Material stock solution refining and filtering device and cleaning process thereof

A filter device and raw liquid technology, which is applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the following problems such as the influence of raw material liquid purity, increased filter cost, waste of raw material liquid, etc., to achieve backwash residue Controllable water volume, reduced backwash residual water, and improved output and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

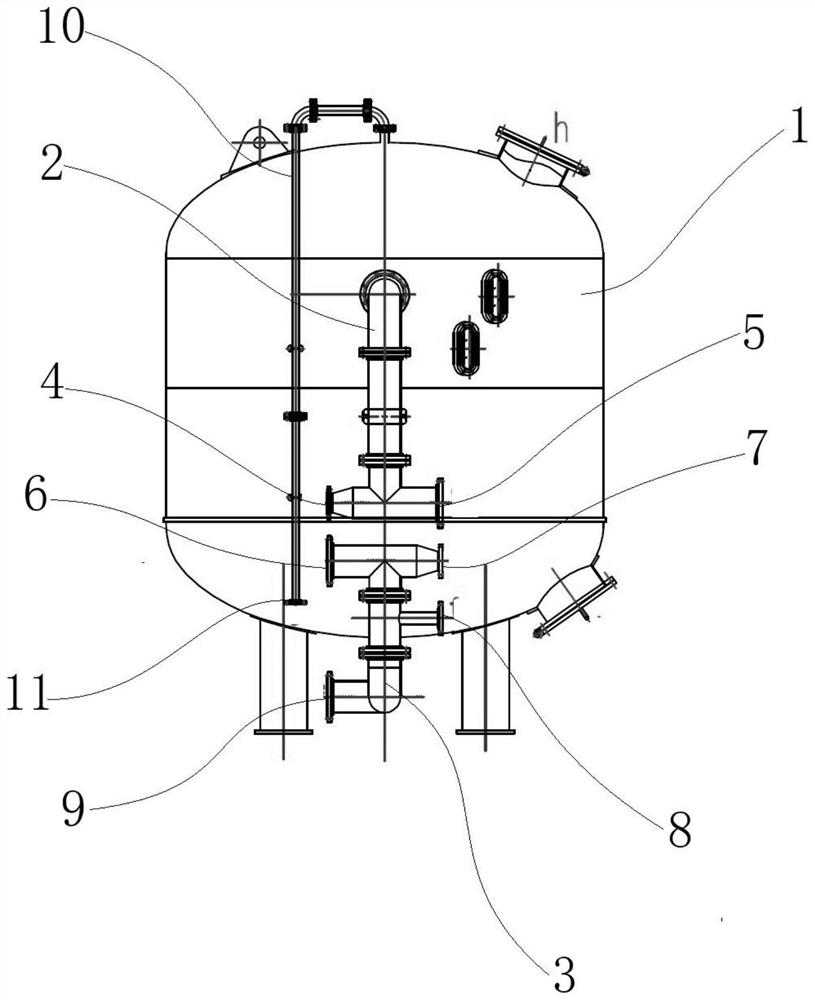

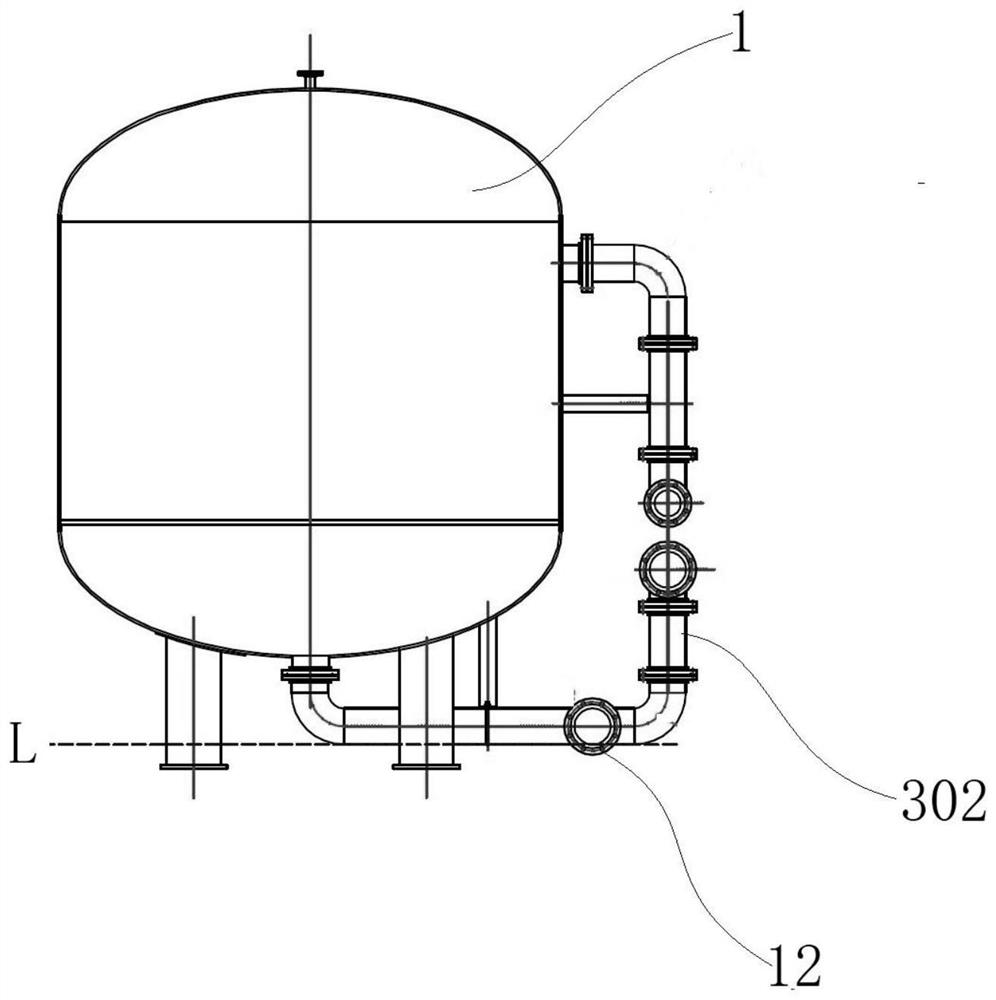

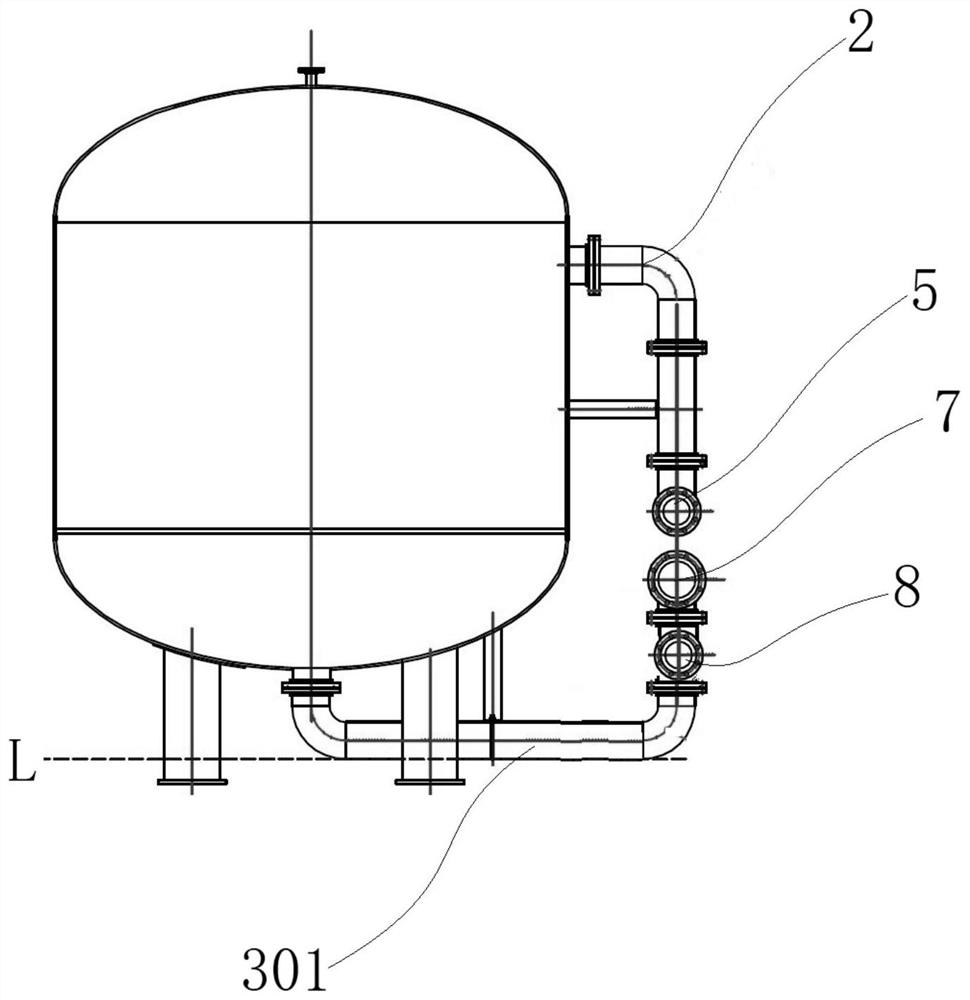

[0036] Such as figure 1 , figure 2 with image 3 As shown, in Embodiment 1, a material raw liquid refining and filtering device provided by the present invention includes a filter tank body 1 with a filter layer inside, and the filter tank body 1 is also provided with a cleaning assembly and a ventilator for cleaning the filter layer. Components: The raw material liquid refining filter device can efficiently filter the raw liquid, and at the same time, the cleaning component and the ventilation component arranged on the filter tank body 1 can clean the filter layer in the filter tank body 1, and can prevent the cleaning liquid from remaining in the filter tank body 1 after cleaning , to achieve the purpose of improving the output and efficiency of the raw liquid refining and filtering.

[0037] Such as figure 1 , figure 2 with image 3 As shown, the cleaning assembly includes an upper pipe body 2 and a lower pipe body 3 arranged at intervals from top to bottom. The uppe...

Embodiment 2

[0045] The purpose of this embodiment is to propose a cleaning process for a raw material liquid refining filter device, which can significantly improve the cleaning effect of the filter tank body 1, which specifically includes the following steps:

[0046] Step 1, liquid-gas mixed backwash: only open the backwash drain valve, backwash water inlet valve, intake valve and exhaust valve; After flowing through the filter layer in the filter tank body 1 from bottom to top, it is discharged through the backwash outlet 5 of the upper body pipeline; at the same time, the gas used for backwashing is input into the filter tank body 1 from the air inlet 8 and discharged from the exhaust port. 11 out. In step 1, the liquid-gas mixed backwashing uses gas and liquid to flush the filter tank body 1 at the same time to ensure the backwashing effect and greatly reduce the impact of backwashing water on the concentration of the raw material filtered water.

[0047] Step 2, backwash emptying: ...

Embodiment 3

[0051] In some embodiments, the cleaning of the filter layer in the filter tank body 1 does not require the introduction of gas, and the cleaning specifically includes the following steps;

[0052] Step 1. Liquid backwashing: only open the backwash drain valve and the backwash water inlet valve; the backwash water enters the filter tank body 1 through the backwash inlet 6 through the lower body pipeline, and flows through the filter tank body 1 from bottom to top. After the filter layer, it is discharged through the backwash outlet 5 of the upper body pipeline; in step 1, the filter layer is backwashed with tap water and other liquids to reduce the impact of backwash water on the concentration of raw material filtration influent.

[0053] Step 2, backwash emptying: after closing the backwash drain valve and the backwash water inlet valve, only open the forward wash drain valve, so that the forward wash drain 9 remains open, and the residual backwash water in the filter tank bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com