Filter device with capabilities of switching operation and automatic backwashing and control method

An automatic backwashing and filtering device technology, which is applied to chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of unsatisfactory backwashing effect, damage, system shutdown, etc., and achieve good promotion and use value and stable operation Reliable, low operating cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

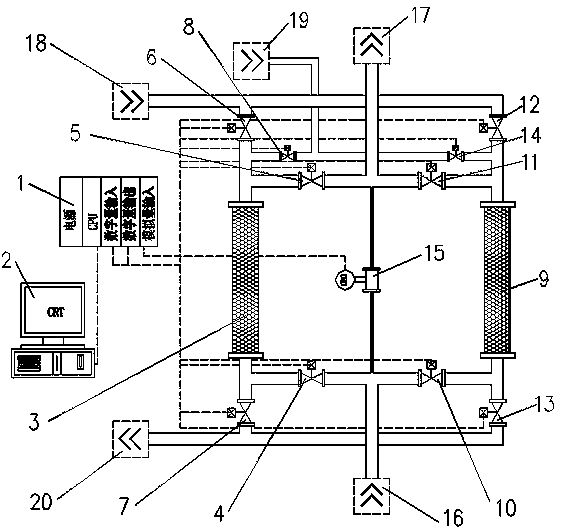

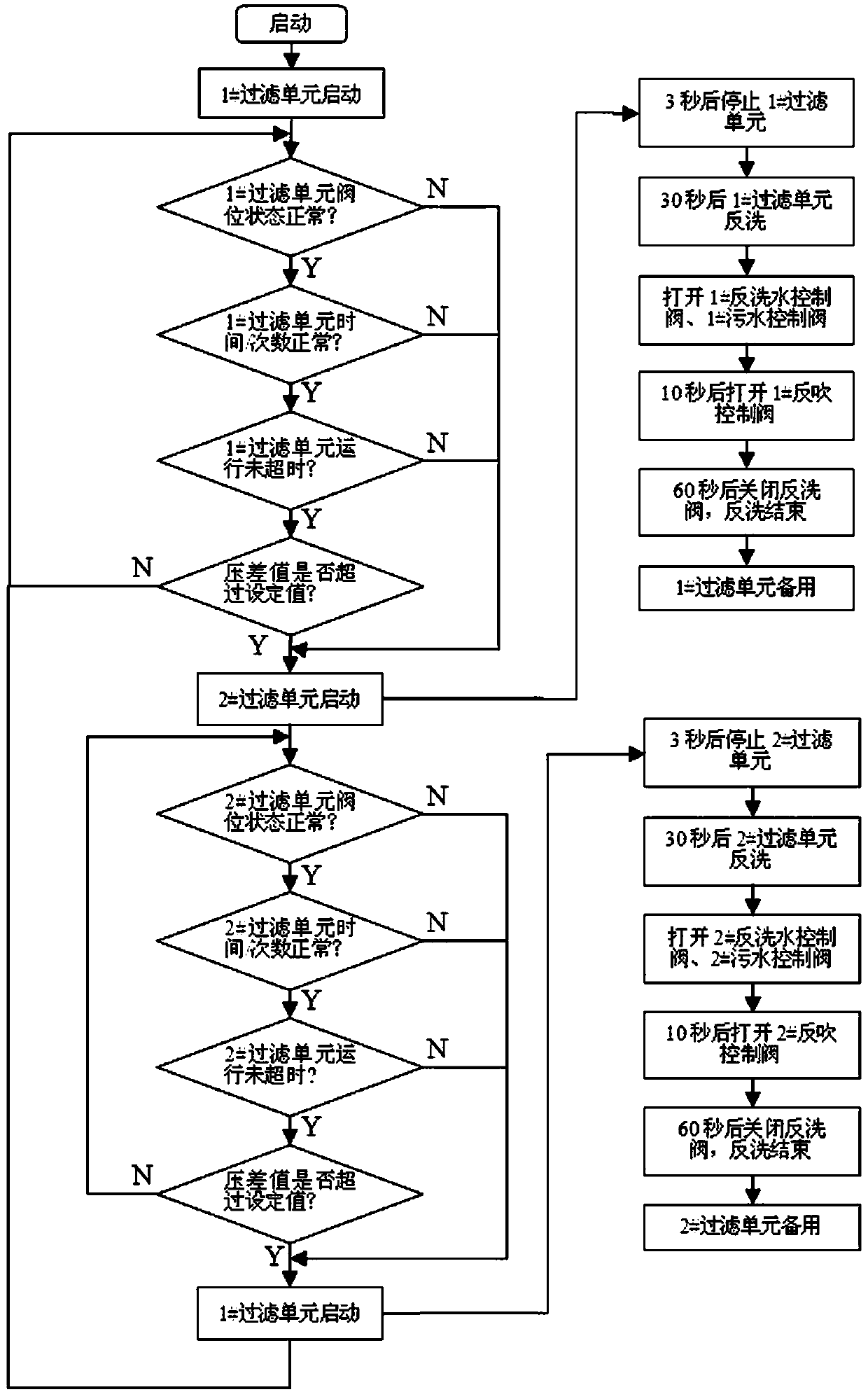

[0029] The filter device with switchable operation and automatic backwashing provided in this embodiment adopts two filter units with the same structure arranged in parallel, and the differential pressure transmitter monitors the pressure values of the filter inlet and outlet of the filter unit, and can be programmed The program controller switches the operation of the two filter units through the pressure value monitored by the differential pressure transmitter or the set running time to ensure the continuity of the filter operation. The filter unit that stops running is controlled by the programmable controller. Backwashing to ensure the effect of backwashing.

[0030] figure 1 Display, 1# filter unit is composed of 1# filter 3, 1# inlet control valve 4, 1# outlet control valve 5, 1# backwash water control valve 6, 1# sewage control valve 7, 1# b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com