Formula and preparation method of caramel corn popcorn

A technology for popcorn and corn, which is applied to the formulation of caramel corn popcorn and the field of preparation thereof, can solve the problems of pure caramel having a sweet and greasy taste, and insufficient puffing of corn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: 6 parts of corn, 2 parts of caramel, 4 parts of edible oil, 1 part of honey, 7 parts of water, 4 parts of caster sugar, and 1 part of salt.

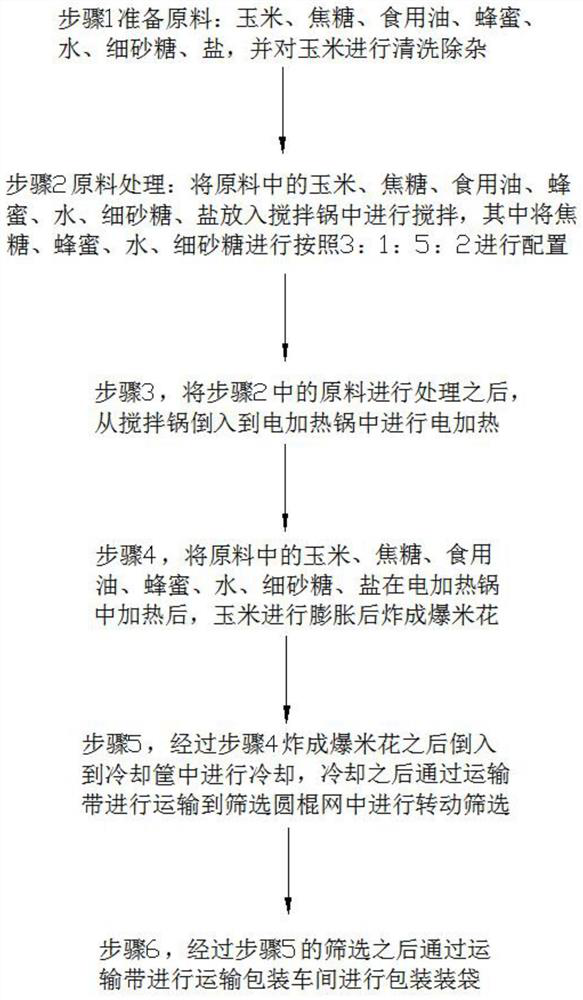

[0027] A preparation method of caramel corn popcorn, comprising the following steps: Step 1: prepare raw materials: corn, caramel, edible oil, honey, water, fine sugar, and salt, and clean the corn to remove impurities;

[0028] Step 2: Raw material processing: put the corn, caramel, edible oil, honey, water, caster sugar and salt in the raw material into a stirring pot for stirring, wherein the caramel, honey, water and caster sugar are mixed according to 3:1: 5:2 for configuration;

[0029] Step 3, after processing the raw materials in step 2, pour it from the stirring pot into the electric heating pot for electric heating;

[0030] Step 4: After heating the corn, caramel, edible oil, honey, water, caster sugar and salt in the raw material in an electric heating pot, the corn is expanded and then fried into popcorn; ...

Embodiment 2

[0037] Example 2: 10 parts of corn, 3 parts of caramel, 5 parts of edible oil, 2 parts of honey, 10 parts of water, 5 parts of caster sugar, and 3 parts of salt;

[0038] A preparation method of caramel corn popcorn, comprising the following steps: Step 1: prepare raw materials: corn, caramel, edible oil, honey, water, fine sugar, and salt, and clean the corn to remove impurities;

[0039] Step 2: Raw material processing: put the corn, caramel, edible oil, honey, water, caster sugar and salt in the raw material into a stirring pot for stirring, wherein the caramel, honey, water and caster sugar are mixed according to 3:1: 5:2 for configuration;

[0040] Step 3, after processing the raw materials in step 2, pour it from the stirring pot into the electric heating pot for electric heating;

[0041] Step 4: After heating the corn, caramel, edible oil, honey, water, caster sugar and salt in the raw material in an electric heating pot, the corn is expanded and then fried into popco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com