Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Flexible feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

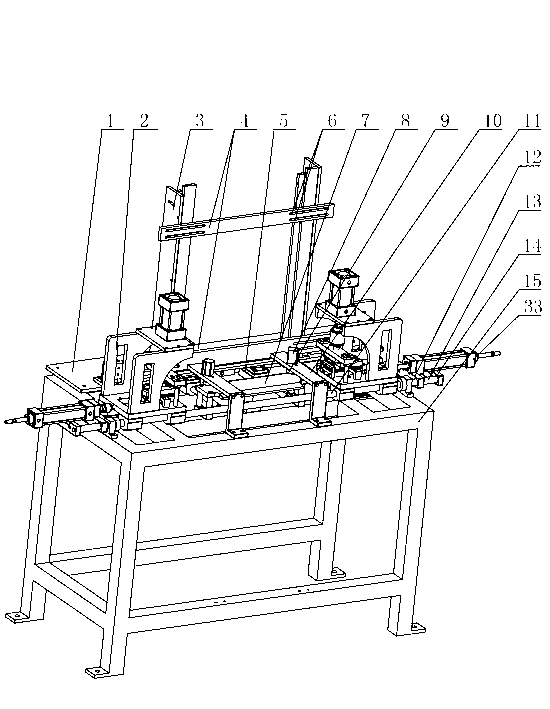

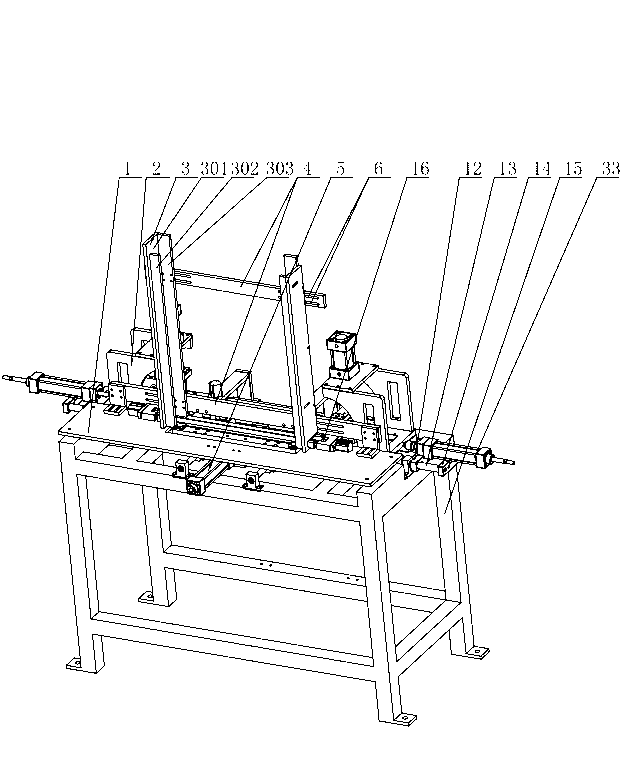

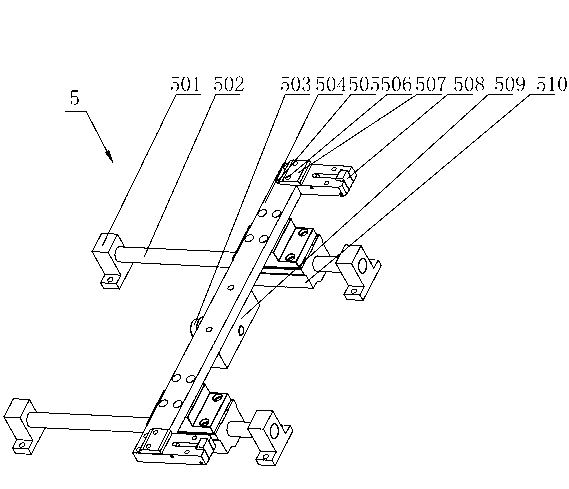

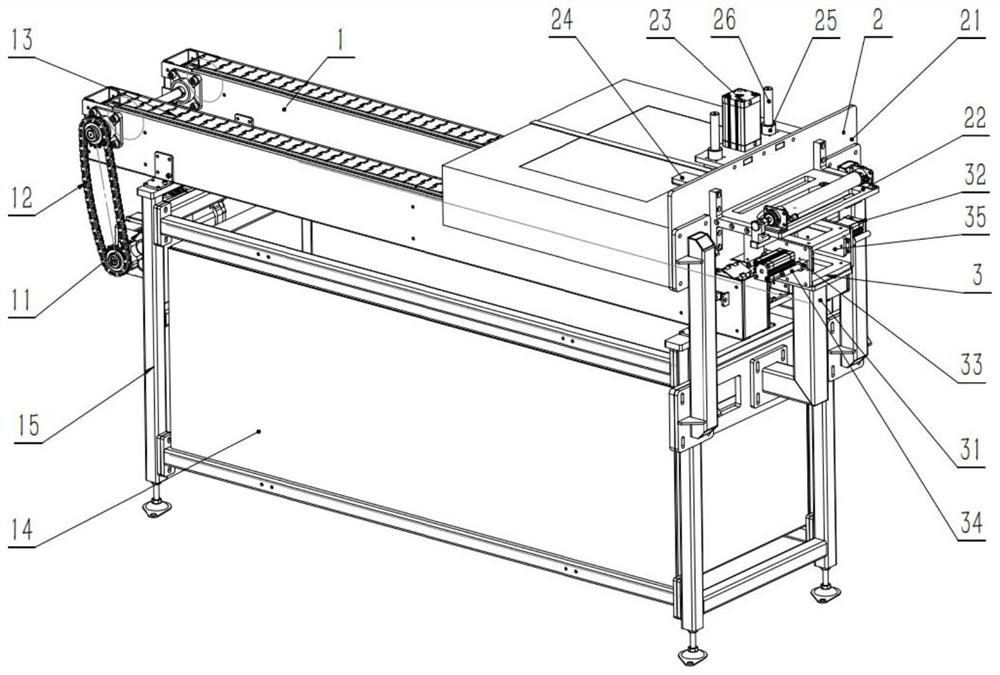

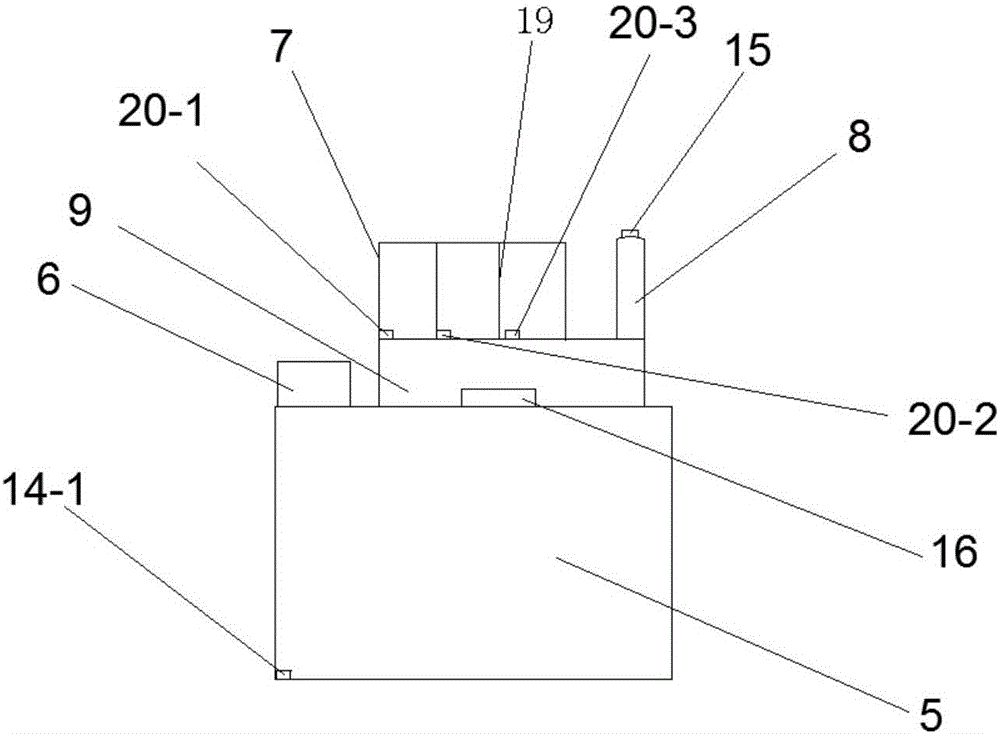

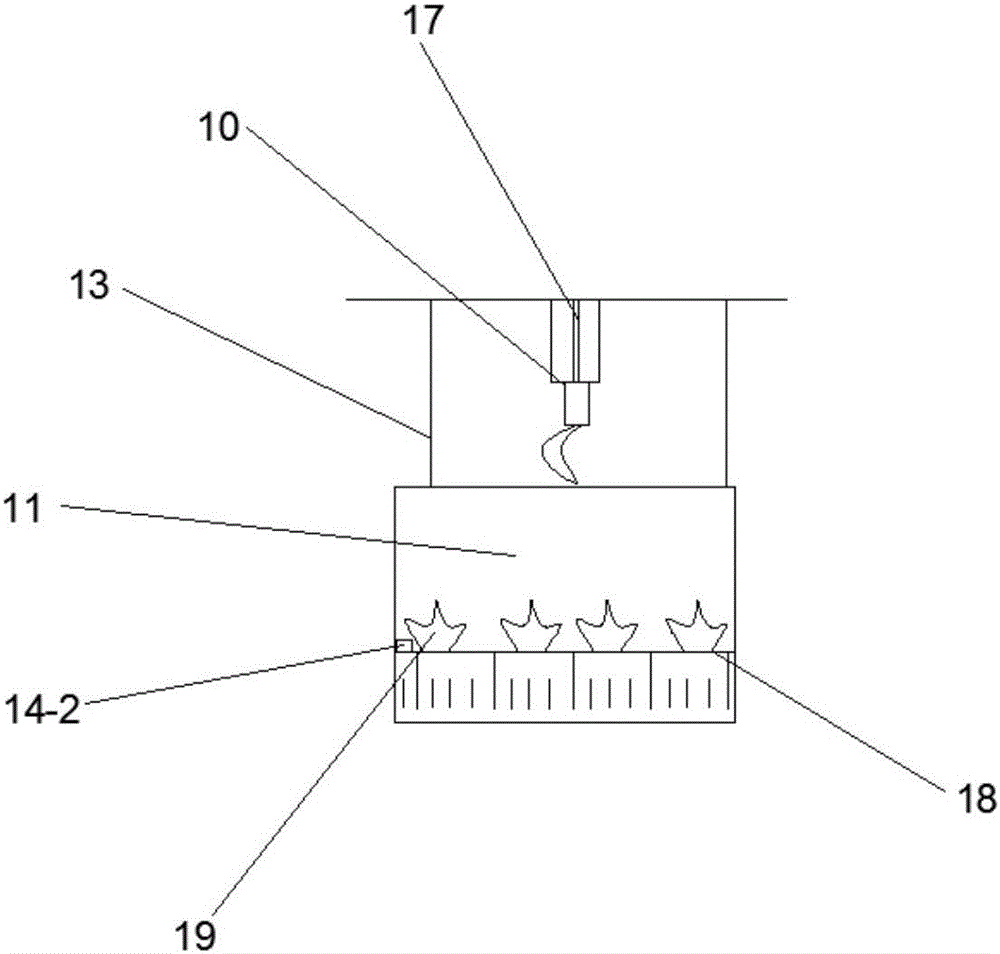

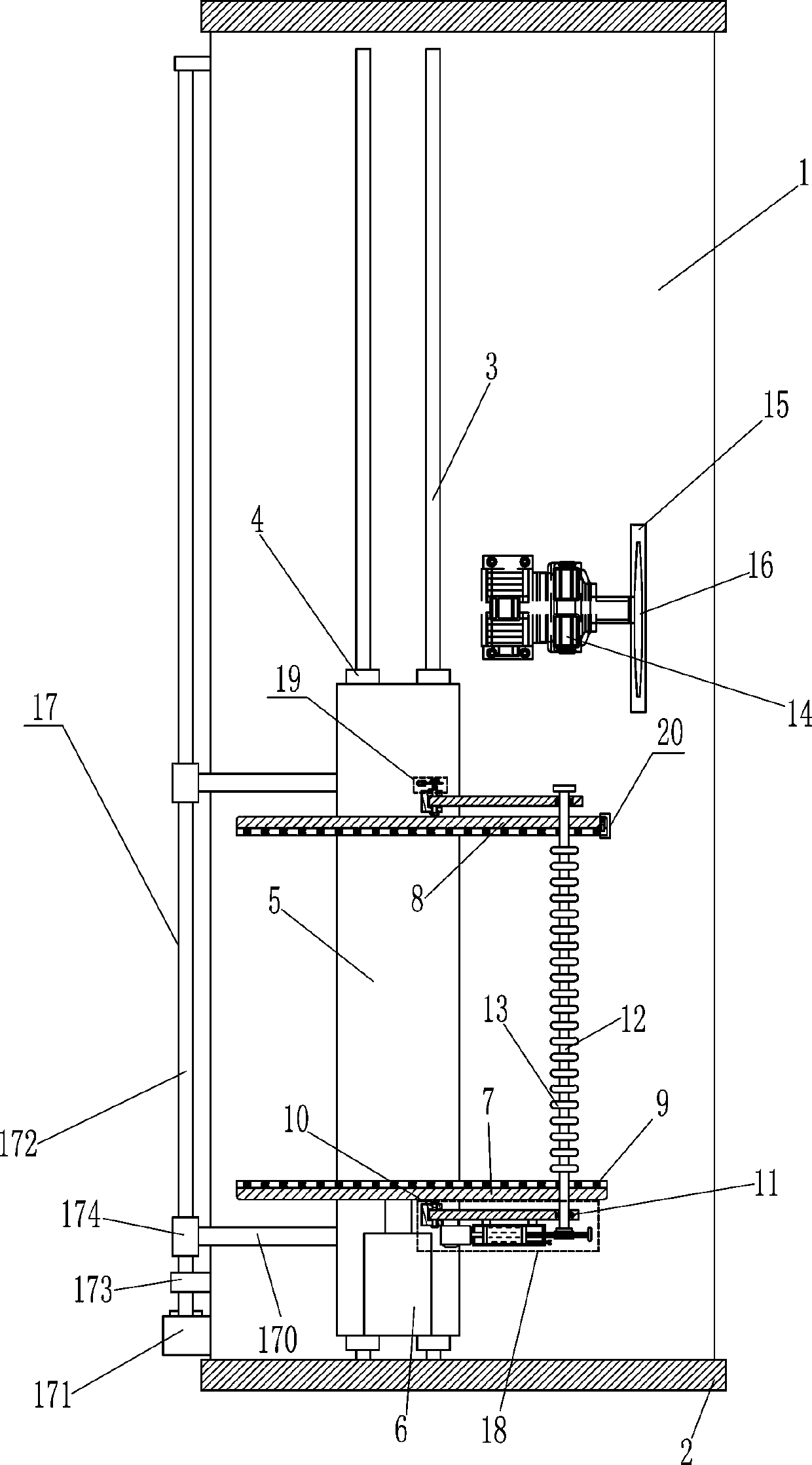

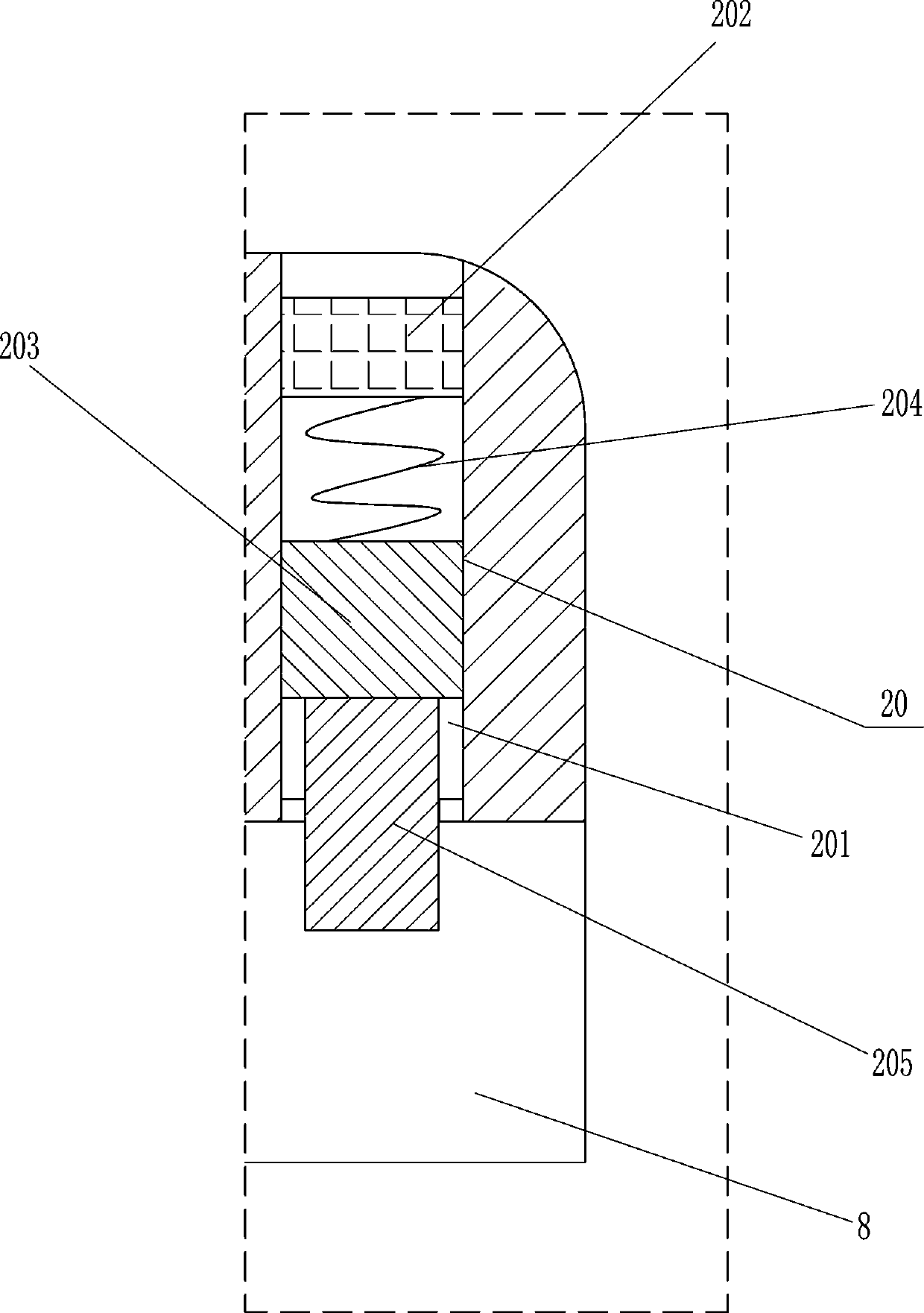

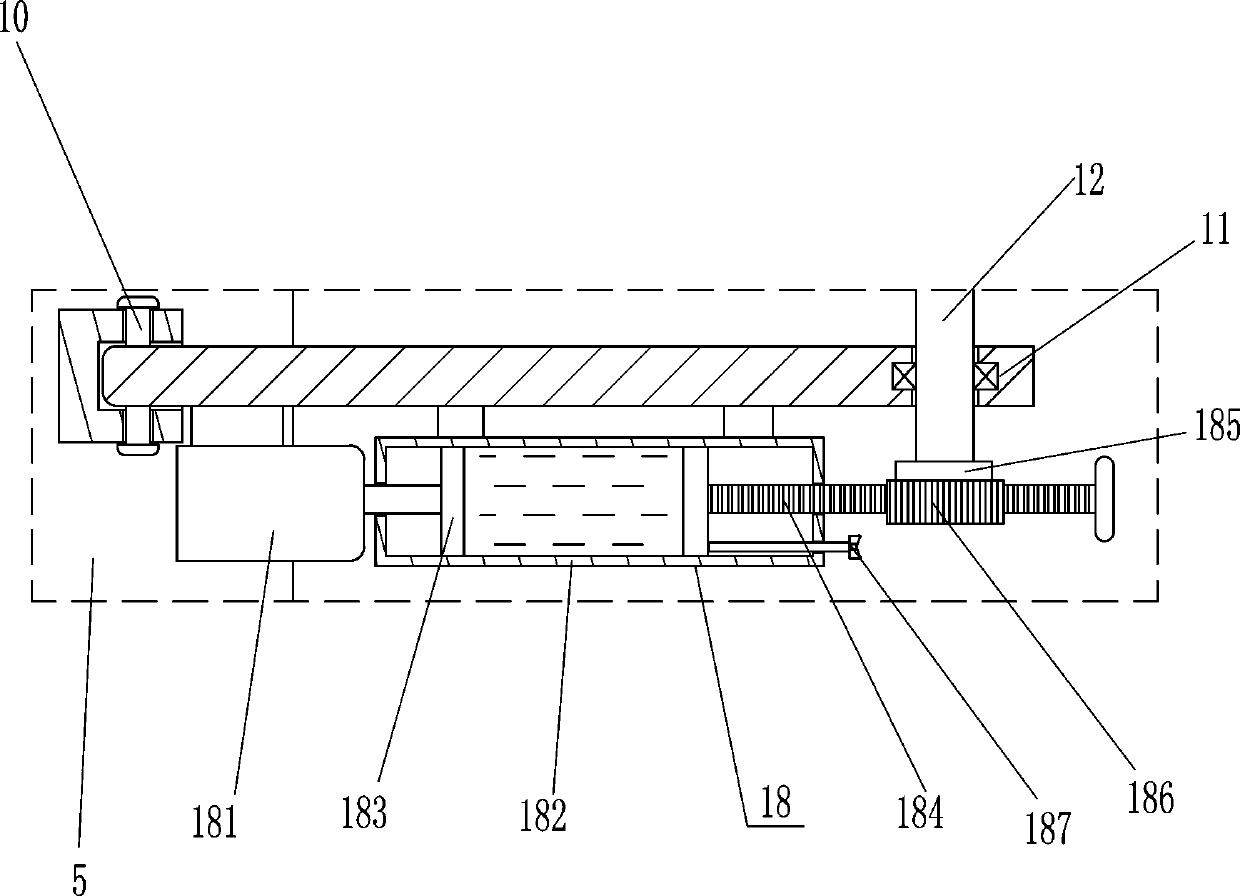

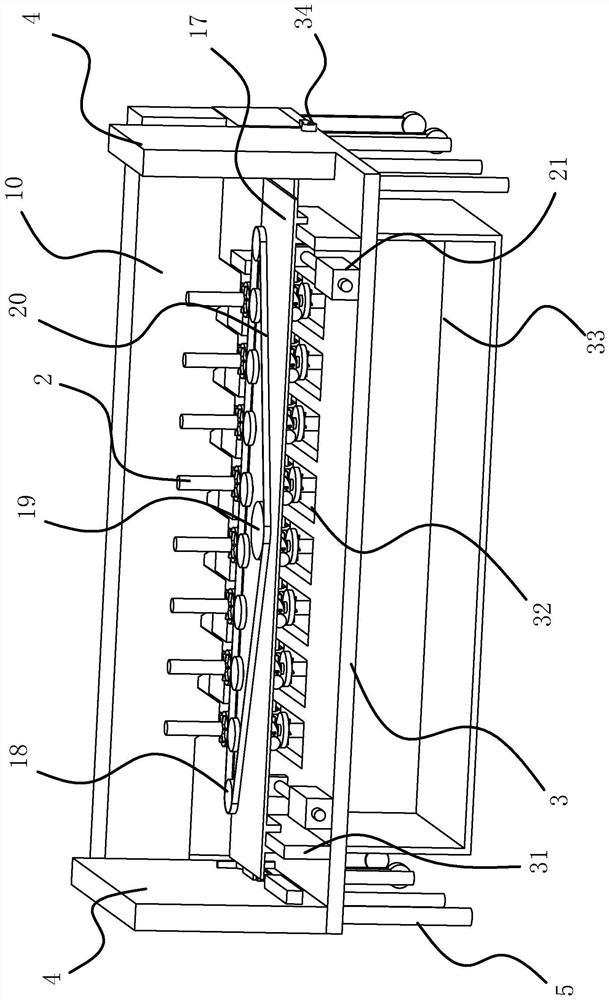

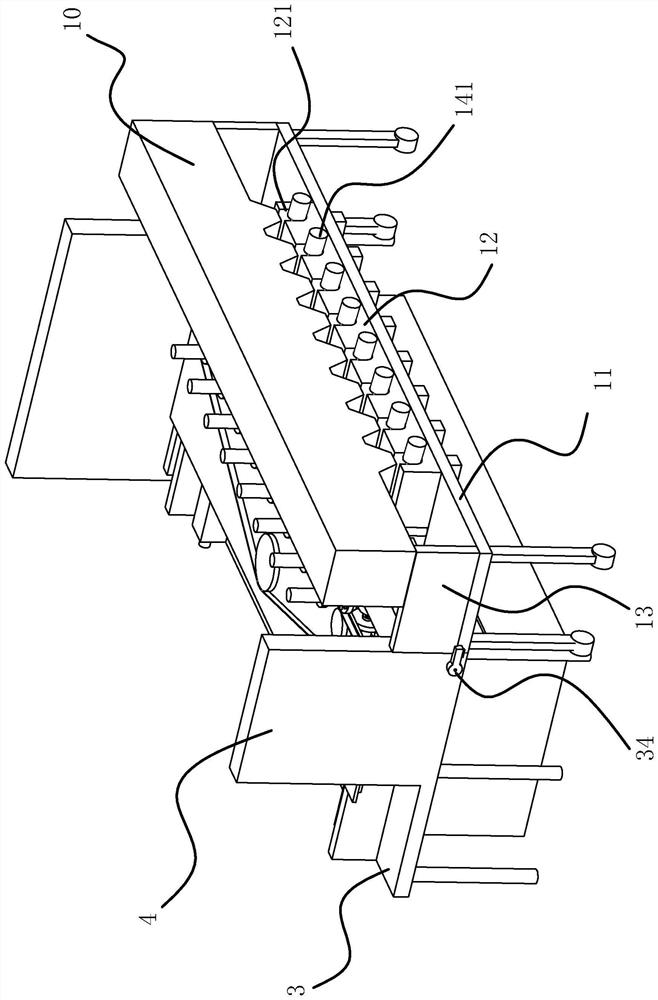

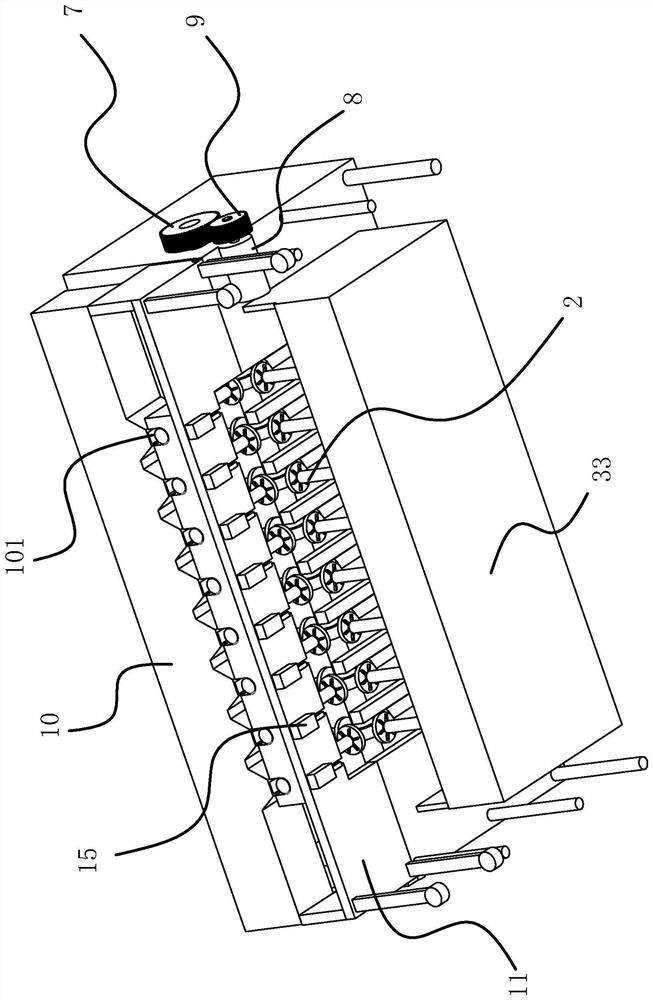

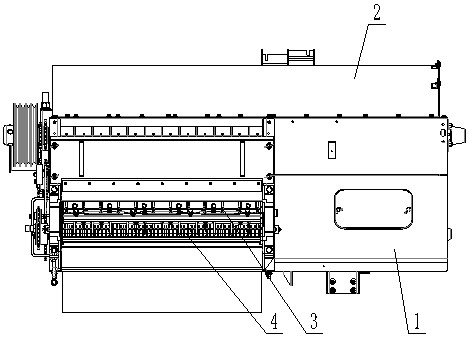

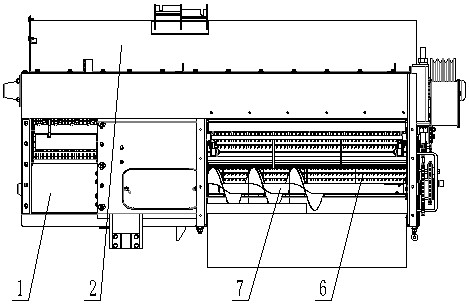

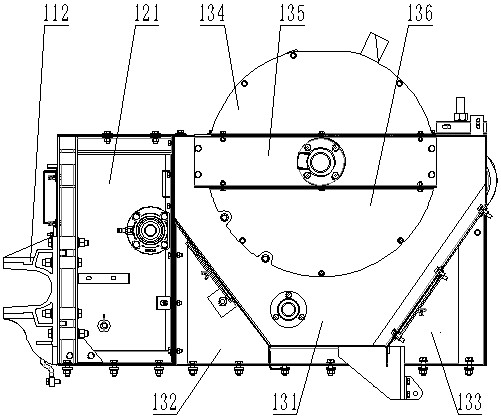

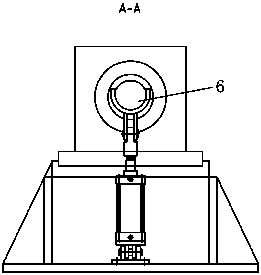

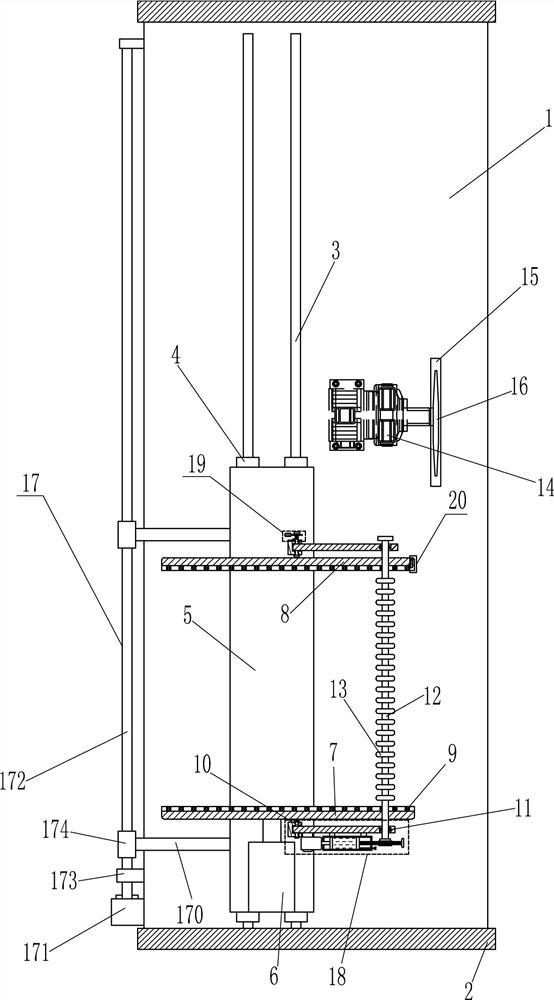

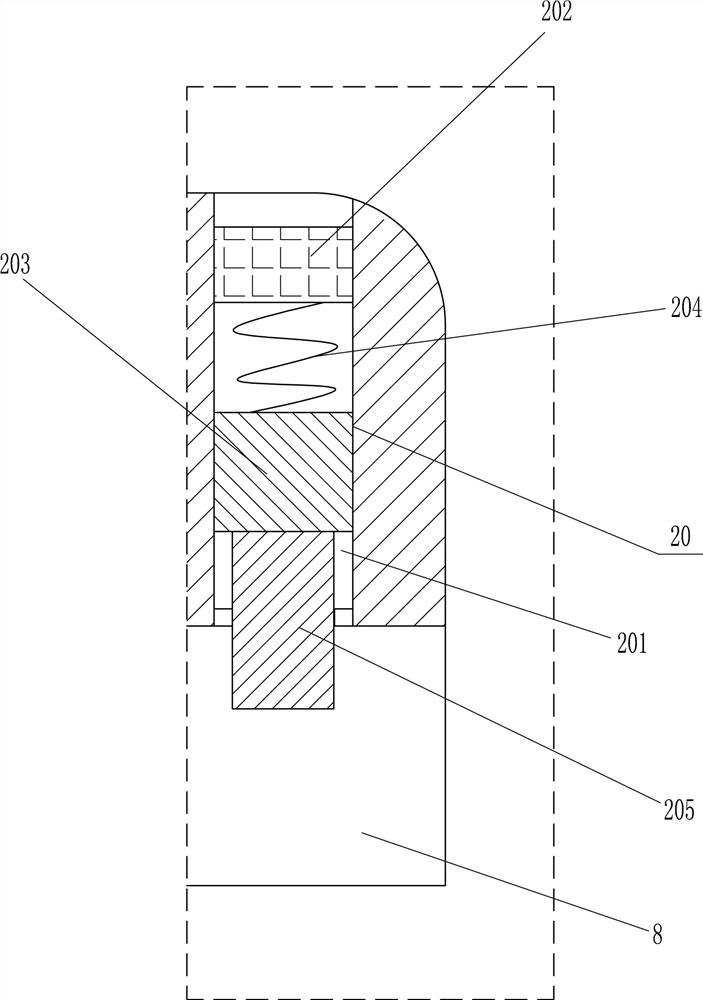

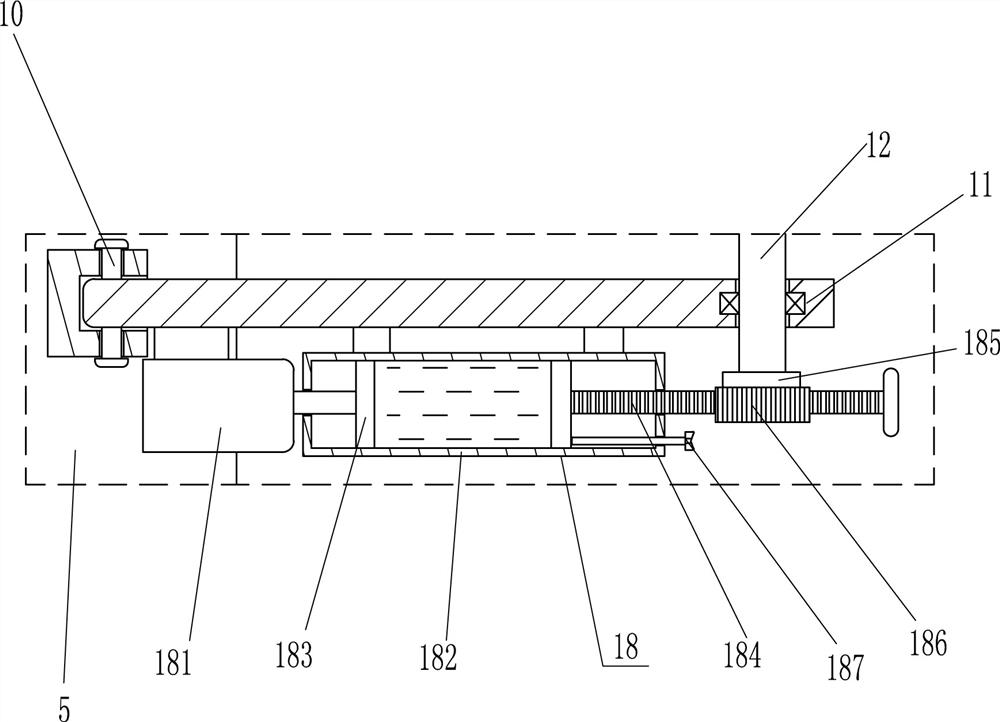

Semi-automatic punching machine for packaging tube

ActiveCN102862183AReasonable structureSimple and fast operationMetal working apparatusPunchingEngineering

The invention relates to a semi-automatic punching machine for a packaging tube, comprising a base, wherein steps are formed on the upper surface of the base, a workbench is arranged at the middle of the first step surface, a main guide rail is arranged on the lower part of the workbench, and punching mechanisms are symmetrically installed on the main guide rail and at the both ends of the workbench respectively; a bottom plate is installed on the second step surface of the base, a groove opening is formed at the middle of the bottom plate, an arranging frame is arranged at the groove opening, packaging tube limit mechanisms are arranged at the outer ends of the bottom of the arranging frame respectively, and a feeding mechanism is arranged on the lower part of the bottom plate; and a pressing mechanism is further arranged above the workbench. The semi-automatic punching machine reduces labour intensity, is high in production efficiency and reliable in working, and guarantees the product quality.

Owner:WUXI JIAXIN ELECTRONICS PRODS

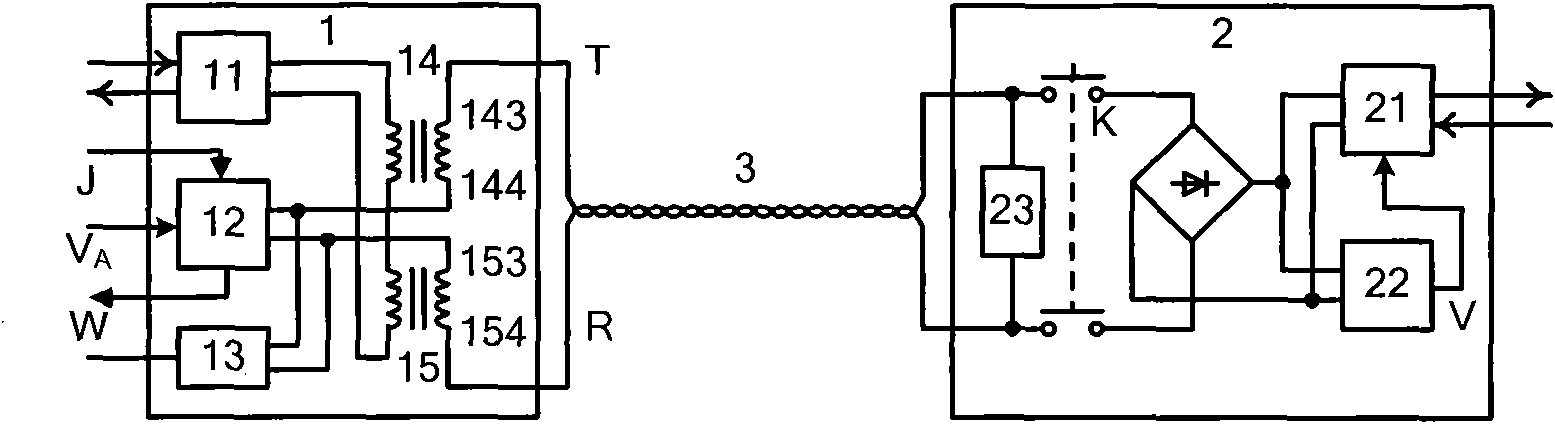

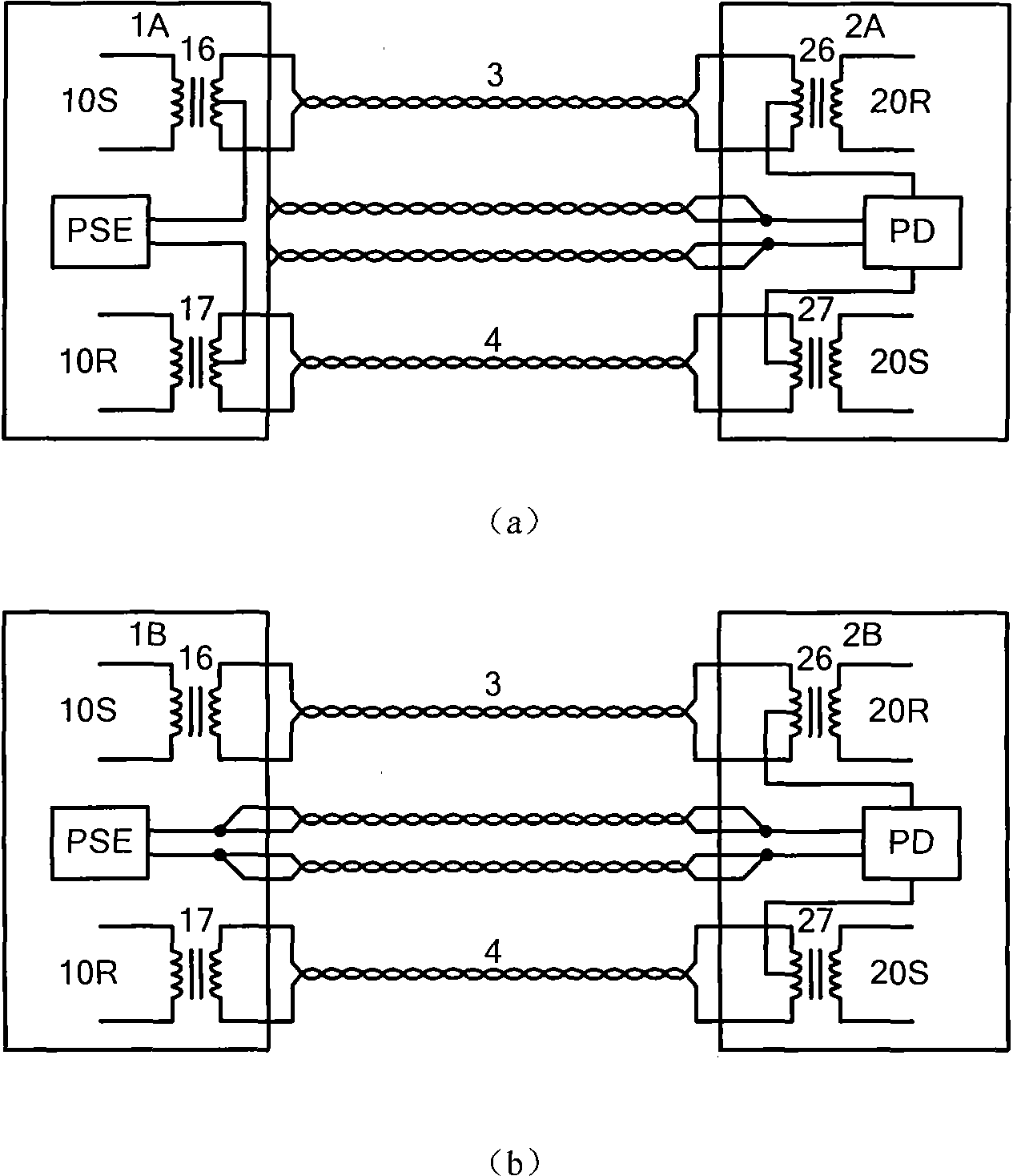

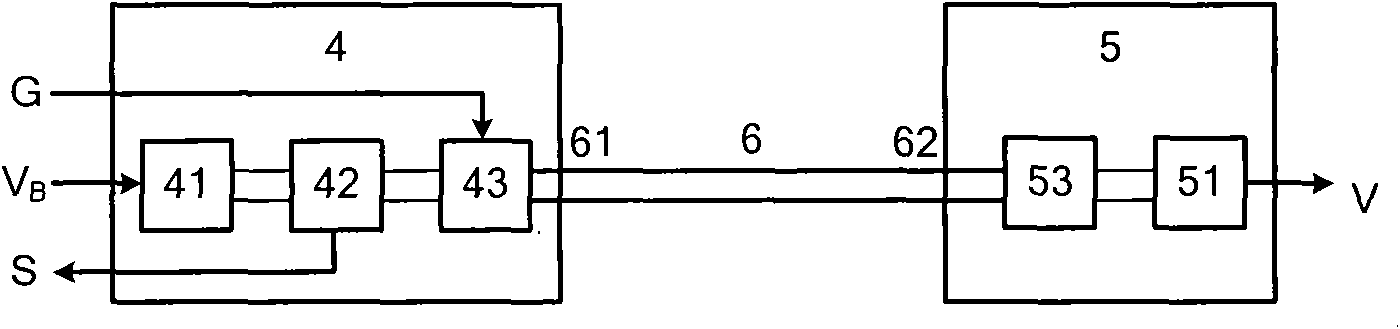

Remote constant-voltage feeding method and system with waking function

ActiveCN101980472AFlexible feedingEfficient separationEnergy efficient ICTAc-dc network circuit arrangementsVoltage polarityElectrical polarity

The invention discloses a remote constant-voltage feeding method and a remote constant-voltage feeding system with waking function in a wired mode. An intelligent power supply module in local side power supply equipment generates feed voltage from a local side power supply, and the feed voltage is fed into a terminal power supply module through a feeder line. The system is characterized in that: the intelligent power supply module can continuously provide constant-voltage feed for the terminal power supply module and change the polarity of the feed voltage according to a determined rule when the terminal power supply module in a sleeping mode needs to be woken remotely; and a voltage polarity monitoring module in the terminal power supply module determines whether to wake the terminal power supply module in the sleeping mode to enter a normal power supply state by monitoring the polarity of the voltage fed on a local side. The method and the system have the advantages that: feeding isflexible, feeding power is high, energy efficiency is high, a feeding circuit and a waking method are simple, and easy to realize, and the requirement of a withstand voltage process is reduced.

Owner:NANJING UNIV

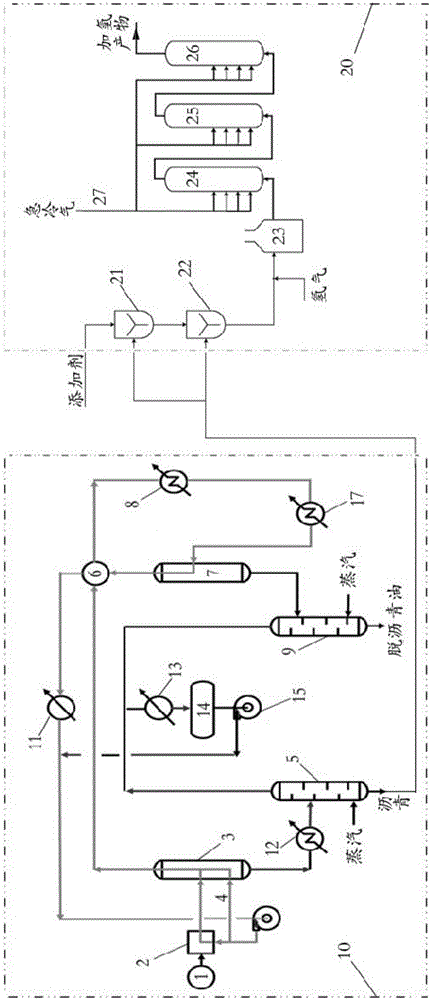

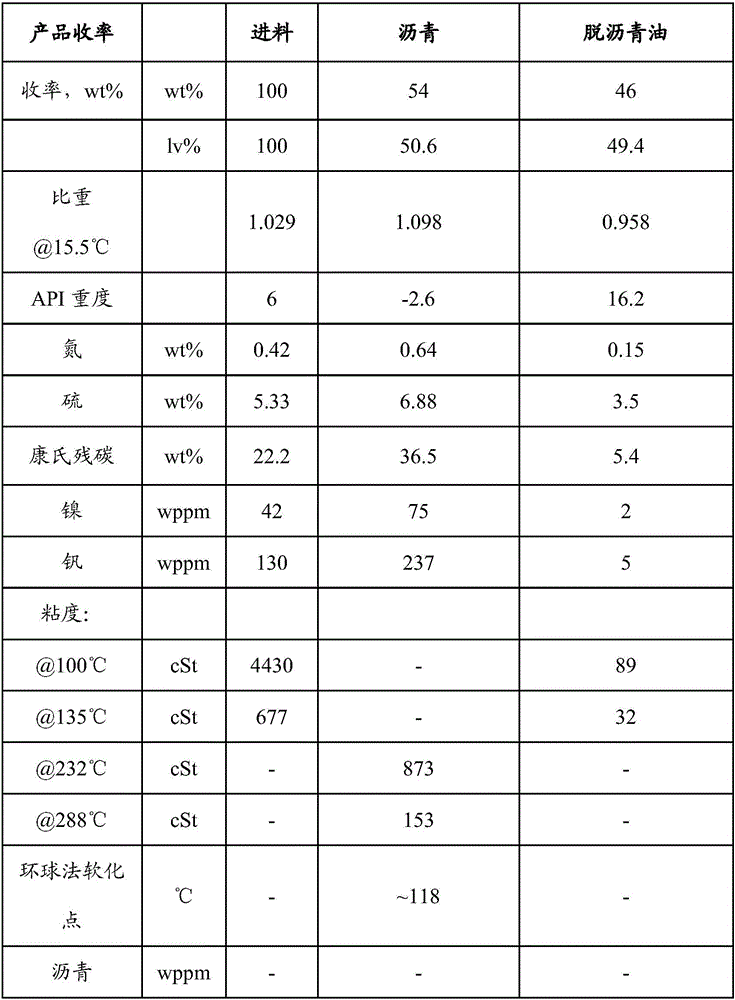

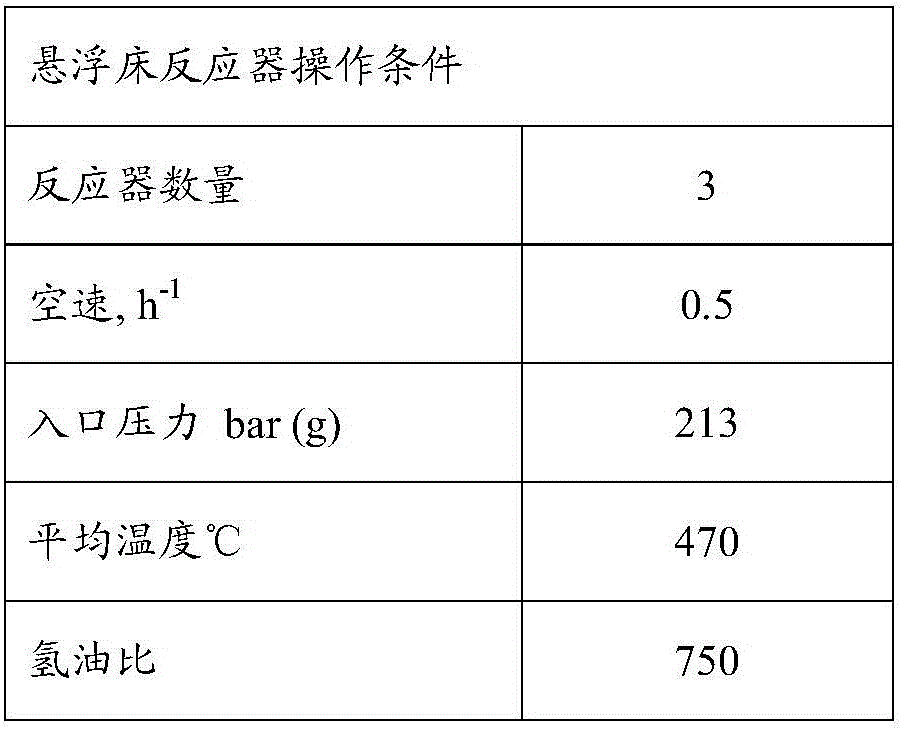

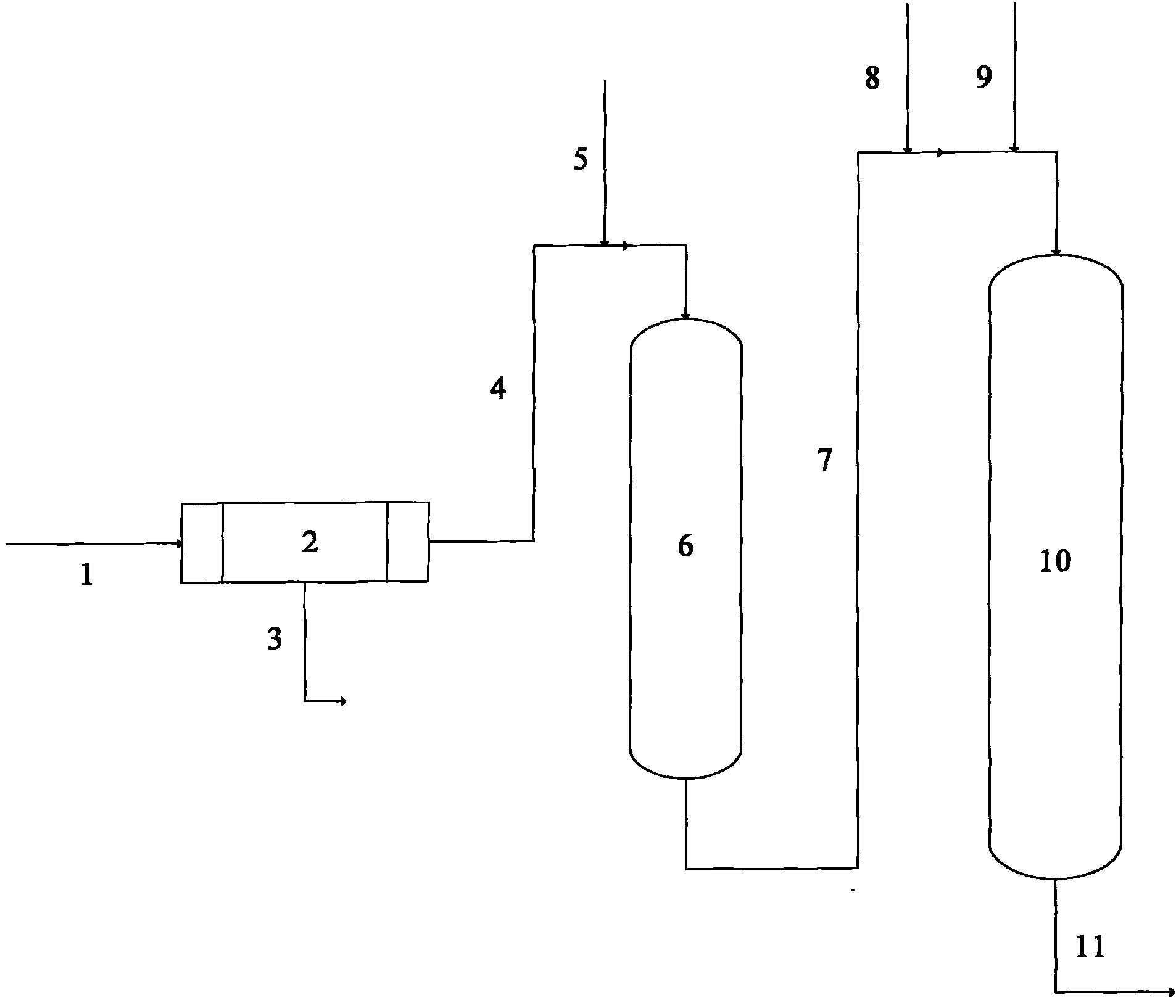

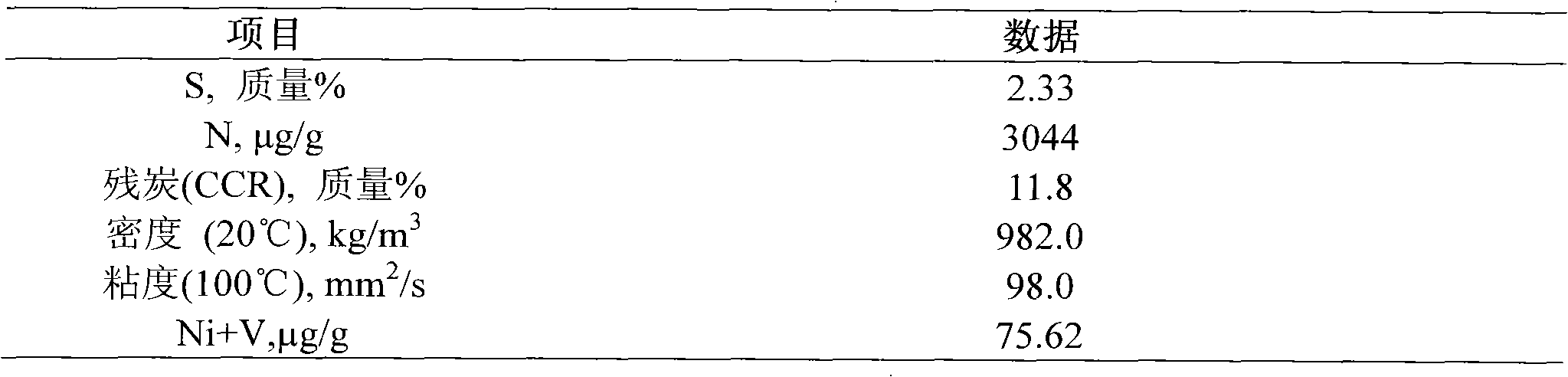

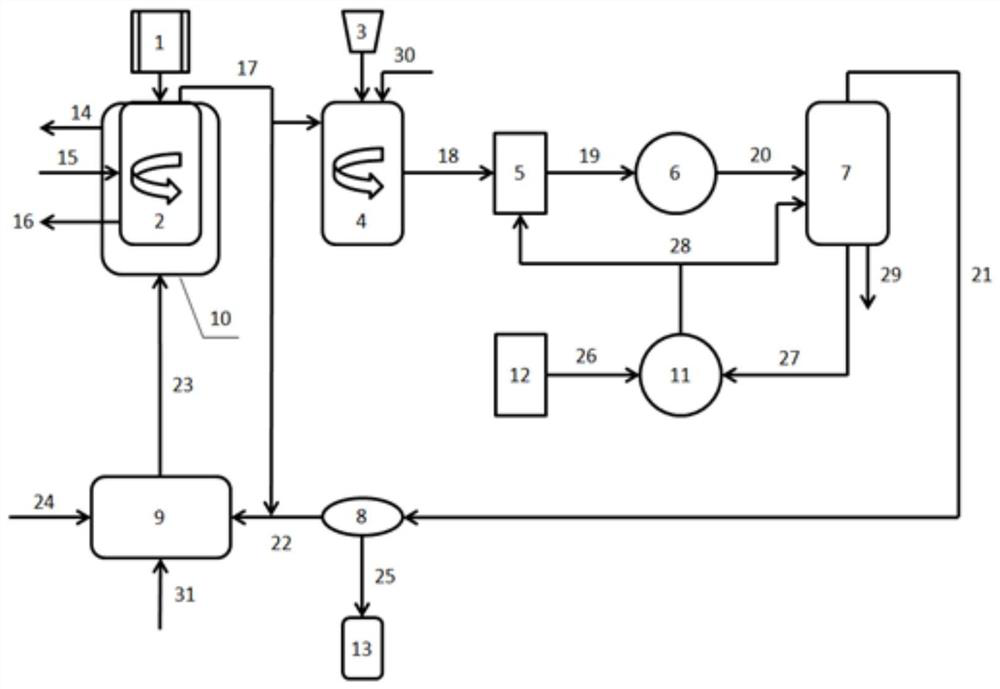

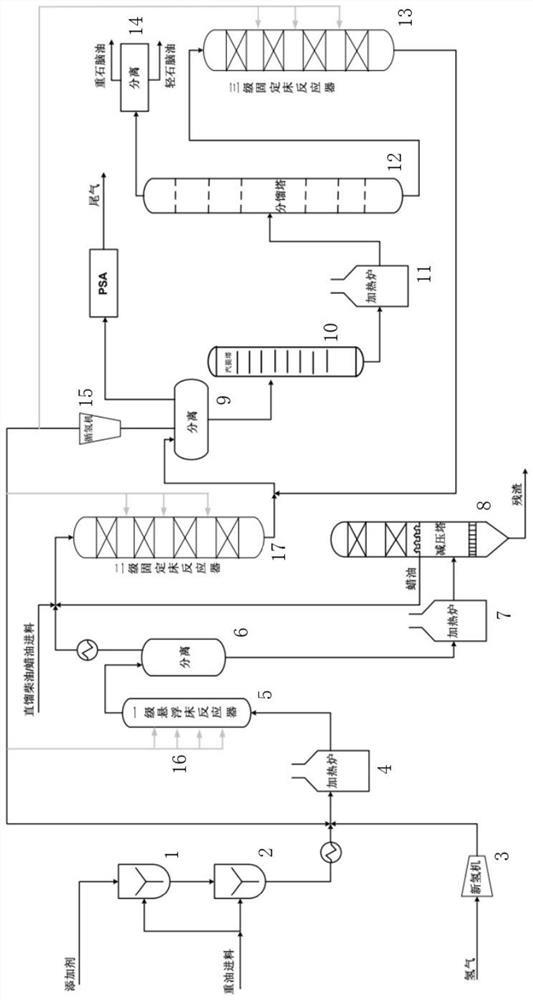

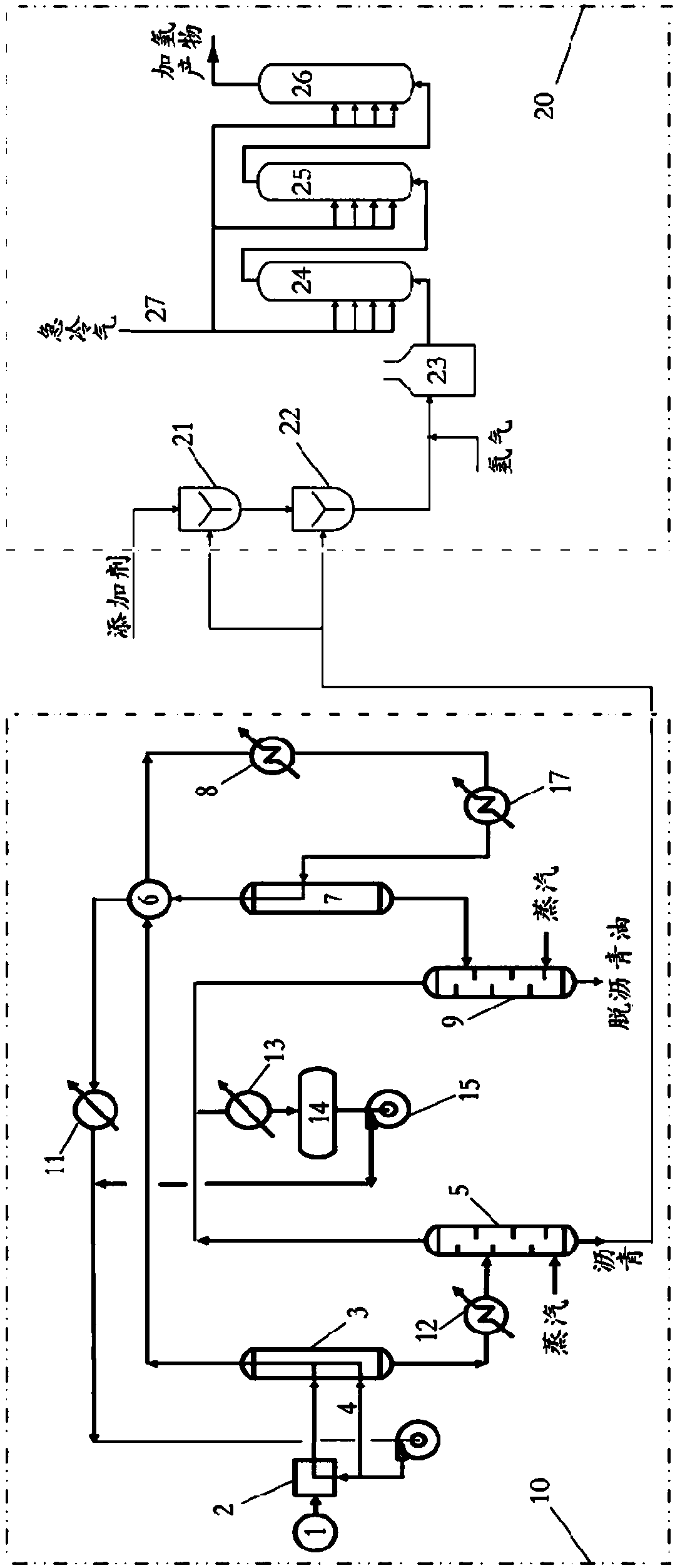

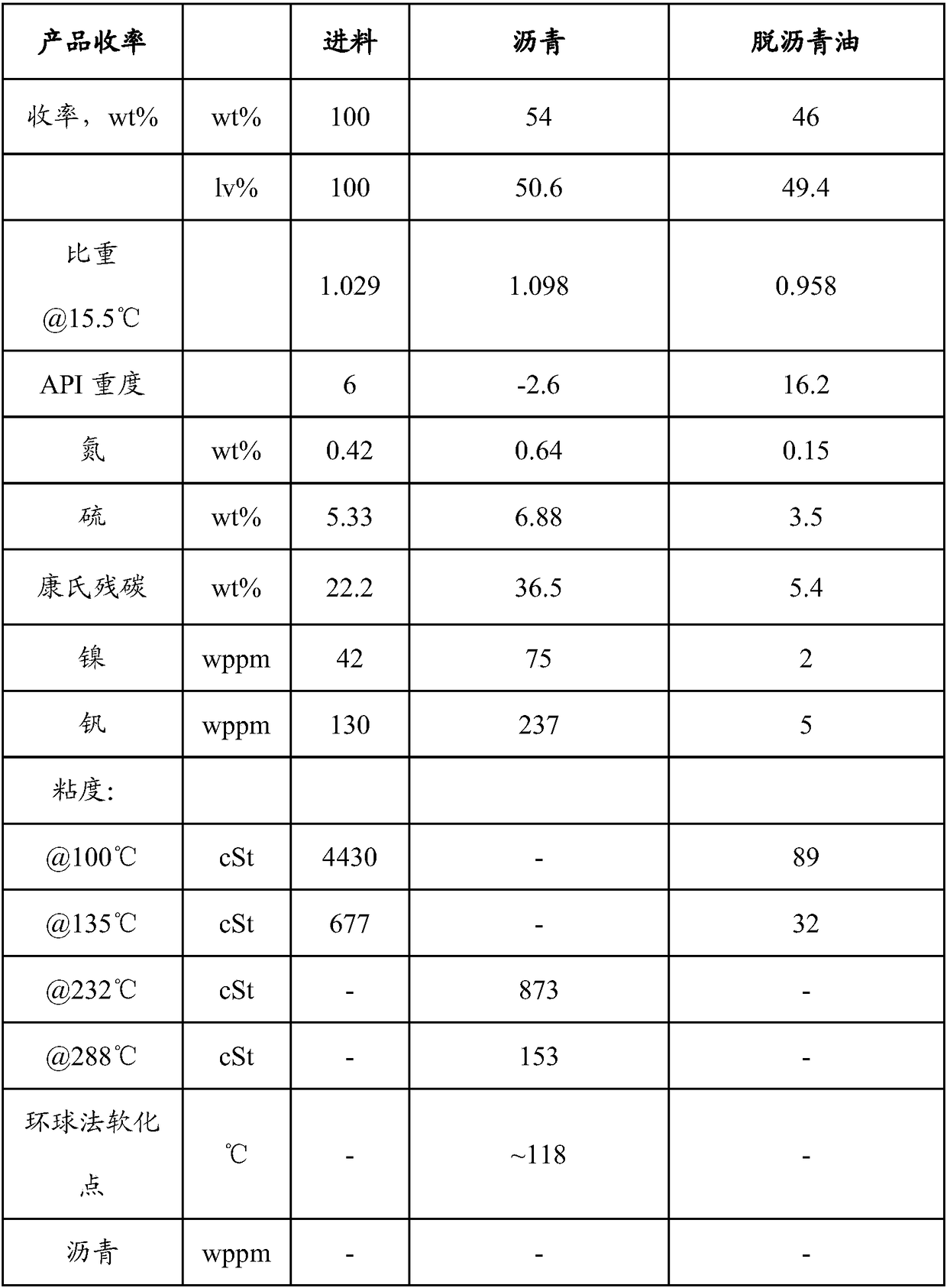

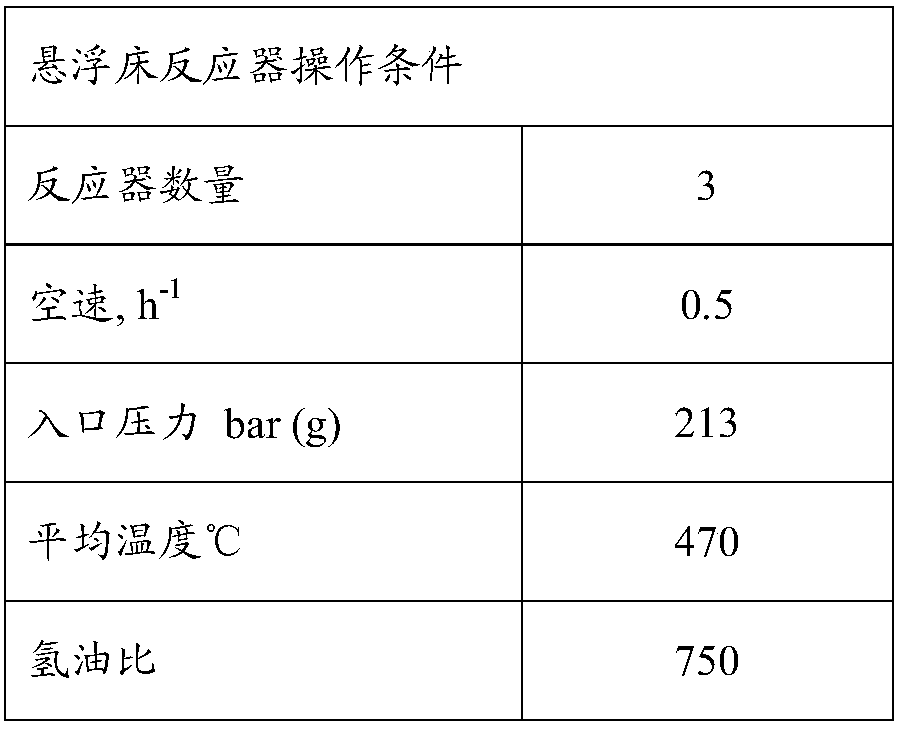

Supercritical extraction and suspension bed hydrogenation combined system for heavy oil raw material and method

ActiveCN107177378AReduce lossesFlexible feedingTreatment with hydrotreatment processesFuel oilAsphaltene

The invention discloses a supercritical extraction and suspension bed hydrogenation combined system for a heavy oil raw material and a method. The combined system comprises a supercritical extraction unit and a suspension bed hydrogenation unit, wherein the supercritical extraction unit is used for extracting and separating the heavy oil raw material so as to separate out an asphaltic product; the suspension bed hydrogenation unit is used for carrying out suspension bed hydrocracking treatment on the asphaltic product coming from the supercritical extraction unit. The supercritical extraction and suspension bed hydrogenation combined system can greatly improve the conversion rate of heavy components of the raw material and asphaltene and reduce the scale of suspension bed unit, thus reducing investment and further greatly reducing the hydrogen consumption.

Owner:北京和利凯石化技术有限公司

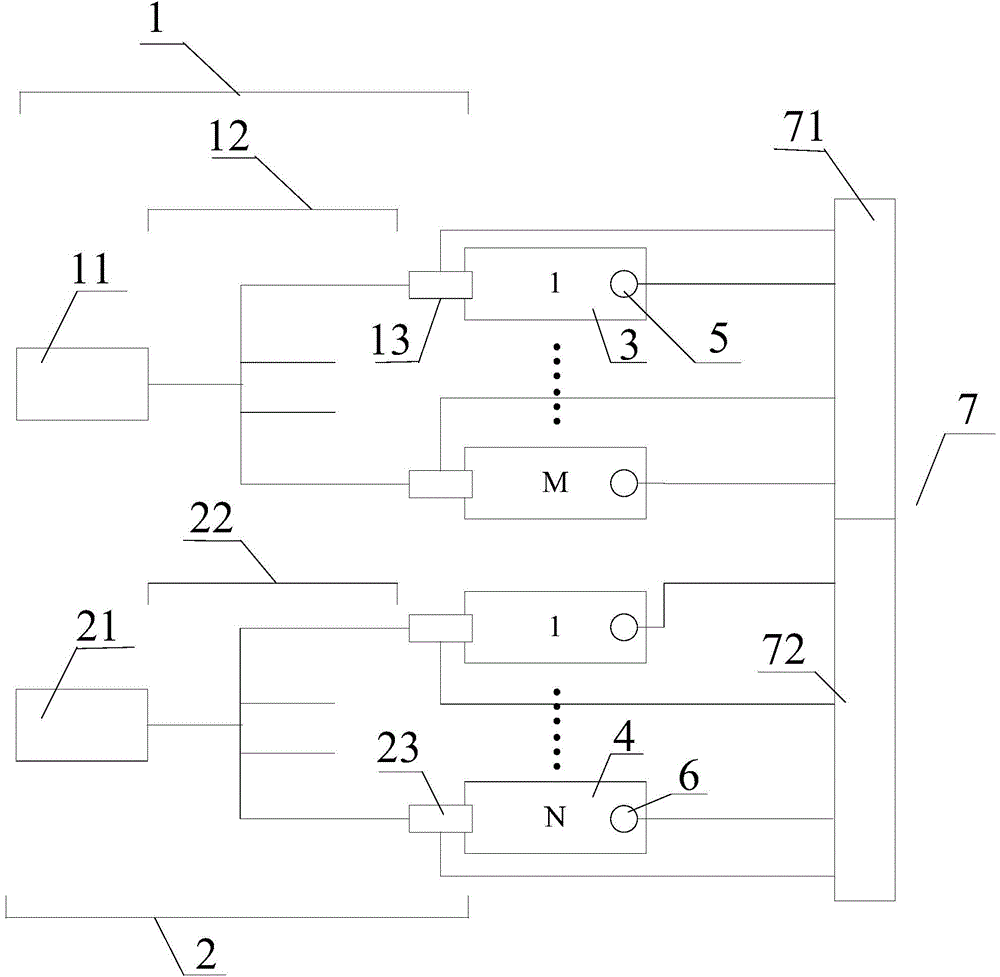

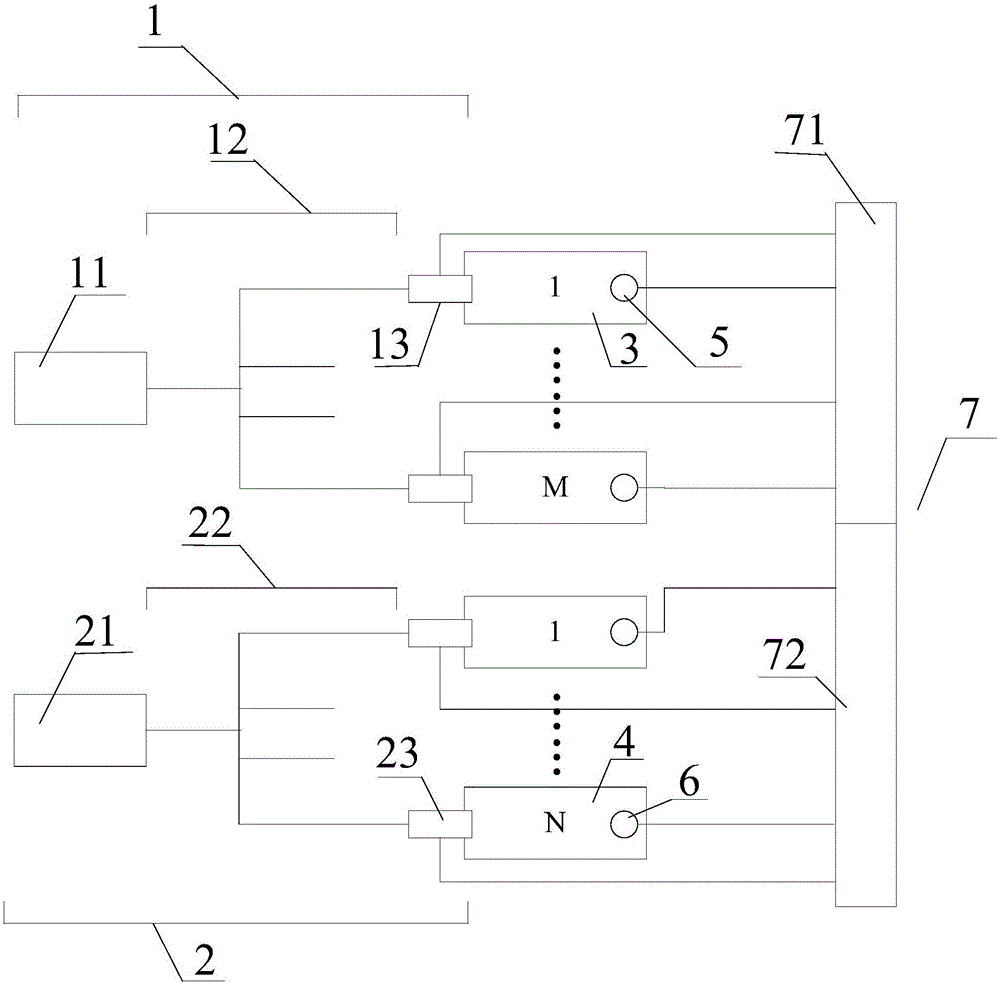

Automatic feeding system for pig farm

InactiveCN104082169AShortened growth timeReduce the cost of farmingAnimal feeding devicesInductorEngineering

The invention provides an automatic feeding system for a pig farm. The automatic feeding system is high in automation degree and small in manpower requirement, reduces feed waste, saves the cost and improves pig group habitus. The automatic feeding system comprises a lard pig feeder, a piglet feeder, M lard pig troughs, N piglet troughs, M first feed inductors, N second feed inductors, a control module and a remote management module. The lard pig feeder comprises a lard pig feed storage bunker, a first conveying mechanism and M first discharging valves. The lard pig feed storage bunker is connected with the first conveying mechanism. The first conveying mechanism is respectively communicated with the M lard pig troughs through the M first discharging valves. The M lard pig troughs are arranged in the lard pig farm in a dispersing mode. The M first feed inductors are arranged in the M lard pig troughs respectively. The M first discharging valves and the M first feed inductors are respectively connected with the control module. The piglet feeder comprises a piglet feed storage bunker, a second conveying mechanism and N second discharging valves.

Owner:上海红马饲料有限公司

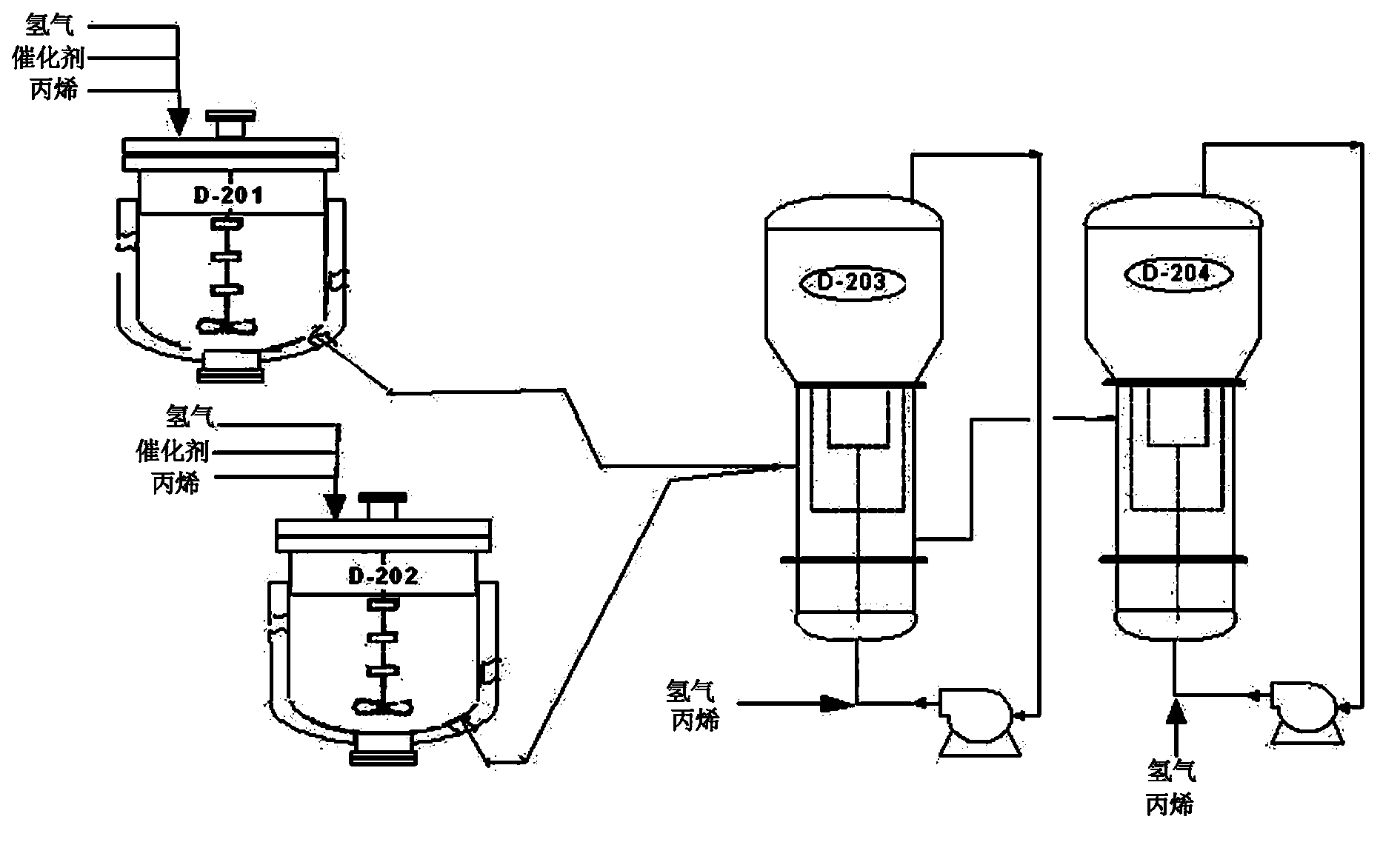

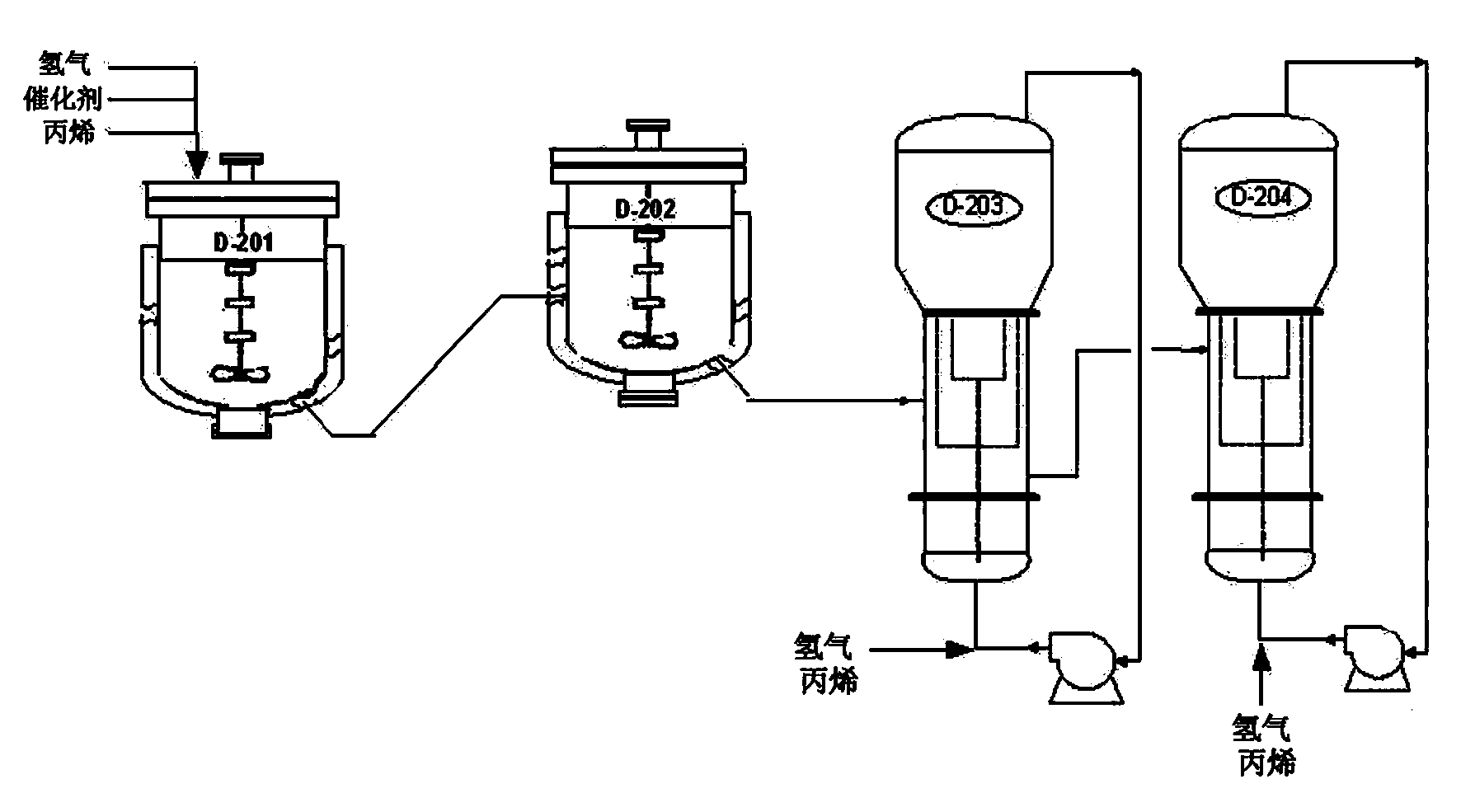

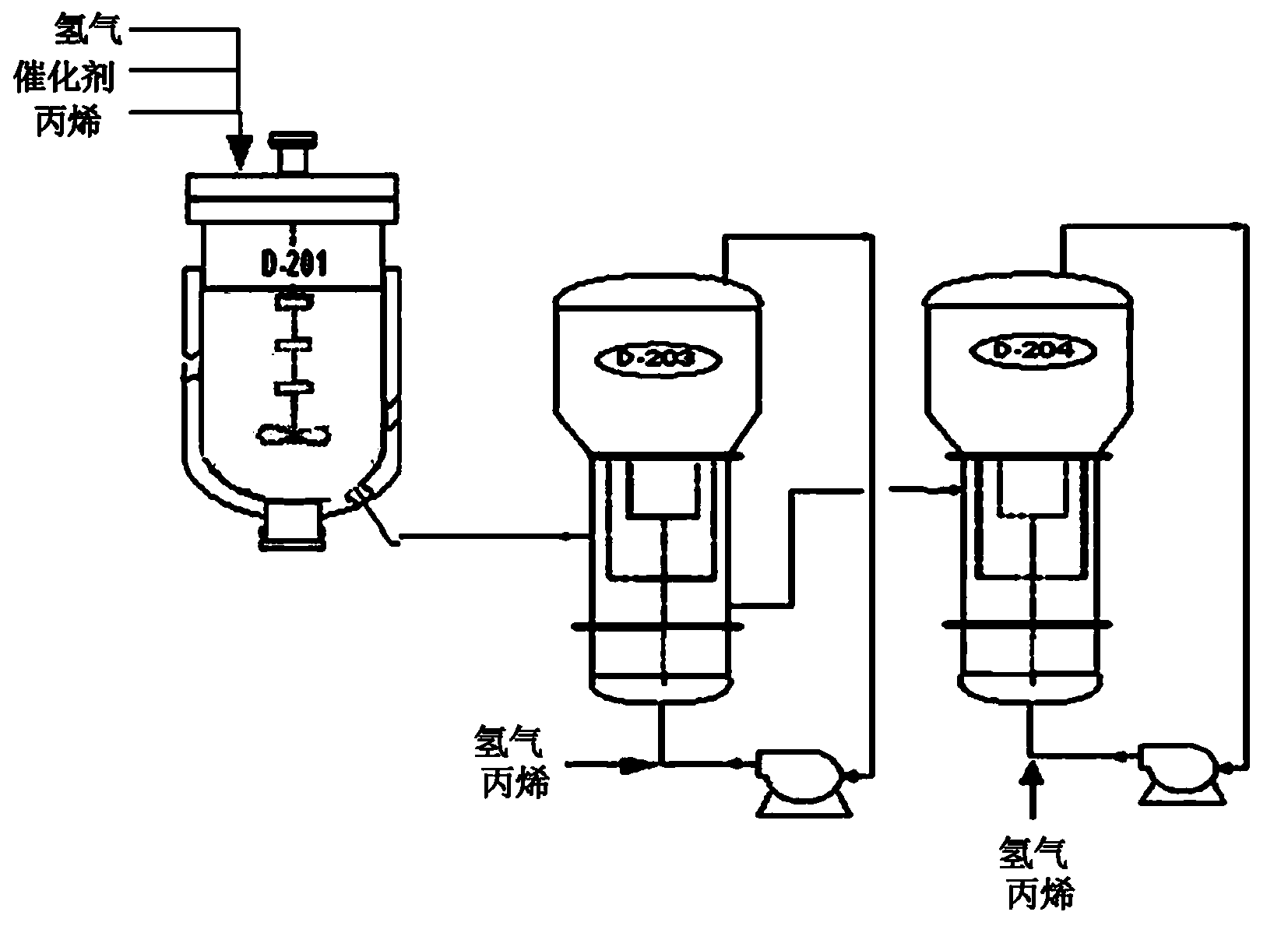

Method for preparing polypropylene

The invention relates to a method for preparing polypropylene. In the presence of a catalyst, a mode that at least two liquid phase stirring reactors are connected in parallel and are connected with a gas phase fluidized bed reactor in series is adopted to perform polymerization reaction of propylene, and the catalysts in the liquid phase stirring reactors comprise main catalysts, auxiliary catalysts and external electron donors. The method provided by the invention is based on the basic principle that liquid phase propylene and gas phase propylene are polymerized, a process that the liquid phase stirring reactors are connected in parallel and are further connected with a gas phase kettle is adopted, and a mode that the main catalysts with different polymerization properties and electron donors with different hydrogen regulation sensitivities are added into the liquid phase kettle, and a mode of differential hydrogen regulation and control, are adopted, so that a polypropylene product with wide molecular weight distribution and novel polypropylene products with excellent property can be developed.

Owner:CHINA PETROLEUM & CHEM CORP +1

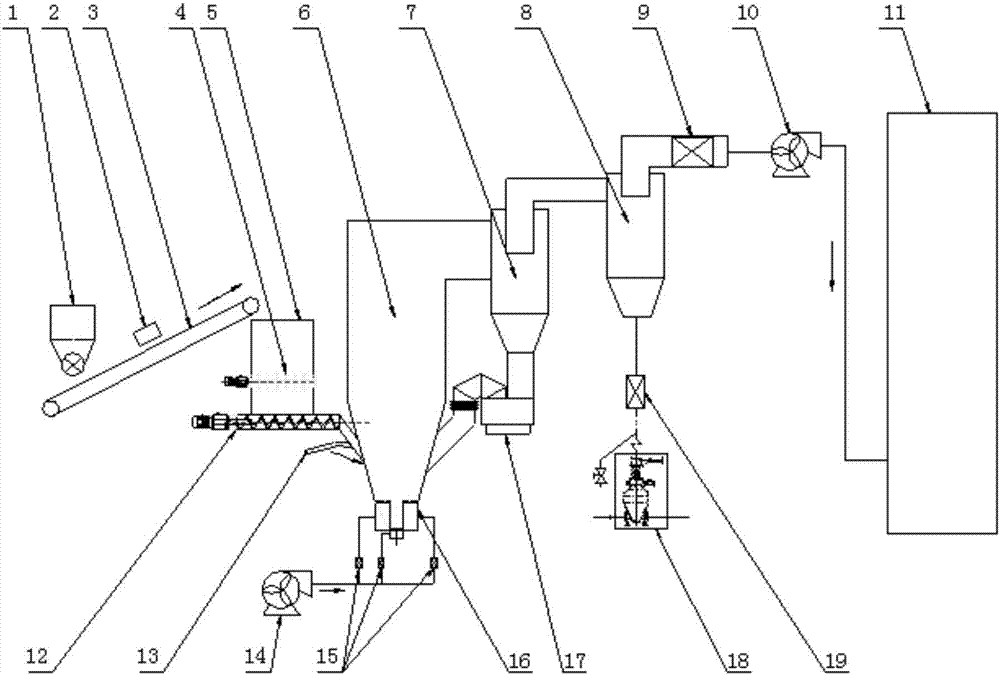

Biomass-and-city-solid-waste comprehensive utilization device and method

InactiveCN106929108APrevent bridgingAvoid entanglementGasification processes detailsGranular/pulverulent flues gasificationPollutant emissionsFuel gas

The invention discloses a biomass-and-city-solid-waste comprehensive utilization device and a method. The biomass-and-city-solid-waste comprehensive utilization device comprises a crushing machine for crushing materials; a conveying belt is arranged below a material discharging opening of the crushing machine, an iron-removing device is arranged above the conveying belt, the tail end of the conveying belt is arranged on an inlet of a material cabin, a material shifting device is arranged in the middle of the material cabin, the bottom of the material cabin is connected with a screw feeding machine, an outlet of the screw feeding machine is connected with a gasification furnace, and a winnowing wind part is arranged on the outlet of the screw feeding machine; a fluidization separating device is arranged at the bottom of the gasification furnace, an outlet in the top of the gasification furnace is connected with a separator, the bottom of the separator is connected with a material returning device, and an outlet of the material returning device is connected with the gasification furnace; an outlet in the top of the separator is connected with a dust collector, the bottom of the dust collector is connected with a cool gray device, and the bottom of the cool gray device is connected with a pneumatic transmission device; a heat exchanger is arranged in an outlet flue channel of the dust collector, and fuel gas after heat exchanging is conveyed to a boiler. The biomass-and-city-solid-waste comprehensive utilization device and the method have the advantages of being controllable in pollutant discharging, small in cost, high in efficiency, capable of continuously and stably running, flexible in device arrangement, capable of achieving automation, easy to collectively control and the like.

Owner:HUANENG CLEAN ENERGY RES INST

Automatic cable tie dismounting device

PendingCN113247395AFlexible feedingHigh speedUnpacking by cuttingElectric machineryStructural engineering

The invention discloses an automatic cable tie dismantling device. The automatic cable tie dismantling device is characterized by comprising a conveying assembly and a tie dismantling assembly, wherein the conveying assembly is used for conveying a box body with a tie to be disassembled and comprises a driving motor, a plate chain module which is in driving connection with the driving motor and a recycling box which is arranged below the plate chain module and used for recycling the tie, the tie dismantling assembly is arranged beside the plate chain module and comprises a pressing air cylinder, a pressing guide bearing, a pressing guide column and a pressing plate, the pressing guide column is mounted on the pressing guide bearing through a pin shaft, the pressing plate is arranged on the pressing guide column in a sleeving manner, is connected with the pressing air cylinder and is driven by the pressing air cylinder to press the box body with the tie to be disassembled, and a tie cutting module used for cutting off a cable tie is further arranged at the position where the cable tie of the box body with the tie to be disassembled is located. According to the automatic cable tie dismantling device, disassembly of box body ties of various sizes can be achieved integrally, and the production efficiency of a packaging line body is greatly improved.

Owner:SHANGHAI ROBOT IND TECH RES INST CO LTD

Automatic charging machine for smelting furnace

PendingCN110966859AImprove securityPlay a lifting roleCrucible furnacesProcess engineeringMechanical engineering

The invention relates to the technical field of smelting furnace feeding, and further discloses an automatic charging machine for a smelting furnace. The automatic charging machine for a smelting furnace comprises a workbench, a containing box, a suction cup slicing device, a feeding device and a clamping device. The containing box is located on one side of the workbench. The suction cup slicing device is located above the containing box. A groove is formed in one side of the top of the workbench, the feeding device is arranged in the groove, the clamping device is located on the other side ofthe workbench, a distribution box is fixedly connected to the bottom of the workbench, a U-shaped bearing plate is fixedly connected to the outer wall of one side of the distribution box, and a control box is fixedly connected to the outer wall of the other side of the distribution box. The automatic charging machine for a smelting furnace has the functions of conveying and overturning copper plates at the same time, the feeding time is greatly saved, the working efficiency is also improved, the quality of molten copper can be improved, and the product quality is improved.

Owner:QINGDAO HONGTAI COPPER IND

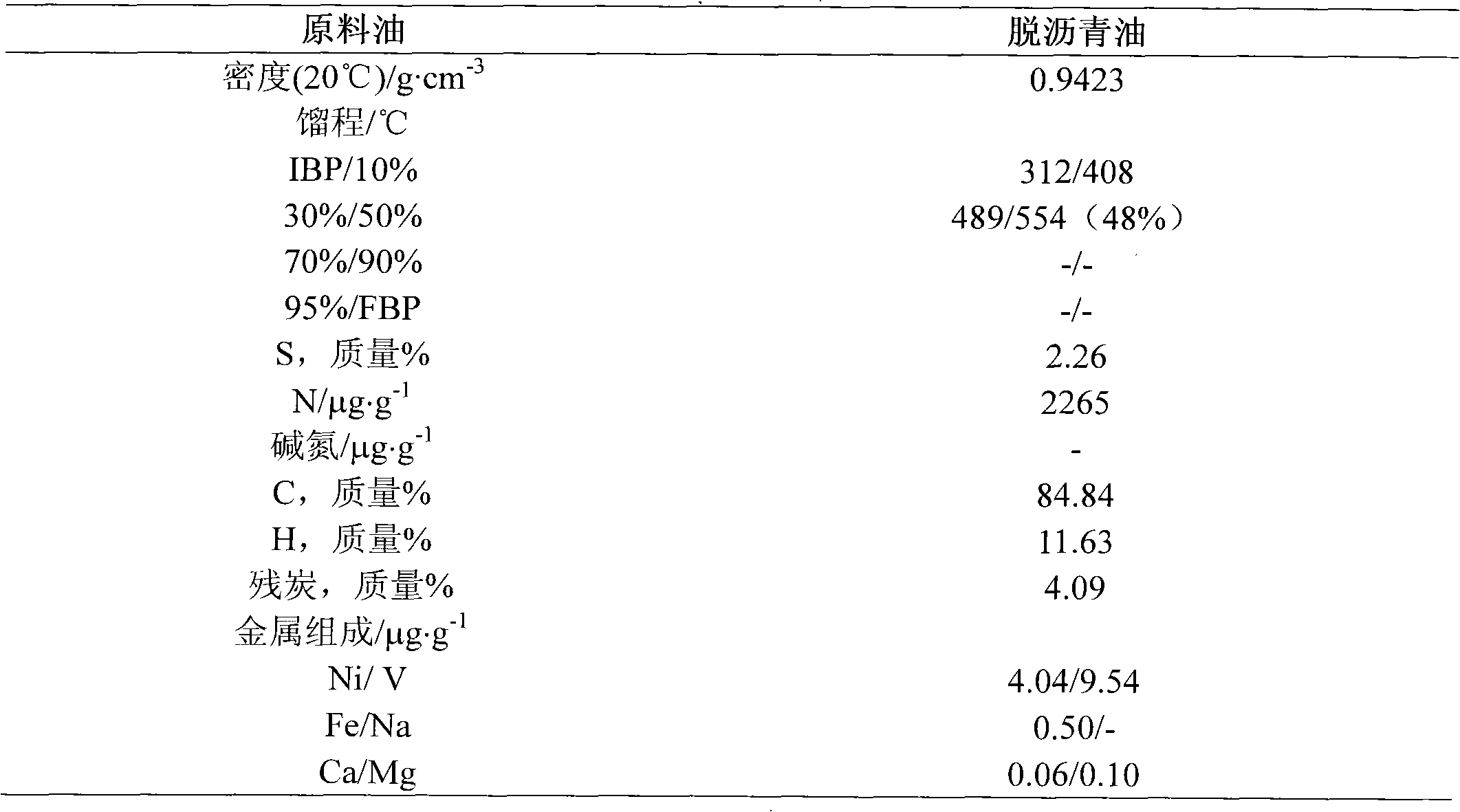

Catalytic cracking material pretreatment method

InactiveCN102311793AIncrease flexibilityImprove desulfurization efficiencyTreatment with hydrotreatment processesSolventWax

The invention discloses a catalytic cracking material pretreatment method, which comprises the following steps: filling a residual oil raw material into a solvent deasphalting device to perform deasphalting treatment; delivering the mixture of deasphalted oil and deeply drawn vacuum gas oil (VGO) to a hydrodemetallization region to perform a reaction in the presence of hydrogen and a demetallization catalyst; and finally, mixing the efflux of hydrodemetallization with one or two of the light wax oil and coker gatch, delivering the mixture to a hydrogenation treatment reaction region to perform a reaction in the presence of hydrogen and a hydrogenation treatment catalyst, wherein a liquid phase separated from the efflux of the hydrogenation treatment reactor is used as a catalytic raw material. When the method disclosed by the invention is used, different catalytic cracking raw materials can be treated stage by stage, the flexible operability and desulfuration efficiency of the device can be improved, and the cost can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

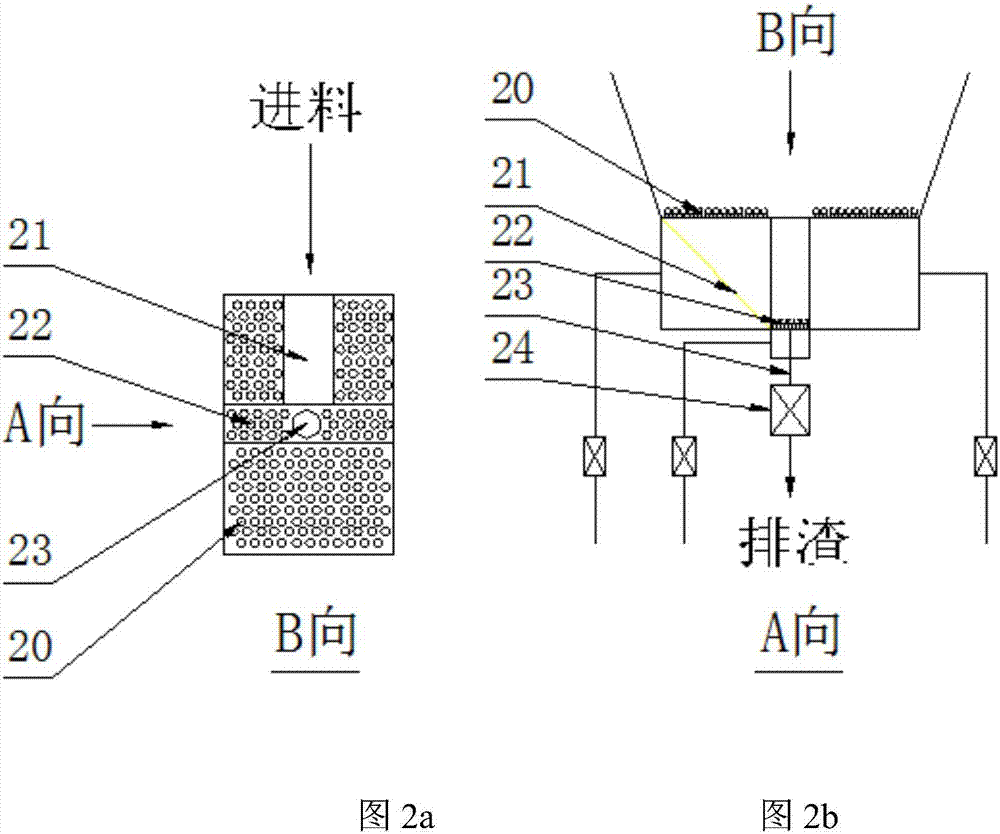

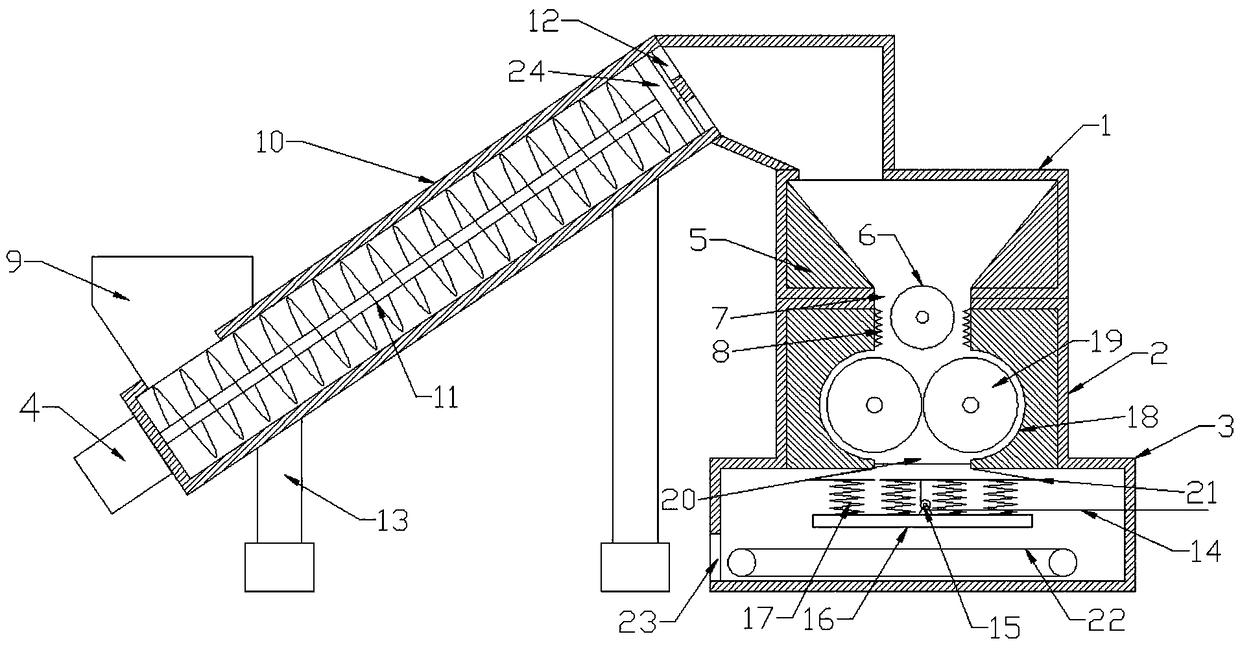

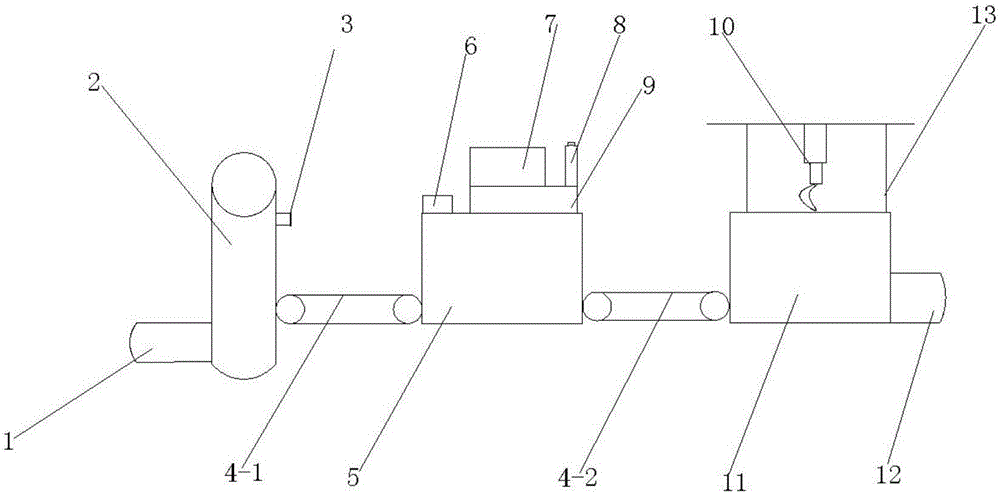

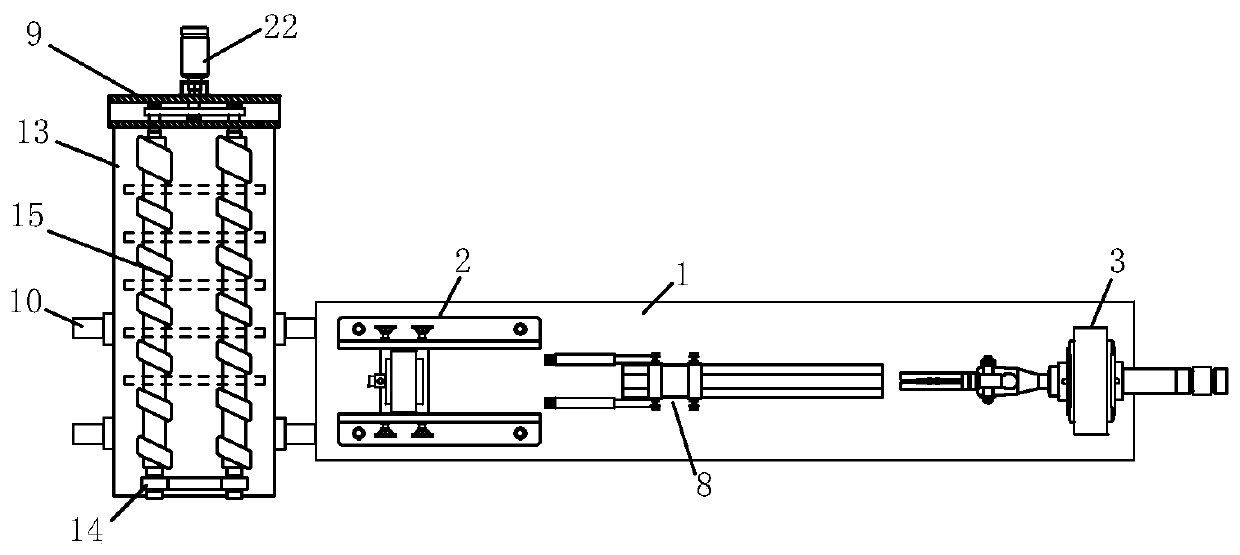

Dry separator feeding device and feeding method

InactiveCN109675792AFlexible feedingUniform and stable feedingSievingScreeningEngineeringMechanical engineering

The invention discloses a dry separator feeding device and feeding method. The dry separator feeding device comprises a grading sieve, and further comprises a reversed loader and a vibrating distributing device. A feeding opening of the reversed loader communicates with a discharging opening of the grading sieve. A feeding opening of the vibration distributing device communicates with a discharging opening of the reversed loader. A discharging opening of the vibrating distributing device is used for communicating with a feeding opening of a dry separator. The dry separator feeding method is used for feeding by the dry separator feeding device. By means of the dry separator feeding device and feeding method, the arrangement flexibility of the grading sieve and dry separator is improved, rawcoal is uniformly laid on the dry separator, and the sorting precision and sorting effect of the dry separator are improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Efficient stone crusher for mines

The invention discloses an efficient stone crusher for mines. The efficient stone crusher comprises a precrushing box, a crushing box, a collecting box, a feeding motor, a feed hopper and a feeding cylinder; the top of the precrushing box communicates with the upper end of the feeding cylinder inclined downwards; an output shaft of the feeding motor is fixedly connected with a spiral auger; a horizontal precrushing roller is mounted in an unloading port; multiple crushing teeth, longitudinally arranged, are fixed on the side wall of the unloading port; two horizontal main crushing rollers, cooperating with each other, are arranged in the crushing cavity; and a baffle plate is arranged in the collecting box under a blanking port. Stones crushed by the main crushing rollers can be contactedwith the main crushing rollers by multiple times from the bottoms, so that the crushing of the stones is facilitated; the crushed stones fall down from gaps at the two ends of the baffle plate, so that the stones fall smoothly, and are not easy to block; the stones in the blanking port can be totally discharged through manual operation to achieve the use flexibility; and during loading, through the feeding cylinder inclined upwards, more time and power are saved in feeding, and the labor intensity of workers is relieved.

Owner:WUHAN UNIV OF TECH

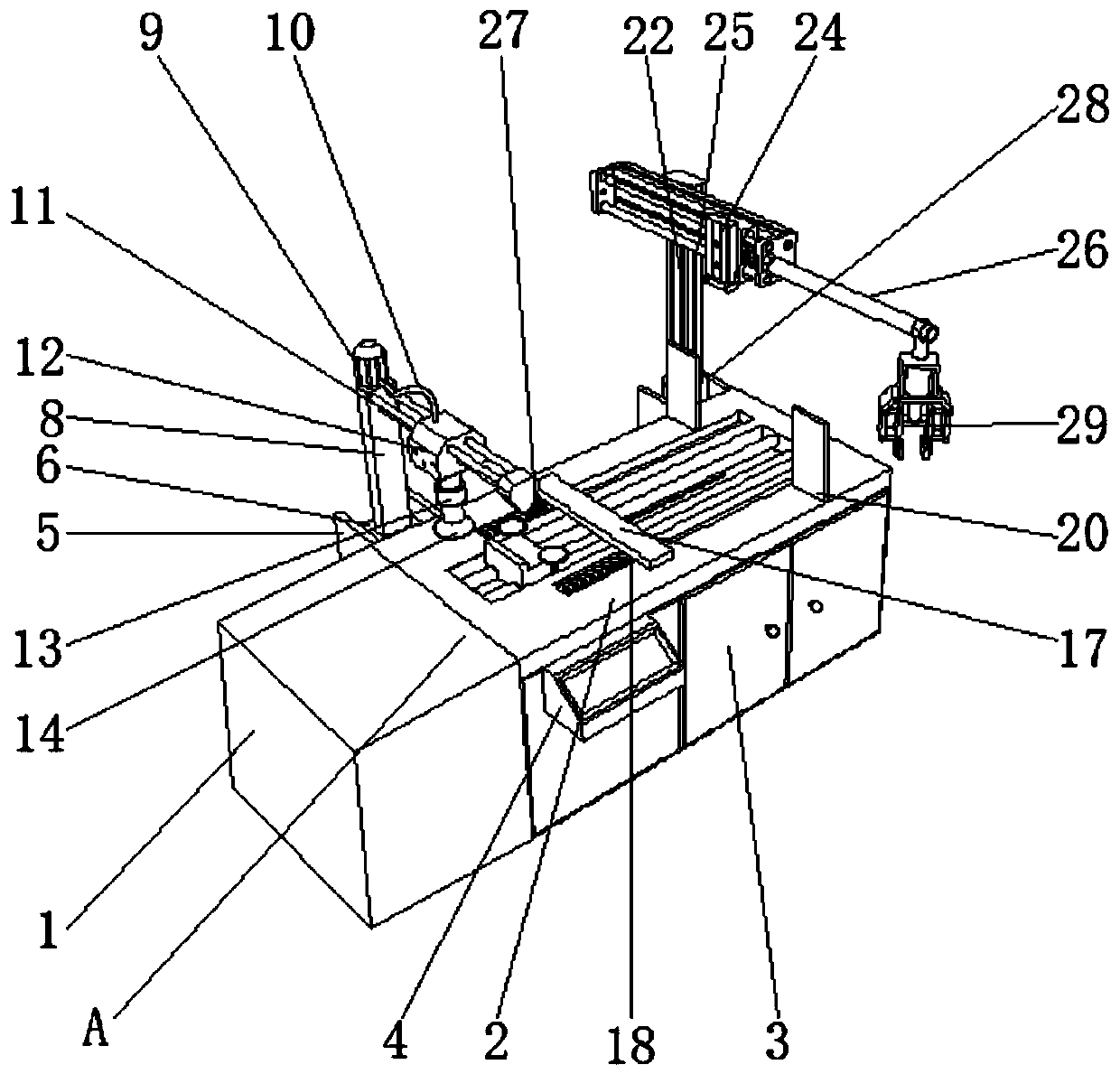

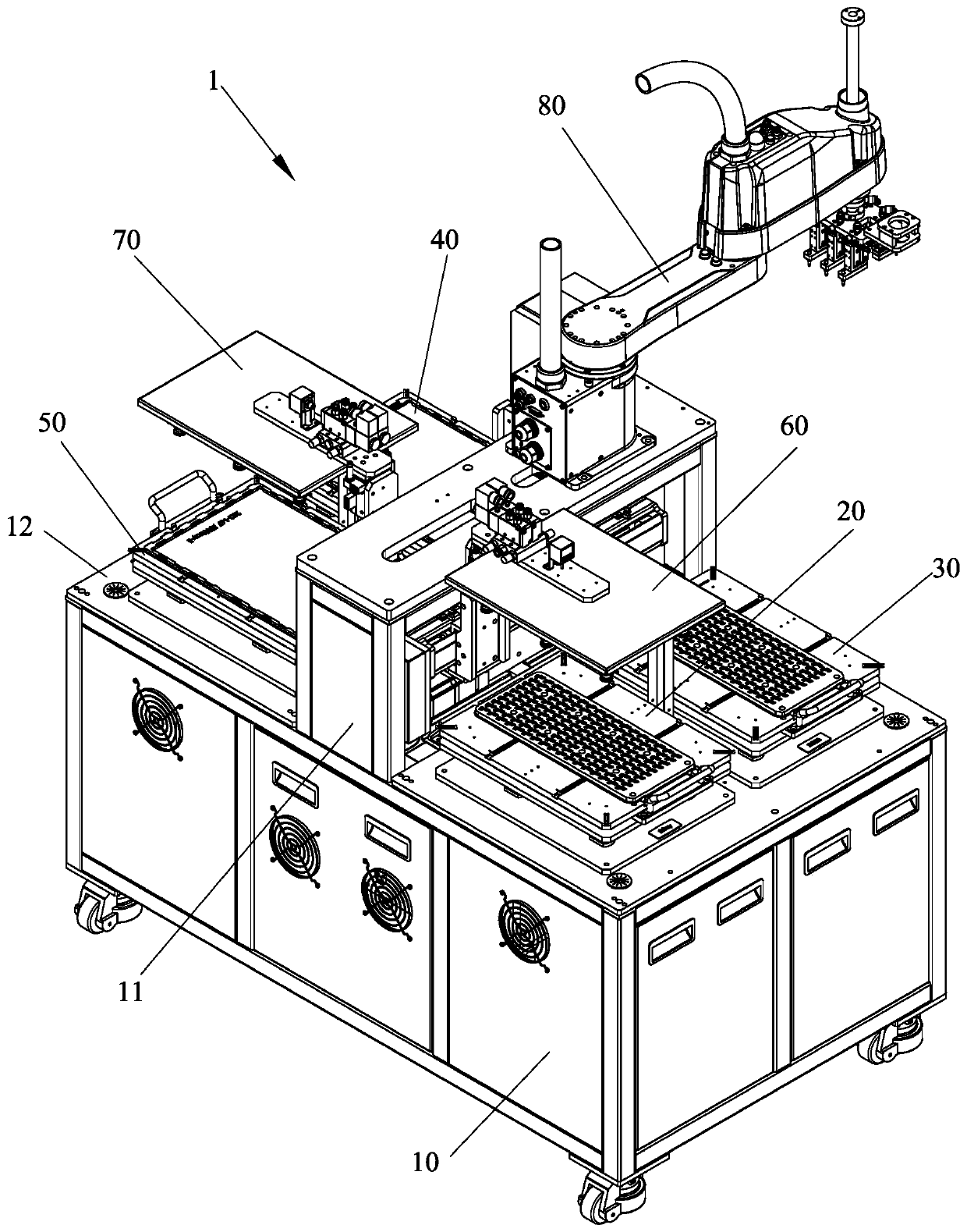

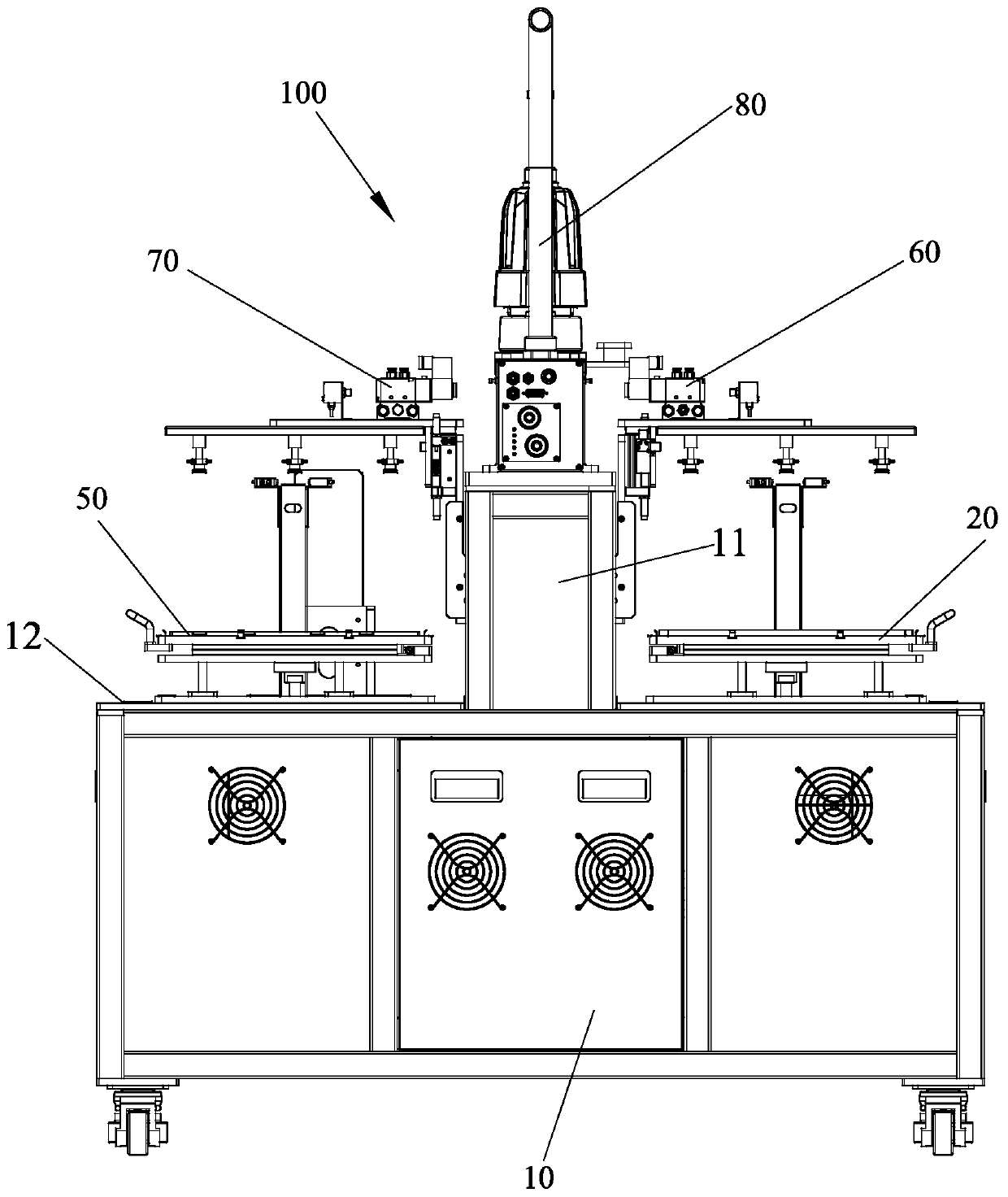

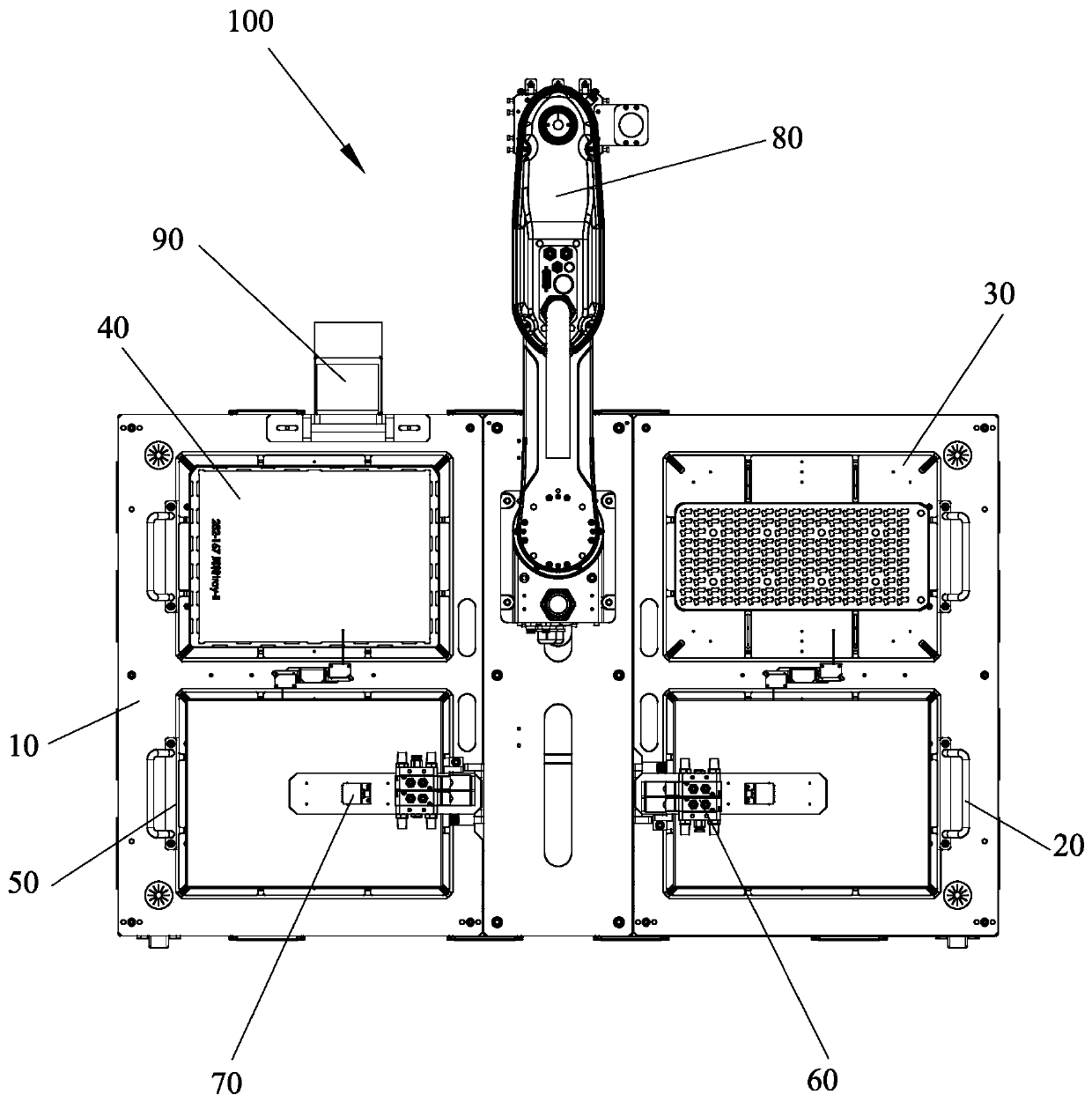

Burning loading and unloading equipment

PendingCN111348433APrecise feedingAccurate receiptControl devices for conveyorsLifting framesSemi automaticStructural engineering

The invention discloses burning loading and unloading equipment. The equipment comprises a rack, a first tray lifting mechanism, a second tray lifting mechanism, a third tray lifting mechanism, a fourth tray lifting mechanism, a first tray carrying mechanism, a second tray carrying mechanism and a material moving mechanism; the first tray lifting mechanism, the second tray lifting mechanism, the third tray lifting mechanism and the fourth tray lifting mechanism are arranged on two sides of the middle of the rack, and the first tray carrying mechanism and the second tray carrying mechanism aremovably arranged on two sides of a mechanism frame of the rack; the material moving mechanism is arranged on a rear side of an upper portion of the mechanism frame and can move above the mechanism frame in a multi-station mode. The burning loading and unloading equipment can be matched with existing semi-automatic burning equipment, so the existing semi-automatic burning equipment can be transformed into full-automatic burning equipment, existing equipment resources are fully utilized, automation of the product burning process is achieved, one person can operate multiple sets of equipment, andthe labor cost is reduced.

Owner:XIAMEN HONGXIN ELECTRON TECH

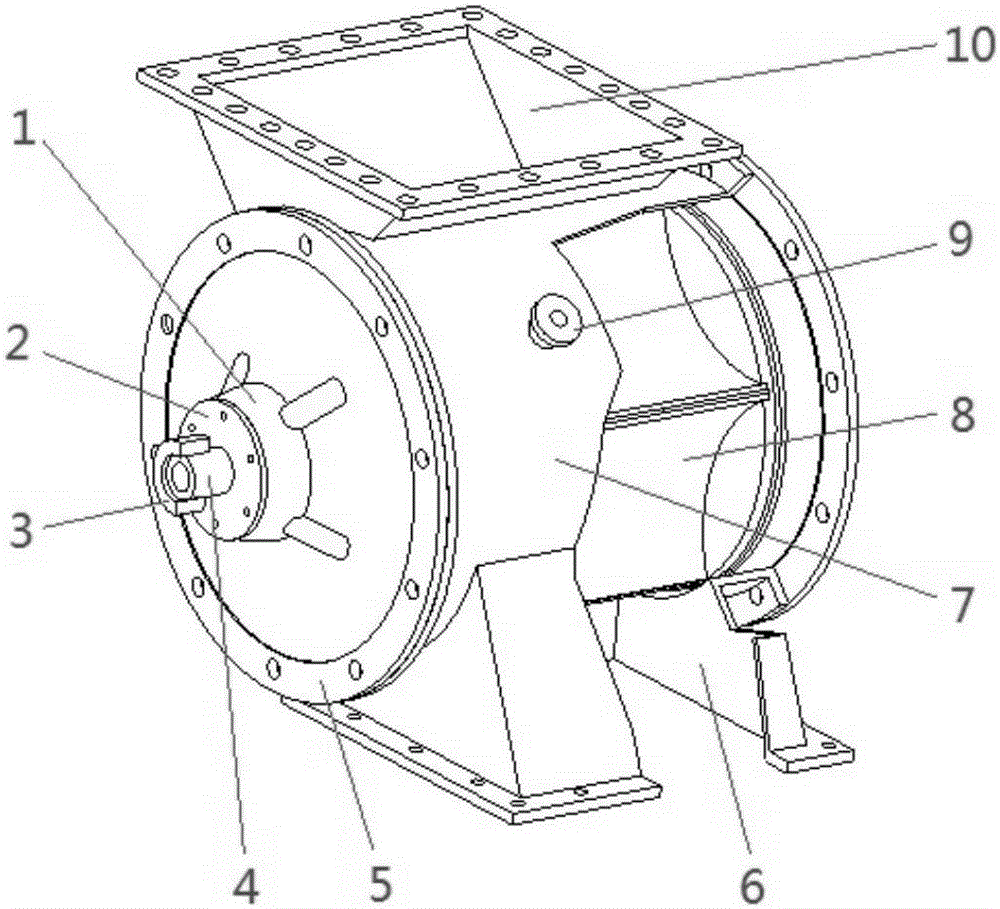

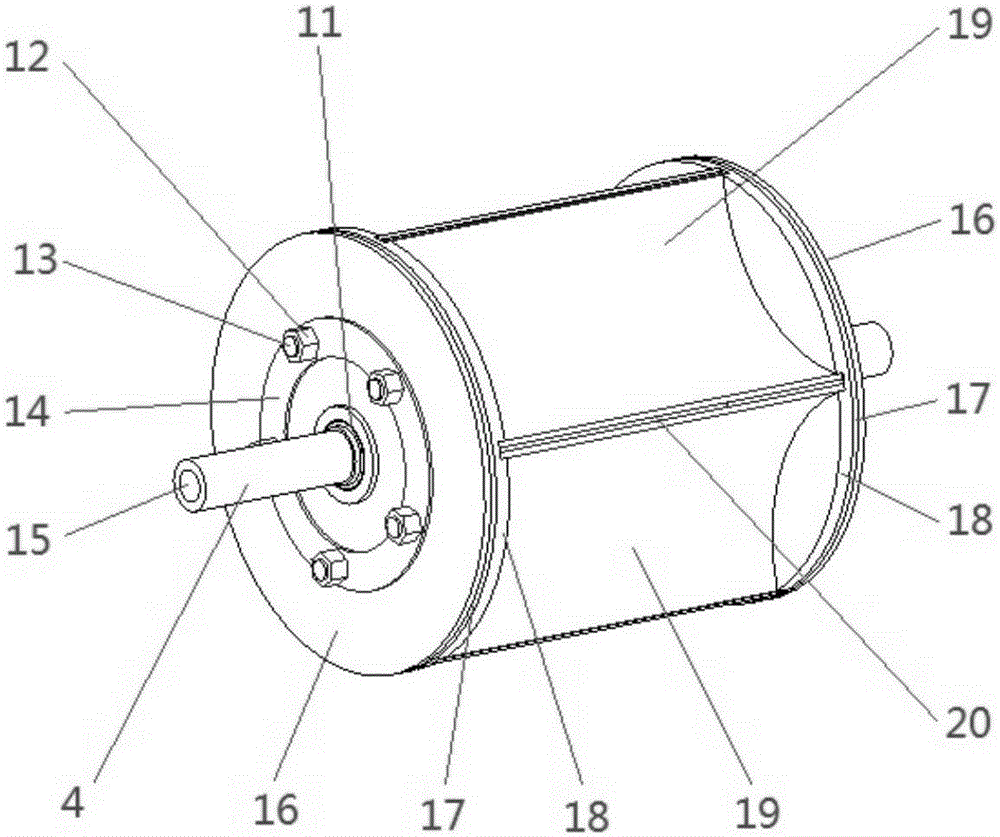

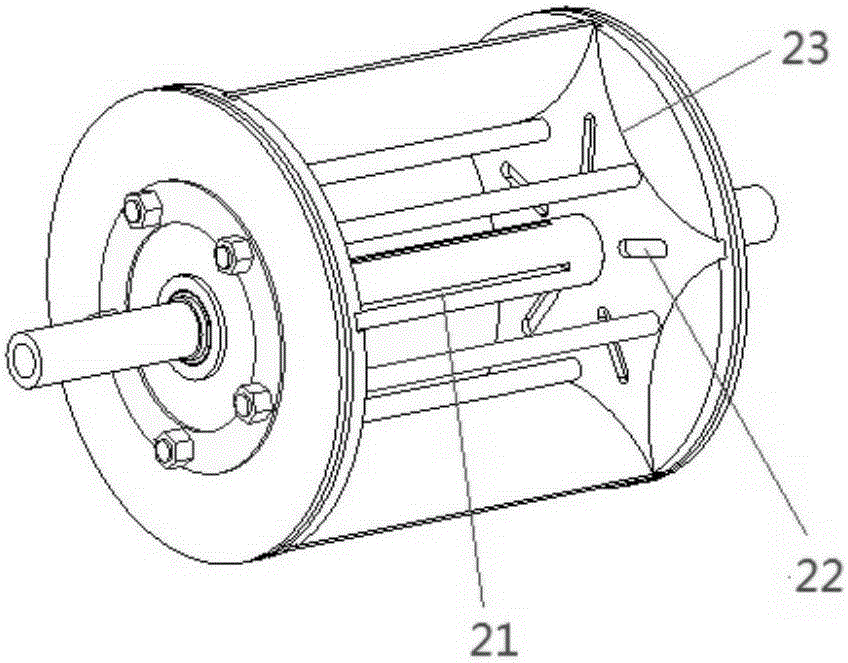

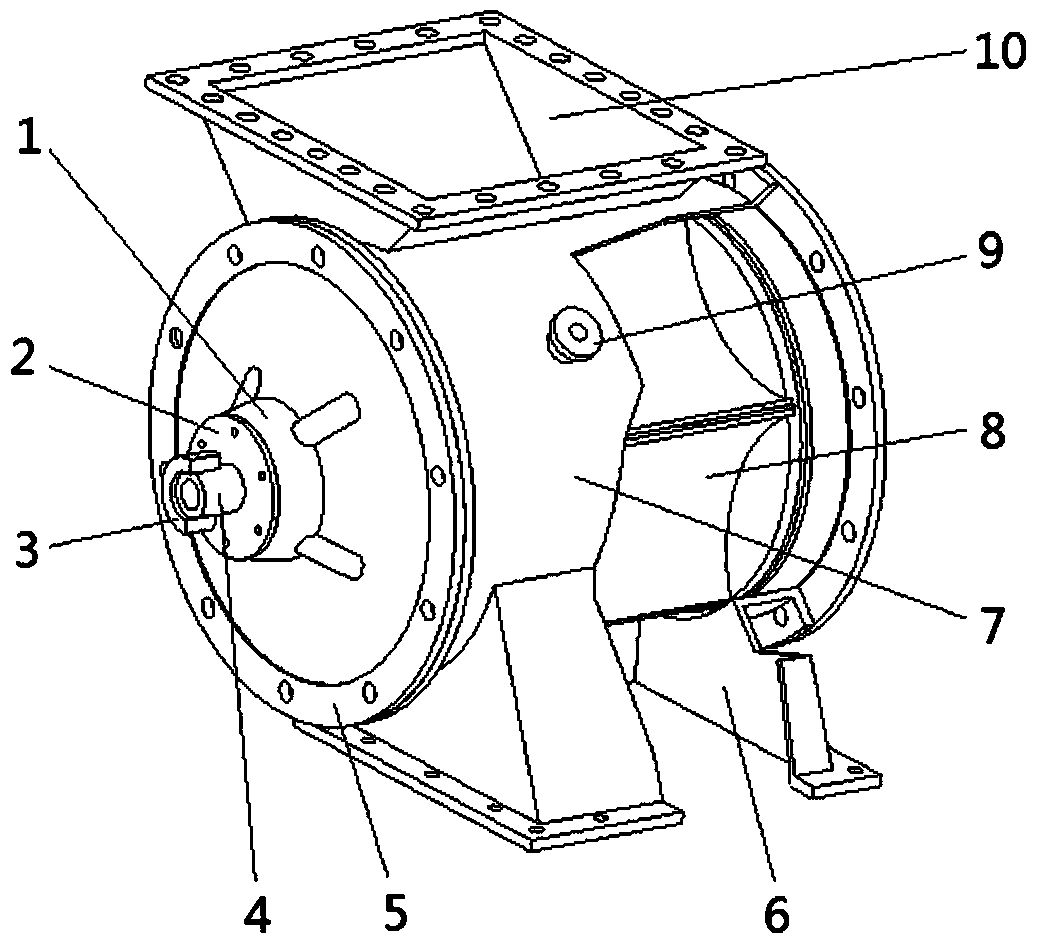

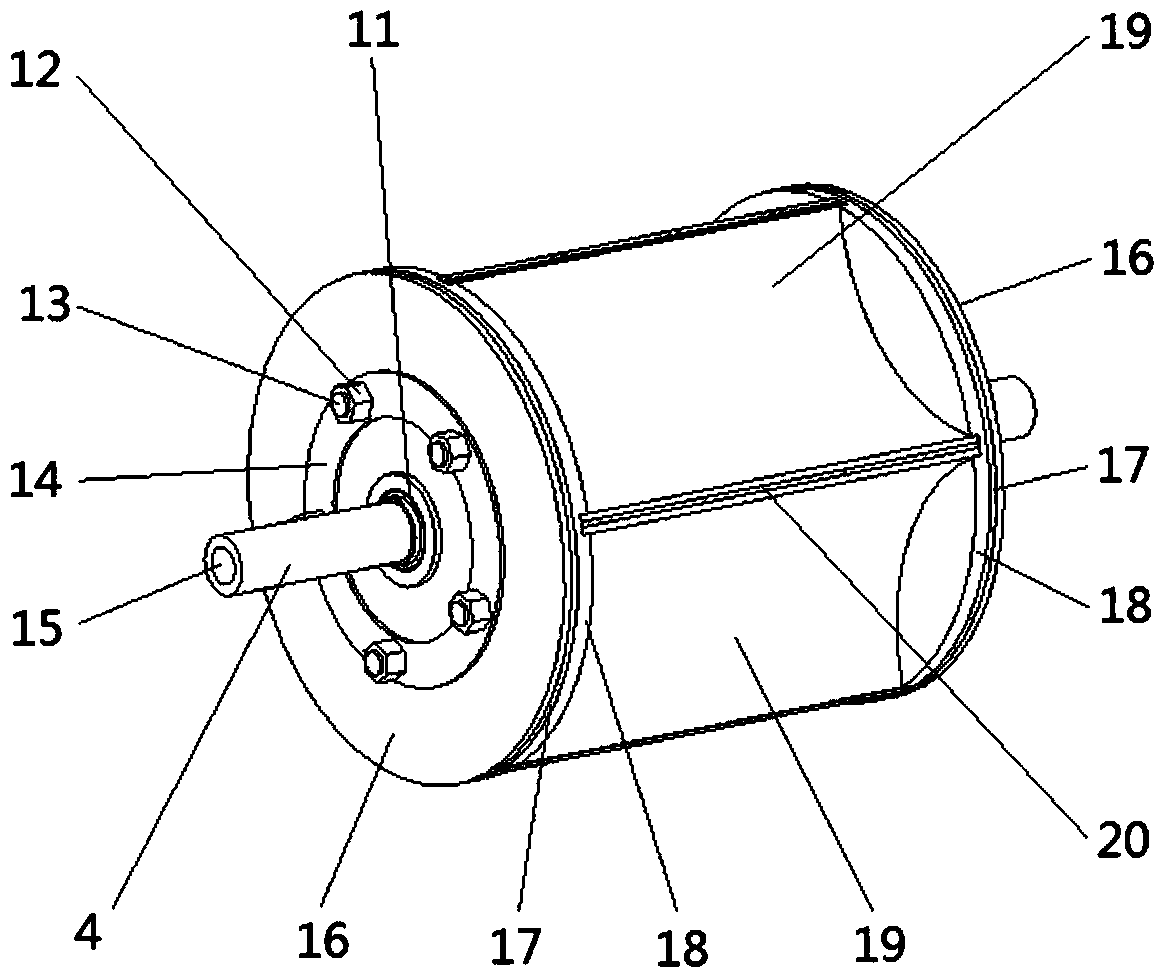

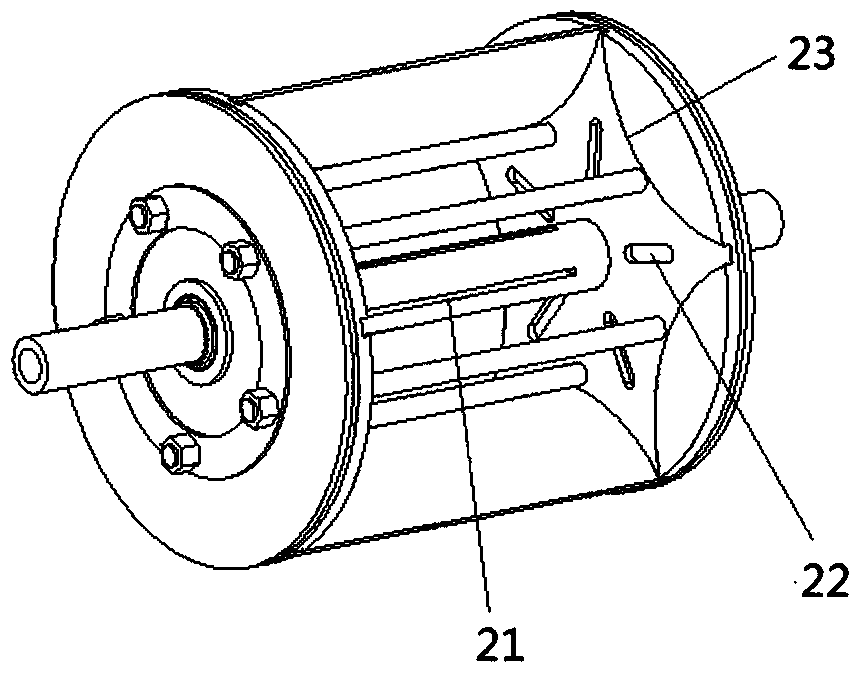

Rotary feeder sealed through air curtains

The invention provides a rotary feeder sealed through air curtains. The rotary feeder comprises a cambered impeller rotor, a shell body, a pressure limiting valve, a feeding inlet, a discharging outlet, rotating joints, externally-arranged bearings, big end caps, small end caps and conical sleeves. The cambered impeller rotor is of a hollow structure, and is provided with cambered plates evenly distributed along the circumference. An axial clearance taken as an airflow channel for the axial sealing air curtain is arranged between the tops of every two adjacent cambered plates. Annular clearances taken as airflow channels for the end face sealing air curtains are arranged between inner side plates and outer side plates. A hollow shaft, the cambered plates, the inner side plates and the outer side plates are connected into a whole. The cambered impeller rotor is detachably connected through the conical sleeves, studs, nuts, annular gaskets, arc-shaped grooves and the like. Compared with an existing feeder, the closed air curtains formed in the rotary feeder are good in sealing effect. The rotor does not make contact with the inner surface of the shell body, and the rotor is free of abrasion, so that the service life of parts and components is long. The rotor is flexible in operation and convenient to disassemble and clean. The rotary feeder can be taken as a non-contact rotary sealed feeding device which is capable of achieving continuous conveyance of materials.

Owner:CHANGZHOU UNIV

Device for treating polluted soil

InactiveCN106734136AReduce labor burdenRealize automatic feedingContaminated soil reclamationPollution soilEngineering

Owner:CHENGDU KECHUANGCHENG TECH

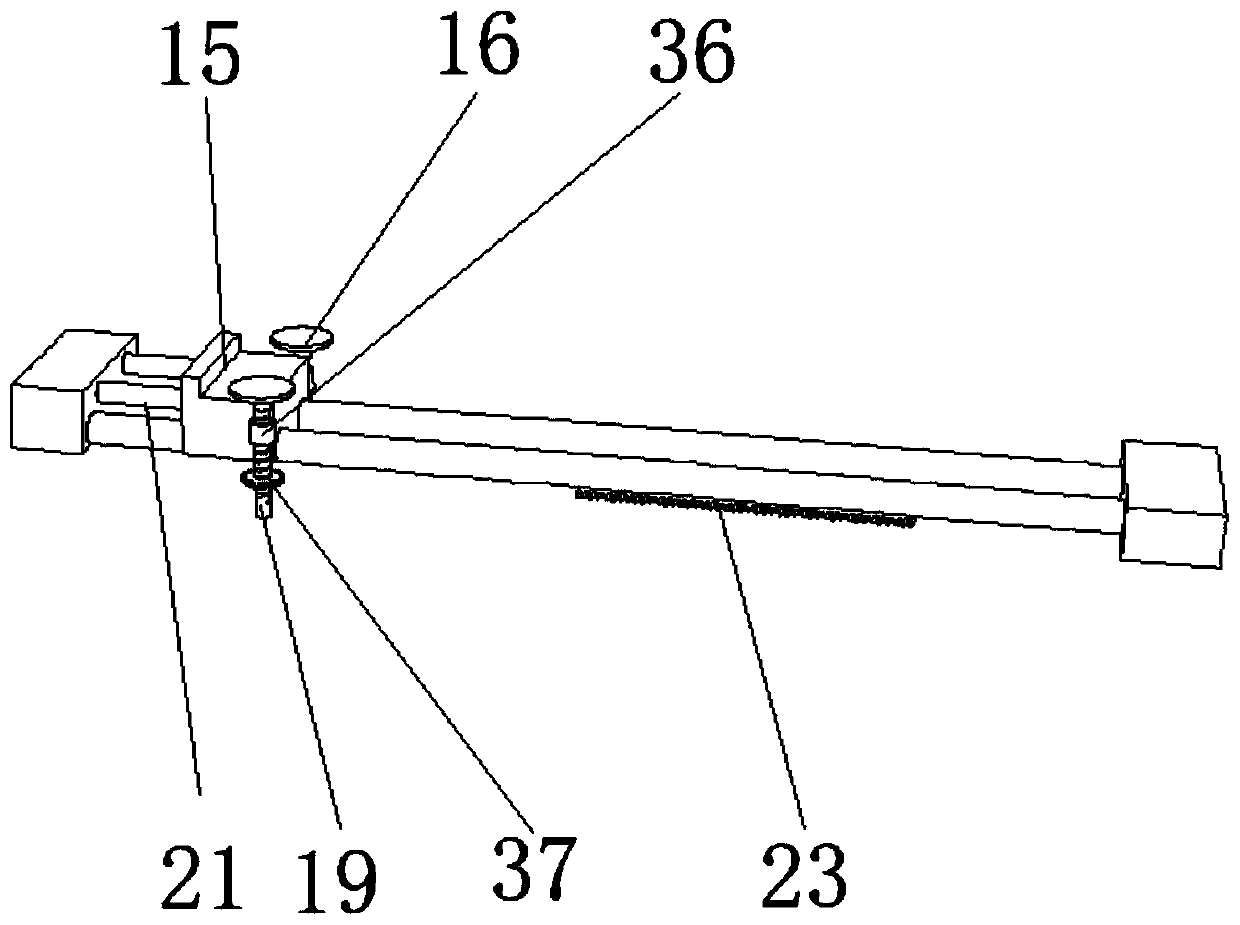

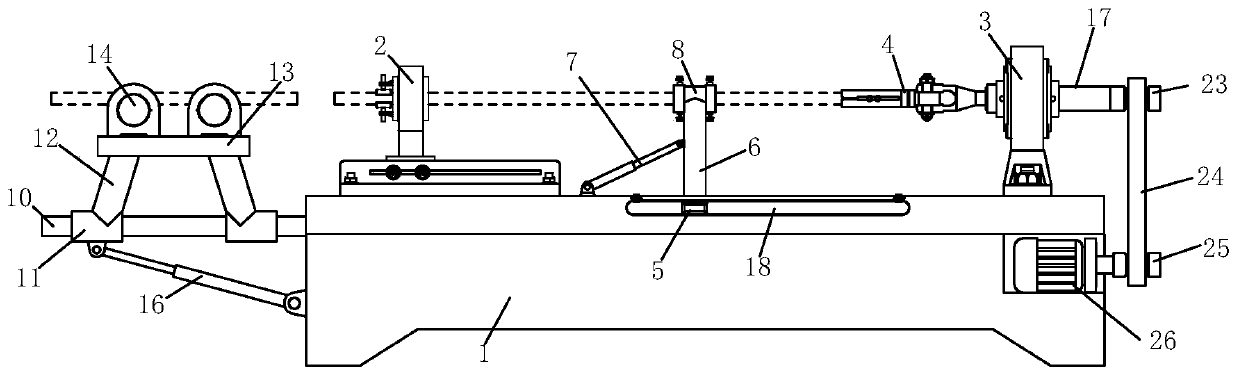

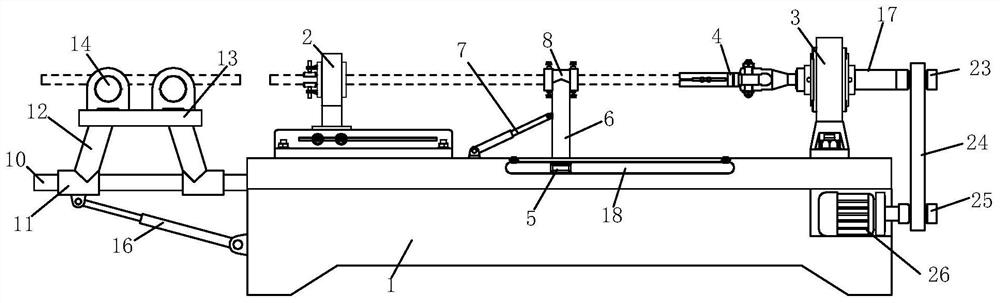

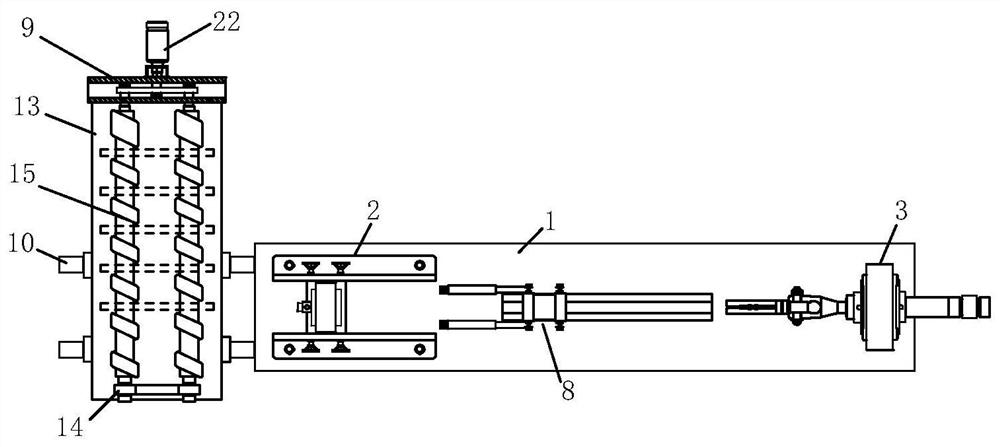

Rapid blank centering device of cold rolling mill

ActiveCN106077108AEasy to operateSo as not to damageGuiding/positioning/aligning arrangementsComing outButt joint

The invention belongs to the technical field of appliances of cold rolling mills, and particularly relates to a rapid blank centering device of a cold rolling mill. The rapid blank centering device of the cold rolling mill comprises a clamping and grasping mechanism and a feeding device; a guiding and connecting mechanism is arranged between the feeding device and the clamping and grasping mechanism; and a blank passes through a slope in a guide groove and comes out of a U-shaped guide groove to be in butt joint with a core rod. The rapid blank centering device of the cold rolling mill has the beneficial effects that operation is simplified, secondary operation of adjusting the height of a feeding chute and the centering device is avoided when specifications of blanks are replaced, and a feeding chain and a front clamping jaw are protected from being damaged by impact of pipe blanks.

Owner:ZHEJIANG MINGHE STEEL PIPE CO LTD

Ceramic tile cutting device

ActiveCN111002200AGuaranteed stabilityGuaranteed accuracyGrinding carriagesGrinding drivesGear wheelPiston

The invention relates to a cutting device, in particular to a ceramic tile cutting device. Therefore, the technical problem of the ceramic tile cutting device is that the ceramic tile cutting device which is high in working efficiency, capable of automatically feeding ceramic tiles, ensures the safety of operators, and cuts accurately is provided. According to the technical scheme, the ceramic tile cutting device comprises a bottom plate, baffles, a slide rail, first sliding blocks, mounting seats, first air cylinders, and a mobile clamping seat; the front side and the rear side of the bottomplate is connected with the baffles, the slide rail is symmetrically arranged on the left side of the top of the bottom plate, the first sliding blocks are arranged on the slide rail, the mounting seats are connected to the tops of the first sliding blocks on the left side and the right side, and the air first cylinders are arranged on the front sides of the tops of the mounting seats. According to the ceramic tile cutting device, the ceramic tiles can be fed through a feeding mechanism, an adjustment bolt can be screwed for moving left and right in a cylinder body, the distance of a piston moving to the right can be adjusted, the rotation ranges of a first gear and a rubber roller can also be adjusted, thus the feeding distance of ceramic tiles is adjusted, and feeding by using the deviceis more flexible.

Owner:广东长海建设工程有限公司

Organic waste gasification treatment system and method

PendingCN112377915AGuaranteed uptimeNo pollution in the processIndirect carbon-dioxide mitigationIncinerator apparatusSyngasCombustion chamber

The invention discloses an organic waste gasification treatment system and method. The system comprises a primary gasification device, a secondary gasification device, a spraying cooling device, a synthesis gas purifying device, a gas distributing device and a combustion device which are sequentially connected, wherein the combustion device connects with a combustion chamber; the primary gasification device connects with a gasification process air pipeline; the primary gasification device is fixedly arranged in the combustion chamber; the secondary gasification device connects with a high-temperature plasma torch device; and a supercharging water pump is arranged between the spraying cooling device and the synthesis gas purifying device. The organic waste gasification treatment system canconvert organic waste into gasification synthesis gas and discharge organic waste gasification residual inertial ash slag on site; and meanwhile, the gasification synthesis gas is recycled, so that stable operation of the system is realized, and pollution is avoided. Besides, the system is integrated and mounted in a standard container with high integration degree.

Owner:南京德仓生态技术有限公司

Automatic spool loading and unloading device of two-for-one twister

The invention provides an automatic spool loading and unloading device of a two-for-one twister, which comprises a rack, a rotating shaft, a spool positioning seat for positioning a spool, a driving mechanism and a feeding mechanism, the rack is provided with a bottom plate and two side plates, the lower end of the bottom plate is connected with supporting legs, the side plates are vertically fixed on the bottom plate, the rotating shaft is rotatably connected between the two side plates, and the rotating shaft is connected with the driving mechanism. The rotating shaft is evenly and fixedly sleeved with a plurality of installation discs in the axial direction of the rotating shaft, the four bobbin positioning bases are evenly distributed and installed on the installation discs in the circumferential direction, one end of the rotating shaft penetrates out of the side plate and is connected with a driven gear, a loading and unloading motor is fixed to the lower end face of the bottom plate, and a driving gear meshed with the driven gear is fixed to an output shaft of the loading and unloading motor. The device is high in automation degree, the feeding mechanism is arranged, and empty bobbins can be automatically loaded; the spool positioning seat is arranged on the rotating shaft, and the rotated spools can automatically fall off from the positioning sleeve and fall into the collecting box.

Owner:陈定洲

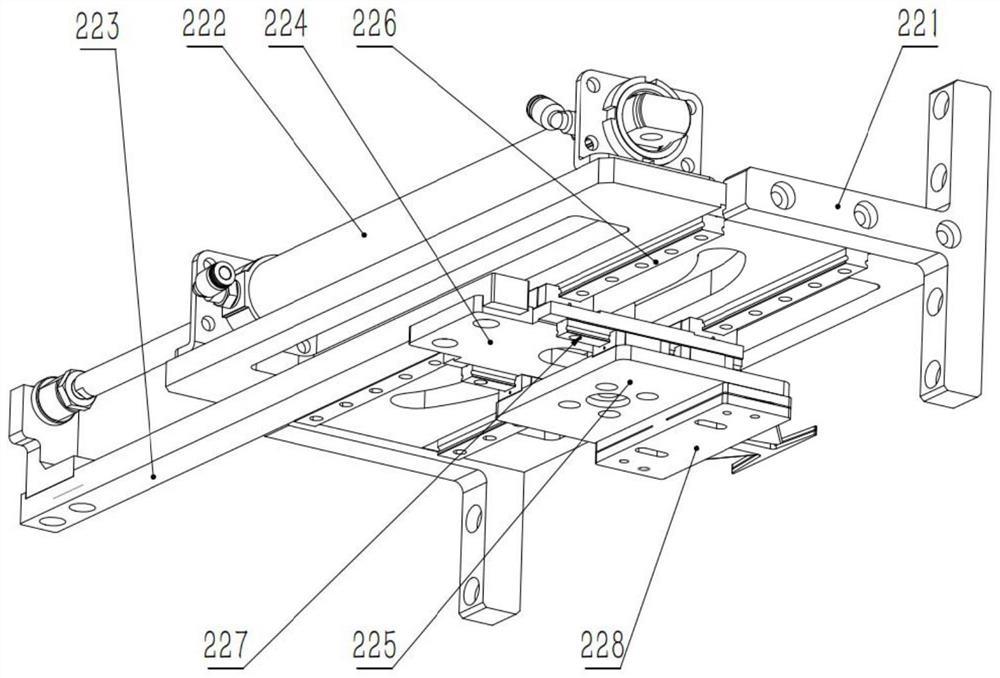

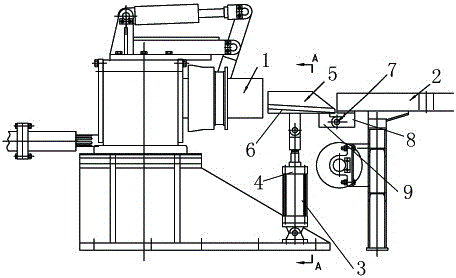

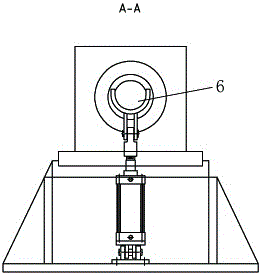

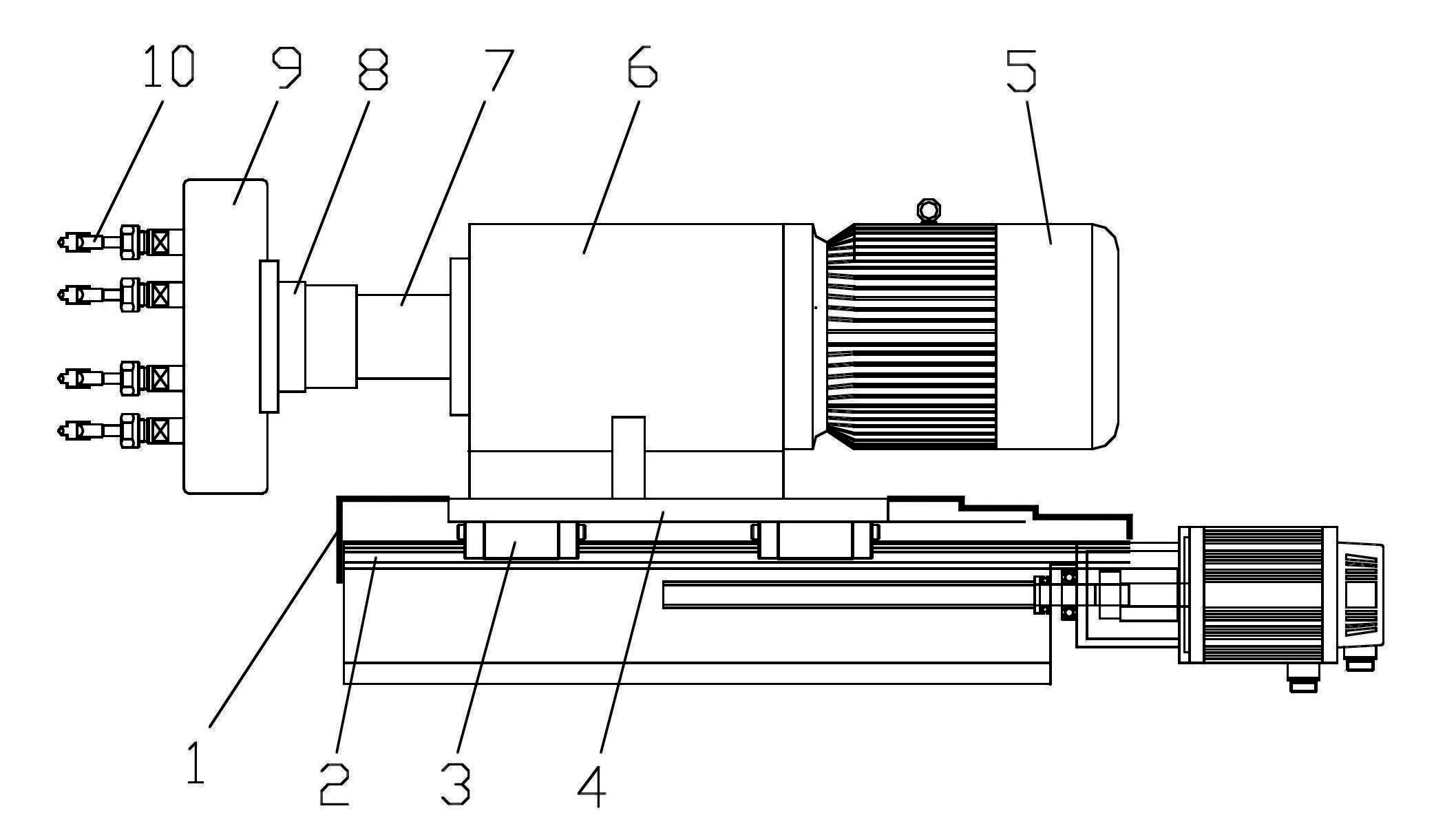

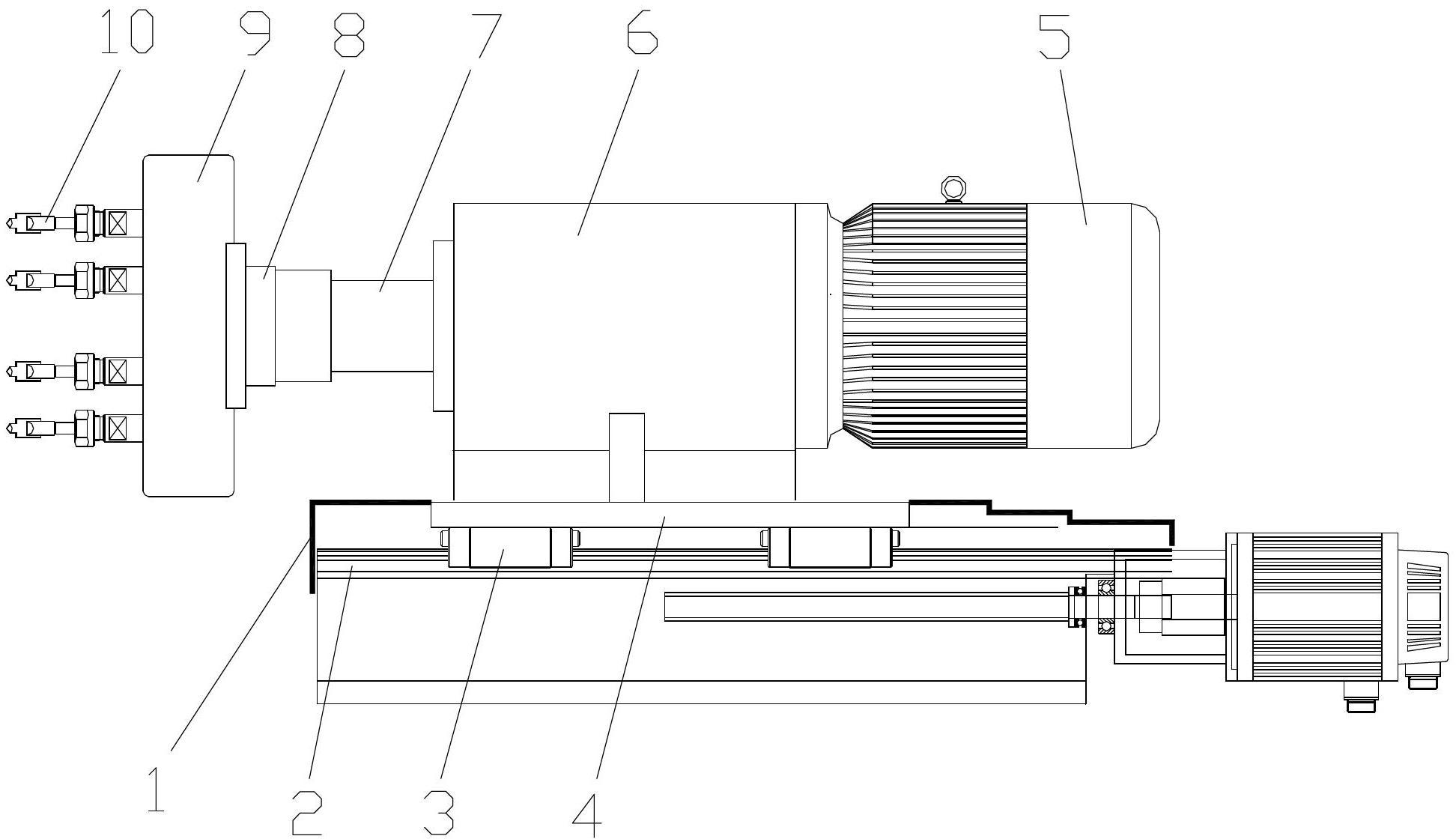

Transmission mechanism of fixed handpiece of drill press for brake pad of automobile

InactiveCN102672742AFlexible feedingSimple structural designMetal working apparatusOptical axisForming processes

The invention relates to a transmission mechanism of a fixed handpiece of a drill press for a brake pad of an automobile, and relates to the field of drilling equipment of the brake pad of the automobile. The transmission mechanism of the fixed handpiece of the drill press for the brake pad of the automobile comprises a motor fixed on an installing base. The motor is connected with a multi-shaft machine installing base through a shaft extension optical shaft. A multi-shaft machine is connected on the left side of the multi-shaft machine installing base and drills are installed on the left side of the multi-shaft machine. The installing base is fixed on a sliding installing plate. The bottom of the sliding installing plate is arranged on a linear guide rail through a linear slide block. Two or four drills are installed. A protective cover is arranged above the linear guide rail and fixed on the sliding installing plate. The transmission mechanism provided by the invention is simple and reasonable in structural design, stable and reliable in power transfer effect and agile in tool bit feed, and can realize multi-rotary shaft matched processing and complete drilling at one time and counterboring forming process, and is simple in operation and high in processing efficiency.

Owner:余锐光

Automatic loading and thread-rolling production line

ActiveCN110202080APrevent poor thread rolling effectEasy to cleanMetal-working feeding devicesScrew-threads articlesProduction lineMilling cutter

The invention provides an automatic loading and thread-rolling production line. The automatic loading and thread-rolling production line comprises a base, wherein one side of the upper surface of thebase is equipped with a fixed structure, and the other side of the upper surface of the base is vertically equipped with a first bearing base; a rotary shaft is horizontally mounted in the first bearing base; one end of the rotary shaft is equipped with a clamping structure, and the other end of the rotary shaft is equipped with a first belt wheel; one side of the base is horizontally equipped with a drive motor; a second belt wheel is mounted on the output shaft of the drive motor; the first belt wheel is linked with the second belt wheel through a belt; a slide slot is horizontally formed inthe middle part of the upper surface of the base; a slide block is mounted in the slide slot in a sliding mode; the upper surface of the slide block is vertically equipped with a supporting rod; oneside of the supporting rod is rotatably connected with the top end of a first hydraulic rod; the bottom end of the first hydraulic rod is rotatably connected to one side of the upper surface of the base; the top end of the supporting rod is equipped with a threaded milling cutter assembly; and the top end of one side of the base is equipped with a charge device.

Owner:浙江瑞昭科技股份有限公司

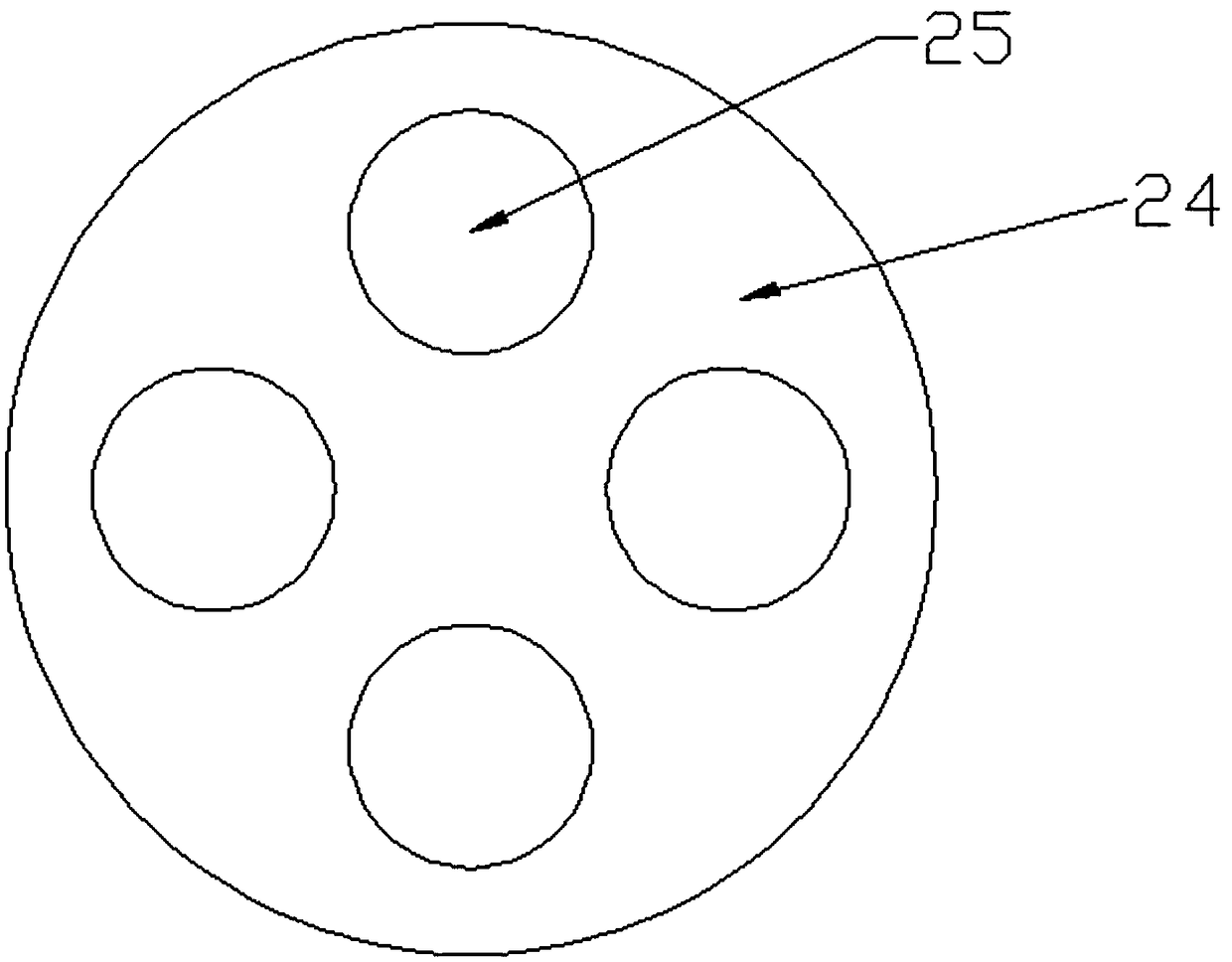

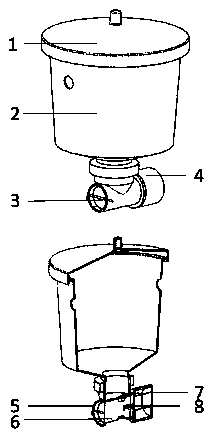

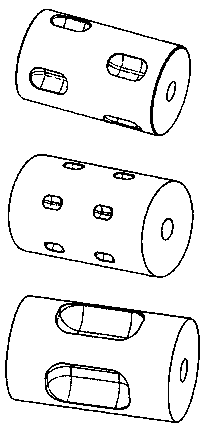

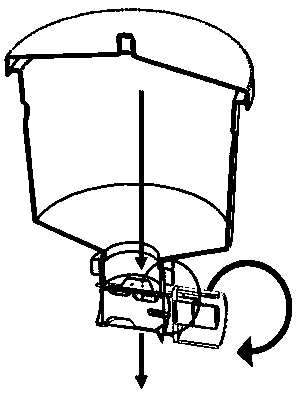

Cave-type accurate automatic bait feeder

PendingCN110074032ASuitable for growthThe feeding effect is suitableClimate change adaptationPisciculture and aquariaMotor driveElectric machinery

The invention discloses a cave-type accurate automatic bait feeder, comprising a storage bin portion and a charging and feeding portion connected to a lower mouth of a storage bin. The storage bin portion is composed of a bait bin and a bait bin cover. The charging and feeding portion is composed of a quantitative discharger, a gear motor, a neck bush, a connecting shaft and a shell. The bait in the bait bin covers on the quantitative discharger which is provided with a cave and the cave are fully filled with the bait; when working, the gear motor drives the quantitative discharger to rotate,when the cave rotates to the opening below the shell, bait in the cave falls automatically, so as to realize feeding. Through customizing the size and number of the cave and setting the rotation speedand working duration of the gear motor, the timed and quantitative feeding of the bait is realized by the structure, the workload of bait feeding is greatly reduced, the waste of the bait is greatlyreduced, and large amount of manpower and material resources are saved.

Owner:苏州益品德环境科技有限公司

Production system and production method of heavy oil productive naphtha

InactiveCN111909719AImprove conversion rateHigh yieldTreatment with hydrotreatment processesProcess engineeringFuel oil

The invention relates to a heavy oil productive naphtha production system, which comprises a feeding unit, a first-stage reaction unit, a second-stage reaction unit, and a third-stage reaction unit, wherein the first-stage reaction unit comprises a first-stage heating furnace, a first-stage suspended bed hydrogenation reactor, and a first-stage separation unit, the secondary reaction unit comprises a secondary heating furnace, a secondary fixed bed hydrogenation reactor, a vacuum tower and a secondary separation unit; and the third-stage reaction unit comprises a stripping tower, a third-stageheating furnace, a fractionating tower, a third-stage fixed bed hydrogenation reactor and a third-stage separation unit. The heavy oil productive naphtha production system further includes a circulating hydrogen system. The invention relates to a production method of heavy oil productive naphtha. According to the production system and the production method of heavy oil productive naphtha, the conversion rate of components in heavy oil at 525 DEG C or above is 95%, the naphtha product yield is greater than 80%, and meanwhile, the production system and the production method are simple in process, compact in occupied area, reasonable in commercial investment, flexible in feeding and relatively low in hydrogen consumption.

Owner:张家港保税区慧鑫化工科技有限公司

An automatic feeding system for pig farms

InactiveCN104082169BShortened growth timeModerate exerciseAnimal feeding devicesPig farmsEngineering

The invention provides an automatic feeding system for a pig farm. The automatic feeding system is high in automation degree and small in manpower requirement, reduces feed waste, saves the cost and improves pig group habitus. The automatic feeding system comprises a lard pig feeder, a piglet feeder, M lard pig troughs, N piglet troughs, M first feed inductors, N second feed inductors, a control module and a remote management module. The lard pig feeder comprises a lard pig feed storage bunker, a first conveying mechanism and M first discharging valves. The lard pig feed storage bunker is connected with the first conveying mechanism. The first conveying mechanism is respectively communicated with the M lard pig troughs through the M first discharging valves. The M lard pig troughs are arranged in the lard pig farm in a dispersing mode. The M first feed inductors are arranged in the M lard pig troughs respectively. The M first discharging valves and the M first feed inductors are respectively connected with the control module. The piglet feeder comprises a piglet feed storage bunker, a second conveying mechanism and N second discharging valves.

Owner:上海红马饲料有限公司

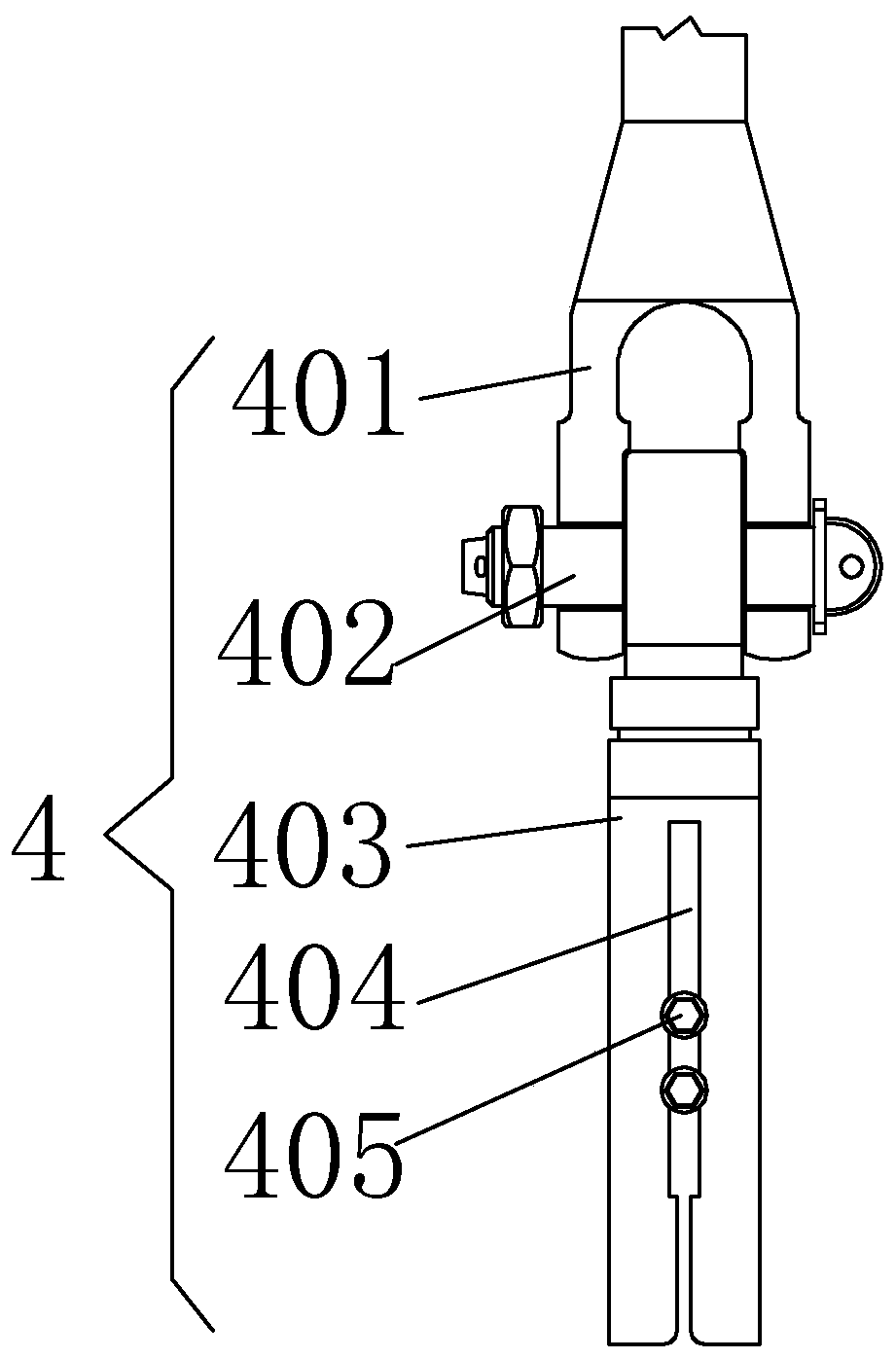

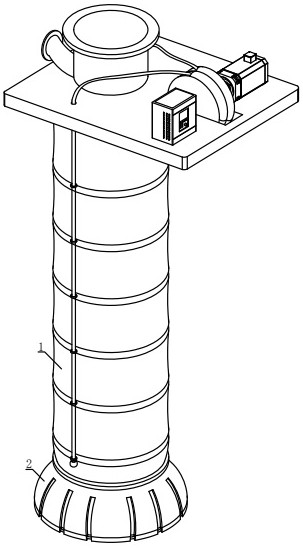

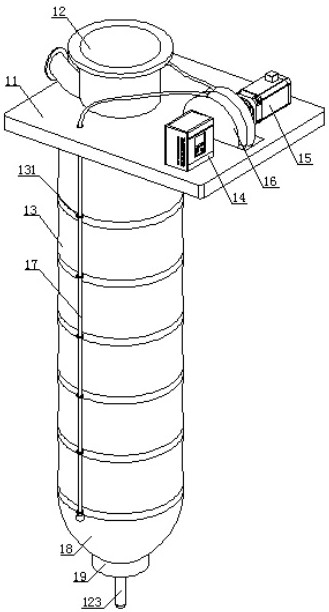

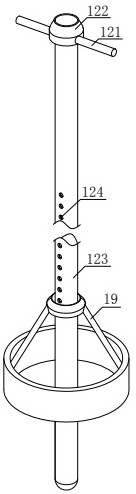

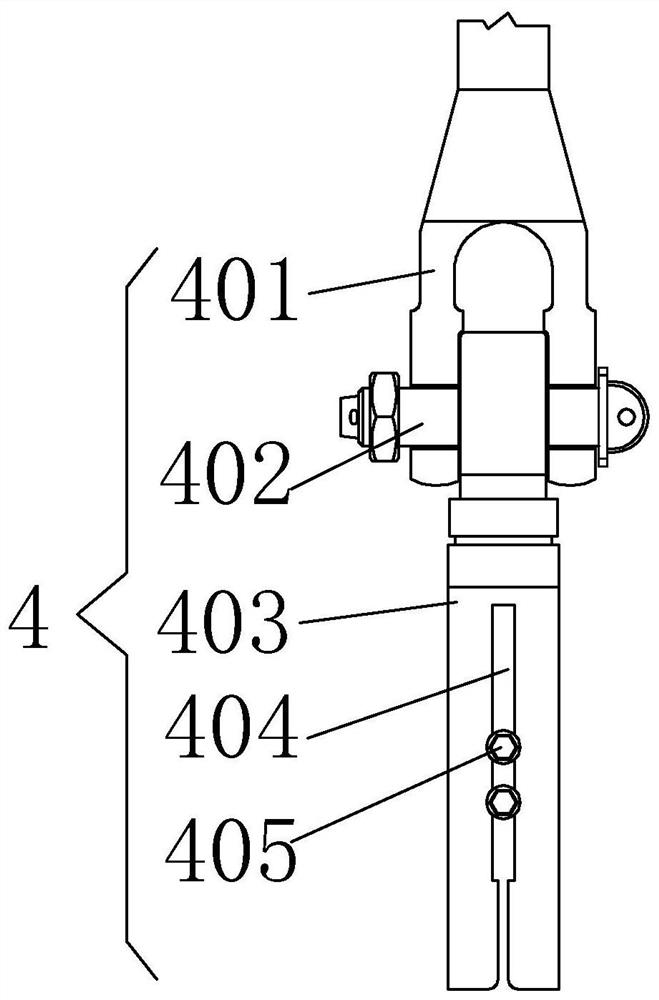

Bulk packing machine with material level detection structure for charging and method thereof

ActiveCN113501342BIncreased flexibility of useFlexible feedingLoading/unloadingInductorMaster controller

The invention relates to the technical field of bulk equipment, and discloses a bulk loading machine with a material level detection structure and a method thereof for charging, comprising a main body of the bulk loading machine, a dust-proof component is arranged at the lower end of the main body of the bulk loading machine, and a detection piece is installed at the lower end of the connecting cover. The dust-proof parts include the connection ring and the closure set at the lower end of the connection ring. The lower end of the closure is provided with an extension. Both the receiver and the sensor are electrically connected to the main controller, and the distance between adjacent receivers is 5-10cm , the sensor corresponds to the receiver, and the distance between the lower surface of the casing and the bottom of the detection rod is 20cm. The beneficial effect of the present invention is that when charging, as the material in the device to be loaded continues to increase, the telescopic tube Gradually move up under the control of the servo motor, at this time the ferrule is moved up, the cooperation between the sensor and the receiver, the formula calculates the material level height of h=5i+20, and then realizes real-time detection in the loader The material level is high, which is convenient for flexible feeding and improves the flexibility of the bulk machine.

Owner:南通普斯勒机械设备有限公司

Threshing device of tangential-transverse flow grain combine harvester

PendingCN111727744AReduce the burden onStrong threshing abilityMowersThreshersAgricultural engineeringStructural engineering

The invention discloses a threshing device of a tangential-transverse flow grain combine harvester. The threshing device comprises a threshing chamber wall, an axial flow roller cover plate, a tangential flow roller, a tangential flow concave plate, a transverse axial flow roller, a movable concave plate and an auger. The rotating speed of the tangential flow roller is between the bridge crossingspeed and the rotating speed of the axial flow threshing roller, crop acceleration and partial threshing are achieved in the tangential flow roller, the speed of crops entering the transverse axial flow roller is increased, partial threshing is conducted on the crops, and the burden of a subsequent threshing system is relieved; the transverse axial flow roller is divided into three sections, the threshing capacity is high, the threshing gap of the axial flow concave plate is adjustable, operation is flexible, and the requirements of different feeding amounts are met. The purposes of smooth feeding, loss rate reduction and threshing efficiency improvement are achieved, the feeding amount of the grain harvester is increased, and the compactness of the structural design is achieved.

Owner:UNIV OF JINAN

Rapid Centering Device for Billet of Cold Rolling Mill

ActiveCN106077108BEasy to operateSo as not to damageGuiding/positioning/aligning arrangementsComing outButt joint

The invention belongs to the technical field of appliances of cold rolling mills, and particularly relates to a rapid blank centering device of a cold rolling mill. The rapid blank centering device of the cold rolling mill comprises a clamping and grasping mechanism and a feeding device; a guiding and connecting mechanism is arranged between the feeding device and the clamping and grasping mechanism; and a blank passes through a slope in a guide groove and comes out of a U-shaped guide groove to be in butt joint with a core rod. The rapid blank centering device of the cold rolling mill has the beneficial effects that operation is simplified, secondary operation of adjusting the height of a feeding chute and the centering device is avoided when specifications of blanks are replaced, and a feeding chain and a front clamping jaw are protected from being damaged by impact of pipe blanks.

Owner:ZHEJIANG MINGHE STEEL PIPE CO LTD

A kind of tile cutting equipment

ActiveCN111002200BGuaranteed stabilityGuaranteed accuracyGrinding carriagesGrinding drivesGear wheelIndustrial engineering

The invention relates to a cutting device, in particular to a ceramic tile cutting device. Therefore, the technical problem of the present invention is to provide a ceramic tile cutting device that has high working efficiency, can automatically feed ceramic tiles, ensures the safety of operators, and can cut accurately. Technical solution: A ceramic tile cutting equipment, including a bottom plate, a baffle, a slide rail, a first slider, a mounting seat, a first cylinder, and a moving deck; baffles are connected to the front and rear sides of the bottom plate, and the left side of the top of the bottom plate is symmetrically arranged. There is a slide rail, the slide rail is provided with a first slide block, the tops of the first slide blocks on the left and right sides are connected with mounting bases, and the front side of the top of the mounting bases is provided with a first cylinder. The invention can feed the ceramic tiles through the feeding mechanism, and by turning the adjusting bolt to make it move left and right in the cylinder, the distance of the piston moving to the right can be adjusted, and the rotation range of the first gear and the rubber roller can also be adjusted , so as to adjust the distance of ceramic tile feeding, making the equipment more flexible when feeding.

Owner:广东长海建设工程有限公司

Combination system and method of supercritical extraction and suspension bed hydrogenation of heavy oil feedstock

ActiveCN107177378BReduce lossesFlexible feedingTreatment with hydrotreatment processesFuel oilAsphaltene

Owner:北京和利凯石化技术有限公司

An automatic feeding thread rolling production line

ActiveCN110202080BPrevent poor thread rolling effectEasy to cleanMetal-working feeding devicesScrew-threads articlesMilling cutterElectric machinery

The invention provides an automatic loading and thread-rolling production line. The automatic loading and thread-rolling production line comprises a base, wherein one side of the upper surface of thebase is equipped with a fixed structure, and the other side of the upper surface of the base is vertically equipped with a first bearing base; a rotary shaft is horizontally mounted in the first bearing base; one end of the rotary shaft is equipped with a clamping structure, and the other end of the rotary shaft is equipped with a first belt wheel; one side of the base is horizontally equipped with a drive motor; a second belt wheel is mounted on the output shaft of the drive motor; the first belt wheel is linked with the second belt wheel through a belt; a slide slot is horizontally formed inthe middle part of the upper surface of the base; a slide block is mounted in the slide slot in a sliding mode; the upper surface of the slide block is vertically equipped with a supporting rod; oneside of the supporting rod is rotatably connected with the top end of a first hydraulic rod; the bottom end of the first hydraulic rod is rotatably connected to one side of the upper surface of the base; the top end of the supporting rod is equipped with a threaded milling cutter assembly; and the top end of one side of the base is equipped with a charge device.

Owner:浙江瑞昭科技股份有限公司

Rotary feeder sealed with air curtain

The invention provides a rotary feeder sealed by an air curtain, which includes an arc-shaped impeller rotor composed of arc panels, inner and outer panels, a hollow shaft, etc., a casing, a material inlet and outlet, a rotary joint, and a tapered sleeve. The rotary joint is connected with the hollow shaft, the hollow shaft is provided with an air inlet, the arc impeller rotor is provided with arc panels evenly distributed along the circumference, and the inner panel is provided with waist-shaped holes and arc-shaped grooves corresponding to the arc panels. The panel is stuck in the arc groove; there is an axial gap between the tops of each adjacent two arc panels as the air flow channel for the axial sealing air curtain, and an annular gap is provided between the inner and outer plates as the air flow for the end face sealing air curtain aisle. The arc-shaped impeller rotor is detachably connected through a tapered sleeve, double-ended studs, and nuts. The sealing effect of the two pressure air curtains of the present invention is good, the rotor does not contact the inner surface of the shell, has no wear, the parts have a long service life, the rotor is flexible in operation, easy to disassemble and clean, and can be used as a non-contact rotary sealing air lock feeding device.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com