Transmission mechanism of fixed handpiece of drill press for brake pad of automobile

A transmission mechanism and brake pad technology, applied in metal processing, etc., can solve the problems of endangering the health of operators, lack of high-efficiency drilling equipment, and low hole position accuracy, so as to achieve flexible feed of the cutter head and stable and reliable power transmission effect , the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

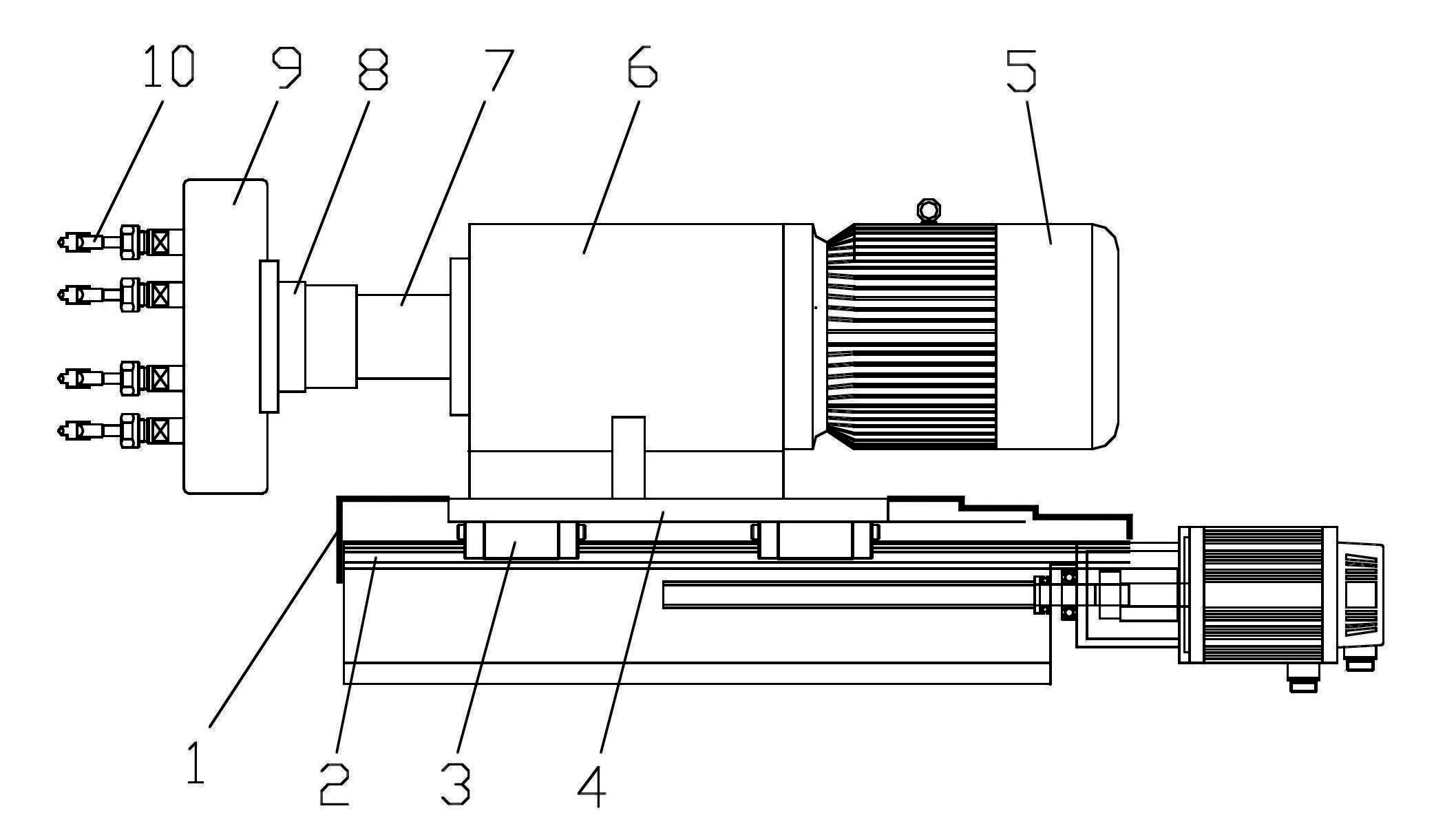

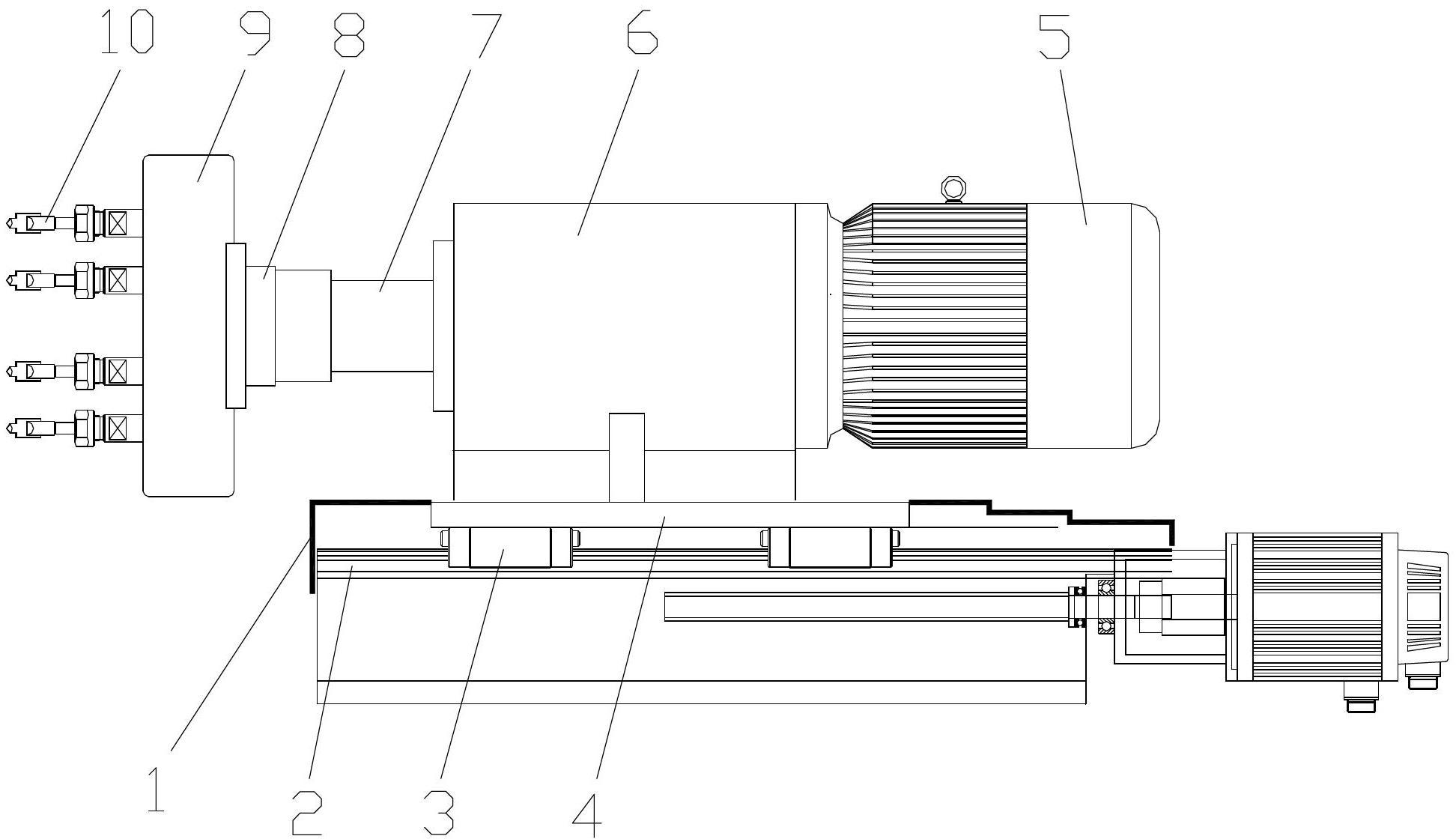

[0011] Such as figure 1 As shown, a transmission mechanism for fixing the machine head of an automobile brake pad drilling machine includes a motor 5 fixed on the mounting base 6, the motor 5 is connected to the multi-axis device mounting base 8 through the shaft extension optical shaft 7, and the multi-axis device mounting base 8. The left side of the multi-axis device 9 is connected to the multi-axis device 9, and the drill bit 10 is installed on the left side of the multi-axis device 9. The installation base 6 is fixed on the sliding mounting plate 4, and the bottom end of the sliding mounting plate 4 is set on the linear guide rail 2 through the linear slider 3. , Two or four drill bits 10 are installed, a protective cover 1 is arranged abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com