Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Facilitate the automation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

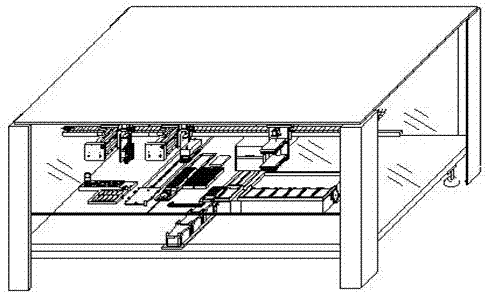

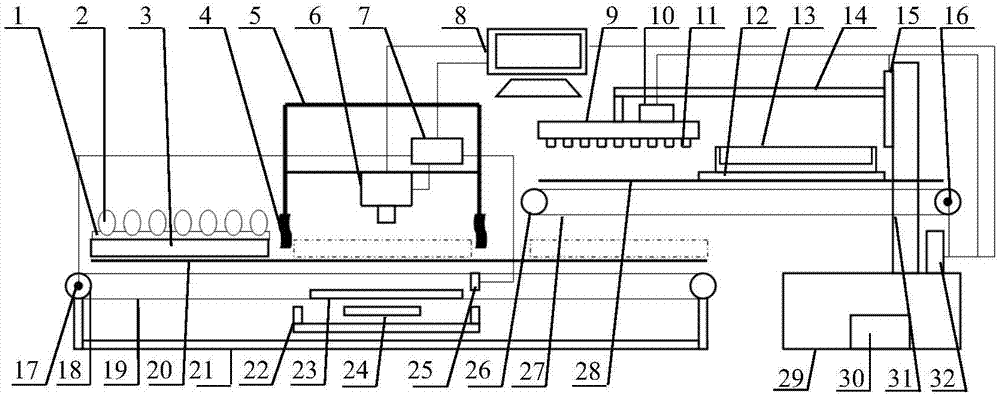

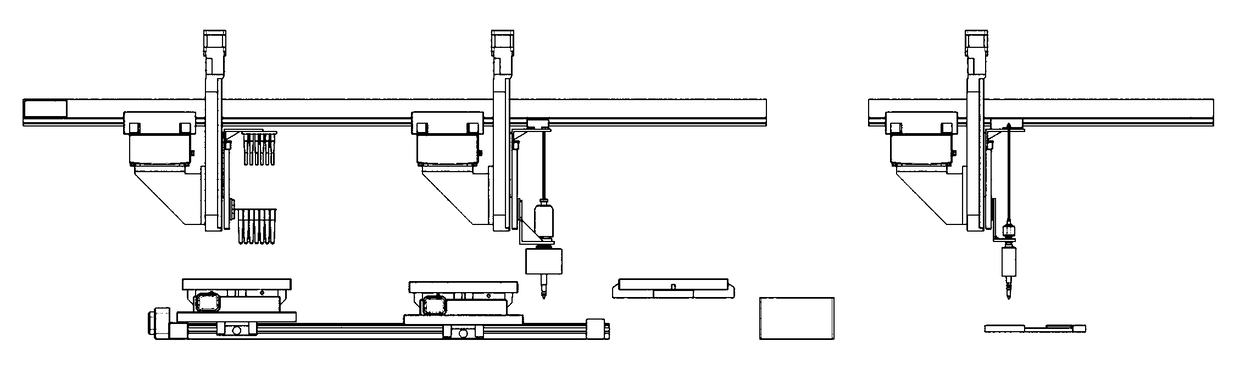

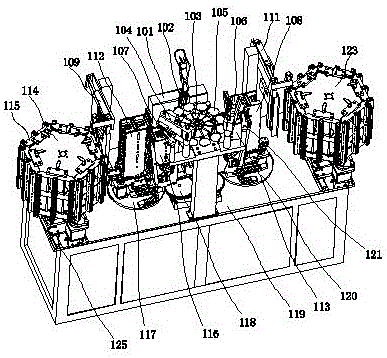

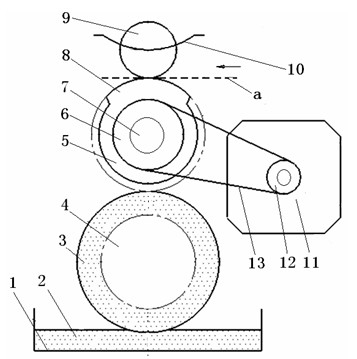

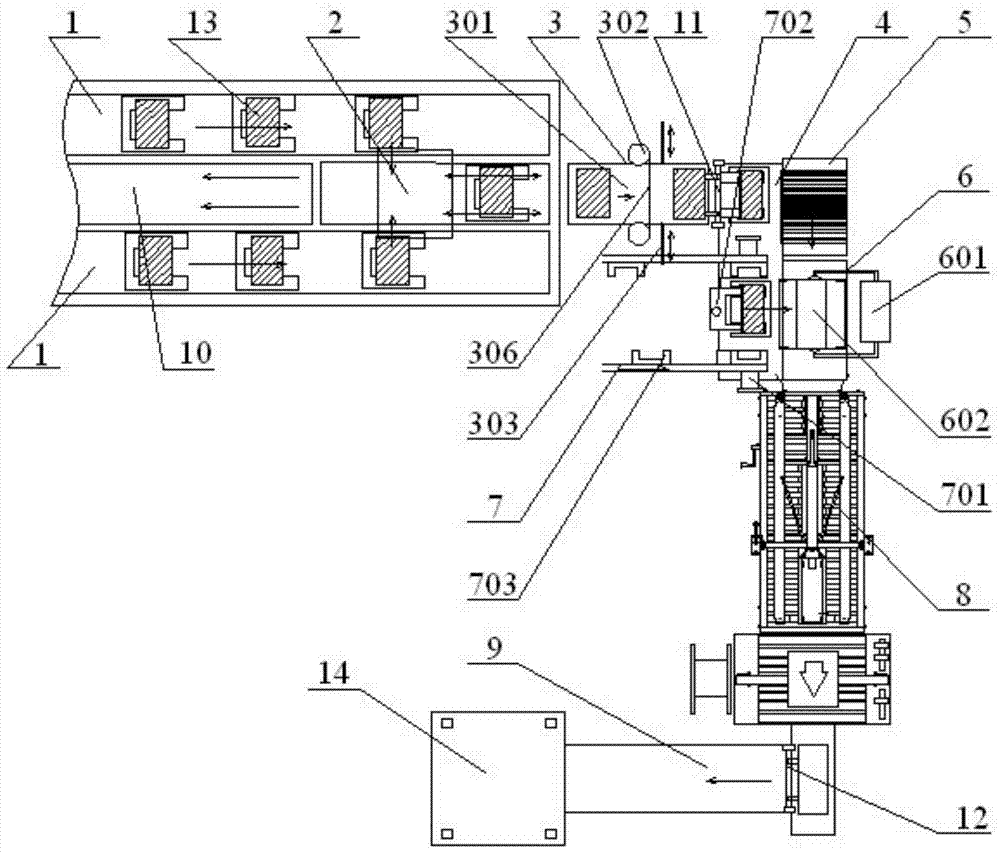

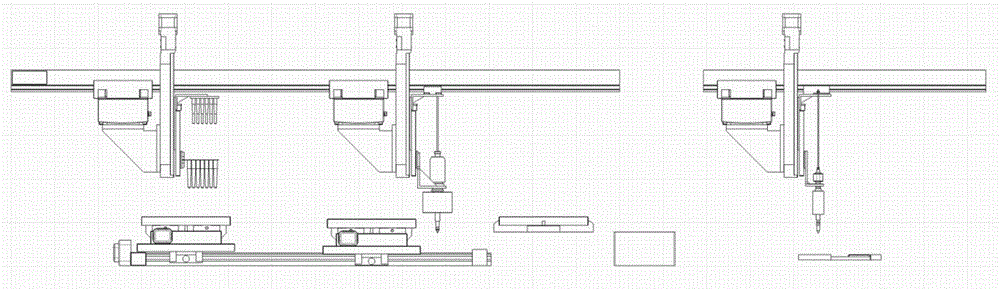

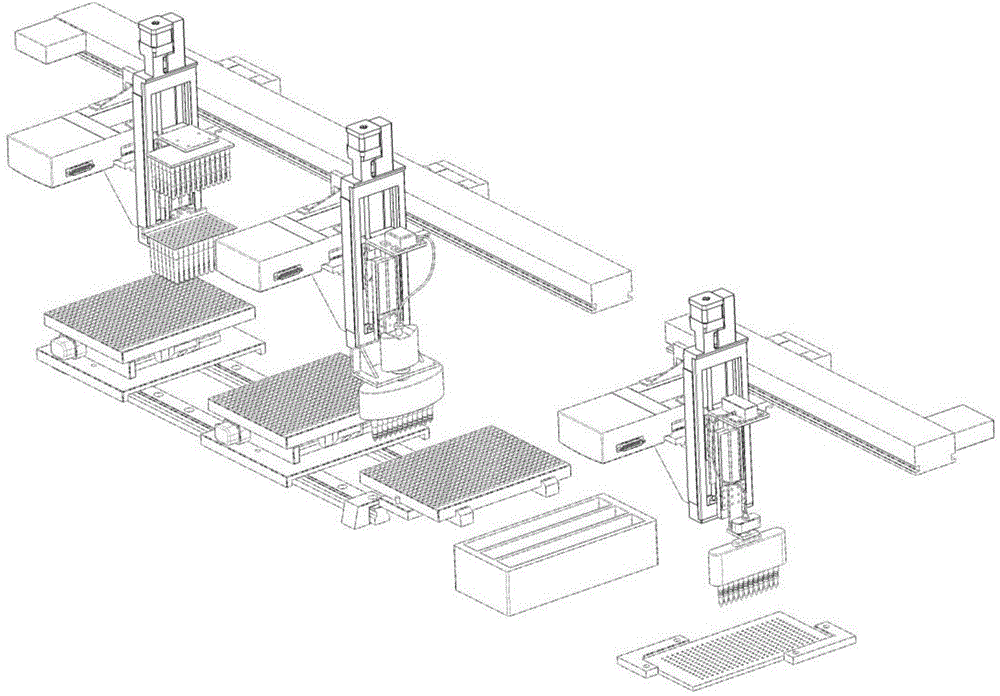

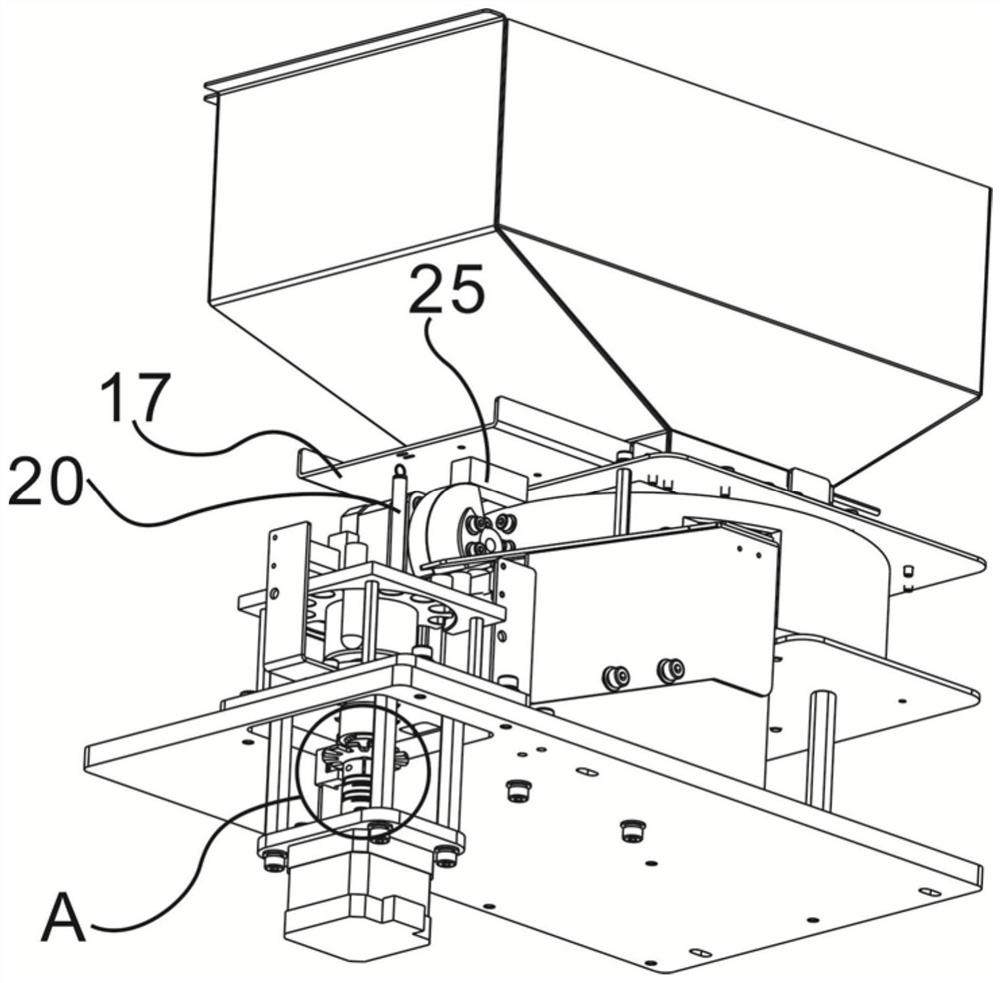

Automated instrument for nucleic acid extraction and mass spectrum sample application

ActiveCN102492603AAccurate extractionReduce infectionBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadMass analyzer

The invention discloses an automated instrument applied to nucleic acid extraction and continuous operation process of a mass spectrum sample application chip in biomass spectrometry analysis of a nucleic acid sample. The automated instrument comprises three main devices, namely, a nucleic acid extraction and purification device, a nucleic acid liquor relief distributing device and a mass spectrum chip sample application device, wherein nucleic acid in body fluid is extracted by using a magnetic bead method, a mechanical arm is utilized to complete a nucleic acid extraction action, the extracted nucleic acid is dispensed onto a sample board through a dispenser, a pipettor is used for transferring the sample board onto a chip sample application instrument, and the mass spectrum and relatedinformation of the nucleic acid are obtained through laser sampling of a mass spectrometer, so that the nucleic acid is analyzed rapidly, directly and continuously. The automated instrument is high-precision in controlling the volume of dispensed liquor, high-cleanliness in controlling the quality of the dispensed liquor and high-efficiency in meeting sample application requirements of large-batch samples; meanwhile, the samples are uniformly distributed under the control of a computer program, volume errors and possible foreign pollution caused by manual operation are avoided, and the speed and efficiency in sample application are increased at the same time.

Owner:BIOYONG TECH

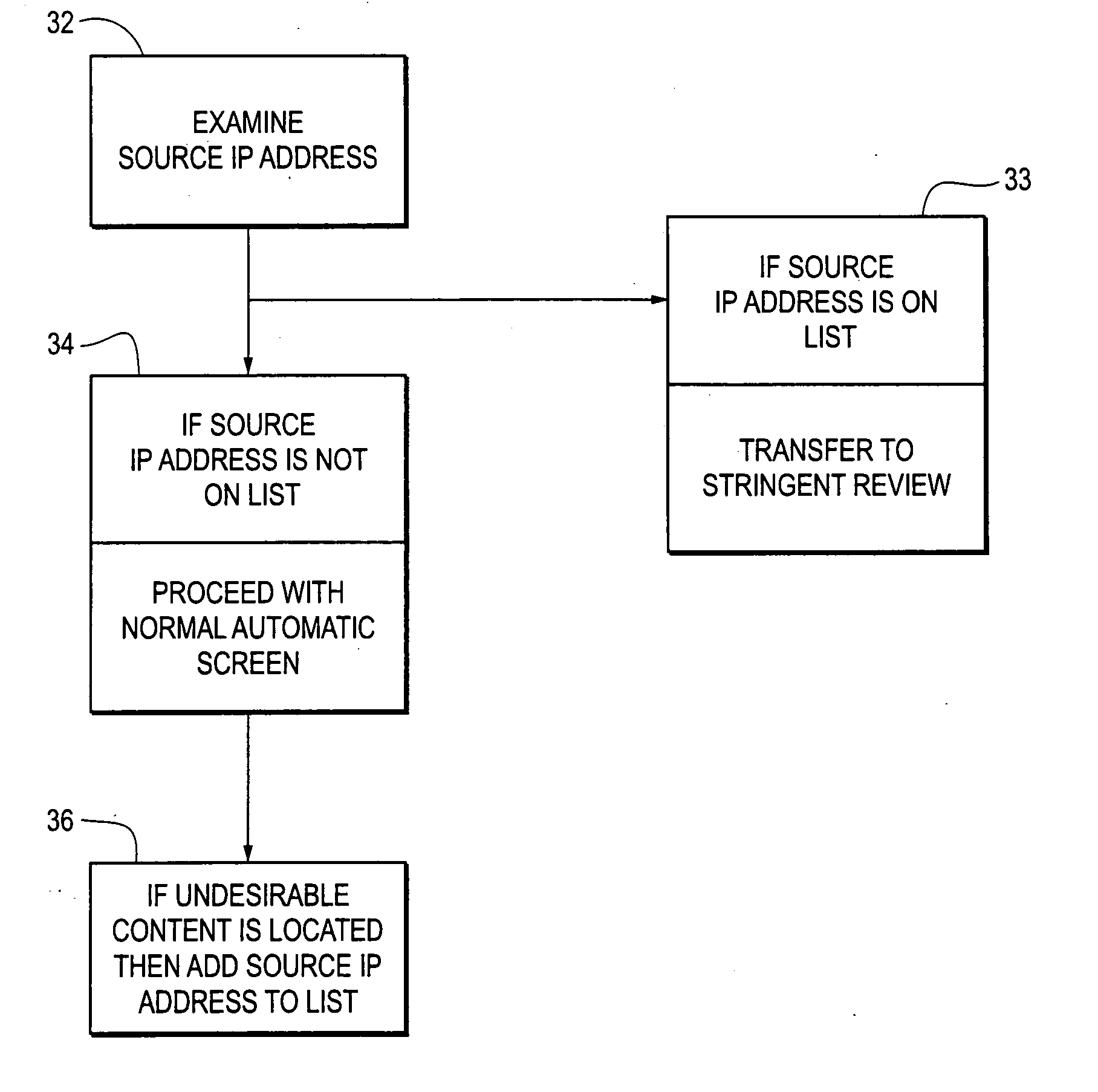

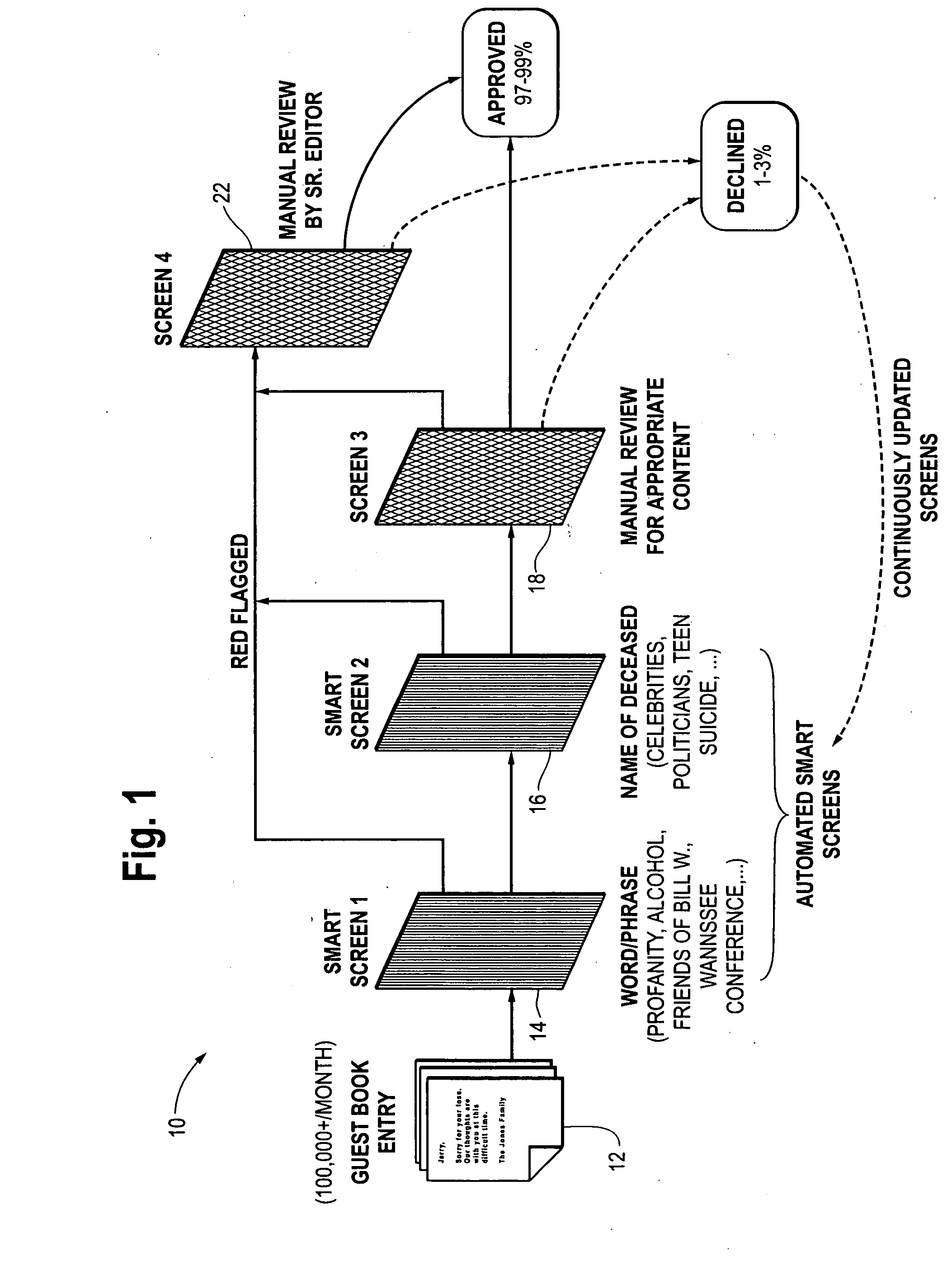

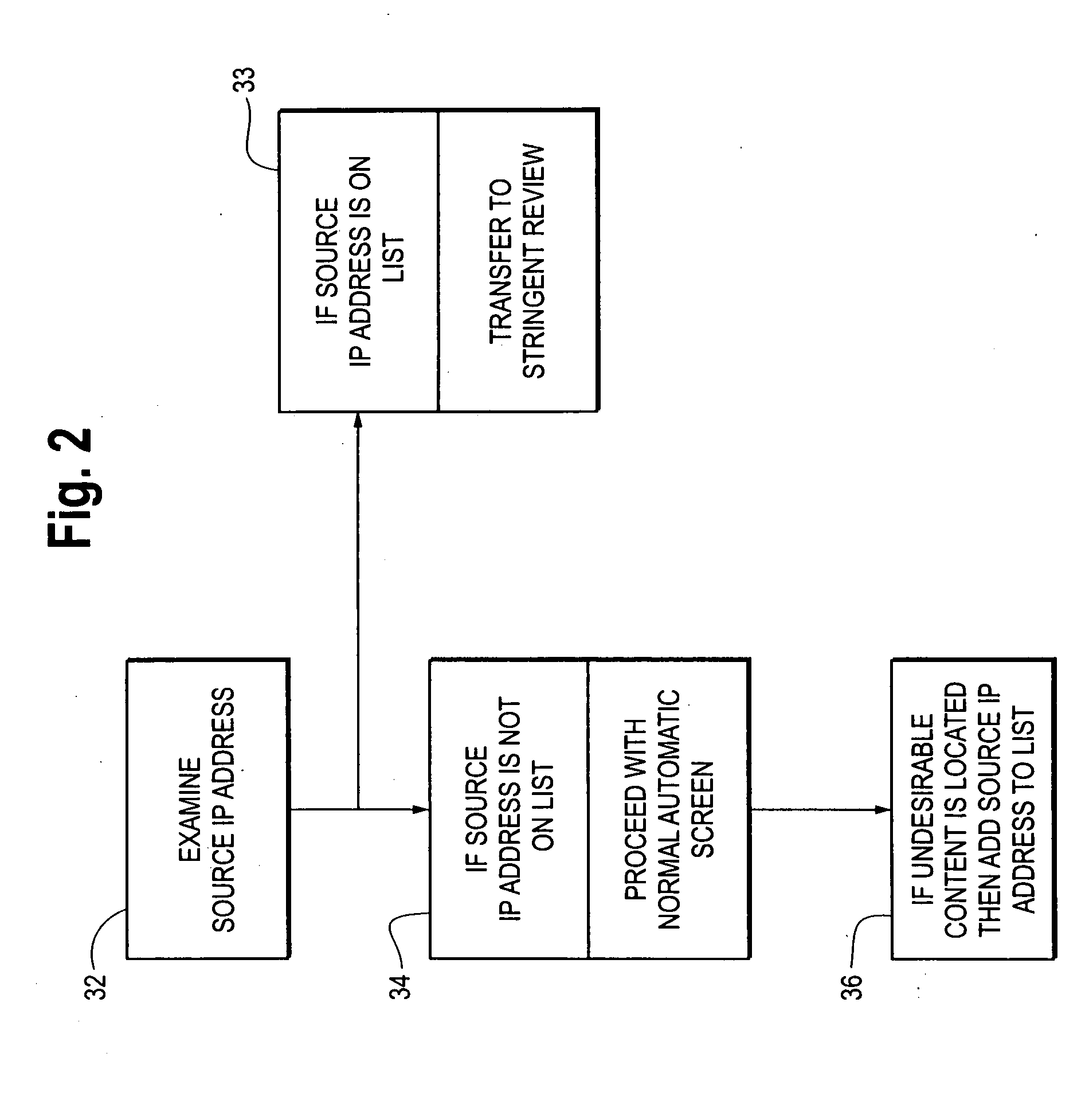

Systems and methods for enhancing the screening of electronic message data

InactiveUS20050256929A1Enhance review processHigh degree of qualityMultiple digital computer combinationsInternet privacyMessage board

Owner:LEGACY COM

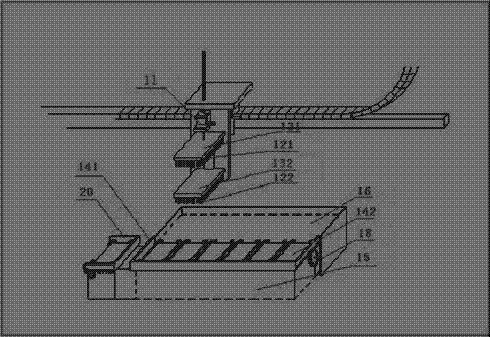

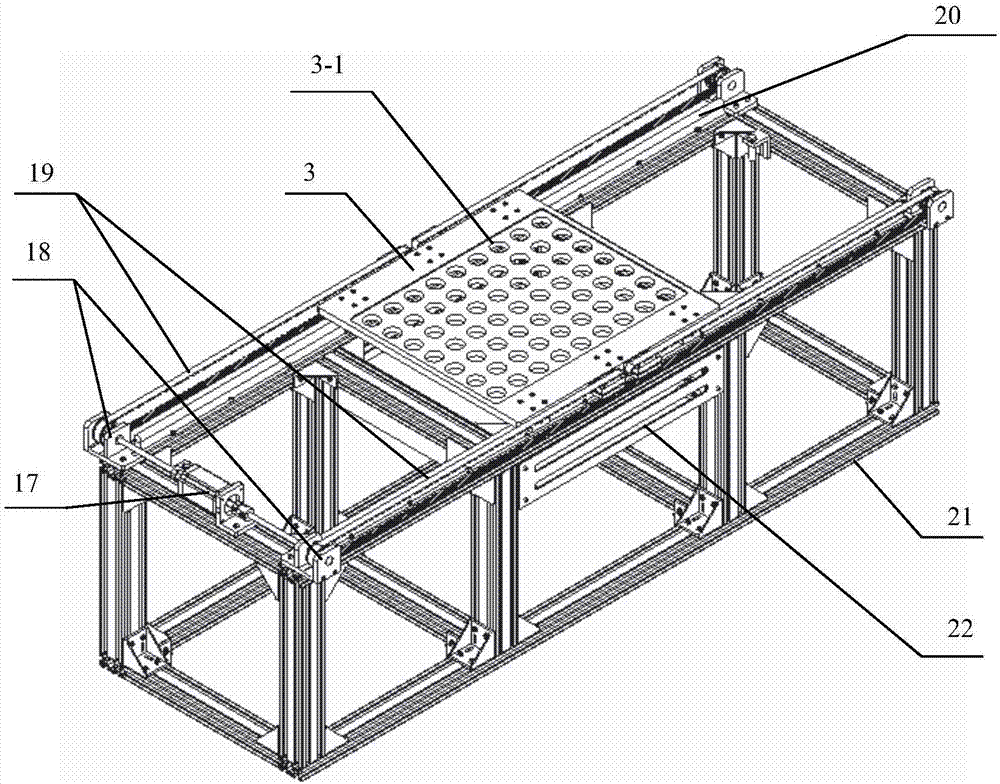

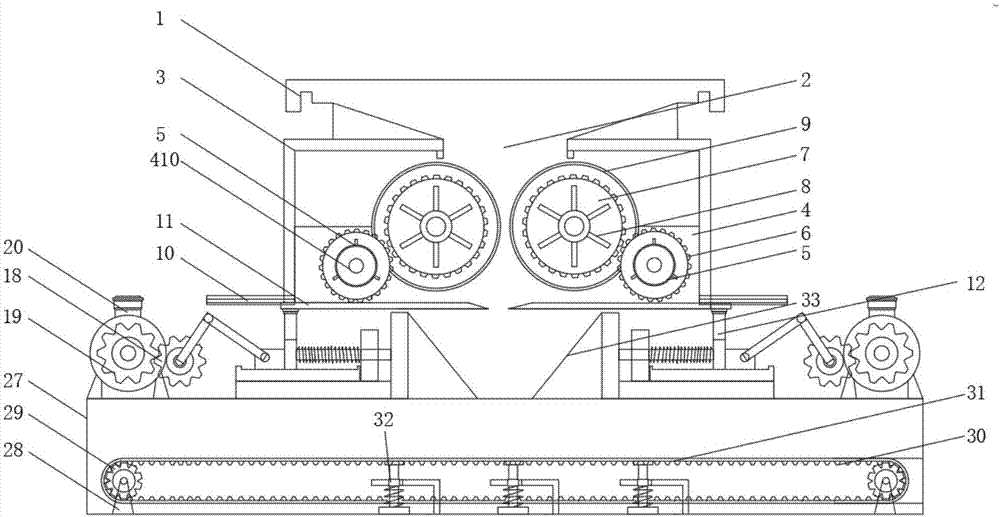

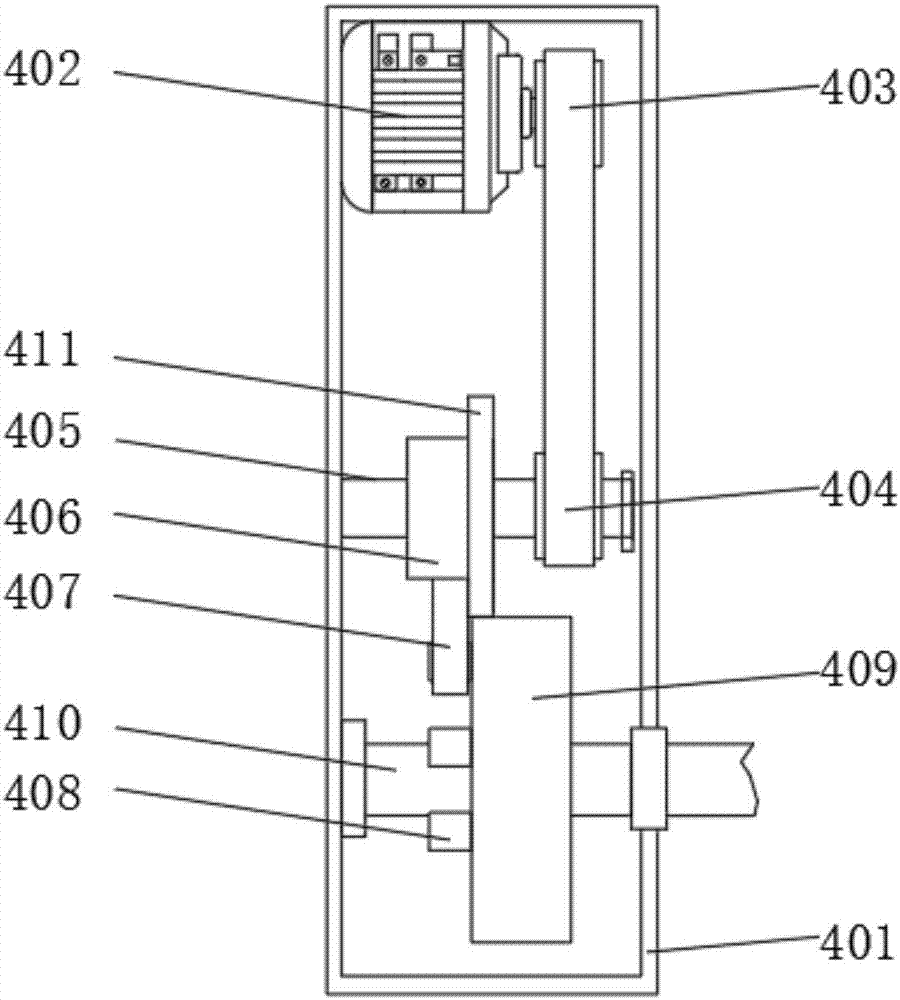

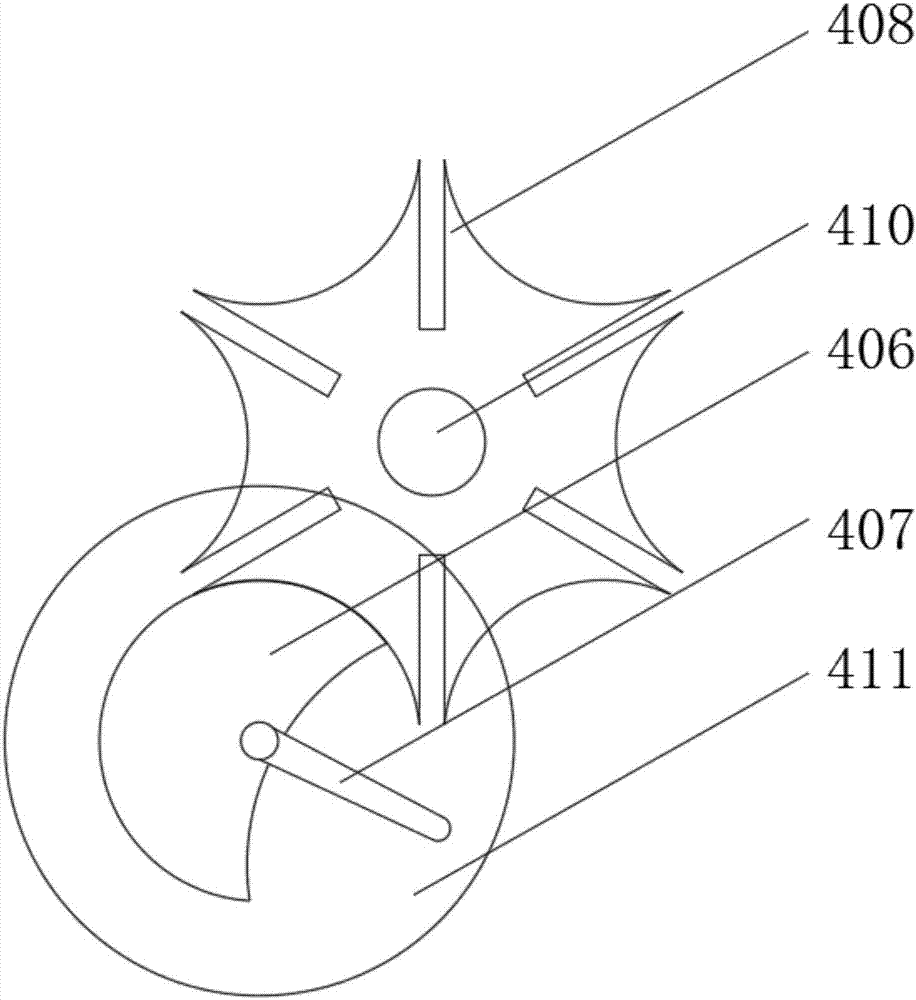

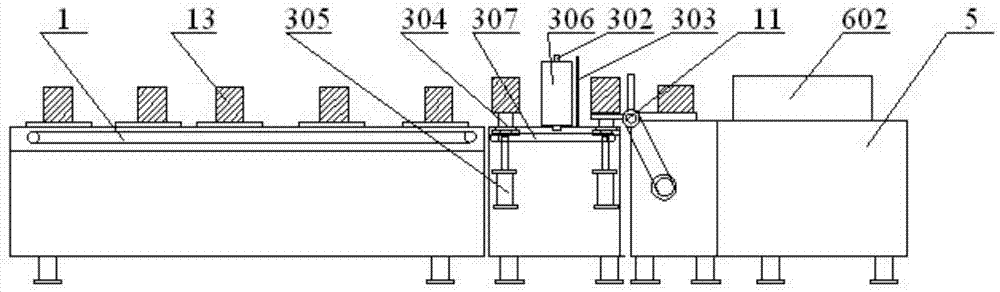

Poultry fertilized egg detection and screening device based on machine vision

ActiveCN106872465AReduce labor intensityStrong speedMaterial analysis by optical meansFowlMachine vision

The invention relates to a poultry fertilized egg detection and screening device based on machine vision. The device comprises a breeding egg conveying unit, an image acquisition unit and a breeding egg sorting unit; the device mainly applies a machine vision technology and a digital image processing technology; a whole disc of breeding eggs to be detected are detected and the light transmission property of each breeding egg to be detected in an image is extracted; whether each breeding egg to be detected is fertilized or not is judged according to the light transmission property of the breeding eggs to be detected; infertile eggs are sucked through a suction disc by utilizing a vacuum generation technology, so that separation of the infertile eggs and the fertilized eggs is realized. The device provided by the invention can replace artificial egg candling so that the labor intensity of workers is alleviated, and the speed and accuracy of breeding egg detection are improved; more importantly, the device takes a hatching tray in actual production as a foundation and has very high practicability; the device is invented so that an infertile egg detection industry of China reaches a new stage, and the device has important significance on an automation level of agricultural product detection.

Owner:CHINA AGRI UNIV

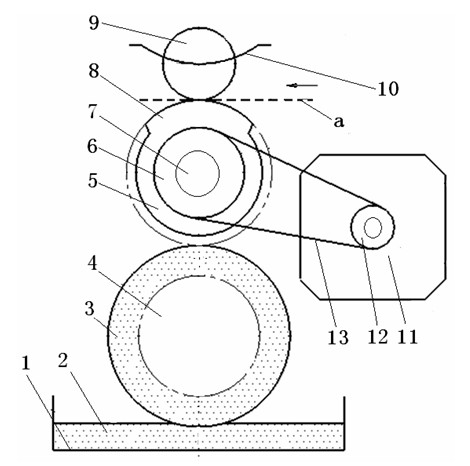

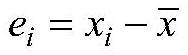

Lining viscosity measurement instrument

The invention relates to a lining viscosity measurement instrument which is provided with a shear type lifting table (1), wherein a bottom plate (2) is arranged at the top of the shear type lifting table (1); a guide light rod (3) and a ball screw nut pair (4) are arranged on the bottom plate (2); a platform (5) is arranged above the bottom plate (2) and is driven by the ball screw nut pair (4) to move up or down; power of the ball screw nut pair (4) is provided by a first motor (21) mounted on the bottom plate (2); a second motor (51), a gear rack mechanism (52) and a linear guide rail (53) are mounted on the platform (5); a pressing head (54) is mounted at the end part of the linear guide rail (53); a sensor (55) is arranged on the pressing head (54) and connected with a controller and a display; the gear rack mechanism (52) is driven by the second motor (51) to push the linear guide rail (53) to horizontally move. According to the device, the lining viscosity can be quickly measured.

Owner:HUZHOU TEACHERS COLLEGE

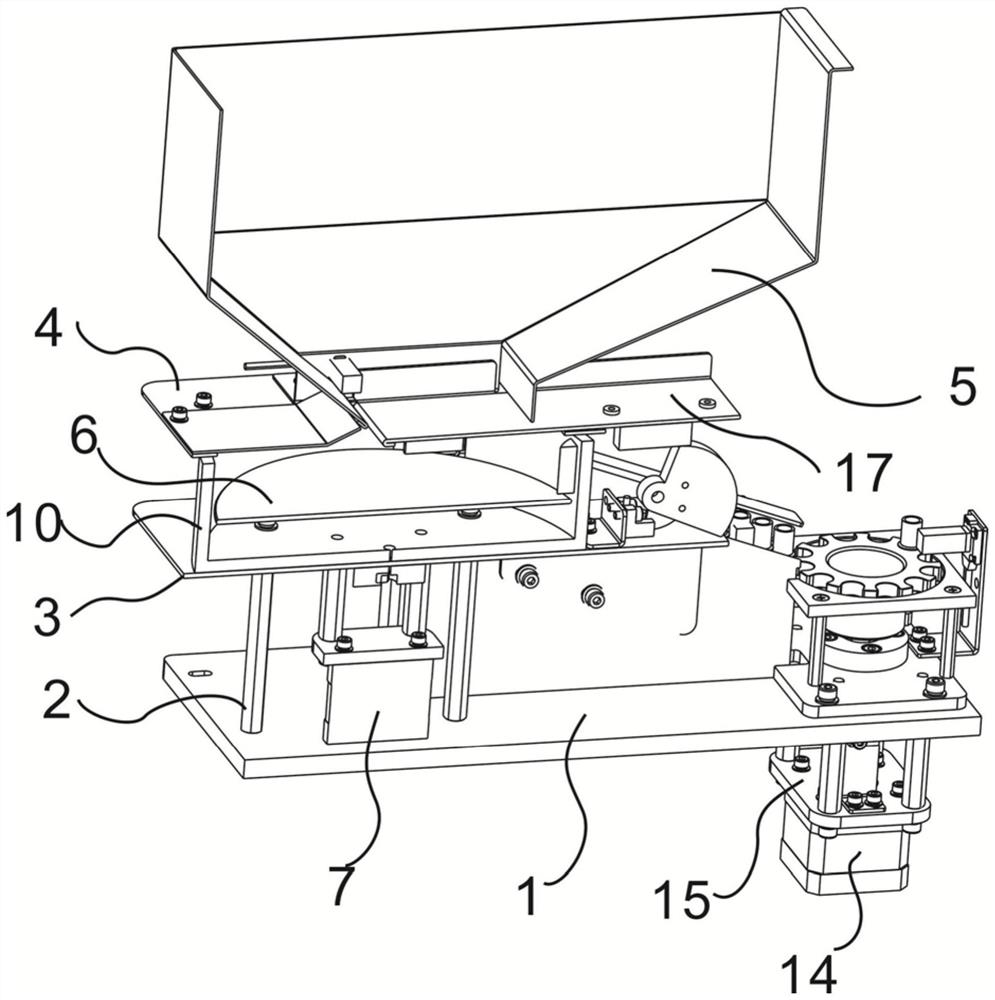

Automatic discharge online inspection submitting device for production line

ActiveCN105170481AFacilitate the automation processImprove yieldSortingProduction lineTransmission belt

The invention provides an automatic discharge online inspection submitting device for a production line. The automatic discharge online inspection submitting device comprises a feeding mechanical arm and a transfer conveying belt. A detection mechanism is fixedly arranged on the outer side of one end of the transfer conveying belt. The feeding mechanical arm places workpieces machined through a former procedure in the detection mechanism for detection. A turnover mechanism is arranged above one end of the transfer conveying belt. A discharge conveying belt stretching across the transfer conveying belt is further arranged between the turnover mechanism and the transfer conveying belt. The turnover mechanism places the workpieces qualified in detection of the detection mechanism in the transfer conveying belt for conveying and places the workpieces disqualified in detection of the detection mechanism in the discharge conveying belt for discharging. According to the automatic discharge online inspection submitting device for the production line, the machined workpieces are judged and screened, the automation process of the production line is increased, and the production and detection efficiency is improved; and the disqualified workpieces can be screened out in the production process, machining procedures are saved, production efficiency is improved, and the yield of the workpieces is better increased.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

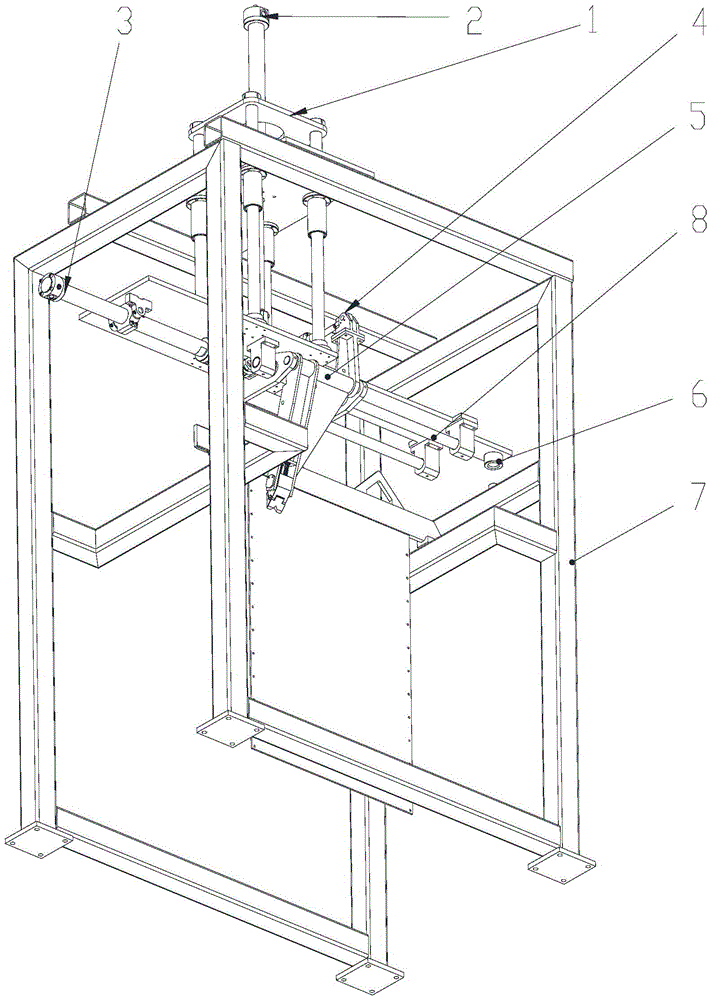

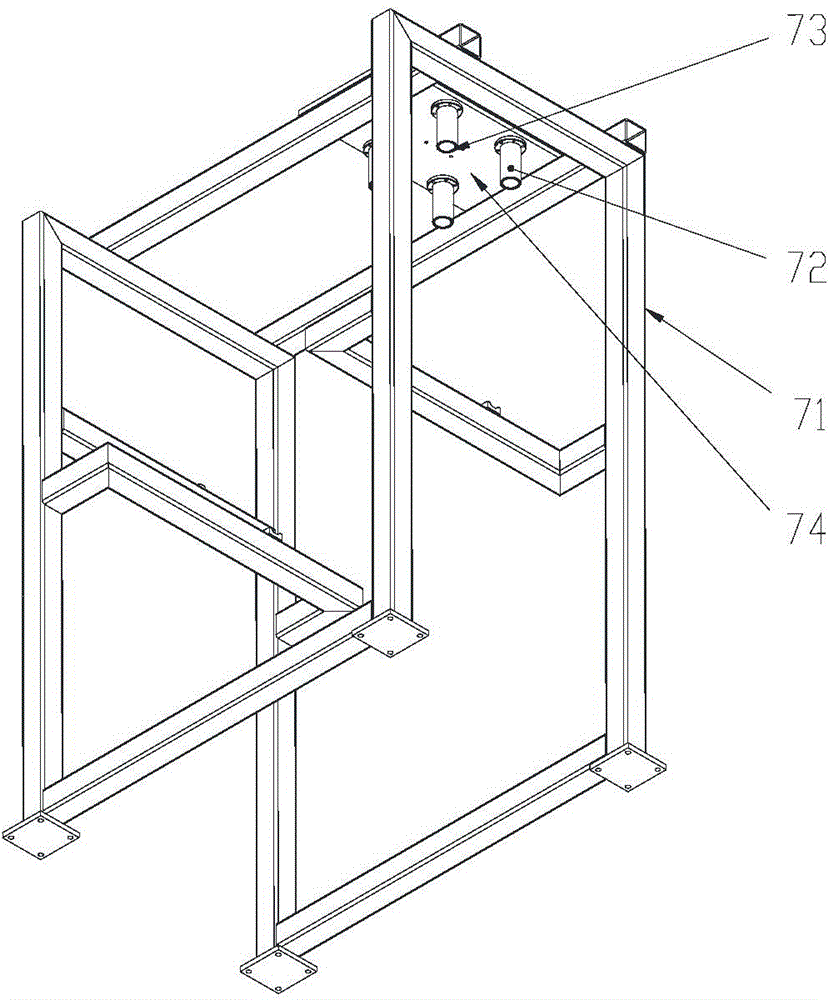

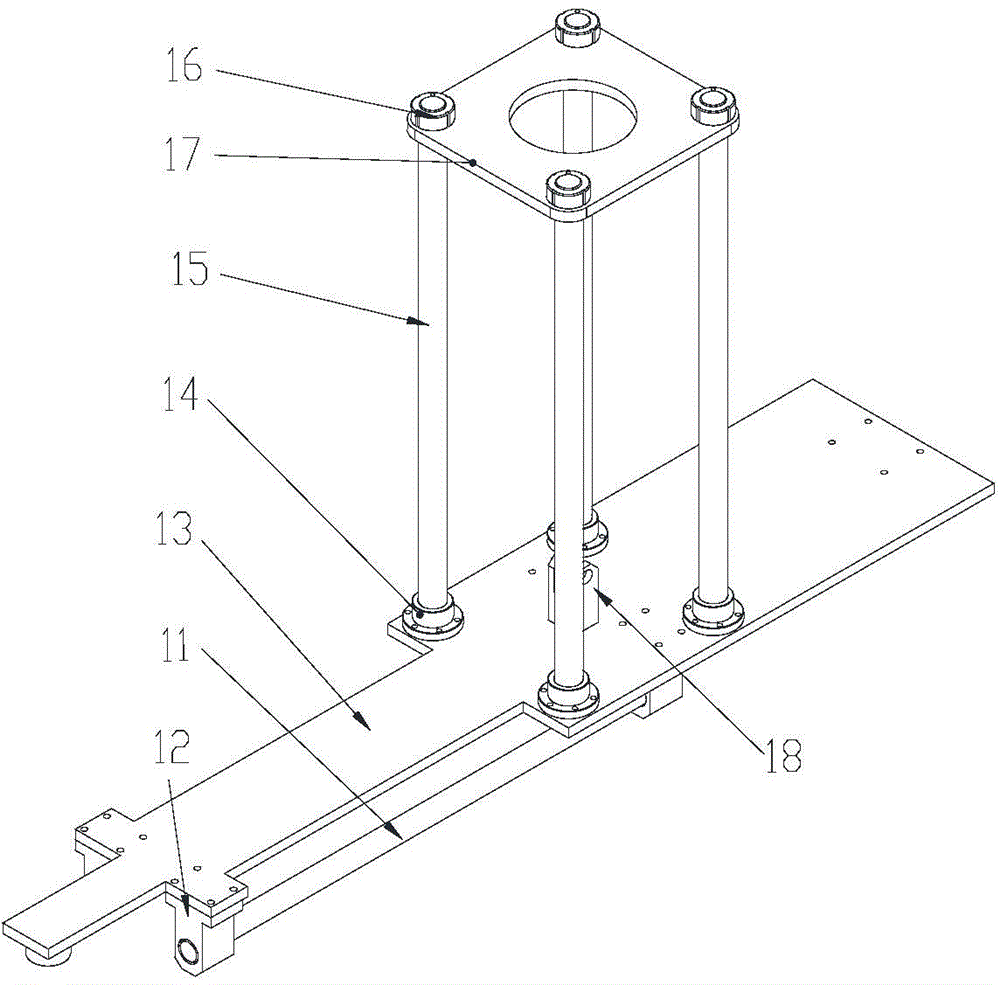

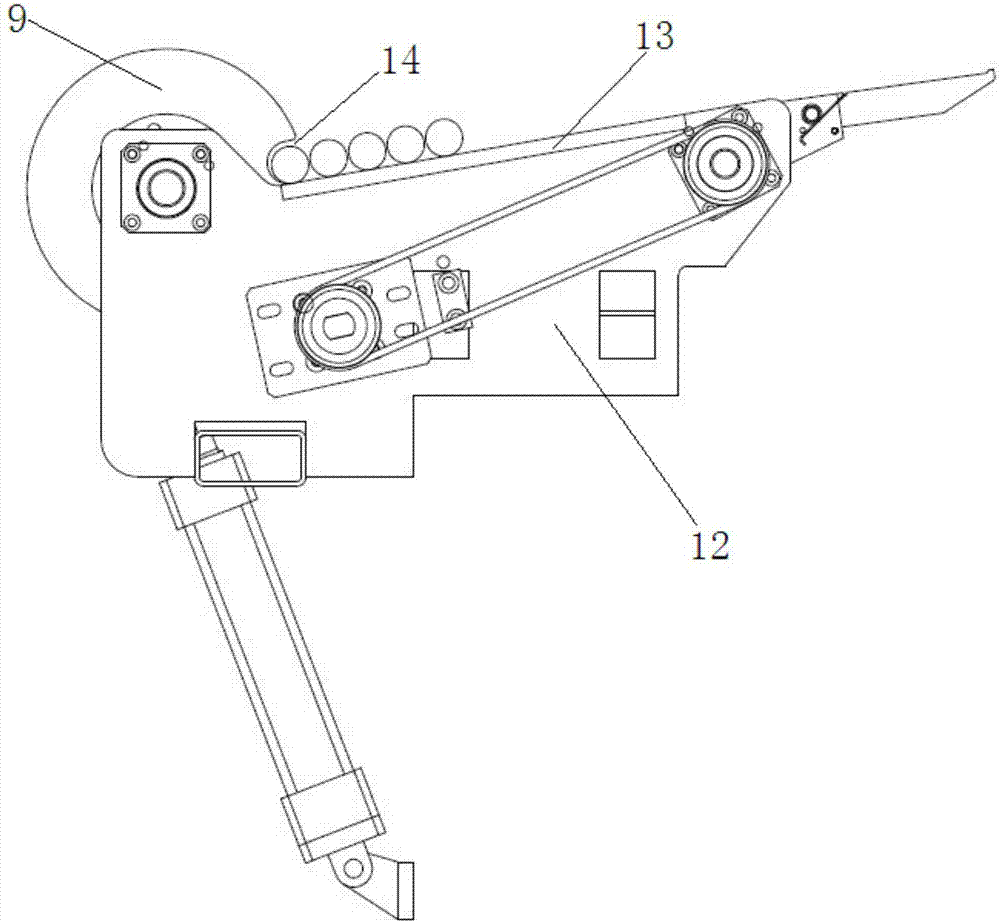

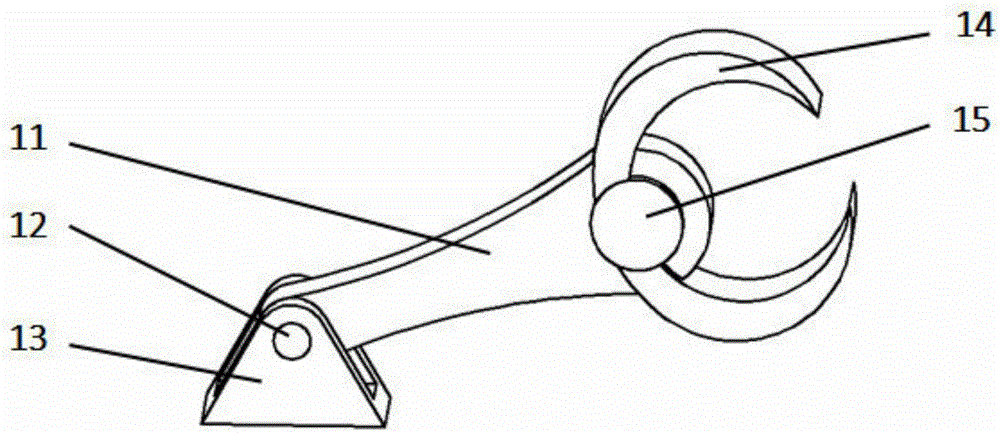

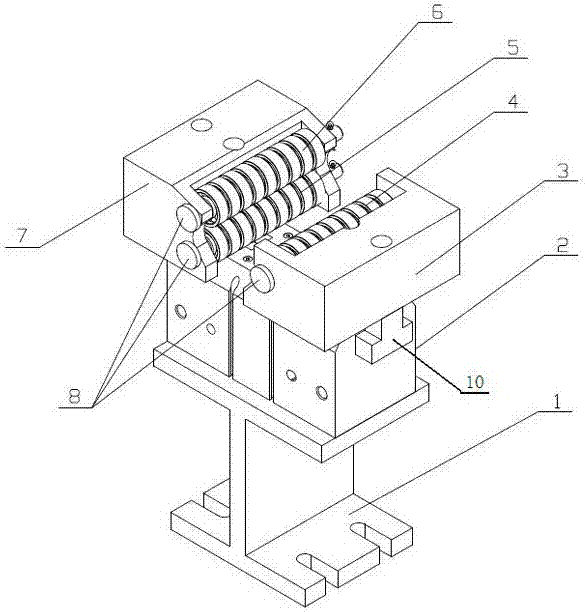

Cathode zinc plate pre-stripping device

ActiveCN104862746AFacilitate the automation processThe overall structure is simple and reliablePhotography auxillary processesElectrolysis componentsZincMechanical engineering

The invention relates to a cathode zinc plate pre-stripping device. The device comprises a rack, a vertically-sliding four-column frame, a small knife swing arm mechanism and a stripping knife frame, wherein the vertically-sliding four-column frame is connected with four guiding sleeves in the rack through four guiding columns and hinged to hinge points arranged on a movable plate through a four-column frame driving cylinder; the stripping knife frame is connected with a horizontal guiding column in the vertically-sliding four-column frame through stripping sliding frames and is in hinged connection through a stripping knife frame driving cylinder, and the stripping knife frame driving cylinder is fixed on the movable plate; first hinge pins are sleeved with a left swing arm and a right swing arm in the small knife swing arm mechanism respectively and fixed in the two stripping sliding frames, a support lug is arranged on the left swing arm, a forked seat is arranged on the right swing arm, and the forked seat and the support lug are connected through a clamping cylinder. The device has the benefits as follows: practice of the automatic process of a zinc stripping unit is facilitated, and the device has the advantages of simple and reliable structure, environment-friendliness and capability of reducing noise at the production site.

Owner:SANMEN SANYOU TECH CO LTD

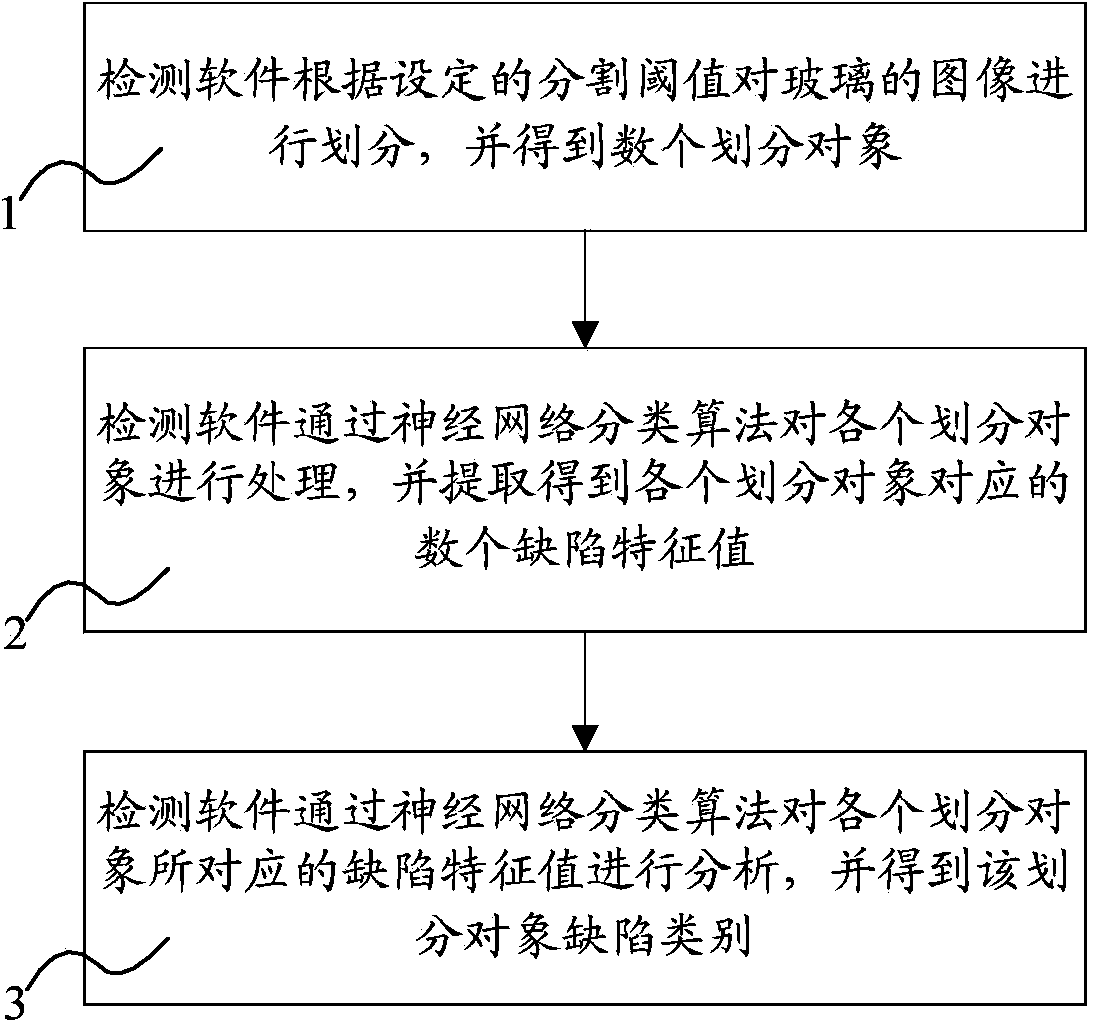

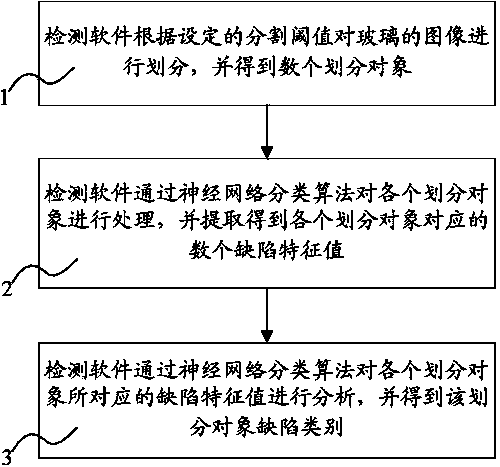

Method for achieving automatic detection and classification of glass defects on basis of computer software

InactiveCN104318256AImprove inspection efficiencyGuaranteed factory qualityImage enhancementImage analysisPattern recognitionComputer software

The invention relates to a method for achieving automatic detection and classification of glass defects on the basis of computer software. The method includes the steps that the detection software divides an image of glass according to a set partition threshold value to obtain a plurality of divided objects; the detection software processes the divided objects according to a neural network classification algorithm, and a plurality of detect feature values corresponding to the divided objects are extracted; the detection software analyzes the detect feature values corresponding to the divided objects through the neural network classification algorithm, and defect categories of the divided objects are obtained. The method for achieving automatic detection and classification of glass defects on the basis of the computer software is applicable to automatic production operation of electronic glass or other types of glass, glass check efficiency is improved, the quality is ensured when glass leaves a factory, the labor cost is lowered, the automatic progress of enterprises is accelerated, an automatic glass detection system can be popularized conveniently on a large scale, and the application range is wider.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

Steel ball polishing and transporting device

ActiveCN107877348AAchieve the purpose of polishingAchieve work uniformityPolishing machinesGrinding drivesGear wheelSteel ball

The invention discloses a steel ball polishing and transporting device, which comprises a feeding top cover. A feeding inlet is formed in the bottom part of the feeding top cover; a polishing work boxis fixedly connected to the bottom part of the feeding top cover; power devices are fixedly connected to two sides of the bottom part of an inner wall of the polishing work box and are fixedly connected with power rotating wheels; each power rotating wheel is rotatably connected with a first gear through an output shaft; each first gear is located on the upper part of the inner side of the polishing work box and is engaged with a second gear; each second gear is rotatably connected with a polishing roller wheel through a rotary shaft; and a detachable fixing handle is arranged on the surfaceof each second gear. The invention relates to the technical field of steel ball polishing transporters. The steel ball polishing and transporting device can be used for polishing, discharging and transporting steel balls, the stability of the rotating speed and the working evenness are ensured, the polishing quality and the polishing efficiency are ensured, the possible problems occurred during work are reduced, the transportation efficiency is ensured, and the automatic process is improved.

Owner:临沂临港经济开发区合顺物流有限公司

Full-automatic polypeptide extraction time-of-flight mass spectrum detector

ActiveCN109142501AAccurate extractionReduce infectionWithdrawing sample devicesPreparing sample for investigationPhysical chemistryMass analyzer

Owner:BIOYONG TECH

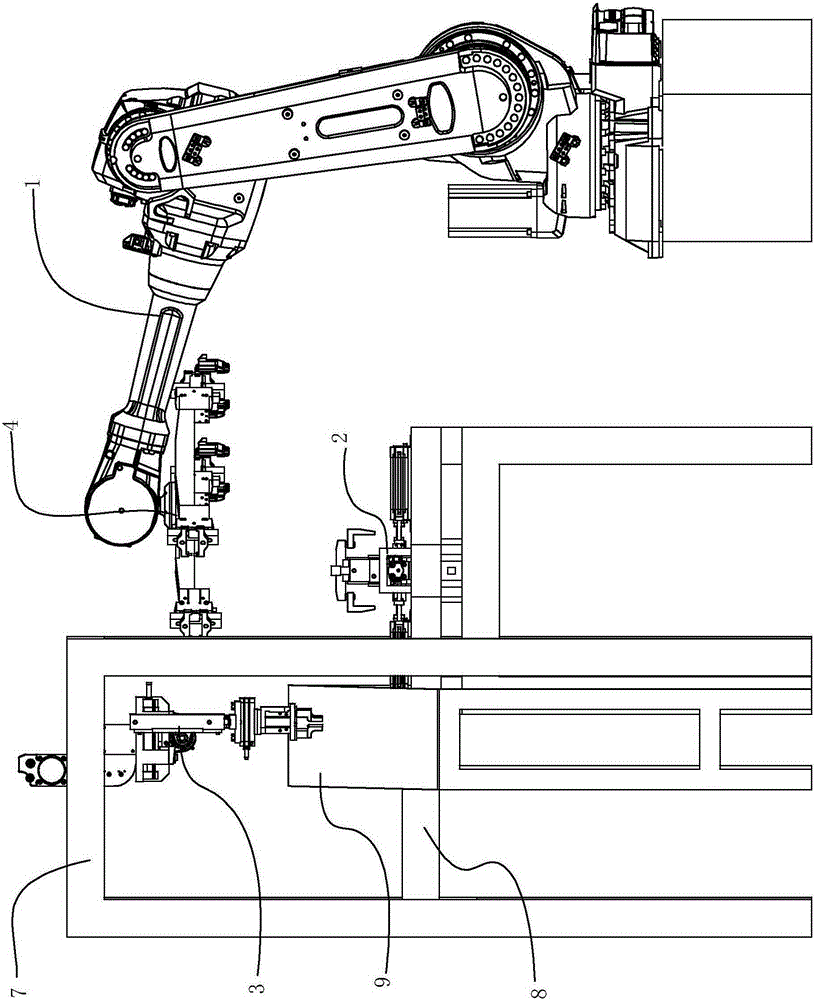

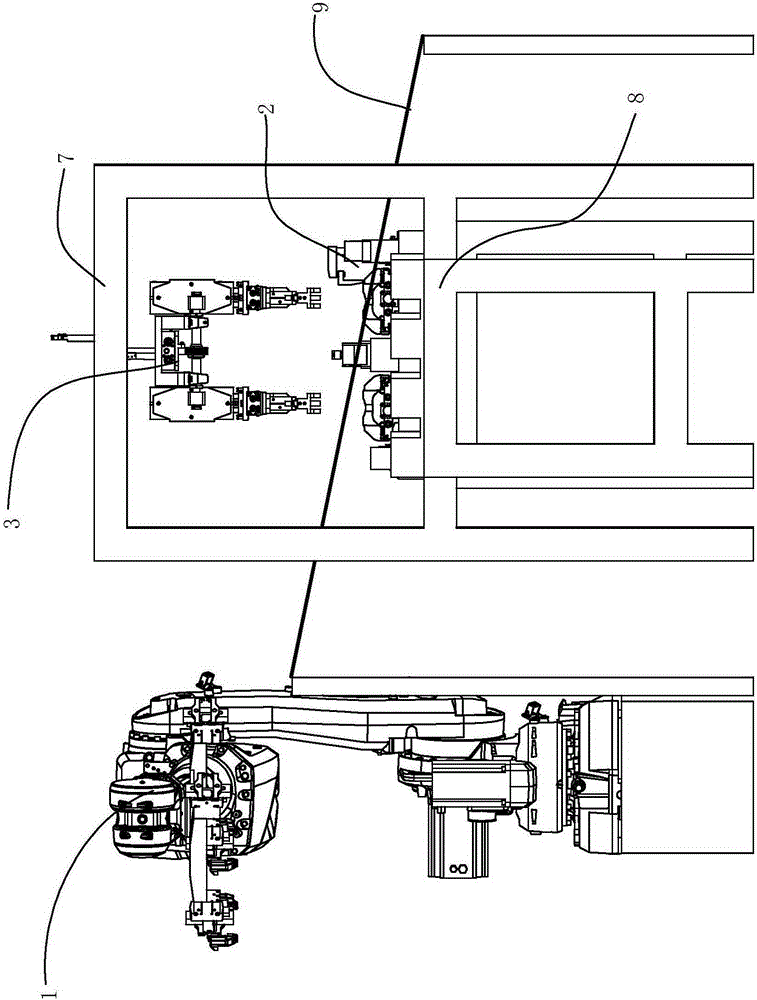

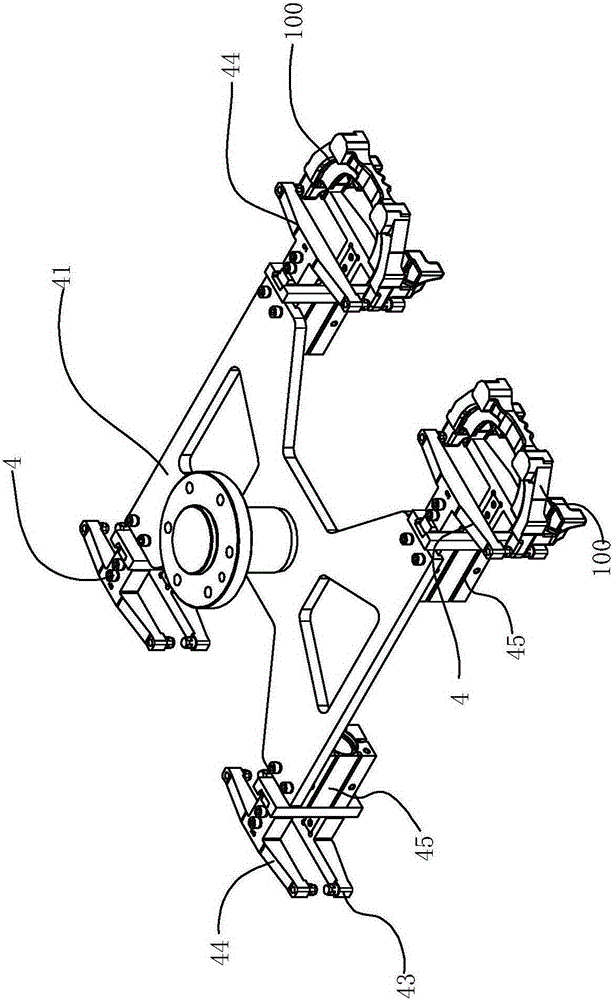

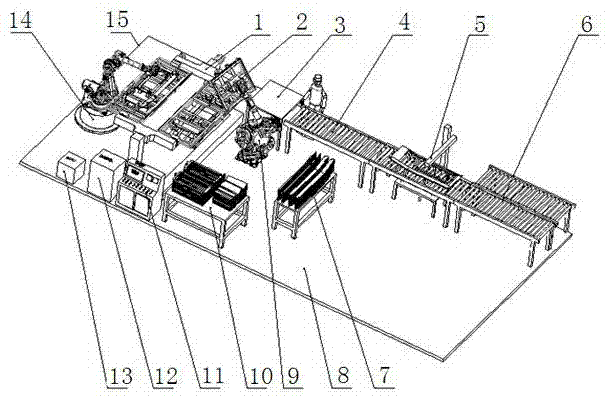

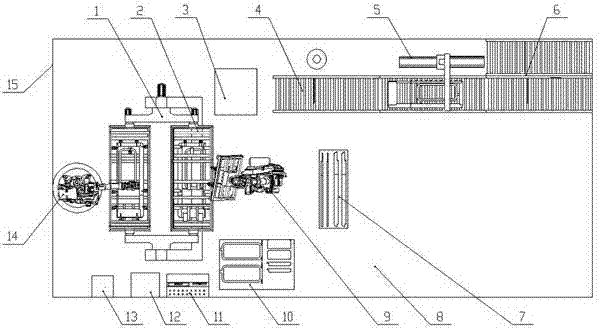

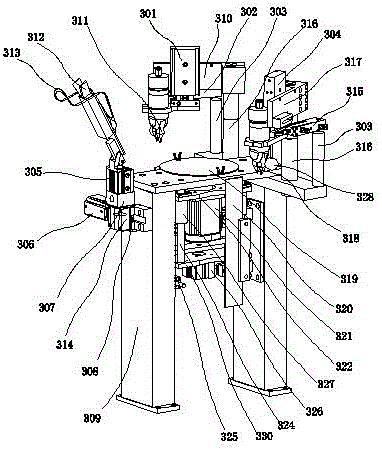

Automatic production line and method used for welding and milling door frame of railway vehicle

ActiveCN104759890AHigh degree of automationFacilitate the automation processOther manufacturing equipments/toolsProduction lineNumerical control

The invention discloses an automatic production line and method used for welding and milling a door frame of a railway vehicle. The automatic production line comprises a working platform, the working platform is provided with a triaxial numerical control positioner, a door frame pneumatic clamping unit, a tool caching table, a manual polishing region, a quality automatic detection unit, a product automatic sorting unit, a first door frame storage table, a first robot, a second door frame storage table, a welder and a second robot; the door frame pneumatic clamping unit is divided into two groups, each group is arranged on the triaxial numerical control positioner, the two groups of the door frame pneumatic clamping unit are controlled by the triaxial numerical control positioner to overturn, and each door frame pneumatic clamping unit is used for fixing a to-be-processed door frame. The automation degree of the welding and the milling is high, a gap welding automatic tracking unit, a milling automatic compensation unit and an online automatic detection unit are obtained, the problems that gap welding of a welding production line is poor and the welding quality is not reliable are solved, the procedures of welding and milling are completed on the same production line, and a good application prospect is obtained.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

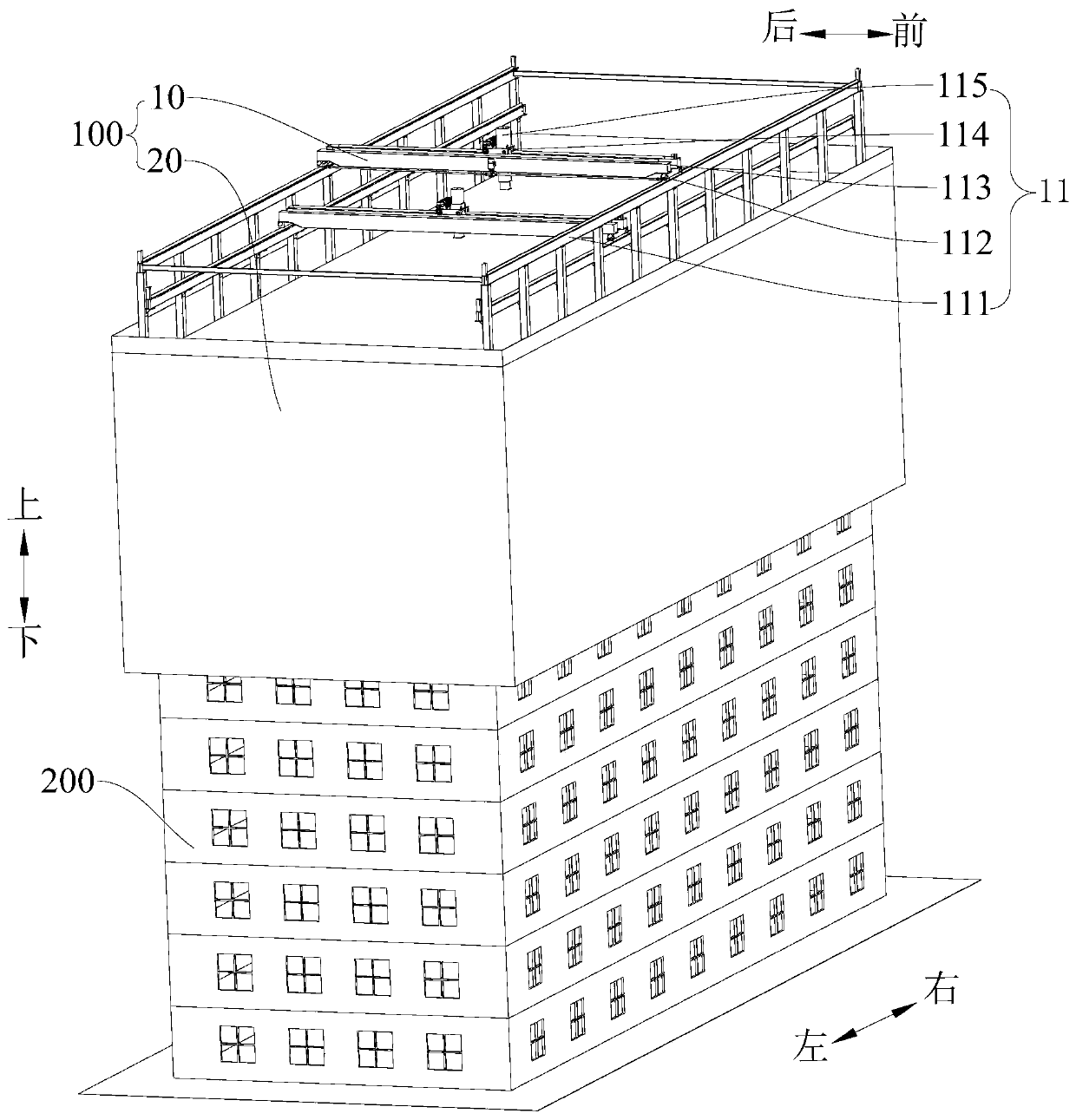

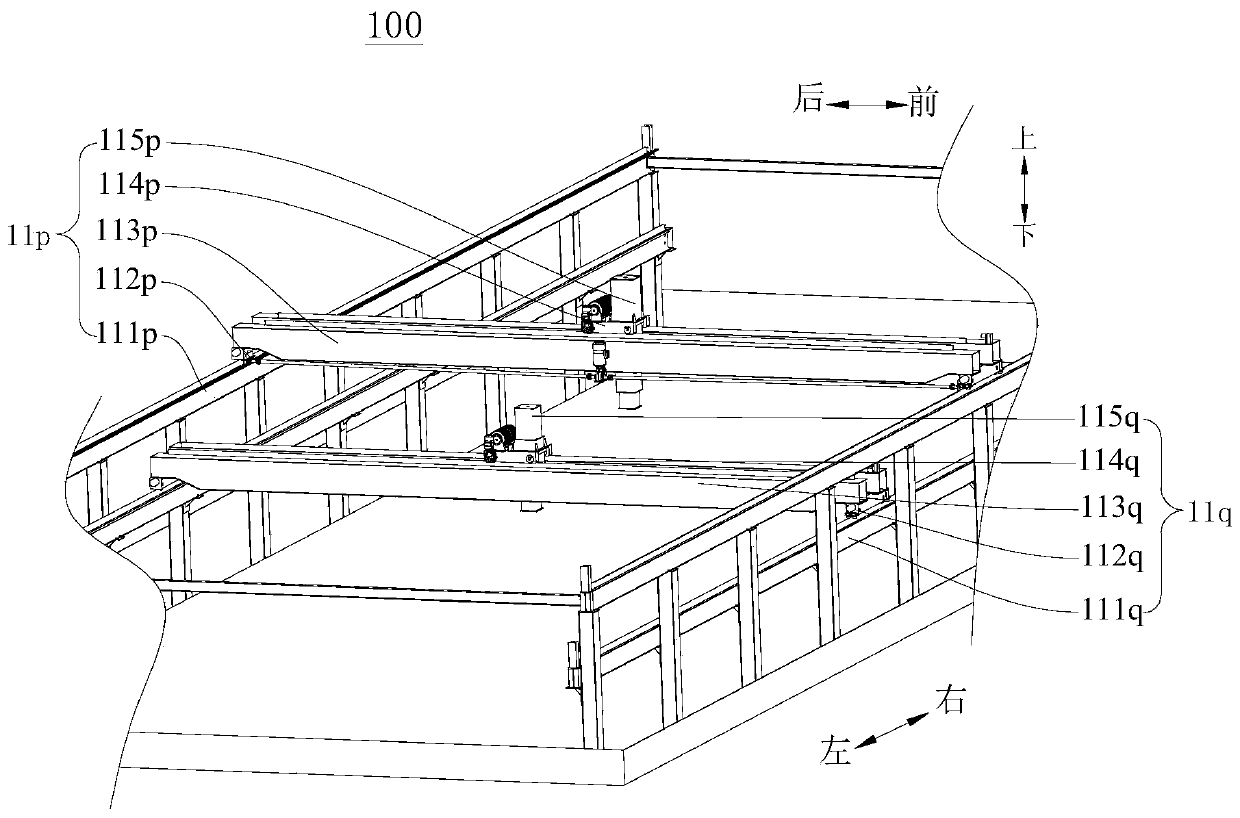

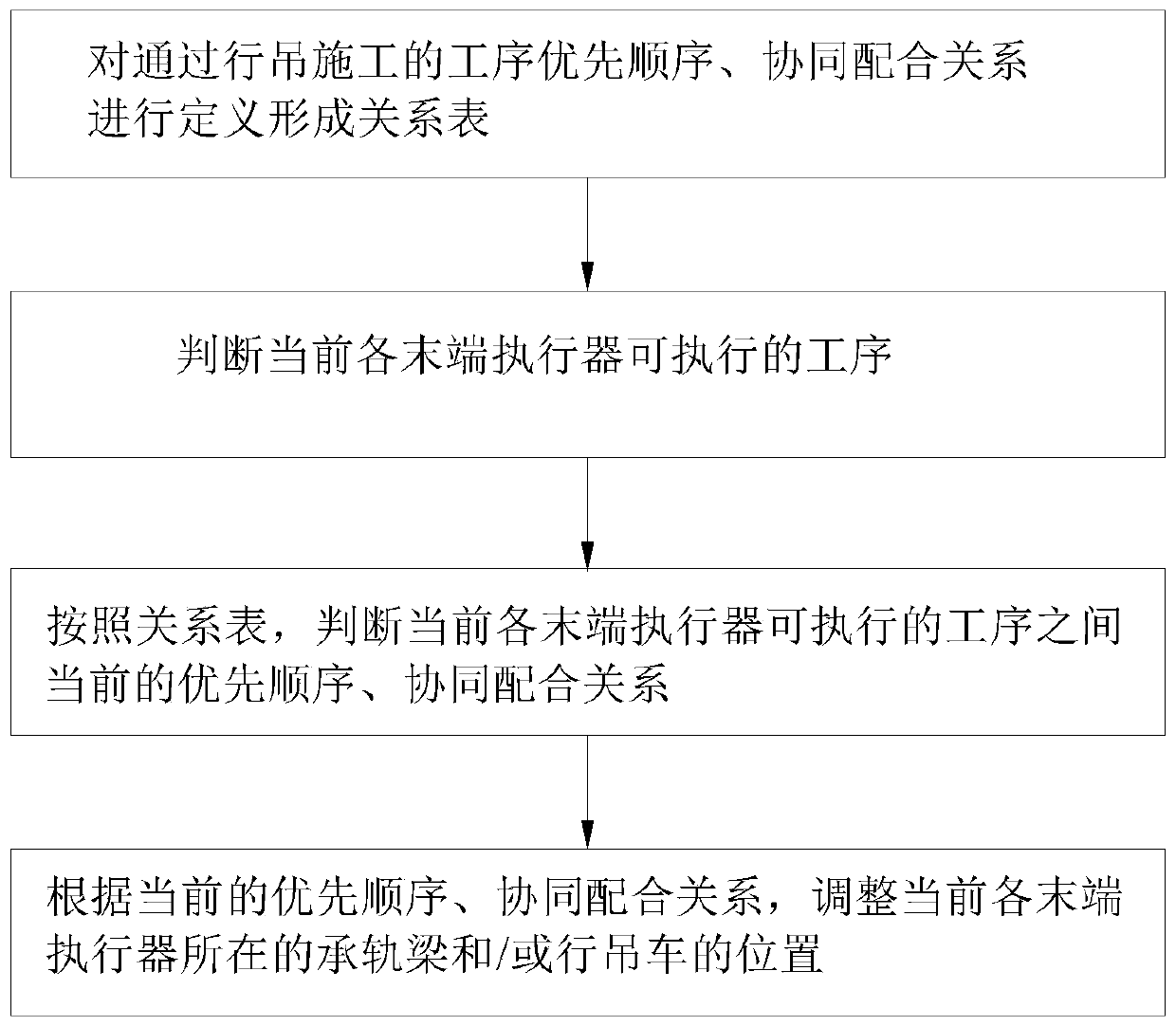

Building construction system and control method

InactiveCN110294421AMeet the requirements of simultaneous construction on multiple working surfacesMeet the requirements of simultaneous constructionTravelling cranesSafety gearArchitectural engineeringActuator

The invention discloses a building construction system and a control method. The building construction system comprises a climbing frame system and a crane system. The crane system comprises a plurality of crane devices, each crane device comprises a crane track, a walking device, a bearing rail beam and a crane, each crane is applicable to craning an end effector, and the heights of the bearing rail beams of the multiple crane devices are different; except for the crane device where the lowest bearing rail beam is located, the other crane devices all need to be avoided, at least the crane devices needing to be avoided are provided with telescopic booms, and the telescopic booms are connected to the cranes and used for installing the end effectors. The requirement for constructing multipleworking faces of a construction layer at the same time can be met, the working efficiency is improved, the end effectors carried on the cranes can replace relatively without mutual restriction, cooperative work of some construction procedures can be achieved, the construction progress can be accelerated, and time and labor are saved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

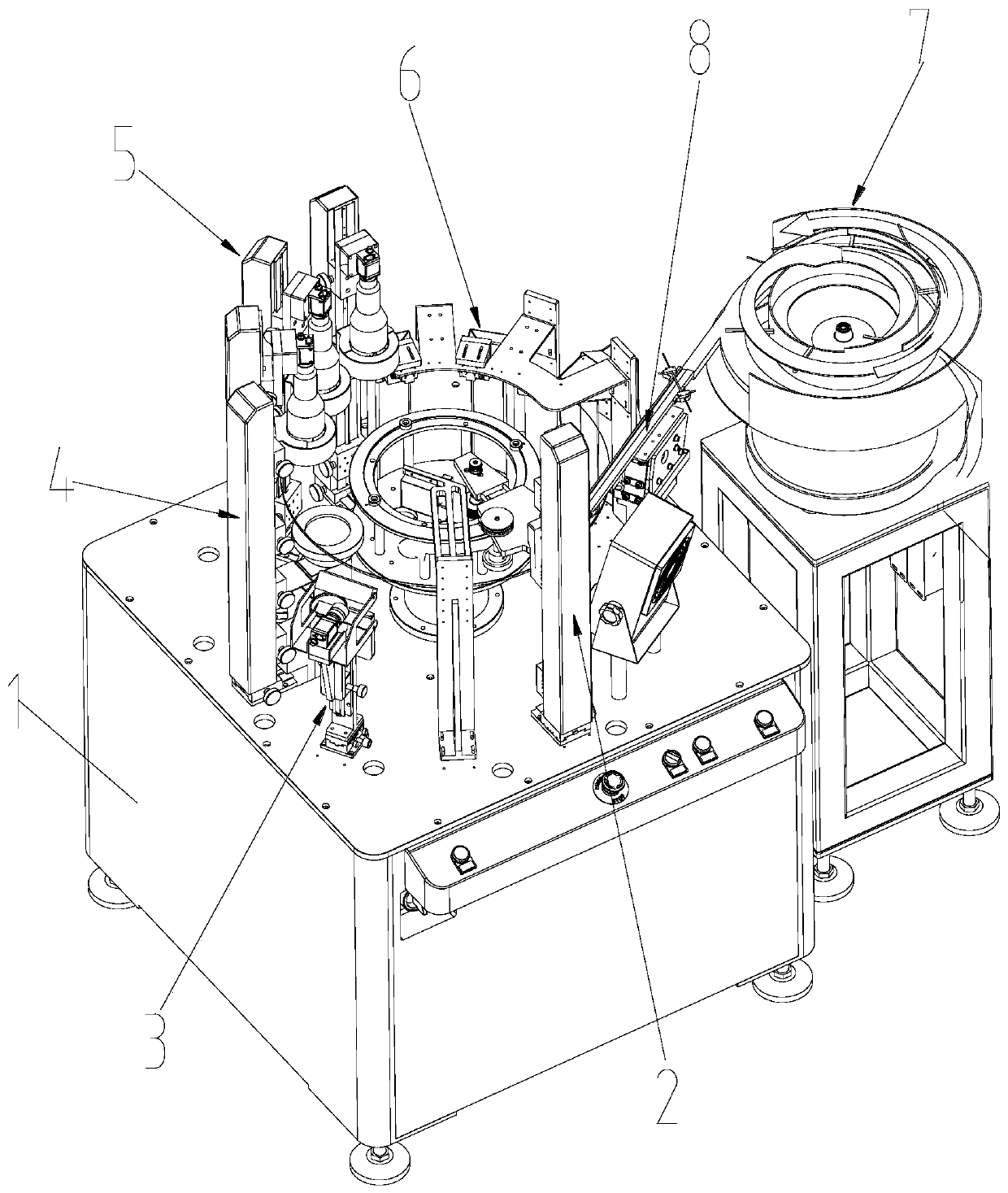

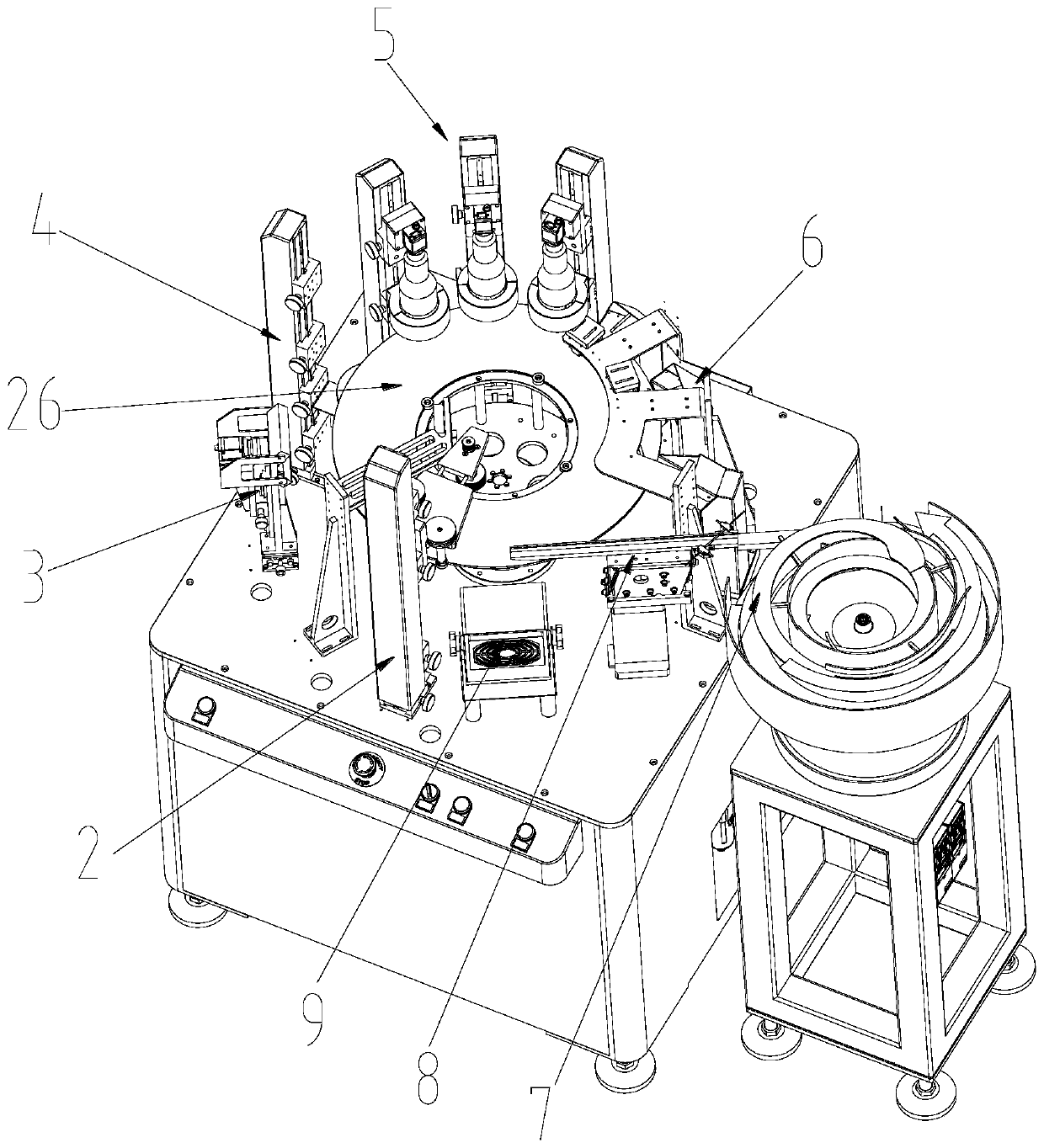

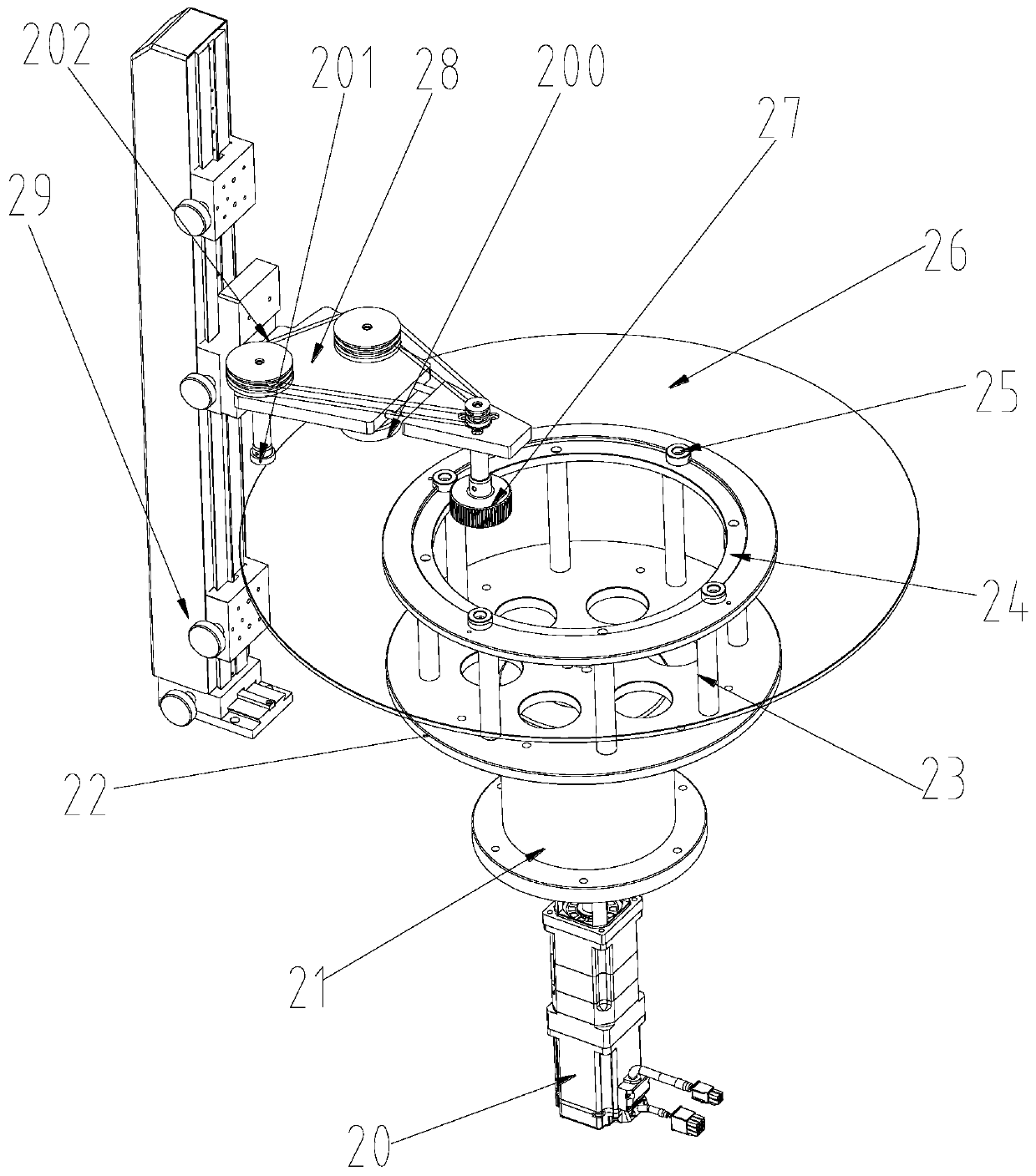

Universal multi-view workpiece flaw disc type inspection machine based on multi-color light source

PendingCN110530892ALow costImprove versatilityOptically investigating flaws/contaminationFace detectionLinear vibration

The invention relates to a universal multi-view workpiece flaw disc type inspection machine based on a multi-color light source. The inspection machine comprises a product rotary type pre-guiding assembly mounted on an equipment rack. The product rotary type pre-guide assembly is used for locating and rotating a product. A linear vibration disc assembly and a circular vibration disc assembly thatare connected are arranged at one side of the product rotary type pre-guiding assembly. A product side face detection station, a product bottom face detection station, a size / upper surface common appearance / upper surface fine defect visual detection station and a product classification station are sequentially arranged on the periphery of the product rotary type pre-guiding assembly. According tothe invention, with the multi-color light sources with various shapes and specifications, the multi-color light source emits light to cooperates with a visual system to check a multi-color product effectively and thus difficult-to-inspect items such as dark cracks and chromatic aberration are accurately detected, thereby lowering the costs of manufacturing enterprises, providing the foundation forthe size / appearance inspection automation of the corresponding difficult-to-inspect products, promoting the automation process of detection, reducing the misjudgment, and reducing the cost in the aspect of quality control.

Owner:苏州诠泰智能装备有限公司

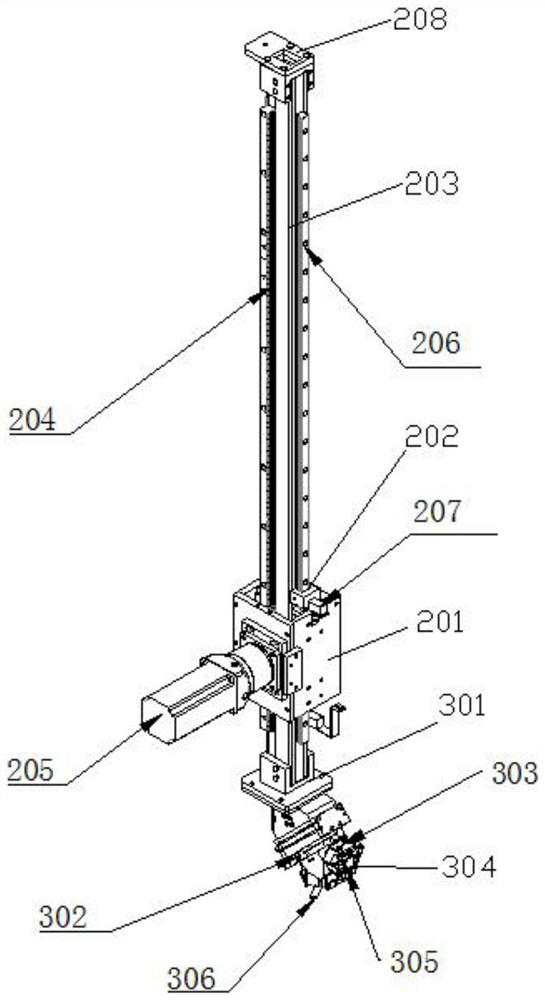

Feeding and discharging dual-grabbing manipulator

The invention discloses a feeding and discharging dual-grabbing manipulator, and belongs to the technical field of manipulator workpiece grabbing. The feeding and discharging dual-grabbing manipulatorcomprises a translation assembly, a lifting assembly and a double-material-claw reversing clamping tooth mechanism. The lifting assembly comprises a lifting driving seat arranged on the front side ofa translation sliding seat. A linear guide rail seat is connected to the lifting driving seat through a sliding groove. A vertically arranged straight rack II is arranged on the linear guide rail seat. A servo motor II is arranged on the lifting driving seat. A driving gear II corresponding to the straight rack II is arranged at the output end of the servo motor II. A linear guide rail II corresponding to the sliding groove is formed in the linear guide rail seat. A lifting sensor is arranged on the lifting driving seat. The feeding and discharging dual-grabbing manipulator is simple in structure, and can realize automatic feeding and discharging. Two material claws are operated, wherein one material claw is used for feeding, and the other material claw is used for discharging. The idle running of the manipulator is reduced, and the production efficiency is greatly improved.

Owner:浙江平川智能装备股份有限公司

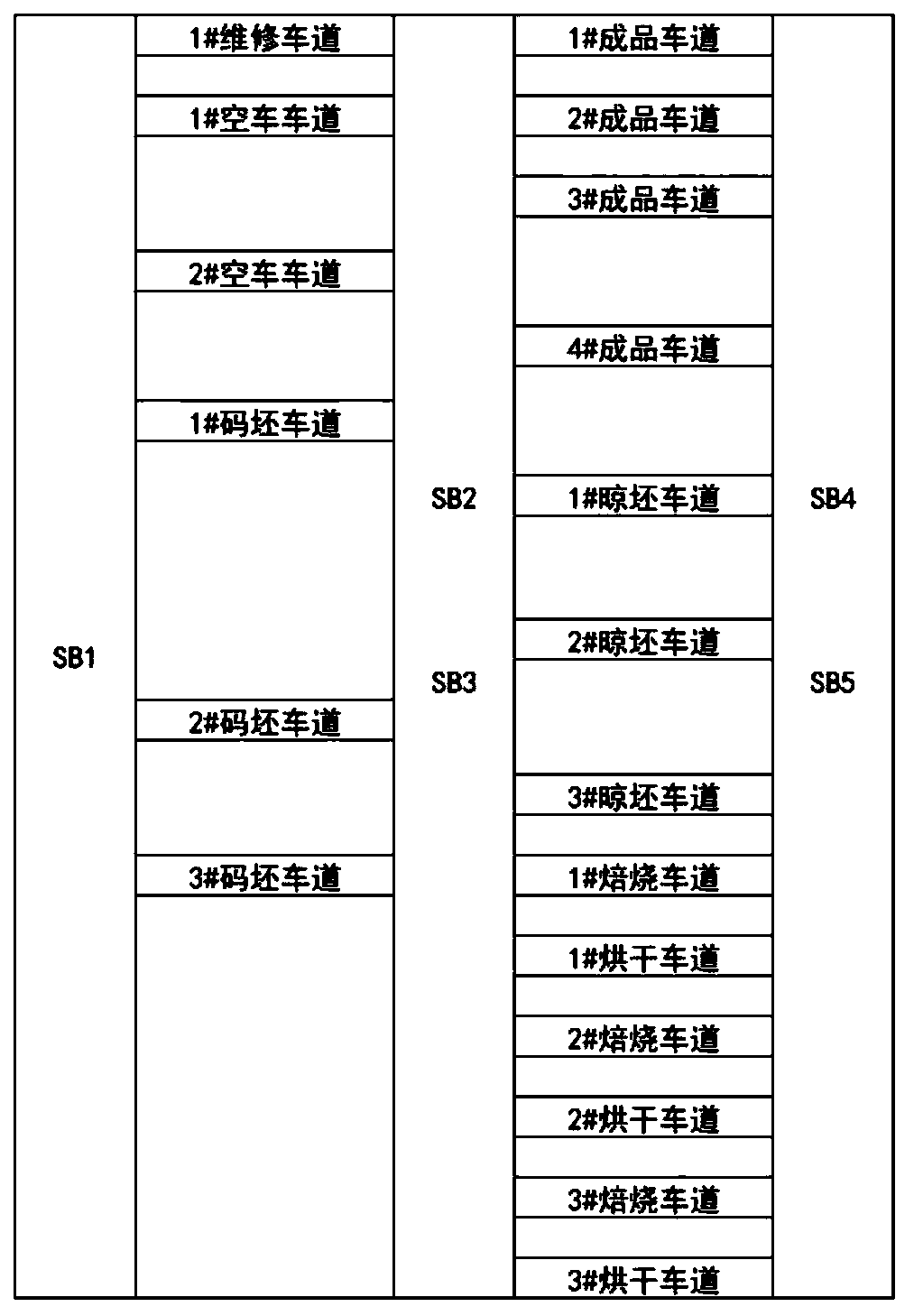

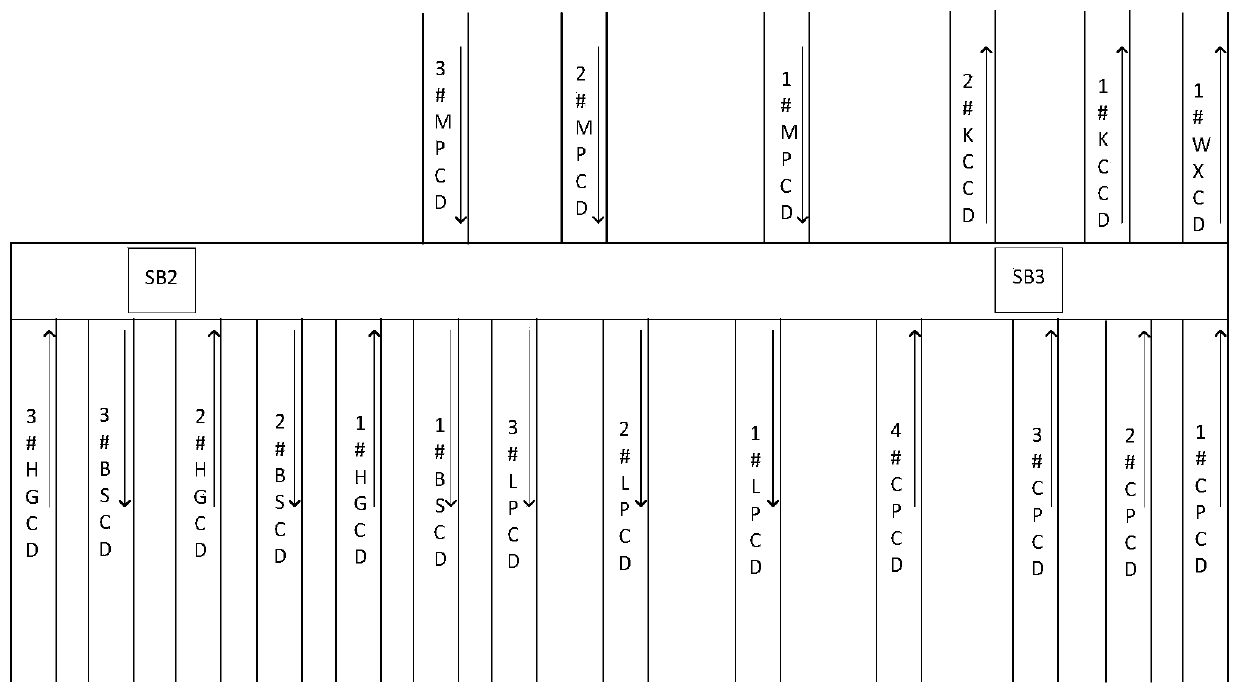

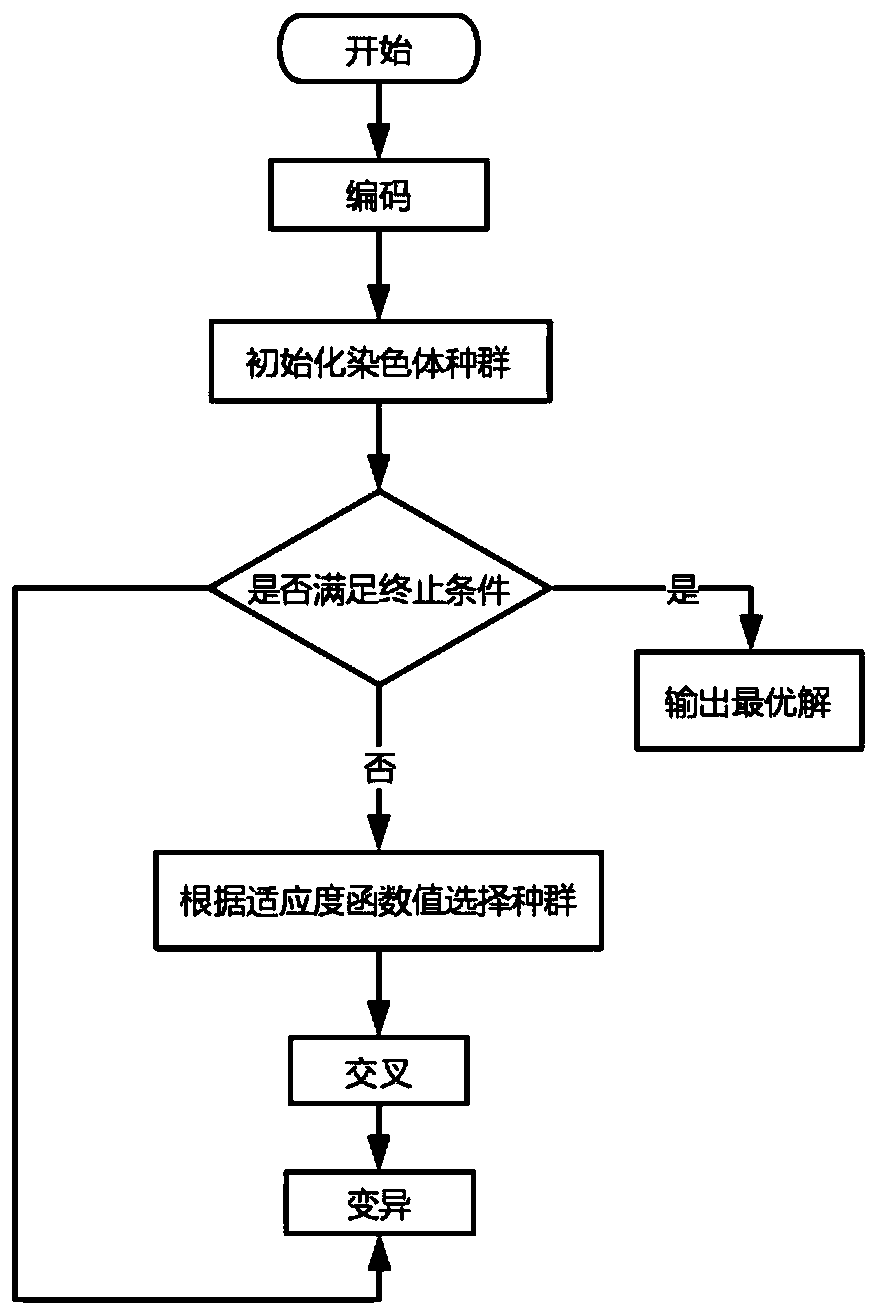

Minimum-energy-consumption-based method for establishing scheduling optimization of brick factory ferry vehicles

PendingCN110188951AQuality improvementIncrease productionForecastingResourcesSelf adaptiveTransfer system

The invention relates to a minimum-energy-consumption-based method for establishing scheduling optimization of brick factory ferry vehicles. The minimum-energy-consumption-based method comprises the following steps: 1) establishing a topological structure diagram of a brick factory transfer system, and analyzing the operation condition of the ferry vehicles based on a field arrangement diagram; 2)according to actual working conditions, aiming at scheduling of the double ferry vehicles on the same track, establishing double ferry vehicle operation and task distribution constraint conditions; 3) with the minimum energy consumption as an optimization objective function, planning a task execution sequence of the ferry vehicles; 4) analyzing a calculation formula of the variation probability pm and the crossover probability pc in the genetic algorithm; and 5) establishing an improved adaptive pm and pc genetic algorithm according to the calculation of the variation probability pm and the crossover probability pc. The invention provides a method for scheduling optimization of double ferry vehicles in a brick factory by taking the minimum energy consumption as a target, and establishes an improved genetic algorithm capable of solving the mixed integer nonlinear mathematical programming problem, being beneficial to the realization of the automation of the whole brick and tile productproduction line and the improvement of the efficiency.

Owner:CHONGQING UNIV

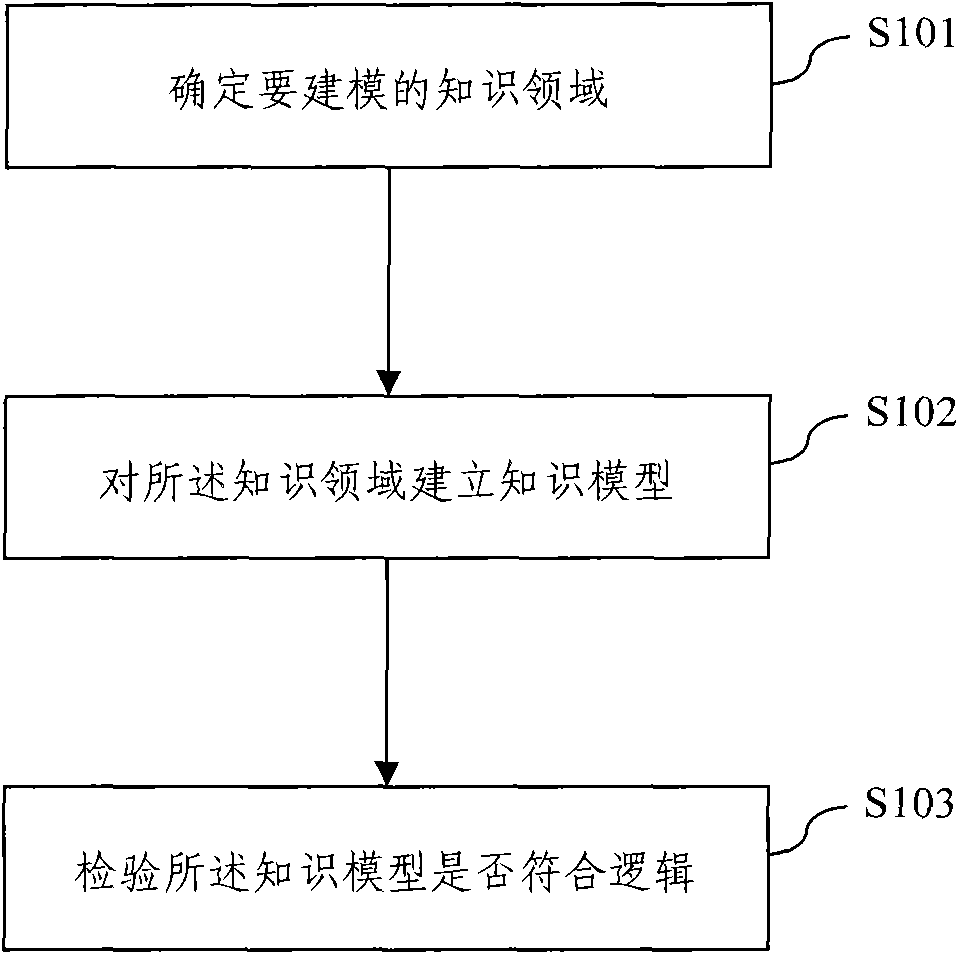

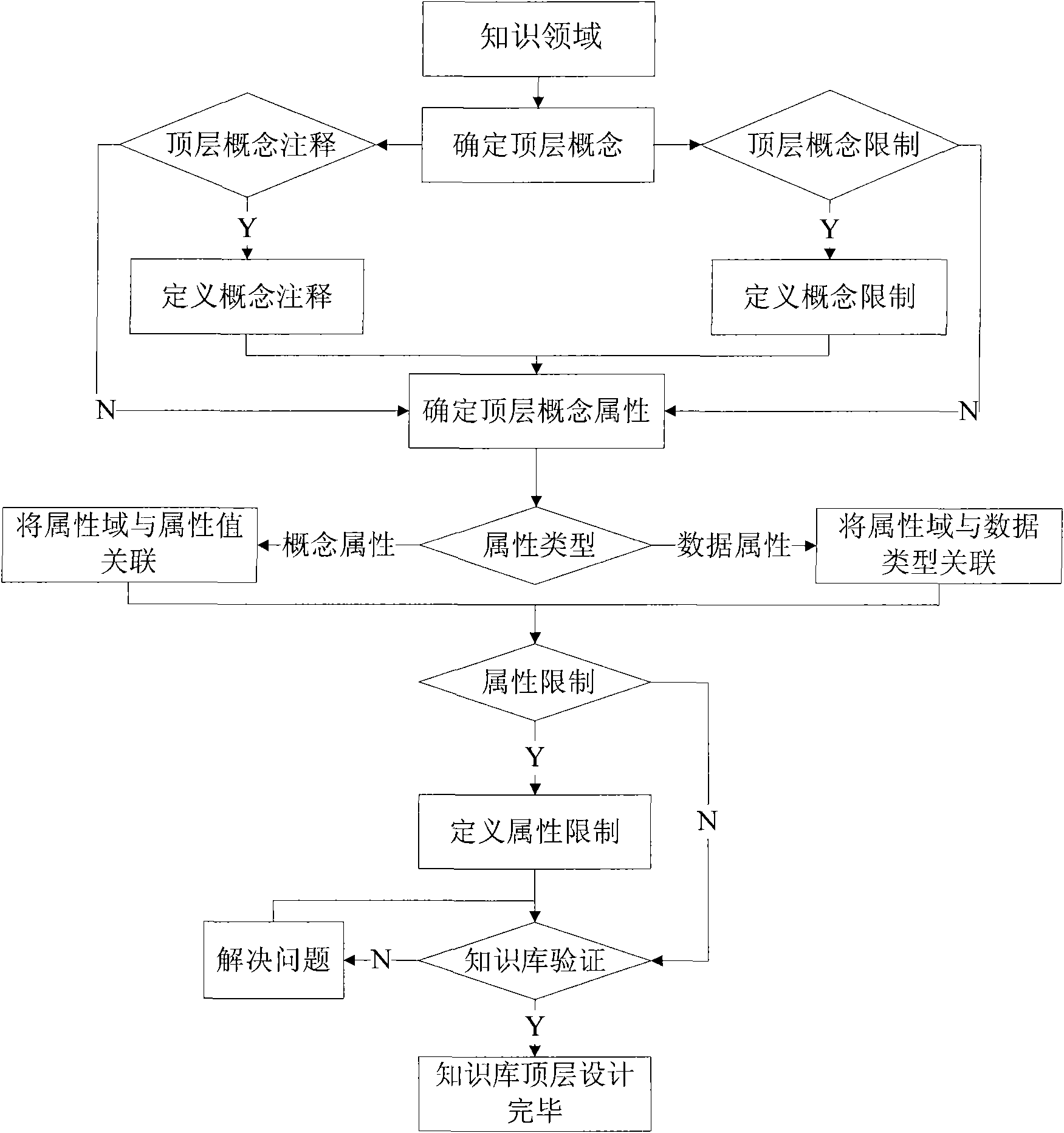

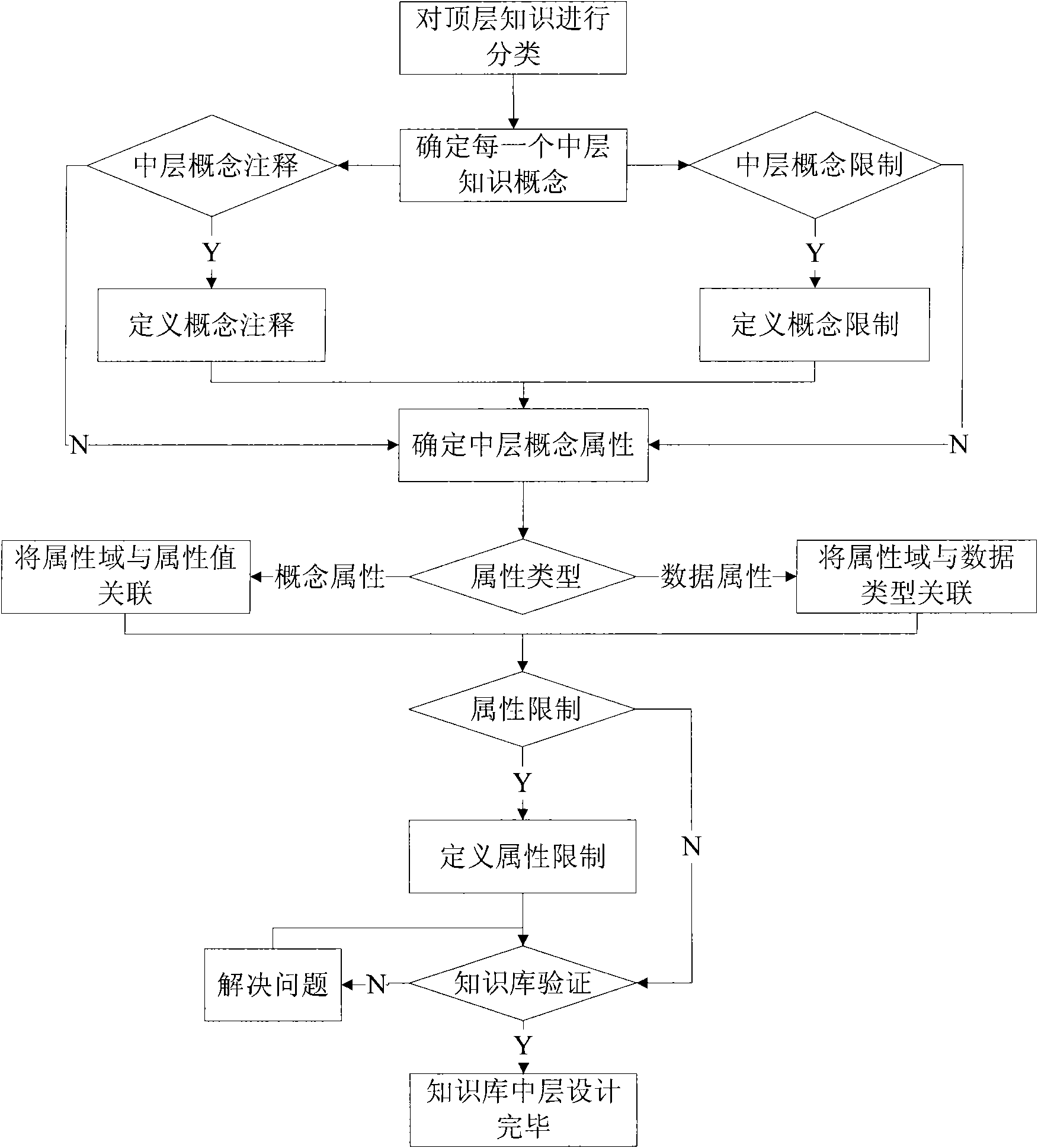

Method for modeling layered network knowledge model and method for establishing knowledge warehouse system

InactiveCN101799822AExtensible withImprove integrityCommerceSpecial data processing applicationsFault toleranceExtensibility

The invention discloses a method for modeling a layered network knowledge model, which comprises the following steps of: confirming a knowledge field to be modeled; establishing a knowledge model of the knowledge field; and detecting whether the knowledge model is logic or not. The invention also discloses a method for establishing a knowledge warehouse system by utilizing the knowledge model, comprising the following steps of: establishing a knowledge database group for storing knowledge concepts and examples thereof; establishing a non-knowledge database for recording the storage position of each example in the knowledge database group; and establishing a knowledge edition database for managing different knowledge editions in the knowledge warehouse. The invention uses the layered network knowledge modeling method to facilitate data modeling, provides maximum expandability for knowledge models and organizes all knowledge related in the system by adopting distributed storage and multi-computer automatic mutual backup strategies to form a data warehouse in a true meaning, thereby improving the robustness, the fault tolerance and the recoverability of the whole system.

Owner:李祯

Automatic feeding device and method for machining lead screw parts

PendingCN106862991ASolve loading and unloadingHigh degree of automationMetal working apparatusMachine toolAutomation

The invention discloses an automatic feeding device and method for machining lead screw parts. The automatic feeding device comprises a feeding workbench; the feeding workbench is provided with a distributing and charging assembly, a plurality of supporting cylinder assemblies, a charging bracket assembly, a feeding trolley assembly, a distributing and discharging assembly, a discharging bracket assembly and a discharging assembly; the charging bracket assembly and the discharging bracket assembly are respectively arranged at two sides of the feeding workbench; the feeding trolley assembly is mounted on a sliding rail of the feeding workbench and is used for clamping to-be-machined or machined lead screw parts and feeding the to-be-machined or machined lead screw parts into a machine tool for machining and taking the to-be-machined or machined lead screw parts out of the machine tool; the plurality of supporting cylinder assemblies are mounted at the lower part of the charging bracket assembly; the distributing and charging assembly is mounted at the upper part of the charging bracket assembly; the discharging assembly is mounted on the discharging bracket assembly; and the distributing and discharging assembly is mounted on the discharging bracket assembly; The automatic feeding device is relatively high in automation degree, high in machining efficiency and favorable in application prospect and is used for solving the problem of manual charging and discharging of the lead screw parts and reducing the manual labor intensity.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

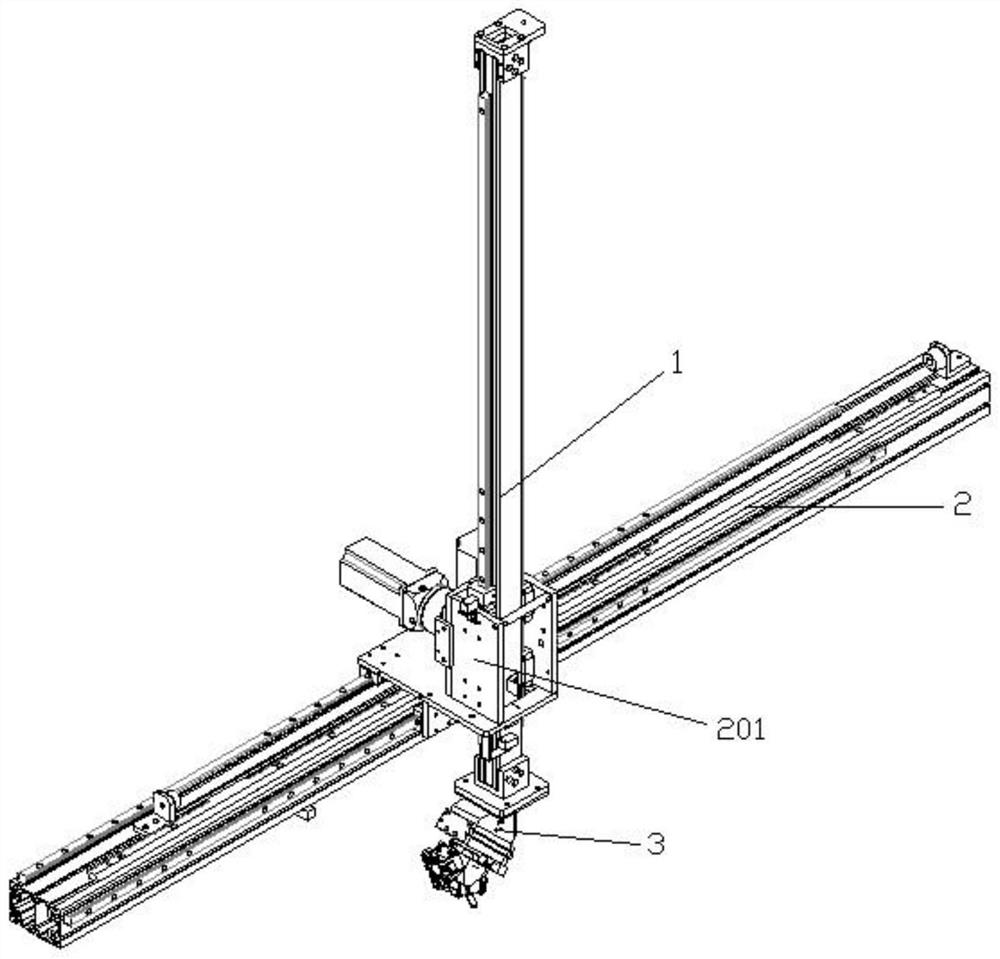

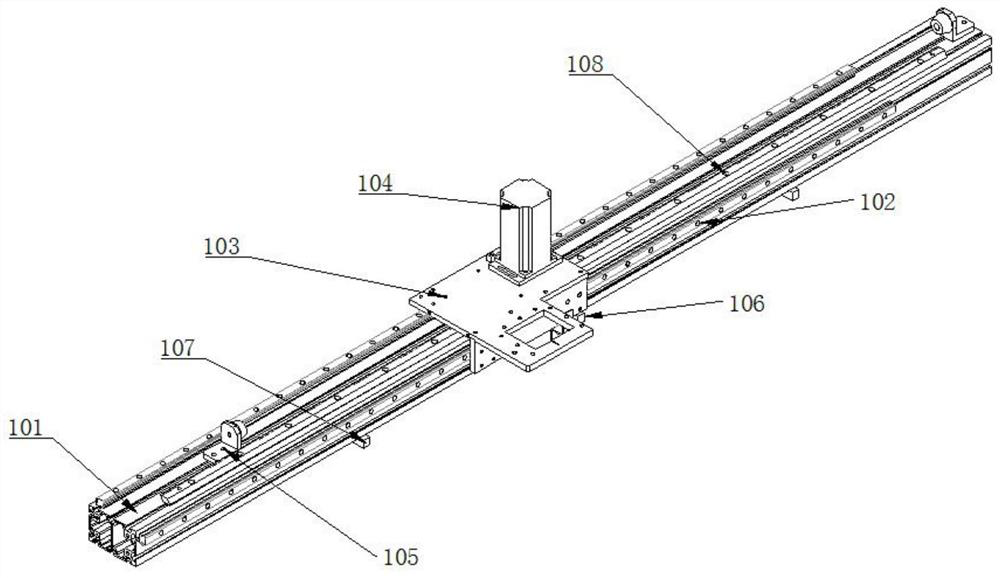

Automatic shearing and arranging frame mounting machine of lens injection molding semi-finished product

ActiveCN105965759AFacilitate the automation processLabor savingOptical articlesHuman–machine interfaceMan machine

The invention discloses an automatic shearing and arranging frame mounting machine of a glasses injection molding piece semi-finished product. A lens lifting rotary shearing mechanism, a nozzle removing mechanism, a man-machine interface, an alternating mechanism A, an alternating mechanism B, a lens stacking mechanism A, a lens stacking mechanism B, a lens arranging mechanism, hanging frame bins and hanging frames are included; the lens lifting rotary shearing mechanism is arranged in the middle position of a working table, the alternating mechanism A and the alternating mechanism B are arranged on the left side and the right side correspondingly, the lens stacking mechanism A is arranged on the left alternating mechanism A, and the lens stacking mechanism B is arranged on the right alternating mechanism B; the lens arranging mechanism is arranged beside the alternating mechanism A and the alternating mechanism B, the left end and the right end of the working table are provided with the hanging frame bins, and each hanging frame bin is provided with six hanging frames; and the machine is combined with a three-axis mechanical arm to work, the semi-finished product is taken out of an injection molding machine automatically, automatic shearing is achieved, automatic stacking is achieved, automatic arrangement is achieved, the automatic frame mounting working procedure is achieved, and therefore manual operation is completely replaced, manpower is saved, cost is reduced, the automation progress of an enterprise is promoted, and management is better achieved.

Owner:王刚

Automatic stamping device

The invention provides an automatic stamping device, which is characterized by comprising a stamp roller which is provided with a protruding stamp, a driving component connected with the stamp roller, a floating compression roller set and a stamp pad ink roller set which are respectively matched with the stamp roller, and a bill channel formed between the stamp roller and the floating compression roller set. The automatic stamping device can automatically stamp various bills easily in a mechanical stamping mode instead of a manual stamping mode, reduces the labor intensity of workers, improves work efficiency of stamping the bills, and reduces the error rate; the automatic stamping device can be matched with other bill processing devices such as a printer and a conveyer to realize a series of automatic bill processing actions such as printing, conveying, stamping and the like, improves the bill processing speed of a bank system, accelerates the automation process of processing the bills, and has the advantages of simple structure, convenience of use, good stamping effect, convenience of overhaul and maintenance, high automation degree and the like.

Owner:YUNNAN NANTIAN ELECTRONICS INFORMATION CORP +1

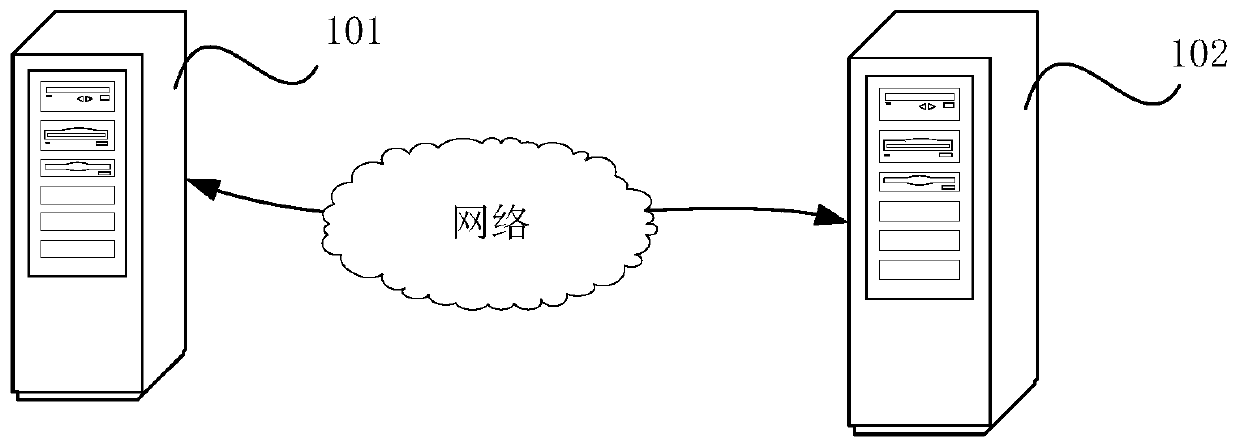

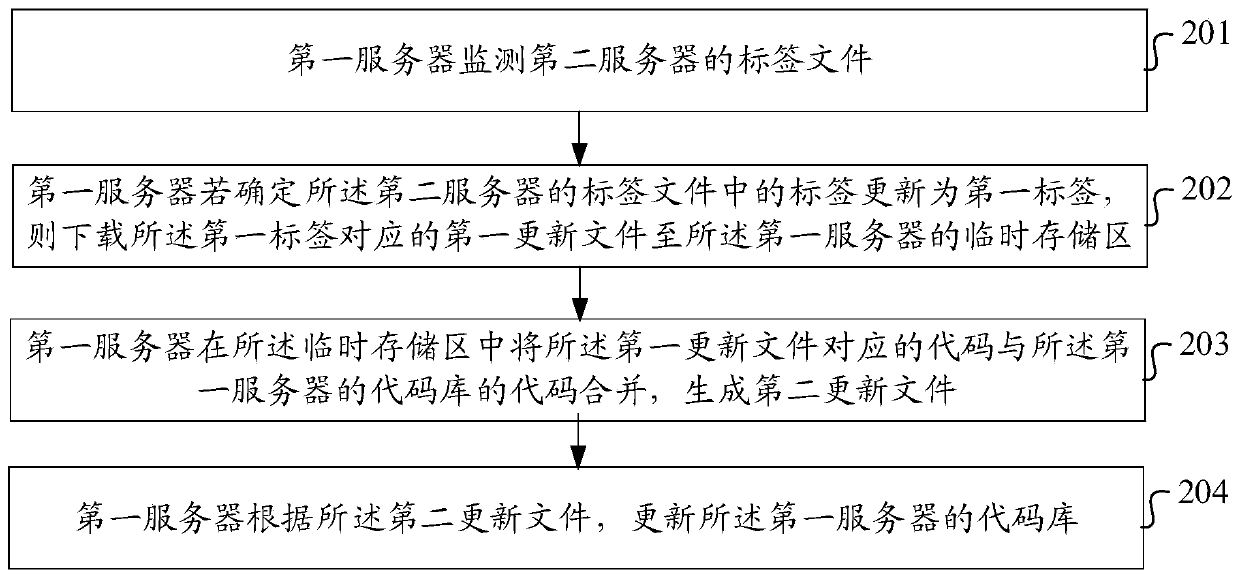

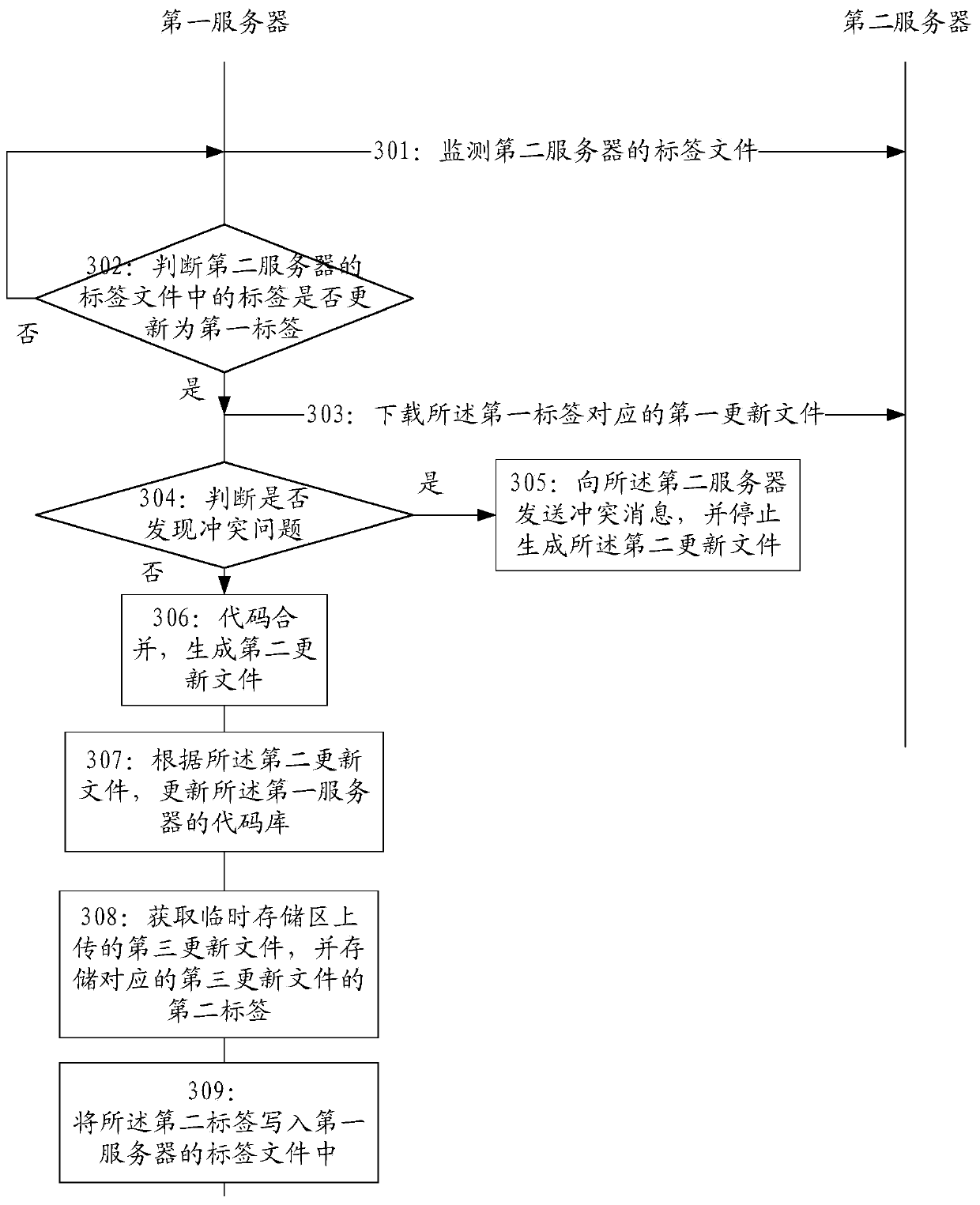

Code management method and device, storage medium and computer program product

PendingCN110162334AFacilitate the automation processVersion controlCode refactoringTransient storageApproaches of management

Owner:SHANGHAI MORUAN COMM TECH

Automatic packaging production line for gas water heaters

ActiveCN104773387AEasy to operateFacilitate the automation processFlexible coversWrappersLabelling machineManufacturing efficiency

The invention provides an automatic packaging production line for gas water heaters. The automatic packaging production line comprises a conveying production line, a label machine, a film sealing machine, a product conveying bench, a carton conveying bench, a carton opening machine, a plastic concave pad conveying line, a carton sealing line, a finished product line and a robot stacking machine; the label machine is arranged on one side of the conveying production line; the label machine is connected with the film sealing machine through a conveying mechanism; the film sealing machine and the product conveying bench are arranged in a 90-degree corner; the carton conveying bench is parallel to the product conveying bench; the carton conveying bench, the carton opening machine and the carton sealing line are sequentially connected in the conveying direction; the finished product line the carton sealing line are arranged in a 90-degree corner with. Due to the fact that a 90-degree corner production line is distributed between a film wrapping process and a boxing process, processing equipment can be distributed more scientifically, and the effective utilization rate of workshops is improved. Due to an automatic flow of the processing equipment, the product manufacturing efficiency is greatly improved, production safety accidents in the workshops are reduced, the labor intensity of workers is reduced, and significant social and economic benefits are achieved.

Owner:常州中科科创智能技术有限公司

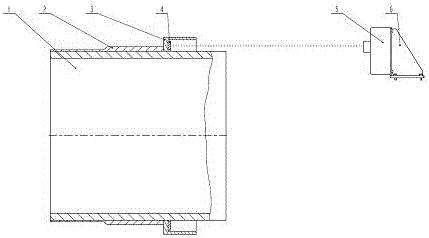

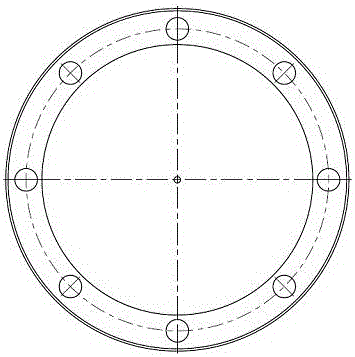

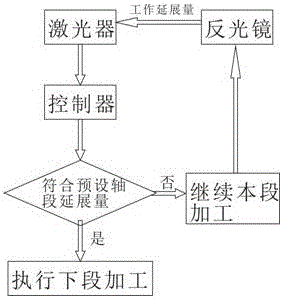

Powerful spinning contrarotation automatic tracking device adopting laser detection and tracking method

ActiveCN106552851AHigh precisionImprove processing qualityMetal working apparatusAutomatic controlEngineering

The invention discloses a powerful spinning contrarotation automatic tracking device adopting laser detection and a tracking method. The automatic tracking device comprises a cylindrical core die and a workpiece arranged on the core die in a sleeving manner; the core die comprises a front end and a back end, when the core die rotates, the workpiece is subject to plastic deformation, and the end generating axial flowing is the back end; a laser device is arranged at the back end of the core die and is installed on a laser device base, a retroreflector installation frame is coaxially arranged at the position, close to the back end, of the core die in a sleeving manner and is in a ring shape, the face, towards the back end, of the retroreflector installation frame is provided with an annular groove, and a plurality of retroreflectors are evenly arranged in the groove; and the center of one retroreflector right faces the transmitting end of the laser device. By means of the device capable of automatically detecting the actual spinning length in real time, the problems that during powerful spinning contrarotation, the lengths of a multi-step cylindrical piece and an any-generatrix part are not likely to be controlled, and the accuracy is low are solved, and the powerful spinning contrarotation automatic tracking device and the tracking method have the beneficial effects of being high in accuracy, capable of achieving automatic control and good in application scope.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

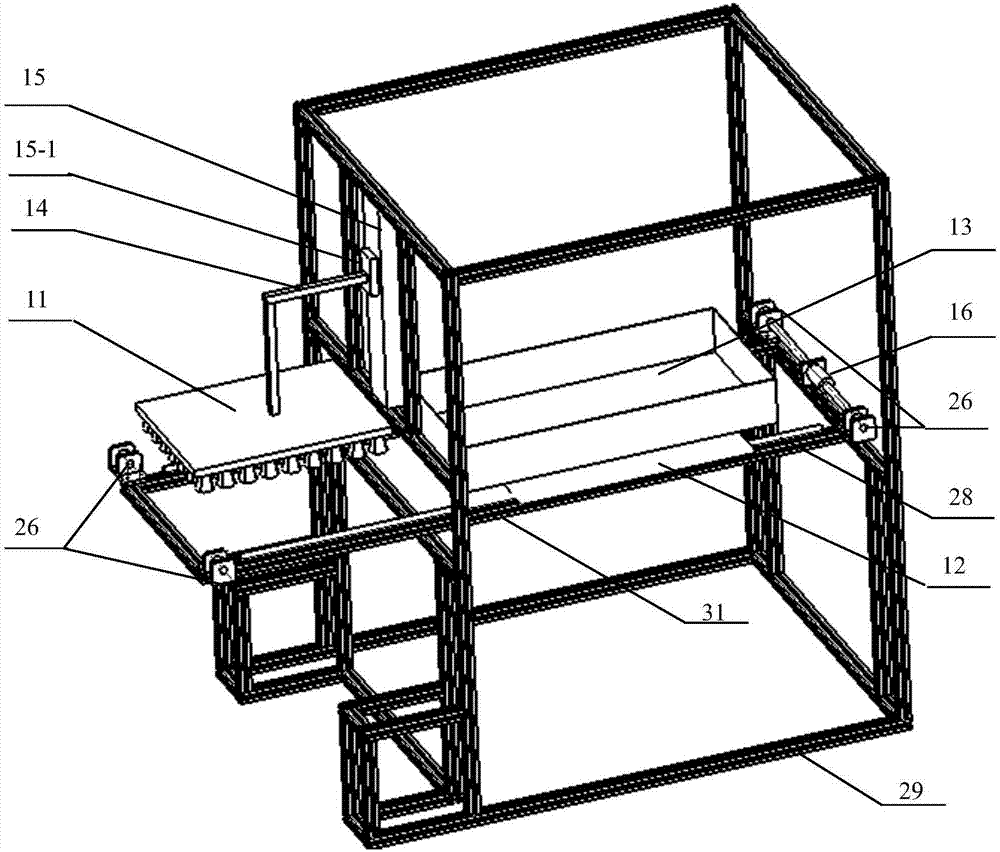

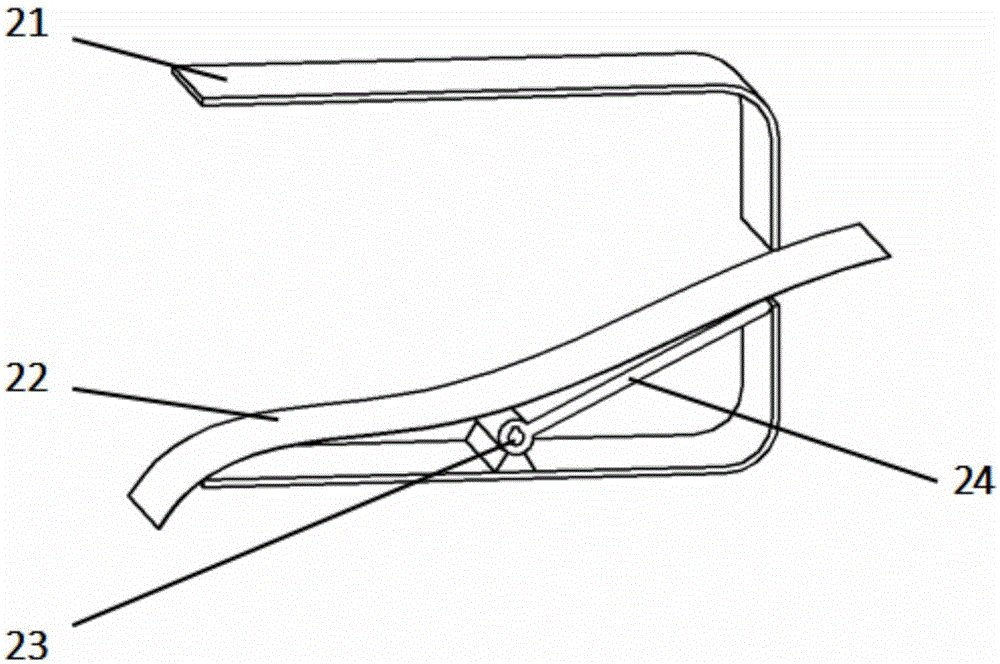

Lead framework production system

ActiveCN110190000AFacilitate the automation processAvoid wear and tearSemiconductor/solid-state device manufacturingTransfer procedureEngineering

The invention relates to a lead framework production system and belongs to the technical field of semiconductor production. The lead framework production system includes an electroplating unit, an overturning unit and a bending unit that are sequentially disposed. After a to-be-electroplated framework (4) is electroplated in the electroplating unit, a framework semi-finished product (10) is obtained and then enters the overturning unit, after the framework semi-finished product (10) is overturned by an overturning bin (13), front and back sides are reversed with each other, the framework semi-finished product (10) is placed on a surface of an overturning output conveyor (15) and conveyed by the overturning output conveyor (15) to a bending input conveyor(23) of the bending unit, separationof a framework single unit (35) and a framework frame (37) in the framework semi-finished product (10) is carried out in the bending unit, and the framework single unit (35) is transferred to a finished product zone (28). The lead framework production system is advantaged in that processes such as electroplating, overturning and bending in the lead framework production process are completed, automation of the lead framework is improved, and wear of the lead framework during transport is avoided.

Owner:新恒汇电子股份有限公司

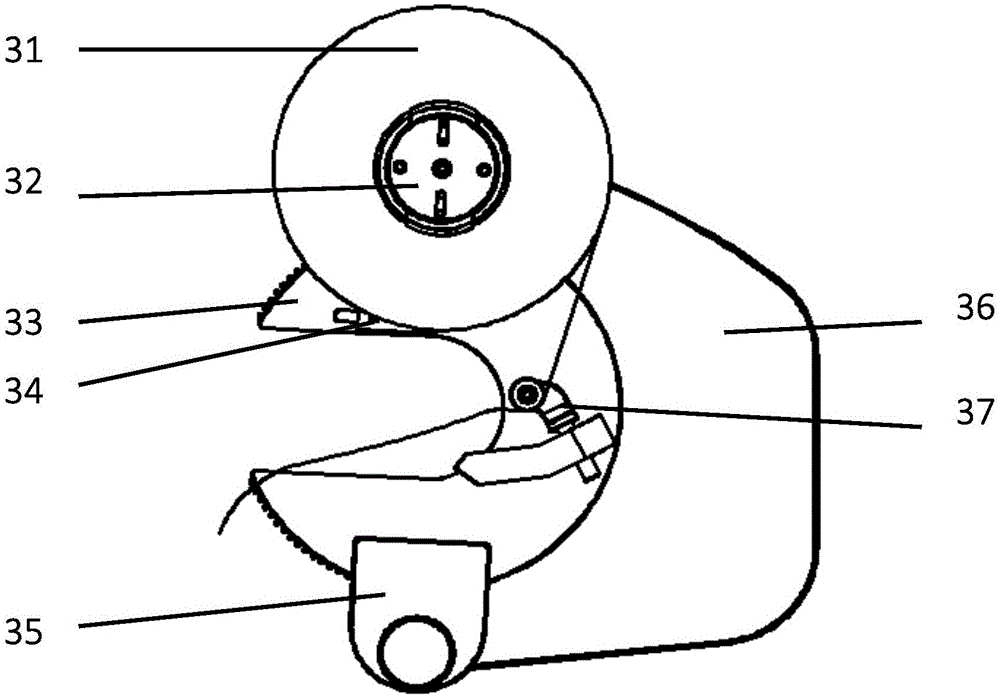

Automatic tape winding technology based on multiple actions and application method

ActiveCN105151369AFacilitate the automation processEarly liberationBinding material applicationBundling machine detailsEngineeringConductor Coil

The invention discloses an automatic tape winding technology based on multiple actions and an application method. The multiple actions comprise the wire gathering action, the tape bonding action, the tape winding action and the tape cutting action. The wire gathering action is the behavior that a messy and scattered wire harness becomes tidy and orderly through the action of a wire gathering mechanism. The tape bonding action is the behavior that the wire harness andtape are in contact and are oppositely fixed in position through the action of a tape bonding mechanism. The tape winding action is the behavior that the tape is attached to or wound to a wound object through the action of a tape winding mechanism. The tape cutting action is the behavior that during tape winding interrupting or after ending of tape winding, the tape is separated from the wound object through the action of a tape cutting mechanism. The automatic tape winding technology can meet the various tape winding technology requirements generated due to different occasions, different wire harnesses and different kinds of adhesive tape, and the actual situation of the production end can be handled.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

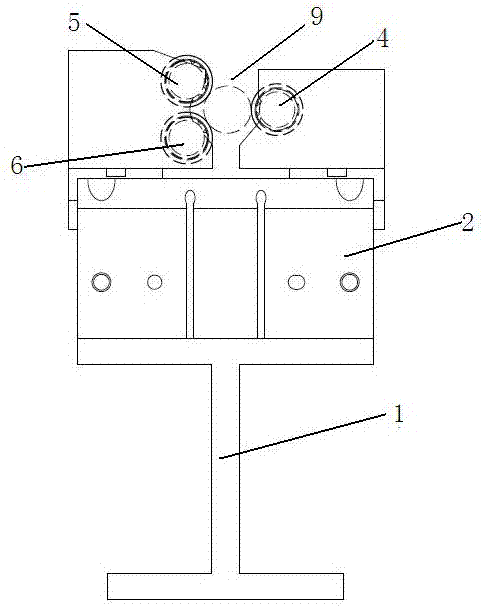

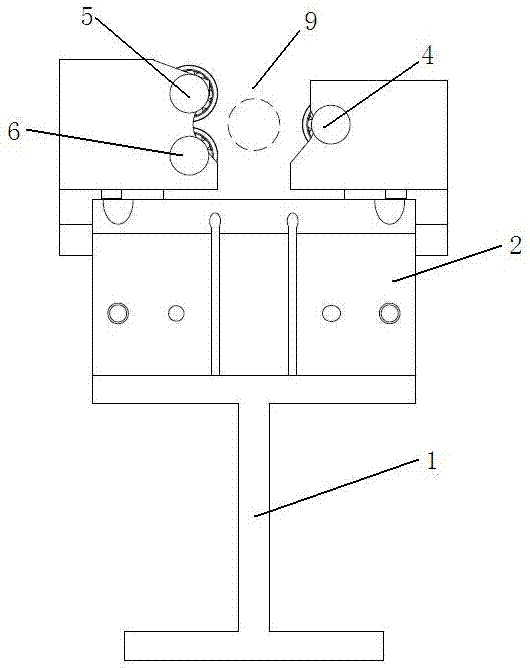

Supporting and rotating device and method for machining long and thin parts

InactiveCN106862946AHigh degree of automationSolve the problem of unreliable supportLarge fixed membersReciprocating motionEngineering

The invention discloses a supporting and rotating device and method for processing slender parts. The first bearing group, the second bearing group, the third bearing group and the second mounting seat, the control cylinder is installed on the upper surface of the support frame, the first mounting seat and the second mounting seat realize reciprocating movement with the action of the control cylinder, the first The bearing group is installed on the inner surface of the first mounting seat through the pin shaft, and the second bearing group and the third bearing group are respectively installed on the inner surface of the second mounting seat through the pin shaft in an upper and lower distribution. The first bearing group and the second bearing group The bearing group and the third bearing group are oppositely arranged, and a region for supporting the elongated parts is formed between the first bearing group, the second bearing group, and the third bearing group. The invention realizes the rotating support for processing the slender parts by controlling the air cylinder, has high degree of automation, simple structure and good application prospect.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

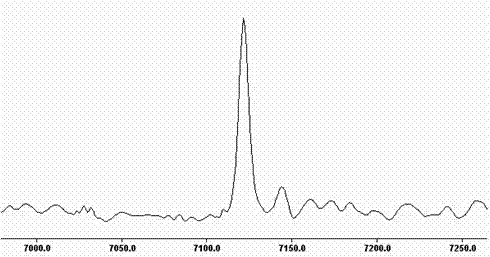

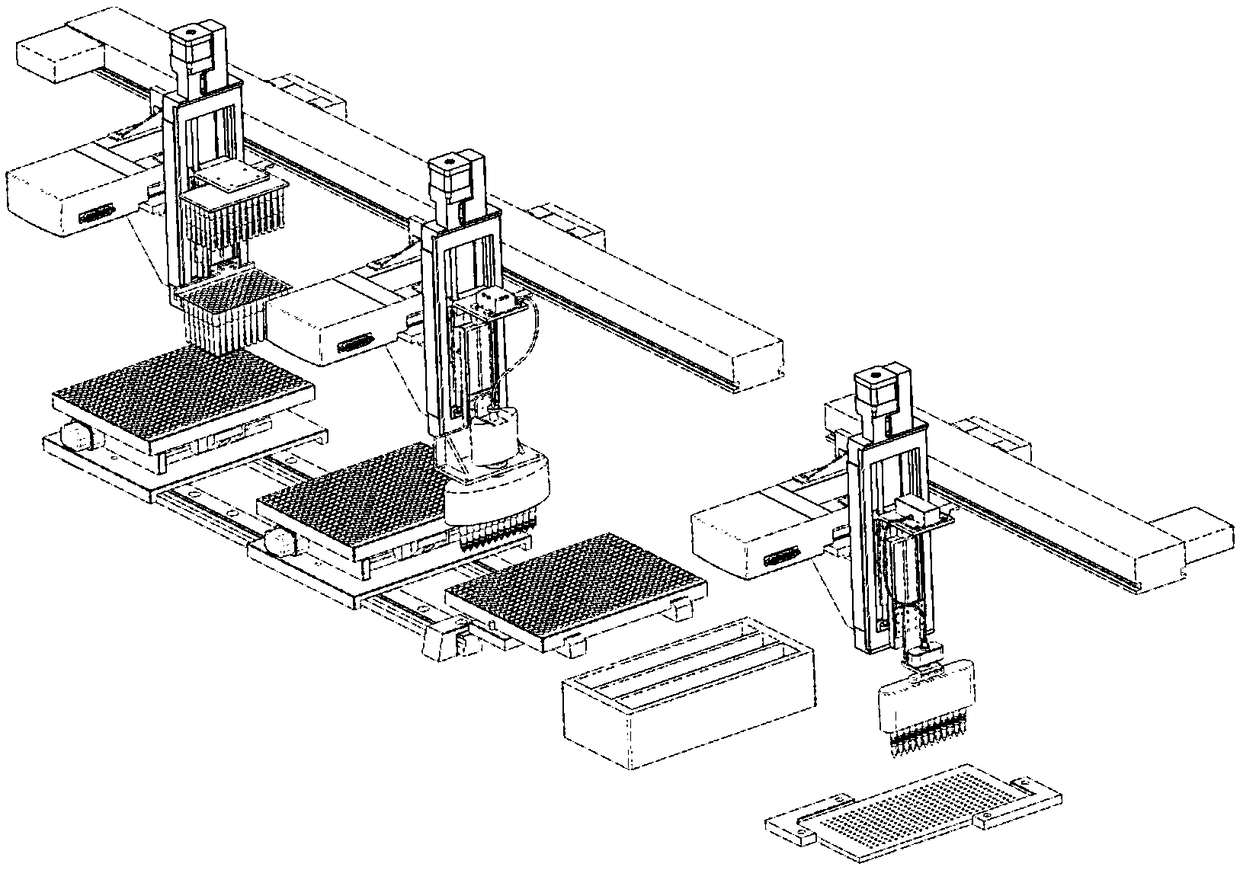

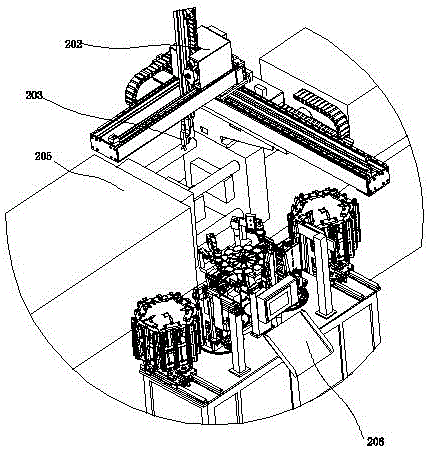

Full-automatic polypeptide extraction time-of-flight mass spectrometry detector

ActiveCN104977349AAccurate extractionReduce infectionPreparing sample for investigationMaterial analysis by electric/magnetic meansTime-of-flight mass spectrometryMass analyzer

The present invention provides a full-automatic polypeptide extraction time-of-flight mass spectrometry detector capable of concurrently extracting bulk samples. The full-automatic polypeptide extraction time-of-flight mass spectrometry detector comprises a polypeptide extraction and purification device, a pipetting distributing device, an automatic sample adding device and a mass spectrometer. According to the present invention, the electromagnetic rod and magnet rod sleeve mode is used so as to completely separate the sample; the polypeptide chip is prepared through the automatic sample adding device; the polypeptide mass spectrum map is obtained through the laser sampling of the mass spectrometer; and the full-automatic polypeptide extraction time-of-flight mass spectrometry detector has characteristics of less time consumption, high efficiency, good uniformity and sample cross-contamination avoiding, and can achieve the same technical effect as the manual operation effect of the existing mass spectrometer.

Owner:BIOYONG TECH

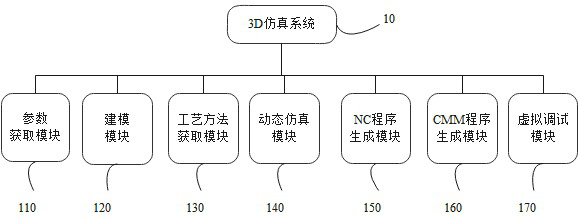

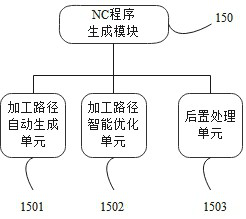

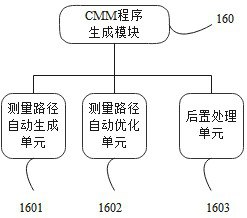

Three-dimensional simulation software system and method for machining digital process

ActiveCN112711871AFacilitate the automation processRealize intelligent production planningGeometric CADDesign optimisation/simulationDimensional simulationMachine parts

The invention provides a three-dimensional simulation software system and method for a machining digitization process, and belongs to the technical field of machining, and the method specifically comprises the steps that a parameter obtaining module obtains the feature resume and original blank parameters of a to-be-machined part, cutter assembly parameters, clamp three-dimensional model parameters, machine tool three-dimensional model parameters and the tree relation among the four parameters; wherein the modeling module is used for respectively establishing an original blank parameter model, a cutter assembly model, a clamp assembly model and a machine tool model; the process method collection module acquires a to-be-verified process method; the dynamic simulation module generates a processing flow, and outputs the processing flow passing the interference verification after dynamic interference verification; the NC program generation module generates a tool machining path and an NC program; the CMM program generation module generates a CMM program; and the virtual debugging module executes the NC program and the CMM program to perform virtual simulation and verification to obtain process method modeling. Through the processing scheme of the invention, an intelligent decision can be provided for a machining digital process.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

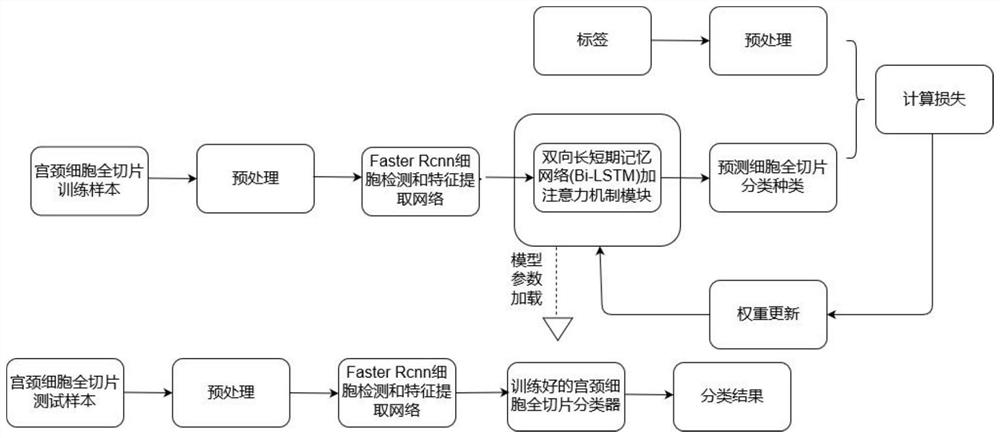

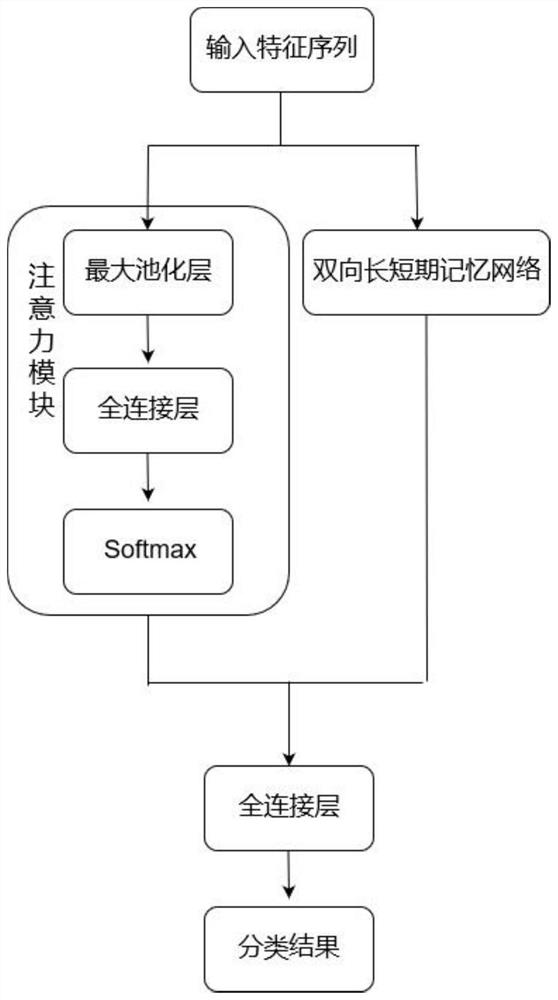

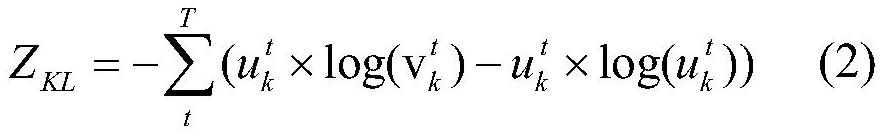

Cervical cell full slice classification method based on context modeling

ActiveCN113378796AEffective classificationReduce labeling costCharacter and pattern recognitionNeural architecturesCervical cellsFeature extraction

The invention discloses a cervical cell full slice classification method based on context modeling. The method comprises the following steps: 1, obtaining T-type cervical cell full slice samples; 2, constructing a Faster Rcnn network-based cell detection and feature extraction module, carrying out cell detection and feature extraction on the cervical cell full slice sample, and extracting features from cell nucleus images with fixed sizes to obtain feature sequences of the cell nucleus images in different types of cell full slices; 3, building a context modeling module fusing the bidirectional long-short-term memory network and the attention mechanism; 4, constructing a cervical cell full slice classifier; and 5, carrying out classification prediction on the cervical cell full slice. More effective learning is carried out on the information obtained after feature extraction is carried out on the cell nucleus images in the input different cervical cell full slices, accurate classification of multiple different cervical cell full slices is completed, and the cell level marking cost of a current cervical cell classification method can be effectively reduced.

Owner:HEFEI UNIV OF TECH

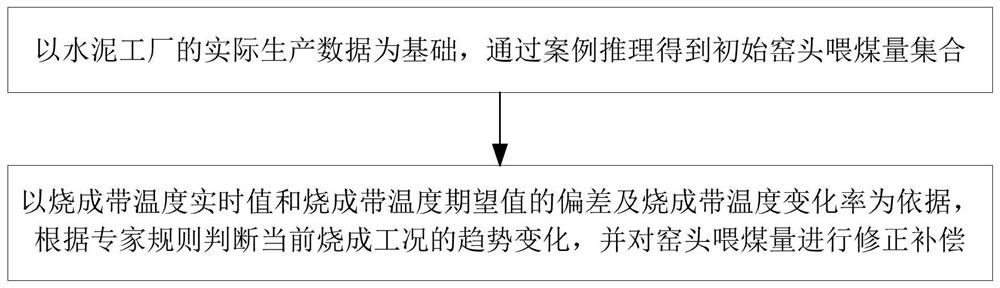

Rotary cement kiln head coal feeding control method

ActiveCN112229206AAdvance the process of production automationFacilitate the automation processRotary drum furnacesControl devices for furnacesCement factoryProcess engineering

The invention discloses a rotary cement kiln head coal feeding control method. The method comprises the following steps: on the basis of actual production data of a cement factory, an initial kiln head coal feeding amount set is obtained through case-based reasoning; and on the basis of the deviation between a firing zone temperature real-time value and a firing zone temperature expected value anda firing zone temperature change rate, the trend change of the current firing working condition is judged according to expert rules, and the kiln head coal feeding amount is corrected and compensatedfor. A design method of the control method for modifying the given rotary cement kiln head coal feeding amount based on case-based reasoning in combination with expert rules is established, and the difference of knowledge and experience among different operation engineers is eliminated.

Owner:UNIV OF JINAN

Automatic feeding system

PendingCN113955432ARealize the zero operationGuaranteed cleanlinessLoading/unloadingConveyor partsControl engineeringControl theory

The invention provides an automatic feeding system. The automatic feeding system is characterized by comprising a bearing mechanism, wherein the bearing mechanism is provided with a centrifugal turntable mechanism, a track mechanism and a separation turntable mechanism, wherein the track mechanism is located between the centrifugal turntable mechanism and the separation turntable mechanism and separately connected with the centrifugal turntable mechanism and the separation turntable mechanism; the centrifugal turntable mechanism is used for dispersing parts to be separated and then conveying the parts to be separated into the track mechanism; the track mechanism receives the parts to be separated in the centrifugal turntable mechanism and conveys the parts to be separated to the separation turntable mechanism; and the separation turntable mechanism is used for separating and arranging the parts to be separated conveyed by the track mechanism one by one. The technical problem that the working efficiency is low in the manual adding process is solved through the automatic feeding structure.

Owner:北京胡曼智造科技有限责任公司

Method for automatically detecting and classifying glass defects

InactiveCN108335283AImprove inspection efficiencyGuaranteed factory qualityImage enhancementImage analysisPattern recognitionSoftware

The invention relates to a method for automatically detecting and classifying glass defects. The method comprises the following steps of: dividing an image of glass by detection software according toa set segmentation threshold value so as to obtain a plurality of divided objects; processing each divided object by the detection software through a neural network classification algorithm, and extracting a plurality of defect feature values corresponding to each divided object; analyzing the defect feature values corresponding to each divided object by the detection software through the neural network classification algorithm, and obtaining a defect type of the divided object. The method for automatically detecting and classifying glass defects is suitable for operations of automatic production of electronic glass and other pieces of glass, so that the glass inspection efficiency is improved, the outgoing quality of the glass is ensured, the labor cost is saved, the automation process ofenterprises is accelerated, benefit is brought to large-scale popularization of automatic glass detection systems, and a wider application range is provided.

Owner:江苏易润信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com