Rapid blank centering device of cold rolling mill

A technology of cold rolling mill and centering device, applied in the direction of guide/positioning/alignment device, etc., can solve the problems of damaged feeding chain, too high or insufficient height, broken guide device, etc., to simplify operation and protect The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

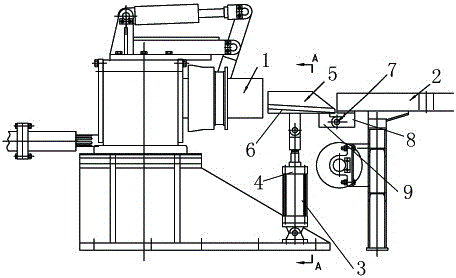

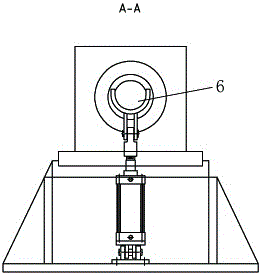

[0011] Combine below figure 1 with figure 2 Specific description embodiment:

[0012] A rapid centering device for cold-rolled pipe mill blanks. The rapid centering device for cold-rolled pipe mill blanks includes a gripping mechanism 1 and a feeding device 2. The middle of the feeding device 2 and the gripping mechanism 1 A guide mechanism 3 is provided, and the guide mechanism 3 includes a cylinder 4 and a guide groove 5. The end of the guide groove 5 close to the catch mechanism 1 is a U-shaped guide groove 6, and the front end of the U-shaped guide groove 6 is inserted into the claw mechanism 1 One end of the guide groove 5 close to the feed device 2 is arranged on the top of the feed device through the rotating shaft mechanism 7, the guide groove is a chute, and the end of the guide groove close to the feed device gradually rises toward the end close to the grabbing mechanism ; The blank enters the guide groove from the feeding device, and comes out from the U-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com