Upward-flow heterogeneous filter material filter tank

A non-homogeneous filter technology, applied to loose filter material filters, filter separation, gravity filters, etc., can solve the problems of affecting the filtering effect, backwashing, time-consuming and water-consuming, etc., and reduce the difficulty of control and requirements, reduce the number of backwashing, and reduce the effect of purchasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

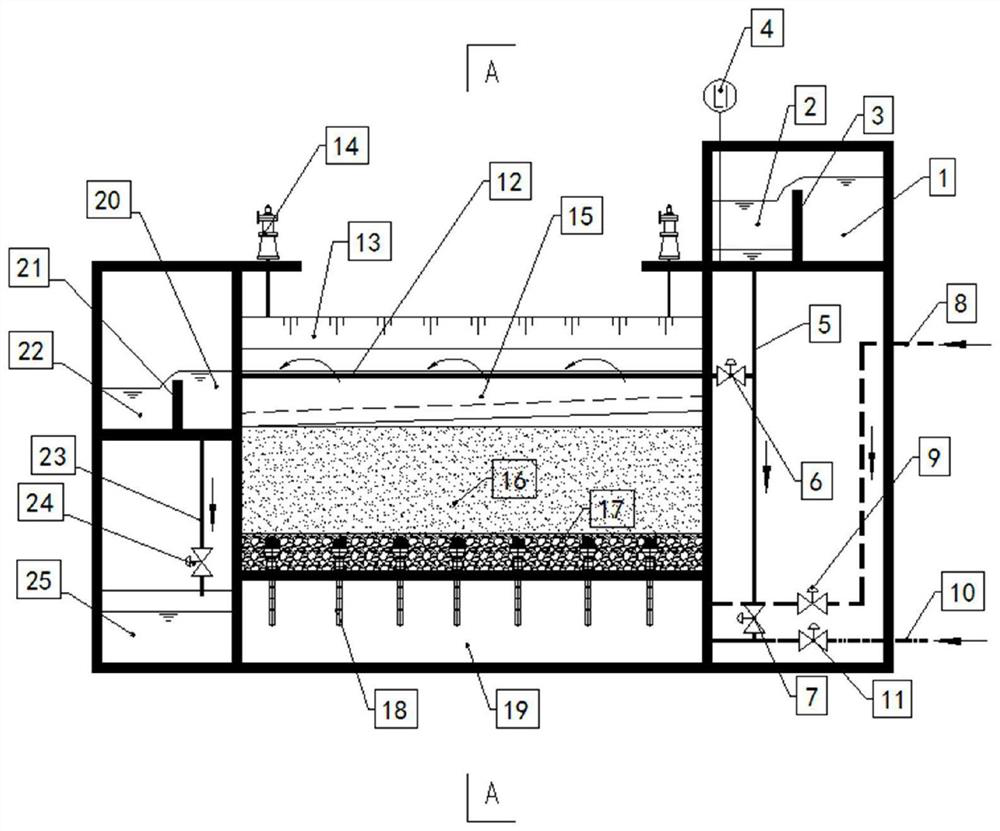

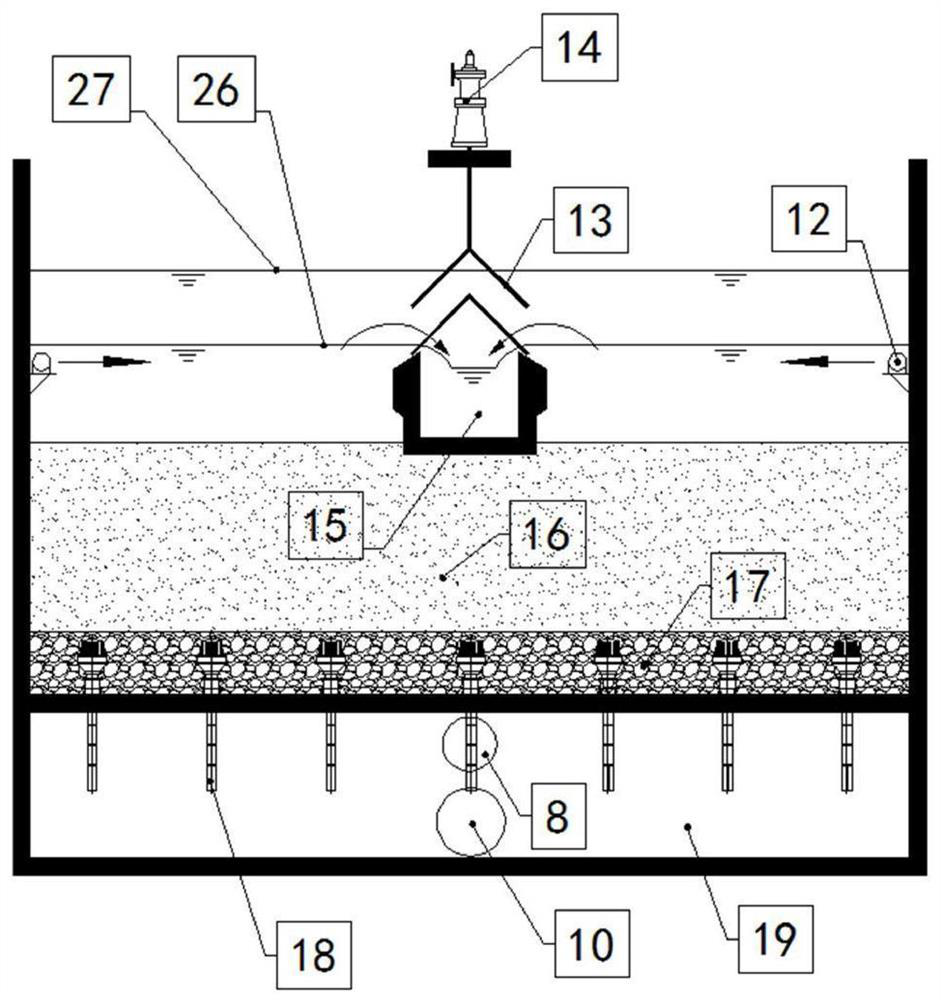

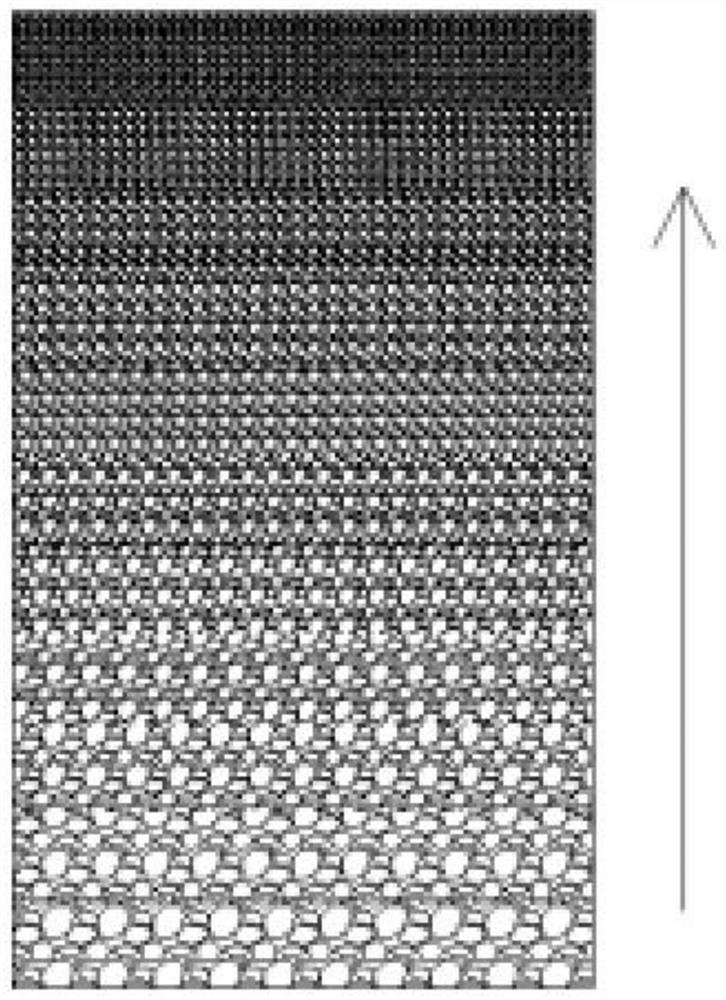

[0032] Embodiments of the present invention: a kind of upward flow heterogeneous filter material filter tank, as attached Figure 1-4 As shown, a filter body is included, and the bottom of the filter body is divided into a water distribution and gas distribution space 19 at the bottom and an upper filter tank by a partition, and a plurality of long handle filter heads 18 are evenly installed on the partition to divide the water distribution and gas distribution space 19 Connected with the filter tank, the bottom of the filter tank is a supporting layer 17, the upper part of the supporting layer 17 is a filter material layer 16, and the upper part of the filter material layer 16 is provided with a water outlet tank 15 along the length of the filter tank, and the tail of the water outlet tank 15 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com