Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guarantee the effect of subsequent use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

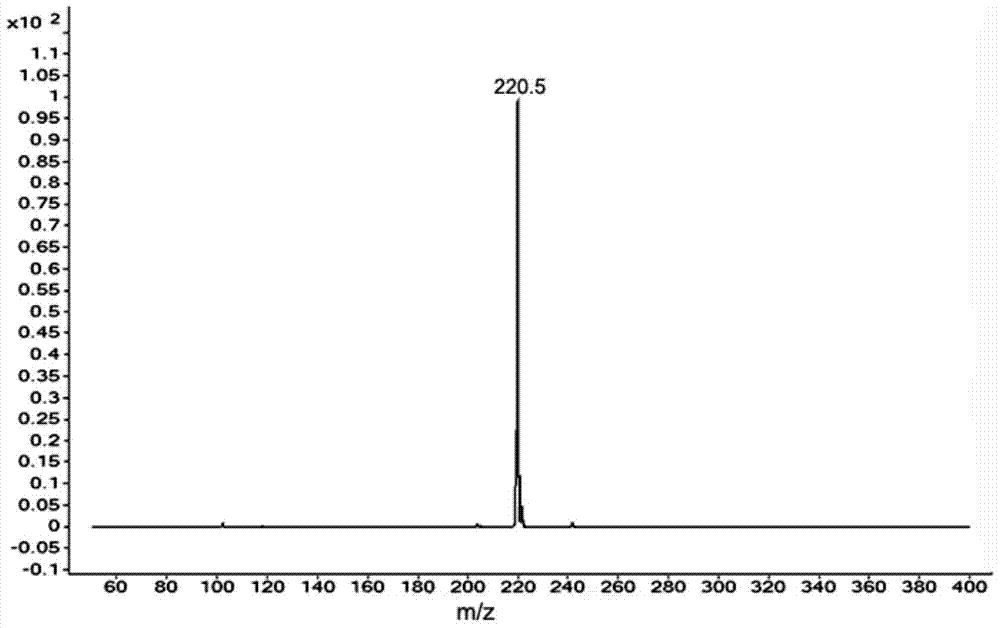

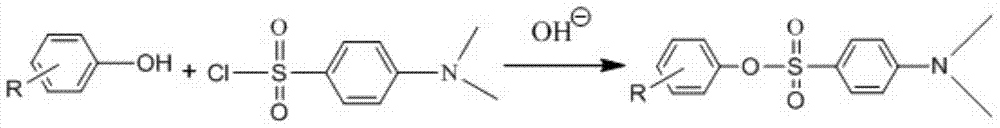

Pretreatment and detection method for biogen amine neurotransmitter and detection kit

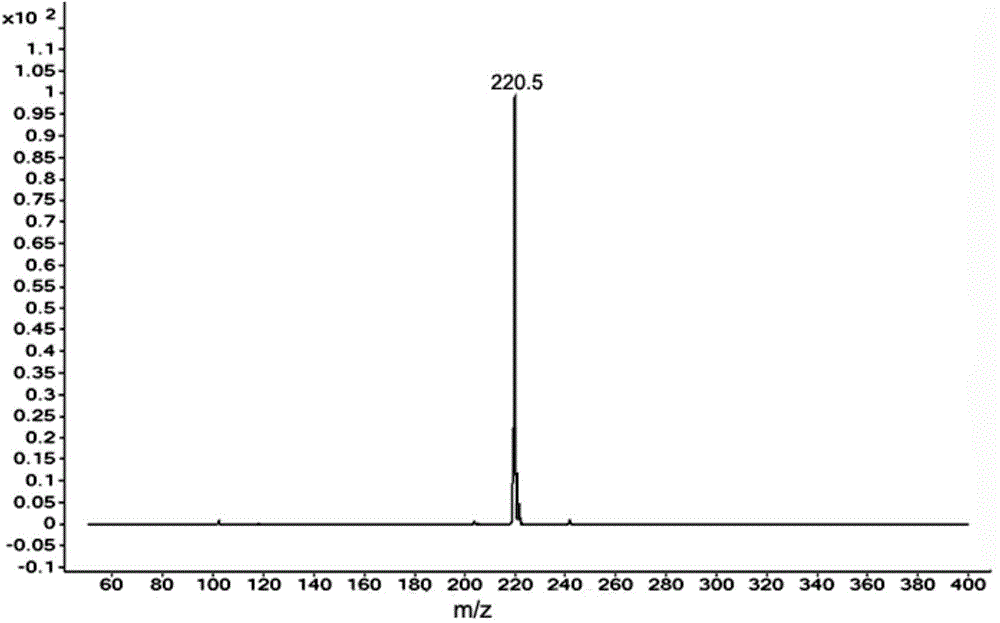

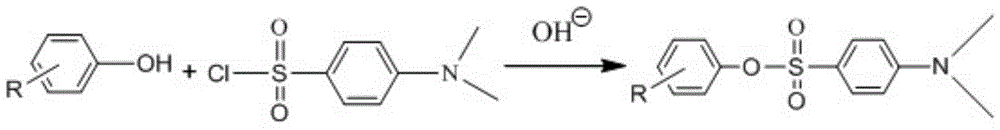

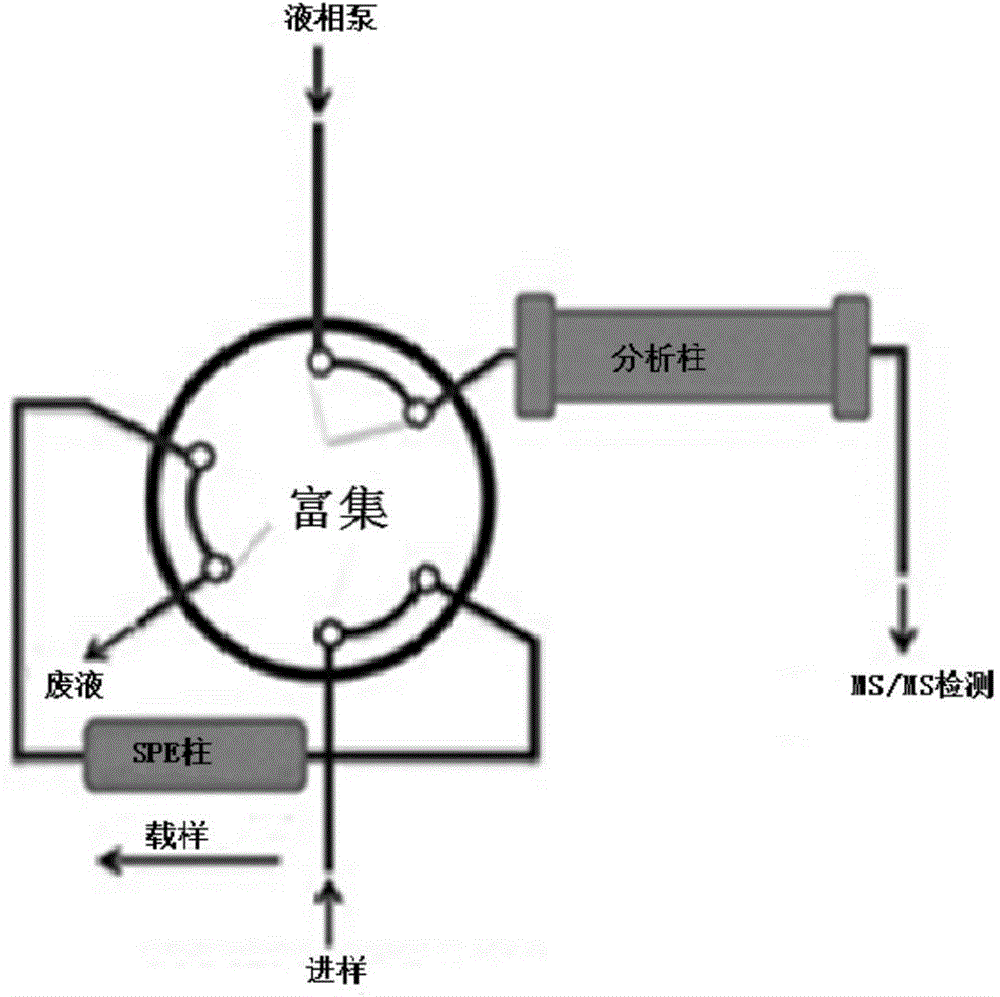

ActiveCN104678028AHigh sensitivityAvoid instabilityComponent separationMetabolitePretreatment method

The invention belongs to the technical field of detection and relates to a pretreatment method for biogen amine neurotransmitter and / or metabolites thereof. The method comprises the following steps of: performing derivatization on a sample containing the biogen amine neurotransmitter and / or the metabolites thereof, and carrying out online solid-phase extraction on derivatization products. On the basis, the invention also relates to a detection method for the biogen amine neurotransmitter and / or the metabolites thereof, a detection kit and application thereof. The pretreatment method has the advantages that impurities in the derivatization products can be eliminated, and after being enriched, the derivatization products with proper concentration are transferred into the following detection steps. The detection method has the advantages that the content of the biogen amine neurotransmitter and / or the metabolites thereof in a biological sample can be fast and accurately measured, and the detection sensitivity is high.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

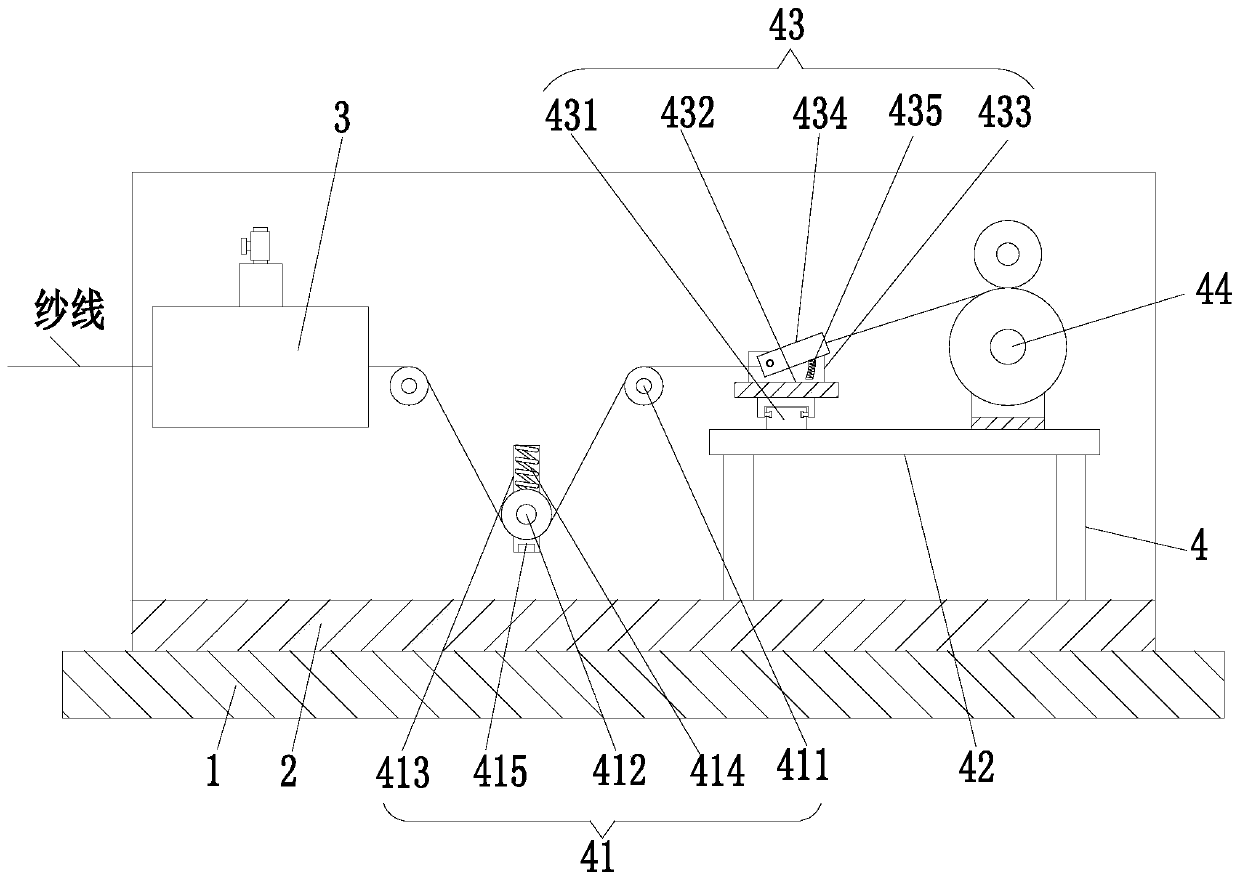

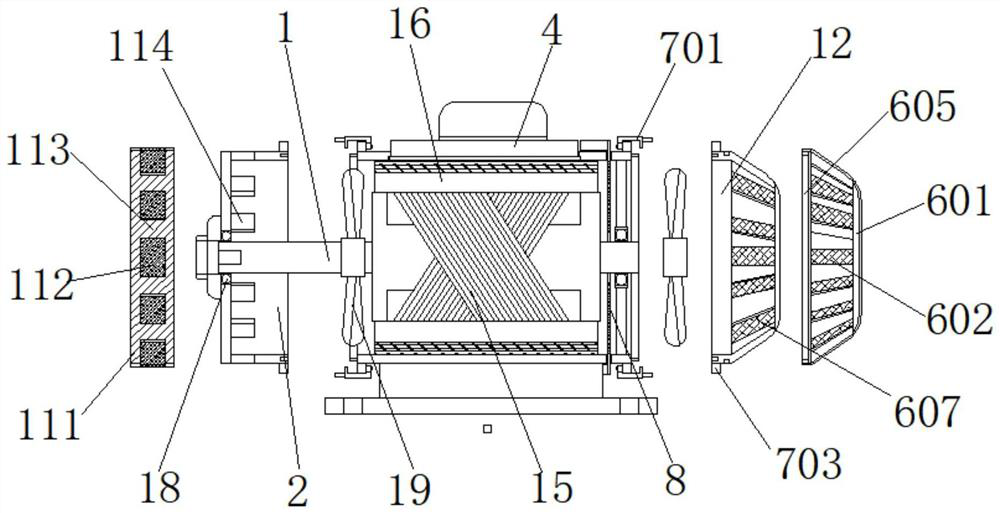

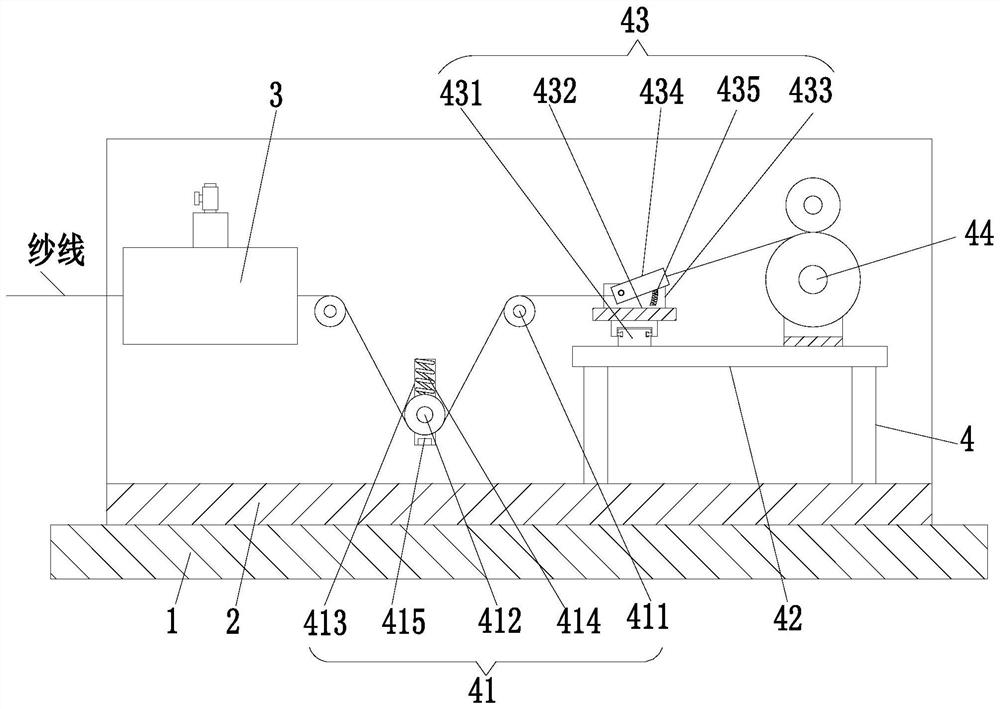

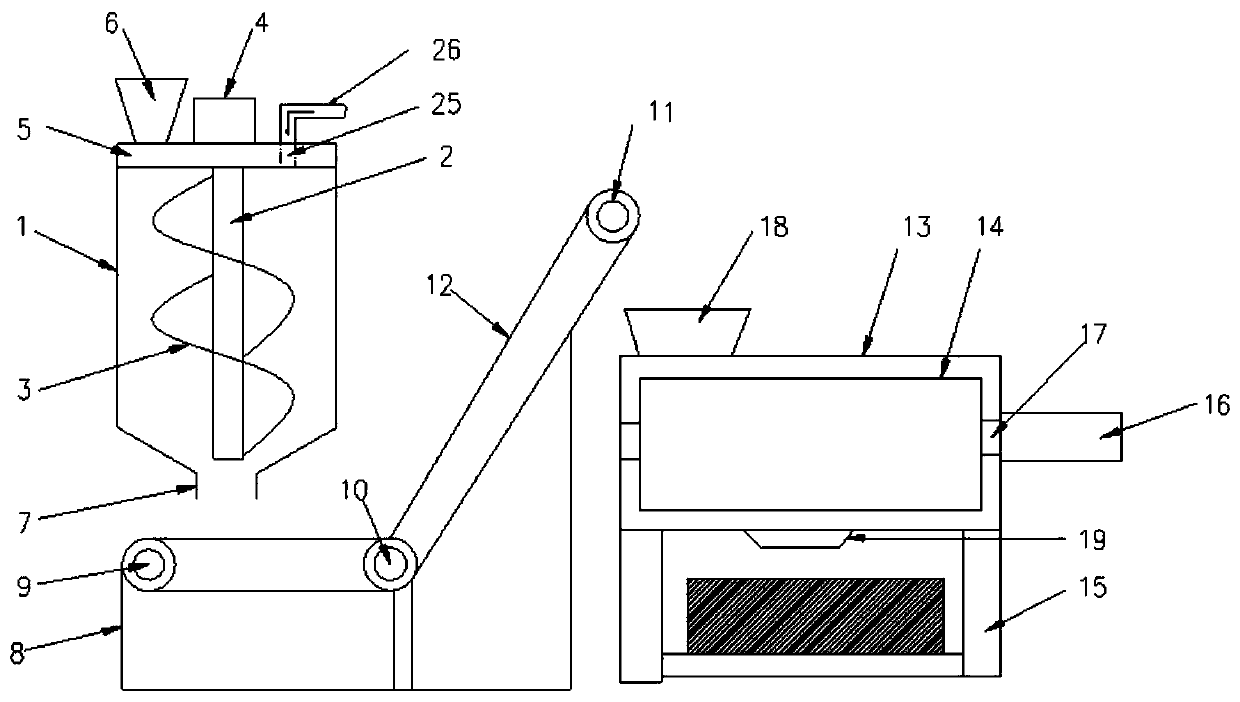

Bobbin yarn winding equipment and bobbin yarn winding process

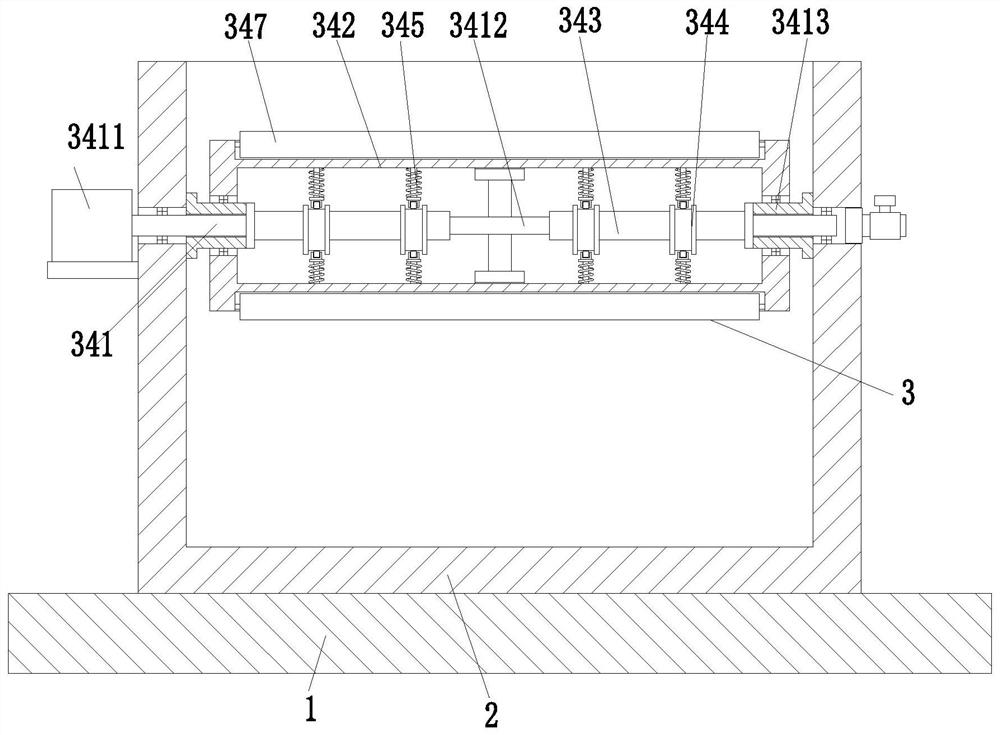

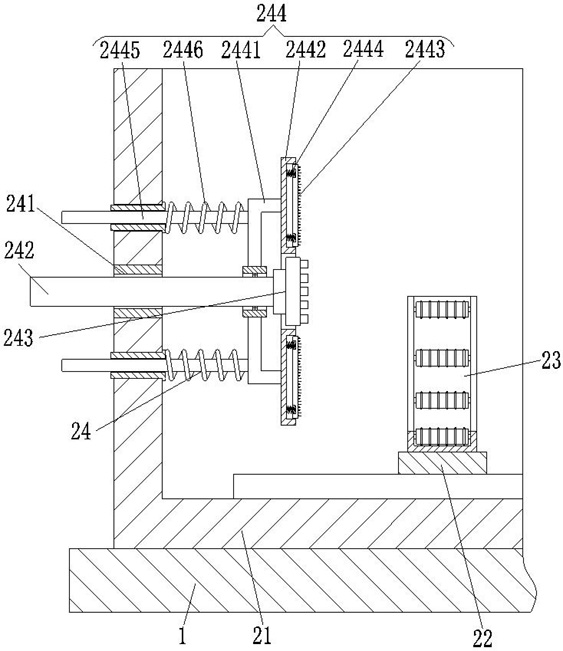

The invention relates bobbin yarn winding equipment and a bobbin yarn winding process. The bobbin yarn winding equipment comprises a bottom plate, a supporting frame, a cleaning device and a winding device; and the supporting frame is installed at the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, the cleaning device is installed on the left side ofthe interior of the supporting frame, and the winding device is installed on the right side of the interior of the supporting frame. According to the bobbin yarn winding equipment and the bobbin yarnwinding process, the problems that when existing equipment is used for winding yarn, the yarn cannot be cleaned generally, fluff attached to the yarn is prone to causing yarn knotting, and the follow-up use effect of the yarn is affected can be solved; and the problem that when the existing equipment is used for winding the yarn, the wound yarn cannot be pressed generally so that the yarn is proneto loosening can be solved; and in addition, the problem that when the yarn is conveyed, the yarn is prone to breakage due to large friction coefficient of the yarn, and then the winding efficiency of the yarn is affected can be solved.

Owner:兰溪市文萱纺织有限公司

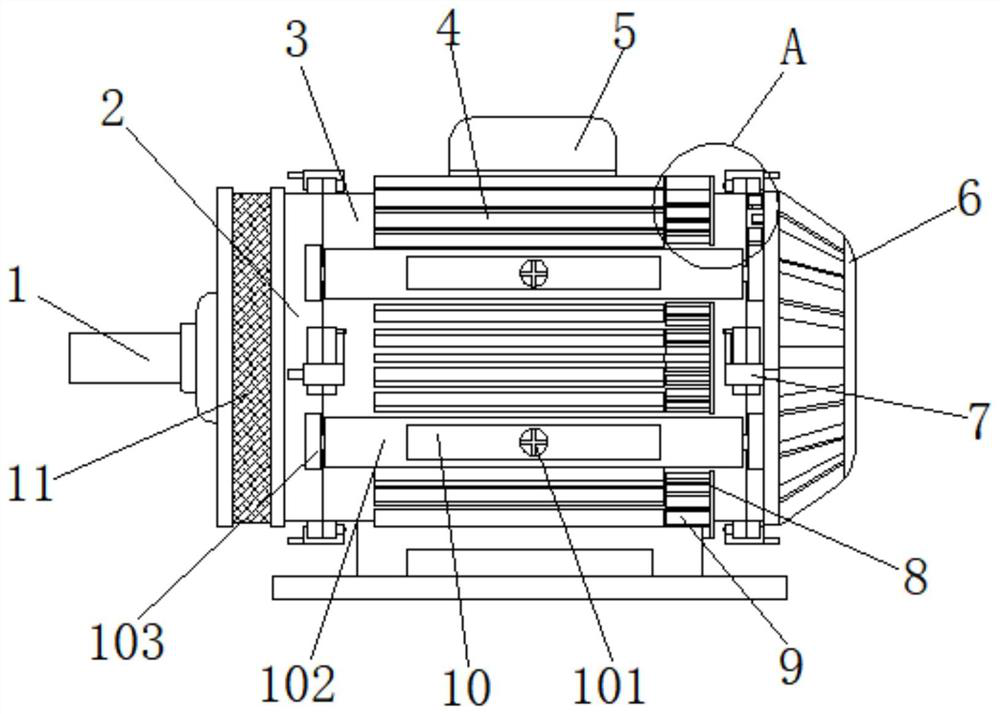

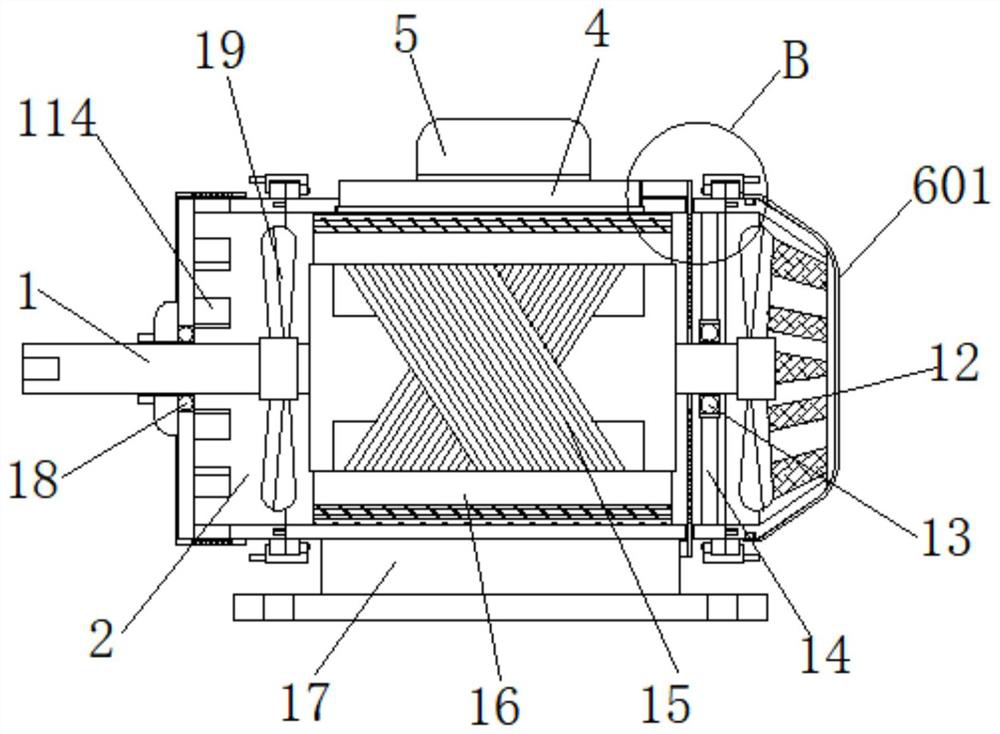

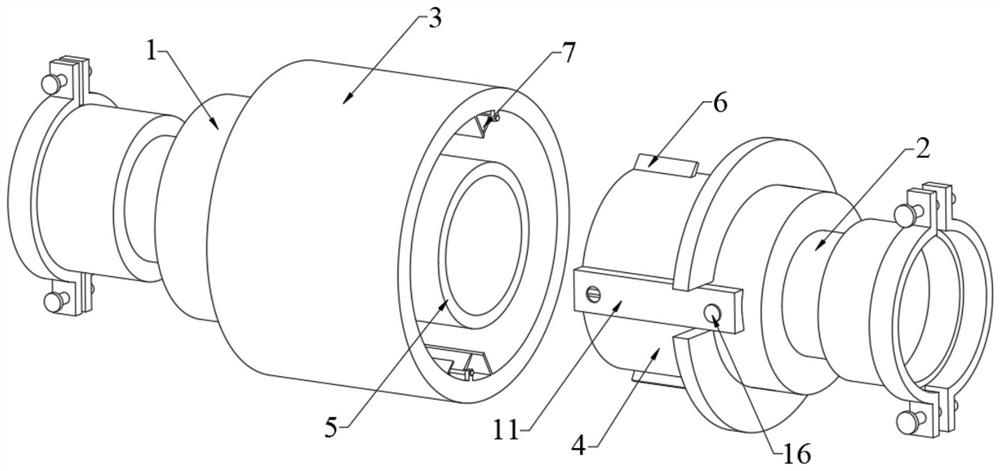

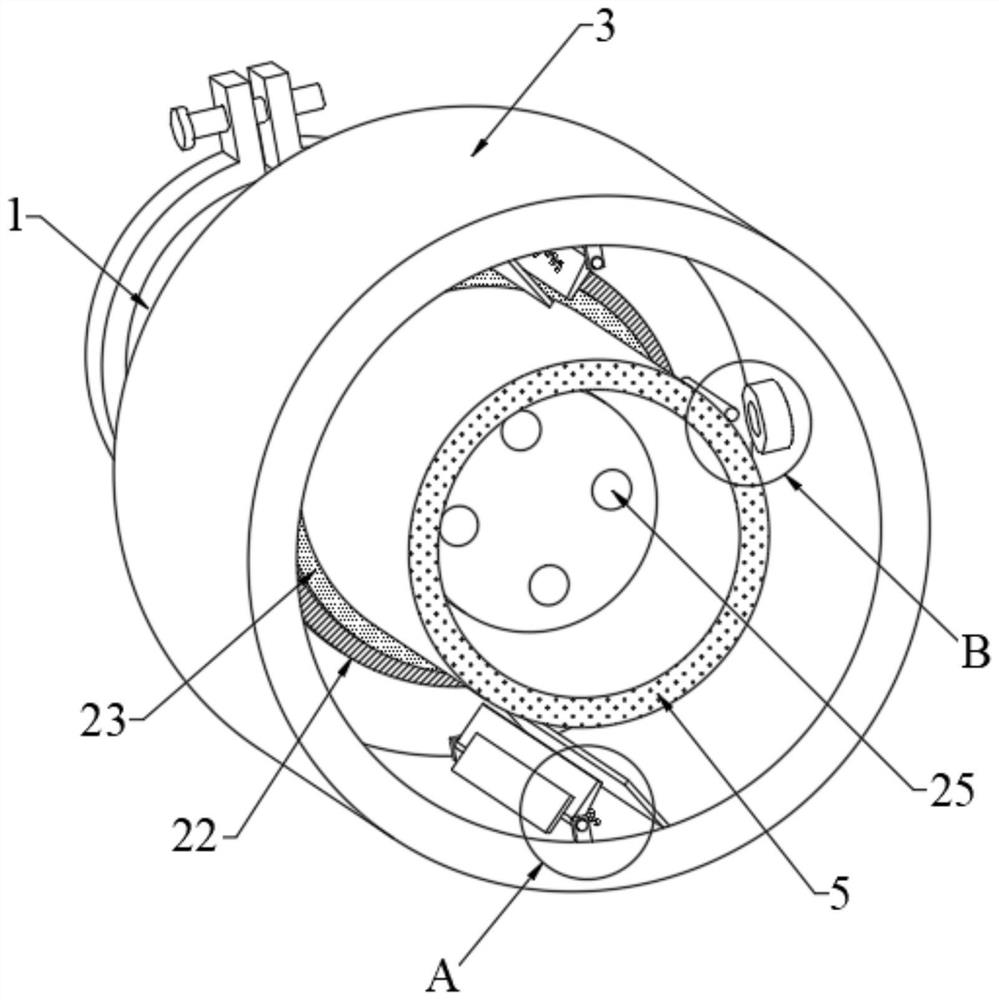

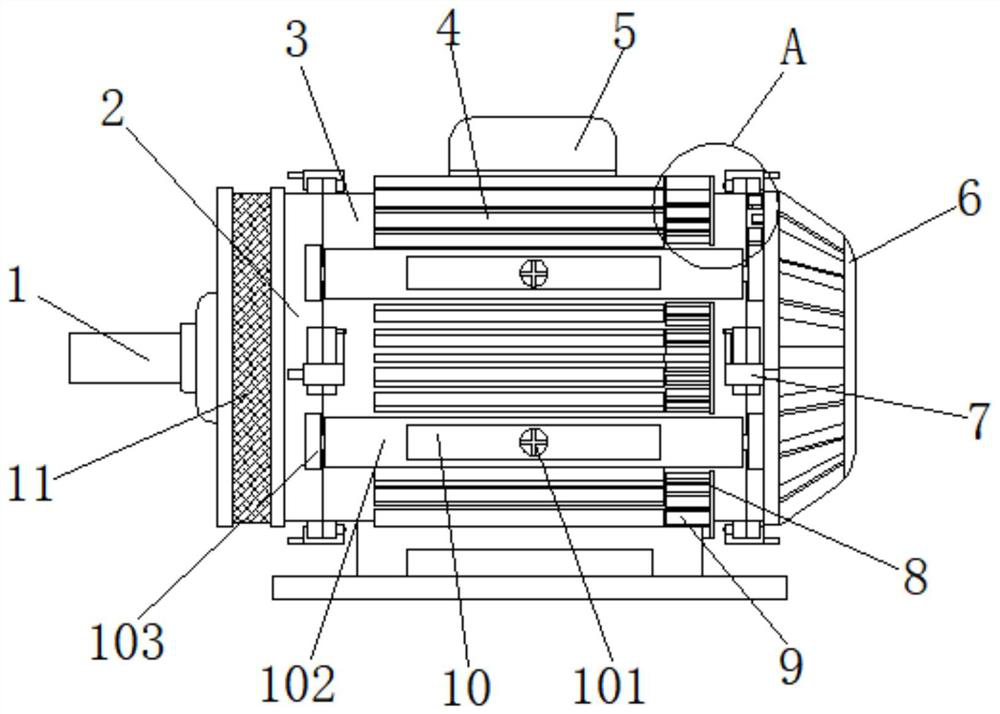

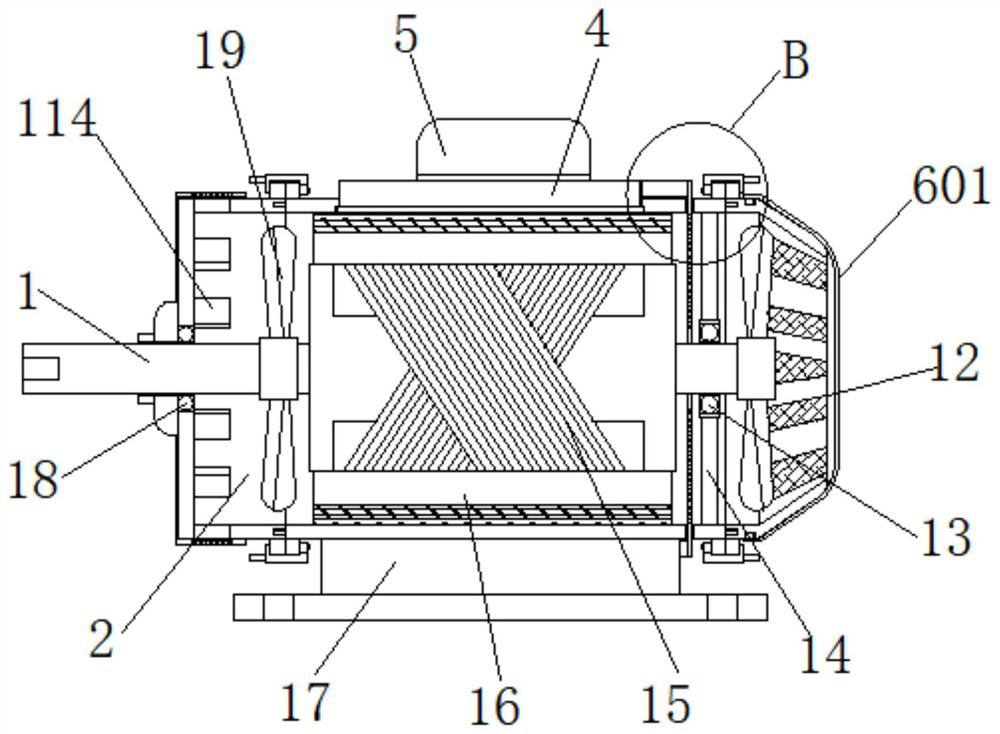

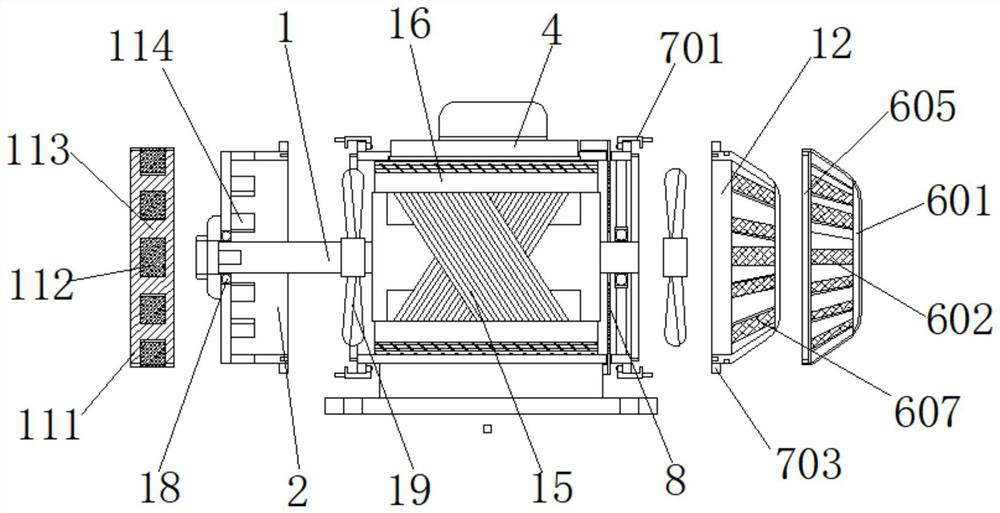

Self-heat-dissipation rare earth permanent magnet synchronous motor

ActiveCN111864960AReduce sizeImprove self-cooling effectCooling/ventillation arrangementSupports/enclosures/casingsPermanent magnet synchronous motorElectric machinery

The invention discloses a self-heat-dissipation rare earth permanent magnet synchronous motor. The motor comprises a machine bin , wherein a front machine cover and a rear machine cover are arranged at two ends of the machine bin correspondingly, a filtering assembly is arranged at the end, away from the machine bin, of the outer side of the front machine cover, a bearing B is arranged in the center of the end, away from the machine bin, of the front machine cover, connecting rods are evenly arranged at the end, away from the front machine cover, of the inner side wall of the machine bin, andbearings A are arranged at the ends, close to each other, of the connecting rods. The motor is advantaged in that the front machine cover, the machine bin, the auxiliary assembly, the fixing assemblyand the rear machine cover are used in cooperation, when the motor is disassembled for maintenance, excessive fixing screws do not need to be disassembled; when the front machine cover and the rear machine cover are installed, the front machine cover and the rear machine cover do not need to be manually supported to keep alignment of screws and screw holes, only the insertion rods need to be inserted into the insertion grooves, convenience of disassembly or assembly of the motor is greatly improved, and stability of connection between the front machine cover and the machine bin and between therear machine cover and the machine bin can be further improved through the auxiliary assemblies.

Owner:湖南普东科技有限责任公司

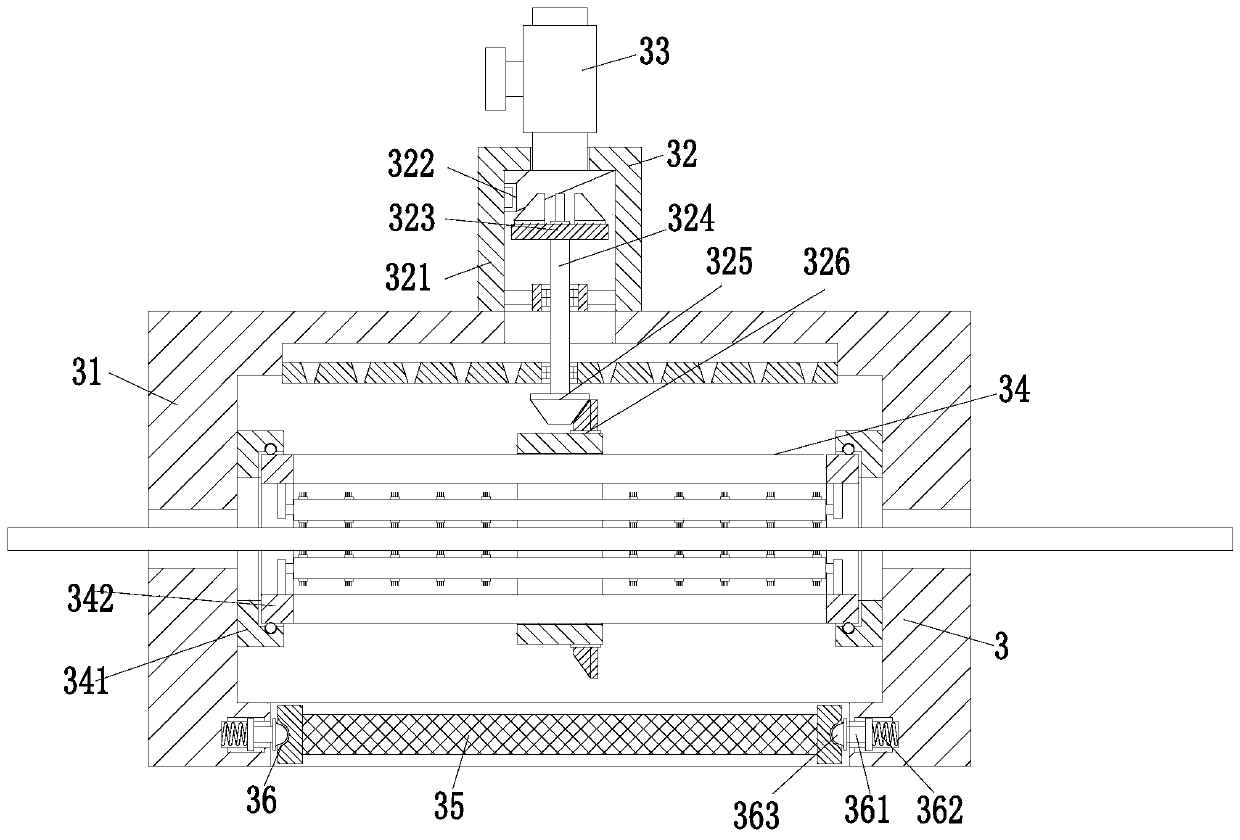

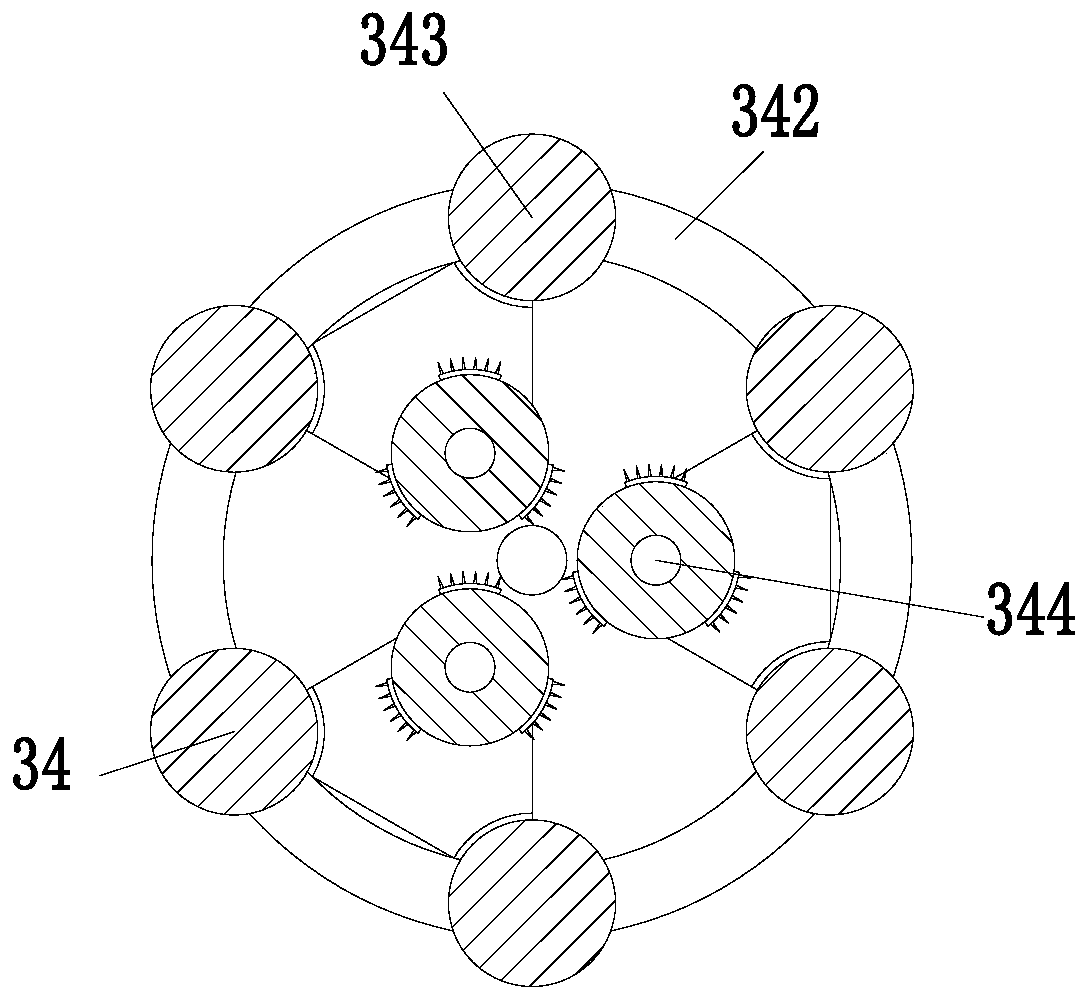

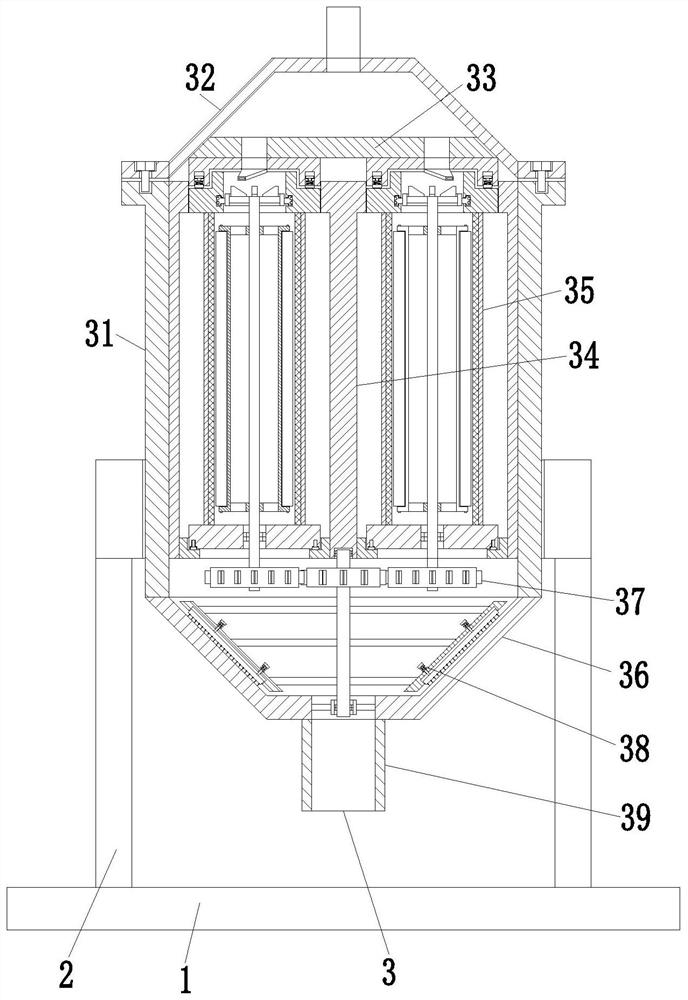

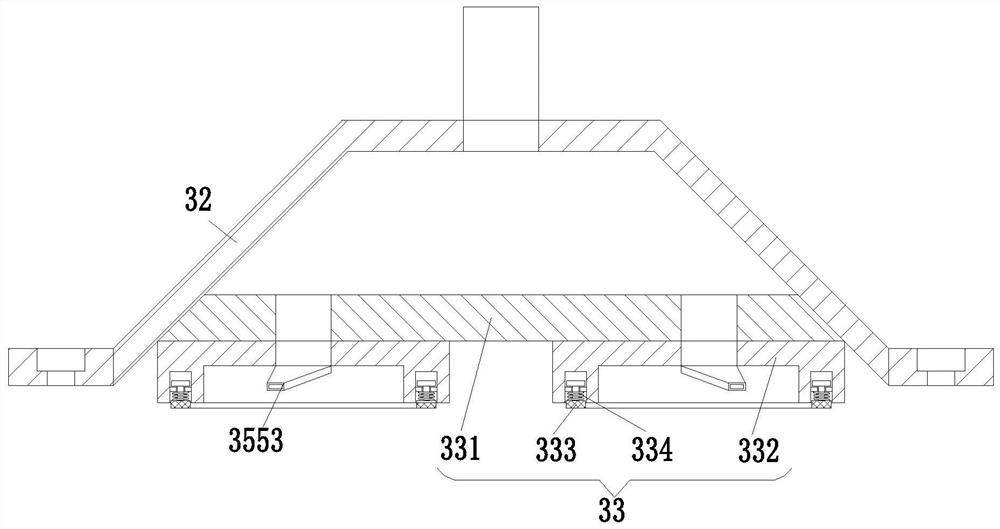

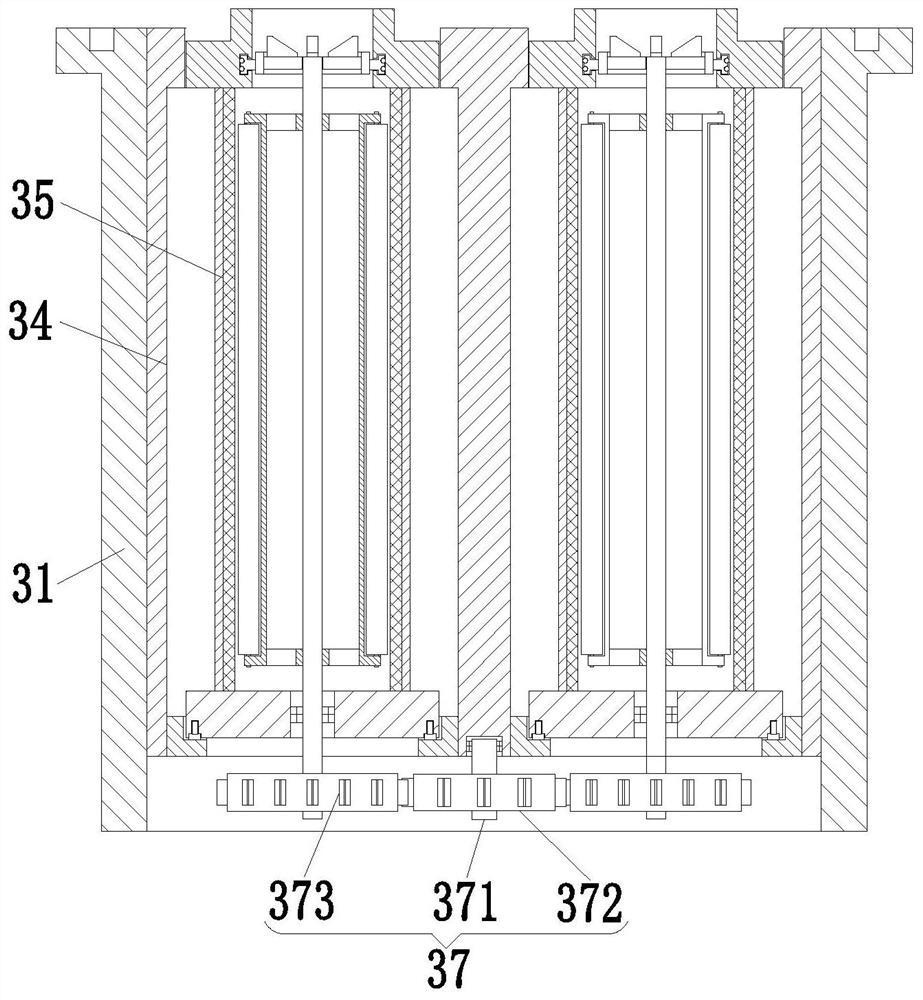

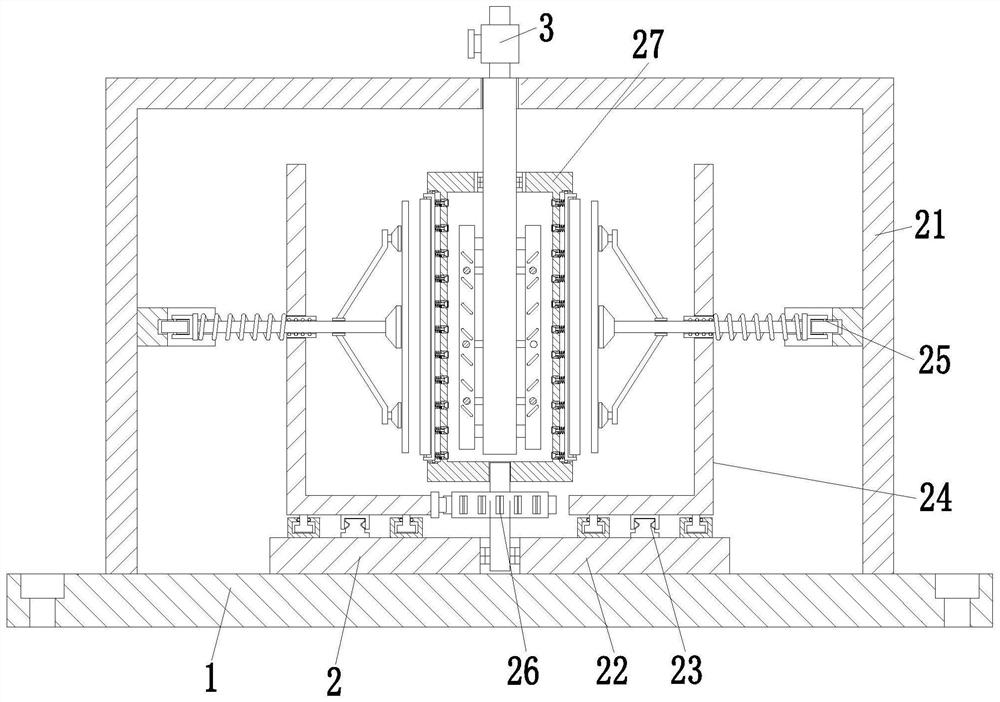

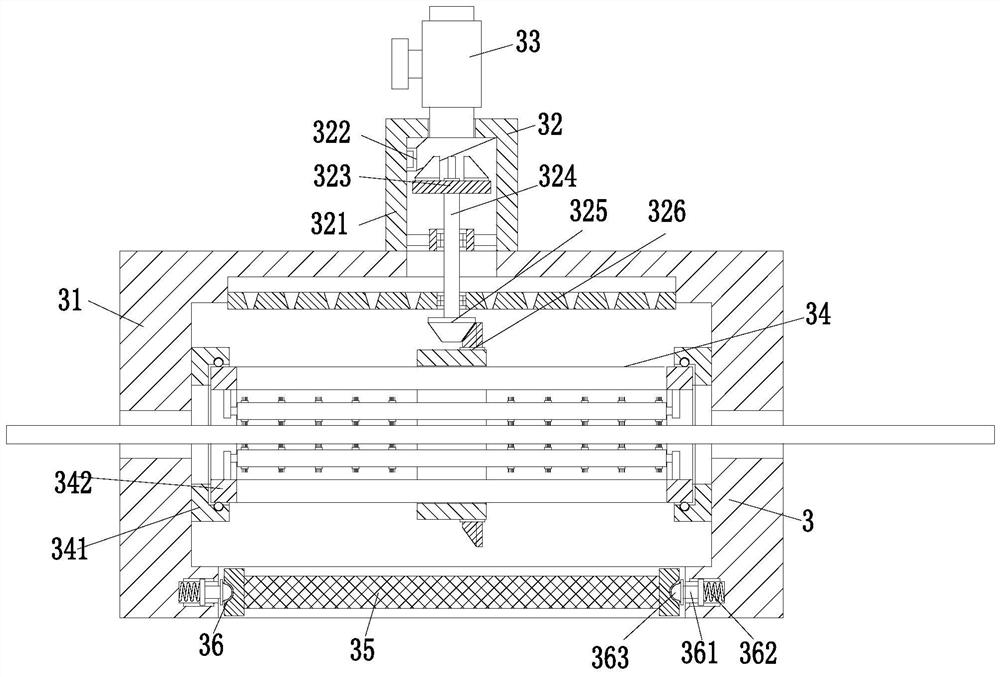

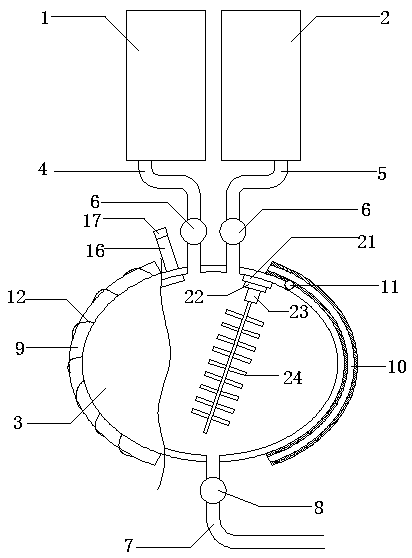

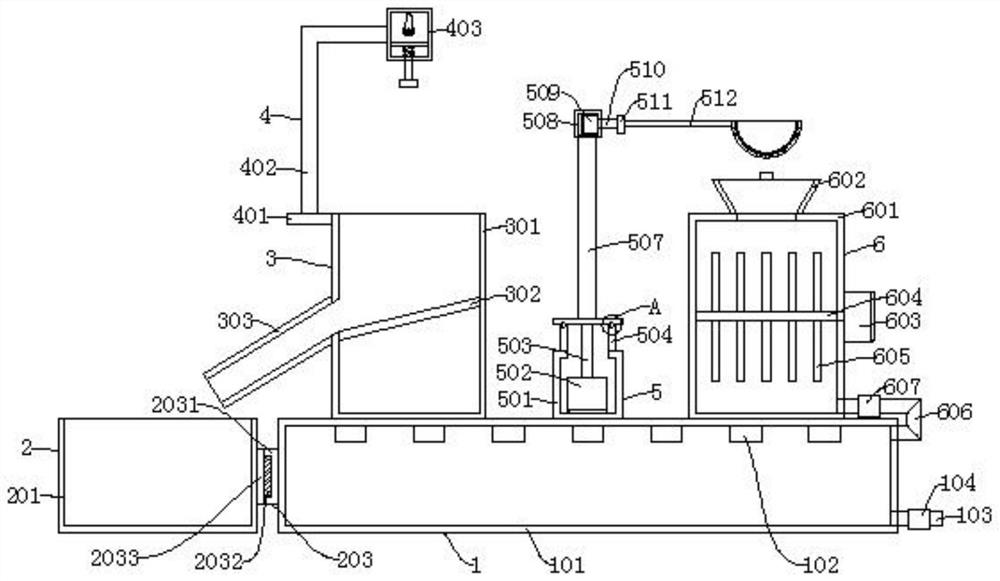

Waterproof coating preparation and processing system

InactiveCN111773953AImprove production efficiencyImprove filtering effectTransportation and packagingRotary stirring mixersEngineeringProcess engineering

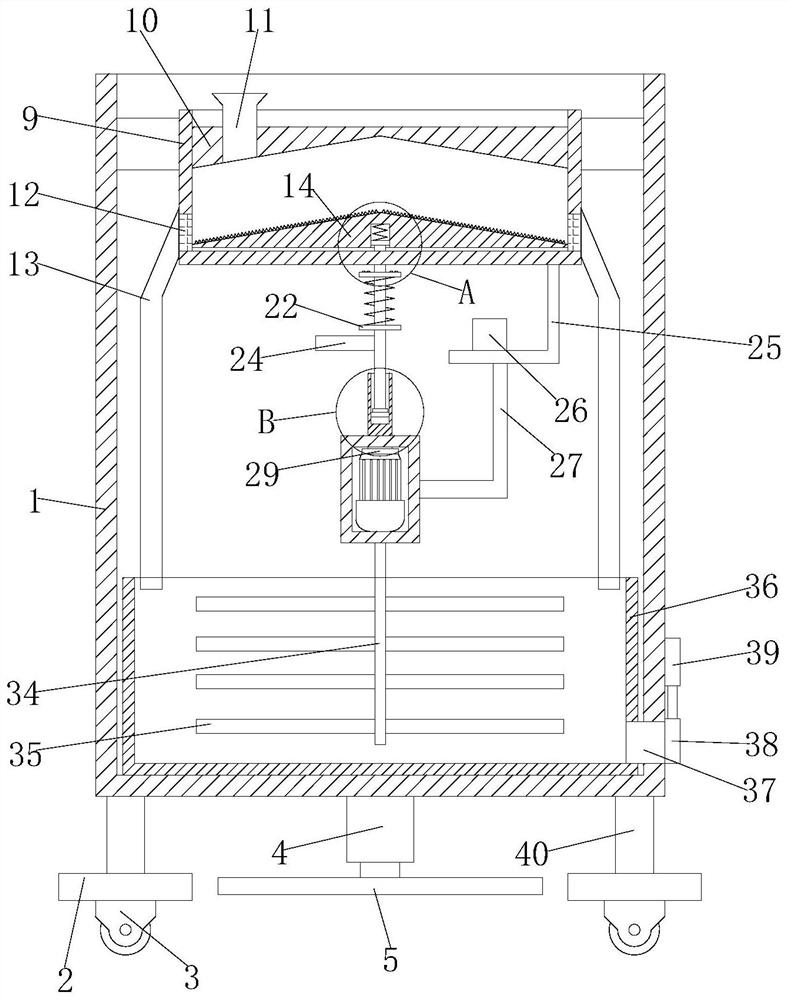

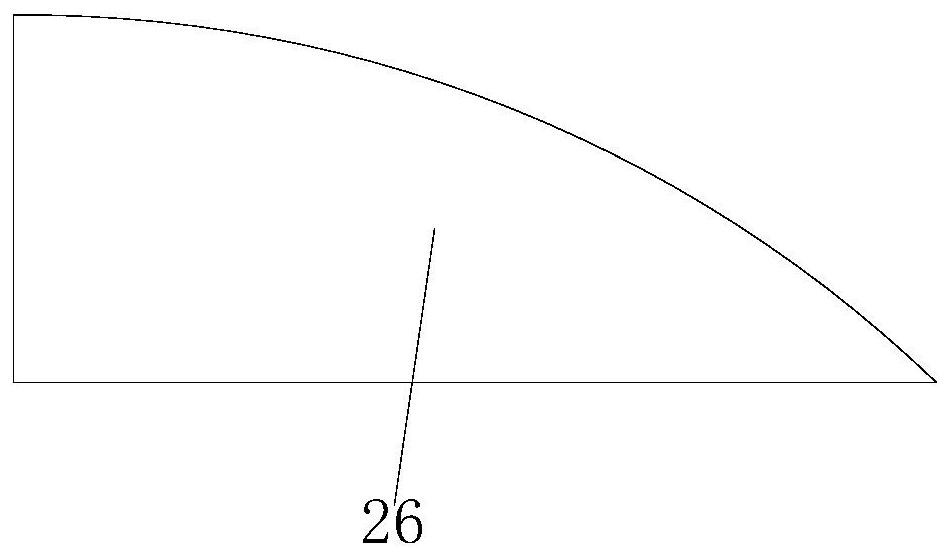

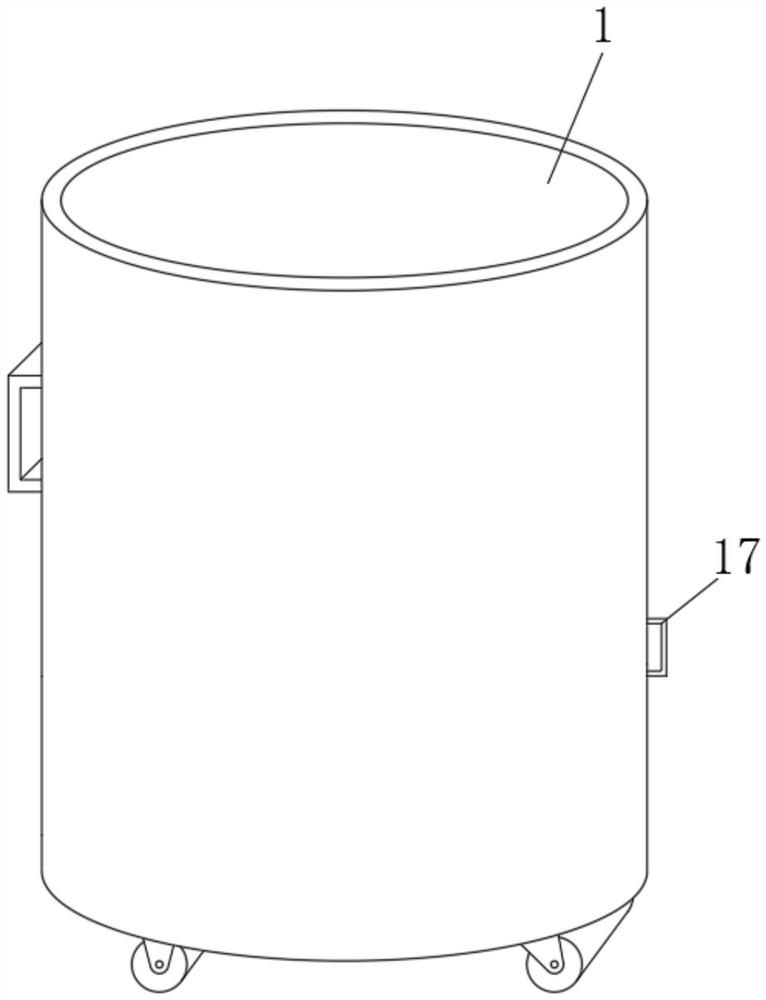

The invention relates to a waterproof coating preparation and processing system, which comprises a bottom plate, supporting frames and a mixing device; the supporting frames are evenly installed at the upper end of the bottom plate, and the mixing device is installed between the upper ends of the supporting frames and located above the bottom plate. Avoided are the problems that existing equipmentcannot effectively filter large-particle impurities in raw materials, the filter effective is bad, the efficiency is low, large-particle impurities are easily accumulated in a filter screen, the meshes of the filter screen are blocked by the impurities, when the equipment is used for preparing a coating, the filtered raw materials cannot be effectively and uniformly mixed, the mixing effect is bad, and the subsequent using effect of the coating is influenced.

Owner:陕西喜嘉彩新型材料有限公司

Building concrete gravel mixing equipment

InactiveCN113427636AQuick mixImprove the mixing effectCement mixing apparatusGrain treatmentsDrive shaftArchitectural engineering

The invention belongs to the technical field of concrete gravel mixing, and particularly relates to building concrete gravel mixing equipment. The building concrete gravel mixing equipment comprises a box body and a box cover, a moving device is mounted at the bottom of the box body, a supporting device is mounted at the bottom of the box body, a handle is mounted at the top of the box cover, a blocking rod is mounted at the bottom of the box cover, and a grinding box is mounted in the box body. An upper shielding plate is mounted in the grinding box, a feeding pipe is fixedly mounted on the upper shielding plate, a filter screen is fixedly mounted on the grinding box, a plurality of material guiding pipes are fixedly mounted on the grinding box, a mounting rod is fixedly mounted at the bottom of the grinding box, a bottom rod is fixedly mounted at the bottom of the mounting rod, a mounting box is fixedly mounted on the bottom rod, a double-shaft motor is fixedly mounted in the mounting box, a driving shaft is fixedly mounted on one output shaft of the double-shaft motor, and the bottom end of a movable rod is movably mounted on the driving shaft. The building concrete gravel mixing equipment is convenient to use, gravel is ground and smashed firstly and then stirred and mixed, the mixing effect and efficiency are effectively improved, and the subsequent use effect of concrete is ensured.

Owner:江先庆

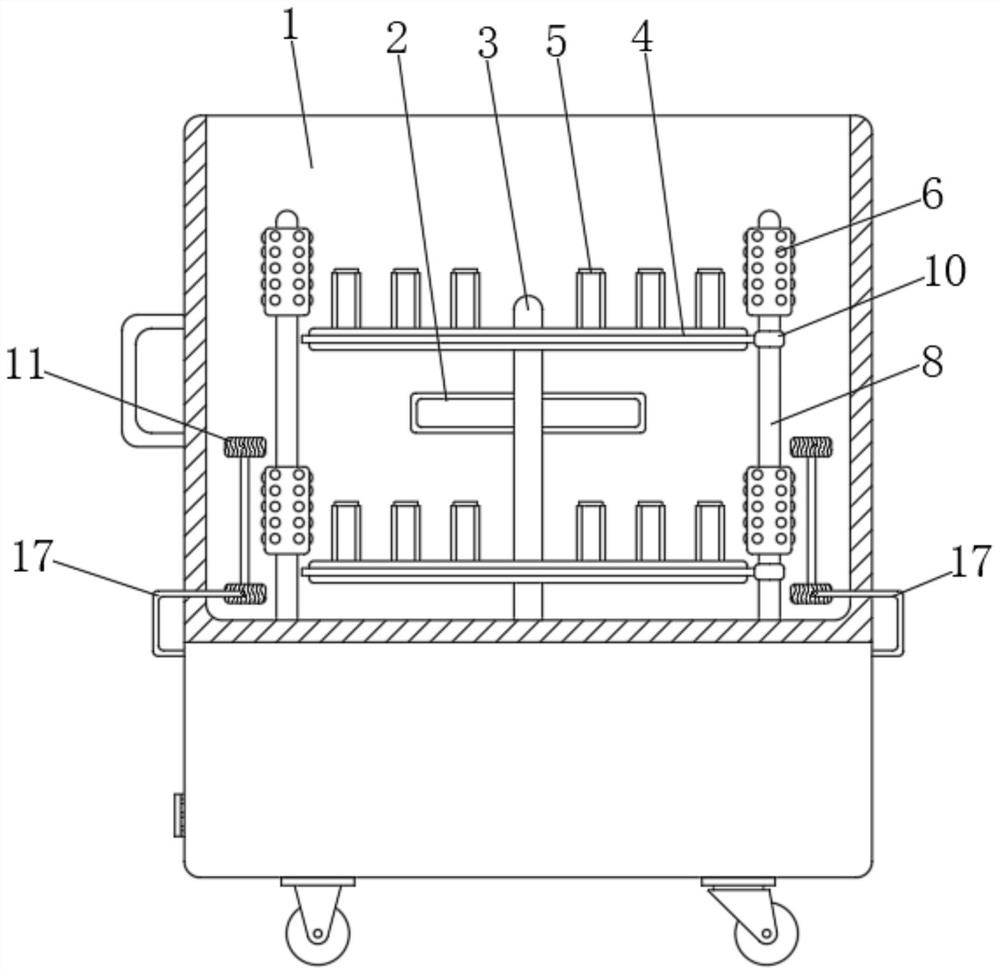

Ultrasonic multifunctional cleaning device for bearing machining

ActiveCN114011770AImprove cleaning qualityUniform cleanlinessCleaning using toolsCleaning using liquidsWater flowEngineering

The invention discloses an ultrasonic multifunctional cleaning device for bearing machining, and relates to the technical field of bearing machining, the ultrasonic multifunctional cleaning device comprises a body and an ultrasonic generator, the ultrasonic generator is arranged on the inner wall of the body, the inner wall of the body is fixedly connected with a rotating shaft, and a shaft arm of the rotating shaft is rotatably connected with two rotating plates; inserting rods are circumferentially arranged on the surfaces of the two rotating plates, two groups of cleaning assemblies are arranged in the body, a cleaning part for driving the two groups of cleaning assemblies to rotate and synchronously driving the two rotating plates to rotate is arranged in the body, the cleaning device further comprises an adjusting part for adjusting water flow in the body while the cleaning assemblies operate, and the cleaning part comprises a rotating rod; and two cleaning rods are arranged on the inner wall of the body in a rotating connection manner. According to the ultrasonic multifunctional cleaning device, through mutual cooperation of the structures, the effects of improving the bearing cleaning efficiency and saving human resources are achieved, and the problems that a traditional mode wastes time and labor and is poor in cleaning effect are solved.

Owner:泰州学院

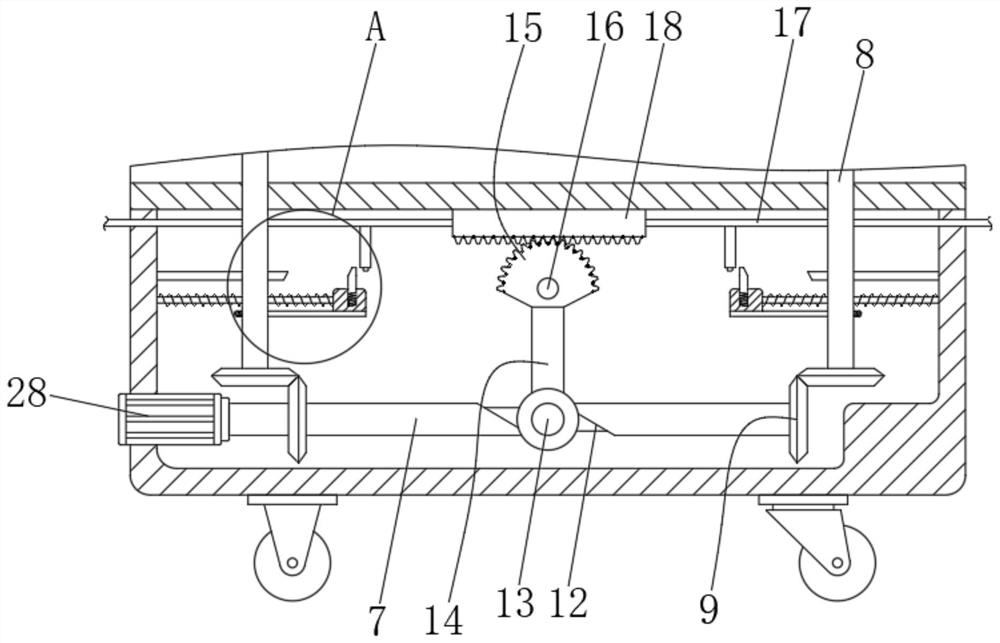

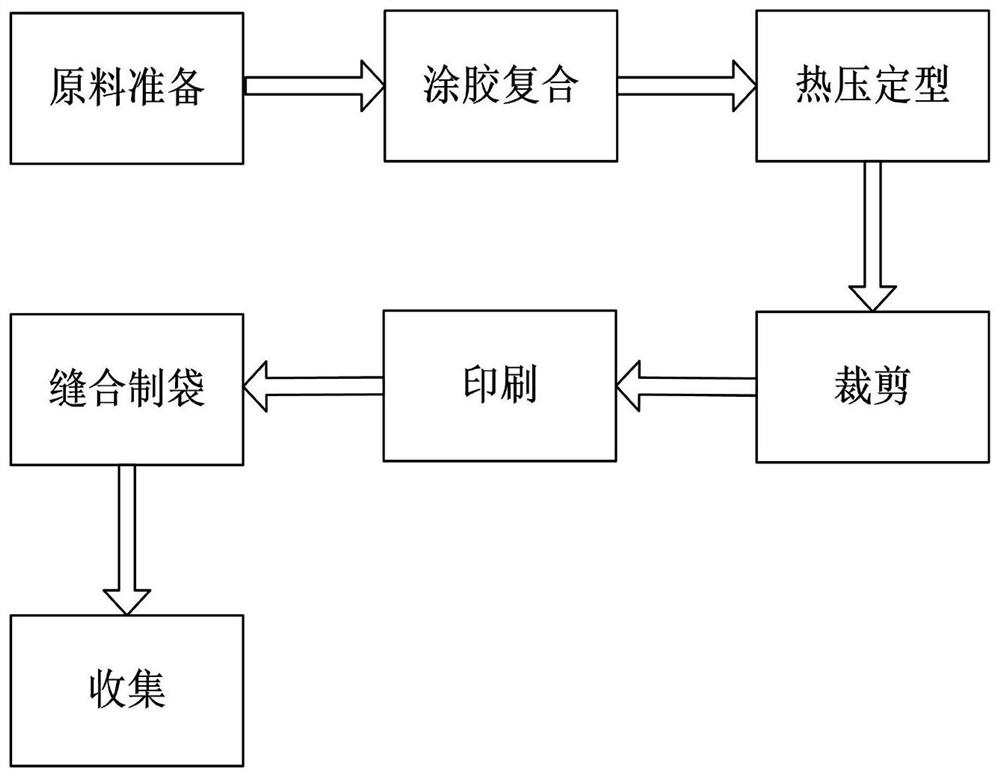

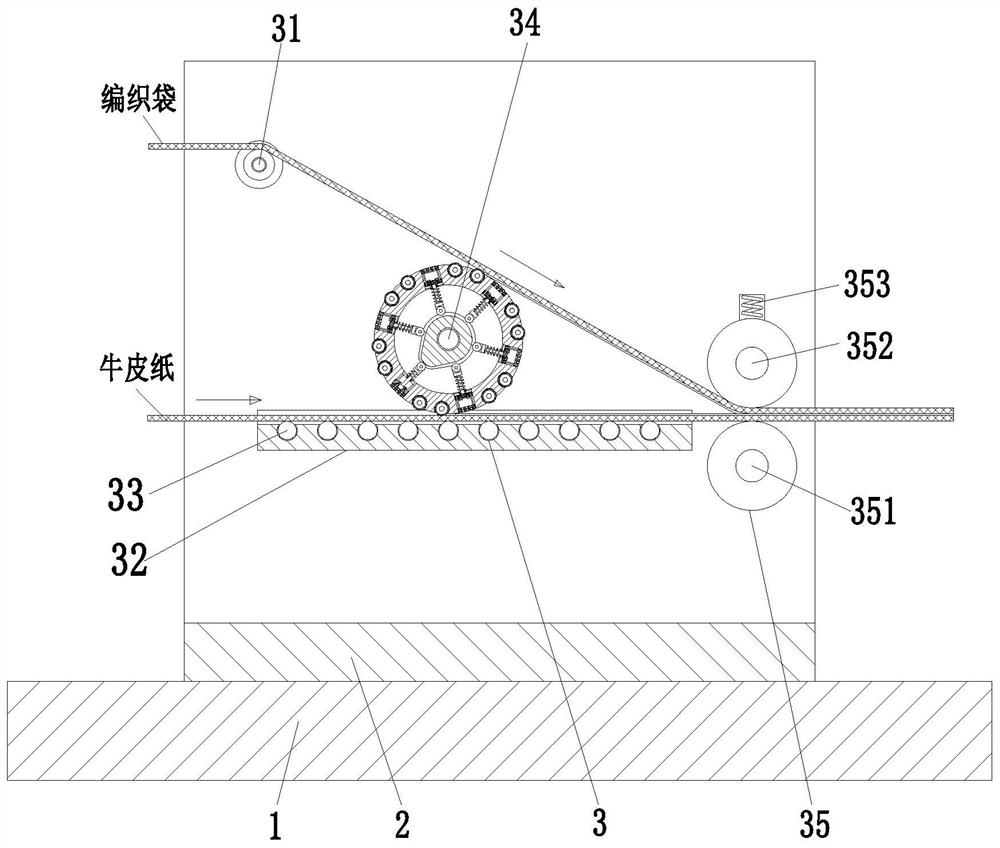

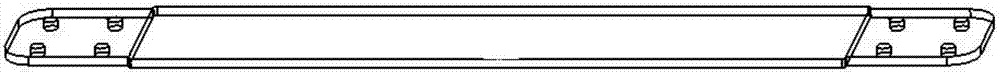

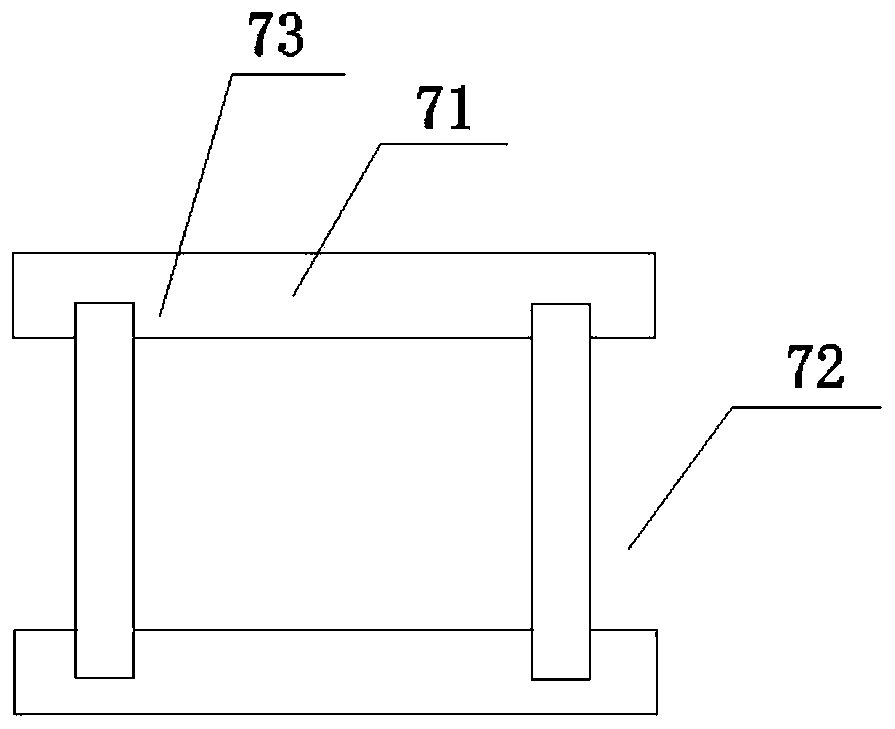

Preparation technology of paper-plastic composite woven bag

InactiveCN112208151AGuarantee the effect of subsequent useGlue effectiveBag making operationsPaper-makingMechanical engineeringKraft paper

The invention relates to a preparation technology of a paper-plastic composite woven bag. A bottom plate, a supporting frame and a composite device are included, the supporting frame is installed at the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, and the composite device is installed in the supporting frame. The technology can solve the problems that when existing equipment performs gluing processing on a composite woven bag, the coating effect of a glue solution is poor, smearing is not uniform, a gap exists between bonded kraft paper and thewoven bag, the subsequent using effect of the composite woven bag is affected, when the existing equipment processes the composite woven bag, generally, the kraft paper and the woven bag cannot be effectively bonded and composited, so that the bonding effect between the kraft paper and the woven bag is poor, bonding is not tight, the kraft paper and the woven bag are prone to falling off and thelike.

Owner:韩光林

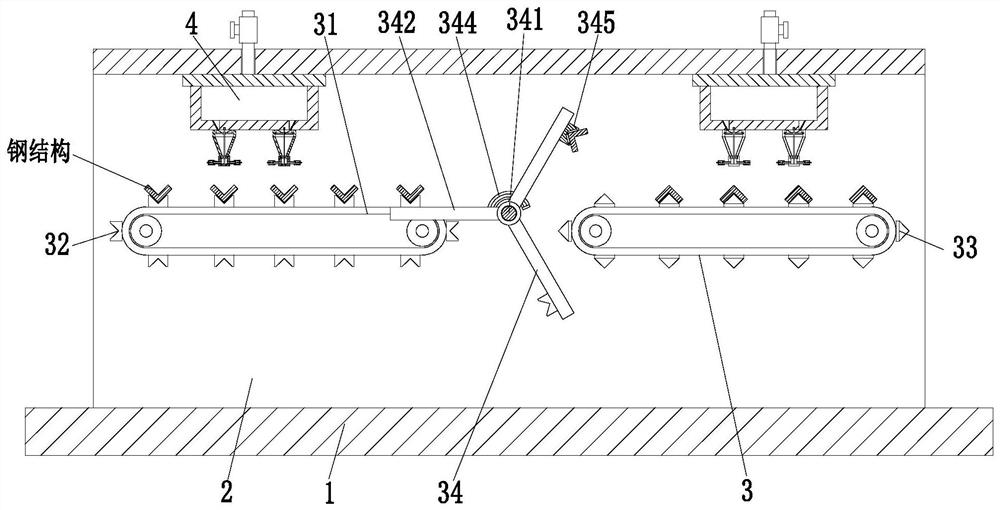

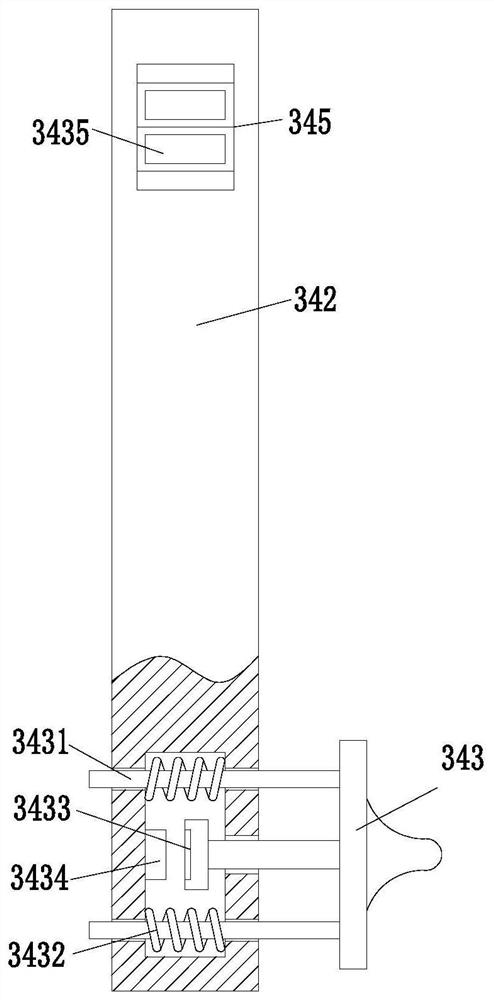

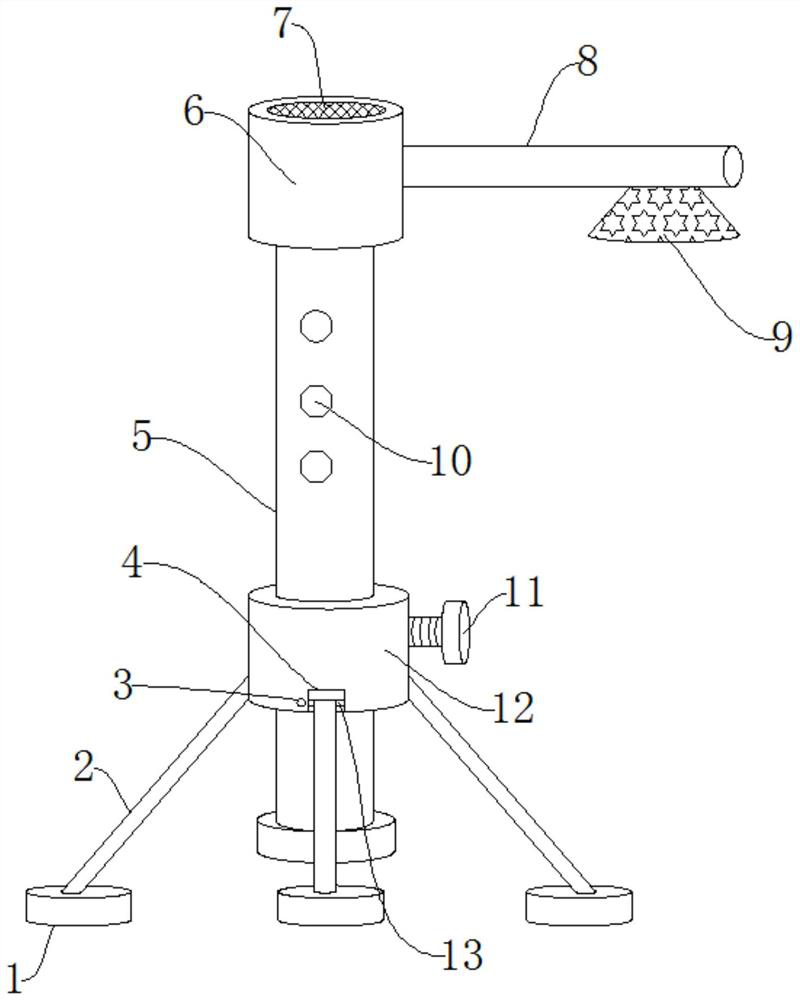

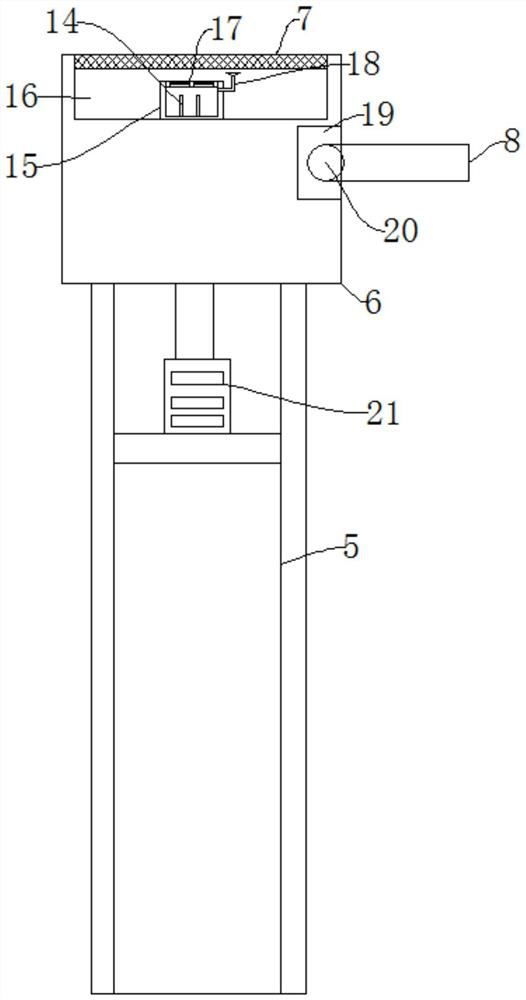

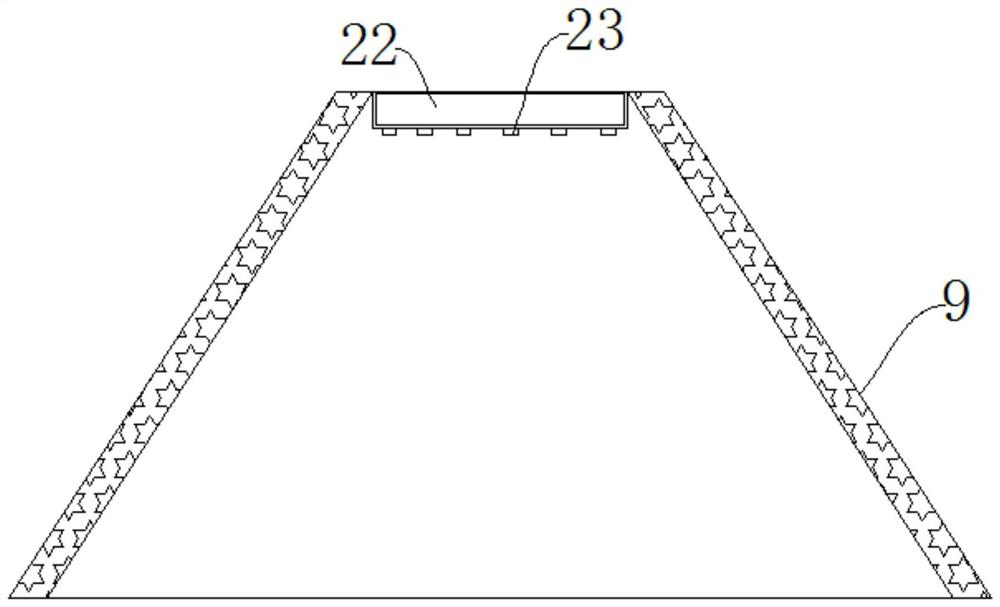

Steel structure spraying facility for power transmission iron tower

ActiveCN111841955AConvenient spray processingGuaranteed service lifeSpraying apparatusTowerIndustrial engineering

The invention relates to a steel structure spraying facility for a power transmission iron tower. The steel structure spraying facility for the power transmission iron tower comprises a base plate, asupporting frame, conveying devices and spraying devices. The supporting frame is installed at the upper end of the base plate, the conveying devices are installed in the middle of the interior of thesupporting frame, and the spraying devices are symmetrically arranged above the conveying devices and installed at the upper end of the interior of the supporting frame. The steel structure sprayingfacility for the power transmission iron tower can solve the problems that when an existing facility sprays rust-resisting materials to a steel structure, only one side of the steel structure can be sprayed in general, the omission phenomenon is prone to happen on the other side of the steel structure, and therefore the spraying effect of the steel structure is poor, spraying operation is not uniform, and the follow-up utilization of the steel structure is not facilitated; and when the existing facility conducts spraying processing operation on the steel structure, the spraying range of a spraying mechanism cannot be accurately adjusted in general, and therefore the phenomenon that a cross exists or a part is not sprayed is prone to exist on the sprayed steel structure, and the follow-up utilization effect of the steel structure is affected.

Owner:FUYANG SANHUAN POWER EQUIP CO LTD

Office table for pharmaceutics experiments

InactiveCN108014858ASolve processing problemsSolve storage difficultiesShaking/oscillating/vibrating mixersDispersed particle filtrationToxic gasActivated carbon

The invention discloses an office table for pharmaceutics experiments. The office table comprises an experiment platform, wherein an accommodating box is arranged below the experiment platform, a waste liquor recovery chamber is formed on the inner left side of the accommodating box, a test tube collecting chamber is arranged in the middle of the upper part of the accommodating box, an experimental paper storage chamber is arranged on the upper right side of the accommodating box, the lower cavity of the accommodating box is divided into a toxic medicine storage chamber by an isolation board,an activated carbon adsorption block is arranged in a tube body of a main exhaust tube, a medicine preparation device is arranged on the upper left platform of the experiment platform, and universal rollers are also arranged at four corners of the bottom of the accommodating box. The problem of difficulty in waste liquor treatment is solved, the problem of difficulty in test tube storage in pharmaceutics experiments is solved, environmental pollution due to the fact that toxic gases float in the air is avoided, and besides, medicines in a plate are more uniformly prepared.

Owner:苏州德特尼罗电子科技有限公司

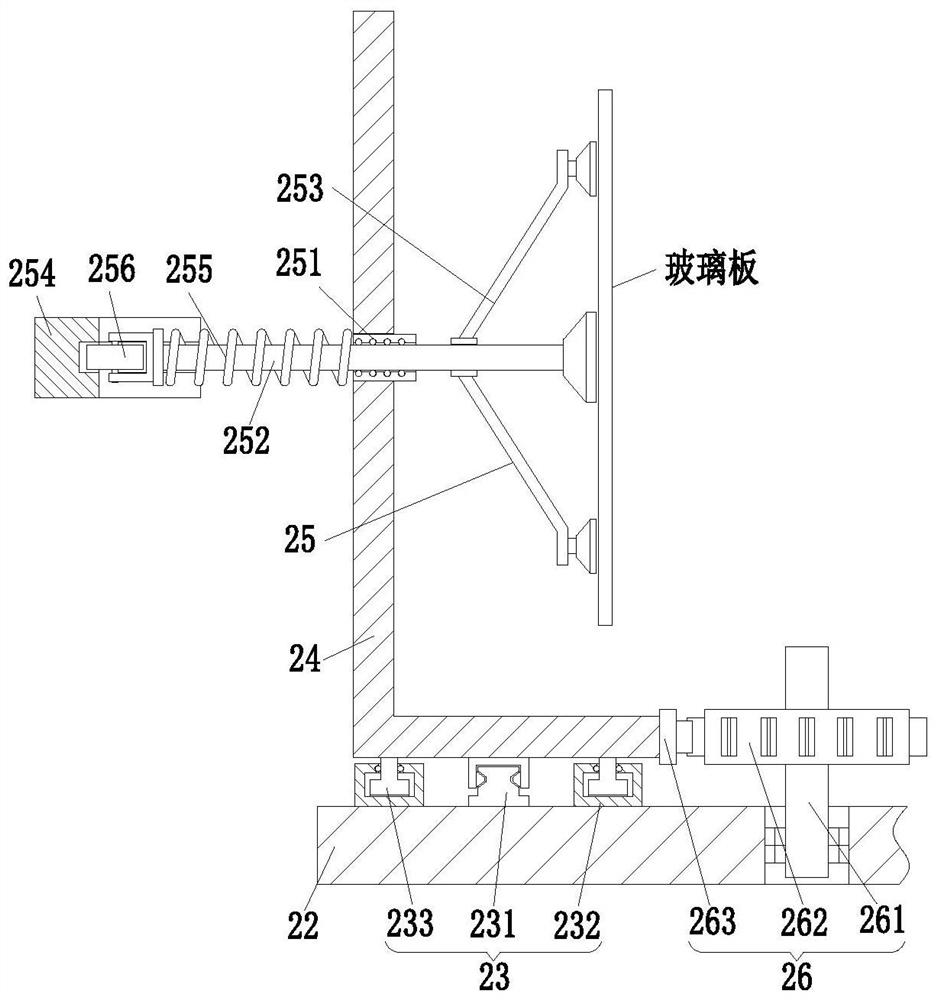

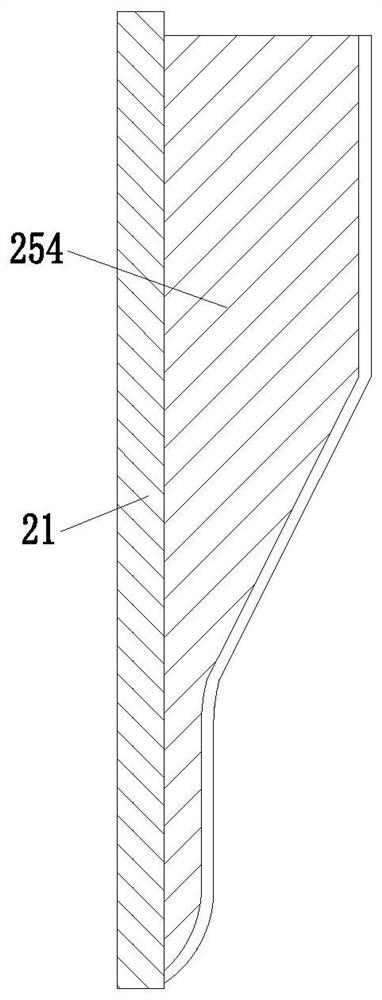

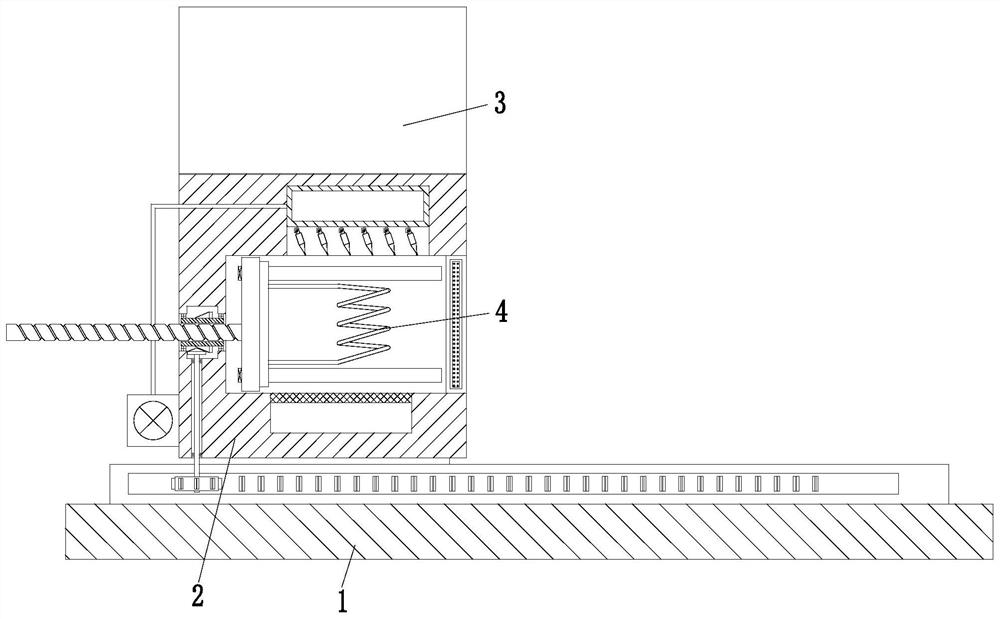

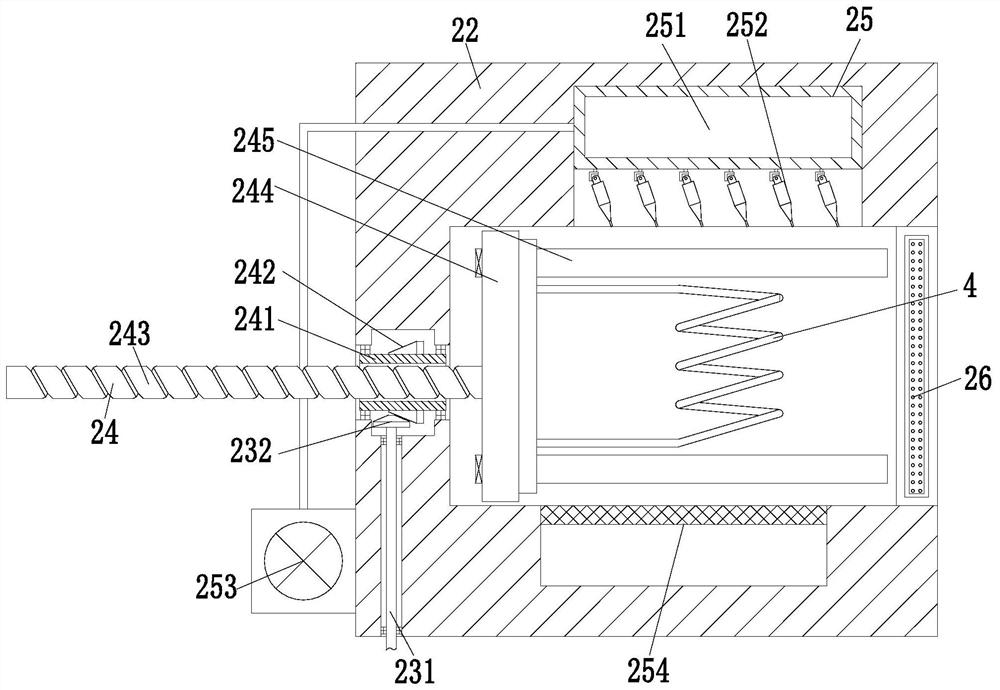

Explosion-proof tempered glass production and processing machine

InactiveCN111890752AGlue effectiveGood for subsequent bondingTransportation and packagingRotary stirring mixersToughened glassGlass sheet

The invention relates to an explosion-proof tempered glass production and processing machine which comprises a bottom plate, a laminating device and a feeding pipe, mounting holes are uniformly formedin the bottom plate, the laminating device is mounted in the middle of the upper end of the bottom plate, the feeding pipe is mounted at the upper end of the laminating device, and the feeding pipe is connected with an external glue pump. According to the invention, when the surface of a glass plate is glued by the existing equipment, the problems that gluing effect is poor, the glue solution cannot be effectively and uniformly coated on the surface of the glass plate, subsequent bonding of the glass plate is not facilitated, and gaps are easily formed between bonded glass plates are solved,when existing equipment is used for bonding the surfaces of the glued glass plates, the glass plates cannot be directly bonded and pressed, generally, the glass plates need to be subjected to secondary positioning, deviation of the bonded glass is easily caused, and the follow-up using effect of the glass is affected.

Owner:袁利华

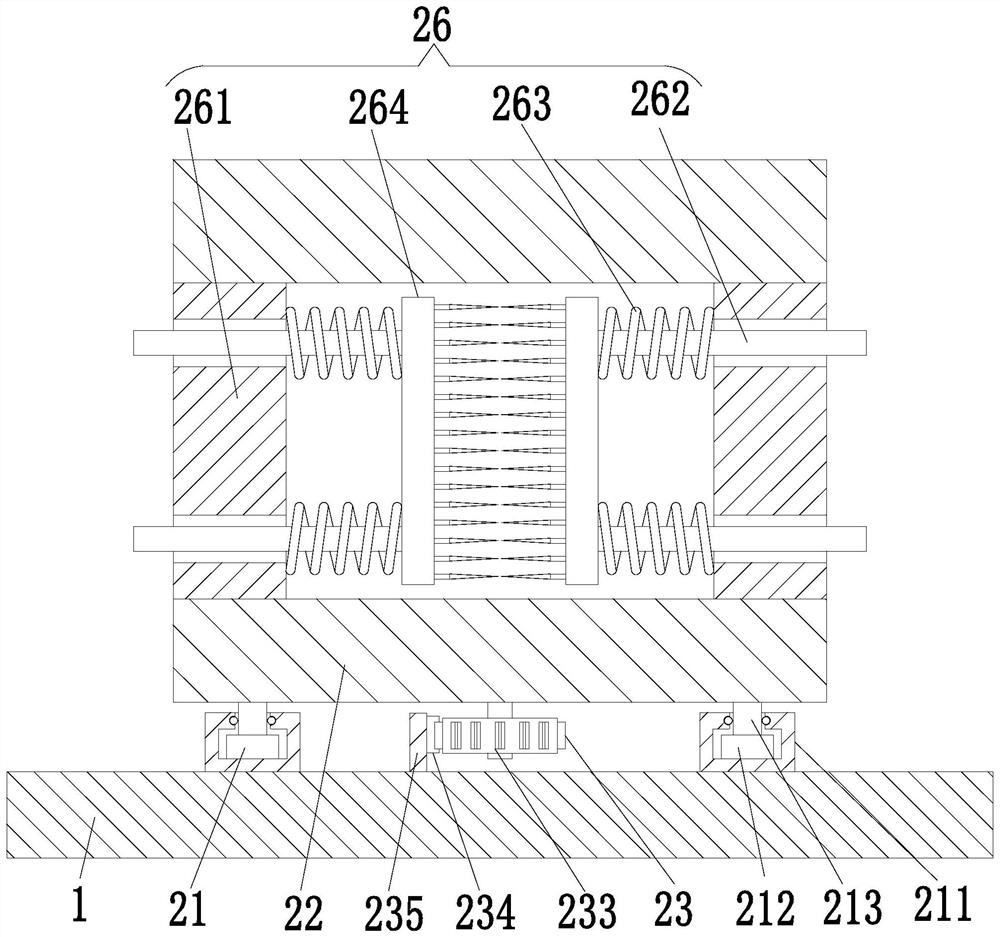

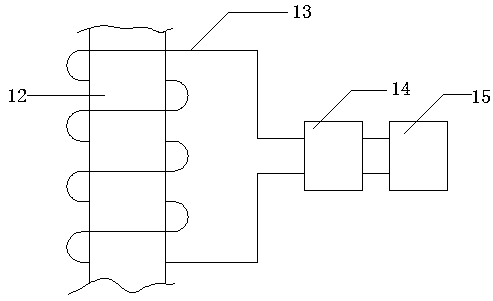

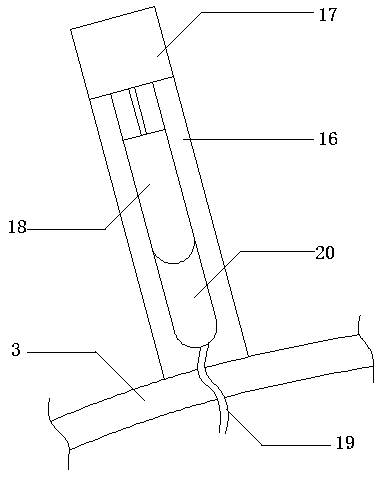

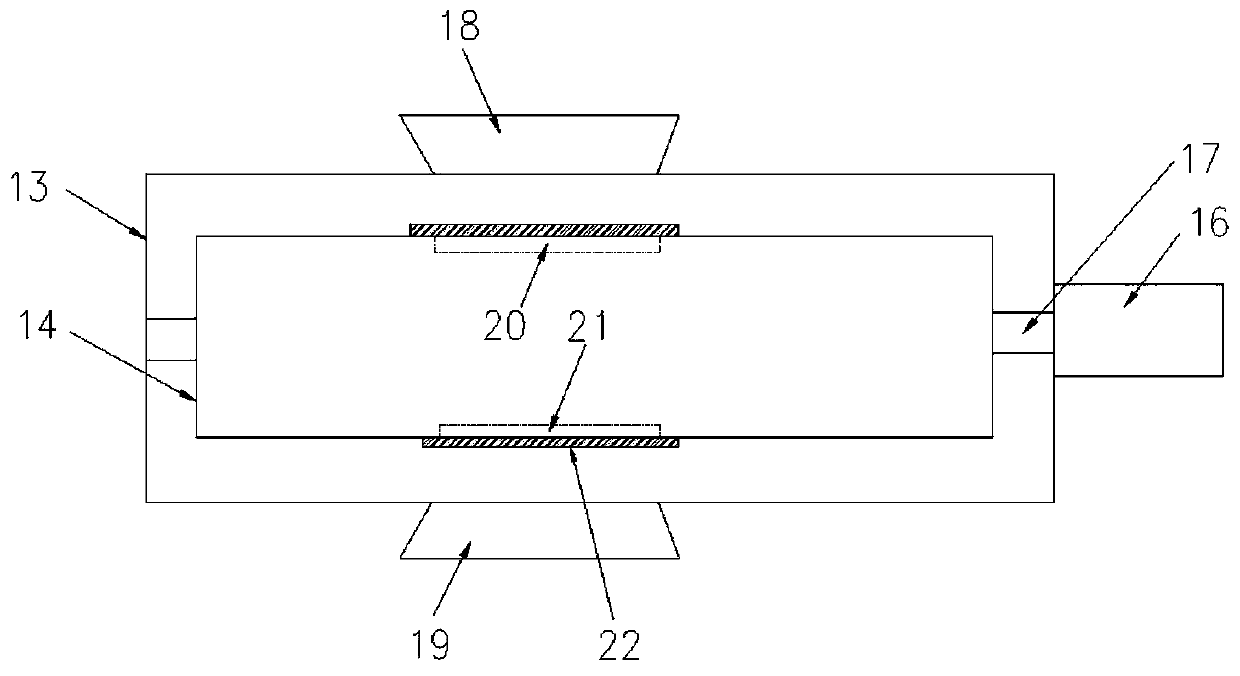

Moving device of super-audio frequency induction heating equipment

PendingCN112746148AConvenience for subsequent useEffective regulationIncreasing energy efficiencyCleaning using toolsPhysicsAudio frequency

The invention relates to a moving device of super-audio frequency induction heating equipment, which comprises a bottom plate, a moving device, super-audio frequency induction heating equipment and a heating coil, wherein the moving device is mounted at the upper end of the bottom plate, the super-audio frequency induction heating equipment is mounted above the moving device, and the heating coil is mounted in the moving device; and the heating coil is electrically connected to the super-audio frequency induction heating equipment. The moving device can solve problems that in the using process of existing super-audio frequency induction heating equipment, the moving effect is poor, use is inconvenient, the position of the heating coil cannot be effectively adjusted, the using effect of the super-audio frequency induction heating equipment is affected, and in the using process of the existing super-audio frequency induction heating equipment, oxide scales generated on the heating coil cannot be quickly removed, so that the oxide scales are accumulated on the outer surface of the coil, the heating effect of the heating coil is influenced, and subsequent quenching processing of mechanical parts is not facilitated.

Owner:安徽金骏感应加热设备有限公司

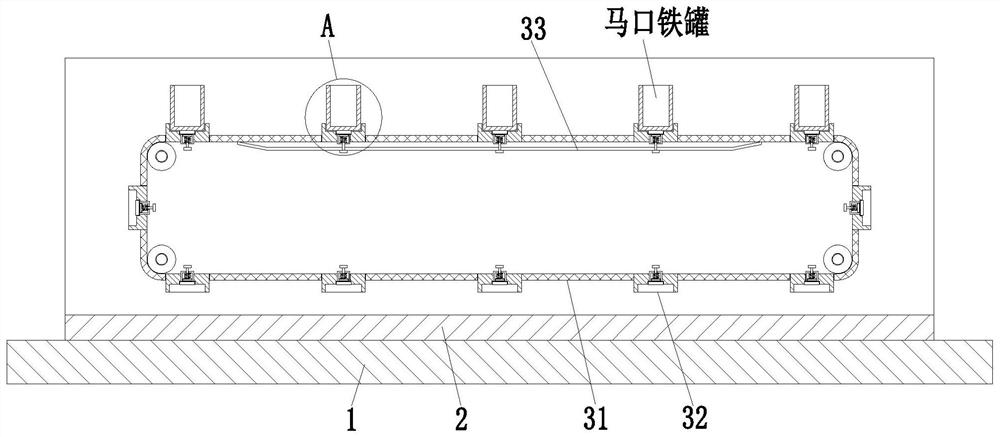

Efficient tinplate can cleaning device

PendingCN111842388AEffective positioningFacilitate subsequent collection and processingHollow article cleaningProcess engineeringIndustrial engineering

The invention relates to an efficient tinplate can cleaning device. The efficient tinplate can cleaning device comprises a bottom plate, a supporting frame and a cleaning device. The supporting frameis installed at the upper end of the bottom plate, the cross section of the supporting frame is of a U-shaped structure, and the cleaning device is installed in the supporting frame. The efficient tinplate can cleaning device can solve the problems that the shaking phenomenon is prone to happening when tinplate cans are cleaned due to the fact that when existing equipment positions the tinplate cans, the positioning effect is poor, the tinplate cans cannot be automatically loosened after being cleaned, the subsequent collection processing of the tinplate cans is not facilitated, the subsequentusing effect of the tinplate cans is affected due to the fact that when the existing equipment cleans the interiors of the tinplate cans, the cleaning effect is poor and incomplete, the tinplate canswith different diameters cannot be cleaned, and the cleaning efficiency of the tinplate cans is reduced.

Owner:合肥铂特精密工具有限公司

Package yarn winding equipment and package yarn winding process

Owner:兰溪市文萱纺织有限公司

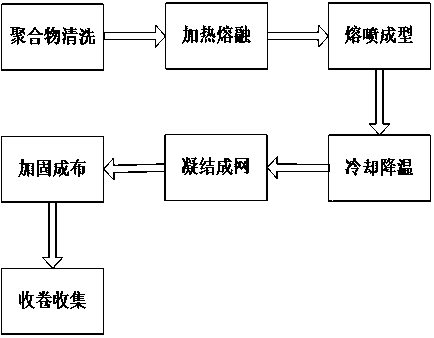

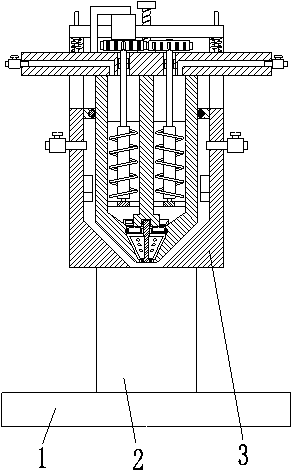

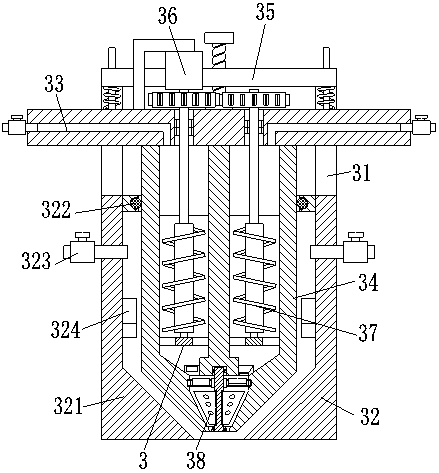

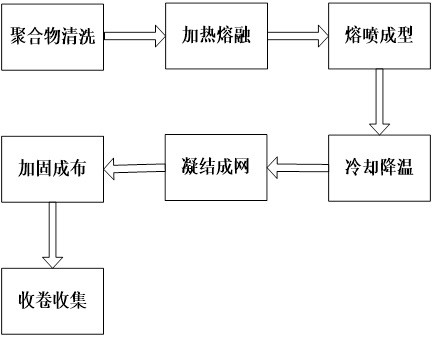

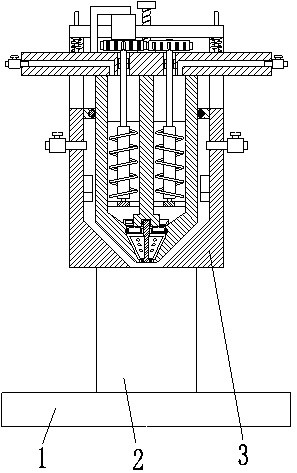

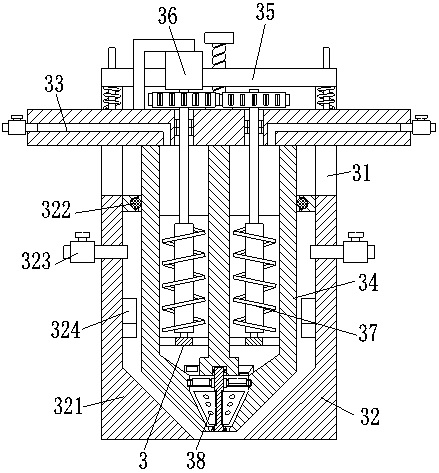

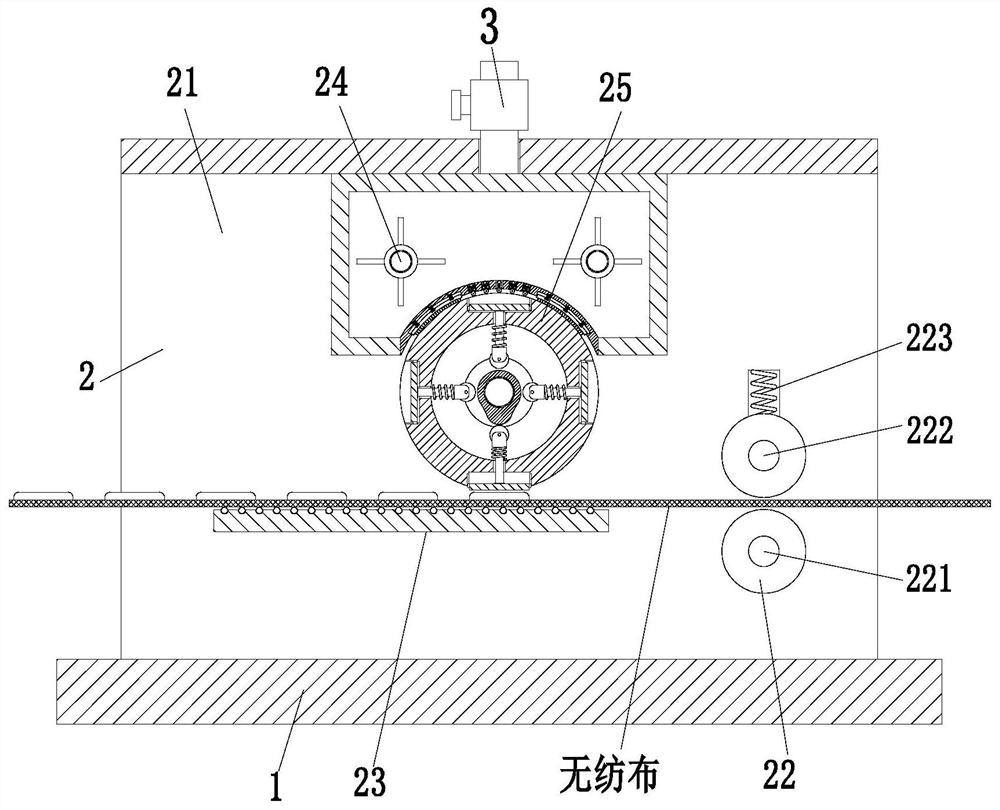

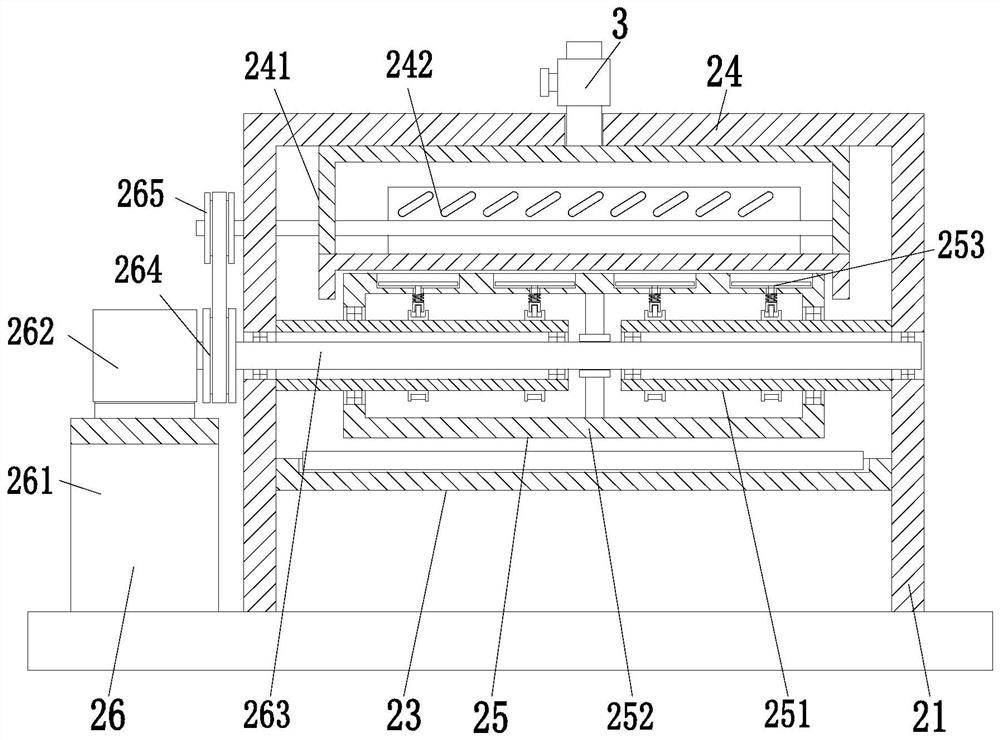

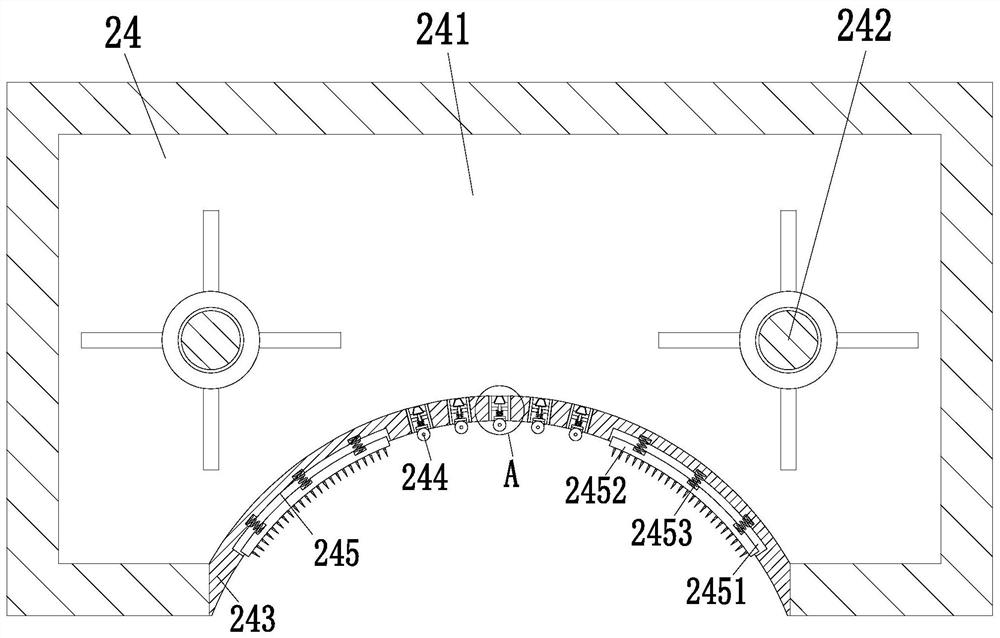

Production and processing method of medical melt-blown non-woven fabric

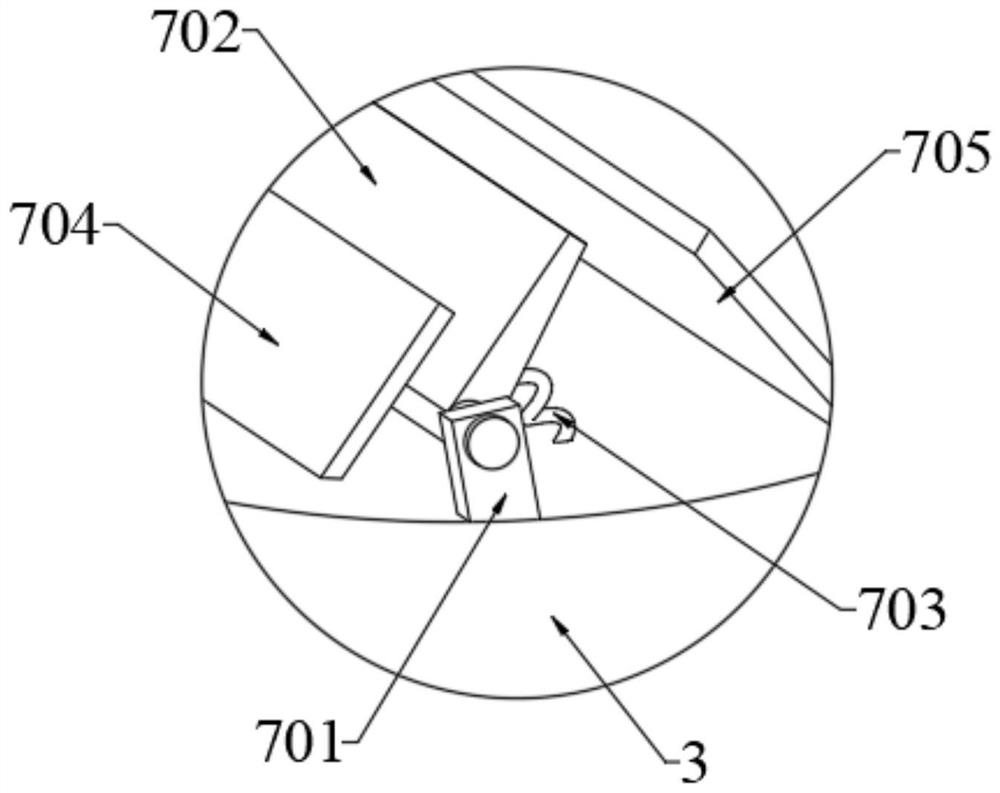

ActiveCN111593488AUniform distribution of fiber thicknessImprove processing efficiencySpinning head liquid feederMelt spinning methodsWoven fabricMelt blowing

The invention relates to a production and processing method of medical melt-blown non-woven fabric. The production and processing method of the medical melt-blown non-woven fabric comprises a base plate, supporting frames and a melt-blowing device, wherein the supporting frames are symmetrically mounted at the upper end of the base plate, and the melt-blowing device is mounted between the upper ends of the supporting frames. By the adoption of the production and processing method of the medical melt-blown non-woven fabric, the problems that when an existing device is used for processing melt-blown non-woven fabric, the air speed during melt blowing cannot be accurately regulated generally, hot air cannot be effectively and uniformly dispersed during melt-blowing, and consequentially, the thickness distribution of fibers after melt-blowing is not uniform, and the subsequent usage effect of the non-woven fabric is affected; and meanwhile, when the existing device is used for processing the melt-blown non-woven fabric, melt-blown polymers cannot be effectively, uniformly and rapidly mixed generally, and consequentially, the melt-blown polymers are likely to be layered, and the qualityand effect of the non-woven fabric are affected are solved.

Owner:SHANGHAI MINGGUAN PURIFICATION MATERIALS

Processing device of cement based enamel paint

InactiveCN109464936AShorten production timeMaintain its own functional characteristicsTransportation and packagingRotary stirring mixersEngineeringMoisture

The invention provides a processing device of cement based enamel paint. The processing device comprises a base raw material tank, an auxiliary raw material tank, a mixed processing tank and a moisture and pressure maintaining mechanism, wherein the base raw material tank and the auxiliary raw material tank are communicated to the mixed processing tank through a base raw material pipe and an auxiliary raw material pipe respectively, and feeding pumps are mounted on the base raw material pipe and the auxiliary raw material pipe in a matched manner; a stirring mechanism is arranged in the mixedprocessing tank in a matched manner, a discharging pipe is communicated with the bottom of the mixed processing tank, and a discharging pump is mounted on the discharging pipe in a matched manner; themoisture and pressure maintaining mechanism comprises a moisture and pressure maintaining casing, a moisture maintaining and heating mechanism and a pressure maintaining mechanism. According to the processing device, mixed processing and finished product storage of the cement based enamel paint are integrated, so that not only is making time of the cement based enamel paint greatly shortened, butalso functional characteristics of raw materials and a finished cement based enamel paint product can be kept all the time in processing and storing processes, the follow-up use effect is guaranteed,and meanwhile, the processing device is novel in structure, convenient to produce and make and moderate in cost and has good market prospect.

Owner:滁州科林新材料科技有限公司

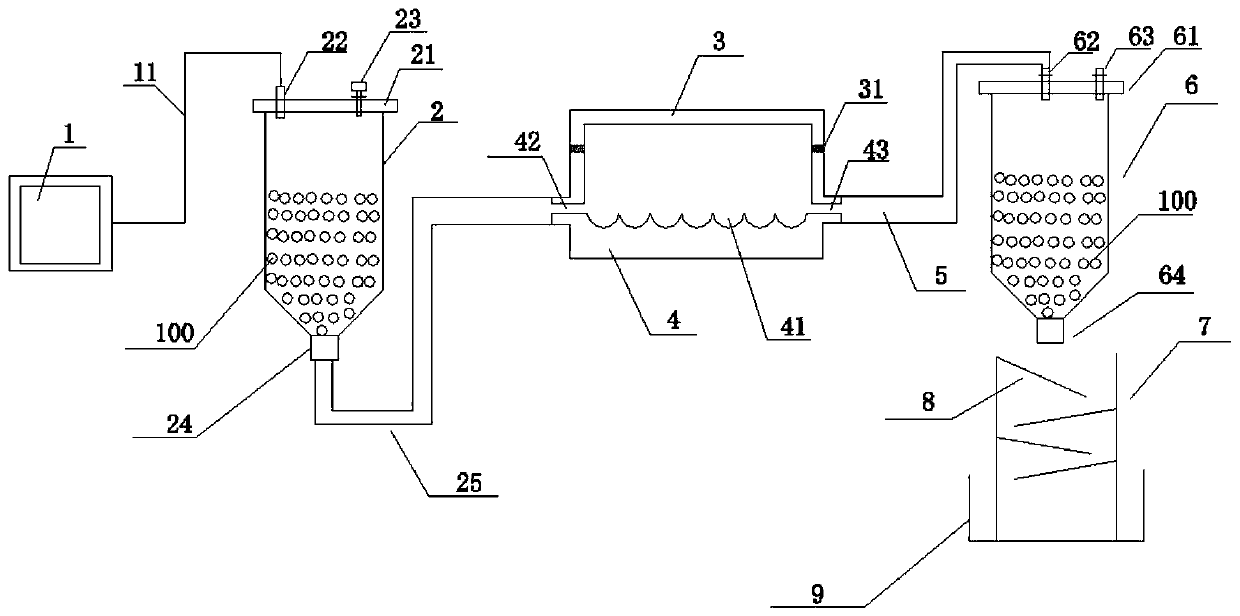

Industrial wastewater treatment device with self-cleaning function

InactiveCN112759154AAutomate cleaningGuarantee the effect of subsequent useSpecific water treatment objectivesTreatment involving filtrationIndustrial effluentElectric machinery

The invention discloses an industrial wastewater treatment device with a self-cleaning function, which comprises a disinfection mechanism, a collecting mechanism for collecting impurities, a conveying mechanism, a knocking mechanism, a filtering mechanism and a neutralizing mechanism, the collecting mechanism is arranged on the side surface of the disinfection mechanism, the conveying mechanism is arranged above the disinfection mechanism, the knocking mechanism is fixed on the conveying mechanism, the filtering mechanism is arranged on one side of the conveying mechanism, and the neutralizing mechanism is arranged on one side, far away from the conveying mechanism, of the filtering mechanism. By arranging the filtering mechanism, when impurities in filter cloth need to be cleaned, a second motor drives a rotating disc to rotate through a second rotating shaft, the rotating disc drives filter cloth to rotate by 180 degrees, a third motor drives a connecting disc to rotate through a third rotating shaft, the connecting disc drives the filter cloth to turn over by 180 degrees, impurities in the filter cloth enter a conveying box under the action of gravity, the impurities can be automatically cleaned, and time and labor are saved.

Owner:陈俊安

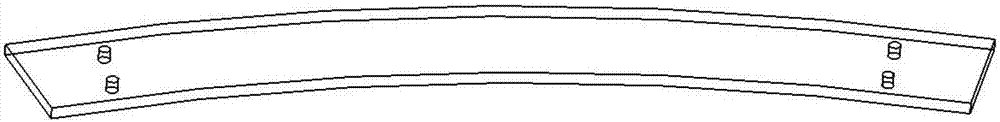

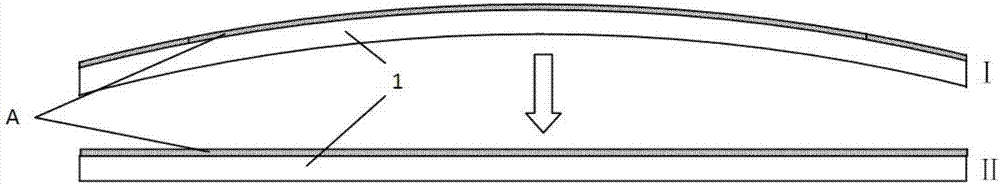

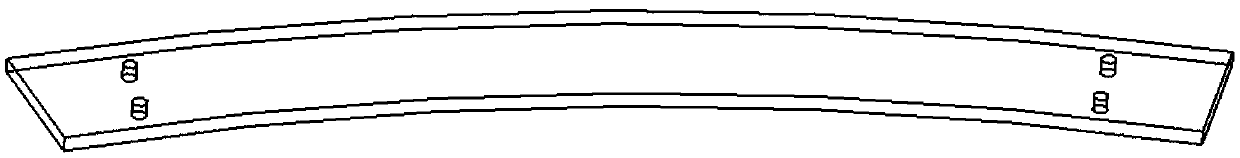

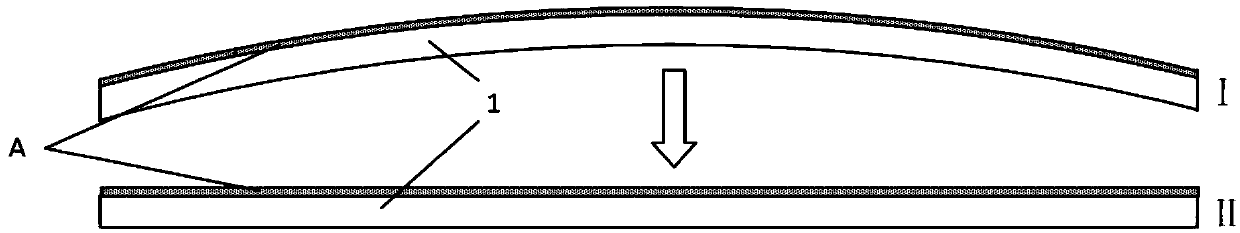

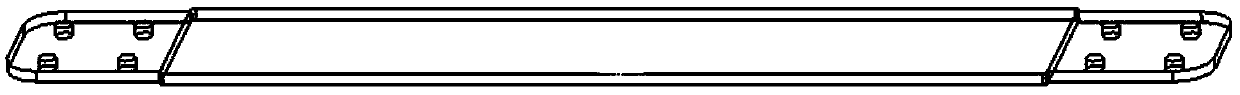

High velocity oxy-fuel sheet type part deformation compensation method

ActiveCN107267907AImprove flatness geometric toleranceGuarantee the effect of subsequent useMolten spray coatingEfficient propulsion technologiesThermal sprayingHigh velocity

The invention relates to a thermal spraying sheet type part deformation compensation method, in particular to a high velocity oxy-fuel sheet type part deformation compensation method. In the sheet type part high velocity oxy-fuel coating process, part deformation is caused by reasons of heat input and particle impact, the manner that high velocity oxy-fuel high-melting metal oxide treatment is carried out on the sheet type part non-spraying surface is adopted, the oxide melting point, the particle size and the technological process parameters are controlled, under the condition that metallic oxide deposition is not achieved, the part deformation process of the sheet type part high velocity oxy-fuel coating during heat input and particle impact is simulated to the maximum degree, and deformation compensation of the sheet type part obtained after coating spraying is achieved. The method effectively solves the problem that deformation offset compensation of the high velocity oxy-fuel sheet type part through methods such as metal plate, heat treatment and shot blasting are adopted for is difficult, and high velocity oxy-fuel sheet type part deformation compensation is achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Electric connector capable of improving signal quality

PendingCN114430132AGuaranteed stabilityReduce difficultyIncorrect coupling preventionTwo-part coupling devicesSignal qualityElectrical connection

The invention discloses an electric connector capable of improving signal quality, and belongs to the technical field of electric connectors, the electric connector capable of improving signal quality comprises an electric connection socket and an electric connection plug, the electric connection socket and the electric connection plug are respectively provided with an outer sleeve and a matching sleeve, and the bottom wall of the inner cavity of the outer sleeve is fixedly connected with a positioning cylinder; two limiting plates are arranged on the outer surface of the matching sleeve in an annular array mode, and two limiting mechanisms used for limiting rotation of the limiting plates are arranged on the side wall of an inner cavity of the outer sleeve in an annular array mode. According to the scheme, the electric connection plug and the electric connection socket can be conveniently plugged through the limiting mechanism, plugging in some narrow and special places is facilitated, the labor intensity is reduced, and the working efficiency is remarkably improved; and meanwhile, by fixing the fixed seat, the situation that the electric connection plug is separated from the electric connection socket due to pulling or external factors in the subsequent use process can be prevented, the subsequent use effect can be ensured, and the signal connection quality is improved.

Owner:DONGGUAN YUXI PRECISE CONNECTOR

A kind of production and processing method of medical melt-blown non-woven fabric

ActiveCN111593488BGuarantee the effect of subsequent useSpread evenlySpinning head liquid feederMelt spinning methodsNonwoven fabricPolymer

Owner:SHANGHAI MINGGUAN PURIFICATION MATERIALS

A waterproof coating preparation and processing system

InactiveCN111773953BImprove production efficiencyImprove filtering effectRotary stirring mixersTransportation and packagingPhysical chemistryEngineering

The invention relates to a waterproof paint preparation and processing system, which comprises a base plate, a support frame and a mixing device. A support frame is evenly installed on the top of the base plate, and a material mixing device is installed between the upper ends of the support frames, and the material mixing device is located above the base plate. . The present invention can solve the problem that the existing equipment cannot effectively filter the large particles of impurities in the raw materials when preparing the paint, the filtering effect is poor and the efficiency is low, and the large particles of impurities are easy to accumulate inside the filter screen, resulting in the impurities being easily Block the mesh of the filter screen, and when the existing equipment is preparing the coating, it cannot effectively mix the filtered raw materials evenly, the mixing effect is poor, and the subsequent use of the coating is affected.

Owner:陕西喜嘉彩新型材料有限公司

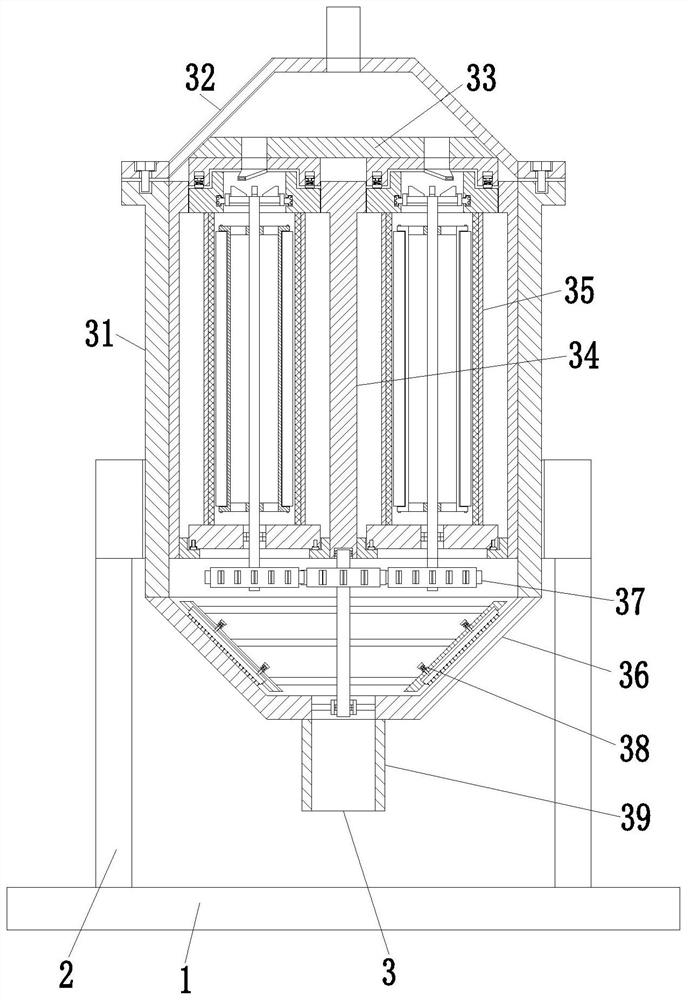

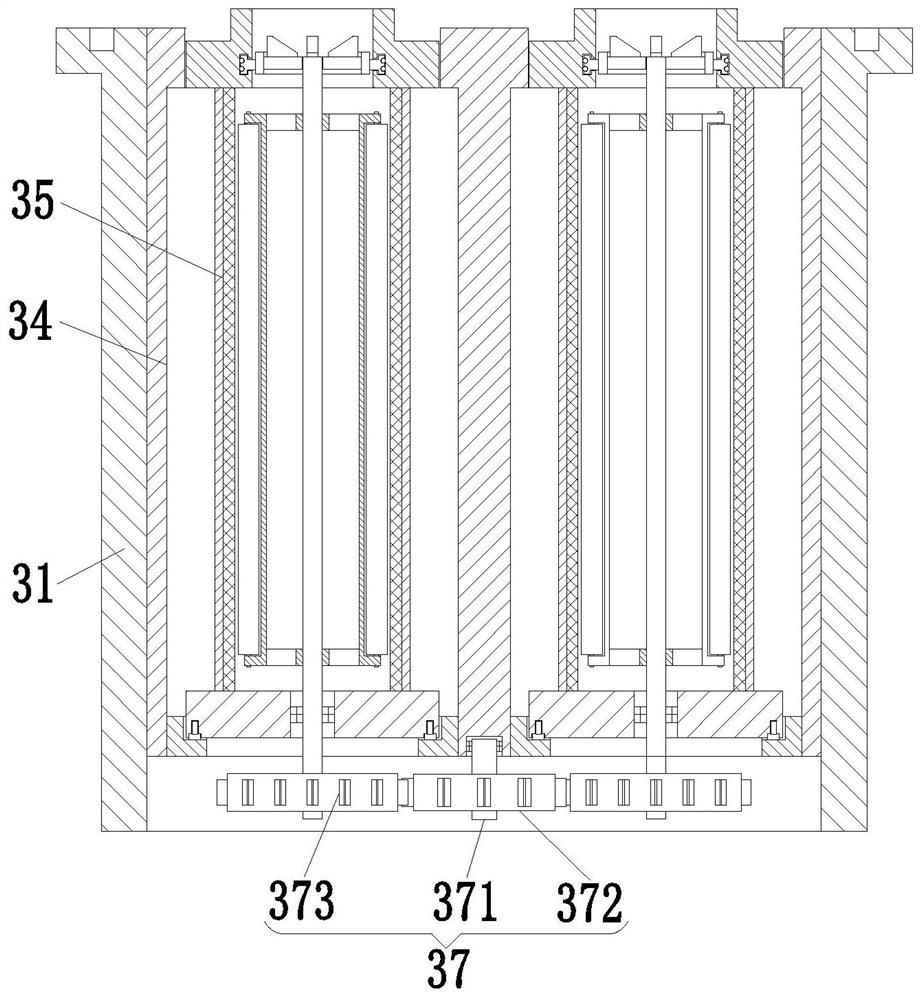

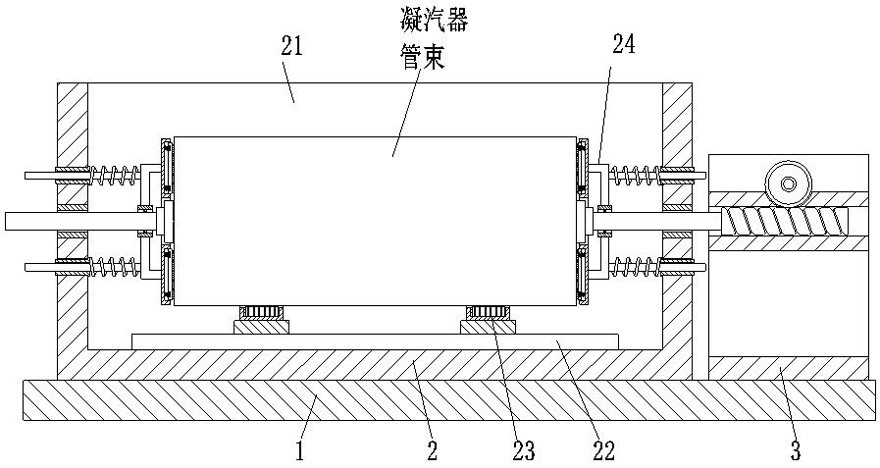

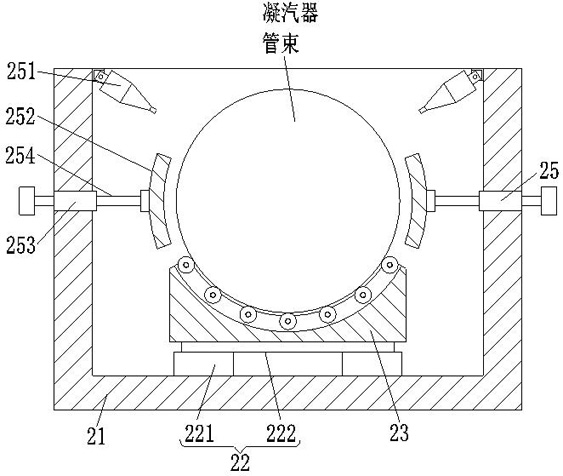

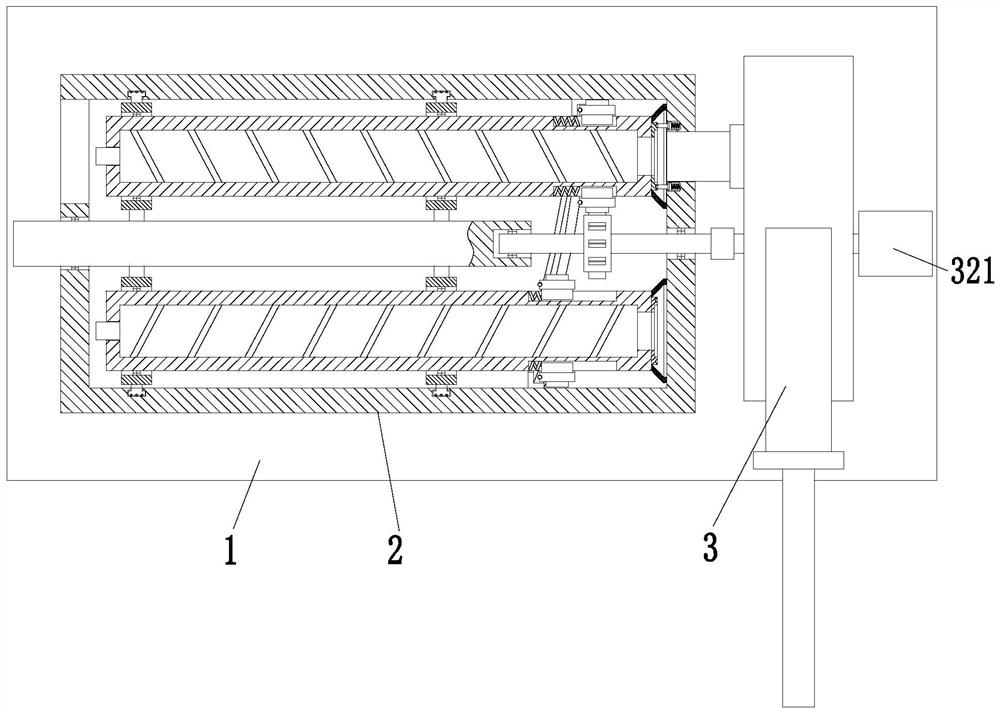

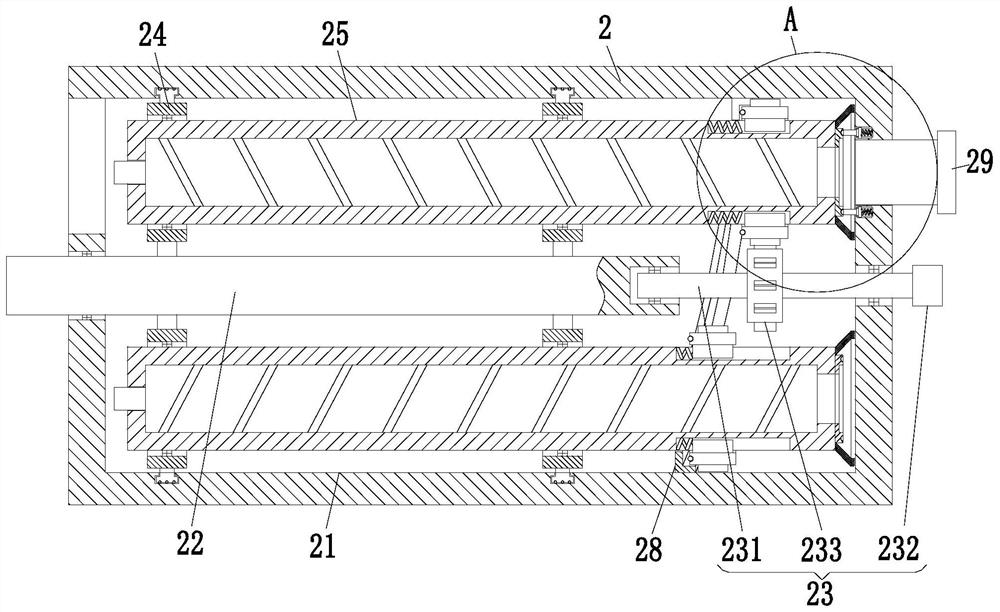

A condenser online cleaning device

ActiveCN112524992BFully contactedEffective flushingFlush cleaningNon-rotary device cleaningEngineeringCleansing Agents

The invention relates to an on-line cleaning device for a condenser, comprising a base plate, a cleaning device and a rotating device. The cleaning device is installed on the upper left side of the base plate, the rotating device is installed on the right side of the cleaning device, and the lower end of the rotating device is installed on the base plate. The invention can solve the problem that when the existing equipment cleans the condenser tube bundle, usually only the cleaning agent is injected into the inside of the condenser, resulting in poor cleaning effect and uneven cleaning of the condenser, and the condenser tube bundle after cleaning There is a large amount of scale attached to the top, which affects the subsequent use of the condenser. Moreover, when the existing equipment cleans the condenser tube bundle, it is usually unable to rotate the condenser tube bundle, resulting in the condenser tube bundle and Insufficient contact of the cleaning agent affects the cleaning effect of the condenser and other problems.

Owner:山东金诺电力科技有限公司

A high-efficiency cotton filling machine

ActiveCN114057150BEasy to fillEasy to replaceUpholstery manufactureProcess engineeringMechanical engineering

The invention relates to a high-efficiency cotton filling machine, which comprises a bottom plate, a feeding device and a cotton filling device. A feeding device is installed on the upper left side of the bottom plate, and a cotton filling device is installed on the upper right side of the bottom plate. device is connected. The present invention can solve the problem that when the existing equipment is used, it can usually only be filled with fillers of one material, the filling effect is poor, the replacement is inconvenient, and the phenomenon of mixing is prone to occur, which affects the subsequent use effect of the toy, and the existing When the equipment is in use, the sealing effect is usually poor, which leads to the leakage of the filling during the filling process, which makes the filling easy to waste and affects the filling effect of the equipment.

Owner:阜阳和益鞋业有限公司

Pretreatment and detection method of biogenic amine neurotransmitter, and detection kit

ActiveCN104678028BReduce the impact of follow-up testingRaise the ratioOrganic chemistryBiological pumpMetabolite

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

Coating equipment for the production of antipyretic stickers

ActiveCN111659579BIncrease productivityGood for coating processLiquid surface applicatorsSpraying apparatusNonwoven fabricMechanical engineering

The invention relates to a coating equipment for cooling plaster production, which comprises a base plate, a coating device and a feeding pipe. A coating device is installed in the middle of the upper end of the base plate, and a feeding pipe is installed at the upper end of the coating device. The feeding pipe The lower end is connected with the coating device, and the upper end of the feeding pipe is connected with an external material pump. The present invention can solve the problem of poor coating effect and uneven application when the existing equipment is coating the gel raw material, and cannot effectively and accurately coat the gel raw material on the non-woven fabric, which affects the antipyretic patch. At the same time, when the existing equipment is coating the gel raw material, a large amount of impurities are usually adhered to the surface of the coating roller, and the impurities of the impurities cannot be removed quickly, causing the impurities to dry and easily adhere to the coating. On the coating roll, it will affect the subsequent use effect of the coating roll and other problems.

Owner:阜阳市贤信堂药业有限公司

Air gap magnetic core burr removing mechanism and application method thereof

PendingCN110202483AImprove removal efficiencyLabor savingAbrasive machine appurtenancesAbrasive blasting machinesProduction lineProcess efficiency

The invention discloses an air gap magnetic core burr removing mechanism. The air gap magnetic core burr removing mechanism comprises an air source, a ceramsite release tank, a burr removing cavity, aceramsite recovery tank and a ceramsite recovery and regeneration device; the air source is connected with a release tank air inlet of the ceramsite release tank through a first guide pipe; the burrremoving cavity comprises an upper cavity and a lower cavity; a removing cavity air inlet and a removing cavity air outlet are respectively formed in the two ends of the lower cavity; a ceramsite tankexhaust port of the ceramsite release tank is connected with the removing cavity air inlet through a second guide pipe; the removing cavity air outlet is connected with a recovery tank air inlet of the ceramsite recovery tank through a third guide pipe; and a waveform curve structured combined groove is formed in the air gap relative position of an air gap magnetic core in the burr removing cavity in the lower cavity. The air gap magnetic core burr removing mechanism uses a production line process device for replacing a traditional file manual burr removing mode, so that the manpower is saved, the labor cost is reduced, the burr removing efficiency can be improved by above 3 times, and the process efficiency is greatly improved.

Owner:无锡集磁科技有限公司

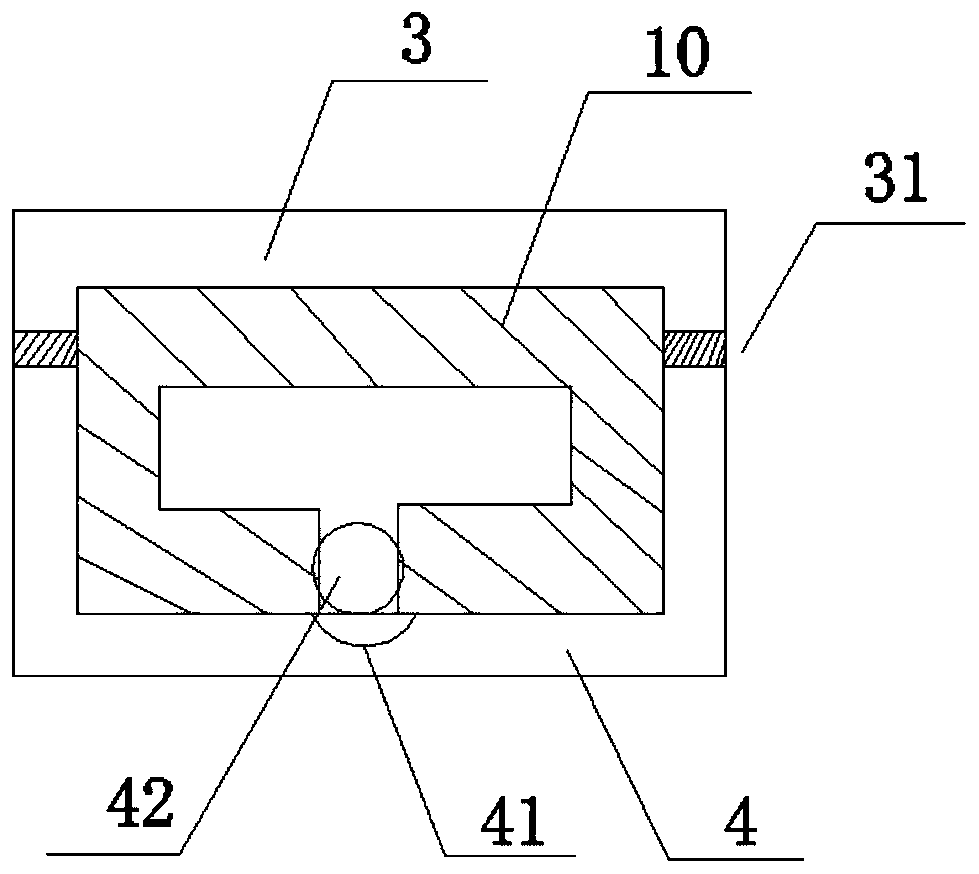

Fine sand recycling and dewatering integrated machine

PendingCN111495857ANovel structural designGuarantee the effect of subsequent useDrying solid materials without heatCleaning using liquidsElectric machineryProcess engineering

The invention discloses a fine sand recycling and dewatering integrated machine. The fine sand recycling and dewatering integrated machine comprises a stirring mechanism, a conveying mechanism and a dewatering mechanism; the stirring mechanism comprises a barrel, a stirring shaft, spiral stirring blades and a motor; a barrel cover is installed on the barrel, a feeding hopper is arranged on the barrel cover, the stirring shaft is installed in the barrel, and the spiral stirring blades are welded to the outer wall of the stirring shaft; the motor is installed on the barrel cover and is in transmission connection with the stirring shaft; a discharge hole is formed in bottom of barrel; the conveying mechanism comprises a supporting frame, a conveying wheel and a conveying belt; the conveying wheel is fixed to the supporting frame, and the conveying belt is wound around the conveying wheel; and a plurality of through holes are evenly distributed in the conveying belt, a fine filter screen is installed on the inner side of the conveying belt, and the conveying belt is located under the discharging hole. The fine sand recycling and dewatering integrated machine is novel in structural design and can realize quick cleaning, water filtration and dehydration of fine sand, and the subsequent use effect of the fine sand can be ensured.

Owner:春晖(南通)环保科技有限公司

A Deformation Compensation Method for Thin Plate Parts by HVOF Spraying

ActiveCN107267907BImprove flatness geometric toleranceGuarantee the effect of subsequent useMolten spray coatingEfficient propulsion technologiesThermal sprayingHigh velocity

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Atmosphere lamp for environmental art design and using method thereof

PendingCN114216077AThe adjustment process is cumbersomeIncreased fatigueLighting support devicesLighting elementsEnvironmental geologyStructural engineering

The invention discloses an atmosphere lamp for environmental art design and a using method thereof.The atmosphere lamp comprises a supporting rod, a sliding sleeve, a fastening bolt and a rotating rod, the sliding sleeve is arranged on the supporting rod, the fastening bolt is arranged on one side wall of the sliding sleeve, and a concave cavity is formed in the bottom end of the side wall of the sliding sleeve; and a connecting shaft is mounted in the concave cavity. The device has the beneficial effects that the connecting shaft, the rotating rod, the fastening screw and the supporting base are arranged, in the using process of the device, the connecting shaft is rotated to drive the rotating rod to rotate, then the supporting angle of the rotating rod is adjusted, after adjustment is completed, the connecting shaft is fixed through the fastening screw, and then the supporting base makes contact with the ground; in this way, the stability of the device during use is improved by increasing the supporting area of the device, the device is prevented from toppling over due to external force, the subsequent use performance of the device is guaranteed, the practicability of the device is improved, and the service life of the device is prolonged.

Owner:SHANDONG POLYTECHNIC COLLEGE

A self-radiating rare earth permanent magnet synchronous motor

ActiveCN111864960BReduce sizeImprove self-cooling effectCooling/ventillation arrangementSupports/enclosures/casingsElectric machinePermanent magnet synchronous motor

The invention discloses a self-radiating rare-earth permanent magnet synchronous motor, which comprises a machine compartment. A front machine cover and a rear machine cover are arranged at two ends of the machine compartment respectively, and a filter is provided at the end of the front machine cover far away from the machine compartment. Assemblies, the front machine cover is provided with a bearing B at the center of the end far away from the machine compartment, the end of the inner wall of the machine compartment far away from the front machine cover is evenly provided with connecting rods, and the ends of the connecting rods that are close to each other are jointly provided with bearings A . In the present invention, through the cooperation of the front machine cover, machine compartment, auxiliary components, fixing components and rear machine cover, when the motor is disassembled for maintenance, it is not necessary to remove too many fixing screws, and when installing the front machine cover and the rear machine cover , no need to manually support the front cover and the rear cover to keep the screws aligned with the screw holes, just insert the insert rod into the slot, which greatly improves the convenience of dismounting or installing the motor, and the auxiliary components can further improve The stability of the connection between the front cover and the rear cover and the cabin.

Owner:湖南普东科技有限责任公司

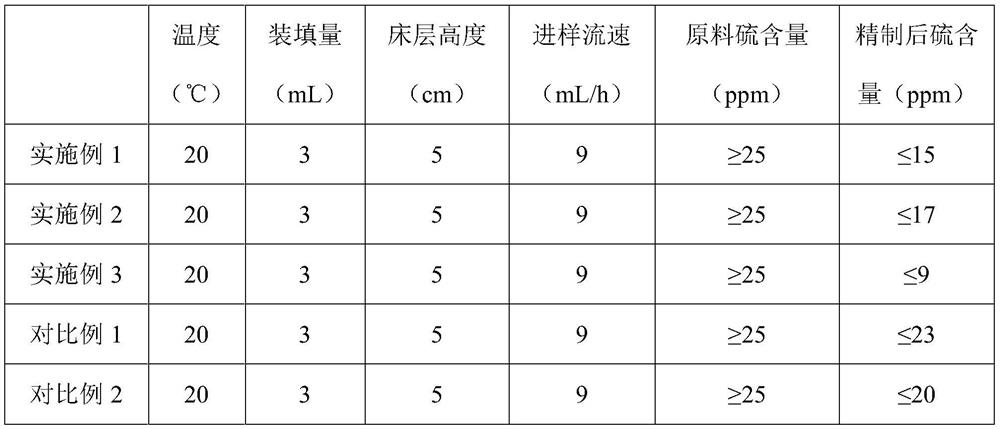

Medical intermediate desulfurizing agent and preparation method thereof

PendingCN113527100AEfficient desulfurizationGuaranteed treatment effectOrganic compound preparationCarboxylic acid esters separation/purificationPotassium hydroxideActivated Aluminum Oxide

The invention discloses a medical intermediate desulfurizing agent and a preparation method thereof. The medical intermediate desulfurizing agent comprises the components in parts by weight: 100-200 parts of an active component, 200-300 parts of a carrier and 1000-2000 parts of deionized water, wherein the active component is a composition of potassium carbonate, potassium hydroxide, sodium hydroxide, methylamine and ethylamine, and the carrier is a composition of coconut shell activated carbon, activated aluminum oxide and a ZSM-5 molecular sieve; a processing flow of the coconut shell activated carbon comprises the steps: screening raw materials, and selecting coconut shells with qualified conditions, preferably Indonesia coconut shells; and carbonizing: putting the screened coconut shells into carbonizing equipment, sintering at a high temperature to a certain degree, sealing a charcoal kiln to enable air to enter, continuously heating by using waste heat, carrying out dry distillation to enable moisture and wood tar in the coconut shells to be distilled out, and thus forming coconut shell charcoal. The medical intermediate desulfurizing agent is excellent in desulfurizing effect, the materials are easy to obtain, and the preparation method is simple to operate.

Owner:昆山市精细化工研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com