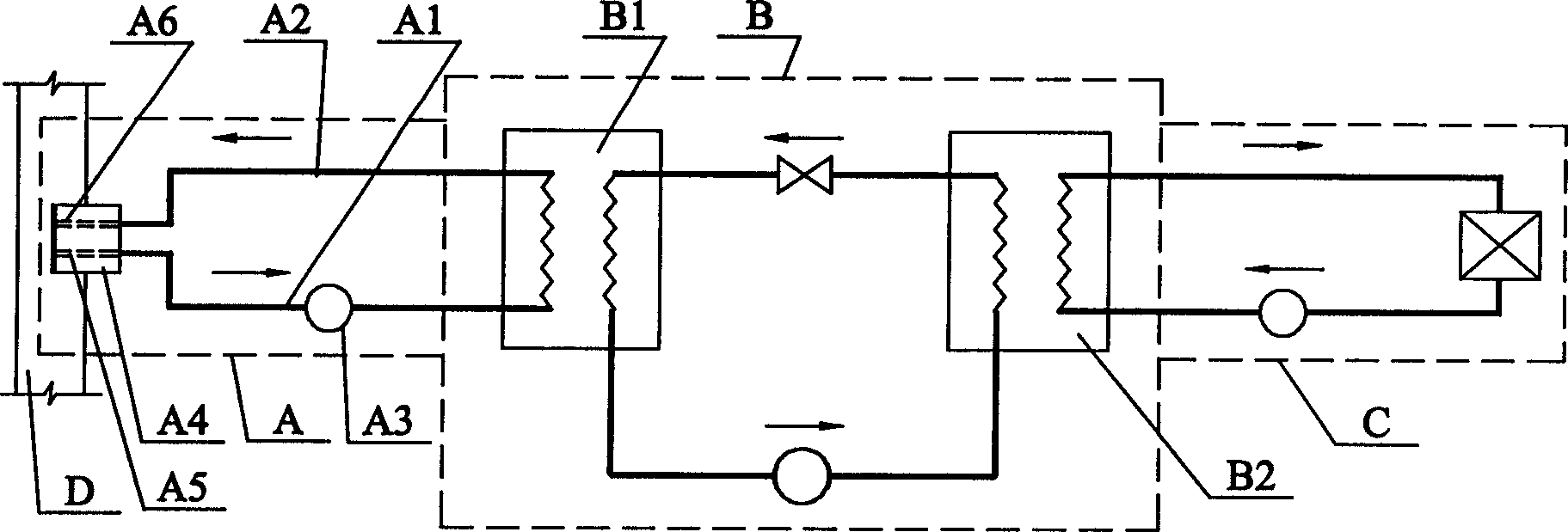

Method and device for using city waste water cold and heat source

InactiveCN1186579CTo achieve the purpose of refrigerationTo achieve the purpose of heatingHeat pumpsClimate change adaptationSewageEnergy recovery

The present invention discloses method and apparatus of using city waste water to provide energy source. The method includes the processes of energy recovery, energy conversion and energy release. Waste water is first pumped from the waste water trunk canal, then passed through heat exchanger and finally returned into the trunk canal. The water inlet and water outlet of the water conveying pipeline share one common filter screen, which is made to rotate in the plane during waste water circulating process. The waste water circulating apparatus consists of waste water pumping pipe, waste water returning pipe, pump and dirt eliminating unit. The waste water pumping port and waste water exhausting port in the waste water trunk canal are provided with dirt eliminating units to prevent the siltation of pollutant.

Owner:HARBIN INST OF TECH

Using method of packer backwashing

ActiveCN111594092AAvoid accidental openingMake sure to turn on stabilityFlushingSealing/packingMechanical engineeringBackwashing

The invention discloses a using method of packer backwashing. The using method of packer backwashing includes the steps that step1, a Y221 packer is connected to a lower well of a pipe column, the pipe column is rotated after lifting the pipe column outside the well after the packer is lowered to a predetermined position, and then the pipe column continues to be lowered to complete packer setting;step 2, when backwashing is needed, casing pipe pressure is increased by injecting liquid into oil sleeve annulus, when the pressure reaches a set value, a backwash piston sleeve 105 is pushed to compress a backwash spring 102 to move upward, a blocking ring 103 is squeezed to ensure that a backwash mechanism opens; step 3, when the pressure in a casing pipe disappears, the backwash piston sleeve105 returns to the original position under the action of the backwash spring 102, and a well washing channel can be closed; and step 4, when unsealing is needed, the pipe column is lifted outside thewell, a rubber tube 108 resets, and unsealing the packer is completed.

Owner:PANJIN DONGFANG RUIFU PETROLEUM TECH

Automatic graded filtering tank device

InactiveCN106693467ALarge filter areaFast filtrationMembrane filtersLoose filtering material filtersEngineeringFilter material

The invention relates to an automatic graded filtering tank device, comprising a tank body, a water collection pipe and a water distribution pipe, wherein a water inlet pipe, a water outlet pipe, a gas outlet pipe and a backwash exhaust water pipe are arranged above the tank body, a manhole and an observation hole are formed in a side face of the tank body, the water distribution pipe is arranged at the upper part of the inner part of the tank body, and is connected with the water inlet pipe, a hole mouth faces upwards, a backwash water inlet is formed in the water outlet pipe, a blow-down pipe is arranged below the tank body, a gas inlet pipe is arranged at the bottom of the inside of the tank body, the water collection pipe is located above the gas inlet pipe, and is connected with the water outlet pipe, a filtering plate is arranged between the water collection pipe and the water distribution pipe, a filtering material layer is arranged above the filtering plate, and a flowmeter and an electrically operated valve of the water inlet pipe are arranged on the water inlet pipe. According to the automatic graded filtering tank device disclosed by the invention, arrangement of filtering materials reverse to the grade is adopted, large-sized and large-proportion filtering materials are arranged at the bottom, and can be graded automatically after backwashing.

Owner:王帅

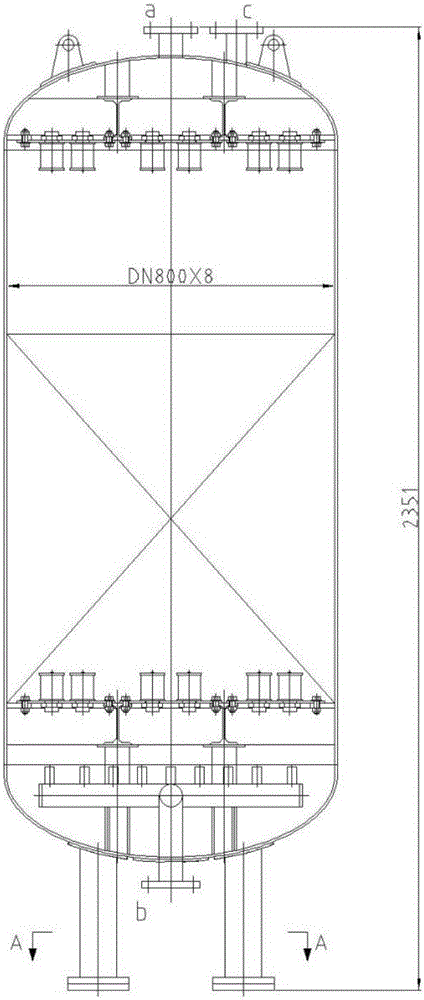

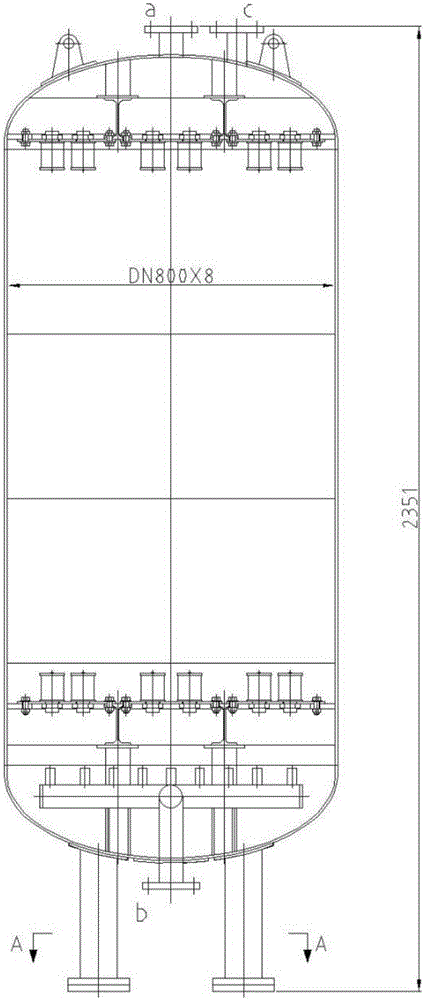

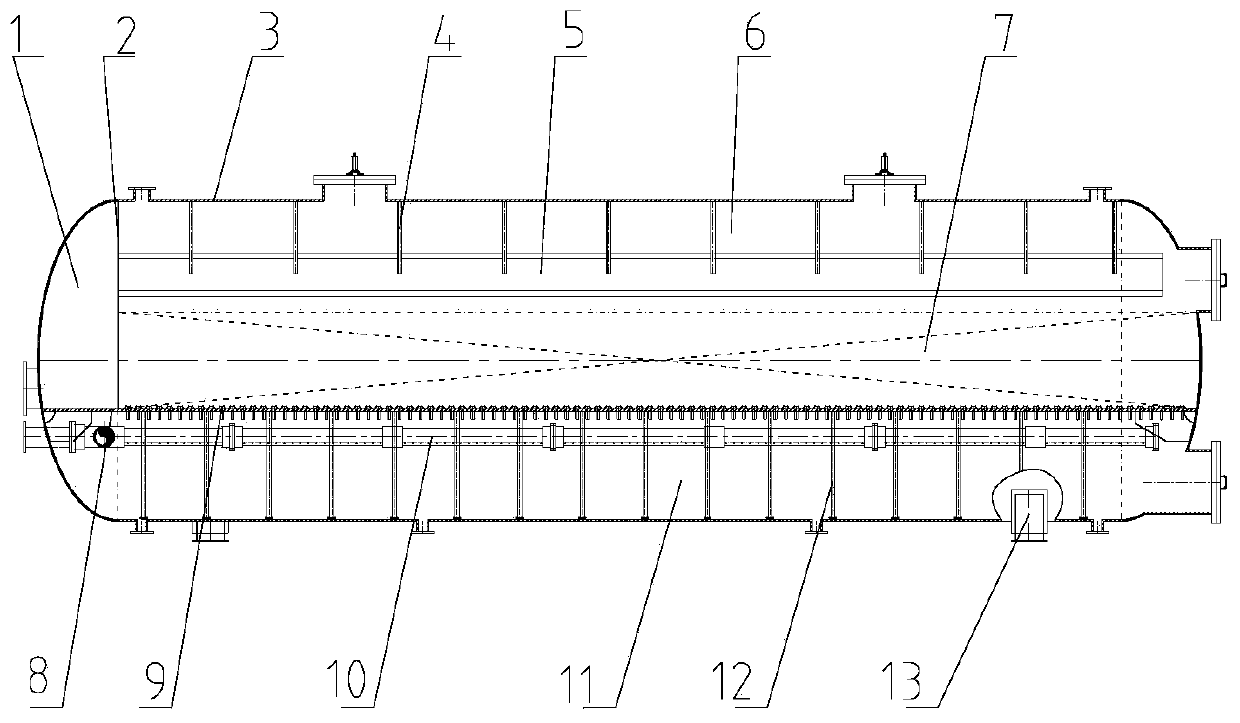

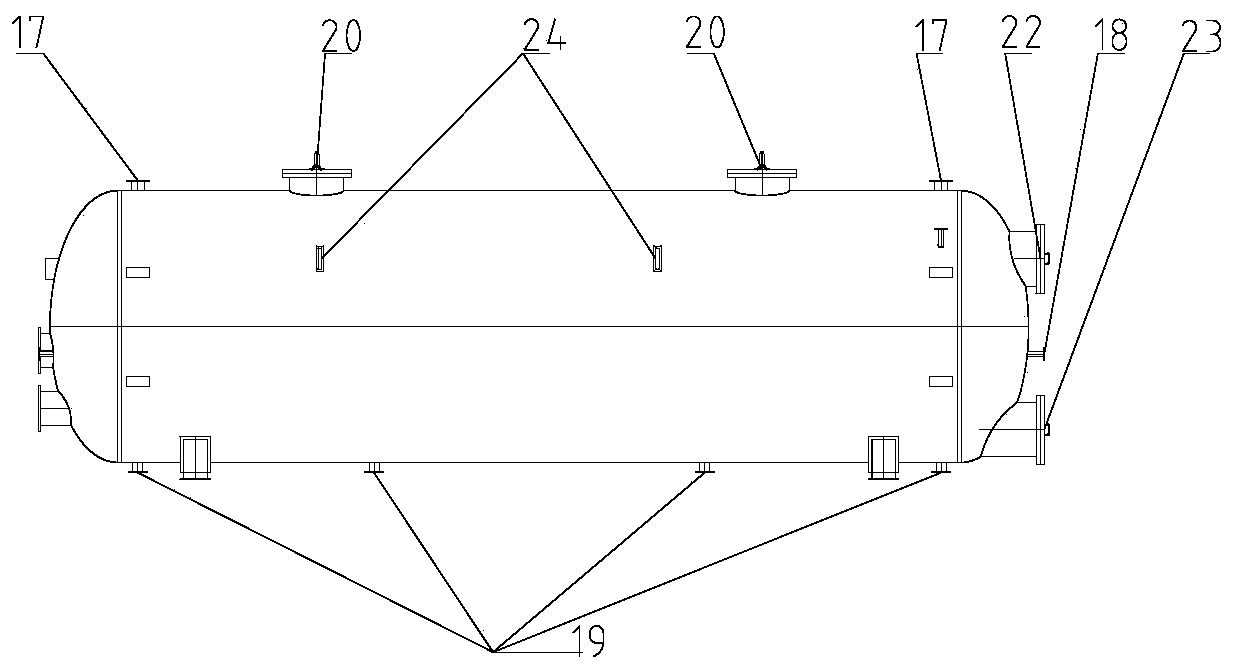

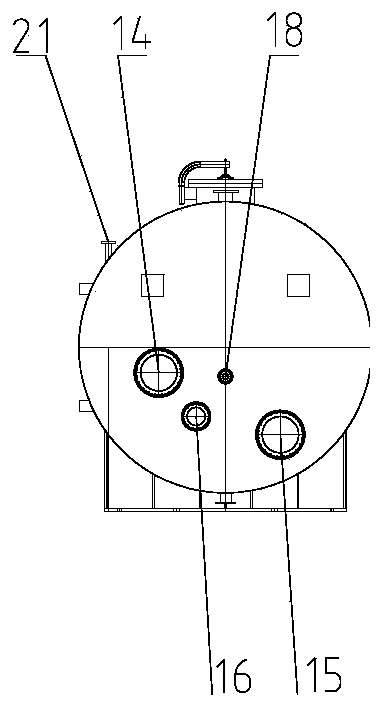

Ultra-large horizontal filter for water treatment

InactiveCN111330320AAvoid deformationScale upTreatment involving filtrationLoose filtering material filtersSewage outfallFilter material

The invention belongs to the field of mechanical devices, and particularly relates to an ultra-large horizontal filter for water treatment. The filter comprises a filter tank body, a water distribution chamber, a filter material layer, a drain outlet, a water inlet and a drain outlet, wherein an upper water inlet and outlet chamber is arranged above the filter material layer in the filter tank body, a lower water inlet and outlet chamber is arranged below the filter material layer, and the filter material layer is supported by a porous plate; and a water distribution chamber side plate is arranged between the water distribution chamber and the filter material layer. The filter has the advantage that the filtering area and the equipment output are greatly improved by 30% or above. Columns are adopted for supporting below the porous plate, and deformation of the porous plate after long-time operation is avoided. Column supporting is adopted, so that the scale of single equipment is further expanded; no dead zone exists in water distribution inside the equipment; a double-speed water cap is used for water distribution, and uniform water distribution can be guaranteed during operationand backwashing of the filter.

Owner:HANGZHOU LIGHTED FLASHLIGHT XIDOUMEN MEMBRANE

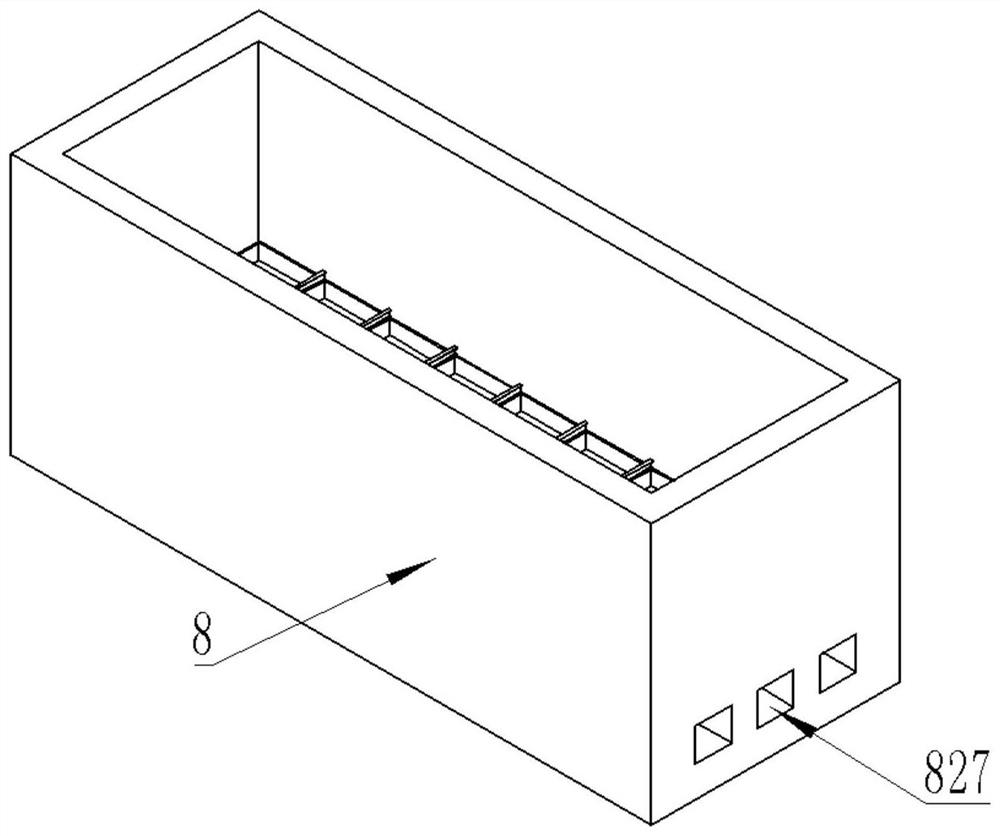

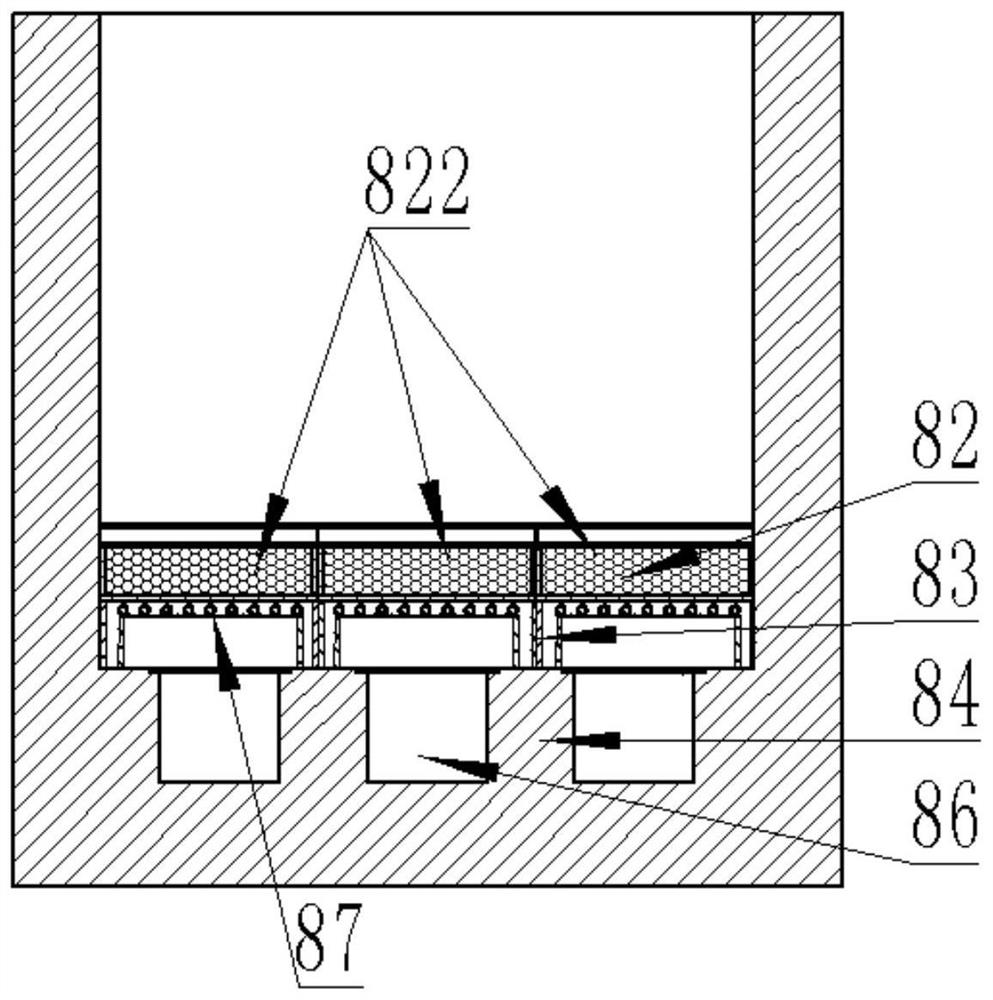

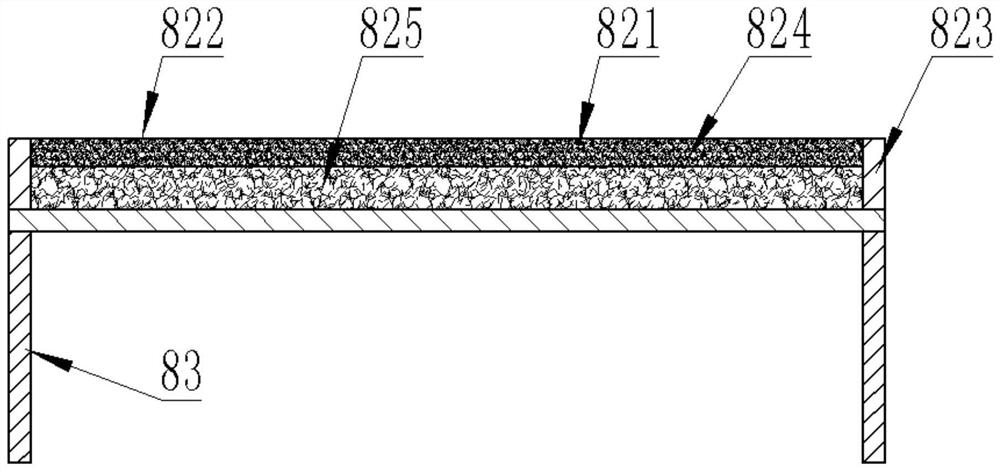

Method for preventing hardening of filter material of blast furnace water slag bottom filter system

ActiveCN114053768ASolve compactionReduce compactionLoose filtering material filtersGravity filtersSlagFilter system

The invention provides a method for preventing hardening of a filter material of a blast furnace water slag bottom filter system. The method comprises the following steps: controlling slag flushing water pressure within a set range; adopting an anti-hardening filter arrangement structure in a bottom filter tank (8); adopting precise slag grabbing equipment to carry out slag remaining and removing operation on a slag particle layer (85) in the bottom filter tank (8); and when the filtering capacity of the surface layer filter material of the filter layer (82) is greatly reduced, replacing the surface layer filter material (821) of the filter layer (82) in the bottom filter tank (8) by adopting the precise slag grabbing equipment. According to the method for preventing hardening of the filter material of the blast furnace water slag bottom filter system, the problem that the filter layer is easy to harden is thoroughly solved through the whole-process treatment from slag flushing water pressure adjustment of source treatment to final slag grabbing and cleaning.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

An upflow heterogeneous filter material filter

ActiveCN112657241BReduce backwash timesUse the filtering abilityLoose filtering material filtersSustainable biological treatmentFilter mediaProcess engineering

The invention discloses an upward flow heterogeneous filter material filter tank, which comprises a filter tank body, the bottom of the filter tank body is divided into a water distribution and gas distribution space at the bottom and an upper filter tank by a partition board, and multiple filters are installed on the partition board A long-handle filter head connects the water distribution and air distribution space with the filter tank. The bottom of the filter tank is a support layer, and the upper part of the support layer is a filter layer. Above the filter material layer is a water outlet along the length of the filter. The outlet channel on one side of the filter is connected, and the other side symmetrical to the filter tank and the outlet channel is provided with a water inlet branch channel. The bottom of the water inlet branch channel is provided with a water inlet pipe. The outlet end of the water inlet pipe is connected with the water distribution and air distribution space. The filter material layer and The supporting layer is filled with filter material, and the filter material is a heterogeneous filter material, and the particle size of the heterogeneous filter material increases sequentially from top to bottom. The filter adopts non-homogeneous filter material, and the acquisition cost of the filter material is low. After backwashing, it will naturally form an arrangement of small particles at the top and large at the bottom, which is more conducive to the improvement of the filtration efficiency of the filter.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Self-cleaning water purifier

ActiveCN106390586AReduce lossesGuaranteed contact filter effectSpecific water treatment objectivesTreatment involving filtrationWater flowBottle

A self-cleaning water purifier comprises a water purifier bottle. A water sealing baffle is arranged inside the water purifier bottle, a raw water storing cavity is arranged inside the water purifier bottle below the water sealing baffle, a raw water inlet and a flushing water outlet are arranged on the water purifier bottle, a primary filter element is mounted in the raw water storing cavity, a filtered water outlet extending out of the water sealing baffle is arranged at the top of the primary filter element, an upper water sealing device is arranged above the filtered water outlet, and a secondary filtering device is arranged between the upper water sealing device and the primary filter element. A central water baffle arranged in the middle of a modularized annular filter element is utilized to force water flow to flow around the central water baffle, and the water flow is enabled to flow along a longest passage to guarantee contact filtering effect; a compression airbag mounted in the upper water sealing device and a one-way valve arranged at a flushing hole of the primary filter element are utilized, so that back-flushing clean water is enabled to flow through a shortest passage to reduce loss, and back-flushing effect is guaranteed.

Owner:BEIJING SIJI MICOE SOLAR ENERGY TECH

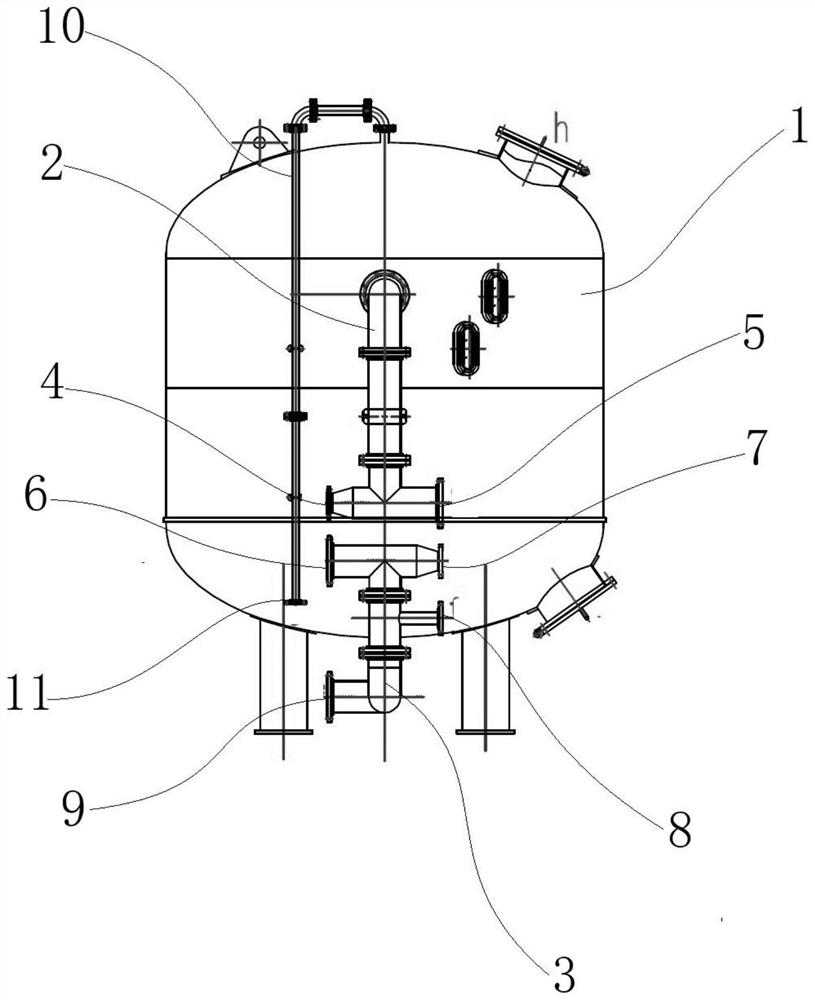

River water pretreatment device

InactiveCN105084601BImprove solubilityEasy to separateMultistage water/sewage treatmentActivated carbonImpeller

The invention discloses a river water pretreatment device. A gas sterilizing chamber, an adsorption chamber and a water collection chamber are arranged in a tank; a water distribution device is arranged in the gas sterilizing chamber, and is communicated with a water inlet, gas sprayers are arranged below the water distribution device, and are communicated with an external gas source pump by means of a gas transmission pipeline, the lower part of the gas sterilizing chamber is provided with a first flexible diaphragm, a first gas cavity is formed between the first flexible diaphragm and a bottom plate of the gas sterilizing chamber, a gas sterilizing chamber water sump is formed between the first flexible diaphragm and the sprayers, and a rotary impeller is mounted in the gas sterilizing chamber water sump; a homogeneous water pore plate is arranged in an adsorption chamber, the adsorption water sump is arranged below the homogeneous water pore plate, the adsorption chamber is filled with a plurality of lightweight porous adsorption carriers, and the lightweight porous adsorption carriers are made from activated carbon materials. The river water pretreatment device provided by the invention integrally adopts a vertical structure, is small in floor space, and suitable for transforming in an existing waterworks or building renewedly and installing, the process is simple, the operation is convenient, the energy consumption and operation cost are low, and a better river water pretreatment effect is realized.

Owner:内乡县水利局

Material stock solution refining and filtering device and cleaning process thereof

InactiveCN111701289AHEPA filterWater volume is reduced and controlledLoose filtering material filtersGravity filtersProcess engineeringExhaust pipe

The invention discloses a material stock solution refining and filtering device and a cleaning process thereof. The material stock solution refining and filtering device comprises a filtering tank body internally provided with a filtering layer, and a cleaning assembly and a ventilation assembly for cleaning the filtering layer are arranged on the filtering tank body; the cleaning assembly comprises an upper pipe body and a lower pipe body which are arranged at intervals from top to bottom; the ventilation assembly comprises an air inlet formed in the lower pipe body and an exhaust pipe arranged at the top end of the filtering tank body; the material stock solution refining and filtering device can efficiently filter the stock solution, and the yield and efficiency of stock solution refining and filtering are improved. The cleaning assembly and the ventilation assembly are used for sequentially carrying out multiple cleaning steps such as liquid-gas mixing backwashing, backwashing emptying and forward washing short washing on a filtering layer in the filtering tank body, so that the influence of backwashing water on the raw material filtering inlet water concentration is greatly reduced, and meanwhile, the characteristics of simplicity, reliability, high backwashing efficiency and the like of the device are also considered.

Owner:率氢技术(北京)股份有限公司

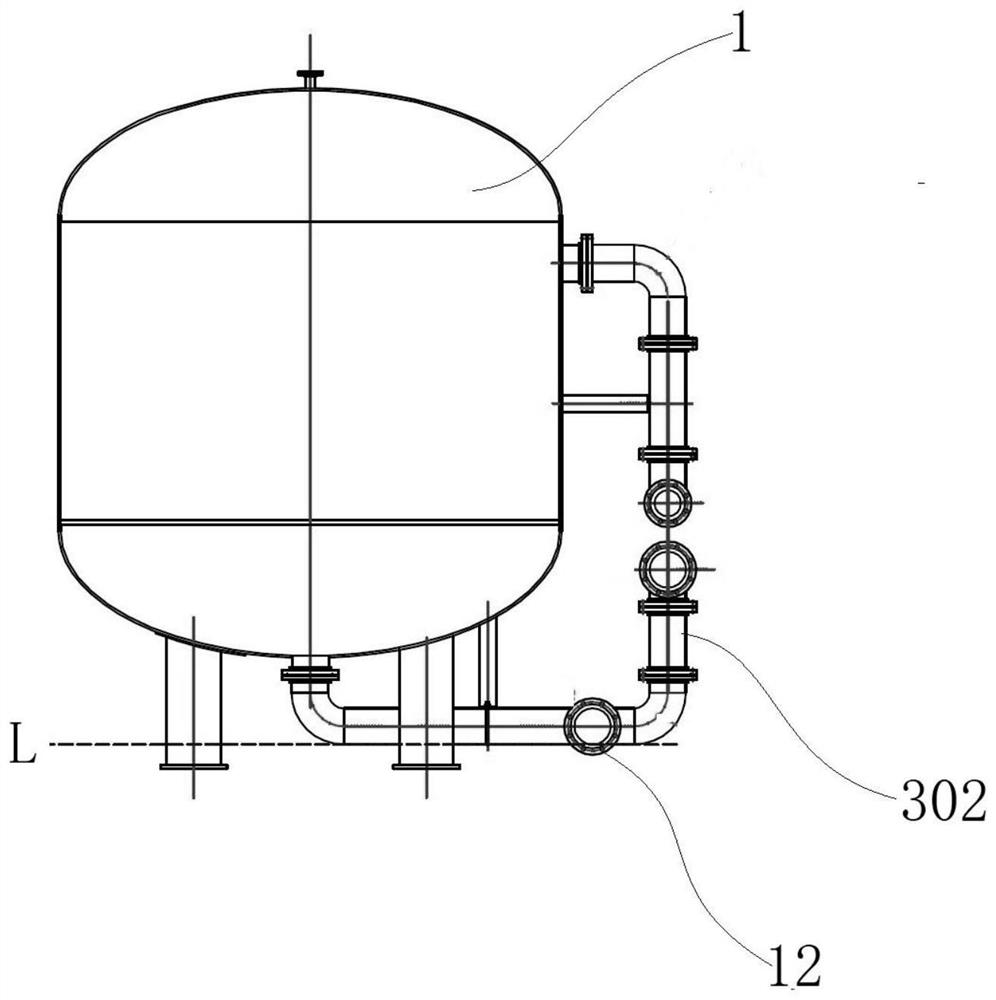

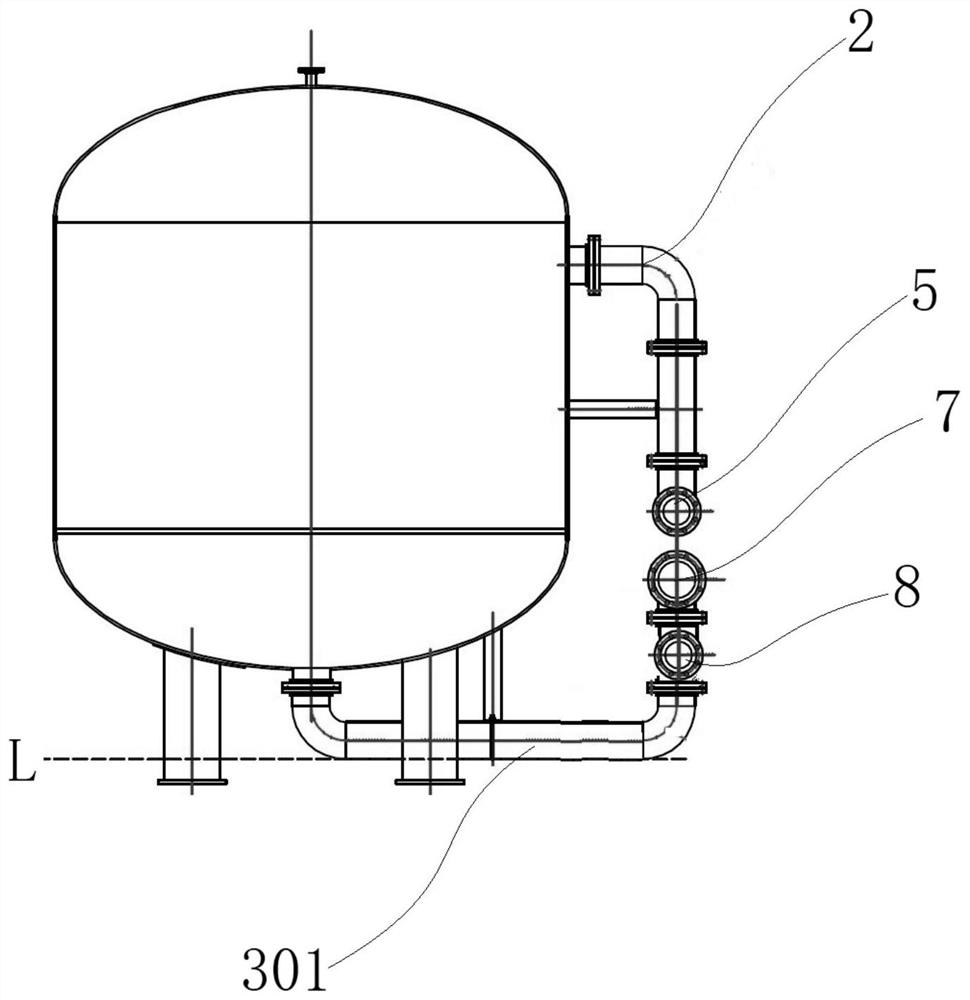

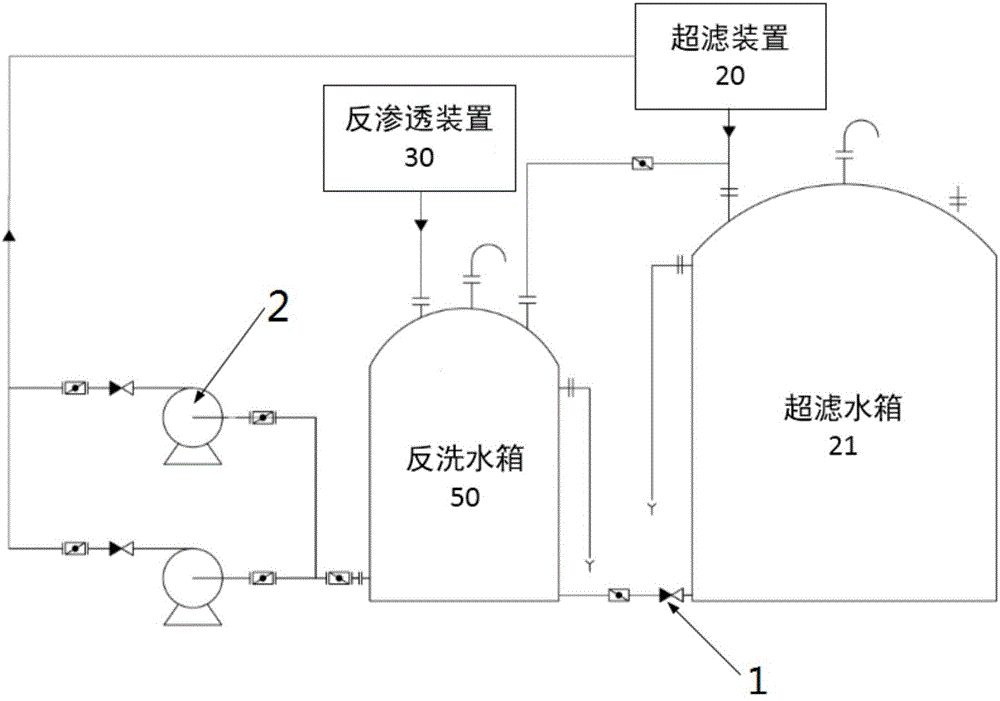

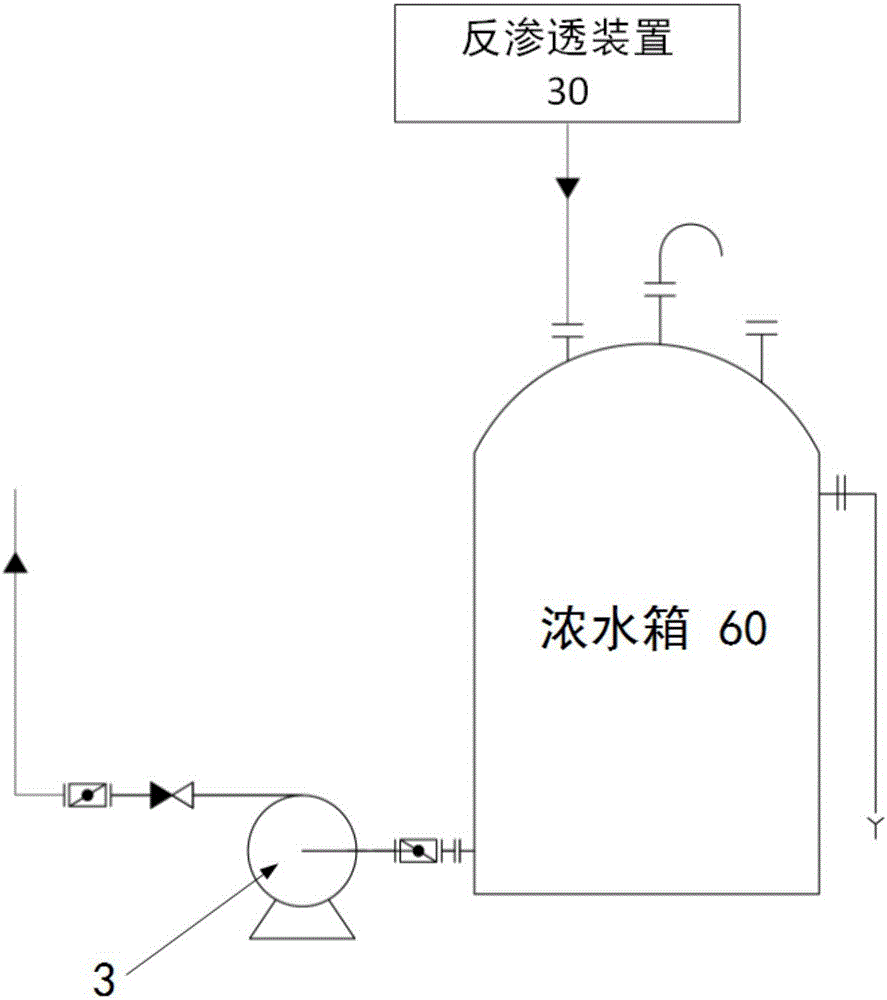

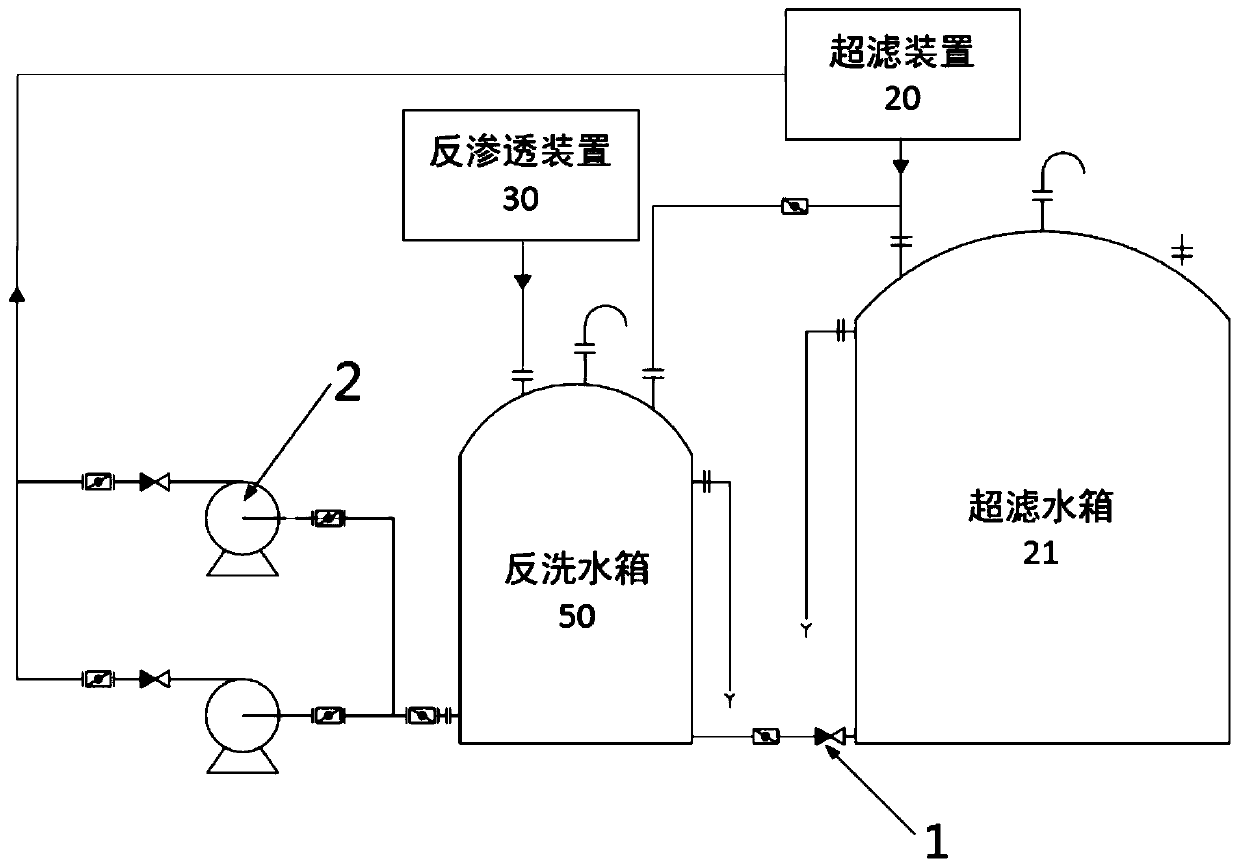

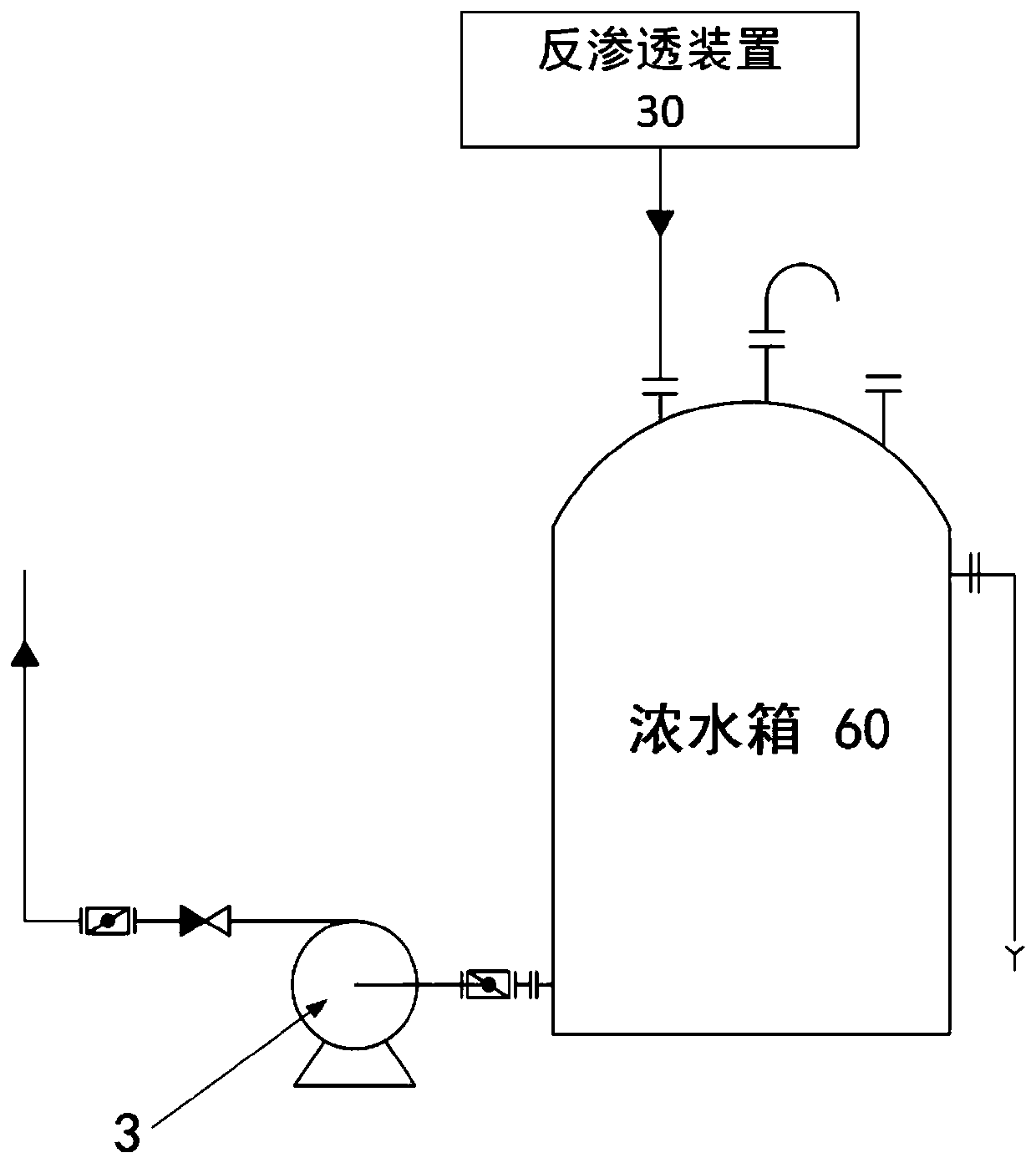

Method and system for recycling reverse osmosis concentrated water

ActiveCN106495275AAchieve recyclingAvoid wastingWater/sewage treatment bu osmosis/dialysisUltrafiltrationSoftened water

The invention discloses a method and a system for recycling reverse osmosis concentrated water. Tap water is filtered by an ultrafiltration device (20) to obtain ultra-filtered water, the ultra-filtered water is subjected to a softening process to obtain softened water, and the softened water is treated by a reverse osmosis device (30) to obtain osmotic water and reverse osmosis concentrated water. The method comprises the steps of mixing the reverse osmosis concentrated water and the ultra-filtered water to obtain back washing water and performing back washing on the ultrafiltration device (20) with the back washing water. By adoption of the technical scheme, the reverse osmosis concentrated water and the ultra-filtered water are mixed for back washing of the ultrafiltration device, so that on the premise of guaranteeing the back washing effect on the ultrafiltration device, the reverse osmosis concentrated water is recycled and waste of water resources is avoided.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

Reverse osmosis concentrated water recycling method and system

ActiveCN106495275BAchieve recyclingAvoid wastingWater/sewage treatment bu osmosis/dialysisUltrafiltrationSoftened water

The invention discloses a method and a system for recycling reverse osmosis concentrated water. Tap water is filtered by an ultrafiltration device (20) to obtain ultra-filtered water, the ultra-filtered water is subjected to a softening process to obtain softened water, and the softened water is treated by a reverse osmosis device (30) to obtain osmotic water and reverse osmosis concentrated water. The method comprises the steps of mixing the reverse osmosis concentrated water and the ultra-filtered water to obtain back washing water and performing back washing on the ultrafiltration device (20) with the back washing water. By adoption of the technical scheme, the reverse osmosis concentrated water and the ultra-filtered water are mixed for back washing of the ultrafiltration device, so that on the premise of guaranteeing the back washing effect on the ultrafiltration device, the reverse osmosis concentrated water is recycled and waste of water resources is avoided.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

Aerating biological filter

InactiveCN100412003CSimple structureReduce manufacturing costTreatment using aerobic processesSustainable biological treatmentBiological filterWater treatment

The invention discloses an aerating biological filter pool in the water disposal device domain, which comprises the following parts: filter pool within aerating device and filtering device, water inlet pipe on the bottom of filter pool, backwash drainage pipe on the bottom of filter pool, pulse air-chamber to interconnect bottom of filter pool through backwash inlet pipe and vent pipe, wherein the vent pipe lies in one end of water sealing pipe in the pulse air-chamber; the other end of vent pipe connects gas-water separator, whose top possesses connection pipe with bottom interconnecting the bottom of pulse air-chamber through connection pipe.

Owner:SHANDONG JIANZHU UNIV

A filter tank

ActiveCN100431657CAvoid cloggingSuitable for useLoose filtering material filtersGravity filtersWater flowDitch

The invention discloses a filter tank, comprising filter chamber (1), water inlet tank (2) above said chamber and backwash water distributing device on side; said filter chamber includes up and down filtering material fending device (3), filtering layer (4), filtering material carrying device (5) and air-water chamber (6); the upper layer of said backwash water distributing device is backwash discharge tank (7) near to filtering material fending device, and lower layer is air-water water distributing ditch (8) connected to air-water chamber; said filtering material fending device is inclined installed above said filtering layer and extends to edge of backwash discharge tank. The backwash water flows into backwash discharge tank after overflowing from filtering materialfending device, and will not retent on filtering material fending device, which avoids impurity substance settling and clogging on filtering material fending device.

Owner:ZHEJIANG DEAN TECH

Novel combined defluorinating device for underground water

ActiveCN103951109BCompact structureSmall footprintMultistage water/sewage treatmentWater qualitySmall footprint

The invention provides a novel combined defluorinating device for underground water. The device comprises a water inlet unit, a defluorinating reaction unit, a pipe chute or cantboard separating area, an initial filter unit, a terminal filter unit, a backwashing device and an electromagnetic exhausting valve which are sequentially arranged from bottom to top, wherein the terminal filter unit comprises a central water inlet pipe as well as a stainless steel filter screen and a closed quartz sand filter layer sequentially arranged from bottom to top, the central water inlet pipe is arranged on the top of the initial filter unit at the bottom and penetrates through the middle parts of the stainless steel filter screen and the quartz sand filter layer, and the lower part of the central water inlet pipe between the stainless steel filter screen and the quartz sand filter layer is stainless steel filter cloth with the aperture of 0-0 mu m; a water collecting area is arranged at the bottom of the quartz sand filter layer, and water outlet pipes which are communicated with each other are arranged on the top of the stainless steel screen and the side wall of the water collecting area. The novel defluorinating device provided by the invention has the advantages of compact structure, small occupied area, low treatment cost, high effluent quality and the like, is convenient to change and flexible to use, and has a good popularization and application prospect.

Owner:HOHAI UNIV

Linkage processing method and apparatus of circulatory flow multiplex biochemistry and filtrating

ActiveCN101357814BAchieving processing powerGuaranteed filtering effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeFiltration

The invention provides a loop multi-biochemical and filtration linked treatment method and a device, a cavity body of a reactor is divided into a reaction zone and a sedimentation zone, wherein, the reaction zone is sequentially divided into an aerobic zone, an anoxic zone and an anaerobic zone from top to bottom, an aerator is arranged in the aerobic zone, a water inlet is arranged at the bottompart of the anaerobic zone, liquid in the reactor generates the loop current through the density difference which is formed by aeration in the aerobic zone; at the same time, a filtration zone is arranged in or out of the reactor, communicated with the sedimentation zone by an overflow pipe and positioned below the sedimentation zone; the filtration process and the backwashing process of the filtration zone can be controlled according to the change of water level of the sedimentation zone through a liquid level travel switch and a controller which are arranged at the upper end of the sedimentation zone. The treatment method and the device fully utilize vertical spatial structure and can realize the loop multi-circulating biochemical linked treatment for removing nitrogen, removing phosphorus and degrading organic matters of sewage; furthermore, the treatment method and the device are characterized by automatic backwashing, power-free sludge reflux, less investment, small and compact device, small occupying area and convenient operation and management.

Owner:SHENZHEN QINGYAN ENVIRONMENTAL TECH CO LTD

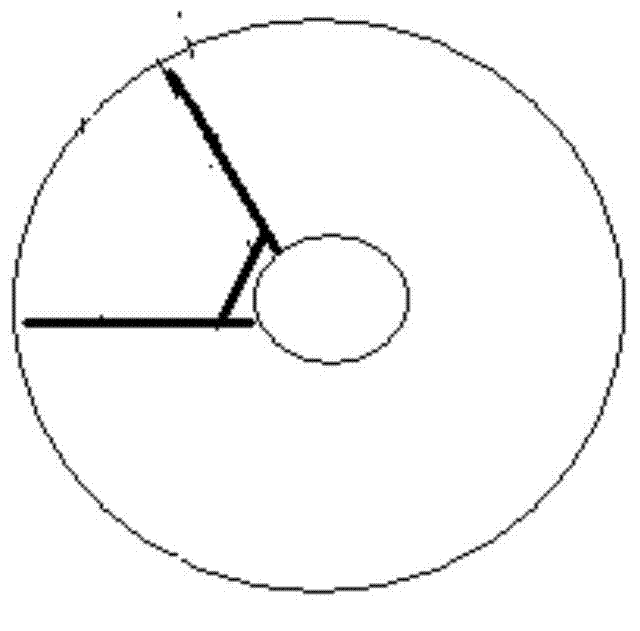

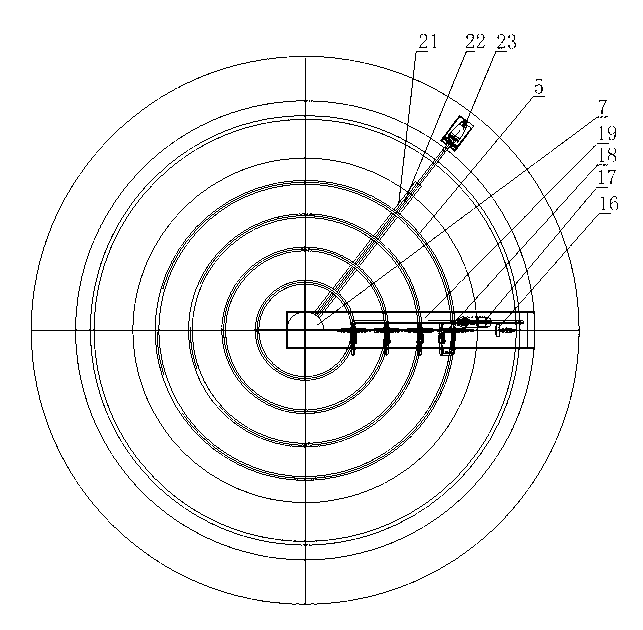

Novel cloth filtering tank

The invention discloses a novel cloth filter which consists of three parts including a tank body, a filtering ring and a backflush device; the tank bottom of the round tank body is of a baffle layer structure; the baffle plate divides the tank body into an upper sewage cavity and a bottom clean water cavity; a plurality of water discharge holes which run through the thickness of a baffle plate are uniformly distributed on the baffle plate in a radially diffusing manner; a plurality of concentric annular filtering rings at equal intervals are arranged on the outer periphery of a central support pier, and the water discharge holes in the baffle plate are communicated with inner cavities of the filtering rings on the upper part; and a suction disc is fixedly elastically arranged on a fixed frame below an operating bridge of the backflush device, and a mud scrapping plate is fixedly arranged on the bottom of the backflush device. According to the novel cloth filter, a concentric filtering ring structure is adopted, and can be adaptive to the upgrading and modification of the round tank body, and meanwhile, the filtering rings at the periphery also have the maximal filtering surface areas, so that great water through amount can be realized. According to the novel cloth filter, raw water automatically flows into the clean water cavity at the bottom from the upper sewage cavity after passing through a filtering layer by utilizing the effect of gravity, and does not need additional power, and therefore, the operation energy consumption and the cost are lowered greatly.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com