Automatic spool loading and unloading device of two-for-one twister

An automatic loading and unloading and two-for-one twisting machine technology, applied in the field of yarn manufacturing, can solve problems such as slowness, and achieve the effects of easy transfer and replenishment, high degree of automation, and flexible feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

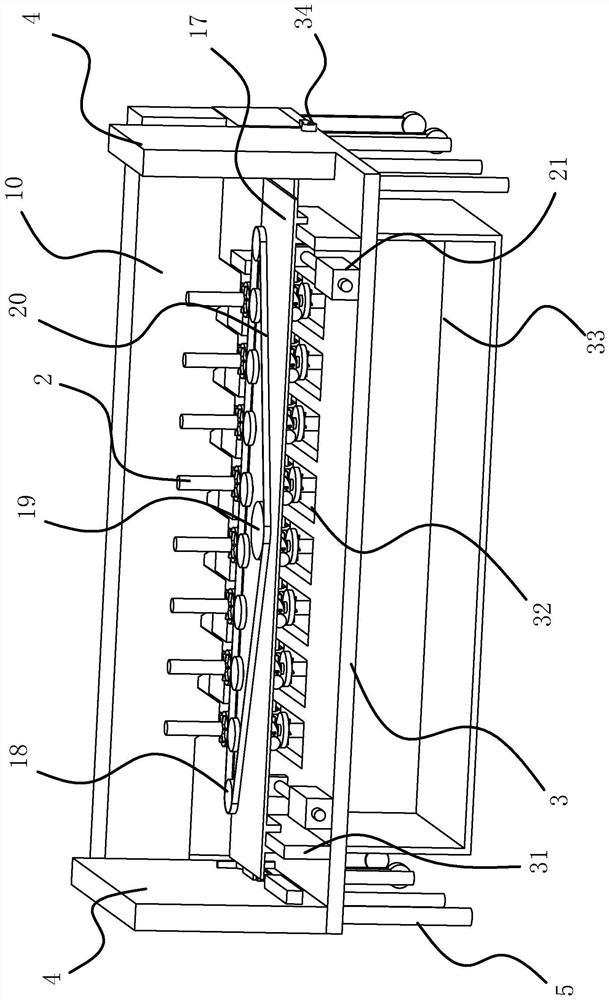

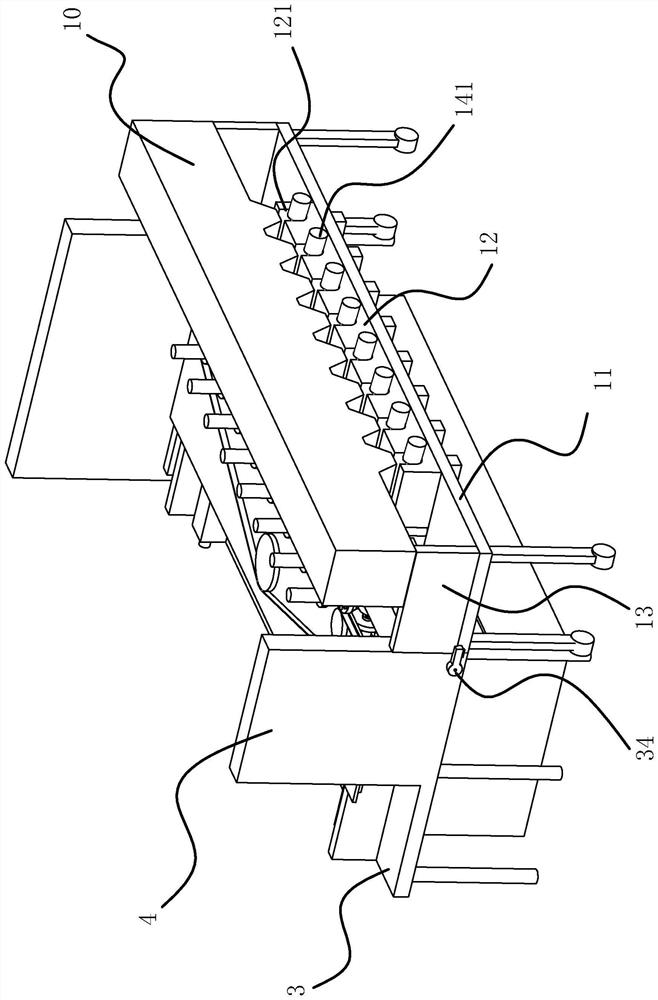

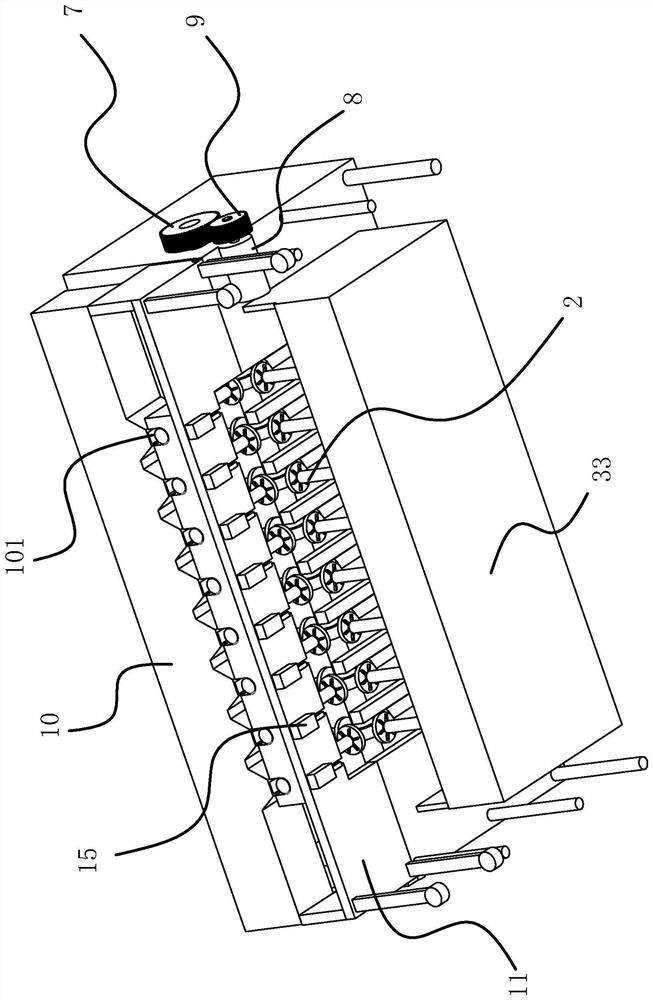

[0027] like Figure 1-4 As shown, the automatic loading and unloading bobbin device of the double twisting machine includes a frame, a rotating shaft 1, a bobbin positioning seat 2 for positioning the bobbin, a driving mechanism, and a feeding mechanism. The frame has a bottom plate 3 and two side plates 4, the lower end of the bottom plate 3 is connected with a supporting foot 5, the side plate 4 is vertically fixed on the bottom plate 3, the rotating shaft 1 is rotatably connected between the two side plates 4, and the rotating shaft 1 A number of mounting discs 6 are evenly fixed and sleeved along its axial direction, and the four bobbin positioning seats 2 are evenly arranged on the mounting disc 6 in the circumferential direction. 3. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com