Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Fully puffed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

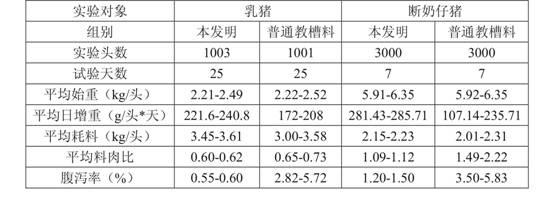

Compound feed for teaching piglets to eat foods other than breast milk

InactiveCN102178115AHealthy micro-ecological balance environmentAvoid damageFood processingAnimal feeding stuffDiseaseSucrose

The invention provides compound feed for teaching piglets to eat foods other than breast milk, which is used for weaning piglets and teaching the piglets to eat foods other than breast milk, and comprises the following components in part by weight: 212.4 parts of corn starch, 154.0 parts of bulked corn, 100.0 parts of 46 percent of bulked bean pulp, 40 parts of fish meal, 100 parts of wheat flour, 5 parts of calcium powder, 21 parts of calcium hydrophosphate, 2 parts of table salt, 20 parts of soybean oil, 5 parts of lysine, 2 parts of threonine, 1.5 parts of choline chloride, 10 parts of premix, 0.2 part of complex enzyme, 0.3 part of pig Duowei, 0.2 part of sweetener, 0.3 part of flavouring agent, 3 parts of baking soda, 20 parts of cane sugar, 30 parts of glucose, 50 parts of egg powder, 70 parts of soy protein concentrate, 50 parts of fermented bean pulp, 6 parts of acidizer, 100 parts of whey powder, 0.5 part of mould removing agent, 0.3 part of antioxidant and 0.3 part of mildewpreventive. In the invention, the problems of incomplete immune functions, low disease resistance, inadequate digestive ferment, incomplete upper gastrointestinal development, low digestion and absorption ability, susceptibility to diarrhea and the like of piglets.

Owner:AGRI SCI & TECH INST CO LTD OF CHENGDU WEST HOPE GRP

Process using organized soybean drawing protein to prepare meat analogue

InactiveCN105379943AHigh protein contentFull of nutritionCheese manufactureVegetable proteins working-upFood itemMetal

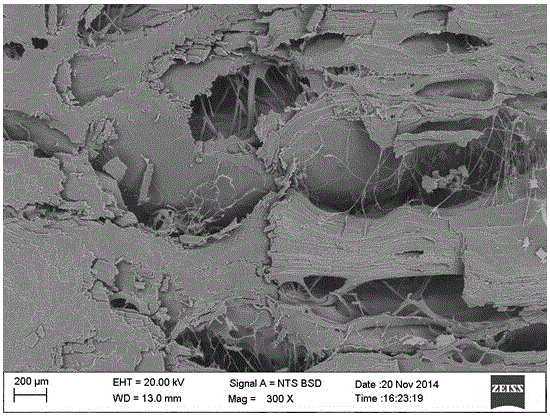

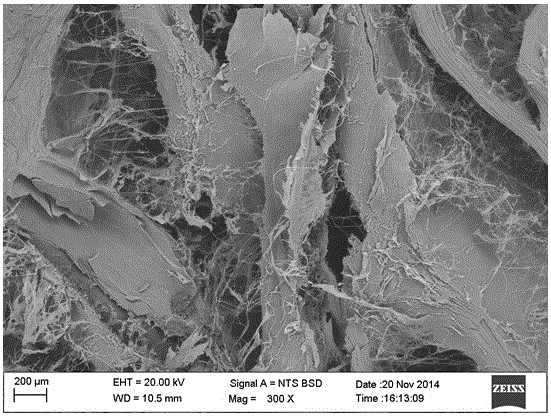

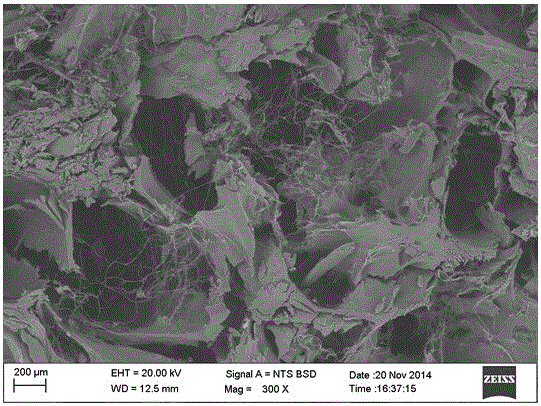

The invention belongs to the technical field of food processing, and relates to a process using organized soybean drawing protein to prepare meat analogue. The qualified meat analogue product is prepared by the following steps: picking raw materials, mixing, puffing and moulding, cutting the mound into slices, drying, soaking, dehydrating, frying the slices in oil, marinating, drying for a second time and cooling, performing vacuum packaging, sterilizing, cooling for a second time and drying for a third time, carrying out metal detection, maintaining the temperature and observing, and finally examining and picking. The meat analogue product has the characteristics of high protein content, rich nutrients, no odor, and good taste.

Owner:JIAXING HONGXIANG FOOD CO LTD

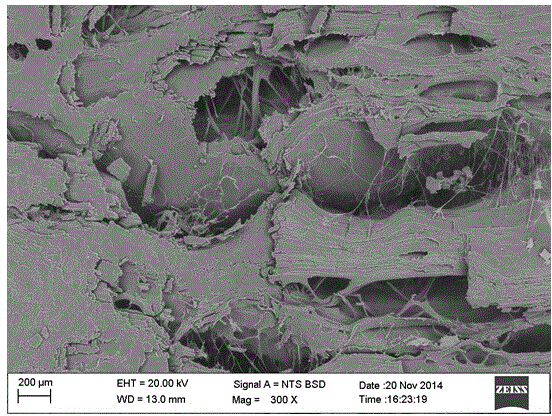

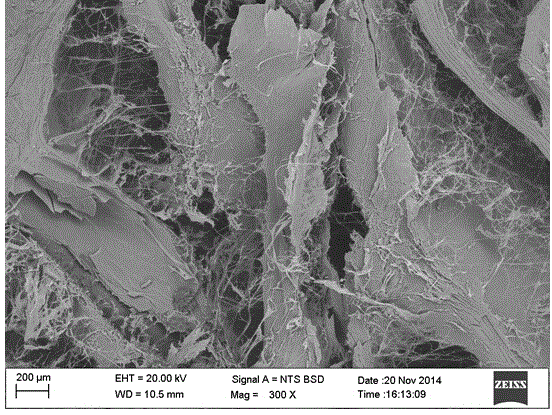

Vacuum microwave production process of meat puffing chips

ActiveCN104351819AImprove meat structureInternal tissue swellingFood shapingFood dryingFlavorMicrowave

The invention relates to a vacuum microwave production process of meat puffing chips, belonging to the technical field of deep processing of agricultural products. The production process comprises the steps of cleaning raw material meat, cutting the cleaned meat into pieces, pickling the meat pieces by pickling seasonings, pre-drying by hot air, carrying out samming treatment, and puffing and drying by vacuum microwave; finally, sterilizing by irradiation to obtain the meat puffing leisure product which is high in crispness and good in flavor. After the preparation technology is adopted, the nutritional ingredients of the raw material are maintained to the utmost extent; the meat puffing chips are crisp in mouth feel and convenient to eat. After the preparation method and the practical technology of the meat puffing chips are used, a practical and feasible new way is provided for deep processing and utilization of meat products.

Owner:南京欧旺食品科技有限公司

Starch mixed shrimp cracker and preparation method thereof

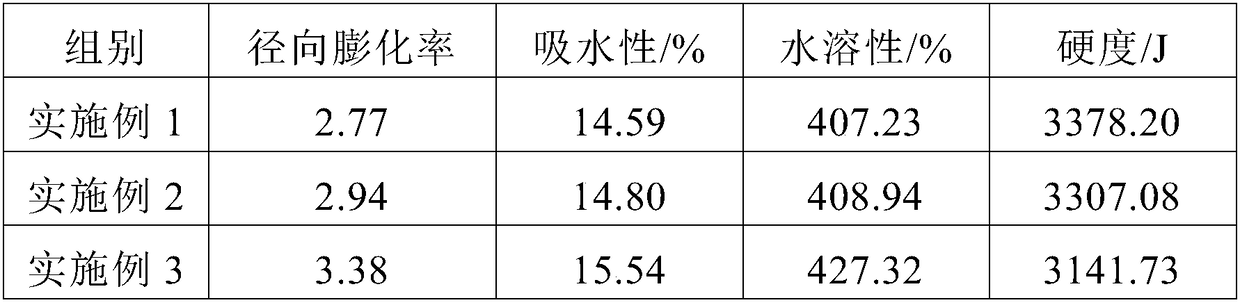

The invention discloses a starch mixed shrimp cracker, which is prepared from the following components in part by weight: 10 to 20 parts of cassava starch, 15 to 20 parts of potato starch, 70 to 85 parts of corn starch, 2 to 4 parts of shelled shrimps, 1 to 3 parts of white granulated sugar, 2 to 4 parts of refined salt, 1 to 2 parts of monosodium glutamate and 40 to 50 parts of water. The invention simultaneously discloses a method for preparing the starch mixed shrimp cracker. By controlling parameters of a co-rotating twin screw extruder, the prepared starch mixed shrimp cracker is diversified in components, comprehensive in nutrient components, good in mouthfeel, fine in appearance, healthy, safe, simple in processing technology, high in degree of automation and low in labor intensityof a worker, reduces the energy consumption and the processing cost, and can meet the requirement of development of modern enterprises and society.

Owner:NINGBO YINFA GREEN FOOD

Production method of pigskin puffed food

The invention provides a production method of a pigskin puffed food, comprising the following steps of: (1) cleaning the pigskin raw material, thoroughly cooking, scarping the meat, cutting into blank blocks; (2) boiling the pigskin blank blocks by water for 5 min, withdrawing and putting into salt to be cured for 5-10min, stoving, and drying; (3) heating edible oil to 170 DEG C, pouring a half of the heated editable oil into a container basin, placing the pigskin blank blocks into the container basin, continuously stirring, adding hot oil, so that the temperature of oil within the container basin is not lower than 160 DEG C, after 2-3min, firstly puffing the pigskin, and splashing the edible oil which is heated up to 240 DEG C onto the pigskin blank blocks which are floated out of the oil surface one by one, so that the pigskin blank blocks can be puffed again; and (4) adding condiments with different tastes as required, and packing to obtain the pigskin puffed food. According to the production method, the frying and puffing method with two different oil temperatures is adopted, so that the pigskin can be more sufficiently puffed, and the nutrient substance in the pigskin can be relatively and stably kept. The pigskin puffed food is crispy and tasty, and has the feel of just melting in the mouth.

Owner:田贵俊

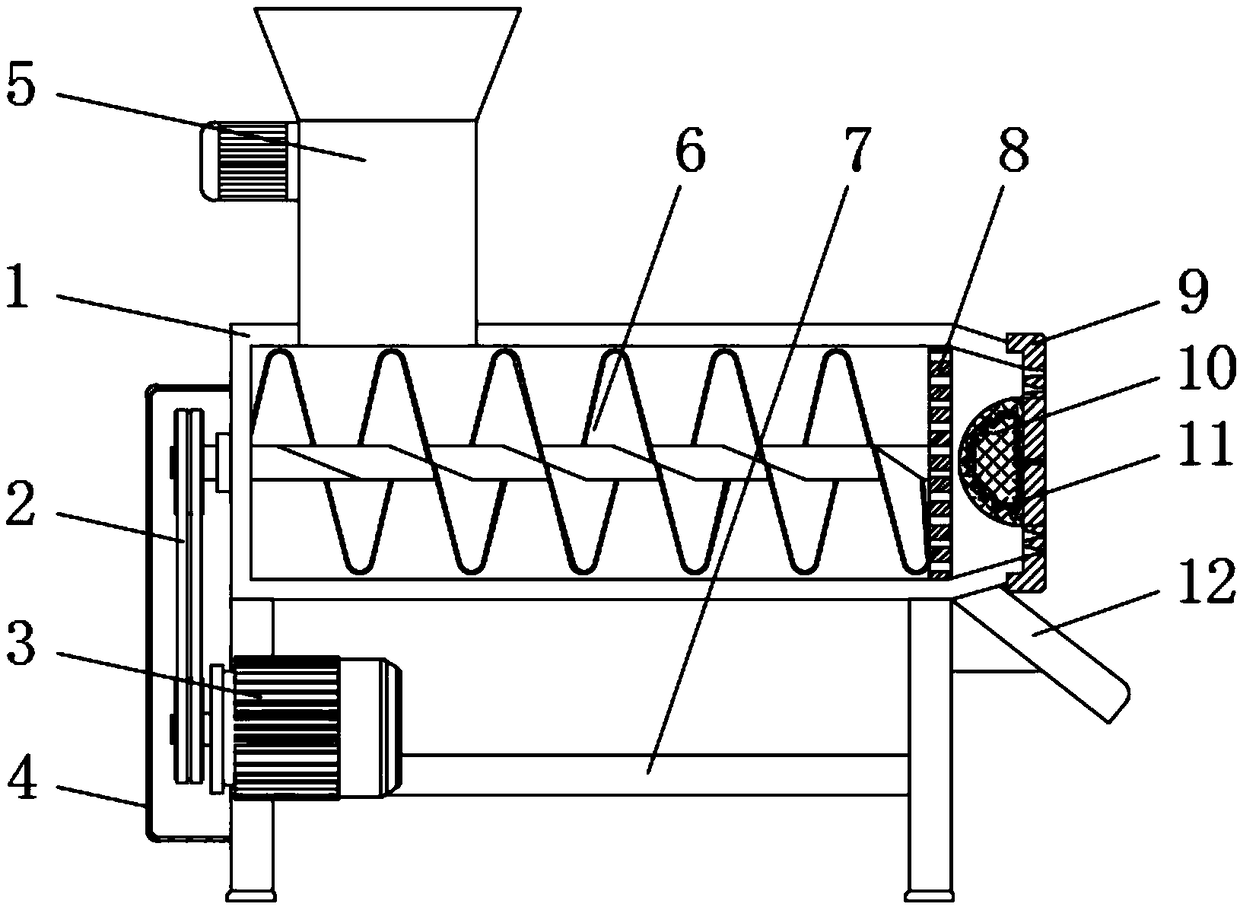

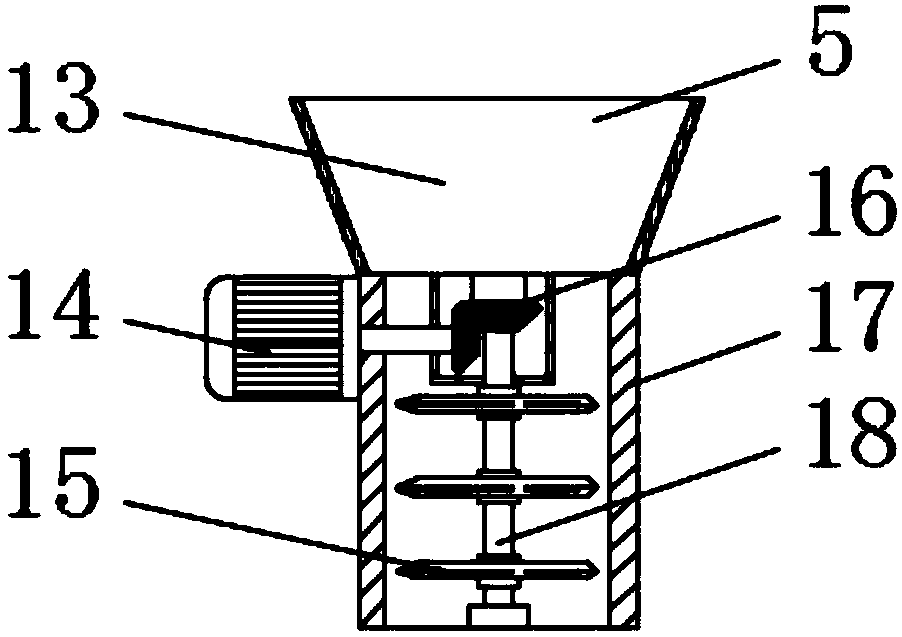

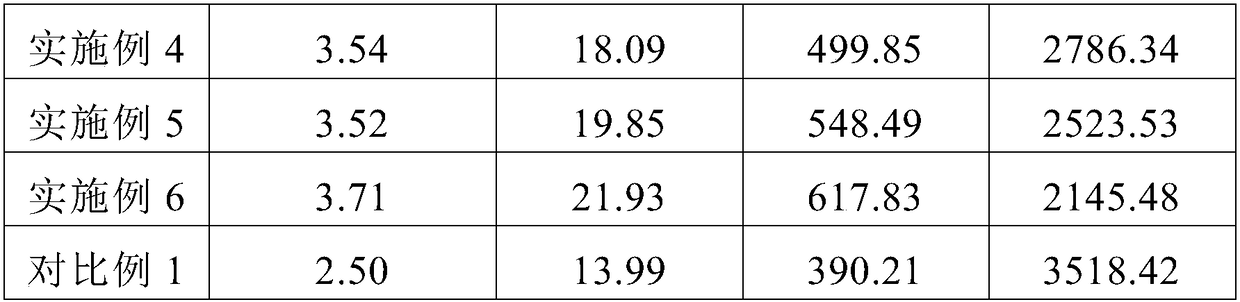

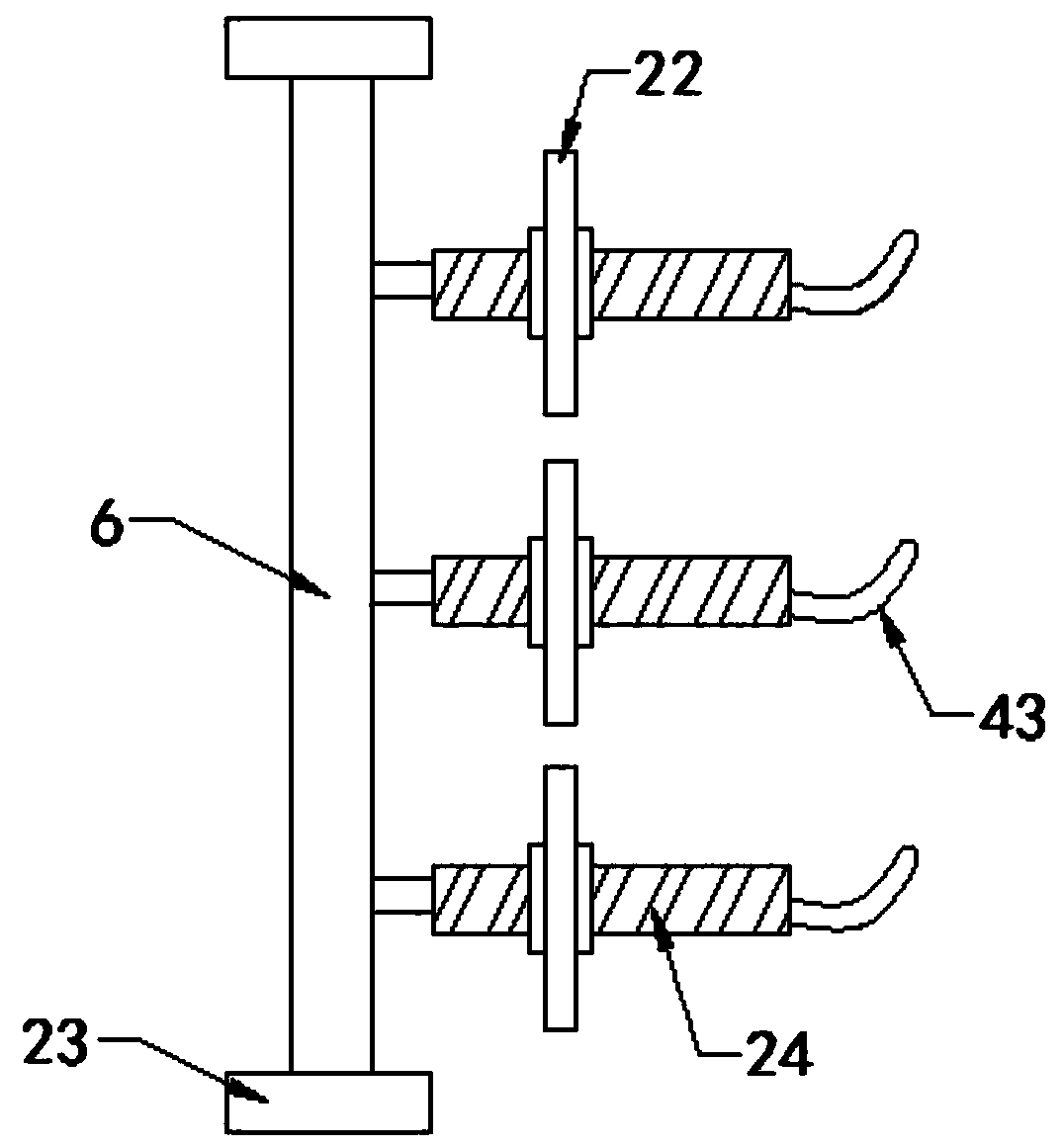

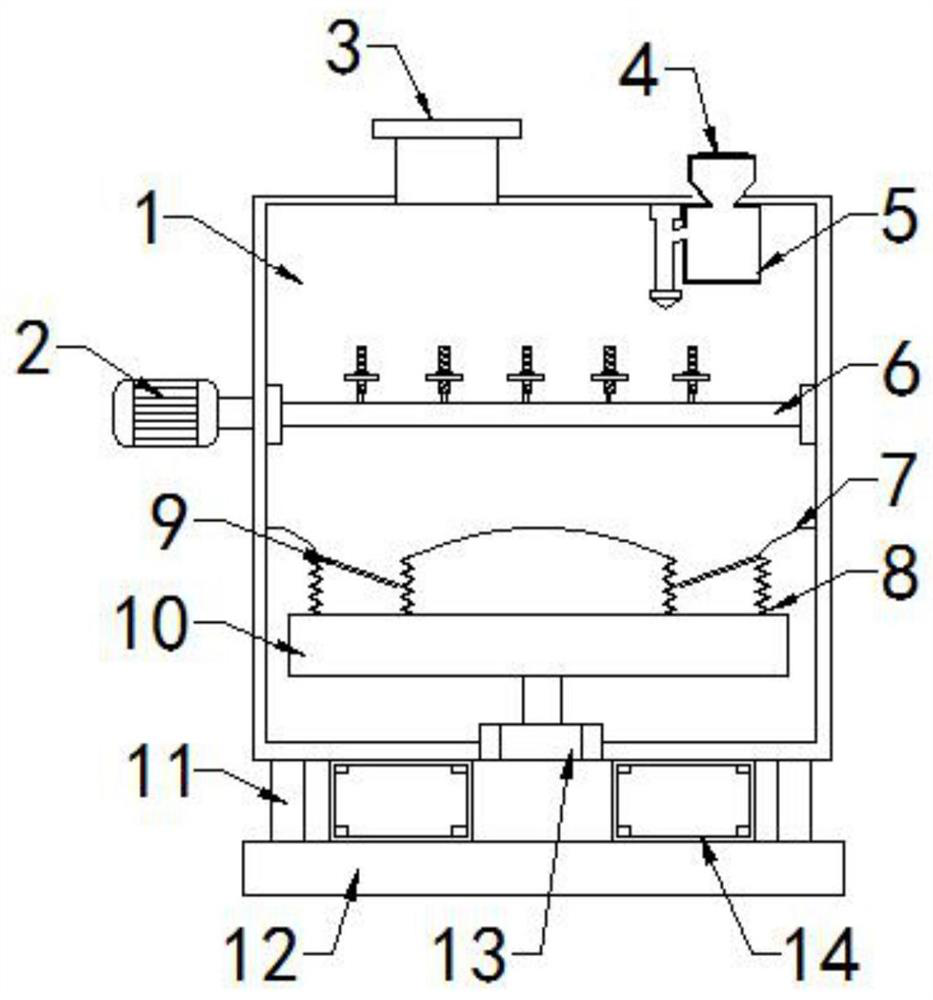

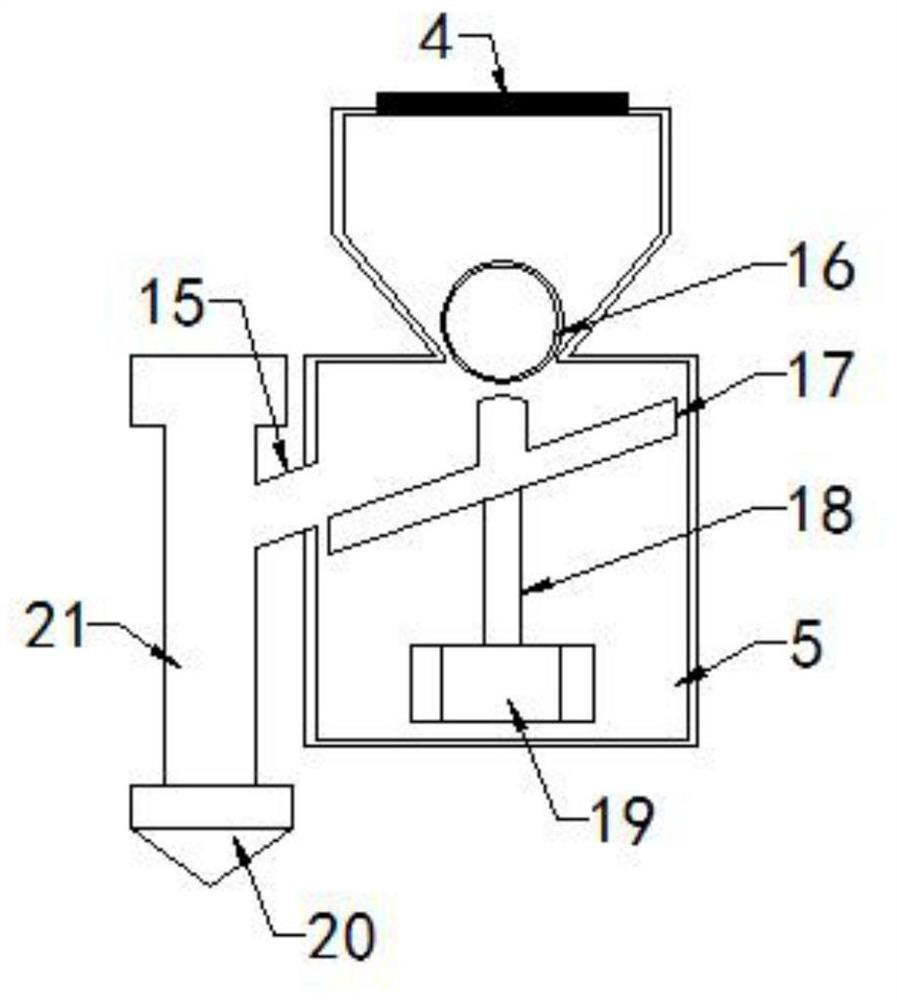

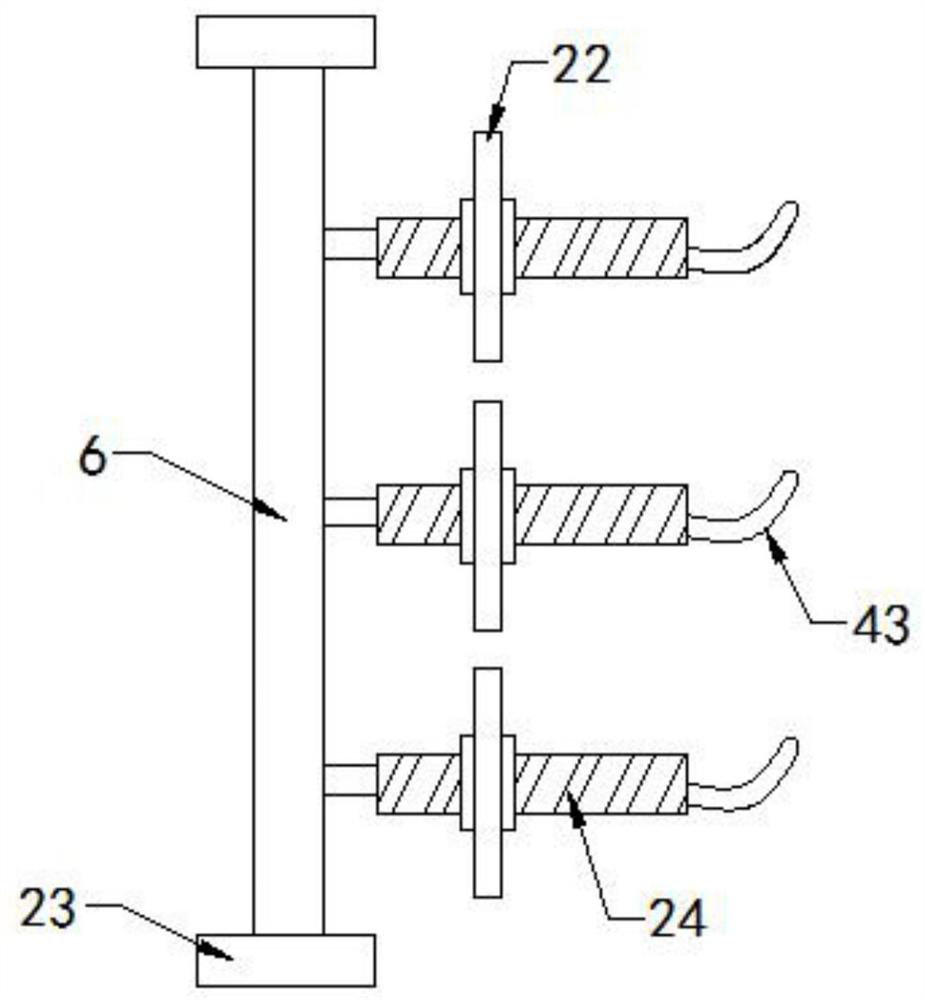

Agricultural straw extruding equipment

PendingCN108968122AEvenly heatedIncrease the heating areaFeeding-stuffCuttersEngineeringEnergy consumption

The invention discloses agricultural straw extruding equipment, which comprises an extruding chamber and a chopping mechanism. The chopping mechanism is mounted above one side of the extruding chamber, a feeding hopper is arranged above the chopping mechanism, a chopping tank is arranged below the chopping hopper, a chopping motor is mounted on one side of the chopping tank, and a bevel gear is connected to one side, in the upper portion of the chopping tank, of the chopping motor through a driving shaft. A chopping shaft is mounted at the lower end of the bevel gear, and chopping blades are mounted on the surface of the chopping shaft. Under the action of a propelling rotating shaft, refined materials in the extruding chamber are filtered through a filter plate, and uniformity in materialheating is realized; due to heating wires in a semispherical distribution projection on one side of an extruding plate, material heating area is increased, a current situation that existing straw extruding equipment depends on material friction between the propelling rotating shaft and the inner wall of the extruding chamber to generate heat is changed, and integral energy consumption is reduced.

Owner:福州立农环保科技有限公司

Dyeing preprocessing process of tatting chinlon cloth

The invention discloses a dyeing preprocessing process of tatting chinlon cloth and belongs to the technical field of fabric dyeing. The method includes the following steps of cold piling, washing and pre-fixing; in the cold piling process, the padder speed for mangling is 40-60 m / min, the immersion liquid temperature in a padder is 35-45 DEG C, and the immersion liquid contains sodium hydroxide, hydrogen peroxide, degreaser, an oil-removing yarn agent, a dispersing agent and hydrogen peroxide stabilizer. The consumption of the sodium hydroxide is 40-60 g / L, consumption of the hydrogen peroxide is 90-110 g / L, consumption of the degreaser is 8-12 g / L, consumption of the oil-removing yarn agent is 5-10 g / L, consumption of the dispersing agent is 5-10 g / L, and consumption of the hydrogen peroxide stabilizer is 5-10 g / L; in the washing process, the temperatures are 50 DEG C, 70 DEG C, 85 DEG C, 85 DEG C, 90 DEG C, 90 DEG C, 75 DEG C, 50 DEG C and 20 DEG C respectively. The dyeing preprocessing process can effectively raise the yield of the dyeing process, reduce water consumption and lower energy consumption.

Owner:ZHEJIANG YINGFENG TECH CO LTD

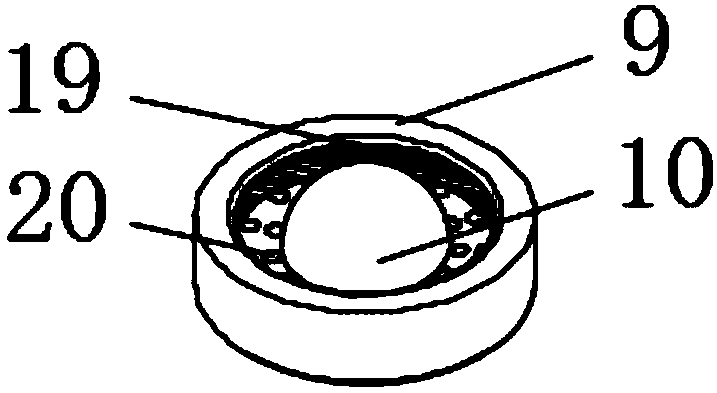

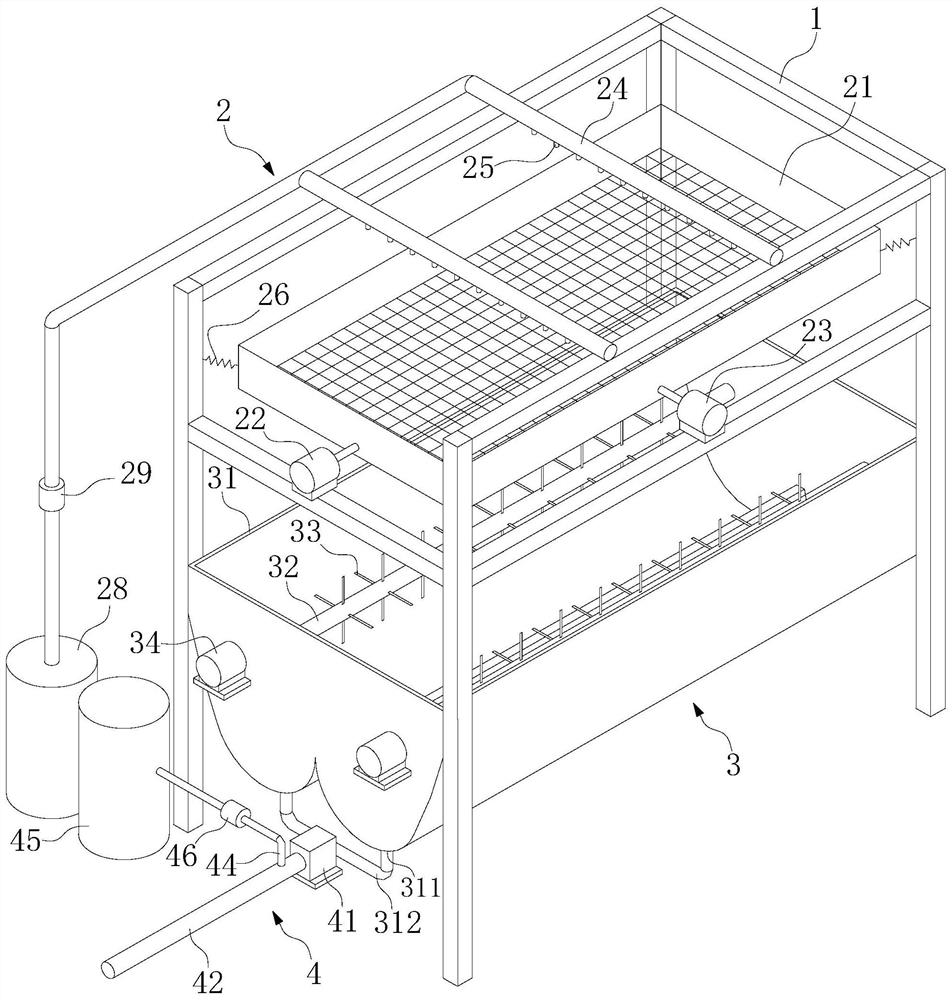

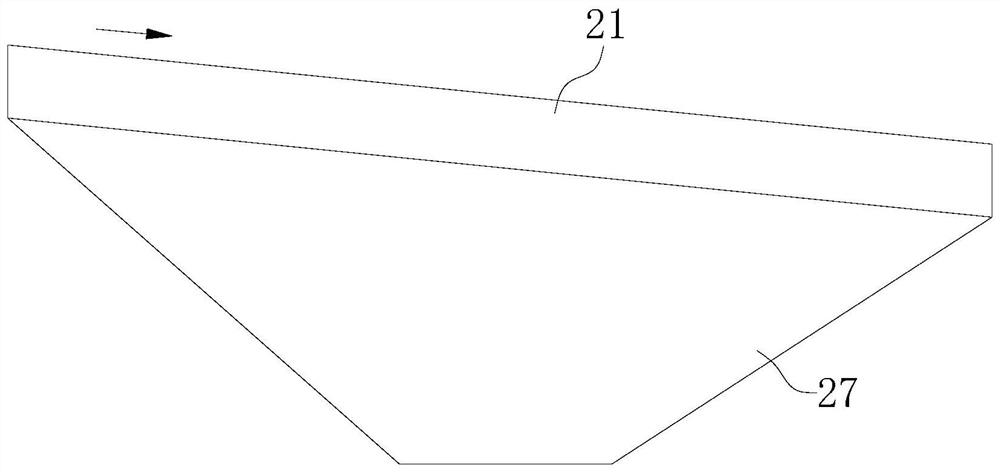

Integrated screening, curing and stirring system for shield tunneling muck and slurry

PendingCN112807816AEasy to eliminateReduce contentTransportation and packagingRotary stirring mixersElectric machineryProcess engineering

The invention discloses an integrated screening, curing and stirring system for shield tunneling muck and slurry. The system comprises a supporting frame, a screening and separating module, a collecting and stirring module and a curing agent adding and homogenizing module, wherein the screening and separating module comprises a square hole screen, a transverse vibration motor, a longitudinal vibration motor and one or more than one spraying pipe; the collecting and stirring module comprises a collecting box and a horizontal stirring device installed in the collecting box, and the collecting box is located below the square hole screen; and the curing agent adding and homogenizing module comprises a slurry pump, a conveying pipe and an automatic curing agent metering and adding device. The integrated screening, curing and stirring system of the invention realizes continuous line production of separation, homogenization, curing and stirring of coarse particles of the shield tunneling muck and the slurry; a curing agent and the slurry are uniformly mixed in the conveying pipe by virtue of the turbulent flow effect formed by the division bars in the conveying pipe, a slurry homogenization pool and a curing and stirring pool do not need to be arranged, and the system is small in occupied space and high in automation degree and provides equipment support for efficient and environment-friendly treatment of the shield tunneling muck.

Owner:中铁十局集团有限公司 +1

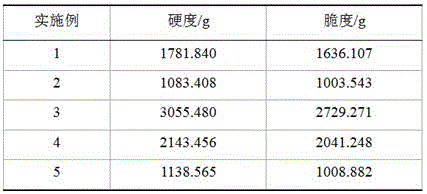

Cereal extruded puffed food and preparation technology thereof

InactiveCN108813365AFully puffedHigh nutritional valueYeast food ingredientsNatural extract food ingredientsSocial benefitsEconomic benefits

The invention discloses a cereal extruded puffed food and a preparation technology thereof. The preparation technology comprises the following steps: I) pretreatment; II) mixed blending; III) extrusion moulding; IV) baking; and V) seasoning. The cereal extruded puffed food is obtained through scientific and reasonable material selection and the preparation technology, has the characteristics of crispy mouthfeel, comprehensive nutrition, and healthy performance, increases the comprehensive value of cereal, and generates large social benefit and economic benefit.

Owner:曾杨列

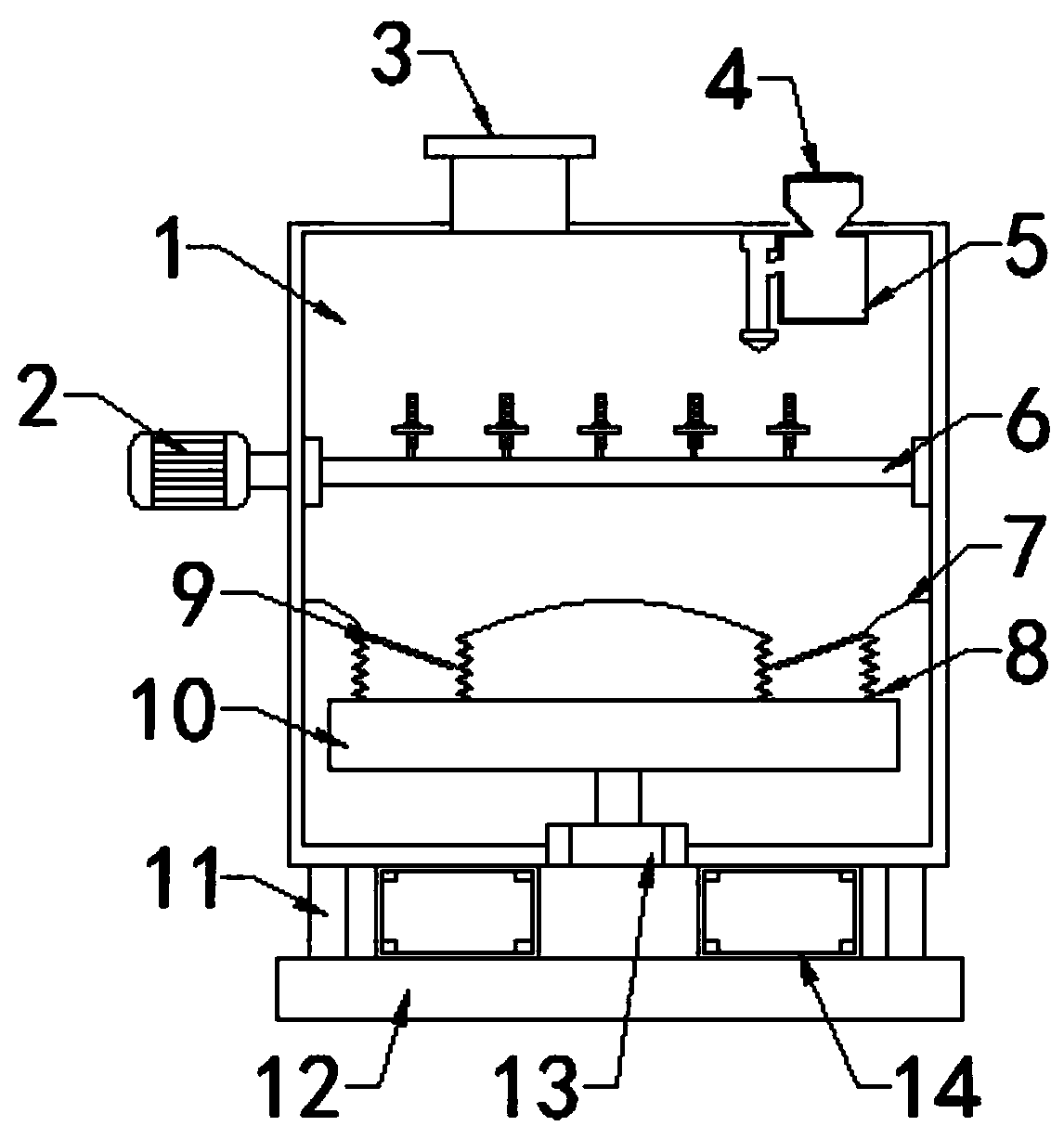

Puffed food processing device

ActiveCN110301663ACut evenlyAvoid wastingRotary stirring mixersTransportation and packagingEngineeringFood item

The invention provides a puffed food processing device, which comprises a processing device, a supporting plate and a cavity body, wherein two support columns are arranged at the lower end of the processing device, a supporting plate is fixedly connected to the bottoms of the support columns, when processed food raw materials fall into a connecting cavity through a movable plate, the food raw materials quickly fall into the cavity body through the inclined angle of an inclined tube, then the food raw materials are expanded through a heating plate in the cavity body, the food raw materials fallinto the cavity body through a movable rod, and a movable block drives the movable rod to slide downwards under the action of gravity of the food raw materials, the movable rod is inclined at this time, and a return spring is in a compressed state, and thus food raw materials can fall down along the inclined angle of the movable rod, so that the movable rod plays a buffering role, the falling speed is convenient to slow down, the puffing time is improved, and the puffing degree of the food raw materials can be improved to fully puff the raw materials.

Owner:HEBEI KANGYUAN XIANGMEIKE FOOD

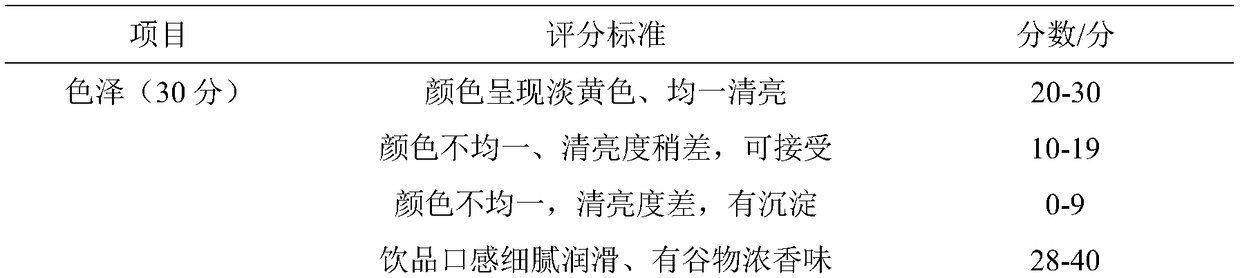

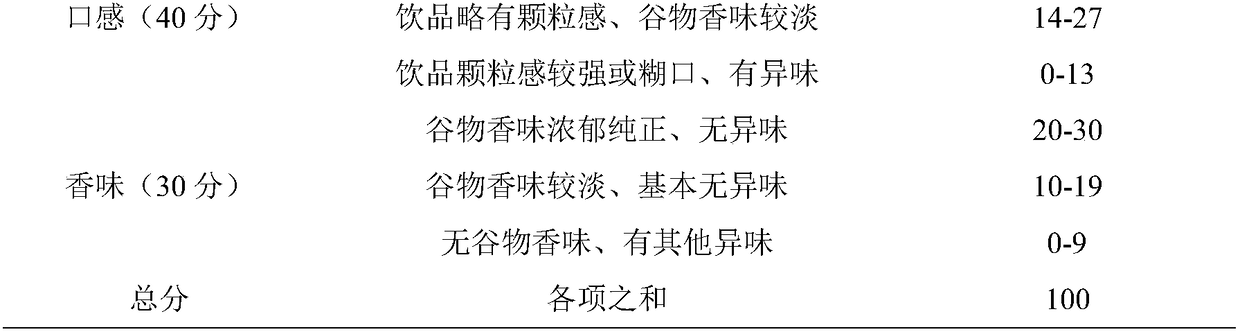

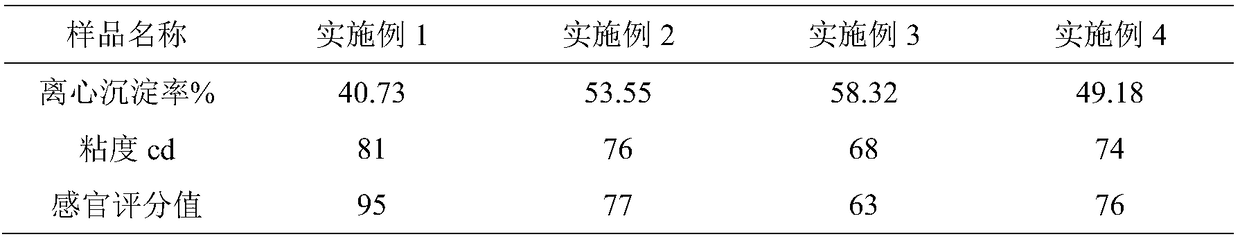

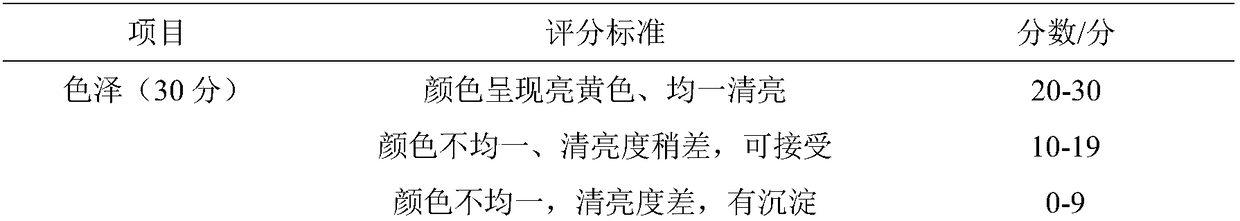

Oat beverage produced by hot-pressing and puffing

InactiveCN108651799ASmall molecular weightGood water solubilityGaseous food ingredientsSodium bicarbonateSolubility

The invention provides an oat beverage produced by hot-pressing and puffing, and belongs to the field of food processing. A production method comprises the following steps: raw material treatment, pressurization and puffing by superheated steam, preparation and classification of dextrin, homogenization, sterilization and filling. The oat beverage produced by hot-pressing and puffing provided by the invention has the characteristics that the cereal grains are taken as raw materials, and are subjected to pressurization and puffing by the superheated steam with sodium bicarbonate and beer, and the purpose of full-puffing is reached by utilizing the release of CO2, the rapid evaporation of water and the volatilization of alcohol in beer in the above process, thereby endowing the cereal grainswith loose and porous structures, enhancing the surface tension and increasing the solubility; and the shelf life is prolonged by fully and effectively passivating the lipase contained in the cereal grains while puffing. A part of the added low-polymerization-degree konjak linear dextrin can penetrate into the cavity of cereal grain flour, and the other part of the added low-polymerization-degreekonjak linear dextrin dissolves in water under the action of the temperature and pressure, thereby playing the role of a surfactant, increasing the water solubility and stability of the cereal grainsand reaching the purpose of no addition of a thickening agent and a stabilizing agent.

Owner:NANCHANG UNIV

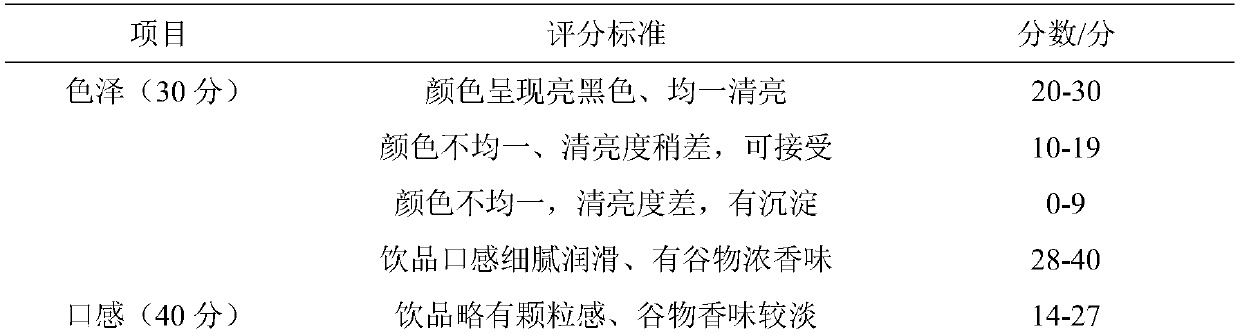

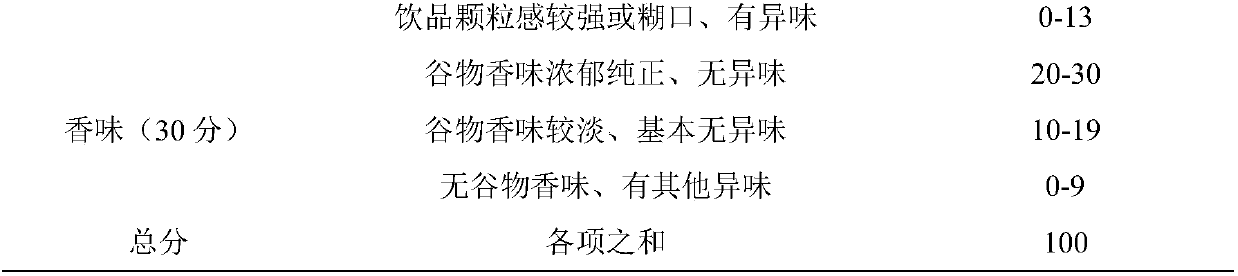

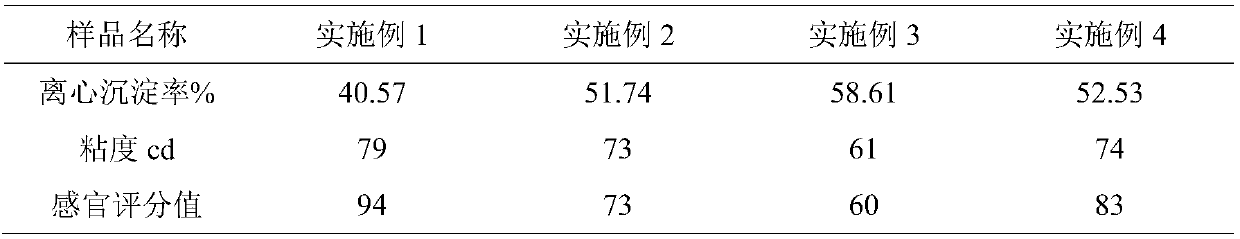

Graded dextrin cross-linking stabilized black rice drink

InactiveCN108669396ASmall molecular weightGood water solubilityMilk substitutesFood scienceSodium bicarbonateSolubility

The invention provides a graded dextrin cross-linking stabilized black rice drink and belongs to the field of food processing. A method comprises steps of raw material treatment, over-hot vapor pressurizing and puffing, dextrin preparation and grading, homogenization, sterilization and filling. The graded dextrin cross-linking stabilized black rice drink has the characteristics that cereals are adopted as raw materials and are treated with combined actions of sodium bicarbonate, beer and hot vapor pressurizing puffing, by virtue of release of CO2, rapid evaporation of moisture and volatilization functions of alcohol in the beer in the process, a complete puffing purpose can be achieved, the cereals are of loosened porous structures, the surface tension can be enhanced, and the solubility can be increased; in addition, lipase in the cereals can be effectively passivated while puffing, so that the preservation life can be prolonged; due to adoption of low polymerization degree konjak straight-chain dextrin, a part of the dextrin can permeate into pore cavities of cereal powder under the action of temperatures and pressure, the other part of the dextrin is dissolved into water, then afunction of a surfactant can be achieved, the water solubility and the stability of the cereals can be improved, and the purposes that neither a thickening agent nor a stabilizer is used is achieved.

Owner:NANCHANG UNIV

Processing method of buckwheat drink

InactiveCN108634145AFully puffedEffective passivationFood ingredient as clouding agentSolubilityBULK ACTIVE INGREDIENT

The present invention provides a processing method of buckwheat drink and belongs to the field of food processing. The method comprises the following steps: the buckwheat drink is mainly prepared frombuckwheat as a raw material and by mixing other cereals; and the buckwheat drink is prepared by raw material pre-treating, cereal porous structure modifying and stabilizing, blending and homogenizing, and sterilizing and canning. The pressing method is characterized in that the cereal is used as the raw material; the raw material is subjected to superheated steam pressurized puffing combined action; an oxygen-free environment during the superheated steam treatment can fully and effectively inactivate lipase and at the same time reduce damages of easily oxidized active ingredients in the cereals; moreover, the superheated steam is also used as puffing power; a closed state of high pressure is instantaneously reduced to normal pressure; so that tissue is fully puffed; no other puffing methods of squeezing, granulating, etc. are needed; added low polymerization degree konjac linear dextrin for solubilizing and stabilizing can partially penetrate into pores of cereal powder under the action of temperature and pressure; the other part dissolves in water to be acted as a surfactant. The processing method increases the water solubility and stability of the cereals and achieves purposes of not adding thickeners and stabilizers.

Owner:NANCHANG UNIV

Nutrient-enriched and stabilized red bean drink

InactiveCN108651798ASmall molecular weightGood water solubilityFood homogenisationFood ingredientsSodium bicarbonateSolubility

The present invention provides nutrient-enriched and stabilized red bean drink and belongs to the field of food processing. The nutrient-enriched and stabilized red bean drink is prepared by the following steps: raw material processing, superheated steam pressurized puffing, dextrin preparing and classifying, homogenizing, sterilizing and filling. The nutrient-enriched and stabilized red bean drink is characterized in that grains are used as raw materials; the grains are subjected to combined action of sodium bicarbonate, beer and heated steam pressurized puffing; release of CO2 in the process, rapid water evaporation and volatilization of alcohol in the beer are used to achieve the purpose of the complete puffing, so that the grains have a loose porous structure, and are increased in surface tensions and solubility; besides, during the puffing, contained lipase in the grains is sufficiently and effectively inactivated; and shelf life is prolonged; besides, low-polymerization konjac linear dextrin is added; and the low-polymerization konjac linear dextrin can partially penetrate into pores of grain flour under actions of temperatures and pressures, and the other part of the low-polymerization konjac linear dextrin dissolves in water to act as a surfactant to increase the water solubility and stability of the grains and to achieve purposes of not adding thickeners and stabilizers.

Owner:NANCHANG UNIV

Processing method of snow pear crisp chips

The invention discloses a processing method of pear chips, which comprises the following steps: cleaning, slicing, color protection, pre-drying, wet equalization treatment, microwave puffing and secondary drying. The invention has the advantages of good color, smooth surface, complete puffing, improved brittleness of crisp chips after secondary drying treatment, delicate taste and no impurities, fast puffing speed, simple process and low production cost.

Owner:LIUZHOU GOURMET UNION ASSOC

Method for preparing chicken feed

ActiveCN104054909APromote digestion and utilizationRich sourcesFood processingAnimal feeding stuffAnimal scienceProtein materials

The invention provides a method for preparing a chicken feed. The method comprises the following steps: firstly, adding mushrooms roots to the feed for the first time, reutilizing the waste mushrooms roots, meanwhile, matching with pigskin and a silkworm chrysalis material, so as to reduce the addition of the conventional protein in the feed. The feed cost is reduced, the puffed pigskin not only can be used as one of the protein materials in the feed by pigskin puffing in the feed, but also the volume is increased, and the space of the stomach is occupied, so that the effect of controlling the food consumption of the chicken can be achieved. Loss of a nutrient substance in the pigskin is reduced on the basis of simplifying the operation process by control of the puffing process of the pigskin in the feed, and the quality of the feed prepared by the method disclosed by the invention is ensured.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

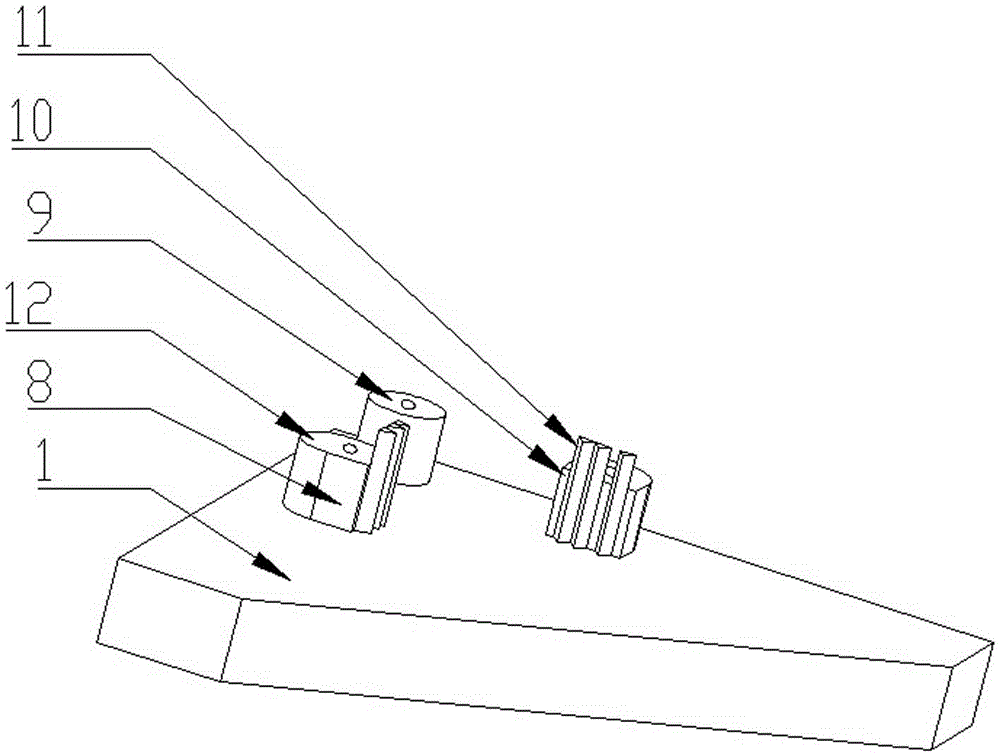

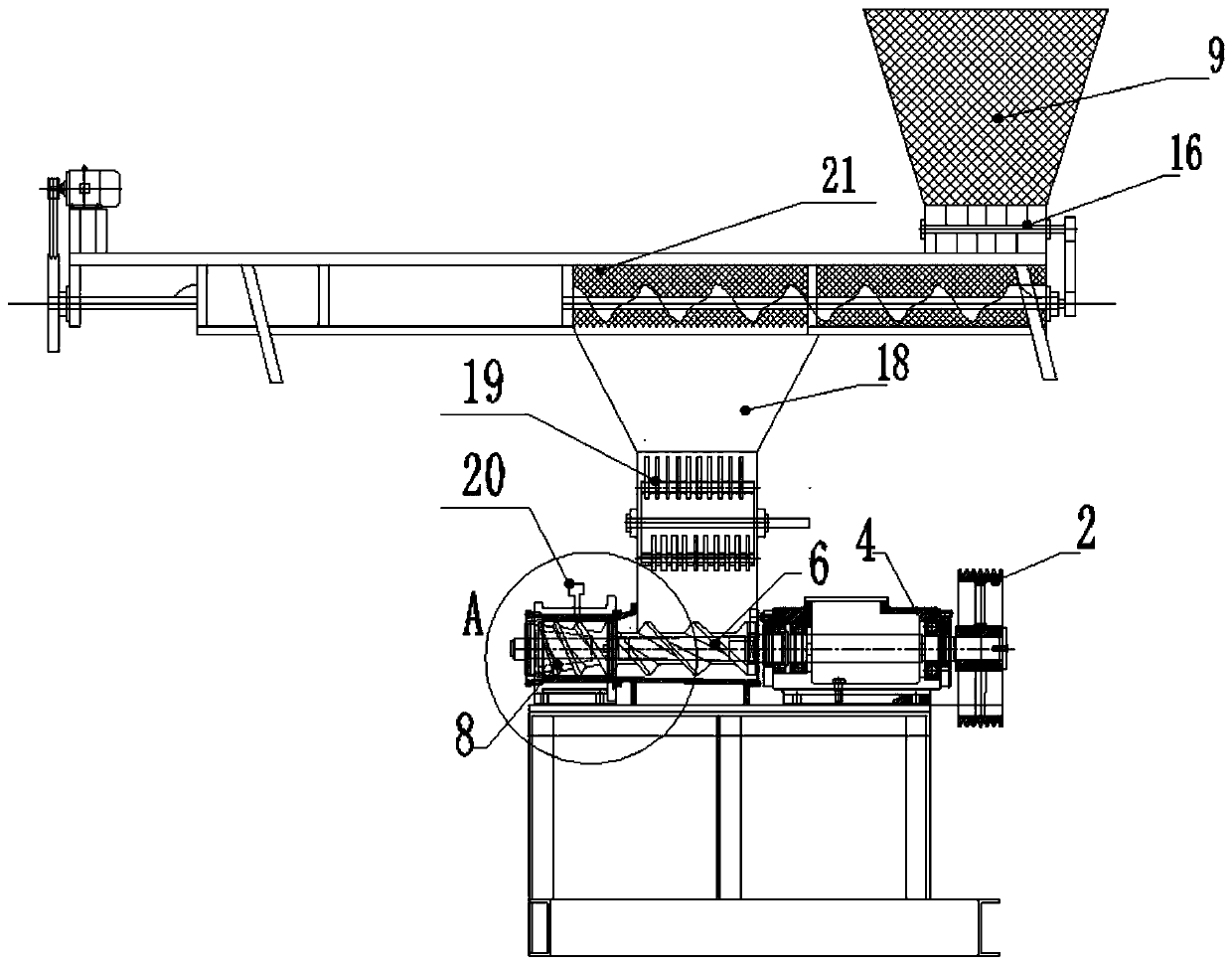

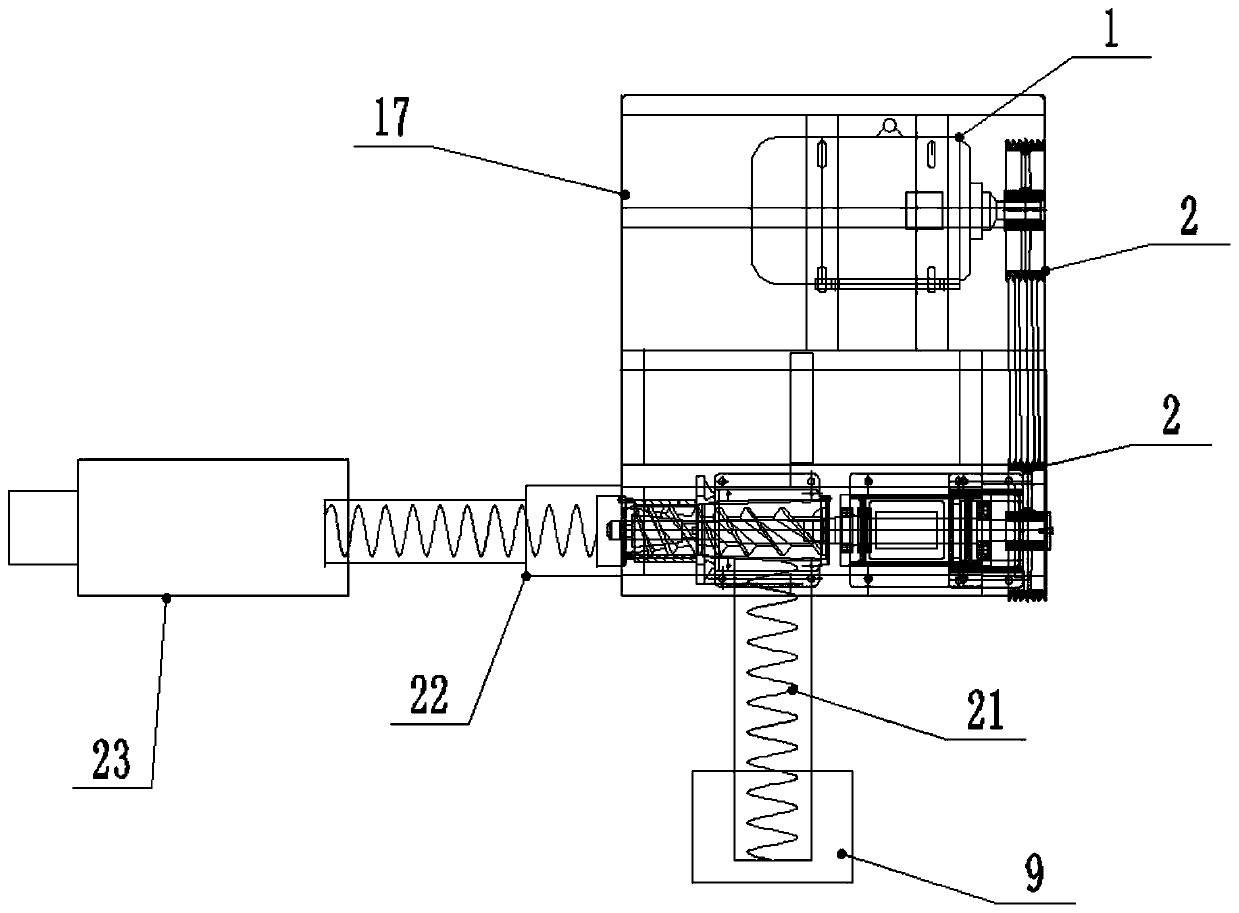

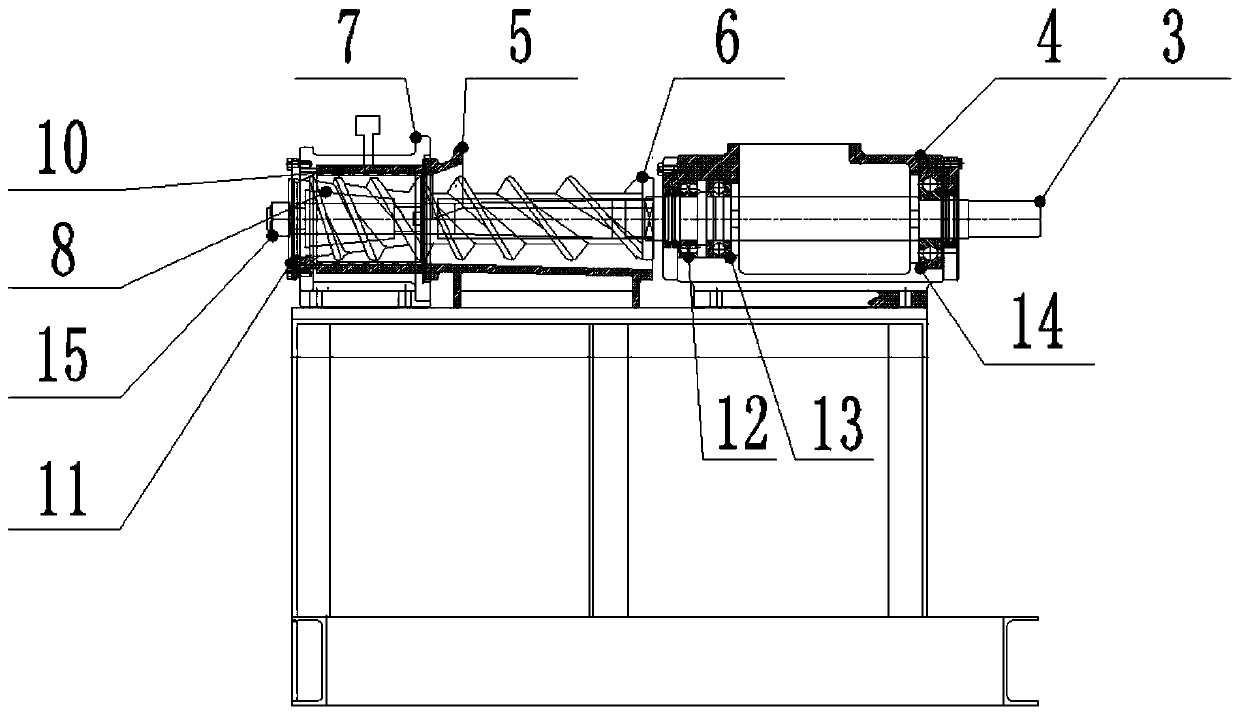

Straw puffing machine

PendingCN110122673AReduce processing costsIncrease profitFeeding-stuffWorking-up animal fodderHelical lineMechanical energy

The invention relates to a straw puffing machine. A disintegrating guide rod is a double-helix guide rod, the lead of the disintegrating guide rod is gradually reduced from a feed inlet to a dischargeoutlet, and the bottom diameter of the disintegrating guide rod is gradually increased from the feed inlet to the discharge outlet. The outer contour of the disintegrating guide rod is of a cylinder.The bifilar-helix design of the disintegrating guide rod makes the equipment convey materials stably, mechanical energy is converted into heat energy, and heat generated by friction is rapid and uniform. Compared with conventional puffing machines, the straw puffing machine has the advantages that compression of the radial force is decreased, the noise is reduced, the service life of the equipment is prolonged, the materials are discharged smoothly, the yield is increased, and the quality of end products is improved. The disintegrating guide rod of the straw puffing machine pushes the materials toward the discharge outlet along with the gradually shallow helical line, and the materials rub and squeeze a spiral sleeve to be broken. High temperature and high pressure are generated during operation, water molecules are rapidly expanded, and the materials are instantaneously sprayed, disintegrated and puffed by a disintegration ring. Compared with the conventional puffing machines, the straw puffing machine has the advantage that the yield is increased by 30% on the basis of the same power.

Owner:内蒙古坤珍天禧农牧科技有限责任公司

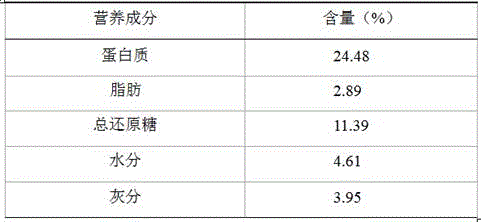

Ready-to-eat crisps containing vegetables and minced fillet and preparation method of ready-to-eat crisps containing vegetables and minced fillet

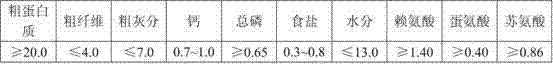

The invention belongs to the field of snack food processing and particularly relates to ready-to-eat crisps containing vegetables and minced fillet and a preparation method of the ready-to-eat crisps containing the vegetables and the minced fillet.The crisps are prepared by steps: taking the minced fillet as a base material; adding 2.0wt%-3.0wt% of salt, 40wt%-45wt% of corn starch, 10wt%-12wt% of defatted soybean protein powder, 35wt%-40wt% of pumpkin puree, 15wt%-20wt% of malabar spinach, 10wt%-20wt% of garland chrysanthemum, 2.0wt%-2.5wt% of white granulated sugar and 15wt%-25wt% of water; performing extrusion forming to obtain finished products.The ready-to-eat crisps have the advantages of freeness of fishy smell, crispiness, tastiness, bright color, high protein, low fat and low calorie, wherein the protein content is larger than 20%, and the fat content is smaller than 3%.In addition, the ready-to-eat crisps have healthcare efficacies of heat clearing, detoxifying, digestion promoting, appetizing, digestive absorption promoting, toxin expelling promoting, blood fat reducing and the like and can be stored at the room temperature.

Owner:武夷学院

Donkey-hide gelatin balls and preparation method thereof

The invention discloses donkey-hide gelatin balls and a production method thereof and relates to a Chinese herbal piece donkey-hide gelatin and a preparation method thereof. The method comprises the following steps of: 1) heating clam meal; 2) burying donkey-hide gelatin blocks in the clam meal to ensure that the donkey-hide gelatin blocks are fully heated to be softened; 3) placing the donkey-hide gelatin blocks which are heated to be softened on a machine and applying force to obtain meshy or perforated donkey-hide gelatin blocks, placing the meshy or perforated donkey-hide gelatin blocks in a container, naturally cooling to harden, and milling the hardened donkey-hide gelatin blocks into particles; 4) grinding the clam meal into fine powder and heating; and 5) heating the cooled clam meal and the donkey-hide gelatin particles for later use to ensure that the donkey-hide gelatin particles and the clam meal are fully nixed and heated uniformly, wherein the donkey-hide gelatin particles are swollen after being heated, and screening out the clam meal to obtain the donkey-hide gelatin balls. The donkey-hide gelatin balls prepared by the method are small, high in purity, good in effect and comfortable in mouthfeel and are not adhered to the clam meal radically.

Owner:李勇

Corn coarse-cereal beverage produced by performing hot-press expansion and cross-linked stabilization

InactiveCN108651800ASmall molecular weightGood water solubilityFood ingredientsSodium bicarbonateSolubility

The invention provides a corn coarse-cereal beverage produced by performing hot-press expansion and cross-linked stabilization, and belongs to the field of food processing. The corn coarse-cereal beverage is prepared by the following steps of treating raw materials, carrying out superheated-steam pressurized expansion, preparing dextrin, carrying out grading, carrying out homogenizing, carrying out sterilizing and carrying out filling. The corn coarse-cereal beverage produced by performing hot-press expansion and cross-linked stabilization is characterized in that the grains are taken as raw materials, in combination with sodium bicarbonate, beer and hot steam in pressurized expansion, so as to synergistically take an effect to achieve the purpose of complete expansion by utilizing CO2 release, rapid water evaporation and alcohol volatilization of the beer; and thus, loose porous structure is formed for the grains so as to increase surface tension and improve solubility. Moreover, lipase in the grains can be fully and effectively inactivated during expansion, so that shelf life of the corn coarse-cereal beverage can be prolonged. In addition, konjac straight-chain dextrin with lowdegree of polymerization is added, so that cavities of the grain powder can be infused by some of the konjac straight-chain dextrin under the effects of temperature and pressure; and the remaining konjac straight-chain dextrin dissolves in water so as to act as a surfactant, so that water-solubility and stability of the grains are increased so as to achieve the purposes of saving addition of thickening agents and stabilizing agents.

Owner:NANCHANG UNIV

Immediately-edible loach foodstuff and preparation method thereof

InactiveCN101983586BGood deodorizing effectEasy to operateFood preparationFlavorNutritional composition

Provided is an immediately-edible loach foodstuff characterized by the preparation method thereof. The method is as follows. Loaches as raw materials are subjected to immersion and fishy removing in a fishy-removing solution. The fishy-removing solution is a mixture consisting of 2-5% NaCl and 0.15-0.35% of acid solution, and the weight ratio of NaCl to acid solution is 1:(1-2). The fishy-removing solution is subjected to drying until the water content thereof is 50-55%. Then the above solution is subjected to softening for 20-30 hours, microwave puffing and drying until the water content thereof is reduced to less than 8% to obtain the immediately-edible loach foodstuff. The preparation method of the immediately-edible loach foodstuff is also provided by the invention. The above foodstuff has the advantages of full puffing, dark yellow color, crisp taste, aromatic flavor, long shelf-life, convenient storage of nutrient compositions, easy absorption by human bodies and free of aging oil.

Owner:HUAIHAI INST OF TECH

A puffed food processing device

ActiveCN110301663BCut evenlyAvoid wastingTransportation and packagingRotary stirring mixersBiotechnologyEngineering

The invention provides a puffed food processing device, comprising: a processing device, a support plate and a cavity; two pillars are arranged at the lower end of the processing device, and the bottom of the pillars is fixedly connected with a support plate, when the processed food raw materials pass through When the movable plate falls into the connecting cavity, the food raw materials are quickly dropped into the cavity through the inclined angle of the inclined tube, and then the food raw materials are puffed by the heating plate in the cavity, and the food raw materials are dropped by the movable rod Among them, under the action of gravity of the food raw materials, the movable block drives the movable rod to slide down, at this time, the movable rod is inclined, and the return spring is in a compressed state at the same time, and the food raw materials can fall along the inclined angle of the movable rod Going down, the movable rod plays a role of buffering, which is convenient for slowing down the speed of descent, increasing the puffing time, and can improve the puffing degree of food raw materials, so that the raw materials are fully puffed.

Owner:HEBEI KANGYUAN XIANGMEIKE FOOD

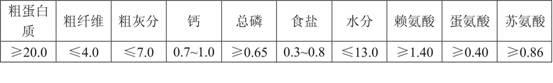

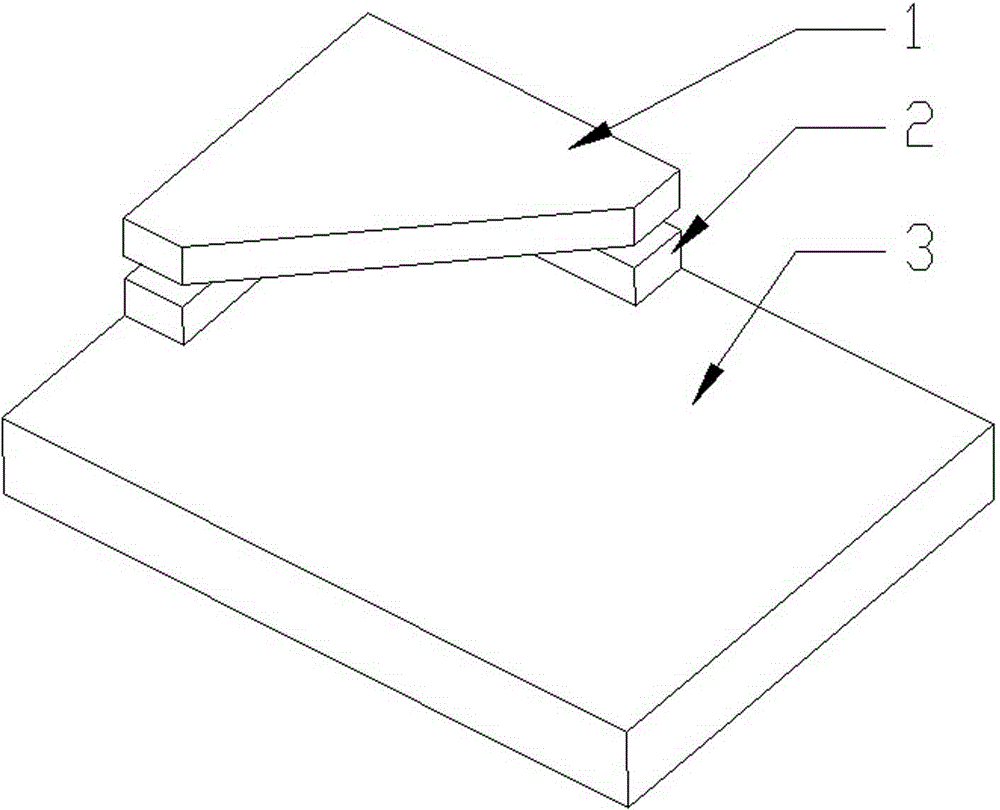

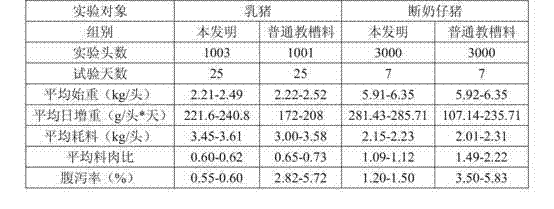

Compound feed for teaching piglets to eat foods other than breast milk

InactiveCN102178115BAvoiding Porcine Contamination ProblemsFully puffedFood processingAnimal feeding stuffDiseaseSucrose

The invention provides compound feed for teaching piglets to eat foods other than breast milk, which is used for weaning piglets and teaching the piglets to eat foods other than breast milk, and comprises the following components in part by weight: 212.4 parts of corn starch, 154.0 parts of bulked corn, 100.0 parts of 46 percent of bulked bean pulp, 40 parts of fish meal, 100 parts of wheat flour, 5 parts of calcium powder, 21 parts of calcium hydrophosphate, 2 parts of table salt, 20 parts of soybean oil, 5 parts of lysine, 2 parts of threonine, 1.5 parts of choline chloride, 10 parts of premix, 0.2 part of complex enzyme, 0.3 part of pig Duowei, 0.2 part of sweetener, 0.3 part of flavouring agent, 3 parts of baking soda, 20 parts of cane sugar, 30 parts of glucose, 50 parts of egg powder, 70 parts of soy protein concentrate, 50 parts of fermented bean pulp, 6 parts of acidizer, 100 parts of whey powder, 0.5 part of mould removing agent, 0.3 part of antioxidant and 0.3 part of mildewpreventive. In the invention, the problems of incomplete immune functions, low disease resistance, inadequate digestive ferment, incomplete upper gastrointestinal development, low digestion and absorption ability, susceptibility to diarrhea and the like of piglets.

Owner:AGRI SCI & TECH INST CO LTD OF CHENGDU WEST HOPE GRP

Printing process of raffia braided fabric

InactiveCN112144303AClear outlineDoes not affect mechanical propertiesDyeing processTextile printerPolymer science

The invention discloses a printing process of raffia braided fabric, and belongs to the technical field of printing processes. The preparation method comprises the following steps of 1) preparing andsynthesizing glue paste (hydroxyethyl saponin gum); adding urea into the synthetic gum paste, scattering a weakly acidic dye according to a mass ratio of the synthetic gum paste to the urea to the weakly acidic dye of 100: (3-5.5): (1.5-3), and uniformly stirring to obtain a printing paste; printing the raffia braided fabric on a machine by using the printing paste to obtain a printed braided fabric; (2) drying the braided fabric printed in the step (1), (3) steaming the braided fabric obtained in the step (2), and (4) washing the steamed and color-fixed braided fabric obtained in the step (3)with water. The printing obtained by the process is clear in printing outline, simple and feasible, and the mechanical performance of raffia is not affected.

Owner:SHANDONG VOCATIONAL COLLEGE OF LIGHT IND

A kind of production technology of vacuum microwave meat puffed crisps

ActiveCN104351819BImprove meat structureInternal tissue swellingFood shapingFood dryingFlavorMicrowave

The invention relates to a vacuum microwave production process of meat puffing chips, belonging to the technical field of deep processing of agricultural products. The production process comprises the steps of cleaning raw material meat, cutting the cleaned meat into pieces, pickling the meat pieces by pickling seasonings, pre-drying by hot air, carrying out samming treatment, and puffing and drying by vacuum microwave; finally, sterilizing by irradiation to obtain the meat puffing leisure product which is high in crispness and good in flavor. After the preparation technology is adopted, the nutritional ingredients of the raw material are maintained to the utmost extent; the meat puffing chips are crisp in mouth feel and convenient to eat. After the preparation method and the practical technology of the meat puffing chips are used, a practical and feasible new way is provided for deep processing and utilization of meat products.

Owner:南京欧旺食品科技有限公司

A kind of donkey-hide gelatin beads and preparation method thereof

ActiveCN107669705BReduce contentFully puffedMolluscs material medical ingredientsGelatin PillColla corii asini

The invention provides donkey-hide gelatin pills and a preparation method thereof. The preparation method comprises the steps that a donkey-hide gelatin block is heated and softened to become into grains of 0.4-0.6 mm; dehumidification, sterilization and drying are performed to reach moisture of 13%; dehumidified and sterilized clam meal is evenly mixed with donkey-hide gelatin grains according tothe ratio of 1 to 2, then the mixture is heated to reach 90-110 DEG C, so that the donkey-hide gelatin grains and the clam meal are fully mixed and evenly heated, the donkey-hide gelatin grains become pills of 1.0-1.5 mm after heated expansion, irregular donkey-hide gelatin pills and the clam meal are screened out, and the donkey-hide gelatin pills are obtained. The prepared donkey-hide gelatin pills are smaller, higher in purity and better in effect, have more comfortable taste, basically do not adhere to the clam meal, meanwhile a production line is adopted for production in the whole process, and the production efficiency is improved.

Owner:四川弘升药业有限公司

Starch mixed shrimp cracker and preparation method thereof

The invention discloses a starch mixed shrimp cracker, which is prepared from the following components in part by weight: 10 to 20 parts of cassava starch, 15 to 20 parts of potato starch, 70 to 85 parts of corn starch, 2 to 4 parts of shelled shrimps, 1 to 3 parts of white granulated sugar, 2 to 4 parts of refined salt, 1 to 2 parts of monosodium glutamate and 40 to 50 parts of water. The invention simultaneously discloses a method for preparing the starch mixed shrimp cracker. By controlling parameters of a co-rotating twin screw extruder, the prepared starch mixed shrimp cracker is diversified in components, comprehensive in nutrient components, good in mouthfeel, fine in appearance, healthy, safe, simple in processing technology, high in degree of automation and low in labor intensity of a worker, reduces the energy consumption and the processing cost, and can meet the requirement of development of modern enterprises and society.

Owner:NINGBO YINFA GREEN FOOD

Making method for pupa-selenium cakes

InactiveCN109221335AIncrease elasticityFully puffedDough treatmentModified nutritive productsChemical additionSelenium

The invention discloses a making method for pupa-selenium cakes. The pupa-selenium cakes do not contain any chemical addition agent and adopt physical fermentation, health is facilitated, and the pupa-selenium cakes are safe and secure green food. A special self-designed oven is adopted, and the aims of environmental friendliness, production safety and the like of the cakes are achieved. Invertedsugar containing oranges, lemon fruits and selenium-rich yellow mealworms are added, the problem that coloring is uneven, or the color is not golden yellow is solved, and the nutritive value and the fragrance of the cakes can be increased.

Owner:湖南袁禾农业科技有限公司

A kind of preparation method of chicken feed

ActiveCN104054909BPromote digestion and utilizationRich sourcesFood processingAnimal feeding stuffAnimal scienceProtein materials

The invention provides a method for preparing a chicken feed. The method comprises the following steps: firstly, adding mushrooms roots to the feed for the first time, reutilizing the waste mushrooms roots, meanwhile, matching with pigskin and a silkworm chrysalis material, so as to reduce the addition of the conventional protein in the feed. The feed cost is reduced, the puffed pigskin not only can be used as one of the protein materials in the feed by pigskin puffing in the feed, but also the volume is increased, and the space of the stomach is occupied, so that the effect of controlling the food consumption of the chicken can be achieved. Loss of a nutrient substance in the pigskin is reduced on the basis of simplifying the operation process by control of the puffing process of the pigskin in the feed, and the quality of the feed prepared by the method disclosed by the invention is ensured.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

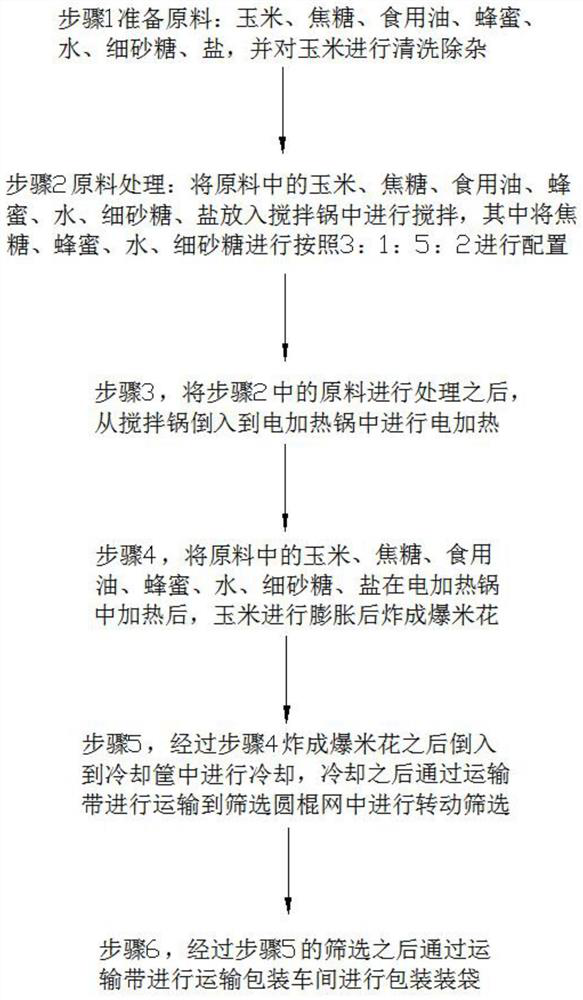

Formula and preparation method of caramel corn popcorn

PendingCN114747731ARelieve sweetnessSolve the problem of too sweet tasteFood thermal treatmentBiotechnologySweetness

According to the formula of the caramel corn popcorn and the preparation method of the caramel corn popcorn, the caramel, the honey, the water and the berry sugar are mixed into the corn according to the ratio of 3: 1: 5: 2, so that the sweet taste of the caramel corn popcorn can be effectively relieved, and the problem that pure caramel tastes too sweet and greasy in the prior art is solved; in the process of treating the raw materials in the step 2, the corn is put into water to be soaked for 25-35 minutes, the temperature is adjusted to be 100-150 DEG C in the process of electrically heating in an electric heating pot, the electric heating is carried out for 20-30 minutes, the popcorn can be fully puffed, the quality of the popcorn is improved, the quality of the popcorn is improved, and the quality of the popcorn is improved. The problem that corn cannot be fully puffed in the heating process in the prior art is solved.

Owner:安徽米自恋保健食品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com