Backwashing method of simulated moving bed device for adsorbing and separating xylene

A technology for simulating moving bed and adsorption separation, applied in separation methods, adsorption purification/separation, solid adsorbent liquid separation, etc. effect, the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

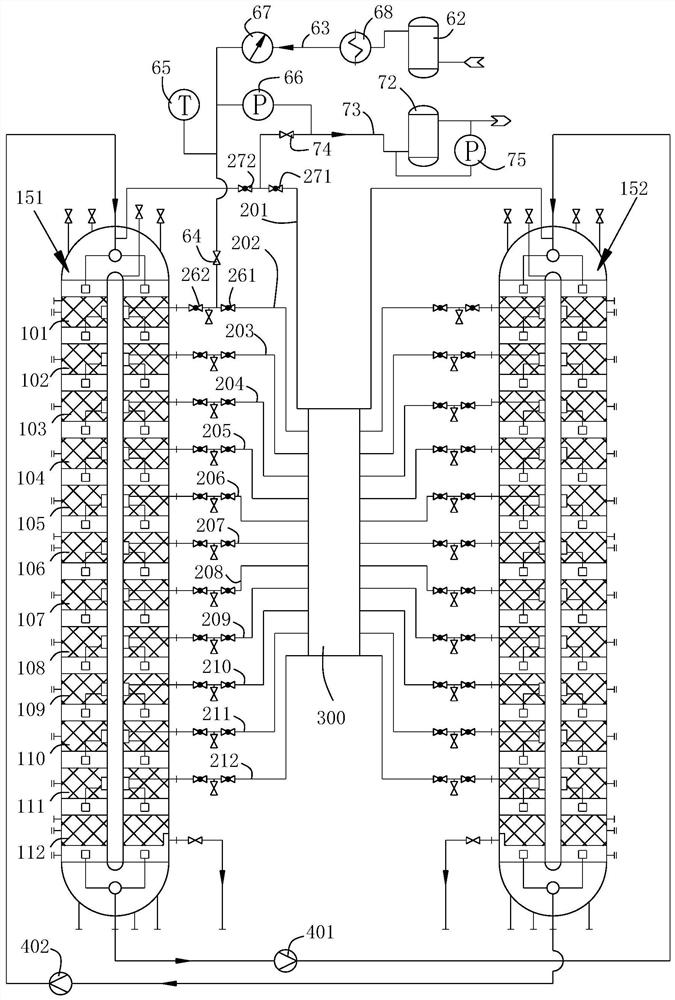

[0026] Firstly, the structure of the simulated moving bed device will be described below, please refer to figure 1 , which includes a first adsorption tower 151 , a second adsorption tower 152 , a first circulation pump 401 , a second circulation pump 402 and a rotary valve 300 . The inlet of the first circulation pump 401 is connected with the tower bottom of the first adsorption tower 152, and the outlet of the first circulation pump 401 is connected with the tower top of the second adsorption tower 152, and the tower bottom of the second adsorption tower 152 of the inlet of the second circulation pump 402, The outlet of the second circulating pump 402 communicates with the top of the first adsorption tower 151 . Driven by the first circulation pump and the second circulation pump, the raw material liquid can flow along the material paths of the first adsorption tower, the first circulation pump, the second adsorption tower and the second circulation pump. In the first adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com