Ultra-large horizontal filter for water treatment

A super-large water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve the problems of membrane system operation risk, poor filtration and backwashing effect, broken siphon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

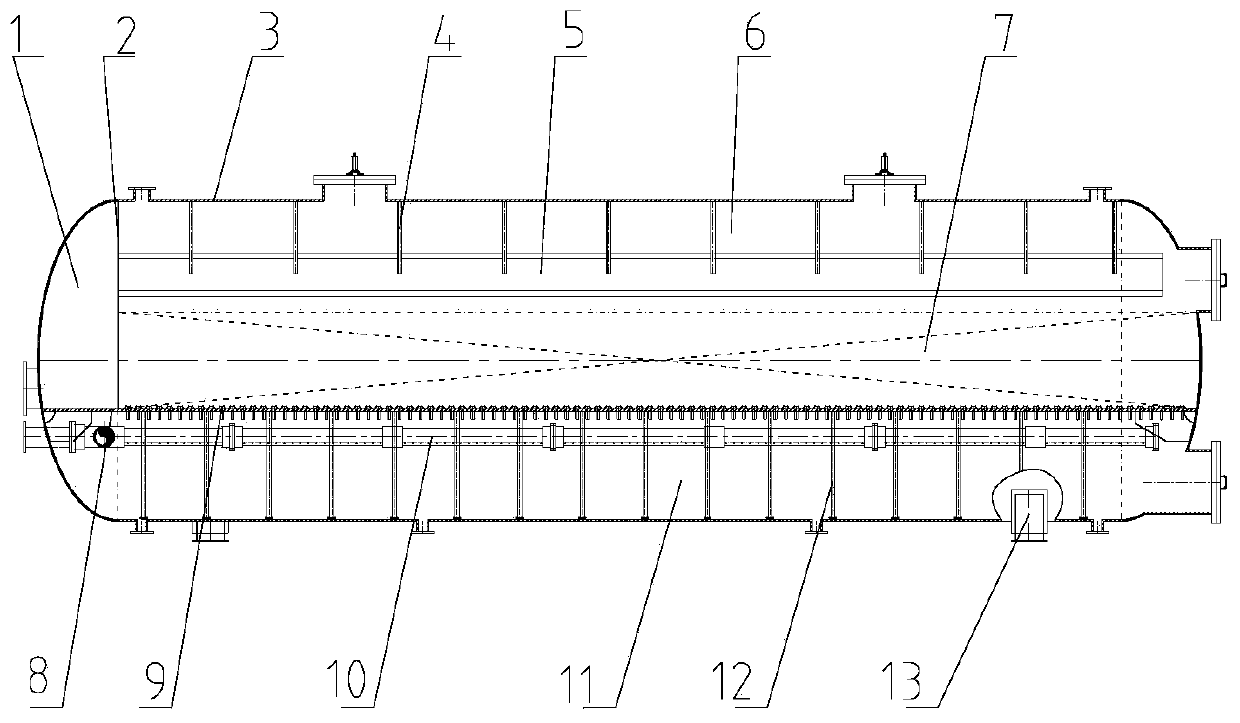

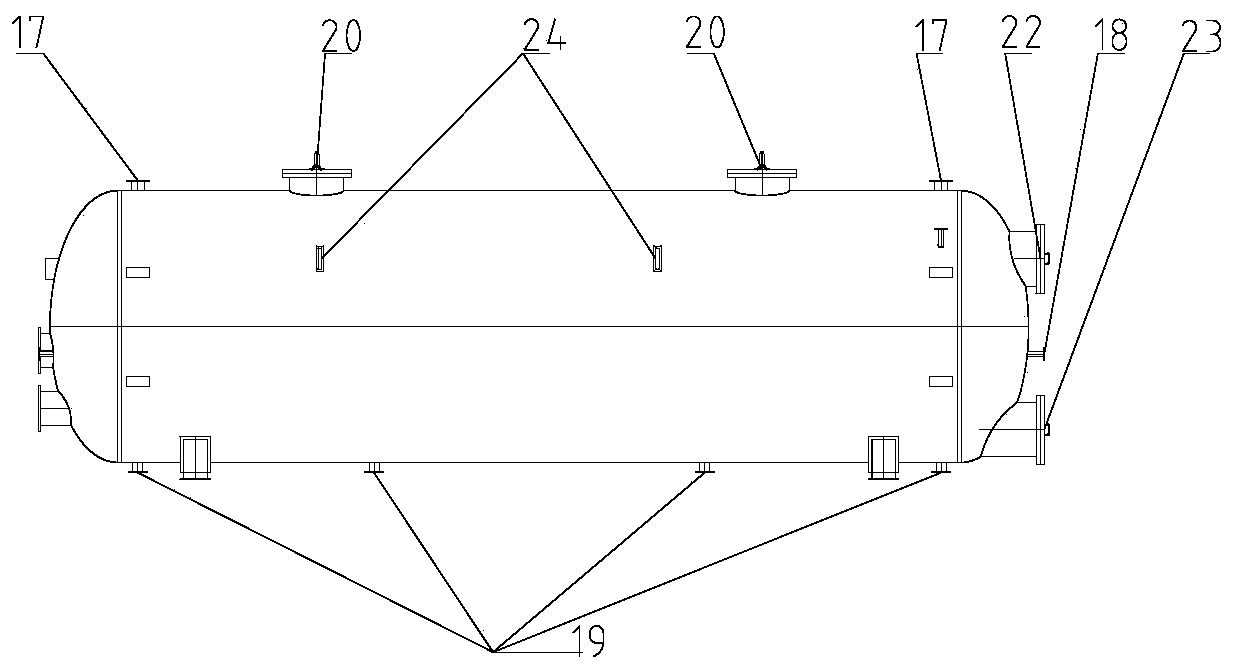

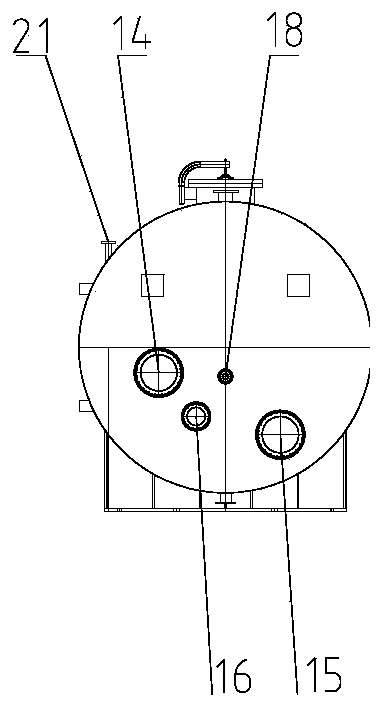

[0091] According to attached figure 1 , attached figure 2 , attached image 3 The structure shown is to manufacture a super large horizontal filter for water treatment, which includes a filter tank body 3, a water distribution chamber 1, a filter material layer 7, a sewage outlet, a water inlet, and a drain outlet, wherein the filter material layer in the filter tank body 3 There is an upper inlet and outlet water chamber 6 on the top of the 7, and a lower inlet and outlet water chamber 11 below, and the filter material layer 7 is supported by the porous plate 8; there is a water distribution chamber side plate 2 between the water distribution chamber 1 and the filter material layer 7.

[0092] This embodiment can fully realize the design purpose from the function, and the operation process is relatively simple. The water to be treated is injected into the water distribution chamber 1 through the water inlet, and then flows into the filter material layer 7 through the upper...

Embodiment 2

[0094] In order to achieve better results, on the basis of Example 1, improve the corresponding technical features, a super large horizontal filter for water treatment, which includes a filter tank 3, a water distribution chamber 1, a filter material layer 7, a sewage outlet, Water inlet and outlet, wherein the filter material layer 7 in the filter tank body 3 has an upper inlet and outlet water chamber 6 and a lower inlet and outlet water chamber 11 below, and the filter material layer 7 is supported by a porous plate 8; the water distribution chamber 1 and the filter There are water distribution chamber side plates 2 between the material layers 7 . There are several water distribution tank hangers 4 in the upper water inlet and outlet chamber 6, and a number of porous plate support columns 12 in the lower water inlet and outlet water chamber 11 to support the porous plate 8; a water distribution tank 5 is arranged between the upper water inlet and outlet chamber 6 and the fil...

Embodiment 3

[0097] A super-large horizontal filter for water treatment, which includes a filter tank body 3, a water distribution chamber 1, a filter material layer 7, a sewage outlet, a water inlet, and a drain outlet, wherein the filter material layer 7 in the filter tank body 3 has an upper There is a lower water inlet and outlet chamber 11 below the water inlet and outlet chamber 6, and the filter material layer 7 is supported by a porous plate 8; there is a water distribution chamber side plate 2 between the water distribution chamber 1 and the filter material layer 7. There are several water distribution tank hangers 4 in the upper water inlet and outlet chamber 6, and a number of porous plate support columns 12 in the lower water inlet and outlet water chamber 11 to support the porous plate 8; a water distribution tank 5 is arranged between the upper water inlet and outlet chamber 6 and the filter material layer 7 . A number of water caps 9 are distributed on the perforated plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com