Rotary feeder sealed through air curtains

A rotary feeding and air curtain technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of large cleaning and maintenance workload, low efficiency of feeding and discharging, and poor sealing, so as to reduce processing costs, work reliably, The effect of preventing secondary breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

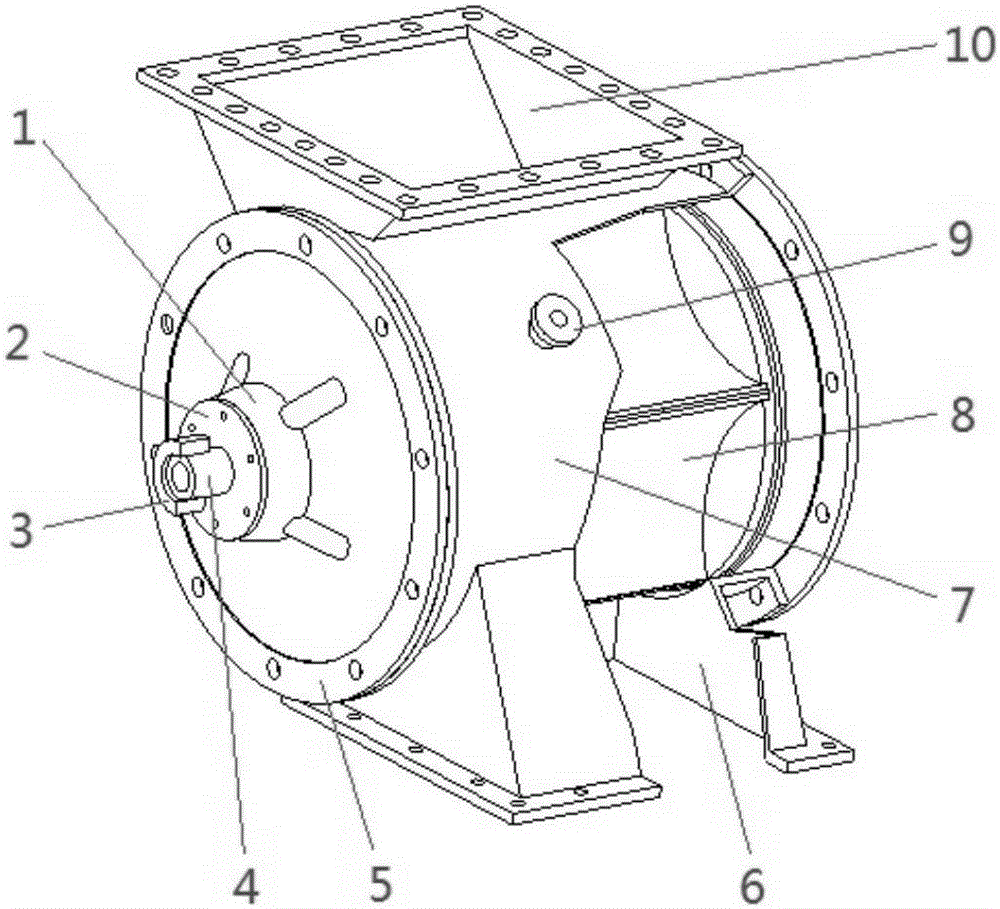

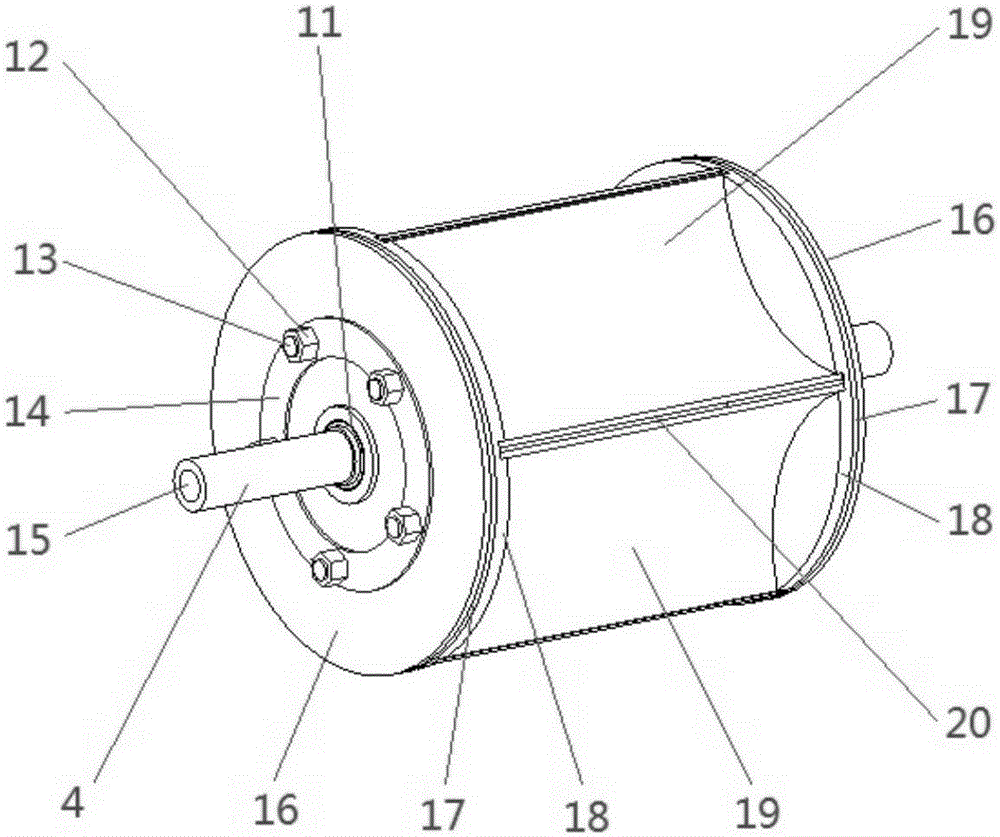

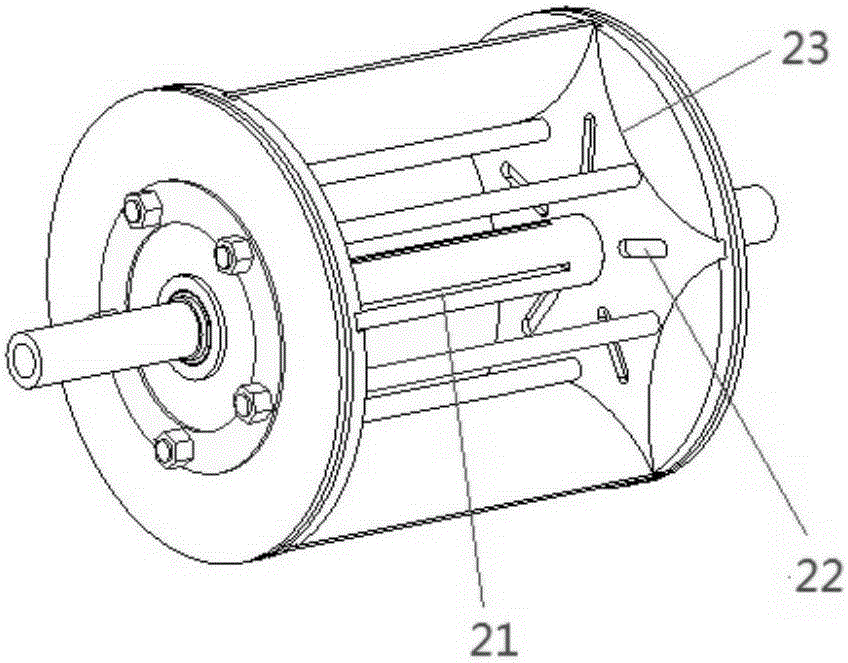

[0019] Such as Figure 1 to Figure 4 The present invention shown utilizes the rotary feeder embodiment of air curtain seal, and this rotary feeder is made up of arc surface impeller rotor 8, housing 7, pressure limiting valve 9, feed inlet 10, discharge outlet 6, rotary joint 3. Outer bearing 1, small end cap 2, large end cap 5, tapered sleeve 11 and other components are assembled. The casing 7 has a hollow chamber structure in the shape of a revolving body, and the arc-shaped impeller rotor 8 is located in the hollow chamber of the casing 7; the top of the casing 7 is provided with a feed port 10, and the bottom is provided with a discharge port 6, and the large end cover 5 is located On both sides of the housing 7 , the hollow shaft 4 of the arc-shaped impeller rotor 8 is supported on the large end covers 5 on both sides through the external bearing 1 .

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com